Patents

Literature

253results about How to "Improve initial tack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

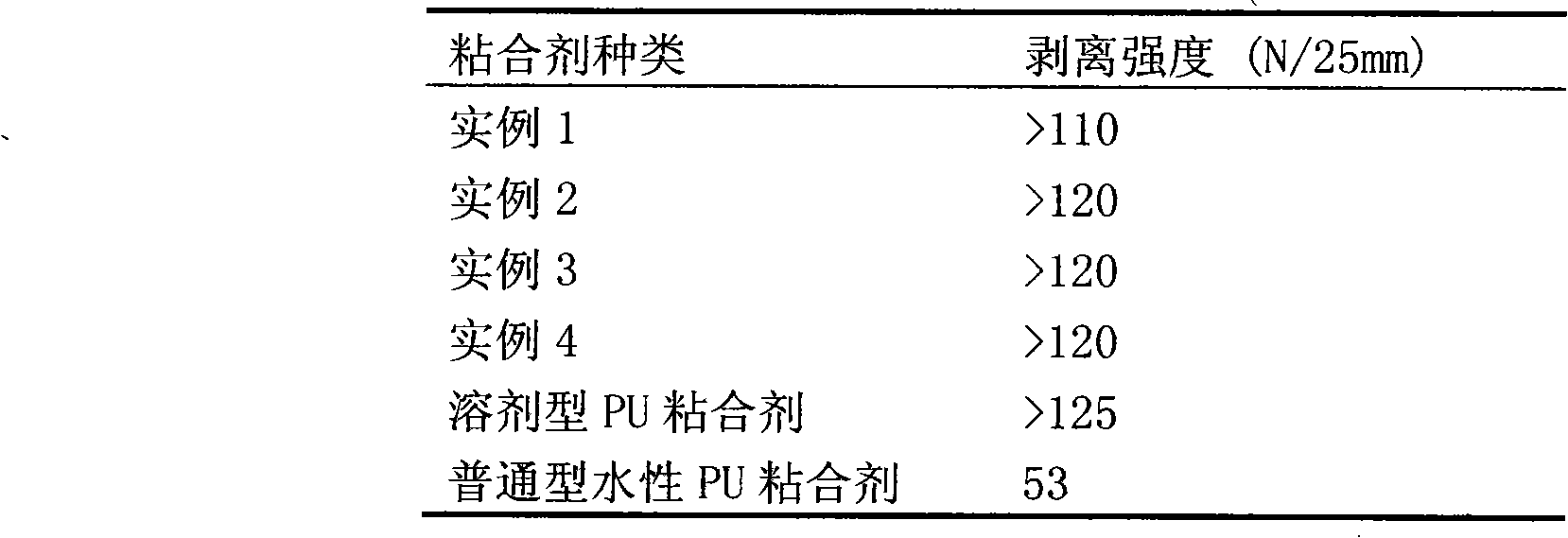

Method for preparing aqueous polyurethane adhesive and superfine fiber synthetic leather

ActiveCN101665675AHigh peel strengthIncrease elasticityPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterFolding endurance

The invention relates to a method for preparing an aqueous polyurethane adhesive and superfine fiber synthetic leather, which belongs to the technical field of chemical products and preparation methods thereof. The method is characterized by comprising the following steps: mixing polyester polyol, isocyanate, a hydrophilic chain extending agent, a micromolecule chain extending agent and an amine environment friendly catalyst to obtain a hydrophilic aqueous polyurethane prepolymer; adding a neutralizing agent to the aqueous polyurethane prepolymer to obtain an aqueous polyurethane latex; then adding an amine chain expanding agent, a thickening agent, a defoaming agent and a flatting agent to the aqueous polyurethane latex to obtain the aqueous polyurethane adhesive; coating the aqueous polyurethane latex on release paper; drying the release paper; then coating the aqueous polyurethane adhesive on the dried release paper; and pressing the release paper and base cloth together to obtain the superfine fiber synthetic leather. The high solid content aqueous polyurethane adhesive prepared by the method has better initial tack and rebound resilience and higher final strength, and the prepared superfine fiber synthetic leather has higher peel strength and low-temperature folding endurance. The preparing process of the method greatly reduces the use and the discharge of organic solvents, reduces the energy consumption and furthest reduce the environmental pollution.

Owner:HUADA CHEM GRP CO LTD

Preparation method of dual-component aqueous polyurethane adhesive agent

The invention provides a preparation method of double-component water-based polyurethane adhesive. Polyisocyanate and oligomer polyol are added into a reaction device for reaction; then chain extender is added for reaction to prepare polyurethane prepolymer; then neutralizer and rosin are added for neutralization; water is added; a high-speed disperser is used for dispersion and emulsification to prepare water-based polyurethane dispersoid; vinyl monomer and initiator are uniformly dropped for reaction to prepare water-based polyurethane dispersoid modified by rosin and vinyl resin; defoamer and wetting agent are added into the water-based polyurethane dispersoid modified by rosin and vinyl resin; Polyisocyanate curing agent is used for mixing to prepare the double-component water-based polyurethane adhesive. The invention improves the cohesive strength and initial viscosity of the water-based polyurethane adhesive, reduces the cost, and eliminates the influence of molecular emulsifier on the coating.

Owner:SOUTH CHINA UNIV OF TECH

High solid content vinyl acetate-ethylene copolymer emulsion and method for synthesizing the same

ActiveCN101200518AReduce consumptionIncrease the conversion rate of the polymerization reactionMonocarboxylic acid ester polymer adhesivesSodium bicarbonatePhenol

The present invention relates to high solid content vinyl acetate-ethylene copolymer latex for binder and the synthetic method, including 55 to 75 portion of vinyl acetate, 24 to 45 portion of ethylene, 3 to 5 portion of N-methylol acrylamide, 2 to 4 portion of PVA1788 and PVA0588, 0.4 to 1.0 portion of the compound of nonionic emulsifying agent nonyl phenol polyoxyethylene alkyl ether and anion emulsifying agent alkyl sulphate with 2:1 mixture ratio, 0.2 to 1.0 portion of 35 percents oxydol with 1:1 mixture ratio, 0.05 to 0.4 portion of formol zinc sulphate, 0.1 to 0.5 portion of ferrous sulphate, 0.5 to 1.0 portion of regular dodeca-carbon thiol-alcohol, 0.05 to 0.35 portion of potassium phosphate, 0.1 to 0.5 portion of sodium bicarbonate and 45 to 55 portion of de-ionized water. With the adoption of latex polymerization, low-residual monomer VAE latex with solid content more than 65 percents is synthesized, which is used as binder to be applied in timber processing industry and packaging industry.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing water polyurethane binder for shoe

InactiveCN101121869AHigh solid contentSimple processSolesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention relates to a method for preparing a water polyurethane adhesive applied to shoes, pertaining to the technical field of polymers. A proper amount of first polyatomic alcohol, second polyatomic alcohol, third polyatomic alcohol and fourth polyatomic alcohol are mixed to achieve polyurethane prepolymers; a proper amount of triethylamine is added for neutralization; the prepared polyurethane prepolymers is dispersed into deionized water and added with surface-active agent to achieve water polyurethane dispersoid; a proper amount of ethylene diamine is added into the water polyurethane dispersoid for chain expanding reaction to achieve water polyurethanes; the acetone is removed by vacuum pressure reduction, and finally mixed with antioxidant, ultraviolet absorbent, leveling agent, antifoaming agent, wetting agent, thickening agent and silane coupling agent to achieve the water polyurethane adhesive. The invention provides a simple process, needs a small dosage of organic solvent, the solid content is above 50 percent, the energy consumption of production is relatively low; besides, the adhesive has excellent bonding strength to various shoe materials such as PVC, polyurethane, leather, SBS, canvas, rubber and so on, and the heat-resistance effect is strong.

Owner:BEIJING CHEM IND RES INST

High strong adhesive and method for preparing same

The powerful adhesive includes neoprene, grafting monomer, thickener, dispersant, adhesion promoter, catalyst, antioxidant, solvent, stuffing, etc. The present invention also discloses the preparation process of the adhesive, and the preparation includes introducing grafting monomer to neoprene molecule chain to raise the adhesion strength, selecting proper adhesion promoting resin to increase the initial adhesion force, and adopting mixed solvent to form high adhering performance. The adhesive has high solid content and excellent environment protecting performance, and has also excellent antiageing performance, high resistance to heat, oil, chemical and corrosion, high weather resistance, good mildew-proof performance, antibiotic performance, etc. and may be used for adhering timber, concrete, rubber, metal, gypsum board, brick and other building material.

Owner:GUANGZHOU GLORYSTAR CHEM

Method for preparing multiple modified self-crosslinking aqueous polyurethane adhesive agent

InactiveCN101182406AIncrease the degree of cross-linkingImprove cohesive strengthPolyureas/polyurethane adhesivesEpoxyCross-link

The invention discloses a preparation method of self cross-linking water-based polyurethane adhesive of multiple modifications. Polyisocyanate and oligomer polyol are added into a reaction device for reaction; then chain extender is added for reaction to prepare polyurethane prepolymer; then polyurethane prepolymer modified by rosin and epoxy resin is added to prepare modified polyurethane prepolymer; finally water is added into the modified polyurethane prepolymer and a high-speed disperser is used for dispersion; neutralizer and cross-linker are added to prepare the self cross-linking water-based polyurethane dispersoid of multiple modifications; thickening agent and defoamer are added into the dispersoid to prepare the modified polyurethane adhesive. The adhesive prepared in the invention has the rapid drying, good water resistance and high bond strength; the adhesive can meet the bonding requirements of vehicles and a plurality of other materials; the invention has the advantages of simple operation, simple process, short production cycle, low cost of operation and easiness of promotion and application.

