Patents

Literature

37results about How to "Moderate modulus of elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

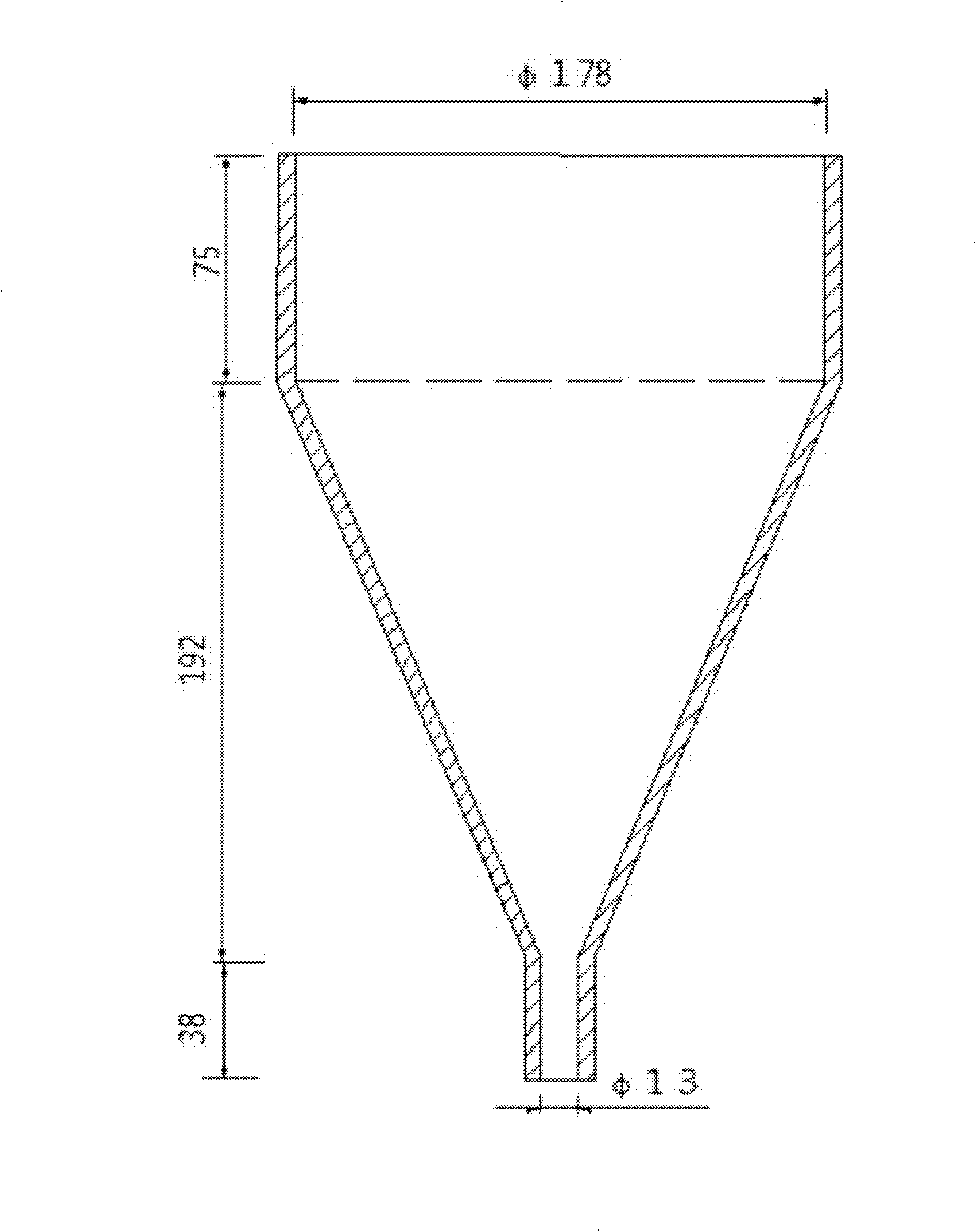

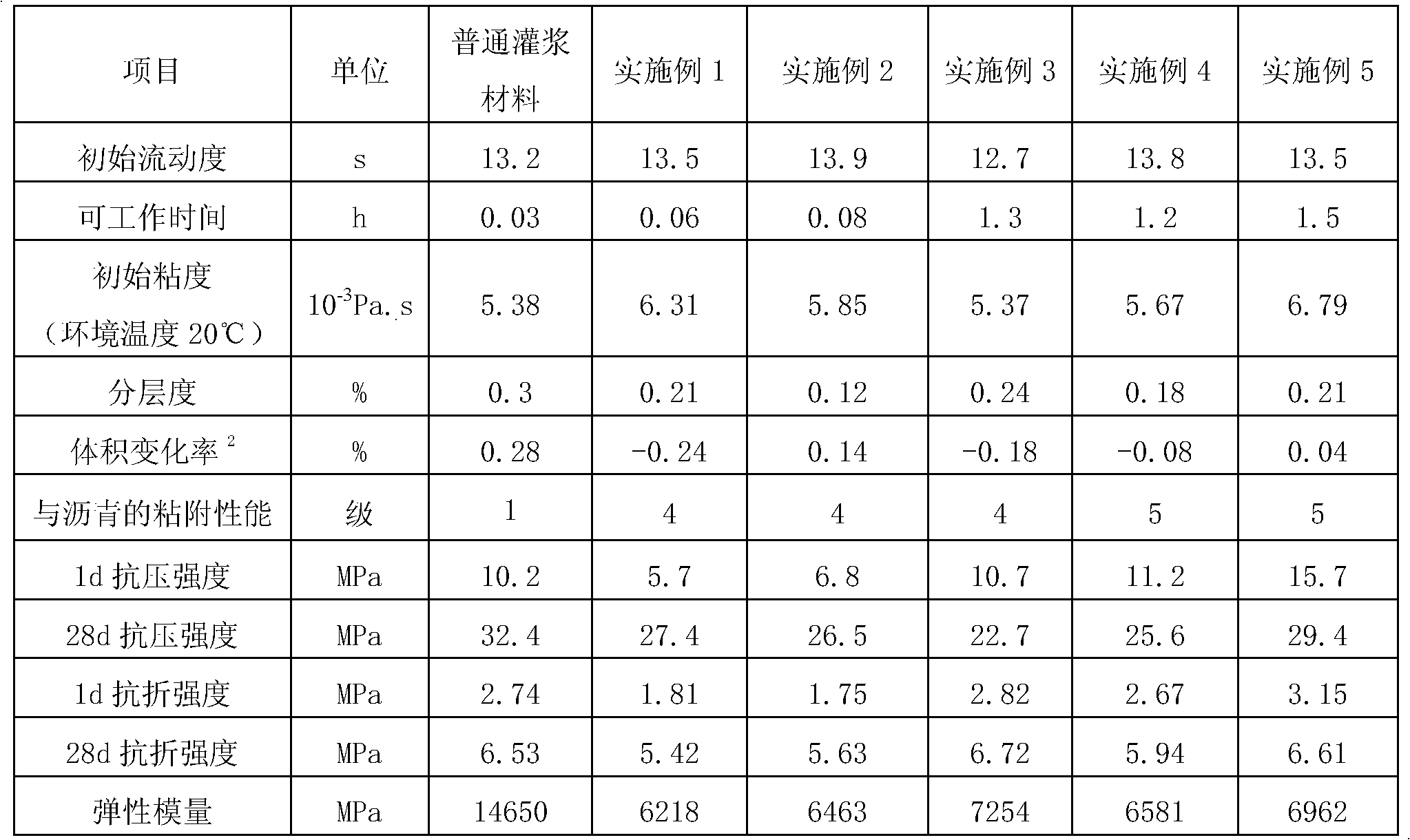

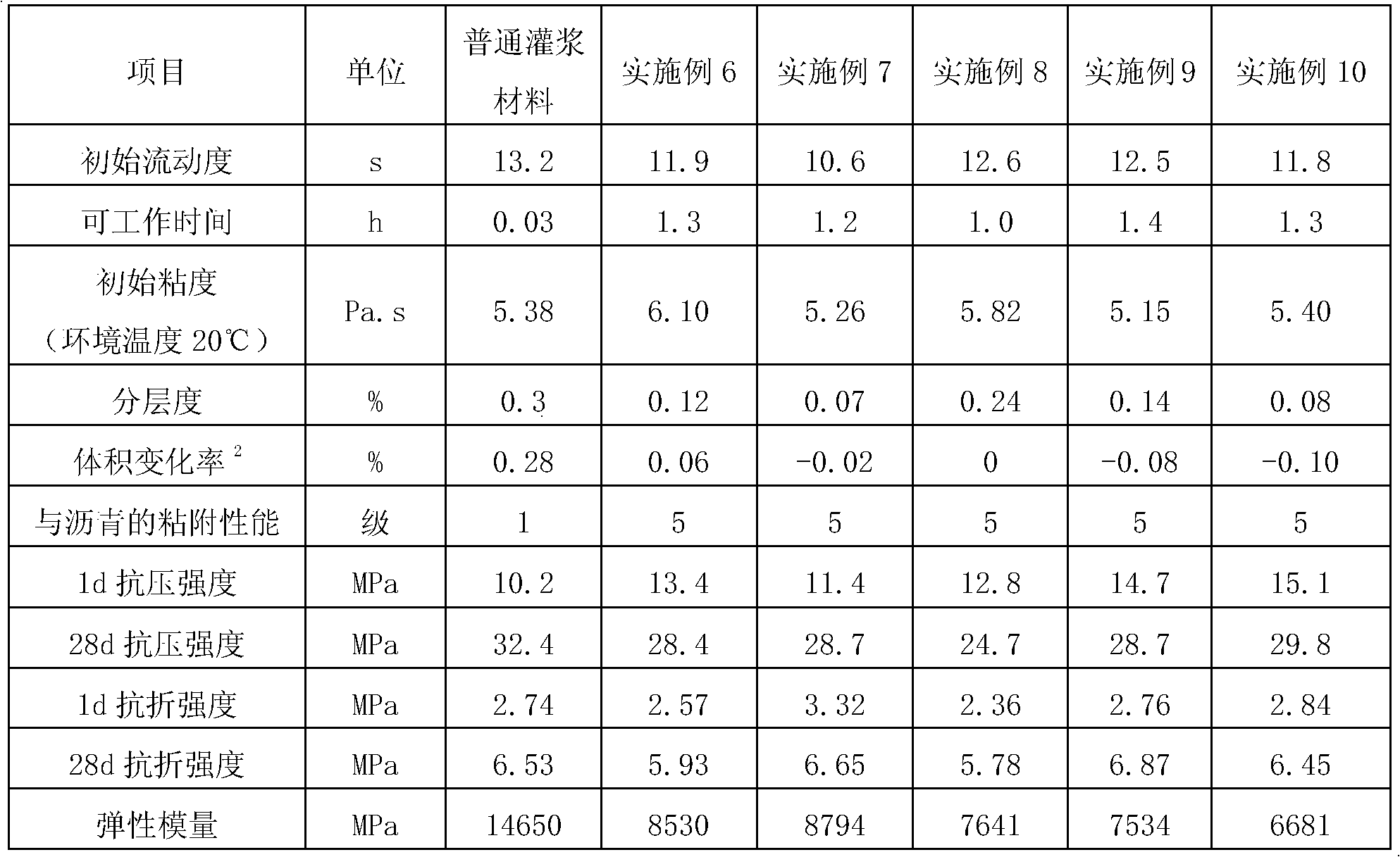

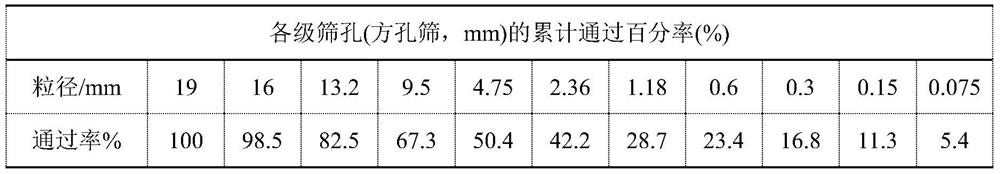

A cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement

The invention discloses a cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement, which comprises 100 parts of cement, 50-150 parts of mineral admixture, 15-40 parts of expansion agent, 0-80 parts of river sand, 0.5-20 parts of water agent, 60-140 parts of water, and 50-150 parts of emulsified asphalt, all of which are parts by weight. The grouting material of the present invention is low in cost, good in fluidity, long in working time, and satisfies the grouting characteristics of self-permeation of slurry; has good interfacial bonding performance with asphalt, and has a certain early strength function; the volume change rate is small, and the degree of delamination is less than 0.3%, with good volume stability; both cationic emulsified asphalt and anionic emulsified asphalt can be used, with a wide range of applications; applying this grouting material to semi-flexible pavement can greatly improve the fatigue life of flexible pavement The shear performance is effectively improved.

