Biological aqueous polyurethane resin, preparation method therefor and application of biological aqueous polyurethane resin

A water-based polyurethane and bio-based technology, applied in the field of polyurethane resin synthesis, can solve the problems of insufficient folding resistance, wear resistance, solvent resistance, ie DOP resistance, mechanical properties, storage performance and constant temperature and humidity performance, and achieve constant temperature Improved constant humidity performance, improved storage performance, and the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

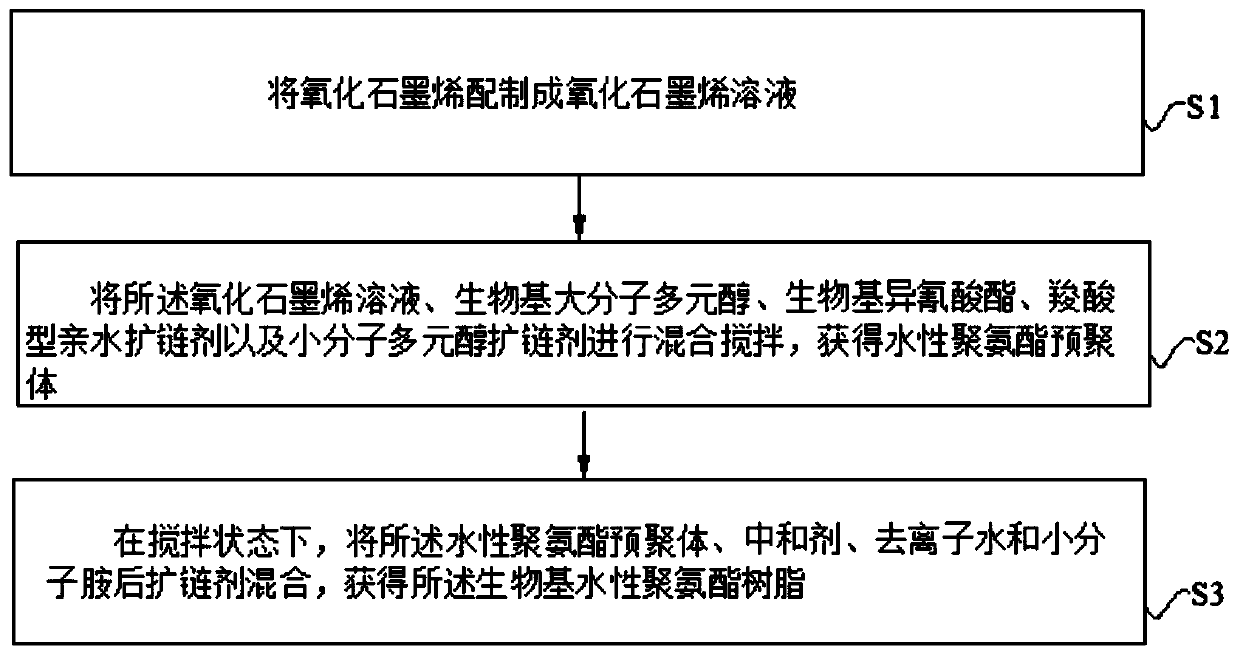

[0024] Such as figure 1 Shown, provide a kind of preparation method of bio-based water-based polyurethane resin, at least comprise the following steps,

[0025] S1, graphene oxide is formulated into graphene oxide solution;

[0026] S2. Mix and stir the graphene oxide solution, bio-based macromolecular polyol, bio-based isocyanate, carboxylic acid type hydrophilic chain extender and small molecule polyol chain extender to obtain a water-based polyurethane prepolymer;

[0027] S3. Mix the water-based polyurethane prepolymer, neutralizer, deionized water and small molecular amine post-chain extender under stirring state to obtain the bio-based water-based polyurethane resin.

