High-initial strength reaction-type polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and reactive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low initial adhesion and initial bonding strength, high melt viscosity, etc., and achieve The effect of improving initial adhesion, moderate elastic modulus, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

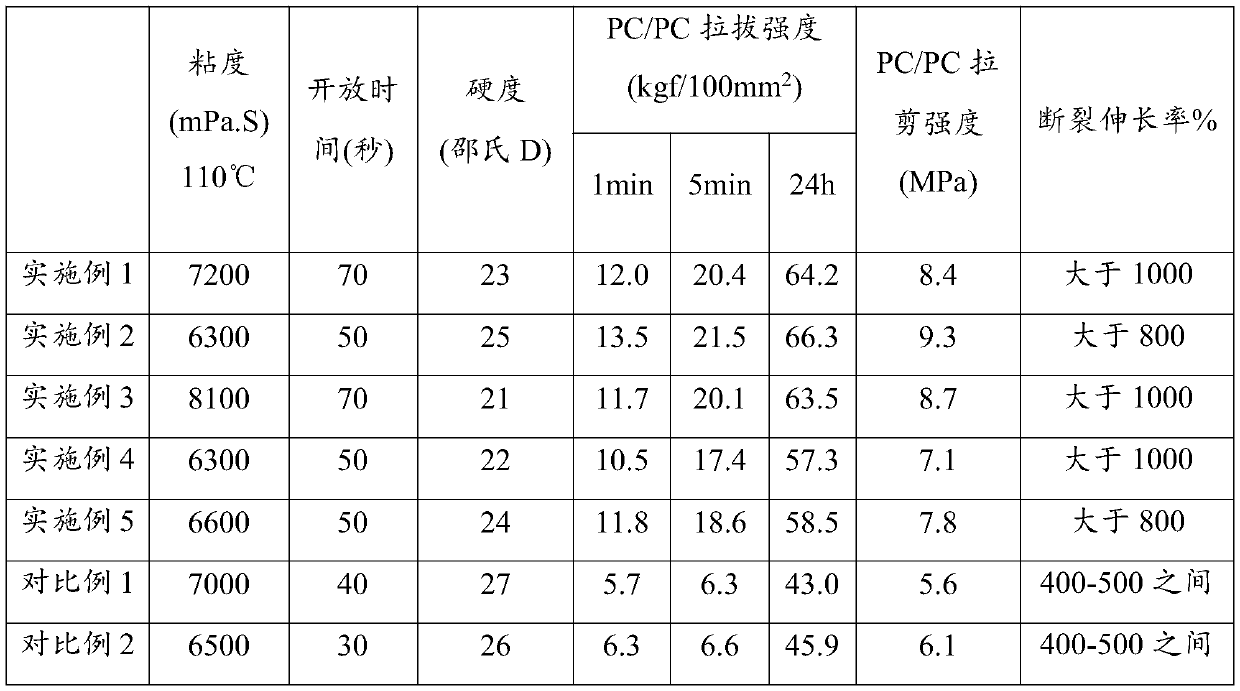

Examples

Embodiment 1

[0020] A high initial strength reactive polyurethane hot melt adhesive, comprising the following components by weight and corresponding preparation method: crystallized polyester polyol XCP-3000 (20 parts), POL-356 (10 parts), high molecular weight crystal Copolyester ST-260 (6 parts), liquid polyester polyol DYNACOLL7230 (25 parts), liquid polycarbonate diol G4672 (15 parts), thermoplastic polyurethane solid resin Desmocoll 500 (8 parts) antioxidant Irganox1010 ( 0.2 parts) into a four-necked bottle, heated to 160°C to melt for 1 hour, cooled to 110°C for 2 hours in vacuum dehydration, tested for water content ≤ 200PPm, cooled to 60°C, protected by nitrogen, and added liquefied MDI-100 ( 15 parts) reaction, temperature control 85-90 ℃, reaction 2-3h, after the NCO% content of sampling analysis reaches the design value, then add catalyst bismorpholine diethyl ether (0.5 parts), KH590 silane coupling agent (0.3 part) Vacuum stirring and mixing for 30 minutes, heat up to 120°C, ...

Embodiment 2

[0022] A high initial strength reactive polyurethane hot melt adhesive, comprising the following components by weight and corresponding preparation method: Copolymerize crystalline polyester polyol DYNACOLL7380 (18 parts), XCP-3000H (17 parts), high molecular weight crystal Ester S3049 (10 parts), liquid polyester polyol ST8870 (20 parts), liquid polycaprolactone polyol PCL2200C (10 parts), thermoplastic polyurethane solid resin TPU-H306 (5 parts), antioxidant Irganox1010 (0.3 parts) Put it into a four-neck bottle, heat up to 160°C for 1 hour, cool down to 110°C for 2 hours, and vacuum dehydrate it for 2 hours, test that the water content is ≤200PPm, cool down to 60°C, protect with nitrogen, and add liquefied MDI-100 (19 parts) while stirring ) reaction, temperature control 85-90 ° C, reaction 2-3h, after sampling analysis NCO% content reaches the design value, then add catalyst bismorpholine diethyl ether (0.4 parts), KH590 silane coupling agent (0.3 parts) Vacuumize and mix ...

Embodiment 3

[0024]A high initial strength reactive polyurethane hot melt adhesive, comprising the following components by weight and a corresponding preparation method: crystalline polyester polyol DYNACOLL7380 (15 parts), polycaprolactone polyol PCL2302 (10 parts), high Molecular weight polycaprolactone PCL-6400 (6 parts), liquid polyester polyol CP-2059 (30 parts), liquid polycarbonate diol G4672 (15 parts), thermoplastic polyurethane solid resin Pearlbond523 (9 parts) antioxidant Irganox1010 (0.3 parts) into a four-necked bottle, heated to 160°C to melt for 1 hour, cooled to 110°C for 2 hours in vacuum dehydration, tested for water content ≤ 200PPm, cooled to 60°C, protected by nitrogen, and added liquefied MDI-100 while stirring (14 parts) reaction, temperature control 85-90 ℃, reaction 2-3h, after the NCO% content of sampling analysis reaches design value, then add catalyst bismorpholine diethyl ether (0.3 part), KH590 silane coupling agent ( 0.4 parts) Vacuum and stir for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com