Owner:JIANGSU SUBOTE MATERIAL +4

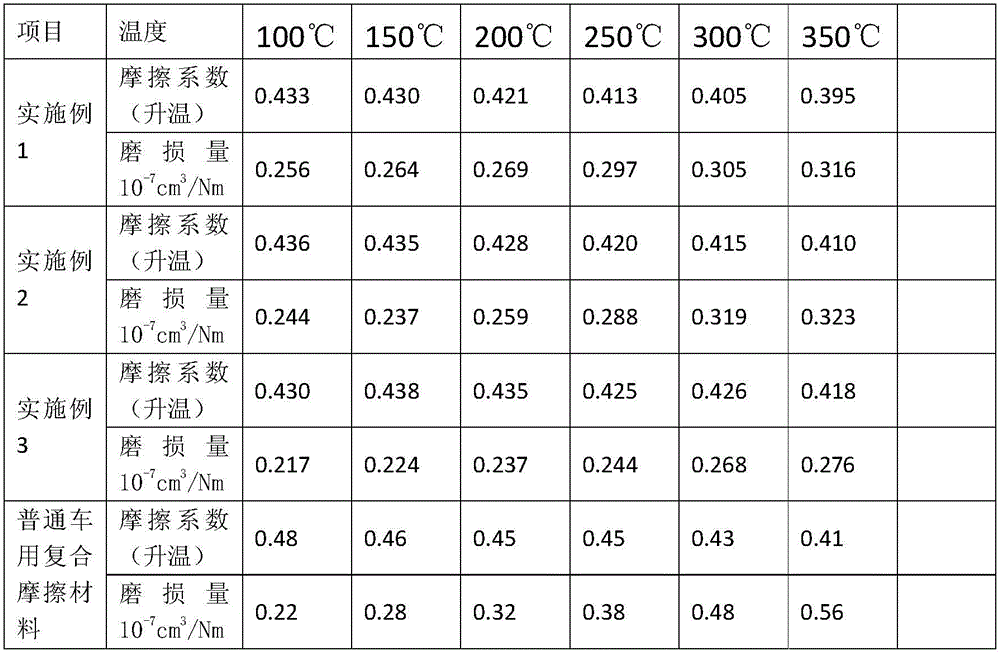

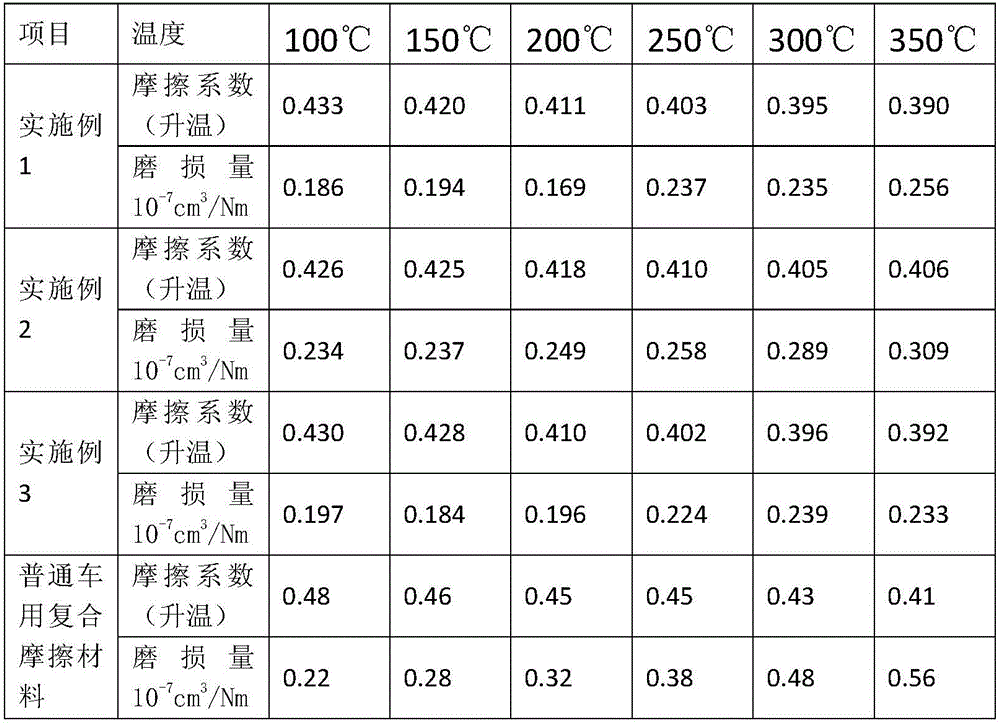

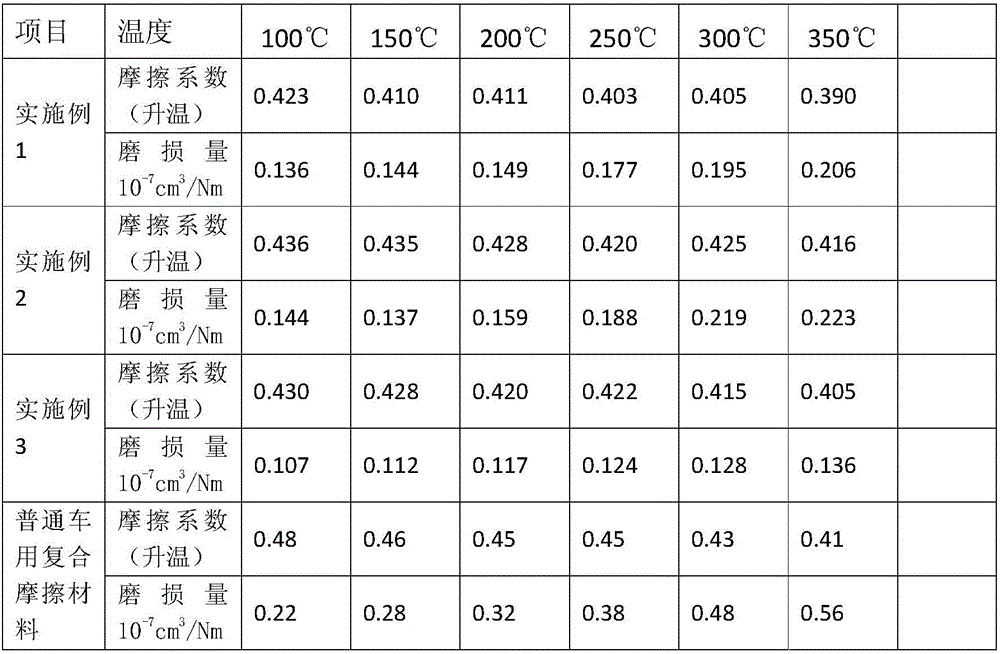

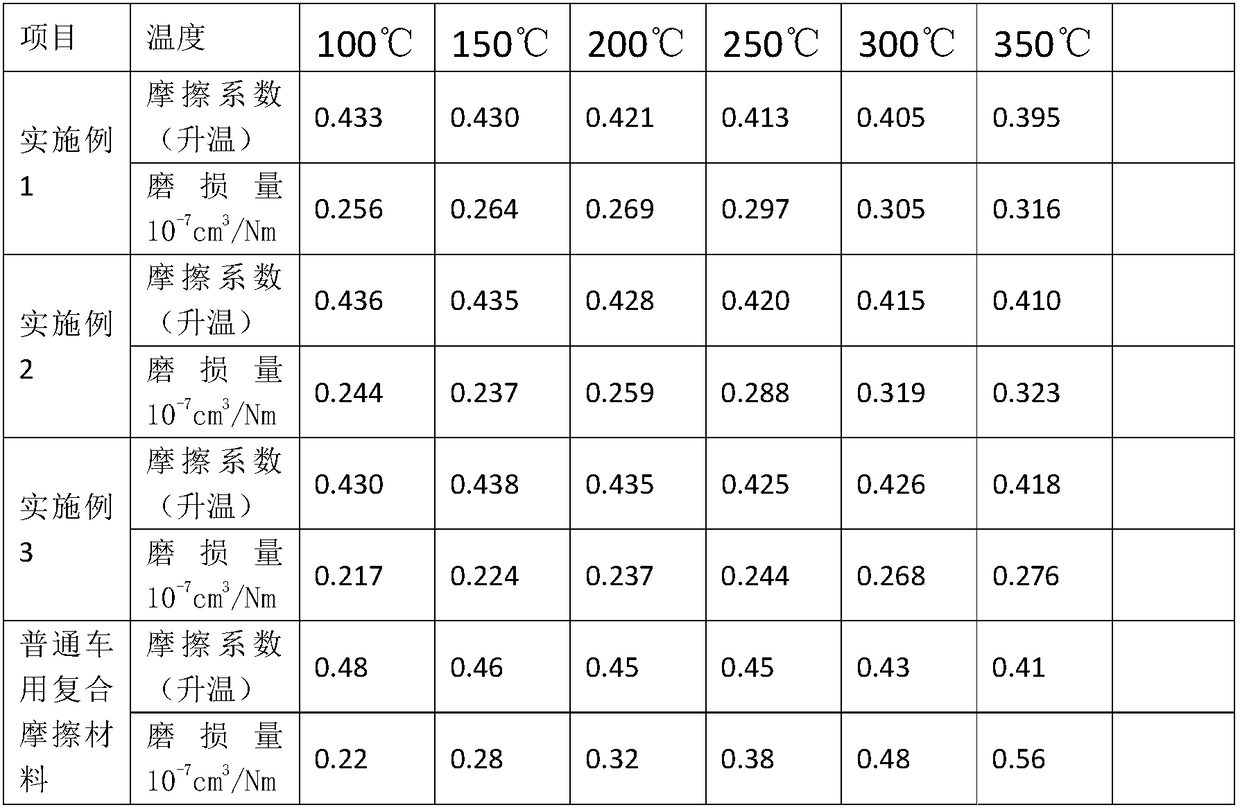

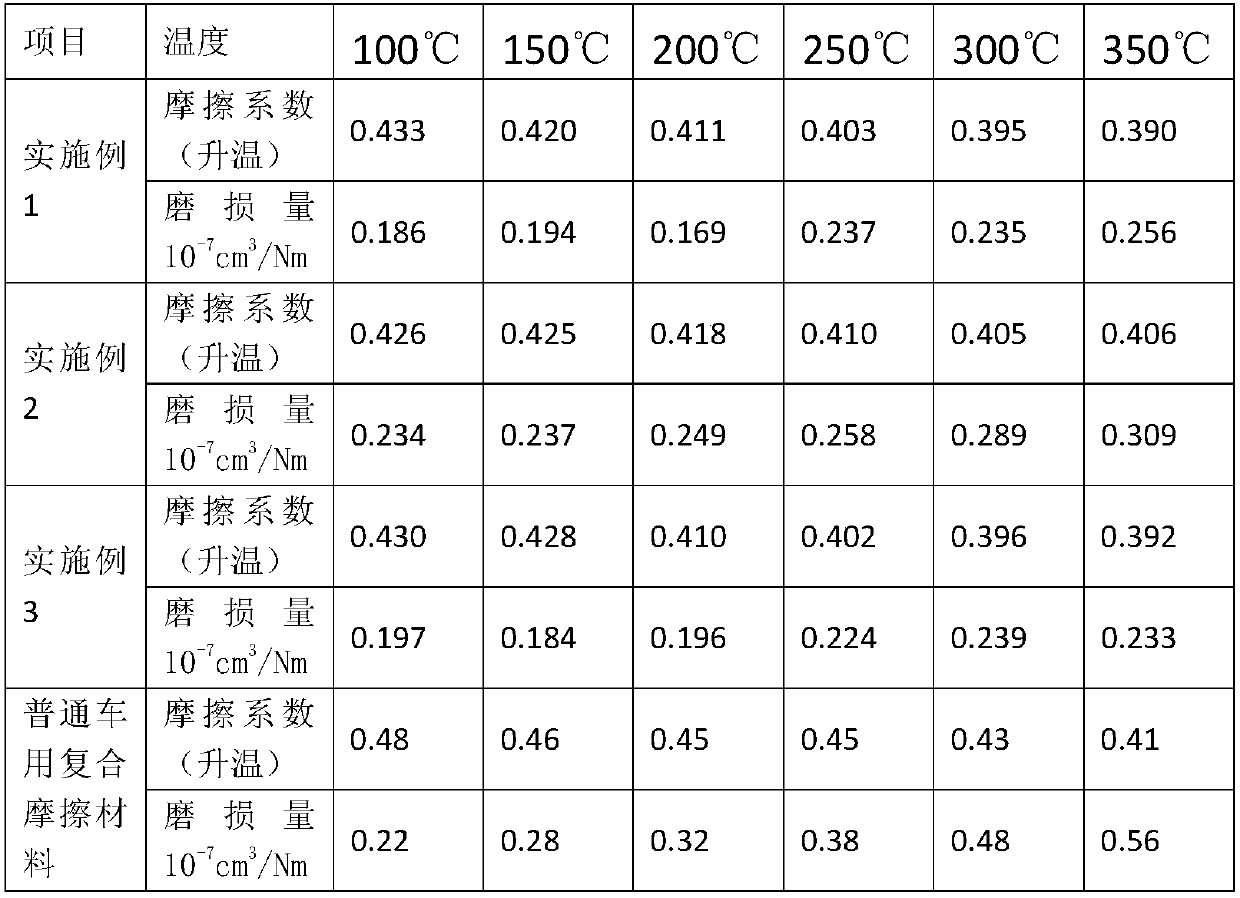

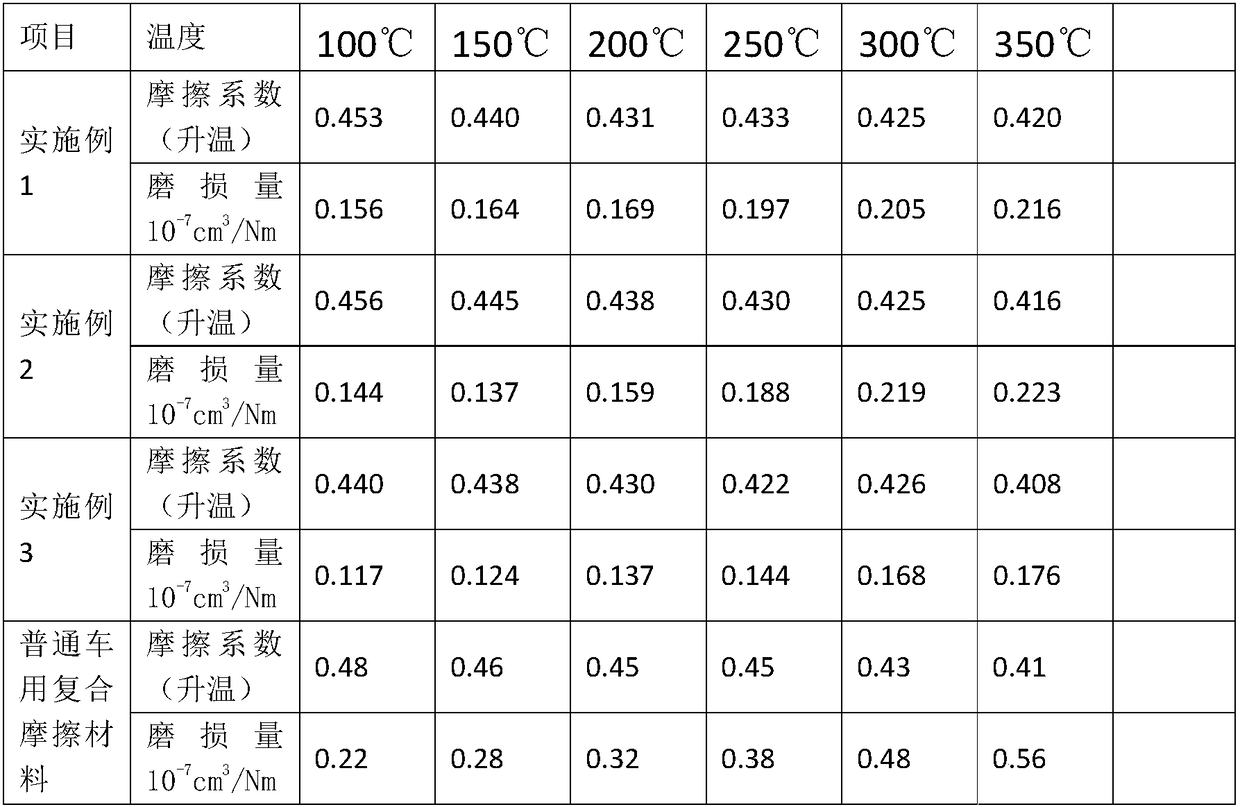

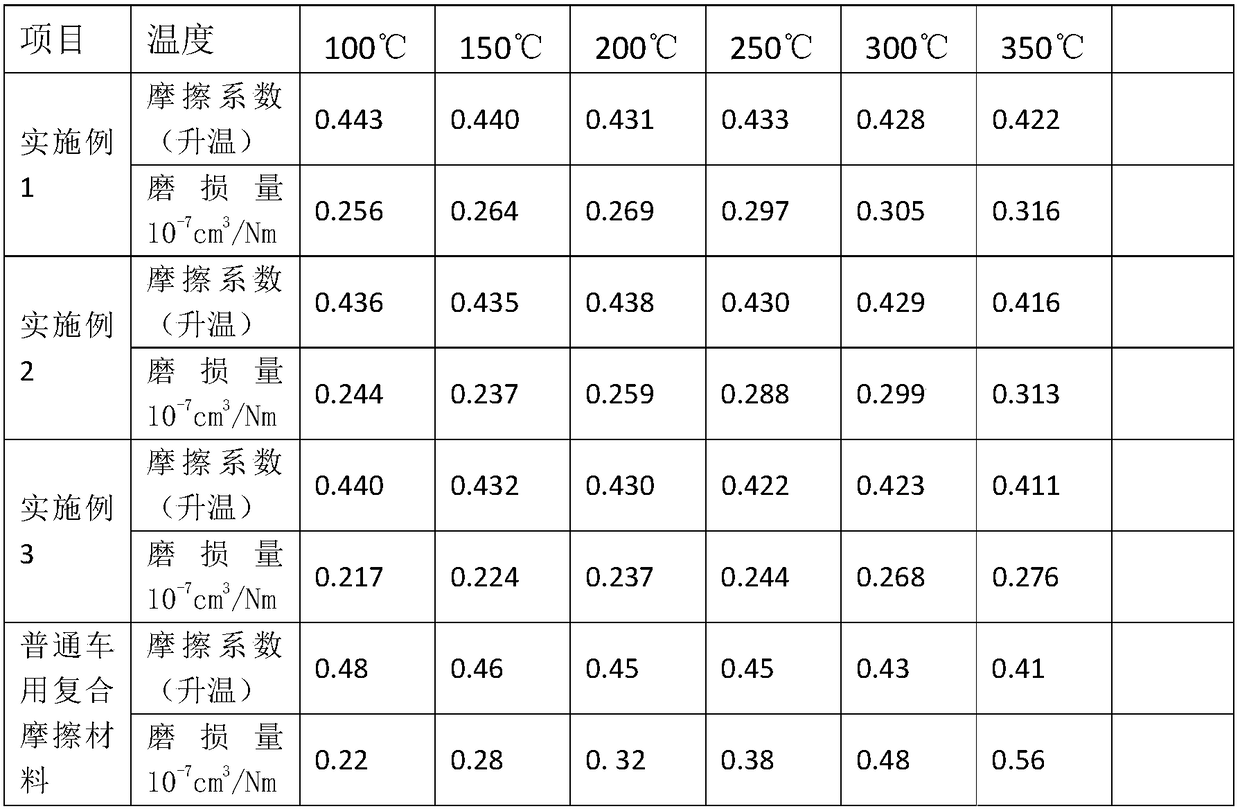

Automotive copper-based powder metallurgy composite friction material and manfuacturing method thereof

InactiveCN105778406AModerate modulus of elasticityStable coefficient of frictionPowder metallurgyPowder mixture

The invention discloses an automotive copper-based powder metallurgy composite friction material and a manufacturing method thereof. The manufacturing method includes that firstly, a basis powder material is mixed with a molding agent uniformly to obtain a mixture, the mixture is poured into a mold and is shaped into slender rods by pressing, the slender rods are compacted and separated and then charged into a sintering furnace, and the sintering furnace is heated up under protection of nitrogen gas or hydrogen gas so that a copper-based powder metallurgy friction material is obtained; secondly, the copper-based powder metallurgy friction material is subjected to processes of shearing, grinding and screening; thirdly, by mass percent, 10-20% of cashew nut oil modified phenolic resin, 30-60% of the copper-based powder metallurgy friction material, 10-20% of reinforced fibers, 5-15% of abrasives, 10-20% of lubricants and 5-20% of fillers are mixed uniformly to obtain a powder mixture, and the powder mixture is then subjected to hot press molding, is cooled to the room temperature and then is discharged from the furnace. The automotive copper-based powder metallurgy composite frictional material has both advantages of high temperature resistance and low abrasion as the copper-based powder metallurgy friction material and high ductility and low hardness as the resin-based composite friction material.

Owner:SOUTH CHINA UNIV OF TECH

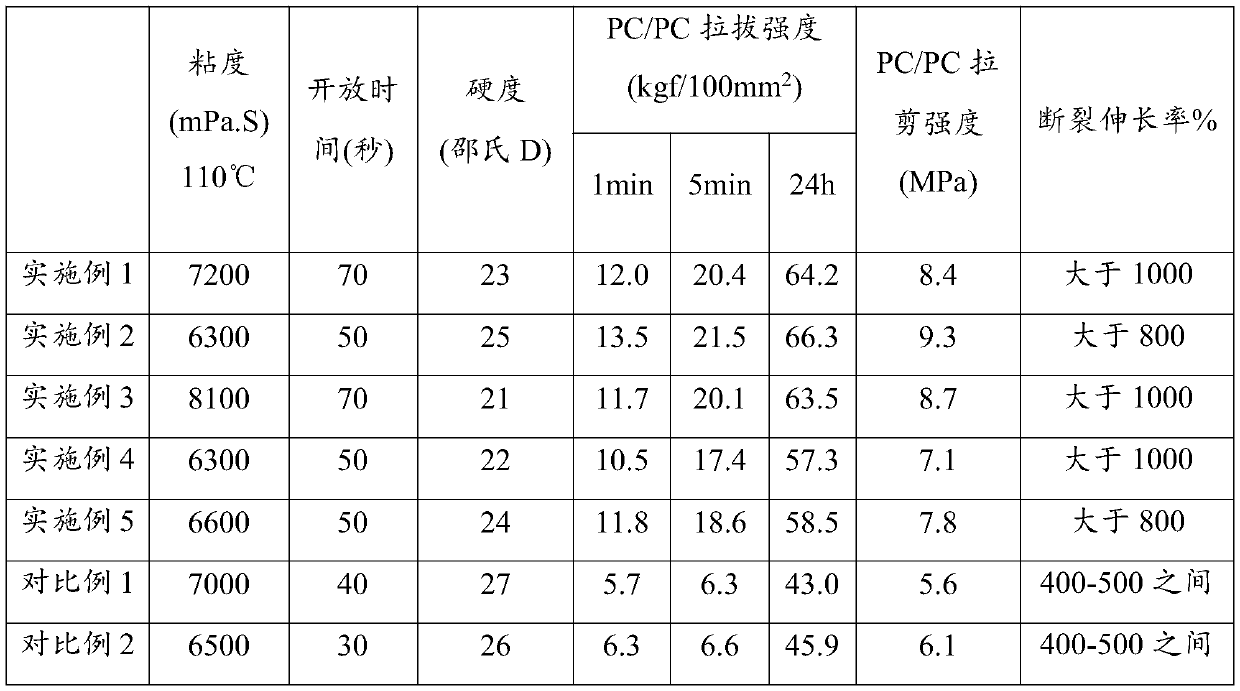

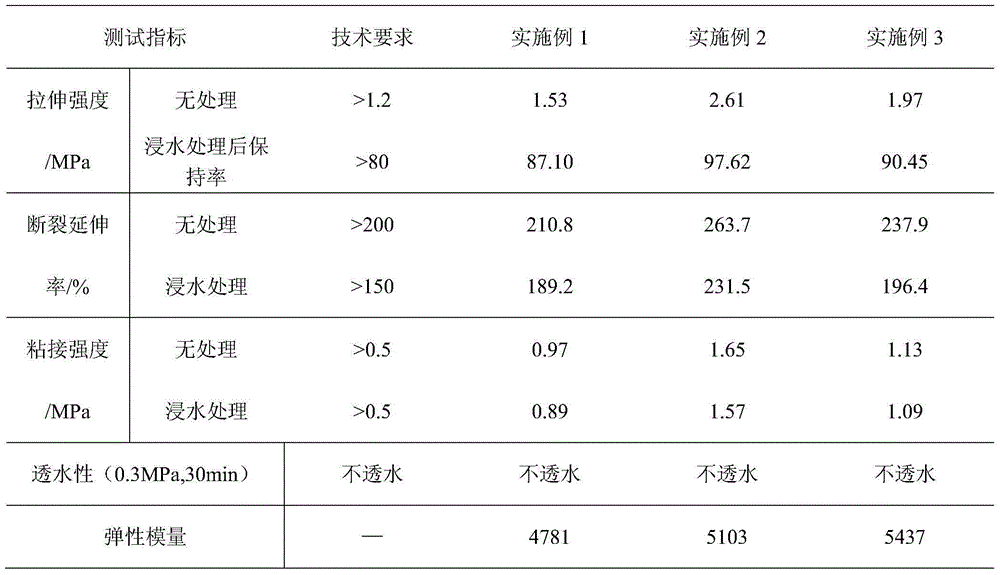

High-initial strength reaction-type polyurethane hot melt adhesive and preparation method thereof

InactiveCN110256999AHigh reactivityIncrease crosslink densityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantPliability

The invention discloses a high-initial strength reaction-type polyurethane hot melt adhesive. The high-initial strength reaction-type polyurethane hot melt adhesive comprises the following components: in parts by weight, 25-35 parts of crystalline polyester polyol, 30-45 parts of amorphous liquid polyester polyol, 5-10 parts of high-molecular weight crystalline polyester, 6-9 parts of thermoplastic polyurethane, 0.1-0.3 part of an antioxidant, 14-19 parts of MDI, 0.3-0.5 part of a catalyst and 0.3-0.5 part of a silane coupling agent. According to the high-initial strength reaction-type polyurethane hot melt adhesive, a reaction is performed on the crystalline and amorphous polyester polyols with lower molecular weights and aromatic diisocyanate, and high reactivity is achieved; the crystalline copolyester with a high molecular weight is adopted, a high crosslinked density is achieved, and high initial adhesive strength and high final adhesive strength are achieved; and the thermoplastic polyurethane resin with good compatibility with the polyester system is adopted, the initial adhesion is improved, good flexibility can also be maintained, and the problems of hardness increase and flexibility decrease which are brought by fast crystallization and high-molecular-weight polyester which are applied to increase of the initial strength in the prior art are solved.