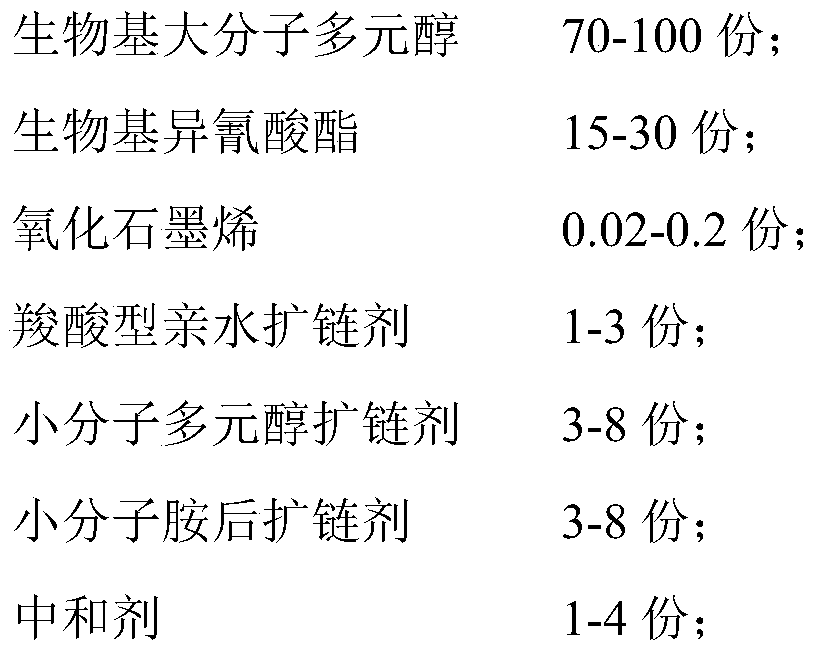

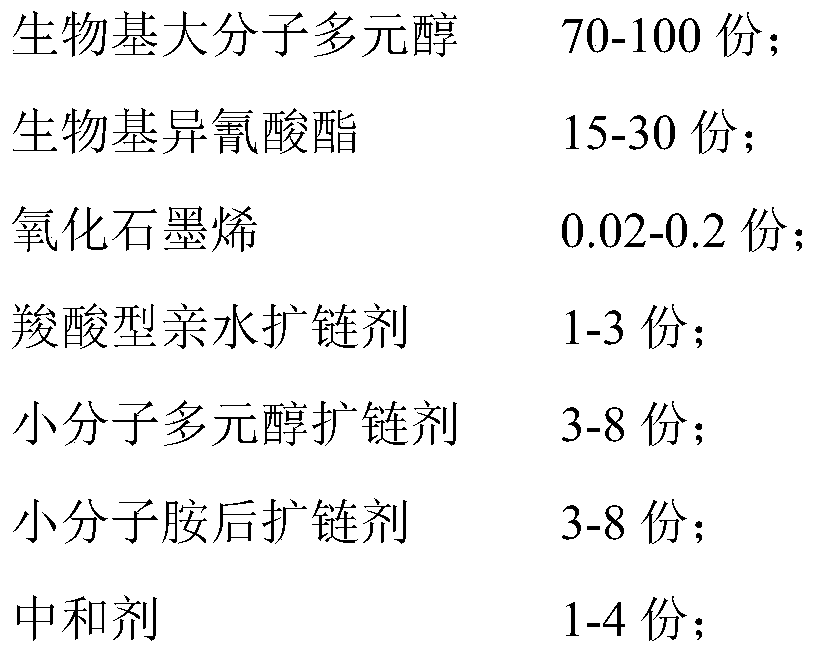

[0028] Specifically, in step S1, 0.02-0.2 parts by mass of graphene oxide is prepared into a graphene oxide solution. For example, 0.02-0.2 mass parts of graphene oxide is prepared into a graphene oxide solution with N-methylpyrrolidone, wherein the graphene oxide is graphene oxide containing hydroxyl an...

Embodiment 1

[0034] A preparation method of bio-based water-based polyurethane resin, comprising the following steps:

[0035] Weigh 75-80g of castor oil derivative polyol (relative molecular mass is 1000), put it into the reactor, add 20-25g of dimer acid diisocyanate under stirring state, keep the temperature at 80-90°C, stir for 2-3 Hour. Add 0.05-1 g of the prepared graphene oxide solution (0.02-0.04 g of graphene oxide), the graphene oxide solution is prepared from, for example, N-methylpyrrolidone, keep the temperature at 80-90° C., and stir for 2-3 hours. Cool down to 65-66°C, add 2.5-3g dimethylolpropionic acid (DMPA), 3-4g trimethylolpropane, raise the temperature to 70-71°C, and keep stirring at 70-71°C for 2-3 hours to obtain Bio-based waterborne polyurethane prepolymer.

[0036] Cool the water-based polyurethane prepolymer to 5-8°C, add 1-1.5g triethylamine, stir for 10-15 minutes, then transfer to a high-speed emulsifier, add 200g-220g at a speed of 1400-1600 rpm Deionized wa...

Embodiment 2

[0039] A preparation method of bio-based water-based polyurethane resin, comprising the following steps:

[0040] Weigh 95-100g of castor oil (relative molecular mass: 1000), put it into a reactor, add 15-18g of dimer acid diisocyanate under stirring, keep the temperature at 80-90°C, and stir for 2-3 hours. Add 0.05-1 g of the prepared graphene oxide solution (0.02-0.04 g of graphene oxide), the graphene oxide solution is prepared from, for example, N-methylpyrrolidone, keep the temperature at 80-90° C., and stir for 2-3 hours. Cool down to 65-66°C, add 3-4g dimethylolpropionic acid (DMPA), 7-8g trimethylolpropane, raise the temperature to 70-71°C, and keep stirring at 70-71°C for 2-3 hours to obtain Bio-based waterborne polyurethane prepolymer.

[0041] Cool the water-based polyurethane prepolymer to 5-8°C, add 1-1.5g triethylamine, stir for 10-15 minutes, then transfer to a high-speed emulsifier, add 200g-220g at a speed of 1400-1600 rpm Deionized water, after 1-3 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com