Owner:SOUTH CHINA UNIV OF TECH

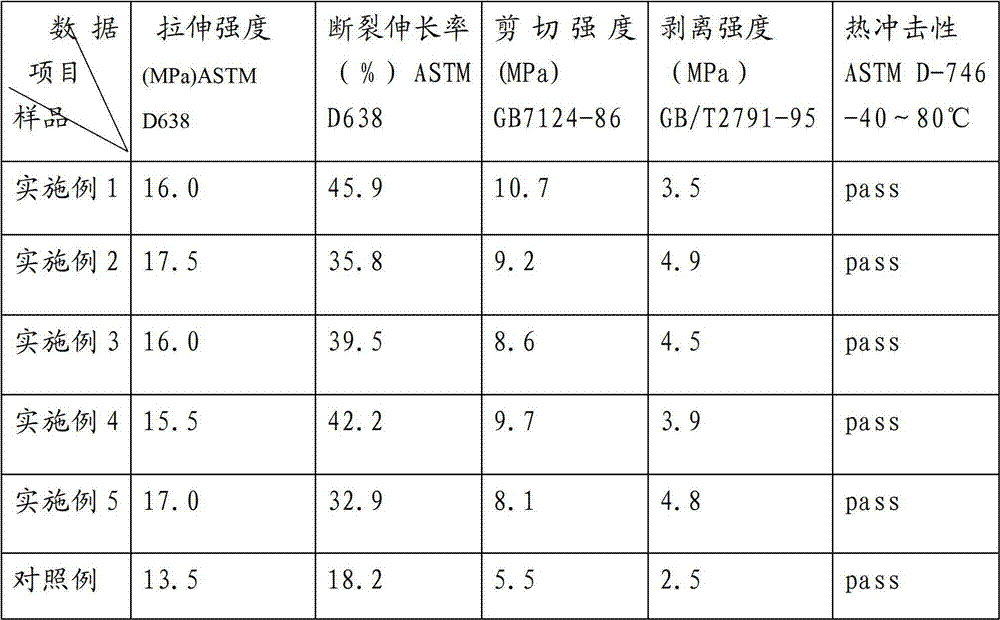

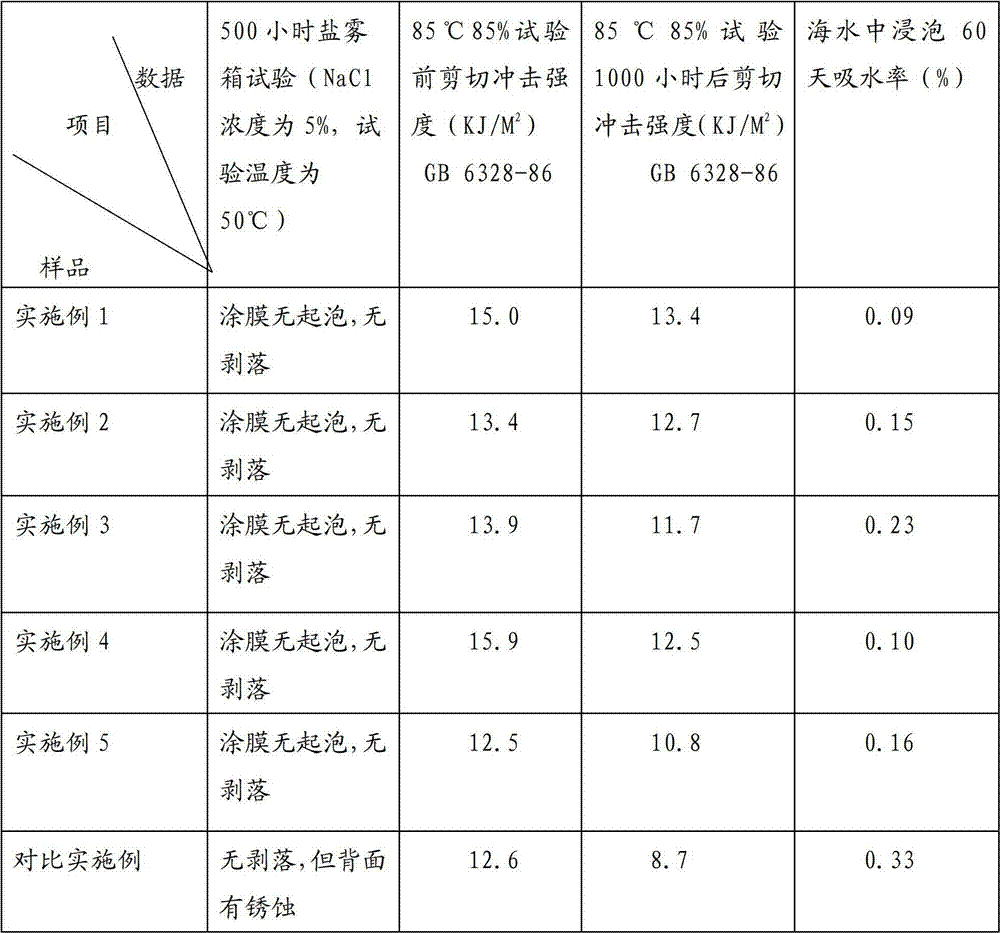

High elastic corrosion resistant epoxy sealant and preparation method thereof

InactiveCN102898988ANo foamingNo peelingNon-macromolecular adhesive additivesOther chemical processesCrack resistanceHigh intensity

The invention relates to a high elastic corrosion resistant epoxy sealant and a preparation method thereof. The epoxy sealant provided by the invention comprises a component A and a component B in a weight ratio of 100:20-100:25. The epoxy sealant provided by the invention has advantages of high strength, high elasticity, low heat release, cracking resistance, good sealing performance and seawater corrosion resistance, is convenient for construction, and greatly improves sealing of key parts of ship stern tube.

Owner:YANTAI DARBOND TECH

Special adhesive for underwater construction and preparation method thereof

InactiveCN103555243AIncrease elasticityGood resistance to cold and heat shockNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveActive agent

The invention discloses a special adhesive for underwater construction, and the special adhesive comprises an A component and a B component at a weight ratio of 100:(20-100):25, wherein the A component is prepared from the following raw materials in parts by weight: 30-60 parts of modified epoxy resin, 5-30 parts of tackifier, 2-10 parts of accelerant, 5-15 parts of reactive diluent, 0.1-0.3 parts of surfactant, and 10-35 parts of filler powder; the B component is prepared from the following raw materials in parts by weight: 0-60 parts of ketimine, 0-60 parts of phenalkamine, 30-65 parts of modified polyamide, 1-6 parts of curing accelerator, and 2-15 parts of moisture repellent. The special adhesive for underwater construction has the advantages of being good in bonding strength in water, good in toughness, water-resistant, capable of resisting chemical attack, strong in initial viscous force and convenient to construct, and great improvement is brought for the underwater construction field.

Owner:YANTAI DARBOND TECH

Low viscosity solvent-free polyurethane laminating adhesive and preparation method thereof

ActiveCN103215006AIncrease crosslink densityHigh functionalityFilm/foil adhesivesPolyureas/polyurethane adhesivesAdhesiveSolvent based

The invention discloses a low viscosity solvent-free polyurethane laminating adhesive, which includes component A and component B. The component A is an isocyanate terminated compound, and the component B is a hydroxyl terminated compound. The component A and the component B are mixed according to that the isocyanate terminated group and the hydroxyl are in a mole ratio of 1.3-1.75, thus obtaining the bicomponent polyurethane laminating adhesive. The invention also discloses a preparation method of the low viscosity solvent-free polyurethane laminating adhesive. The low viscosity solvent-free polyurethane laminating adhesive prepared by the invention has the advantages of low viscosity, fast curing speed, high peel strength and resistance to 100DEG C cooking.

Owner:SOUTH CHINA UNIV OF TECH +1

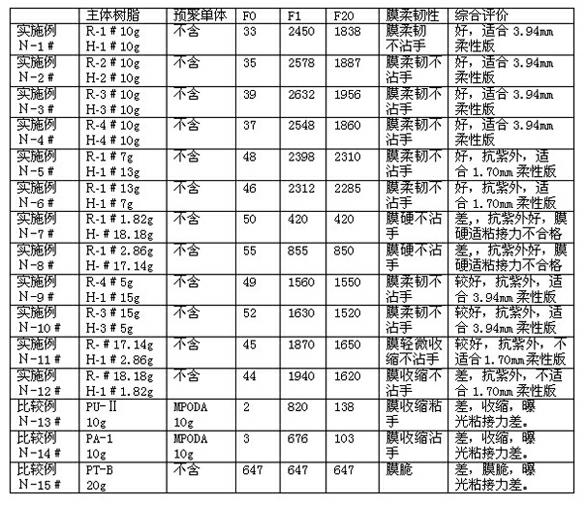

Ultraviolet curing adhesive

ActiveCN102079961ASolve the problem of unexposed initial tackHigh softening pointPolyureas/polyurethane adhesivesPhotosensitive materials for photomechanical apparatusAcrylic resinAdhesive

The invention discloses an ultraviolet curing adhesive comprising a resin main body, a dissolvent, an ultraviolet light initiator and an addition agent, wherein the resin main body is composed of a resin R and a resin H; the R resin is an active polyurethane acrylic resin with a main chain containing a polyether structure and a branch chain containing a vinyl optical active group as well as with a lower molecular weight; and the H resin is an inert polyurethane acrylic resin with a main chain containing a polydiene and aryloxide structure and with a relatively higher molecular weight. The adhesive contains no monomer or prepolymer, has high softening point, can be precoated on a base material, has super strong cohesive force on a high-oilness contact surface and has characteristics of high-temperature resistance, small internal stress and good flexibility.

Owner:LUCKY HUAGUANG GRAPHICS

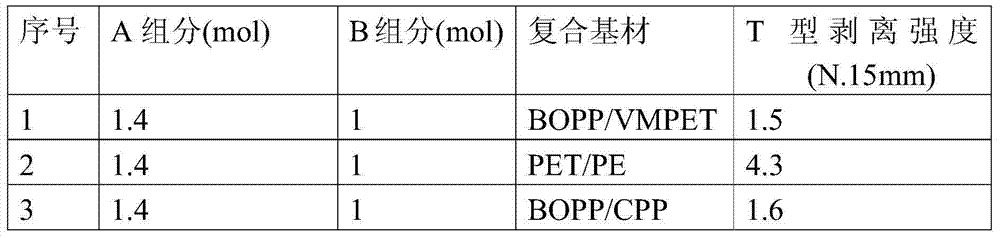

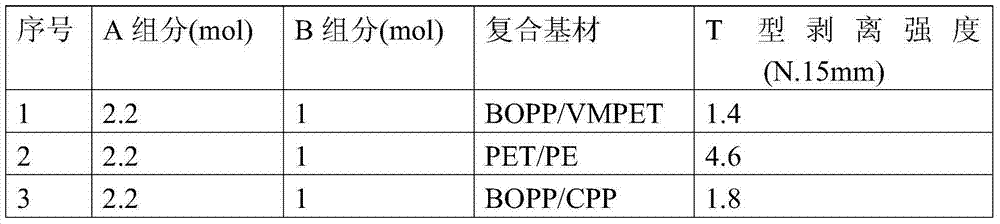

Flexible packaging composite resin and preparation method thereof

ActiveCN103614108ALow viscosityMeet the process requirementsPolyureas/polyurethane adhesivesPolyesterResin-Based Composite

The invention discloses flexible packaging composite resin and a preparation method thereof. The flexible packaging composite resin consists of a component A and a component B, wherein the component A is a polyurethane prepolymer containing isocyanate groups (-NCO); the component B is a mixture of polyester and polyether polyol containing hydroxyl groups (-OH), and the application proportion requirement of the component A and the component B is as follows: the mol ratio of the functional group -NCO to the functional group -OH is (1.4-2.2): 1.0. At the application state, the viscosity of a binder obtained by mixing the component A and the component B according to the stipulated ratio is relatively low, and the binder has an excellent coating performance under the normal-temperature condition, also has extremely high in adhesion strength after being bonded, can meet the technological requirement an existing normal-temperature coating process in China and is relatively high the inertial adhesion, and the quality flaws such as tunnel and crinkling after the binder is coated can be avoided.

Owner:JIANGSU LIHE ADHESIVE

Method for preparing modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive

InactiveCN103435760AGood pressure sensitivityImprove water resistanceGraft polymer adhesivesEpoxyPolyurethane dispersion

The invention discloses a method for preparing a modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The method comprises the following steps: adding polyisocyanate and low polymer polyhydric alcohol into reaction equipment, further adding a hydrophilic chain extender to react to obtain a polyurethane prepolymer, subsequently adding acrylic ester containing hydroxyl and a modified epoxy resin so as to obtain the modified polyurethane prepolymer; further adding a neutralizer to neutralize, adding water, subsequently dispersing by using a high-speed dispersing machine so as to obtain a modified waterborne polyurethane dispersoid; uniformly dripping acrylate monomer, a modified rosin resin and an initiating agent so as to obtain a modified waterborne polyurethane dispersoid; further adding a defoaming agent, and finally adding a curing agent additionally so as to obtain the modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The pressure-sensitive adhesive prepared through the method is high in primary adhesion property, release force, adhesion lasting property and high-temperature adhesion lasting property; a high-temperature-resistant pressure-sensitive adhesive tape prepared from the adhesive can meet the requirements of automobile and electronic industries. According to the invention, the preparation process is simple, the production period is short and the operation cost is low.