Owner:YANTAI TIGHTSEN FINE CHEM

Composite frictional material and preparation method thereof

The invention provides a preparation method of a composite frictional material. The preparation method comprises the following steps that 1, a ferrous-based powder metallurgical frictional material is prepared; 2, shearing, smashing and screening are performed; 3, material mixing is performed; 4, the composite frictional material is prepared; 5 posttreatment is performed; 6, the composite frictional material is machined. Compared with the prior art, the composite frictional material integrates the characteristics of high temperature resistance and low abrasion resistance of the ferrous-based powder metallurgical frictional material and the characteristics of good toughness and low hardness of a resin-based composite material and has the advantages of high temperature resistance, low abrasion resistance, good toughness and low hardness. The ferrous-based powder metallurgical frictional material is used for preparing an automobile braking accessory, scratching of an automobile brake disc or drum is effectively avoided based on good braking performance, and frictional noise is small.

Owner:CHONGQING AOSHUNTE MACHINERY MFG

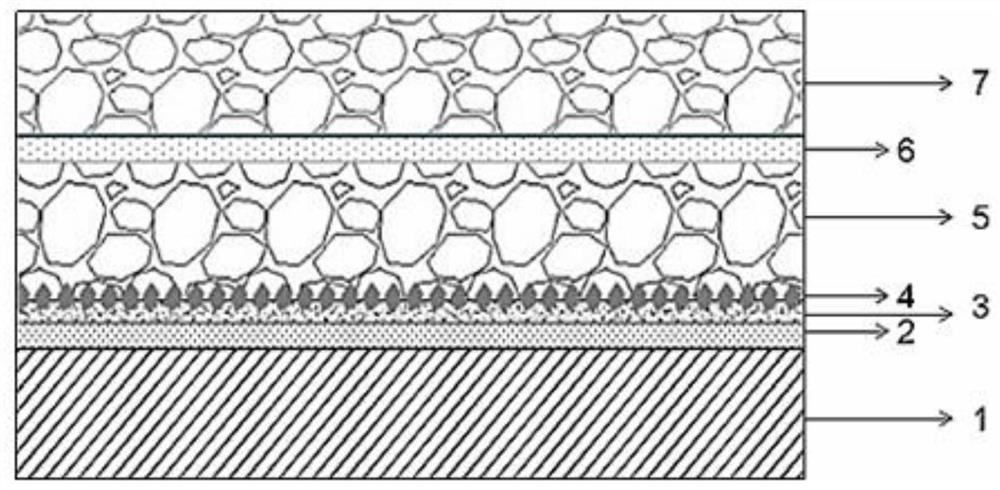

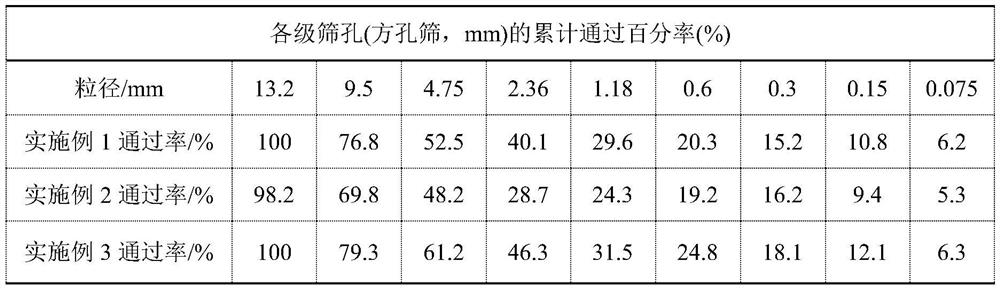

Resin based powder metallurgy composite friction material for vehicles and preparation method thereof

InactiveCN105838023AIncreased frictional surface roughnessIncrease porosity coefficientFriction liningResin-Based CompositeMachining

The invention discloses a preparation method of a resin based powder metallurgy composite friction material for vehicles, wherein the preparation method comprises the following steps: 1) preparing a powder metallurgy friction material: mixing evenly a base material and a forming agent, pouring the mixture into a mold, pressing to slender rods, separating the slender rod-shaped pressed blanks, and sintering, to obtain a powder metallurgy friction material; 2) shearing, crushing and screening; 3) mixing: according to the mass percentage, evenly co-mixing 10-20% of high-temperature-resistant modified resin, 40-60% of the powder metallurgy friction material, 10-20% of a reinforcing fiber, 5-15% of an abrasive, 10-20% of a lubricating material and 5-20% of a filler; 4) producing and preparing a resin based composite friction material; 5) post-treating; and 6) carrying out mechanical processing. The resin based powder metallurgy composite friction material retains the stable friction coefficient and good anti-abrasion properties of the powder metallurgy friction material. The service life and the high-temperature stability of the friction material are improved.

