Asphalt pavement prefabricated block repairing pit slot structure and construction process thereof

A technology of asphalt pavement and construction technology, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of large specific gravity, high equipment requirements, and long closed traffic time, etc., achieve moderate elastic modulus, simple preparation process, and save repair materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

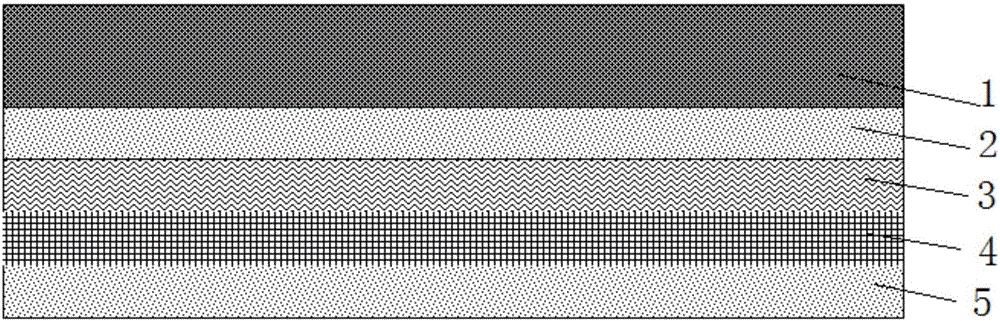

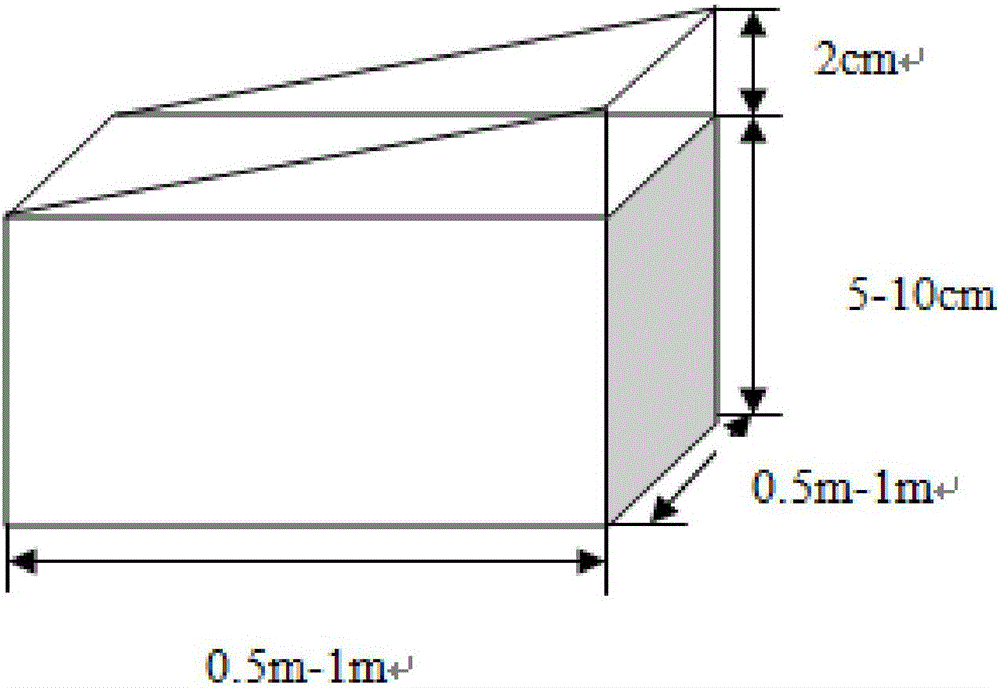

[0029] A kind of asphalt pavement prefabricated block repair pit groove structure of the present invention, such as figure 1 , 3 As shown, from top to bottom are the prefabricated block layer 1, the first interface repair agent layer 2, the CAS layer 3, the geogrid layer 4, the second interface repair agent layer 5, and the bottom of the pit.

[0030] A construction technique for repairing pit structures with asphalt pavement prefabricated blocks, specifically comprising the following steps:

[0031] 1) First, conduct road surface disease investigation, determine the number and size of pits, calibrate the excavation size on site, and then feed back the statistical results to the factory;

[0032] 2) The factory transports the uniformly processed prefabricated block layers of corresponding sizes to the construction site, and at the same time uniformly excavates the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com