Owner:SOUTH CHINA UNIV OF TECH

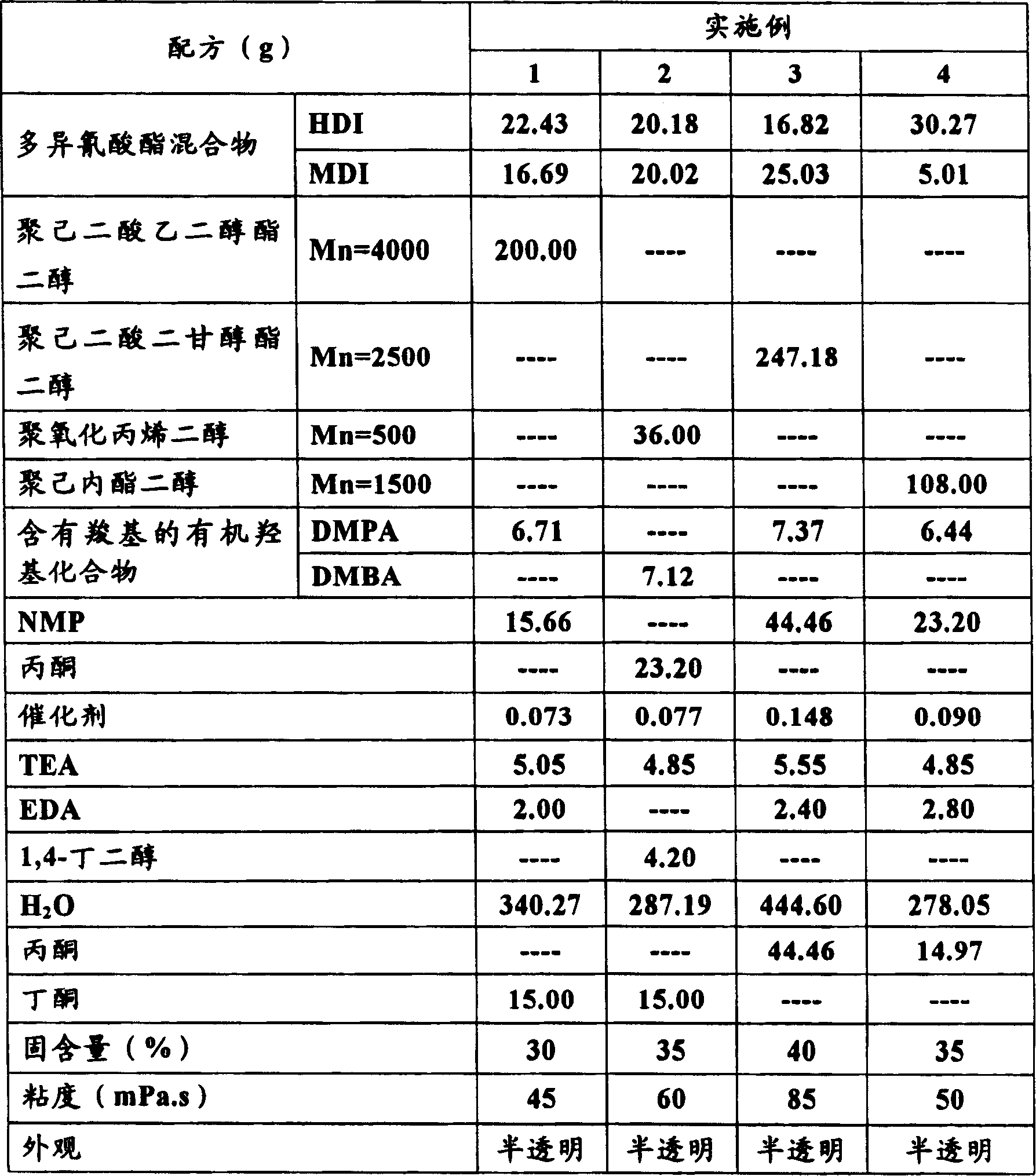

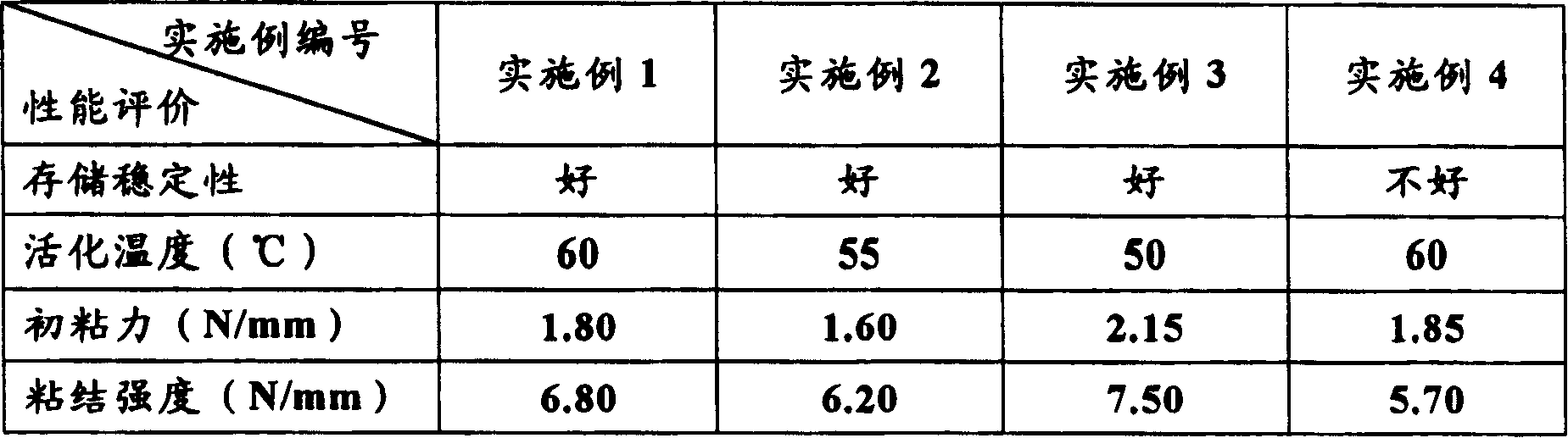

Polyurethane prepolymer, aquosity polyurethane binder and uses thereof

InactiveCN101173031AHigh solid contentImprove initial tackSolesPolyureas/polyurethane adhesivesPolyurethane adhesivePrepolymer

The invention relates to a polyurethane prepolymer, which is characterized in that: the invention comprises the condensation polymerization products of following components: (a) binary isocyanate system formed by diphenylmethane-4, <4>- diisocyanate(MDI) and 1, 6-hexylidene diisocyanate(HDI), (b) polyatomic alcohol, and (c) organic hydroxyl compound with carboxyl. The invention also relates to an aquosity polyurethane adhesive manufactured by the polyurethane prepolymer, and the aquosity polyurethane adhesive manufactured of the invention has the advantages of low manufacturing cost, low activating temperature and high adhesive strength, and more particularly being applicable for shoes making field.

Owner:北京林氏精化新材料有限公司

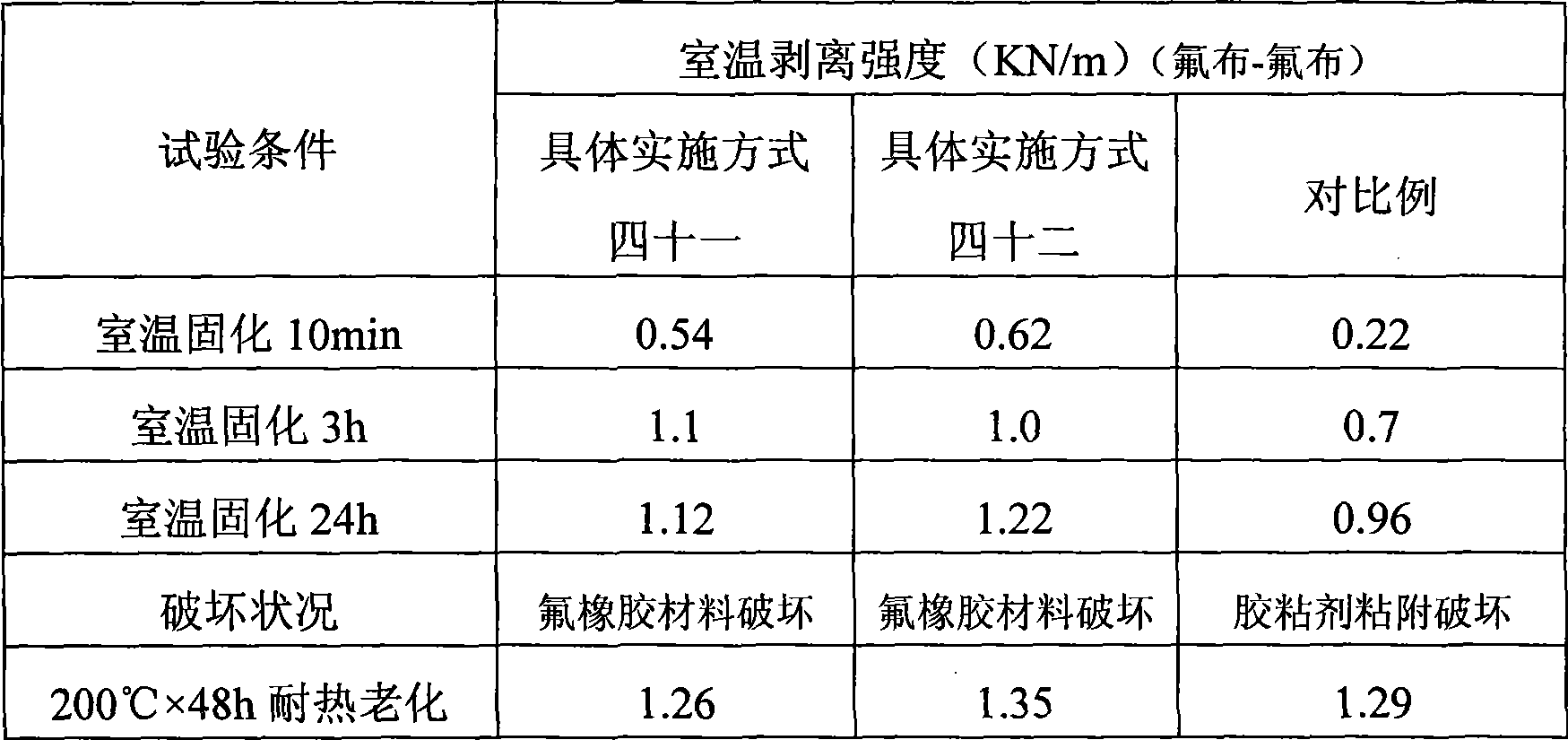

Room curing fluoro rubber adhesive and preparation method

InactiveCN101531872AImprove initial tackFast curing at room temperatureAdhesivesEpoxyOrganic solvent

The invention relates to a room curing fluoro rubber adhesive and a preparation method, solving the problems of low initial adhesive force, low curing rate and low adhesive intensity of current fluoro rubber adhesives. The adhesive of the invention comprises a component A and a component B; wherein, the component A is prepared by a fluoroelastomer compound, an epoxy resin, polyurethane emulsion and organic solvent; the component B is prepared by an organic amine curing agent, a silane coupling agent and solvent. The method is as follows: a. compounding raw fluorubber, an acid-acceptor, reinforcing fillers and a vulcanizing agent, dissolving the components in the organic solvent, adding the epoxy resin and polyurethane emulsion and evenly stirring the mixture to obtain the component A; b. evenly stirring the organic amine curing agent, silane coupling agent and organic solvent to obtain the component B. The adhesive of the invention has the advantages of high initial adhesive force, high room curing rate and adhesive intensity and can be used for adhesion of the fluorubber and metallic materials. The preparation of the adhesive is simple in technology and low in cost.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

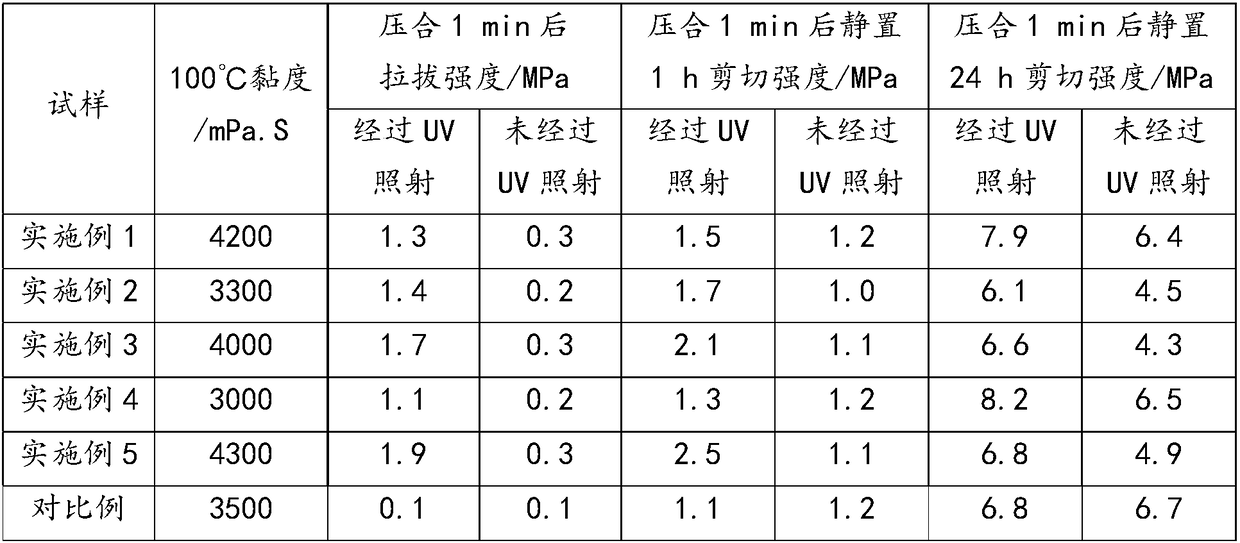

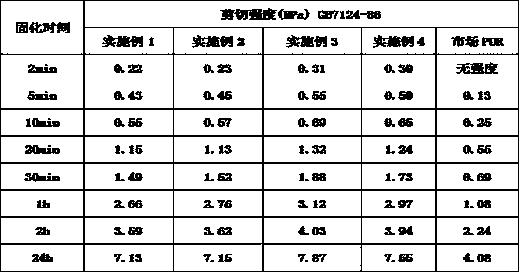

Preparation method of UV pressure-sensitive/moisture double-curing polyurethane hot melt adhesive

ActiveCN108084952APressure sensitivity hasImprove initial tackNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerPolymer science

The invention belongs to the technical field of adhesive and particularly relates to a preparation method of UV pressure-sensitive / moisture double-curing polyurethane hot melt adhesive. Hydroxy acrylamide in the hot melt adhesive generates pressure sensitivity after being subjected to UV / PUR illumination to achieve a key effect; UV irradiation is conducted after hot melt adhesive application and before adhesion, pressure is applied to an adhesion piece after adhesion, a certain time is maintained, and adhesive liquid can be crosslinked into an elastomer polymer in a viscoelastic state and haspressure sensitivity and high initial adhesion; pressing is conducted for 1 minute after assembling and adhesion, and the pull strength can reach to 1 to 2 MPa, so that rapid adhesion and positioningeffects are achieved; after pressing, moisture curing polyurethane reaction is continuously conducted and the pull strength after 24-hour curing can reach to 7 to 9 MPa, so that high adhesion strengthis guaranteed.