Owner:SOUTH CHINA UNIV OF TECH

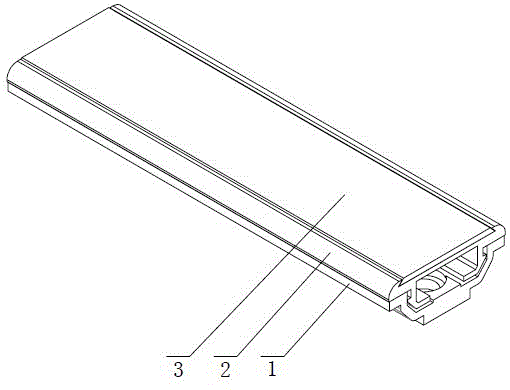

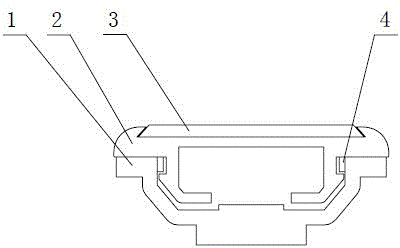

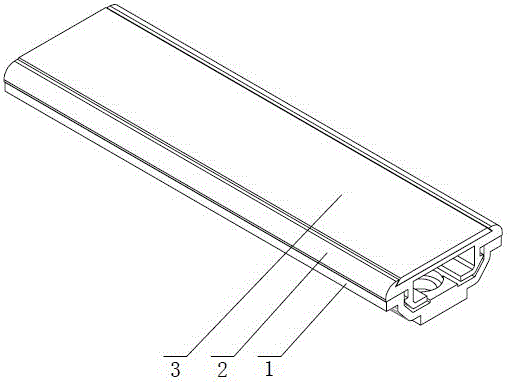

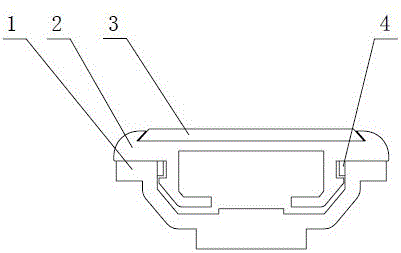

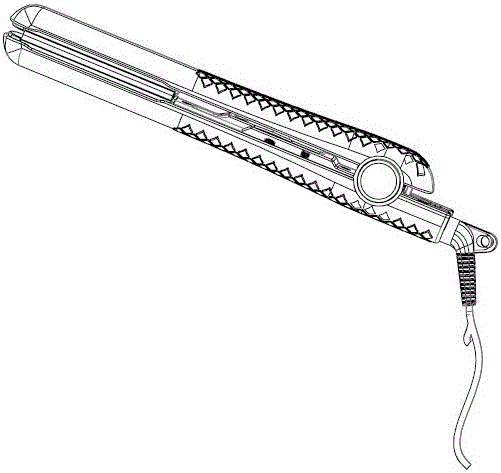

Heat conduction mechanism for personal care device and personal care device

The utility model provides a heat conduction mechanism for a personal care device. The heat conduction mechanism for the personal care device comprises a heat conduction body and an installation frame, wherein the heat conduction body is fixedly installed on the installation frame; the heat conduction body is an aluminum plate; the working surface of the heat conduction body is provided with a carbon fiber layer. The personal care device which adopts the heat conduction mechanism comprises a pair of clamping components; the tail parts of the clamping components are connected in a hinging way; the heat conduction mechanism is arranged in the clamping components; a heating body is built in the heat conduction mechanism; and the heat conduction mechanism contacts with the heating body. According to the heat conduction mechanism for the personal care device and the personal care device, when the aluminum plate is combined with carbon fiber; the advantages of the aluminum plate, i.e. easiness in shaping, low processing requirements and low material cost are utilized; and for example, when the aluminum plate of which the surface is attached with the carbon fiber is adopted as the working surface, the advantages of the carbon fiber such as self-lubrication, high strength, moderate elastic modulus, good heat resisting performance, low weight, small expansion coefficient and wear resistance are utilized.

Owner:ZHEJIANG PAITER ELECTRIC

Resin-based powder metallurgy steel fiber friction material used for vehicle and production method thereof

InactiveCN106084645AReduce surface hardnessModerate modulus of elasticityTransportation and packagingMetal-working apparatusNitrile rubberHydrogen

The invention discloses a method for producing a resin-based powder metallurgy steel fiber friction material used for vehicle. The method comprises the following steps: uniformly mixing a matrix powder material and a forming agent, dumping a mixture in a die for compacting the mixture to obtain several elongated rods, compacting the elongated rods, separating the rods, putting the rods in a sintering furnace, heating the material under condition of introduction of nitrogen or hydrogen to obtain a copper-based powder metallurgy friction material; shearing the material, crushing the material, and sieving the material; uniformly mixing 10-20% of nitrile rubber-modified phenolic resin, 20-40% of the copper-based powder metallurgy friction material, 15-30% of steel fiber, 5-15% of an abrasive, 10-20% of a lubrication material, and 5-20% of a filling material; performing hot press molding, cooling the material, and discharging. According to the enhancement effect of the steel fiber, by combining the characteristics of high temperature resistance, low abrasion of the copper-based powder metallurgy friction material as well as good toughness and low hardness of the resin-based composite friction material, the obtained material has the characteristics of high temperature resistance, low abrasion, good flexible performance and low hardness.

Owner:SOUTH CHINA UNIV OF TECH

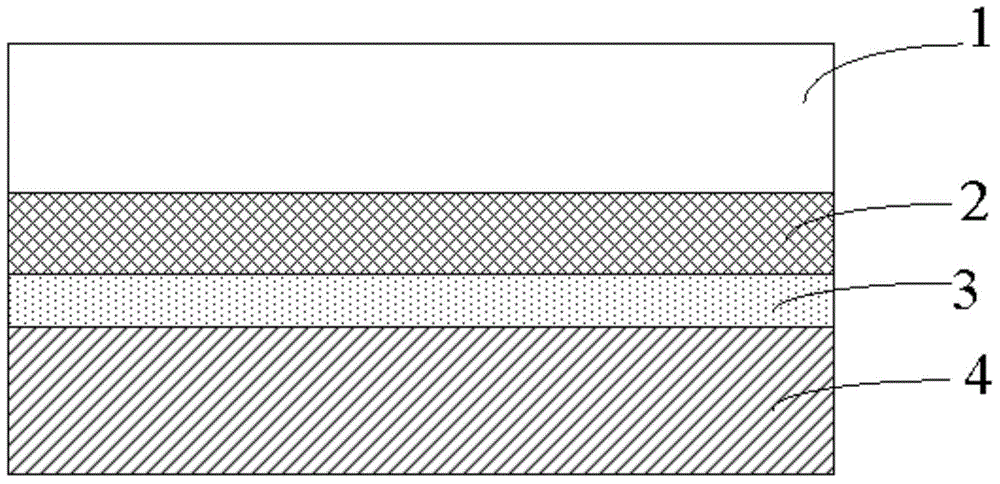

Interface adhesive material, white-to-black overlay structure based on material and construction process of overlay structure

InactiveCN104927759APrevent peelingImprove adhesionIn situ pavingsBituminous material adhesivesStress concentrationEpoxy

The invention relates to an interface adhesive material, a white-to-black overlay structure based on the material and a construction process of the overlay structure. The interface adhesive material comprises the following components in parts by mass: 20 to 60 parts of dry powder, 100 parts of modified emulsified asphalt, 20 to 40 parts of silicone rubber emulsion and 10 to 30 parts of a polyurethane modified epoxy resin material. The interface adhesive material has excellent adhesiveness, waterproofness and ultimate deformation capability, is moderate in elastic modulus, and can firmly bond an asphalt concrete layer with a cement concrete layer to form an integrally stressed composite pavement structure; when the asphalt concrete layer is horizontally pushed, accompanying deformation of an interface adhesive layer consumes partial energy, so that stripping caused by excess relative slip of the asphalt concrete layer is avoided; meanwhile, the elastic modulus of the interface adhesive layer is moderate and between the elastic modulus of the asphalt concrete layer and the elastic modulus of the cement concrete layer, so that the transitional effect can be achieved between the asphalt concrete layer and the cement concrete layer, the stress generated by traffic loads can be uniformly transferred, and the stress concentration phenomenon is effectively solved.

Owner:CHANGAN UNIV

Heavy truck brake pad with man-made skeleton as framework and manufacturing method thereof

InactiveCN103836095ASmooth brakingNo damageOther chemical processesBraking membersFiberCarbon fibers

The invention relates to the field of manufacturing of heavy trunk brake pads, in particular to a heavy truck brake pad with a man-made skeleton as a framework and a manufacturing method of the heavy truck brake pad. The porous man-made skeleton framework is made of carbon fiber toughened ceramic, a porous framework material is filled with resin, friction performance modifier, filler and the like to make a high-performance special brake pad friction material, and thus the heavy truck brake pad can adapt to a special working environment and has the advantages of being low in density, high in strength, good in heat resistance, high in friction coefficient, stable and long in service life. The heavy truck brake pad can adapt to extreme working conditions with high temperature and high loads, is suitable for high-speed heavy trucks, lifting devices for mines and the like and has huge promotional application values.

Owner:QINGDAO UNIV

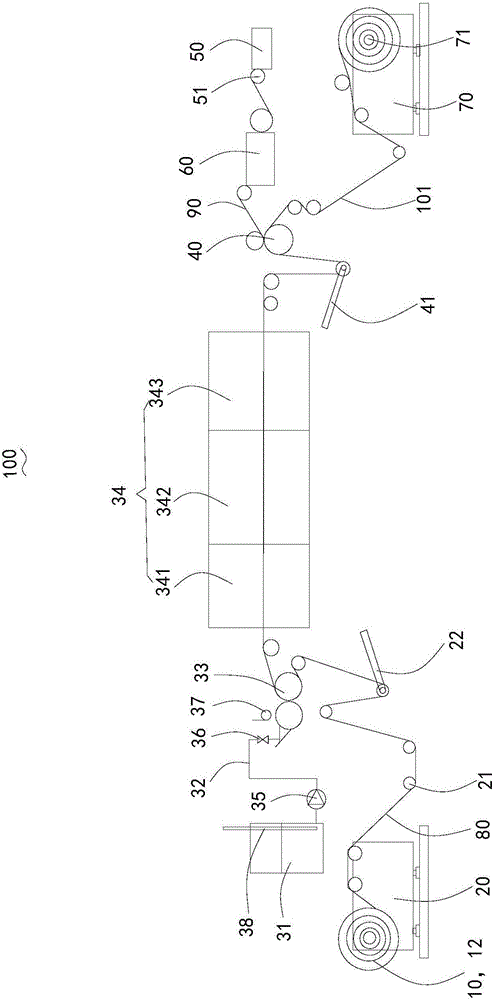

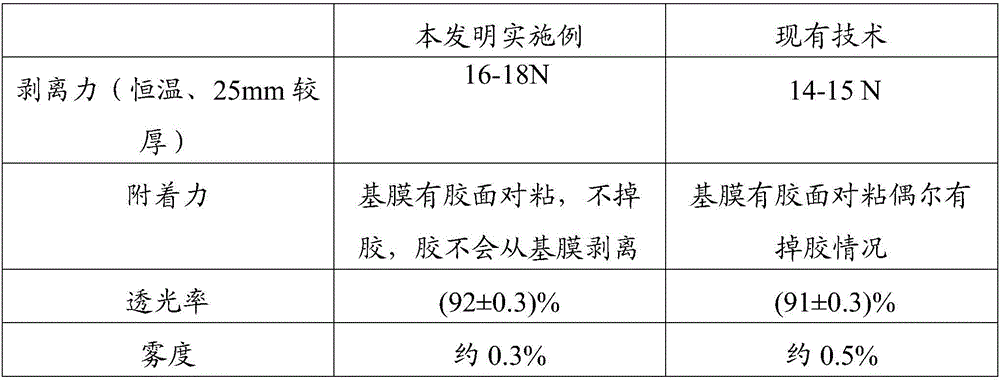

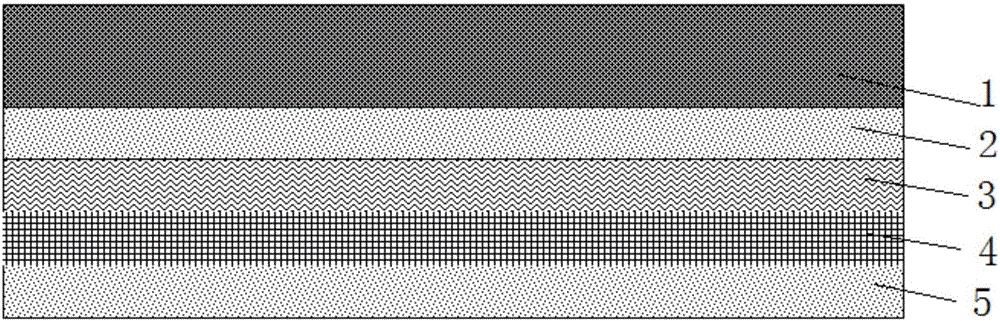

Explosion-proof membrane production method

InactiveCN106183327AExtend your lifeImproved adhesion and peelLamination ancillary operationsLayered product treatmentAdhesiveCoating

The invention discloses an explosion-proof membrane production method. The method comprises the following steps: providing a release film, putting a first uncoiler on the release film, passing the release film through a coating roller and a baking oven of a coating machine in order, then passing the release film through a composite wheel; providing an optical adhesive, adding a hardener in the optical adhesive, uniformly stirring the materials; separating the set temperature of the baking oven of the coating machine from an inlet to an outlet to a first temperature zone, a second temperature zone and a third temperature zone; providing a hardening membrane, putting a second uncoiler on the hardening membrane, passing one end of the hardening membrane through a corona machine and the composite wheel by the second uncoiler, applying a first surface of the hardening membrane and the first surface of the release film at the position of the composite wheel; turning on an explosion-proof membrane production device, coating the optical adhesive to the first surface of the release film by the coating machine, performing corona on the first surface of the hardening membrane by the corona machine, and compositing the first surface and the first surface of the release film on the composite wheel to form the explosion-proof membrane. According to the explosion-proof membrane production method, the produced explosion-proof membrane has the advantages of low cost, high quality and long service life.

