Method for preparing aqueous polyurethane adhesive and superfine fiber synthetic leather

A technology of water-based polyurethane and hydrophilic polyurethane, which is applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems such as poor adhesion of adhesives, and achieve improved peel strength and improved Mechanical properties, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

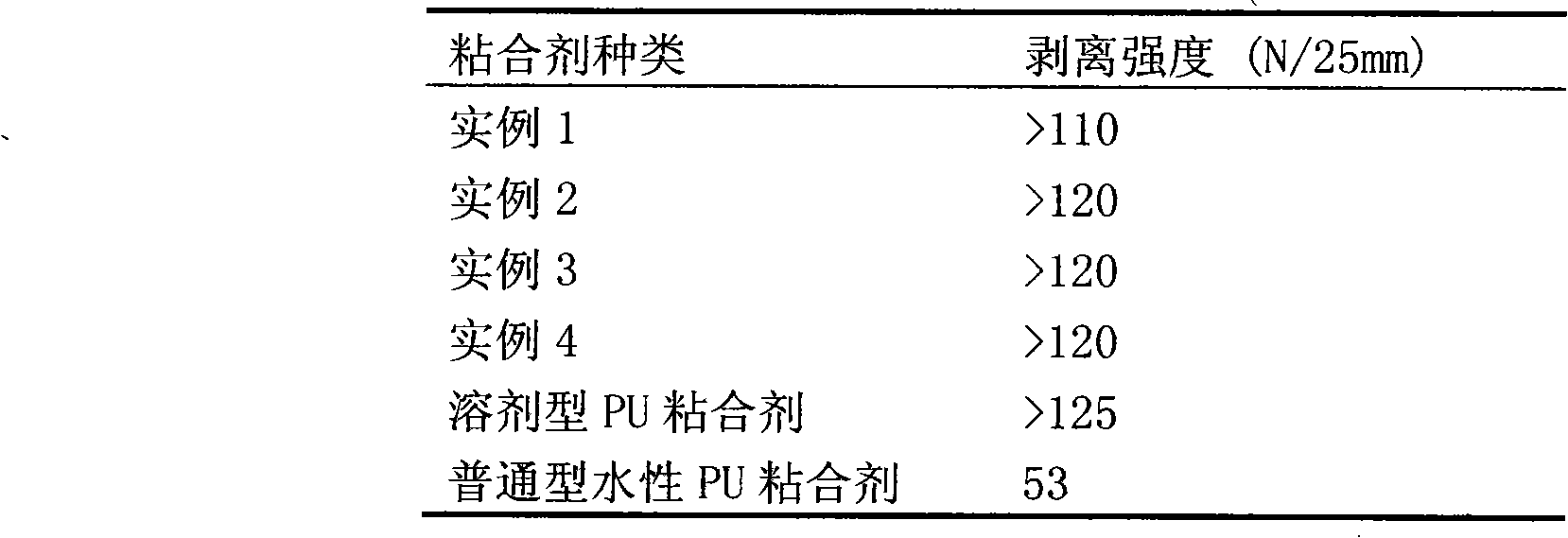

Examples

Embodiment 1

[0042] The specific technological process of the preparation method of the aqueous polyurethane adhesive of the present embodiment and the superfine fiber synthetic leather is as follows:

[0043] 1. Synthesis of hydrophilic polyurethane prepolymer

[0044] Put 42.2g of toluene diisocyanate (T-80 / 20), 48.6g of diphenylmethane 4,4-diisocyanate, Polyhexamethylene adipate diethylene glycol acetal diol 132g, polyethylene adipate butylene glycol ester diol 132g, polyethylene adipate terephthalate diol 88g, hydrophilic Water-based chain extender (this hydrophilic group is used in all formulations) 22.7g of dimethylolpropionic acid, stir well, react at a temperature of 80-90°C for 3 hours, then add 3.1g of small molecule chain extender ethylene glycol At the same time, 2.6g of triethylenediamine, an amine-based environment-friendly catalyst, was added to the alcohol, and then kept at 60°C for 3 hours to form a hydrophilic polyurethane prepolymer.

[0045] 2. Preparation of water-ba...

Embodiment 2

[0052] The preparation method technological process of the aqueous polyurethane adhesive of the present embodiment and superfine fiber synthetic leather:

[0053] 1. Synthesis of hydrophilic polyurethane prepolymer

[0054] Put 48.5g of toluene diisocyanate (T-80 / 20), 30.6g of diphenylmethane 4,4-diisocyanate into a four-neck round bottom flask equipped with strong mechanical stirring, nitrogen, temperature controller, and condensation reflux equipment. Polyhexamethylene adipate diol 120g, polybutylene adipate terephthalate diol polyester polyol 130g, neopentyl glycol butylene adipate phthalate diol 80g, 23g of dimethylolpropionic acid, heat up to 81°C for 3.2h, add 5.6g of diethylene glycol, and add 2.5g of amine-based environment-friendly catalyst triethylamine at the same time, then heat at 62°C for 3.3h to form a hydrophilic polyurethane prepolymer.

[0055] 2. Preparation of water-based polyurethane emulsion

[0056] After the prepolymer is cooled to 10-40°C, triethyla...

Embodiment 3

[0062] The preparation method technological process of the aqueous polyurethane adhesive of the present embodiment and superfine fiber synthetic leather:

[0063] 1. Synthesis of hydrophilic polyurethane prepolymer

[0064] Put 57.8g of toluene diisocyanate (T-80 / 20), 36.5g of diphenylmethane 4,4-diisocyanate, Polyhexamethylene adipate diol polyester polyol 144g, polybutylene adipate succinate diol polyester polyol 192g, dimethylol propionic acid 22.7g, heat up to 84°C and keep the temperature at 3.5 h, add 4.5g of 1,4-butanediol and at the same time add 2.5g of triethylamine, an environmental-friendly amine catalyst, and keep it warm at 64°C for 3.6h to form a hydrophilic polyurethane prepolymer.

[0065] 2. Preparation of water-based polyurethane emulsion

[0066] Cool the prepolymer to 18° C., add metered triethylamine, neutralize and emulsify in water to obtain a water-based polyurethane emulsion with a solid content of 47%.

[0067] 3. Preparation of water-based polyur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com