Owner:信泰永合(烟台)新材料有限公司

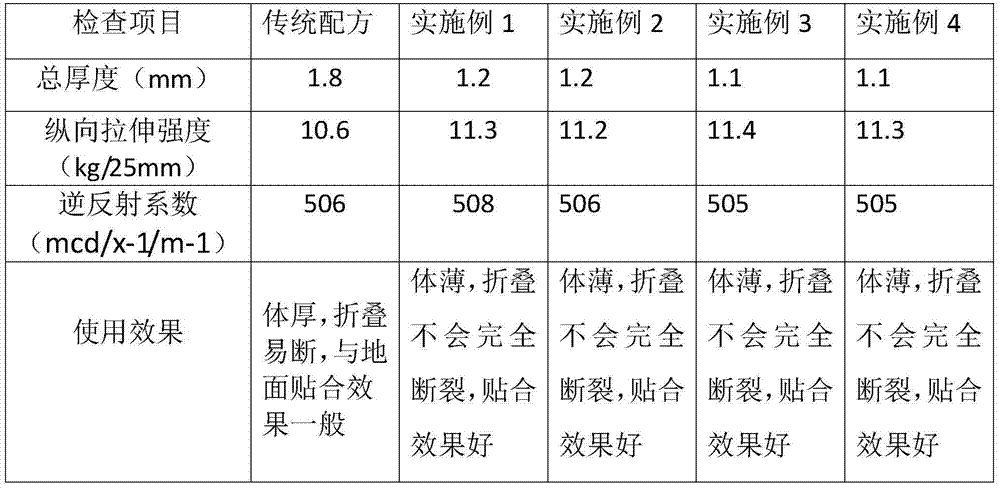

Reflective marking belt base material, base material and method for manufacturing reflective marking belt

The invention discloses a reflective marking belt base material which comprises the following components: 8-15 parts of SBS, 2-6 parts of EVA, 5-10 parts of quartz sand 7-12 parts of rosin, 3-6 parts of a petroleum resin, 30-50 parts of wollastonite powder, 20-40 parts of calcium carbonate, 1-8 pats of pigments, 2-5 parts of a plasticizer, 1-2 parts of paraffin and 8-15 parts of glass beads. In addition, the invention also discloses a base material and a method for manufacturing a reflective marking belt. The reflective marking belt base material disclosed by the invention has the advantages of high compatibility with the ground and asphalt and high strength and toughness.

Owner:SICHUAN JIANGYOU YUSHU YESHILI REFLECTIVE MATERIAL

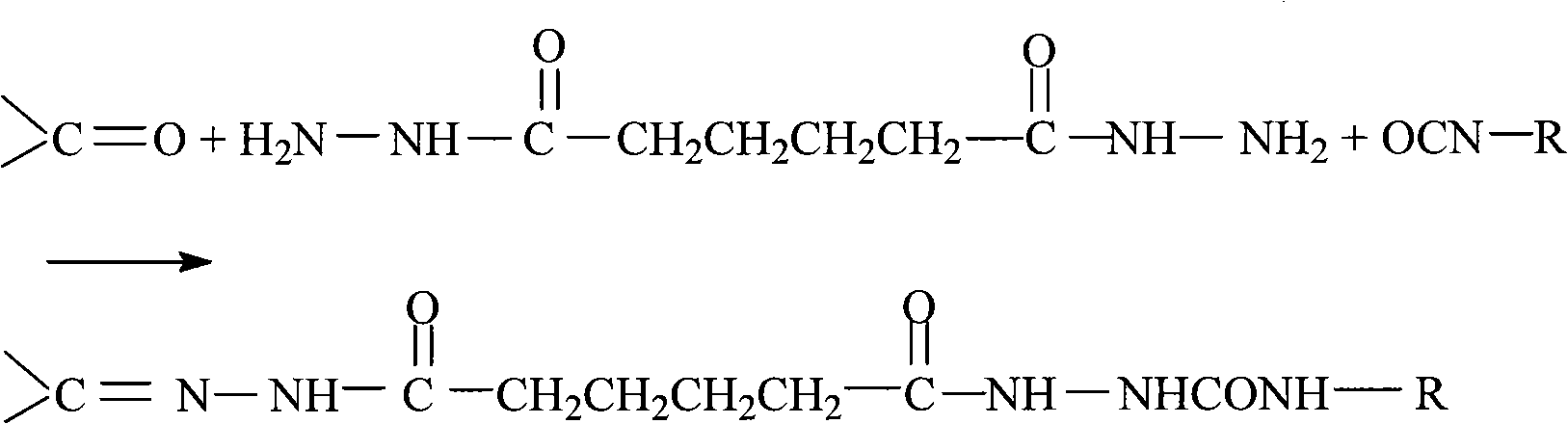

Method for preparing waterborne polyurethane adhesive used for compound soft packaging

InactiveCN101974305AImprove initial tackImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPropanoic acid

The invention discloses a method for preparing a waterborne polyurethane adhesive used for compound soft packaging. The method comprises the following steps of: reacting polycaprolactone diol and toluene diisocynate until the -NCO content of a system achieves 10.66 weight percent; adding a small-molecule chain extender, adding epoxy resin, dimethylol propionic acid and trimethylolpropane, adding rosin or hydrogenated rosin, and uniformly stirring; cooling, and neutralizing; adding ethylenediamine aqueous solution so as to prepare a modified polyurethane emulsion; adding a defoamer, a wetting agent and a coupling agent into the modified polyurethane emulsion; and uniformly mixing so as to prepare the waterborne polyurethane adhesive. The method solves the problem of bonding a hard bonding material polyurethane film; the adhesive has high wettability, bonding strength and initial adhesion to the polyurethane film, solves the technical problem of bonding the hard bonding material polyurethane film, and can meet the requirement on the adhesive by the compound soft packaging field; and the preparation is rational, has simple and reliable process and high operational flexibility, and is easy for popularization and application.