Owner:DONGGUAN XUANLANG IND

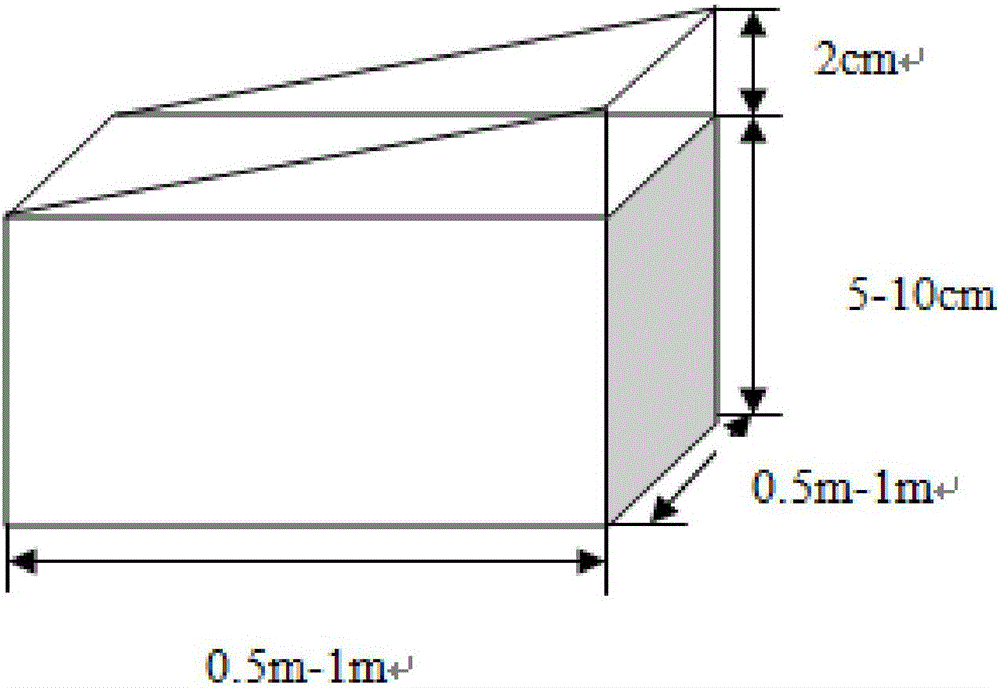

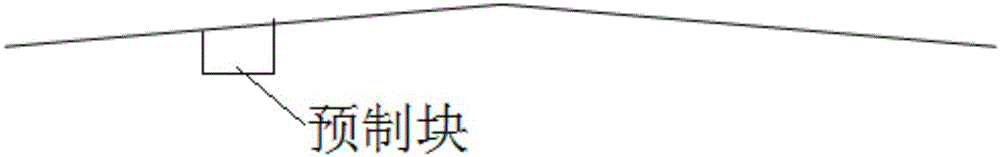

Asphalt pavement prefabricated block repairing pit slot structure and construction process thereof

The invention discloses an asphalt pavement prefabricated block repairing pit slot structure and a construction process thereof. The number and the size of damaged road section pit slots are determined to perform unified processing of prefabricated blocks, the pit slots are excavated in a centralized mode for unified filling repair, a construction period is short, and the influence on traffics is small. According to the process, the closing time is short, used repair materials are convenient to store, and are cold-mixed in a normal temperature state and are easy to form, a preparation process is simple, the early strength is high, the forming time is short, the elasticity modulus is moderate, the cooperativity with the road surface is good, and a second interface healant layer, a geotechnical grid layer, a CAS layer, a second interface healant layer and a prefabricated block layer are sequentially laid and are fixed by an interface healant. The asphalt pavement prefabricated block repairing pit slot structure is simple, high in strength, capable of performing line production and high in repair efficiency and is especially suitable for emergent repairs, such as rescue and relief works for road smoothing. Filling buffer and embedment roles are played between the CAC prefabricated blocks and original road surfaces to prevent water from seeping into joints.

Owner:CHANGAN UNIV

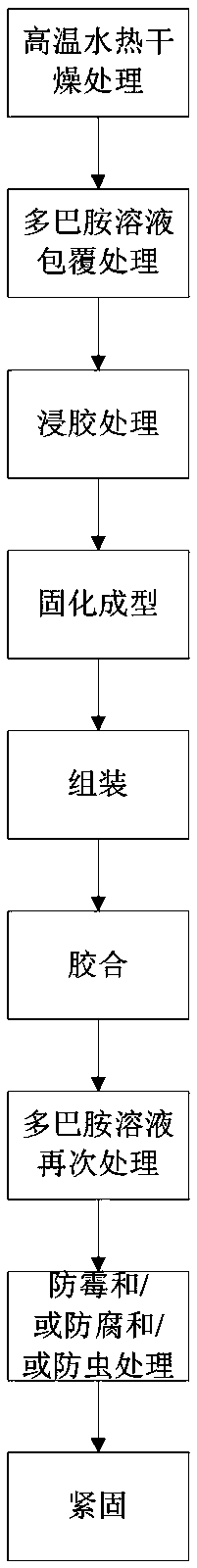

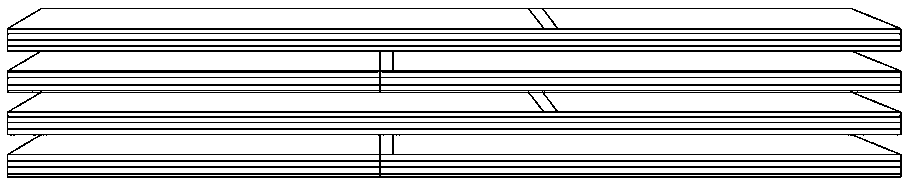

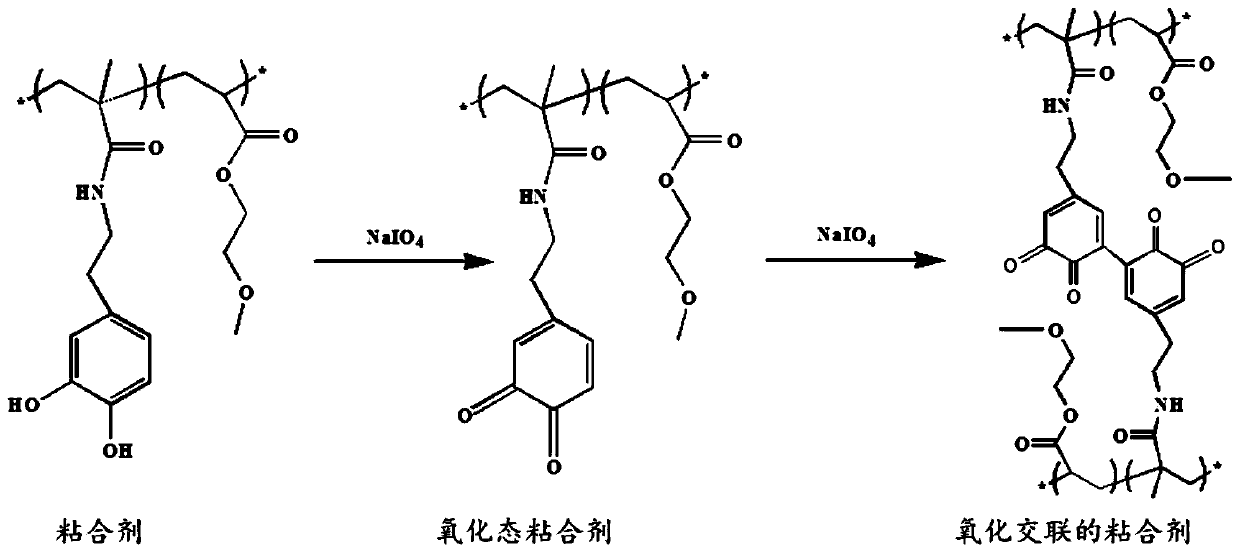

Bamboo sleeper assembled to be formed and preparation method thereof

ActiveCN109747008AIncrease elasticityImprove waterproof performanceBallastwayWood treatment detailsMaterials scienceUrban rail transit

The invention discloses a bamboo sleeper assembled to be formed. The bamboo sleeper is obtained in the modes that a bamboo unit is taken as a raw material, dried and modified at 110-180 DEG C, subjected to cladding treatment through a dopamine solution, impregnated, solidified to be formed, assembled and glued, solidified again, retreated through the dopamine solution, subjected to mould-proof and / or anti-corrosion and / or insect-proof treatment, and tightened. The invention further provides a preparation method of the bamboo sleeper. The prepared bamboo sleeper is environmentally friendly andsuitable for ballast rails of railway and urban rail transit.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD +1

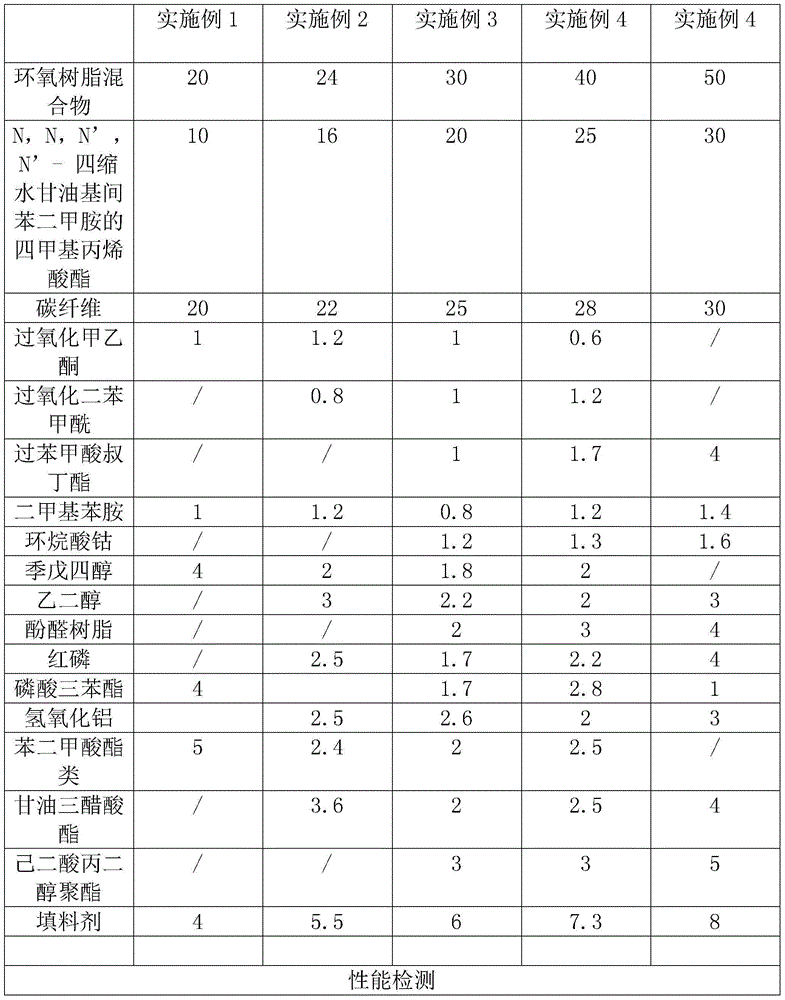

Composite carbon fiber plane grid rib

InactiveCN104151779AHigh strengthModerate modulus of elasticityBuilding reinforcementsFiberMethacrylate

The invention relates to the technical field of reinforcing materials of concrete structures and especially relates to a composite carbon fiber plane grid rib which is composed of following components, by mass: 20-50 parts of an epoxy resin mixture, 10-30 parts of N,N,N',N'-tetraglycidyl-m-xylylenediamine tetramethacrylate, 20-30 parts of carbon fibers, 1-4 parts of a curing agent, 1-3 parts of a promoter, 8-15 parts of a flame retarding agent, 5-9 parts of a plasticizer and 4-8 parts of a filling material. The composite carbon fiber plane grid rib has an excellent mechanical performance, is good in anti-fatigue performance, is more than 94% in strength retention ratio after ten million times of fatigue tests, can greatly improve a tensile strength, a bending strength, a flexibility and an anti-cracking performance of a concrete member, can reduce a weight of the member, is anti-corrosion, has a electromagnetic shielding performance and is suitable in the fields such as bridge plates, pavement plates, building structures and the like.

Owner:CHANGZHOU HUIYUN COMPOSITE MATERIALS

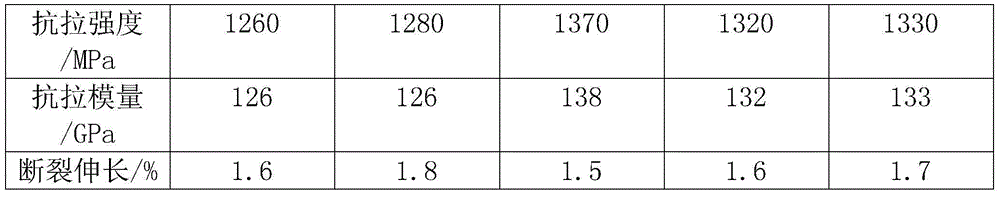

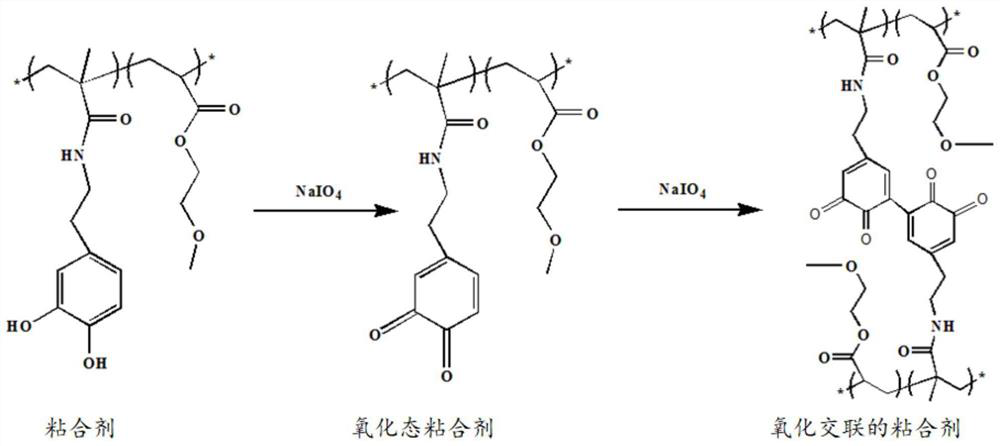

Mussel bionic binder-calcium phosphate high-strength bone repair material, high-strength composite CaP scaffold and preparation method thereof

ActiveCN110180021ASolve the lack of mechanical propertiesEasy to preparePharmaceutical delivery mechanismTissue regenerationTri calcium phosphateSolvent

The invention belongs to the technical field of biological materials, and specifically relates to a mussel bionic binder-calcium phosphate high-strength bone repair material, a high-strength compositeCaP scaffold and a preparation method thereof. In view of the problems of insufficient strength, especially toughness, and insufficient printability and formability of bone repair materials in the prior art, the invention discloses the mussel bionic binder-calcium phosphate high-strength bone repair material and the preparation method thereof. The technical scheme is as follows: the mussel bionicbinder-calcium phosphate high-strength bone repair material is prepared from the following materials in parts by weight: 5-35 parts of a bionic binder, 65-95 parts of calcium phosphate salt and 95-105 parts of deionized water, wherein the bionic binder is prepared by dissolving 1-3 parts by weight of 3.4-dihydroxyphenylmethacrylamide in 10 parts by weight of a mixed solvent, and the calcium phosphate salt is prepared by mixing alpha-tricalcium phosphate, hydroxyapatite, calcium hydrogen phosphate dihydrate and calcium carbonate. The mussel bionic binder-calcium phosphate high-strength bone repair material is applicable to the repair of bone injury.