Owner:SOUTH CHINA UNIV OF TECH

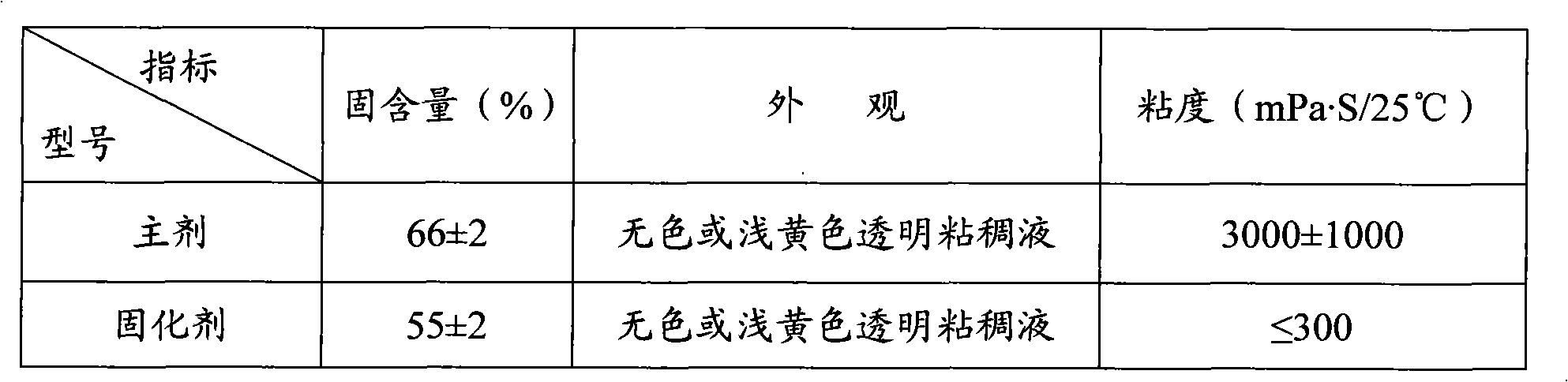

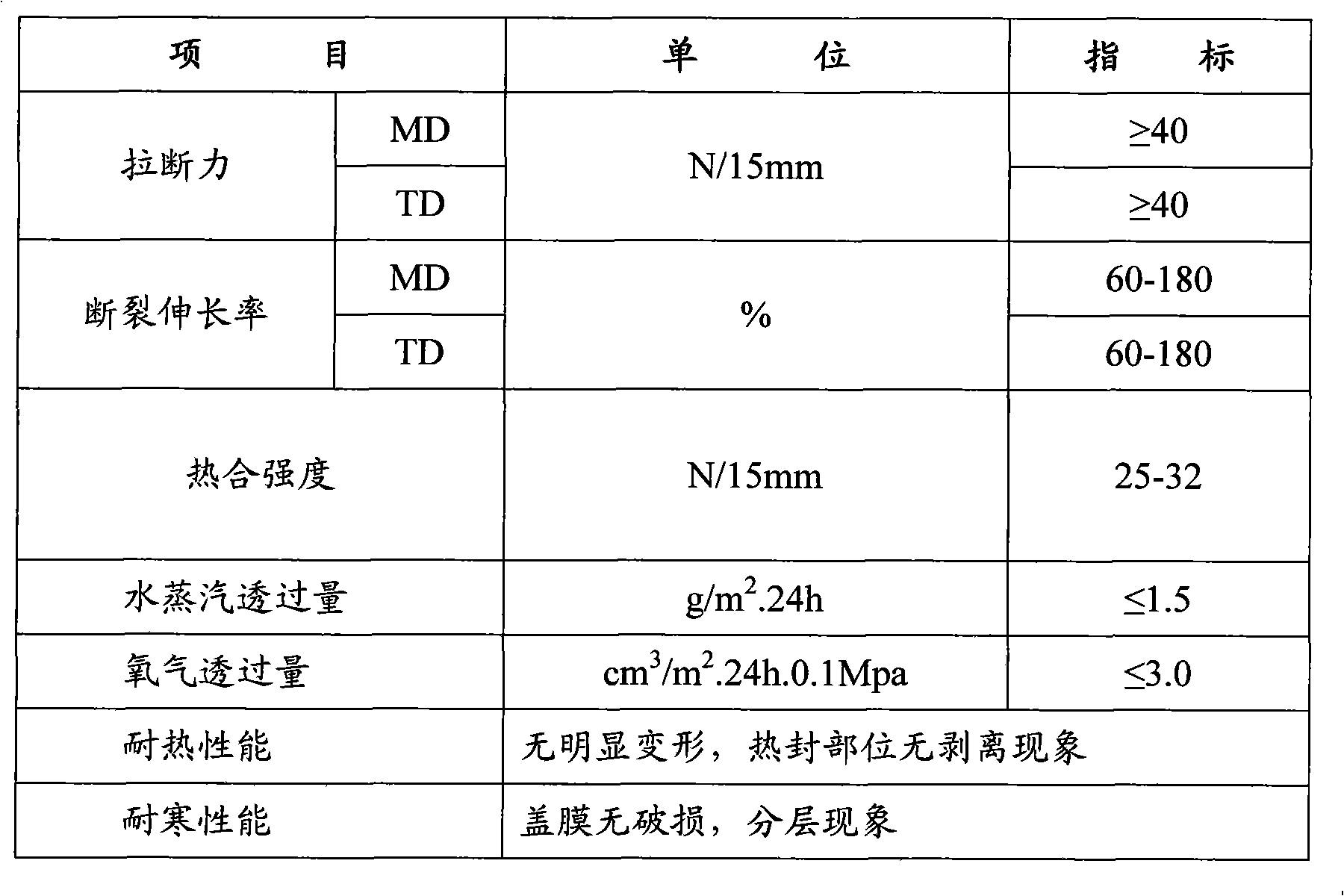

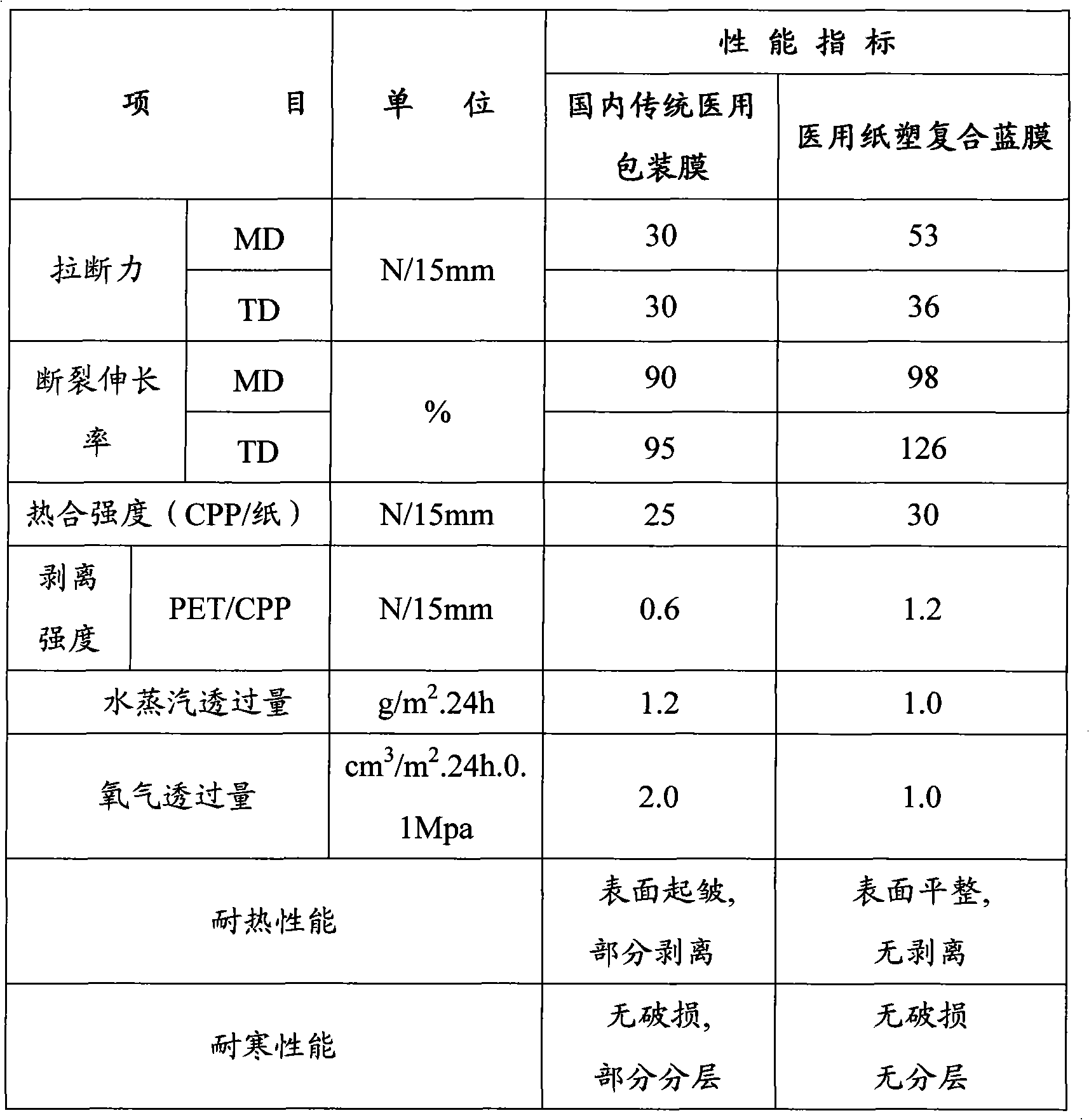

Medical paper-plastic composite blue film and preparation method thereof

ActiveCN101607458AImprove mechanical propertiesImprove folding resistanceNon-macromolecular adhesive additivesLamination ancillary operationsButenePolyester

The invention discloses a medical paper-plastic composite blue film and a preparation method thereof, the medical paper-plastic composite blue film is formed by combining a biaxially orientated polyester film which is printed and coated and a cast polypropylene film, the cast polypropylene film is divided into three layers of a corona layer, an intermediate layer and a heat seal layer, the raw material component of the corona layer is additive-free binary copolymer propylene resin RF401, the raw material components of the intermediate layer are 85-95% of binary random copolymer polypropylene resin F800E and 5-15% of ethylene-butene elastomer A-4085S, and the raw material components of the heat seal layer are 85-90% of binary copolymer propylene resin RF402 containing anti-sticky slipping agent, 5-15% of ethylene-butene elastomer A-4085S, 1-2% of inorganic anti-sticky agent ABPP10S and 0.5-1.5% of slip modified masterbatch SE07PP. The preparation method comprises the steps of printing, preparation of the cast polypropylene film, combination of the biaxially orientated polyester film and the cast polypropylene film and cutting. The medical paper-plastic composite blue film is matched with medical packing paper which can carry out heat sealing, steam sterilization and air infiltration blocking for carrying out packing of medical items, thereby reducing the packing cost and realizing safety performance of packing applications and environment-friendly treatment of packing wastes.

Owner:HUANGSHAN NOVEL

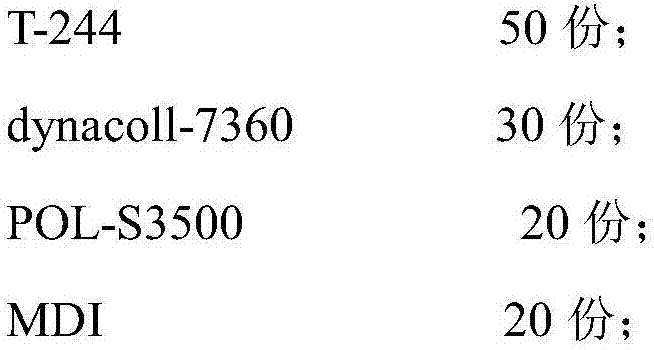

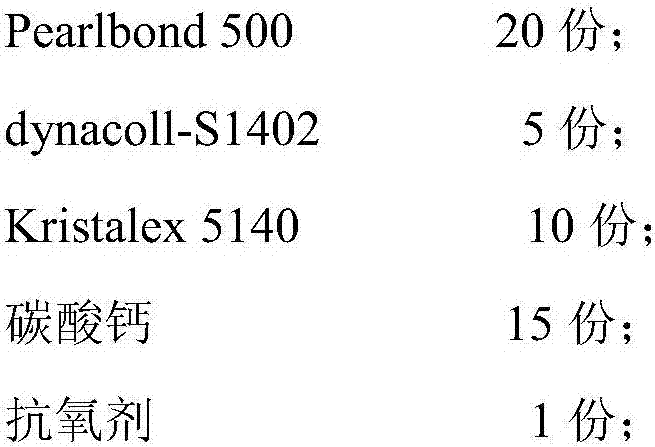

Wet curing polyurethane hot melt adhesive for plate material edge sealing

InactiveCN107502173AGood compatibilityRapid positioningInksPolyurea/polyurethane coatingsPolyesterMoisture cure polyurethane

The invention discloses a wet curing polyurethane hot melt adhesive for plate material edge sealing. The wet curing polyurethane hot melt adhesive comprises ingredients such as liquid polyester polyol, solid polyester polyol, isocyanate, thermoplastic resin and tackifying resin. The adhesive has the advantages that the compatibility among all ingredients is good; the positioning is fast; the high initial bonding intensity and final bonding intensity are realized, and the like. The wet curing polyurethane hot melt adhesive is particularly applicable to plate material edge sealing.

Owner:广州市极威新材料有限公司

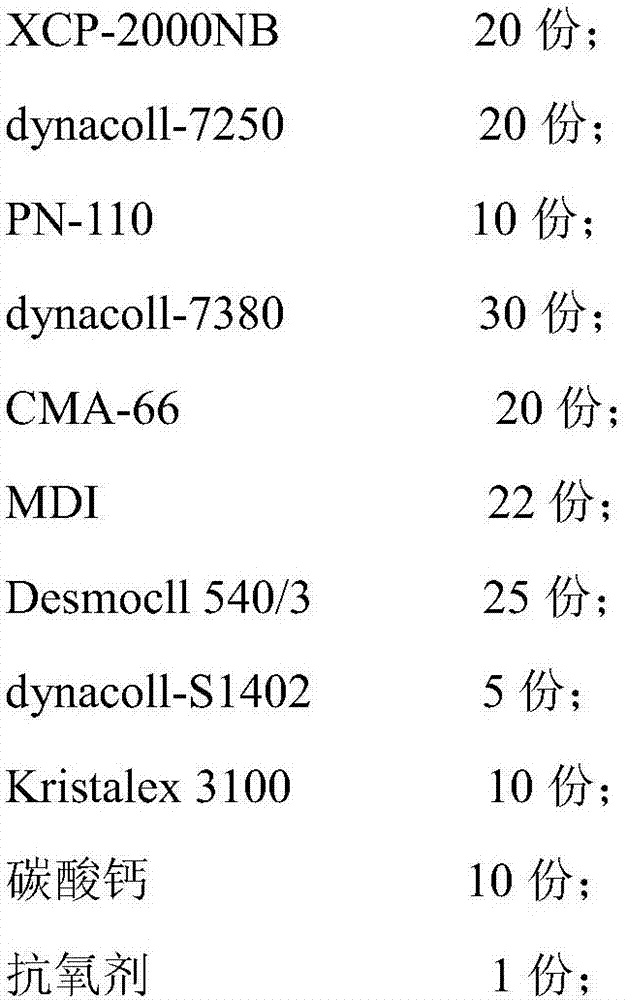

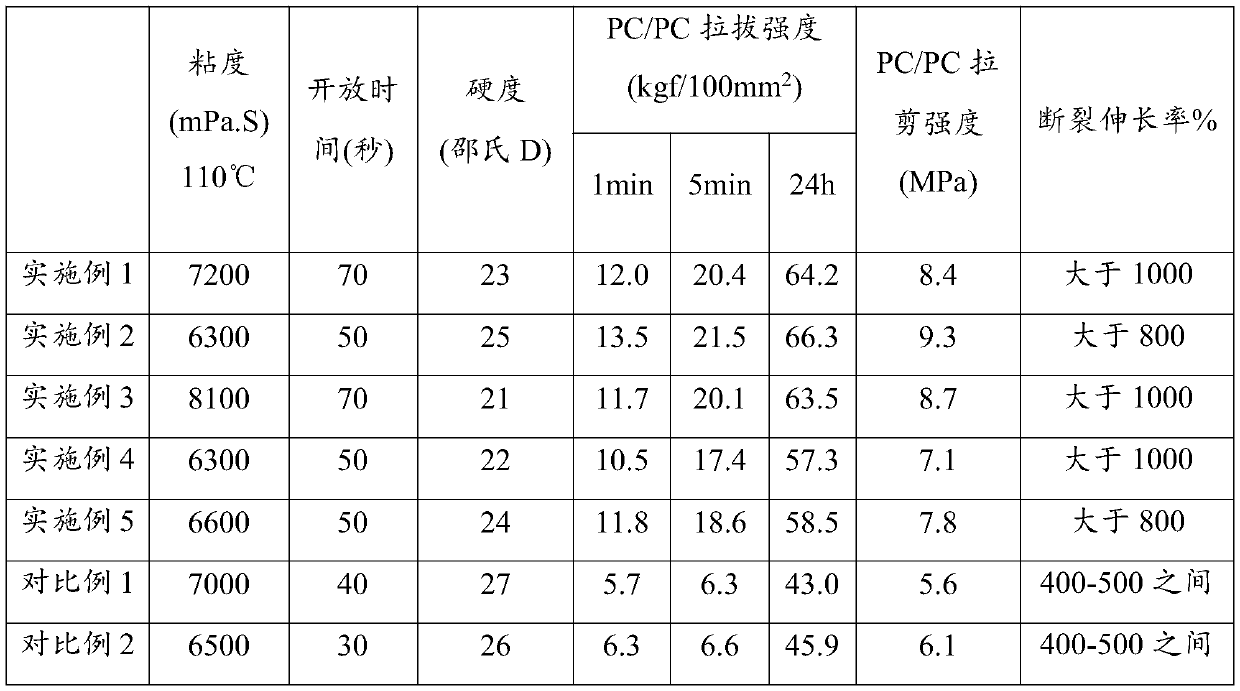

High-initial strength reaction-type polyurethane hot melt adhesive and preparation method thereof

InactiveCN110256999AHigh reactivityIncrease crosslink densityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantPliability

The invention discloses a high-initial strength reaction-type polyurethane hot melt adhesive. The high-initial strength reaction-type polyurethane hot melt adhesive comprises the following components: in parts by weight, 25-35 parts of crystalline polyester polyol, 30-45 parts of amorphous liquid polyester polyol, 5-10 parts of high-molecular weight crystalline polyester, 6-9 parts of thermoplastic polyurethane, 0.1-0.3 part of an antioxidant, 14-19 parts of MDI, 0.3-0.5 part of a catalyst and 0.3-0.5 part of a silane coupling agent. According to the high-initial strength reaction-type polyurethane hot melt adhesive, a reaction is performed on the crystalline and amorphous polyester polyols with lower molecular weights and aromatic diisocyanate, and high reactivity is achieved; the crystalline copolyester with a high molecular weight is adopted, a high crosslinked density is achieved, and high initial adhesive strength and high final adhesive strength are achieved; and the thermoplastic polyurethane resin with good compatibility with the polyester system is adopted, the initial adhesion is improved, good flexibility can also be maintained, and the problems of hardness increase and flexibility decrease which are brought by fast crystallization and high-molecular-weight polyester which are applied to increase of the initial strength in the prior art are solved.