Owner:SOUTHWEST JIAOTONG UNIV

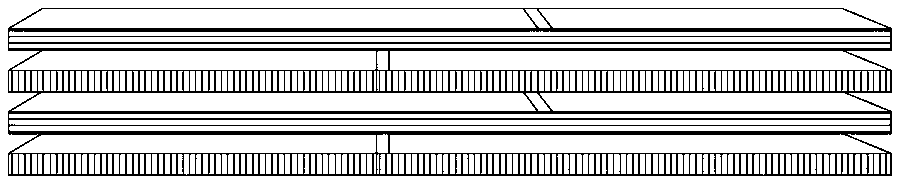

Once integral-molded bamboo sleeper and preparation method thereof

ActiveCN109732733AModerate modulus of elasticityUniform strengthBallastwayWood treatment detailsSolution treatmentWater vapor

The invention discloses a once integral-molded bamboo sleeper. The once integral-molded bamboo sleeper uses bamboo units as raw materials for drying and modification in overheated water vapor with a superheat degree of 10-80 DEG C, impregnation, whirl coating, curing, dopamine solution treatment, mould-proof and / or antiseptic and / or insect-proof treatment and fastening to obtain a finished product; and the density of the once integral-molded bamboo sleeper is 0.9-1.5 g / cm3. The invention further provides a preparation method of the bamboo sleeper. The prepared bamboo sleeper is proper in elastic modulus and suitable for ballast tracks of railways and urban railway systems.

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD +1

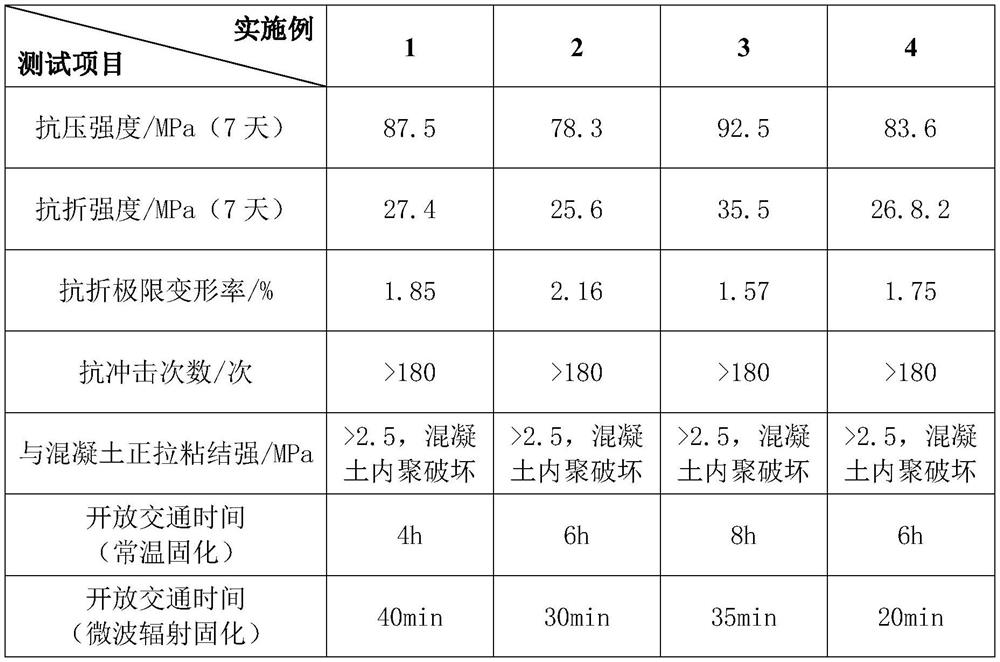

High-strength and high-toughness epoxy resin concrete for bridge expansion joint transition zone and preparation method thereof

The invention discloses a high-strength and high-toughness epoxy resin concrete for bridge expansion joint transition zones and a preparation method thereof. The epoxy resin concrete consists of a component A, a component B and a component C; the component A is prepared from nanoscale rubber-modified epoxy resin, liquid bisphenol-A epoxy resin, epoxy active diluent, defoaming agent and dispersant;the component B is prepared from epoxy curing agent, curing accelerant, coupling agent and pigment; and the component C is prepared from sand, quartz powder, fly ash, waste rubber powder, magnet powder and chopped fibers. The high-strength and high-toughness epoxy resin concrete not only can be cured by normal temperature but also can be cured by microwave radiation. The high-strength and high-toughness epoxy resin concrete has the advantages of good durability, long life, comfort for driving, short time for being open to traffic, constructability in low-temperature environments and the like,can be used in the installation construction of bridge expansion joints as well as the rapid concrete repair of bridge expansion joint transition zones, and can solve the problems of conventional bridge expansion joint transition zone concretes, i.e., short lives and long time for being open to traffic.

Owner:山西省交通科技研发有限公司

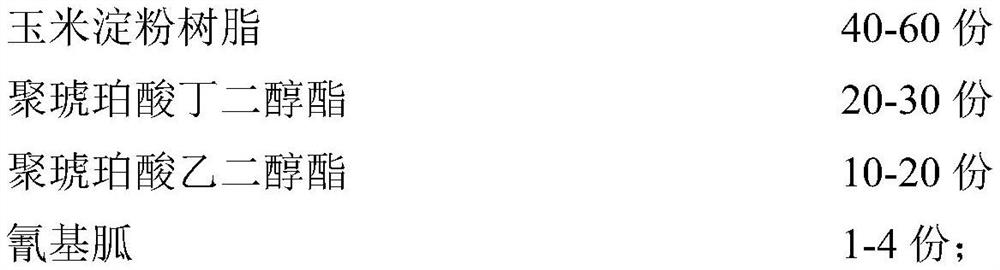

Hydrophilic film and preparation method thereof

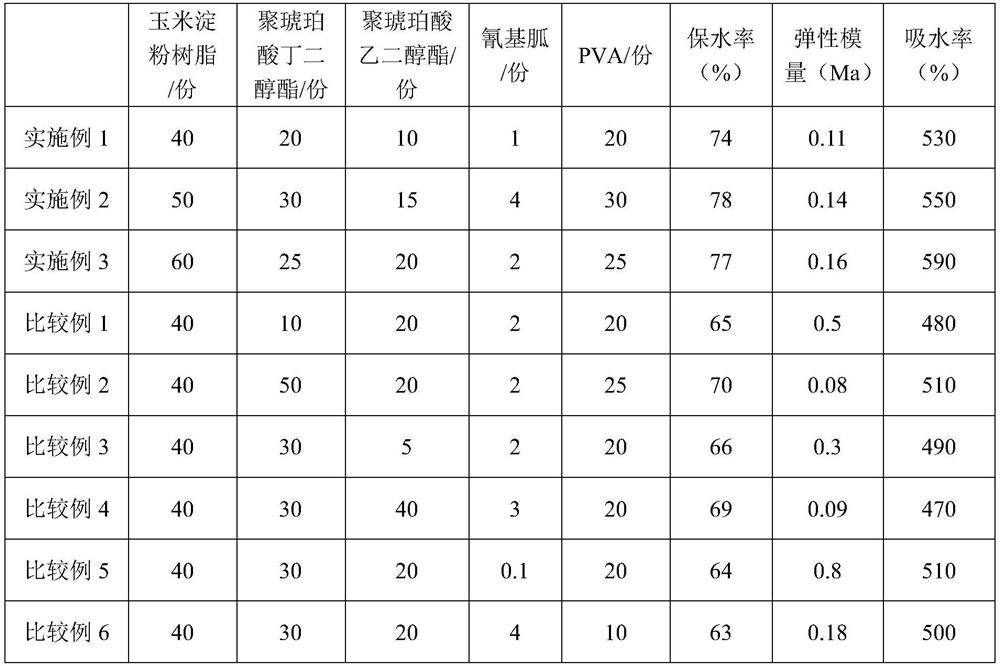

The invention discloses a hydrophilic membrane. The hydrophilic membrane comprises a hydrophilic fiber membrane and a hydrophilic coating coated on the hydrophilic fiber membrane, wherein the hydrophilic fiber membrane is prepared from 40 to 60 parts of corn starch resin, 20 to 30 parts of poly (butylene succinate), 10 to 20 parts of poly (ethylene glycol succinate) and 1 to 4 parts of cyanoguanidine; the hydrophilic coating is formed by coating a hydrophilic coating prepared from 100 parts of an acrylic copolymer, 30-50 parts of deionized water and 20-30 parts of PVA on the hydrophilic fiber membrane. Compared with the prior art, the hydrophilic film disclosed by the invention has the advantages of moderate elastic modulus, good skin fitness, good water absorption rate, higher water retention rate and degradability.

Owner:NINGBO SOKEN CHEM

Heavy-duty truck brake pad with "artificial bone" as skeleton and preparation method thereof

InactiveCN103836095BWear-resistantMacroporous structureOther chemical processesBraking membersFiberCarbon fibers

The invention relates to the field of manufacturing of heavy trunk brake pads, in particular to a heavy truck brake pad with a man-made skeleton as a framework and a manufacturing method of the heavy truck brake pad. The porous man-made skeleton framework is made of carbon fiber toughened ceramic, a porous framework material is filled with resin, friction performance modifier, filler and the like to make a high-performance special brake pad friction material, and thus the heavy truck brake pad can adapt to a special working environment and has the advantages of being low in density, high in strength, good in heat resistance, high in friction coefficient, stable and long in service life. The heavy truck brake pad can adapt to extreme working conditions with high temperature and high loads, is suitable for high-speed heavy trucks, lifting devices for mines and the like and has huge promotional application values.

Owner:QINGDAO UNIV

Mussel bionic adhesive-calcium phosphate high-strength bone repair material, high-strength composite cap scaffold and preparation method thereof

ActiveCN110180021BSolve the lack of mechanical propertiesEasy to preparePharmaceutical delivery mechanismTissue regenerationRestorative materialCalcium pidolate

Owner:SOUTHWEST JIAOTONG UNIV

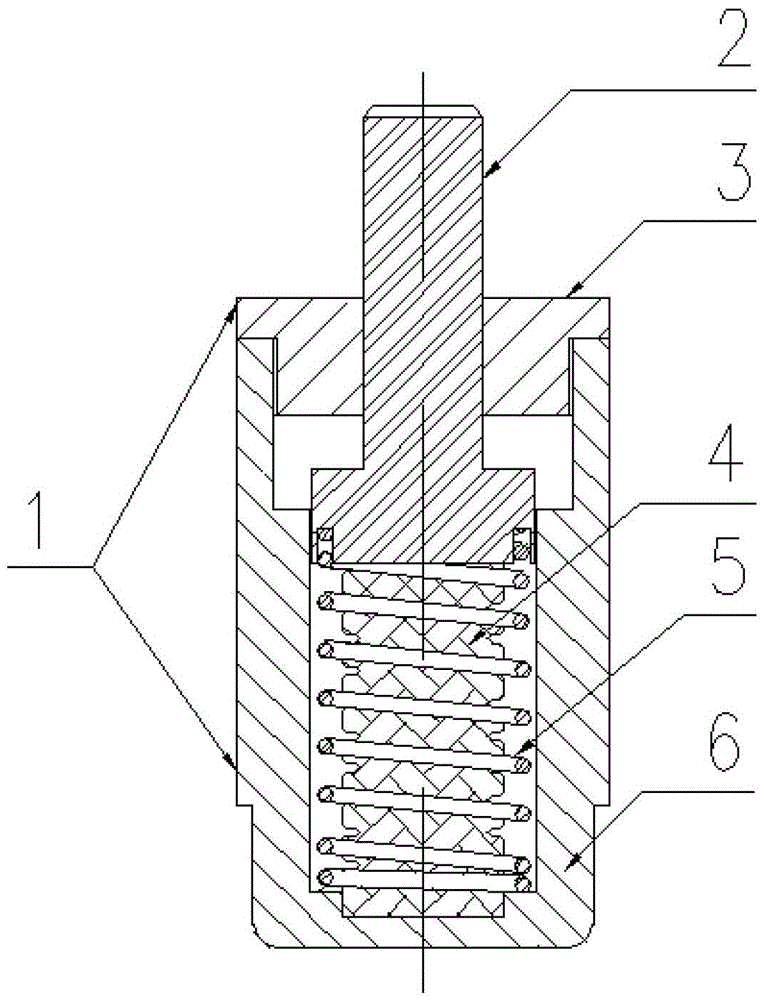

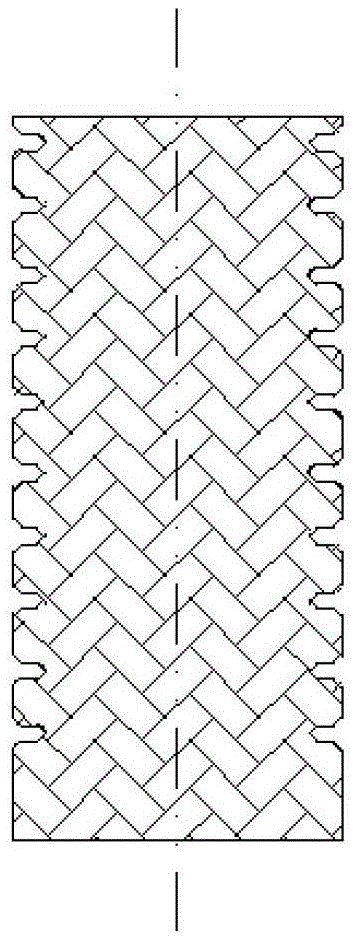

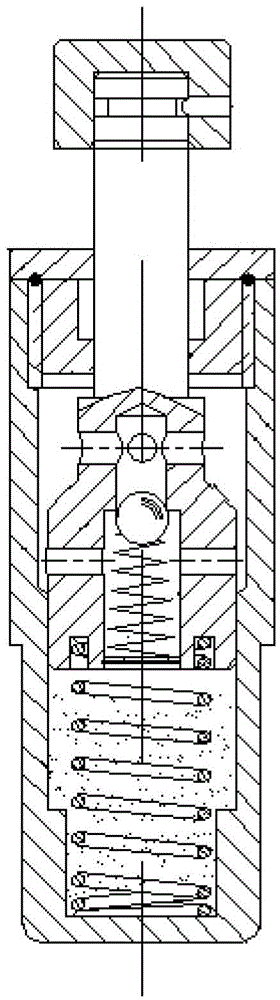

A damping rubber buffer

The invention relates to a damping rubber buffer. According to the damping rubber buffer, damping rubber is taken as a buffering medium, a compressed spring is taken as an auxiliary reset element, the damping rubber buffer structurally comprises a piston, a cylinder cap, the damping rubber, the compressed spring and a cylinder sleeve, the piston, the cylinder cap, the damping rubber and the pressure spring part are assembled wholly in the cylinder sleeve, and the components are combined into an integral structure. The damping rubber buffer can meet the technical requirement that buffers are required to be used on various vacuum circuit breaker structures.