Owner:YANTAI TIGHTSEN FINE CHEM

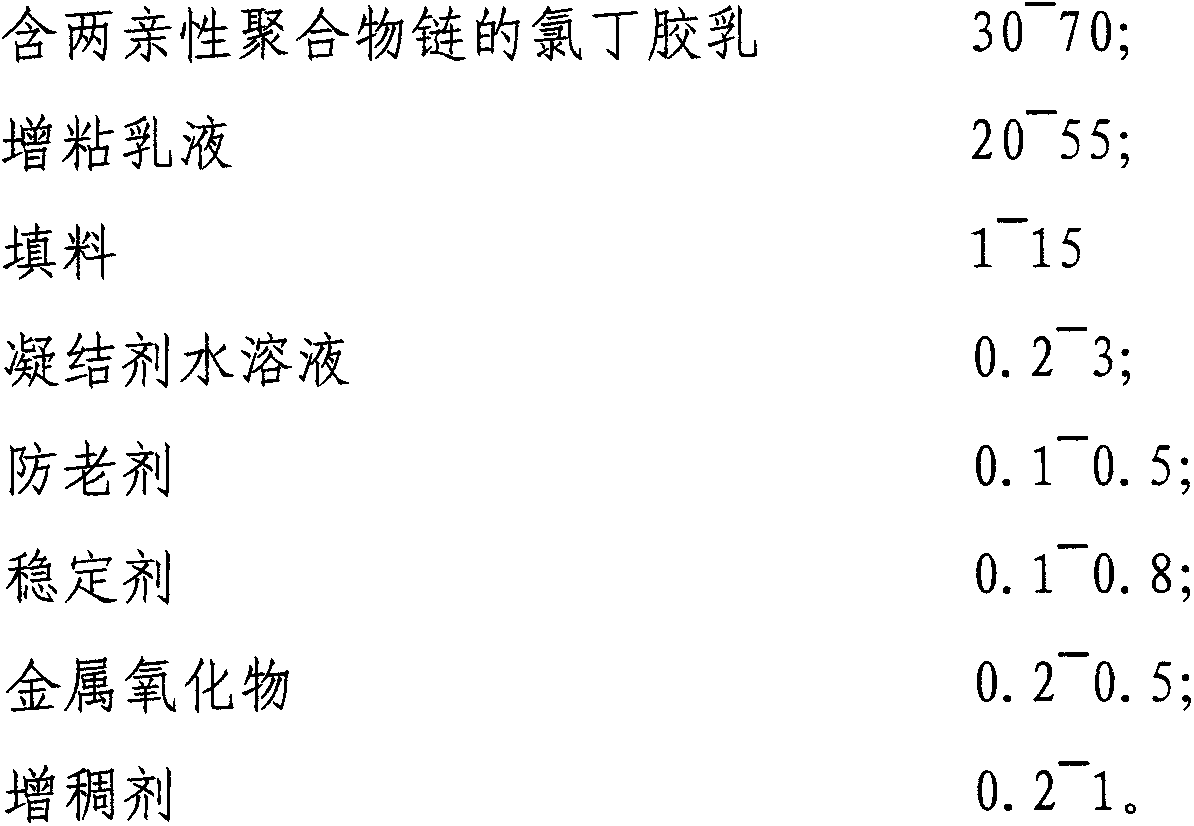

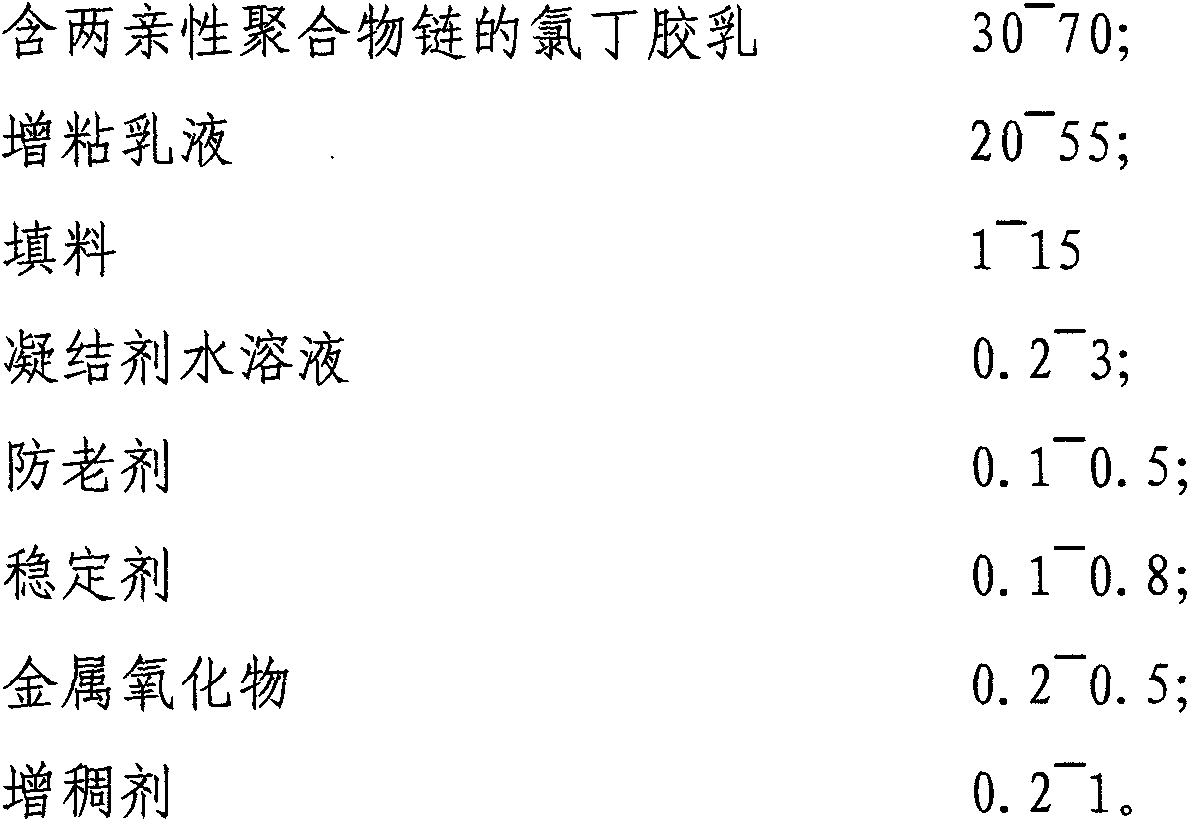

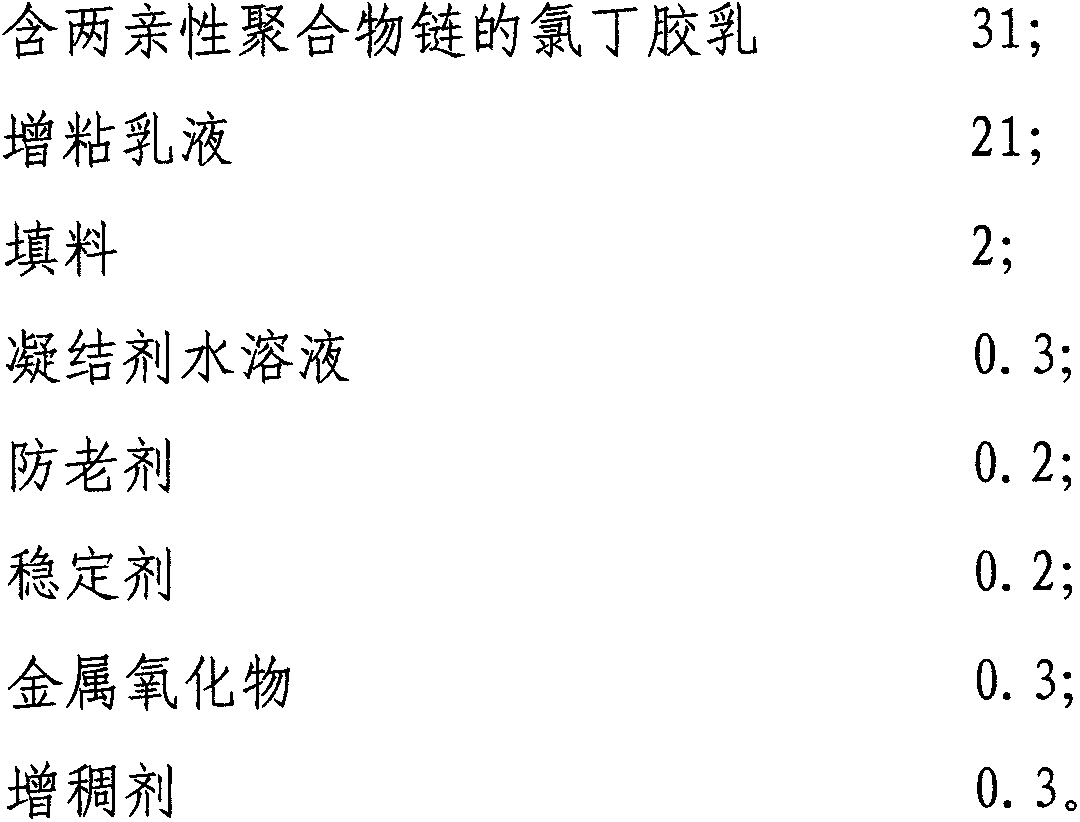

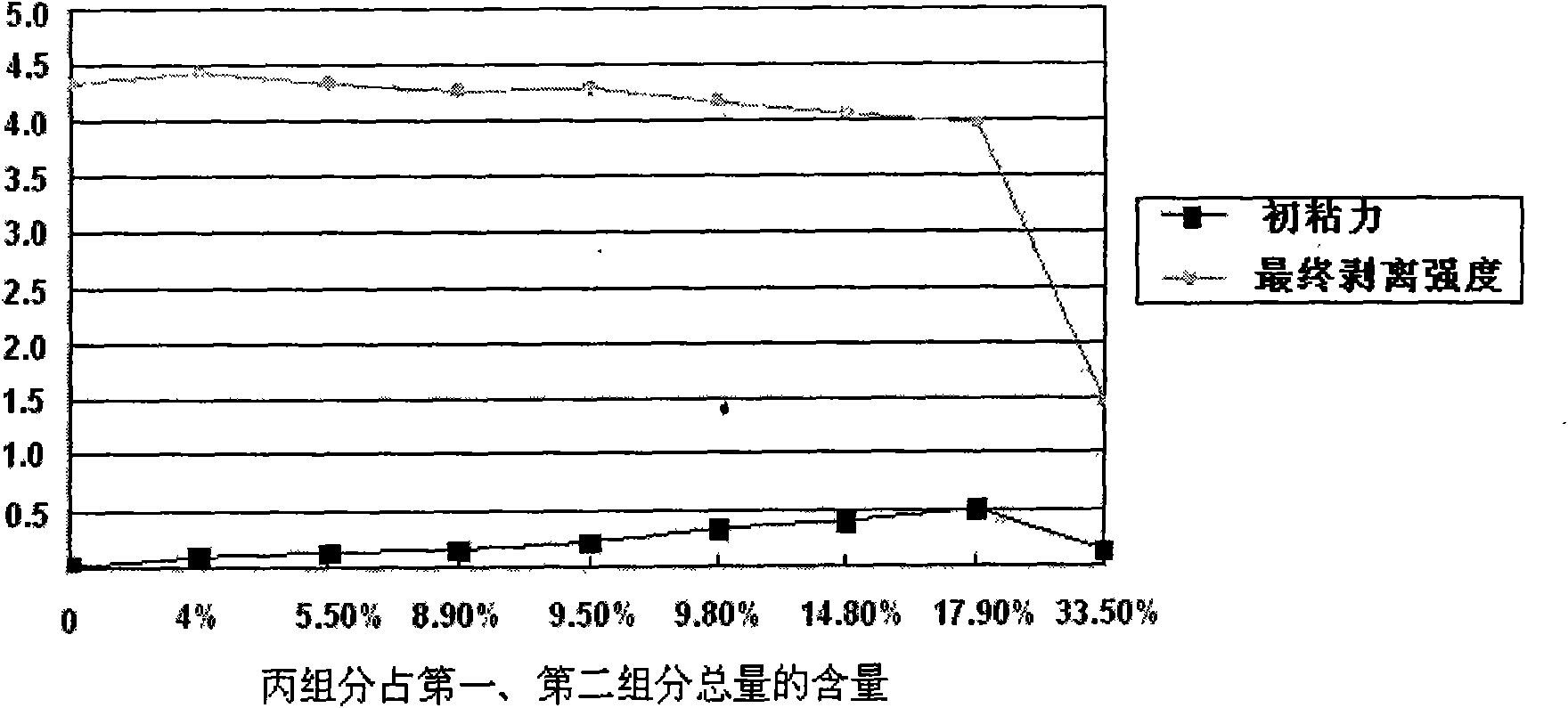

Amphiphilic polymer chain-containing neoprene latex adhesion agent and preparation method thereof

ActiveCN103740304AImprove initial tackImprove dispersion stabilityNon-macromolecular adhesive additivesRosin adhesivesAminoethyl methacrylateDispersion stability

The invention discloses an amphiphilic polymer chain-containing neoprene latex adhesion agent. The adhesion agent comprises the following components in parts by weight: an amphiphilic polymer chain-containing neoprene latex, a tackifying emulsion, a filler, a coagulating agent aqueous solution, an anti-aging agent, a stabilizer, a metal oxide and a thickening agent. With a neoprene latex as a matrix and with methyl methacrylate, methacrylic acid and N,N-dimethyl aminoethyl methacrylate as graft monomers, the amphiphilic polymer chain-containing neoprene latex is prepared by an emulsion graft polymerization reaction. The invention also discloses a preparation method of the amphiphilic polymer chain-containing neoprene latex adhesion agent. The problems of poor storage stability and small initial viscous force are solved, the neoprene latex can be simultaneously skillfully endowed with dispersion stability and demulsification cohesion, and at the same time, the dispersion stability and the initial viscous force of the neoprene latex are improved; and the grafted type neoprene latex adhesion agent has wide application range, high adhesion strength, and remarkable economic benefits and social benefits.

Owner:GUANGDONG TAIQIANG TECH IND CO LTD

Siliconless fire-retardant type quick solidifying covering film for flexible circuit and its preparation method

InactiveCN1537906AGuaranteed stabilityLower volatility pointLiquid surface applicatorsEpoxy resin coatingsEpoxyElastomer

A flame-retarded quickly solidified silicon-free covering film for flexible circuit contains brominated epoxy resin, liquid phenolic epoxy resin, high-activity low-viscosity epoxy resin, acrylate copolymer, diaminodiphenyl sulfone (or methane), aluminium hydroxide, Sb2O3, and toluene / acetone. Its advantages are high adhesion and fire resistance.

Owner:SHENZHEN DANBOND TECH

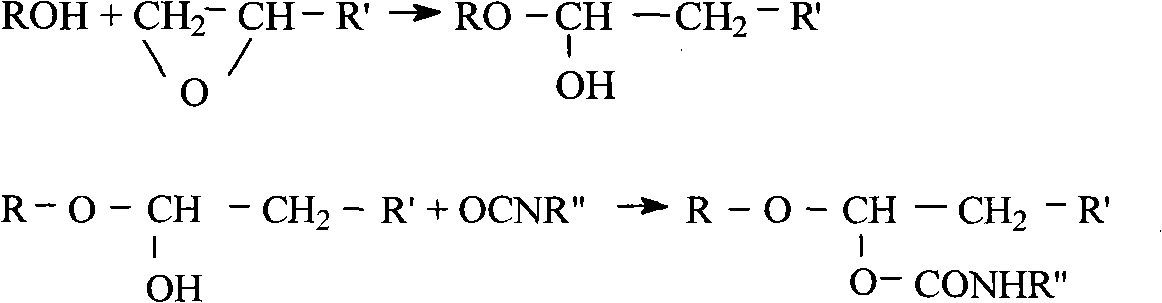

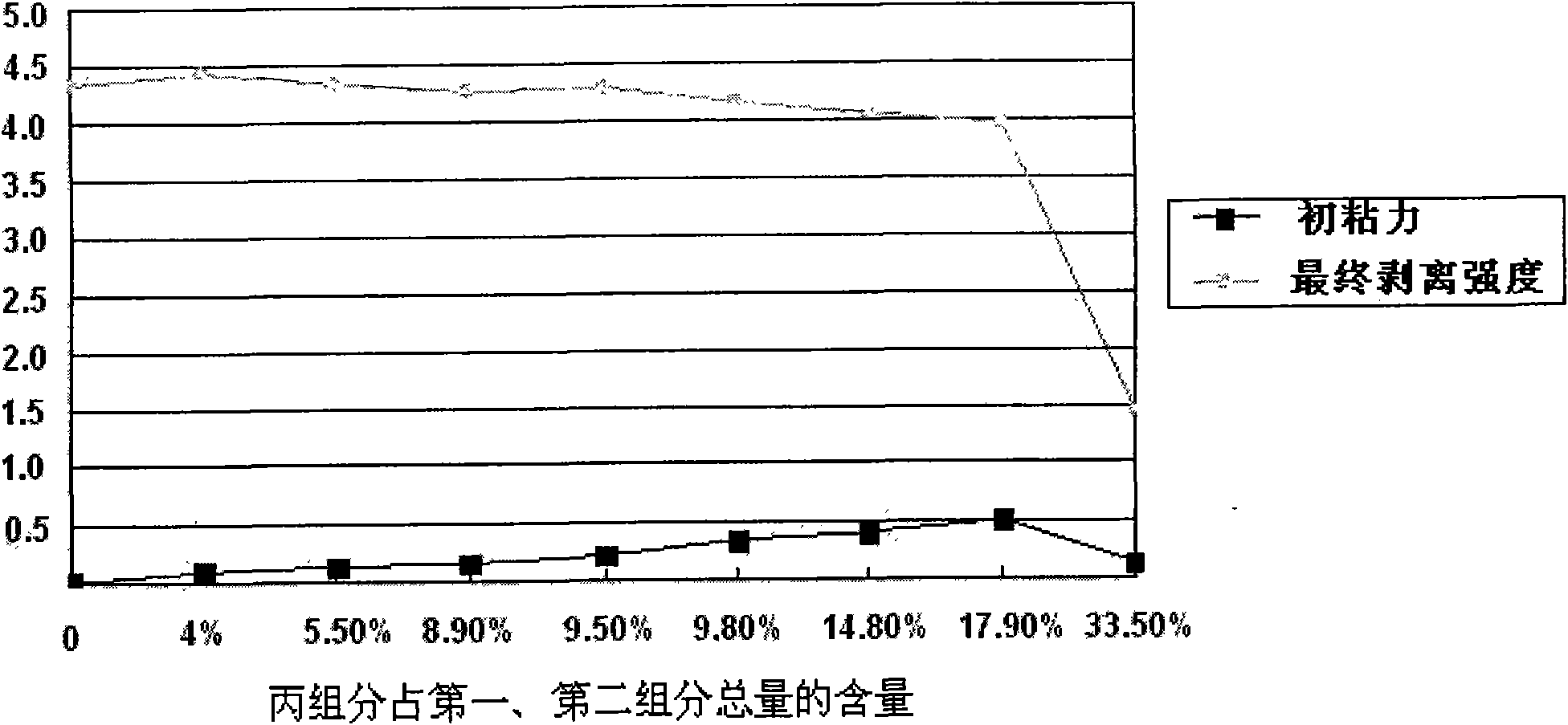

Non-solvent polyurethane laminating adhesive with high initial stick force and preparation method and application thereof

ActiveCN101768419AImprove initial tackHigh molecular weightPolyureas/polyurethane adhesivesLaminationPolymer scienceAdhesive

The invention relates to a non-solvent polyurethane laminating adhesive with high initial stick force and a preparation method and application thereof. The laminating adhesive comprises a first component and a second component, wherein the first component comprises a component A, and the second component comprises a component B. The first component and the second component also comprise a component C independently or simultaneously, and the component C accounts for 1wt%-40wt% of the total weight of the first component and the second component. The component C is prepared by producing a prepolymer of acrylic acid and polyurethane through reaction of the component A with acrylic acid, methacrylic acid, and the like. with 1-5 functionalities and one or more than one mixture of ester monomer compounded by alcohols lower than C18, and adding a light trigger which is 0.1wt%-15wt% of the ester monomer, wherein the ester monomer accounts for 0wt%-100wt% of the total weight of the ester monomer and the component A. Ultraviolet light irradiation with a certain intensity is applied after coating and before compounding the non-solvent polyurethane laminating adhesive so as to achieve the purposes of quickly increasing molecular weight and viscosity in a short time and enhancing initial stick force. Compared with the traditional non-solvent polyurethane laminating adhesives, the laminatingadhesive of the invention has higher initial stick force.

Owner:康达新材料(集团)股份有限公司

High initial strength reaction type polyurethane hot melt adhesive and preparation method thereof

InactiveCN109181555AEasy to masterEasy to prepareMacromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceInitial strength

The invention discloses a high initial strength reaction type polyurethane hot melt adhesive and a preparation method thereof. The hot melt adhesive is prepared from the following raw materials in parts by weight: 60-90 parts of polyhydric alcohols, 5-40 parts of tackifying resins, 10-15 parts of isocyanate compounds, 0.1-1 part of catalyst and 0.1-1 part of adhesion promoter. The preparation method comprises the following steps: (1) adding polyhydric alcohols and tackifying resins into a reaction vessel, heating in vacuum, melting and dehydrating, thereby acquiring a mixture; (2) adding isocyanate compounds or isocyanate group terminated prepolymer compounds into the mixture acquired in the step (1) and then controlling temperature and performing polymerization reaction, thereby acquiringa polymer; (3) adding a catalyst and an adhesion promoter into the polymer acquired in the step (2), controlling temperature and reacting in vacuum; and (4) placing the prepared hot melt adhesive into a container and filling dry inert gas. The high initial strength reaction type polyurethane hot melt adhesive disclosed by the invention has the advantages of high initial strength, excellent temperature resistance and low production cost. The preparation method is simple and is easy for industrial production.