Owner:宁波鑫鑫鑫寅电气有限公司

Copper-based powder metallurgy composite friction material for vehicle and preparation method thereof

InactiveCN105778406BReduce surface hardnessModerate modulus of elasticityPowder mixtureResin-Based Composite

The invention discloses an automotive copper-based powder metallurgy composite friction material and a manufacturing method thereof. The manufacturing method includes that firstly, a basis powder material is mixed with a molding agent uniformly to obtain a mixture, the mixture is poured into a mold and is shaped into slender rods by pressing, the slender rods are compacted and separated and then charged into a sintering furnace, and the sintering furnace is heated up under protection of nitrogen gas or hydrogen gas so that a copper-based powder metallurgy friction material is obtained; secondly, the copper-based powder metallurgy friction material is subjected to processes of shearing, grinding and screening; thirdly, by mass percent, 10-20% of cashew nut oil modified phenolic resin, 30-60% of the copper-based powder metallurgy friction material, 10-20% of reinforced fibers, 5-15% of abrasives, 10-20% of lubricants and 5-20% of fillers are mixed uniformly to obtain a powder mixture, and the powder mixture is then subjected to hot press molding, is cooled to the room temperature and then is discharged from the furnace. The automotive copper-based powder metallurgy composite frictional material has both advantages of high temperature resistance and low abrasion as the copper-based powder metallurgy friction material and high ductility and low hardness as the resin-based composite friction material.

Owner:SOUTH CHINA UNIV OF TECH

Resin-based powder metallurgy composite friction material for vehicle and preparation method thereof

InactiveCN105838023BIncreased frictional surface roughnessIncrease porosity coefficientFriction liningResin-Based CompositeMachining

Owner:SOUTH CHINA UNIV OF TECH

The airport pavement structure and pavement method of adding asphalt layer to the old cement airport runway

ActiveCN113235351BFully consider the integrityFully consider the adhesionIn situ pavingsRoads maintainenceCrack resistanceCrushed stone

Owner:SOUTHEAST UNIV

Iron-based powder metallurgy composite friction material for vehicle and preparation method thereof

Owner:SOUTH CHINA UNIV OF TECH

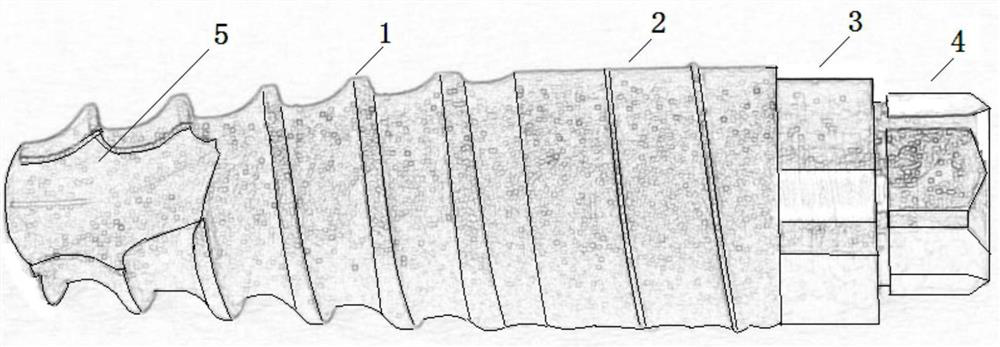

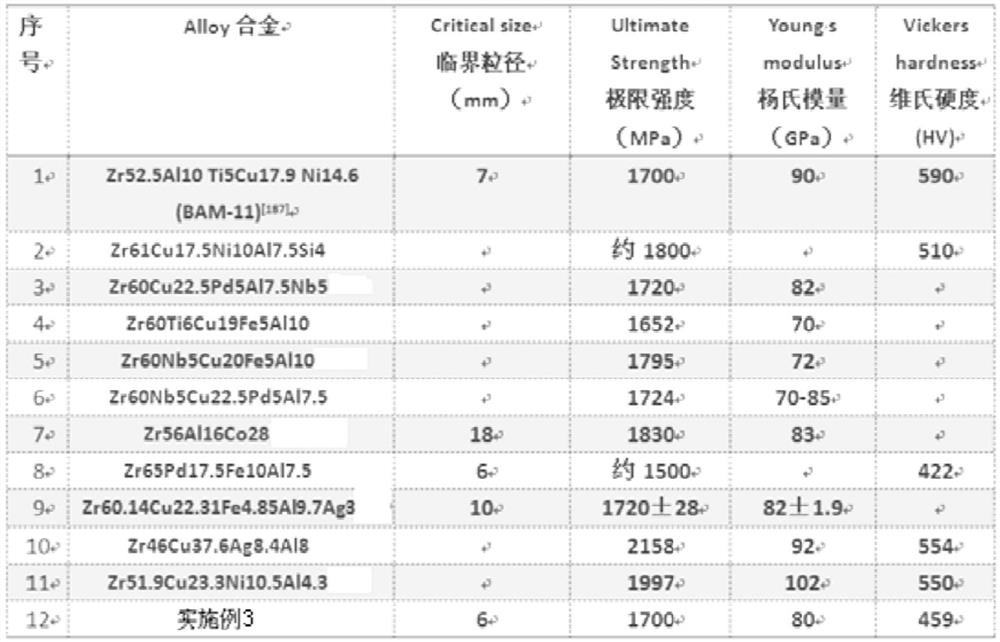

A zirconium-based amorphous metal glass dental implant and its preparation method

ActiveCN110464498BReliable basic mechanical propertiesReduce attack rateDental implantsTissue regenerationBreaking strengthDentistry

The invention relates to a zirconium-based amorphous metal glass dental implant and a preparation method thereof, comprising: 30-65 parts of zirconium, 0-25 parts of titanium, 0-45 parts of copper, 0-20 parts of aluminum, silicon 0‑20 parts, 0‑10 parts of iron, 0‑10 parts of zinc, 0‑5 parts of silver, 0‑5 parts of palladium, the dental implant is an amorphous metallic glass cylindrical rod with a diameter of 2‑6mm and a length of 4‑13mm; The part of the dental implant located in the bone has a self-tapping thread structure with a pitch of 0.7-2mm and a thread depth of 0.3-0.6mm. The thread section is triangular. between the first thread and the third thread. The invention has good fracture resistance, good biocompatibility, moderate elastic modulus and certain antibacterial effect, and is a good metal implant material.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

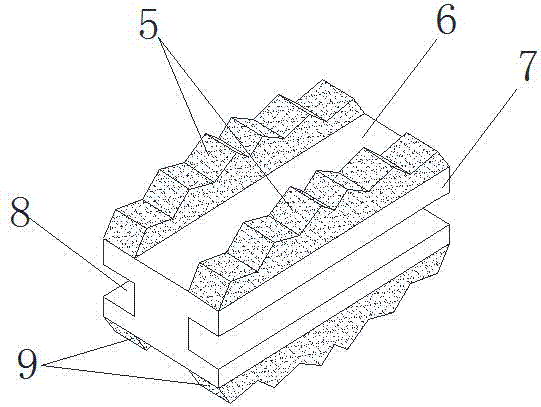

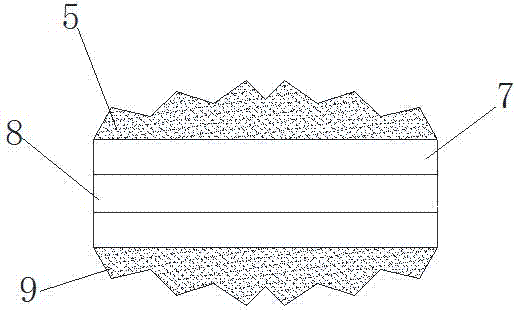

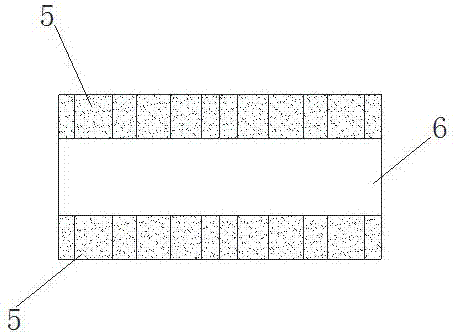

Stable intervertebral fusion cage

InactiveCN106943212ATightly boundSimple structureSpinal implantsTissue regenerationWhole bodyEngineering

The invention relates to a stable intervertebral fusion cage comprising an upper portion, a middle portion (7), and a lower portion; the upper portion comprises two bar shaped bodies (5) arranged at an interval along the long side face direction of the middle portion (7), the two bar shaped bodies (5) are respectively located on two edges of the top end face of the middle portion (7), and a long inlet groove (6) is arranged between the two bar shaped bodies (5); the two opposite long side faces of the middle portion (7) are respectively provided with a groove (8) distributed in the long side face direction; the lower portion comprises two bar shaped bodies (9) arranged at an interval along the long side face direction of the middle portion (7), the two bar shaped bodies (9) are respectively located on two edges of the bottom end face of the middle portion (7), and a long inlet groove (10) is arranged between the two bar shaped bodies (9); the upper and lower portions are respectively made of porous metal material, and fixed with the middle portion (7)so as to form a whole body. The stable intervertebral fusion cage is simple in structure, light in weight, proper in elastic modulus, and can realize self-stability.

Owner:CHONGQING RUNZE PHARM CO LTD

Heat conduction mechanism for personal care device and personal care device

The utility model provides a heat conduction mechanism for a personal care device. The heat conduction mechanism for the personal care device comprises a heat conduction body and an installation frame, wherein the heat conduction body is fixedly installed on the installation frame; the heat conduction body is an aluminum plate; the working surface of the heat conduction body is provided with a carbon fiber layer. The personal care device which adopts the heat conduction mechanism comprises a pair of clamping components; the tail parts of the clamping components are connected in a hinging way; the heat conduction mechanism is arranged in the clamping components; a heating body is built in the heat conduction mechanism; and the heat conduction mechanism contacts with the heating body. According to the heat conduction mechanism for the personal care device and the personal care device, when the aluminum plate is combined with carbon fiber; the advantages of the aluminum plate, i.e. easiness in shaping, low processing requirements and low material cost are utilized; and for example, when the aluminum plate of which the surface is attached with the carbon fiber is adopted as the working surface, the advantages of the carbon fiber such as self-lubrication, high strength, moderate elastic modulus, good heat resisting performance, low weight, small expansion coefficient and wear resistance are utilized.

Owner:ZHEJIANG PAITER ELECTRIC

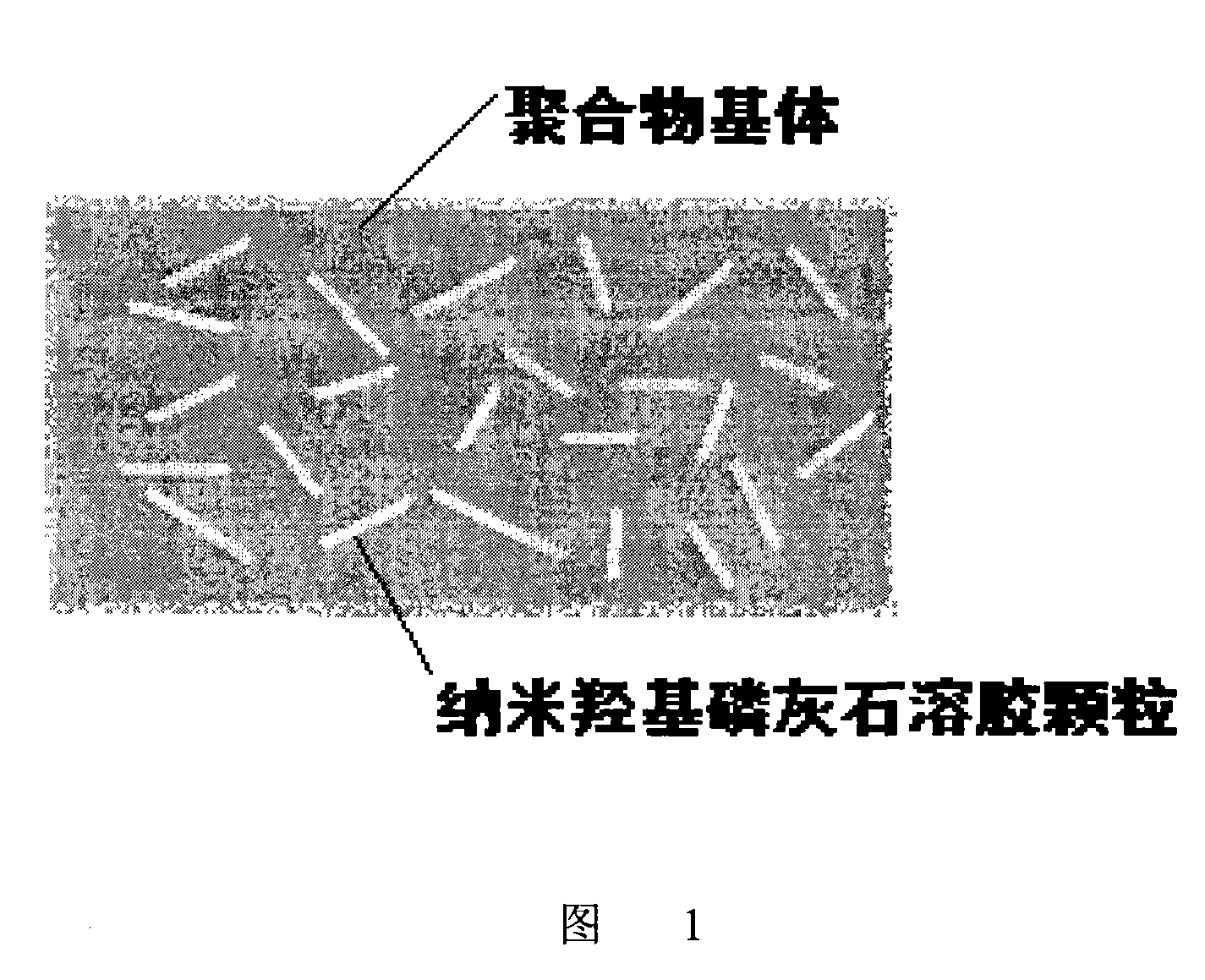

Method for preparing nano hydroxyapatite/polymer composite bone substitution material

The invention relates to a preparation method of a nano-hydroxyapatite / polymer compound bone replacement material, wherein, the content of n-HA of the n-HA / polymer compound bone replacement material which is prepared by in situ blending of the nano-hydroxyapatite (n-HA) non-hydrolytic sol and polymer is 20 to 60wt percent. The preparation method includes: the polar and hydrophilic polymer is dissolved in organic solvent; the mixture is stirred and blended with the n-HA sol to lead the n-HA granules are evenly distributed in the polymer to form chemical bond with the polymer; and then the n-HA / polymer compound material is obtained by centrifugal separation, drying, hot-press molding and so on. The hydroxyapatite with nano-scale in the compound bone replacement material prepared by the invention is evenly distributed in the polymer substrate and forms strong chemical bond with the polymer. The invention not only has high tensile and bending strength, appropriate elastic modulus and other mechanical performances, but can also ensure that the material has good biocompatibility, thus meeting the clinical using requirement of human bearing bone repair material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

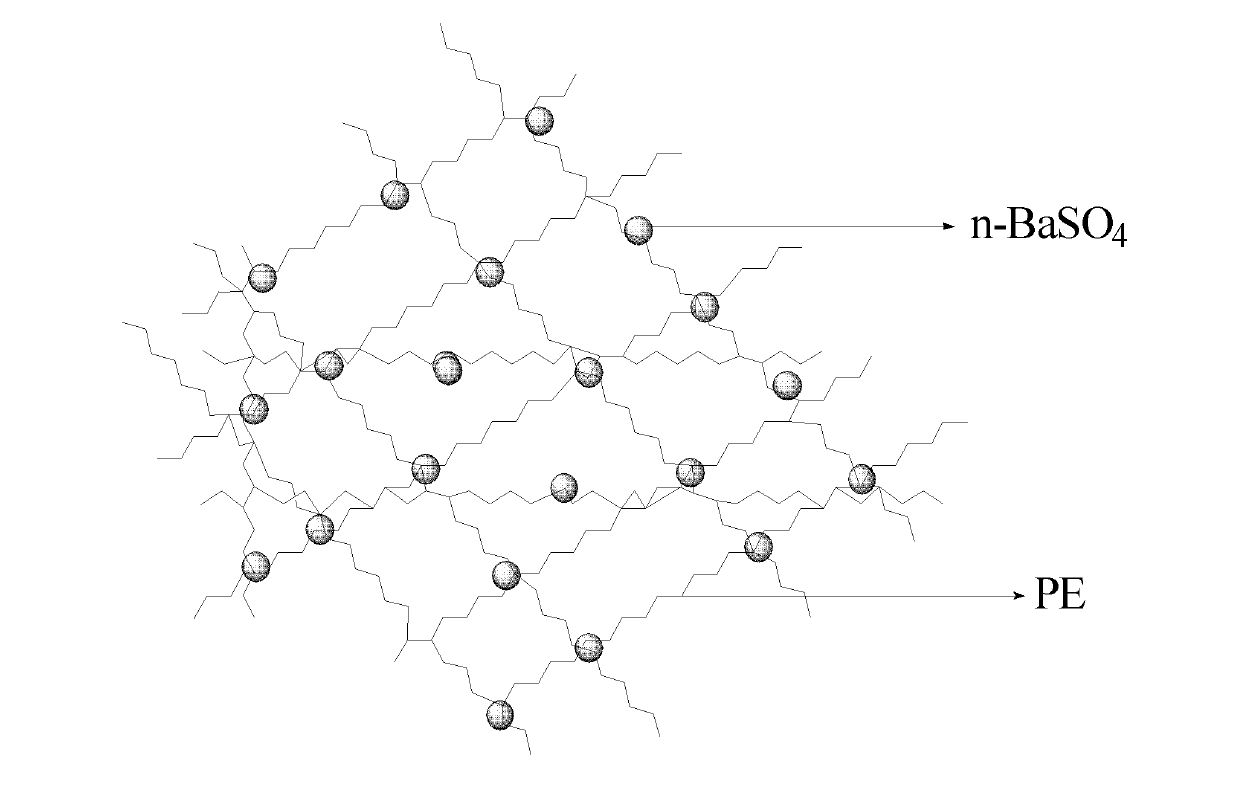

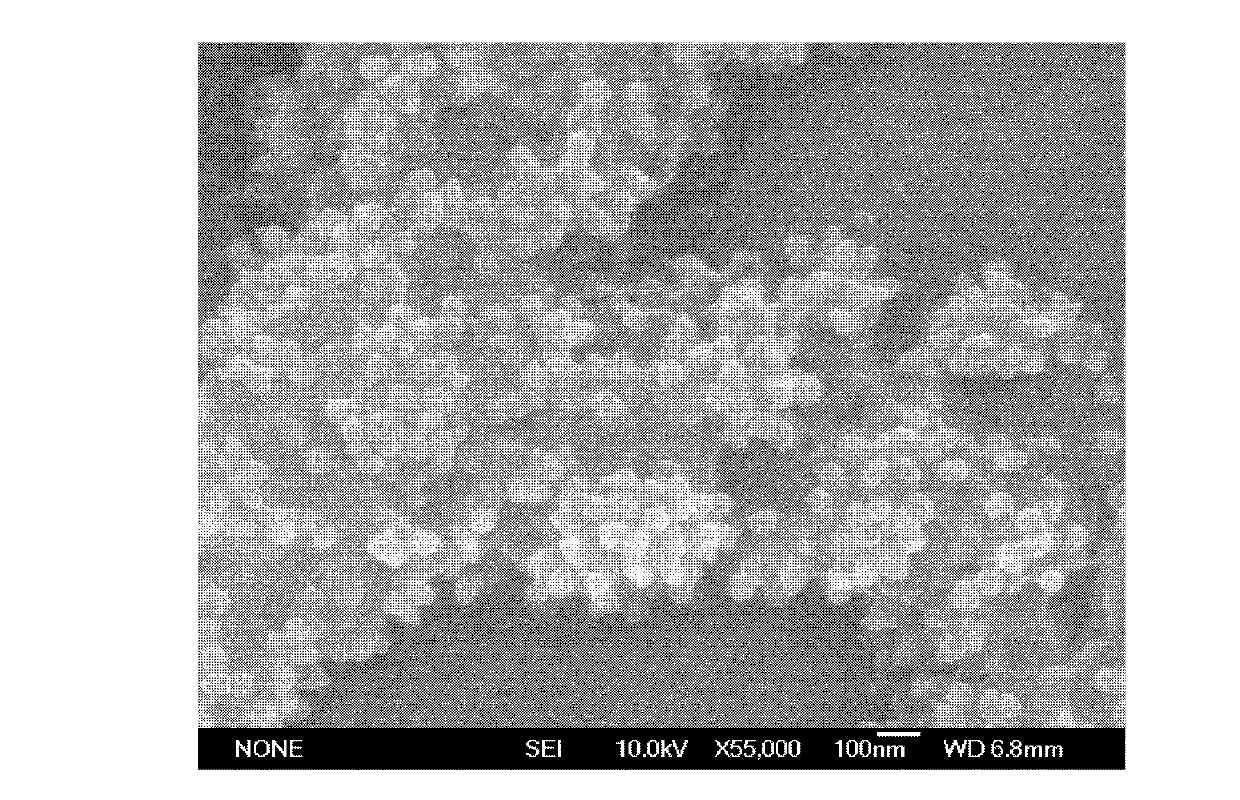

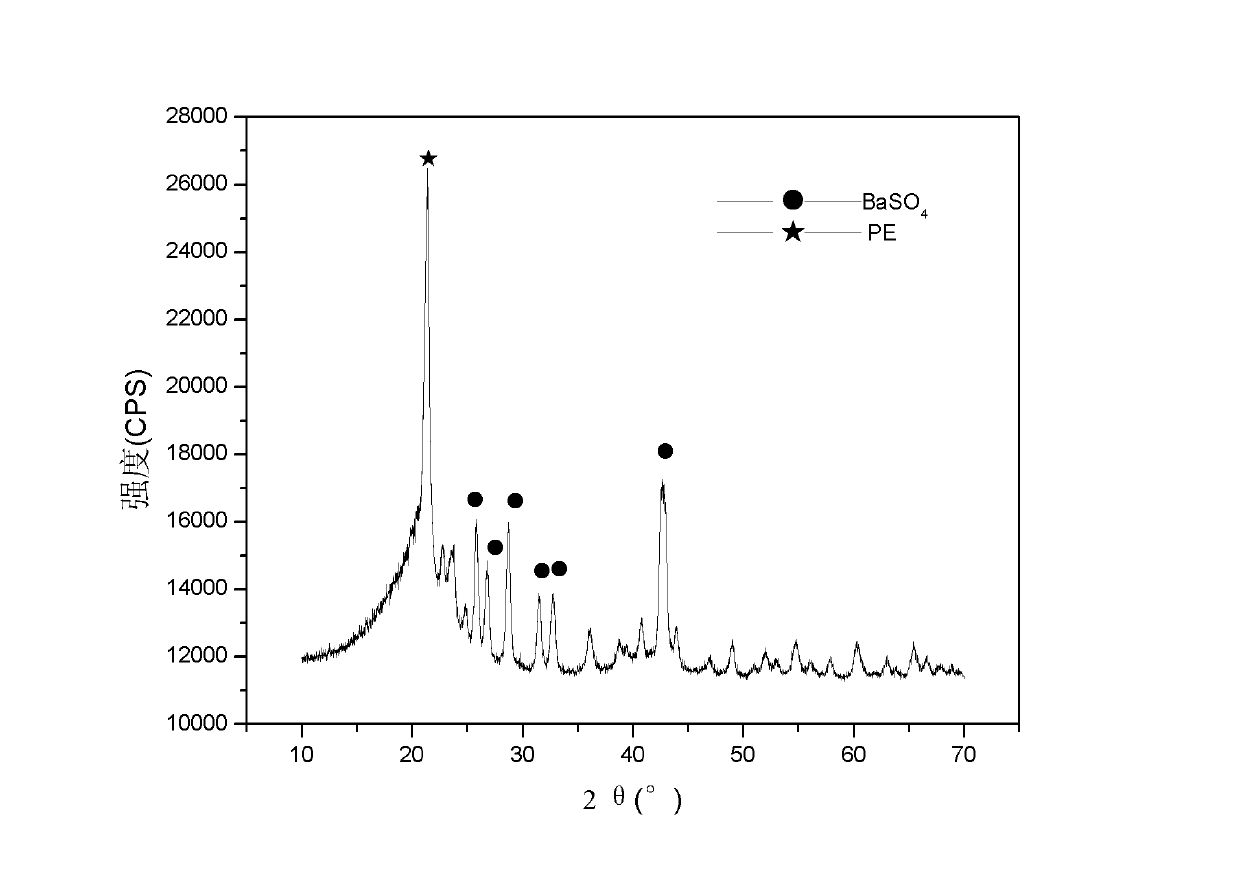

Preparation method for nano barium sulfate/polyethylene copper intrauterine device T-type stent material

InactiveCN102585062BGood biocompatibilityGood dispersionInorganic pigment treatmentSurgeryIn situ polymerizationIntrauterine device

The invention relates to a preparation method for a nano barium sulfate / polyethylene copper intrauterine device T-type stent material. The preparation method comprises the following steps of: activating prepared nano barium sulfate by using TiCl4, and then adding ethylene; adding an organic solvent, the activated nano barium sulfate and ALR3, and keeping monomer pressure and reaction temperature to carry out an ethylene polymerization reaction; stopping the reaction by using alcohol, and then carrying out in-situ polymerization to ensure that n-BaSO4 particles are uniformly distributed in thepolymer and form chemical bonding with the polymer; and carrying out separating, drying and hot-press forming to prepare the nano barium sulfate / polyethylene composite material. The preparation method has the advantages that the nano barium sulfate in the composite material prepared by adopting the in-situ polymerization method has high dispersity and can be uniformly distributed in the polymer matrix, and due to high surface activity, the n-BaSO4 particles can form strong chemical bonding with the polymer, so that the composite material not only has high mechanical properties of high tensileand flexural strength, proper elasticity modulus and the like, but also has good biocompatibility and can meet the use requirement on the copper intrauterine device T-type stent material of clinic.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Automotive resin-based powder metallurgy potassium titanate fiber friction material and preparation method thereof

The invention discloses a method for producing a resin-based powder metallurgy potassium titanate fiber friction material used for vehicle. The method comprises the following steps: uniformly mixing a matrix powder material and a forming agent, dumping a mixture into a die, compacting the mixture to several elongated rods, compacting the elongated rods, separating the elongated rods, putting the elongated rods in a sintering furnace, under condition of introducing nitrogen or hydrogen, heating the materials to obtain a Fe-based powder metallurgy friction material; shearing the Fe-based powder metallurgy friction material, crushing the Fe-based powder metallurgy friction material, and sieving; by metering with mass percentage, uniformly mixing 10-20% of cashew oil-modified phenolic resin, 30-50% of the Fe-based powder metallurgy friction material, 10-30% of potassium titanate fiber, 5-15% of an abrasive, 10-20% of a lubrication material, and 5-20% of a filling material; performing hot press molding on the materials, cooling the materials, and discharging. The friction material combines the characteristics of high temperature resistance and low abrasion of the Fe-based powder metallurgy friction material as well as good toughness and low hardness of the potassium titanate resin-based composite friction material, and the obtained material has the characteristics of high temperature resistance, low abrasion, good toughness, and low hardness.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com