Owner:HUIZHOU DUV ELECTRONICS MATERIALS

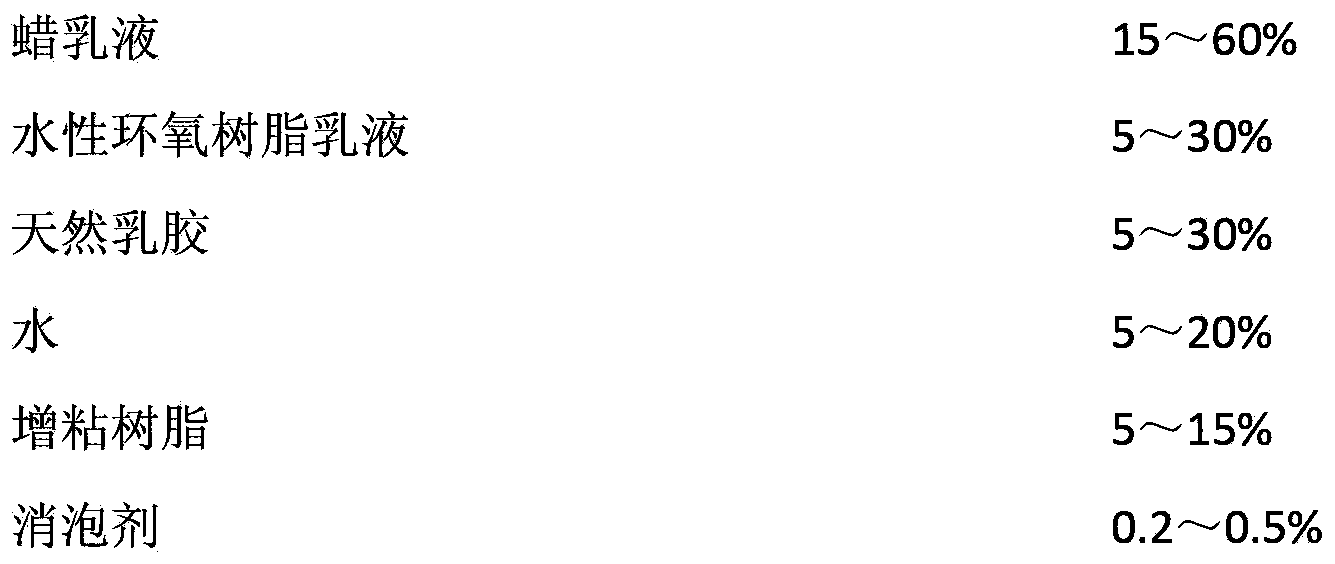

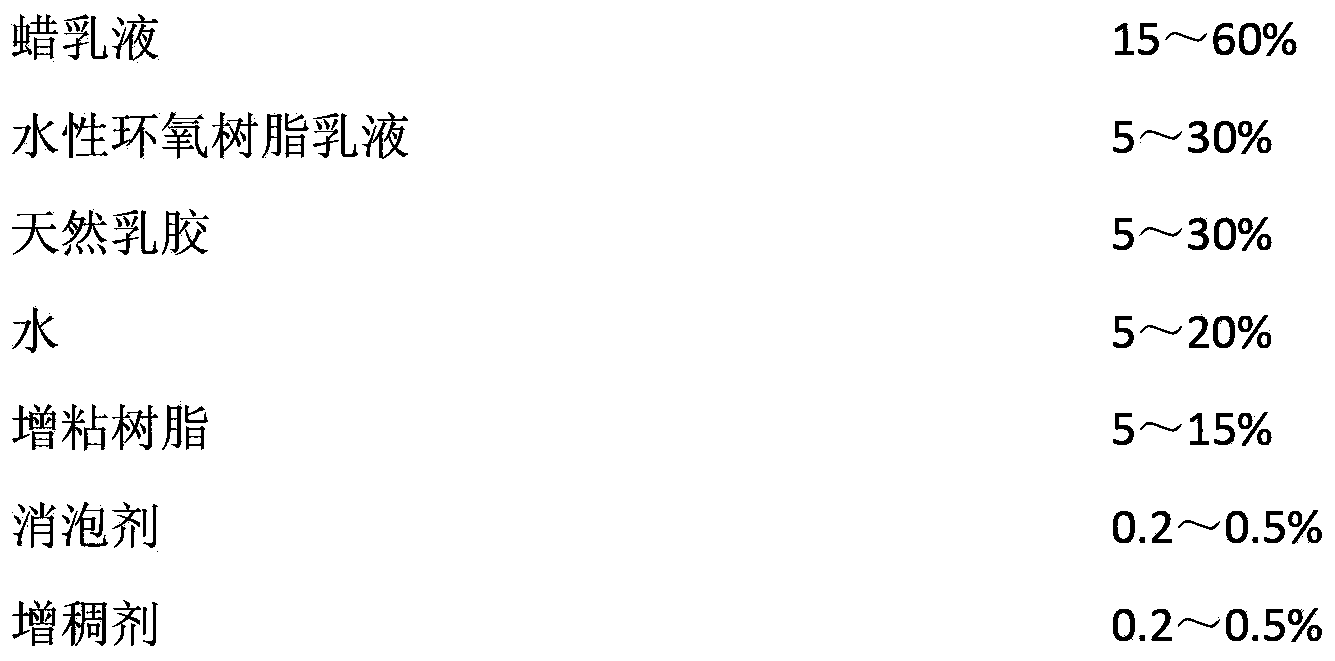

Medical-packaging use paper-plastic lamination adhesive based on waterborne epoxy resin type and preparation method thereof

InactiveCN103361017AMeet environmental protection requirementsImprove adhesionNatural rubber adhesivesLayered productsEpoxyAdhesive

The invention discloses a medical-packaging use paper-plastic lamination adhesive based on a waterborne epoxy resin type and a preparation method thereof. The paper-plastic lamination adhesive comprises: by mass, 15-60 parts of wax emulsion, 5-30 of waterborne epoxy resin emulsion, 5-30 parts of natural latex, 5-20 parts of water, 5-15 parts of tackifying resin, 0.2-0.5 parts of a defoaming agent and 0.2-0.5 parts of a thickening agent. The paper-plastic lamination adhesive is prepared by the following steps: mixing the wax emulsion and the waterborne epoxy resin emulsion, adding the defoaming agent at the room temperature, and dispersing with a stirring speed of 500-1000 rpm; then adjusting the stirring speed to 200-300 rpm; adding the natural latex and dispersing; adding the tackifying resin and dispersing; further adding the water and dispersing; and finally, adding the thickening agent, adjusting system viscosity to construction viscosity, then obtaining a medical-packaging use paper-plastic lamination adhesive product. The medical-packaging use paper-plastic lamination adhesive product has the effects of high-temperature resistance, water resistance, no volatile solvent, dry bonding surfaces after paper-plastic separation and no sticking of paper scraps.

Owner:SOUTH CHINA UNIV OF TECH

Hot melt adhesive for waterproof roll and preparation method of hot melt adhesive

ActiveCN106893536AImprove initial tackImprove cold resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantUltraviolet lights

The invention relates to the technical field of chemical modification high polymer materials, and in particular to a hot melt adhesive for waterproof roll and a preparation method of the hot melt adhesive. The hot melt adhesive is prepared from the following components in parts by weight: 50-200 parts of butadiene styrene rubber, 200-300 parts of benzene alkene thermoplastic elastomer rubber, 200-300 parts of tackifying resin, 5-20 parts of an antioxidant, 5-20 parts of an ultraviolet light absorbent, 0-200 parts of naphthenic oil, 0-200 parts of base oil and 100-200 parts of polyisobutene, wherein the tackifying resin is one or any combination of petroleum resin, hydrocarbon resin and monomer resin. As the butadiene styrene rubber and the benzene alkene thermoplastic elastomer rubber are compounded as a rubber matrix, the hot melt adhesive is high in compatibility; due to addition of the petroleum resin, the hydrocarbon resin and the monomer resin as the tackifying resin, the initial adhesion, the cold resistance, the thermal stability and the adhesion strength of the hot melt adhesive can be improved, the volatility of the hot melt adhesive is reduced, and particularly the adhesion property of the hot melt adhesive in damp building environments such as cement, concrete and big sand can be improved.

Owner:XINXIANG HUAYANG ADHESIVE

Environmental protection type aqueous release film

InactiveCN104961902AHigh tensile strengthDecontaminationNatural rubber coatingsPolyurea/polyurethane coatingsEmulsionPolyvinyl alcohol

The present invention provides an environmental protection type aqueous release film, which comprises a thin film layer and a release layer positioned on the thin film layer, wherein the release layer comprises, by weight, 35-45 parts of an aqueous polyethylene wax emulsion, 45-55 parts of an aqueous polyurethane emulsion, 20-30 parts of an aqueous modified polyvinyl alcohol solution, 5-10 parts of natural latex, 3-5 parts of a silane coupling agent, 0.3-0.5 part of a defoamer, and 0.3-0.5 part of a thickener, and the aqueous modified polyvinyl alcohol solution comprises, by weight, 100 parts of polyvinyl alcohol, 700-800 parts of deionized water, and 30-50 parts of modified calcium carbonate. The release film of the present invention is the aqueous environmental protection type release film, has characteristics of good peel strength and good stretching strength, and is the release film having the good comprehensive performance.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Environment-friendly urea resin adhesive and preparation method thereof

InactiveCN102838956ANo releaseGood for healthNon-macromolecular adhesive additivesStarch adhesivesHuman healthResin adhesive

The invention discloses an environment-friendly urea resin adhesive, prepared from the following components in parts by weight: 30-38 parts of urea, 58-67 parts of oxalaldehyde, 0.5-2 parts of corn starch, 0.5-1.5 parts of borax, 0.6-2 parts of tripolycyanamide. The invention also discloses a preparation method of the environment-friendly urea resin adhesive. The environment-friendly urea resin adhesive prepared by the invention contains no formaldehyde and no irritant smell, is beneficial to human health and environmental protection and has the characteristics of long stable storage period and simple production process.

Owner:HUBEI HONGYUAN PHARMA

Paper starch adhesive and preparation method thereof

ActiveCN101967355ARaw materials are cheapWide range of usesNon-macromolecular adhesive additivesStarch derivtive adhesivesEpoxyHydrogen Sulfate

The invention discloses a paper starch adhesive and a preparation method thereof. The paper starch adhesive comprises the following components in part by weight: 100 parts of starch, 300 to 600 parts of water, 0.1 to 0.3 part of potassium hydrogen peroxymonosulfate, 5 to 10 parts of caustic soda, 1 to 5 parts of epoxy chloropropane, 0.5 to 1.5 parts of boric acid, 1 to 3 parts of sodium sulfite, 4 to 8 parts of light calcium carbonate and 2.5 to 5 parts of bridging agent. The preparation method comprises the following steps of: adding water into a reaction kettle, heating the water to 38 DEG C, adding the starch into the water, stirring the solution, adding potassium hydrogen peroxymonosulfate solution into the reaction kettle, and reacting the mixed solution for 20 minutes with stirring; diluting the caustic soda, then slowly adding the caustic soda into the reaction kettle twice, stirring the solution for about 20 minutes to form milk white or light yellow transparent colloid, then adding the boric acid, the bridging agent and the light calcium carbonate into the colloid, and stirring the mixture uniformly; and adding the epoxy chloropropane, sodium aliphatate and the sodium sulfite into the reaction kettle with stirring, and stirring the mixture uniformly to obtain the paper starch adhesive. The adhesive has the characteristics of stable viscosity, good adhesiveness, low comprehensive cost, good permeability and the like.

Owner:山东荣工建筑工程有限公司

Environment-friendly type effective all-purpose adhesive

InactiveCN101250388AComply with environmental labeling requirementsClean smellMineral oil hydrocarbon copolymer adhesivesRosin adhesivesBenzoic acidAdhesive

The invention discloses an environment-friendly type special universal glue, wherein the formula proposition is that SBS thermoplasticity elastic body 10-15, terpene resin 10-15, C9 petroleum resin 6-12, abietyl glyceride 2-6, ethyl acetate 8-12, butyl acetate 0.5-2, environmental protection solvent oil 30-50, BHT 0.2-1.0, naphthenic oil 0.1-3 and benzoic acid 0.1-0.4. The environment-friendly type special universal glue of the invention has the advantages that first, environmental protection, the universal glue does not contain 'triphenyl'and halogenated hydrocarbon, which is in accordance with the requirement of HJ / T 220-2005 environmental labelling product technical requirement adhesive, second, clean taste and little stimulation, third, fast surface drying speed and strong initial adhesion, fourth, long viscosity retention time, fifth, low viscosity, excellent flowability and convenient construction.

Owner:GUANGDONG SANVO CHEM IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com