Patents

Literature

400 results about "Resilient modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resilient Modulus. The Resilient Modulus (M R) is a measure of subgrade material stiffness. A material’s resilient modulus is actually an estimate of its modulus of elasticity (E). While the modulus of elasticity is stress divided by strain for a slowly applied load, resilient modulus is stress divided by strain for rapidly applied loads – like...

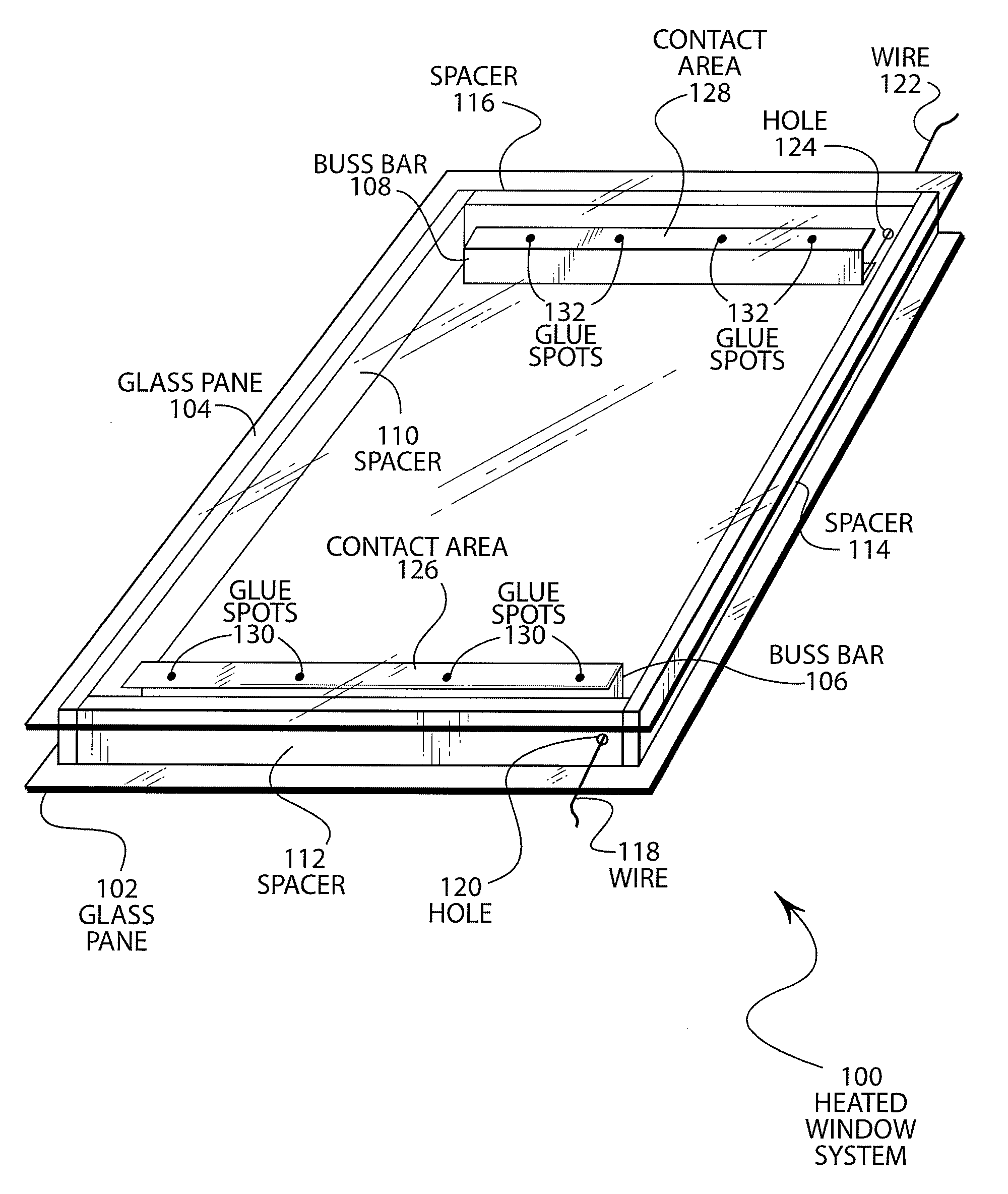

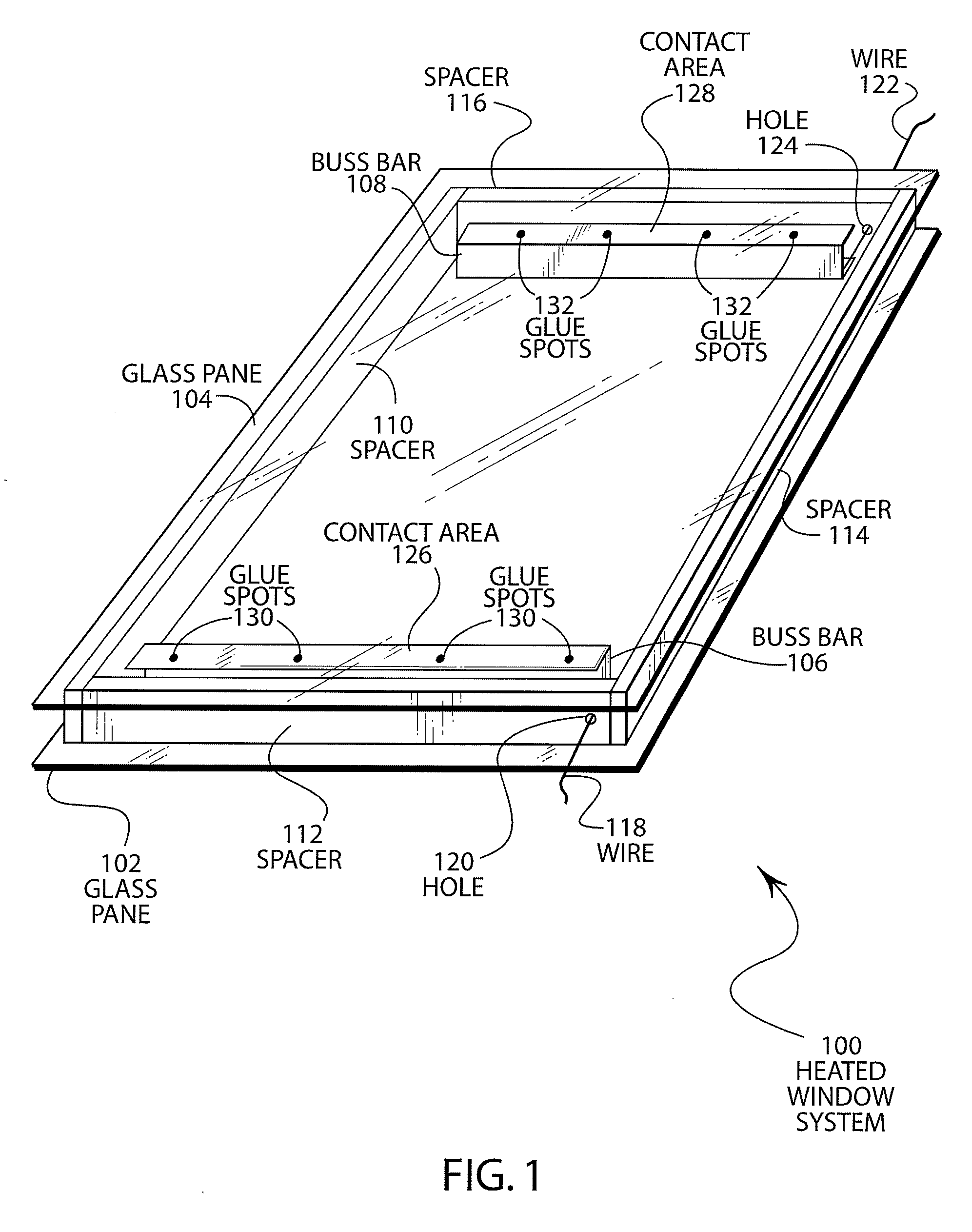

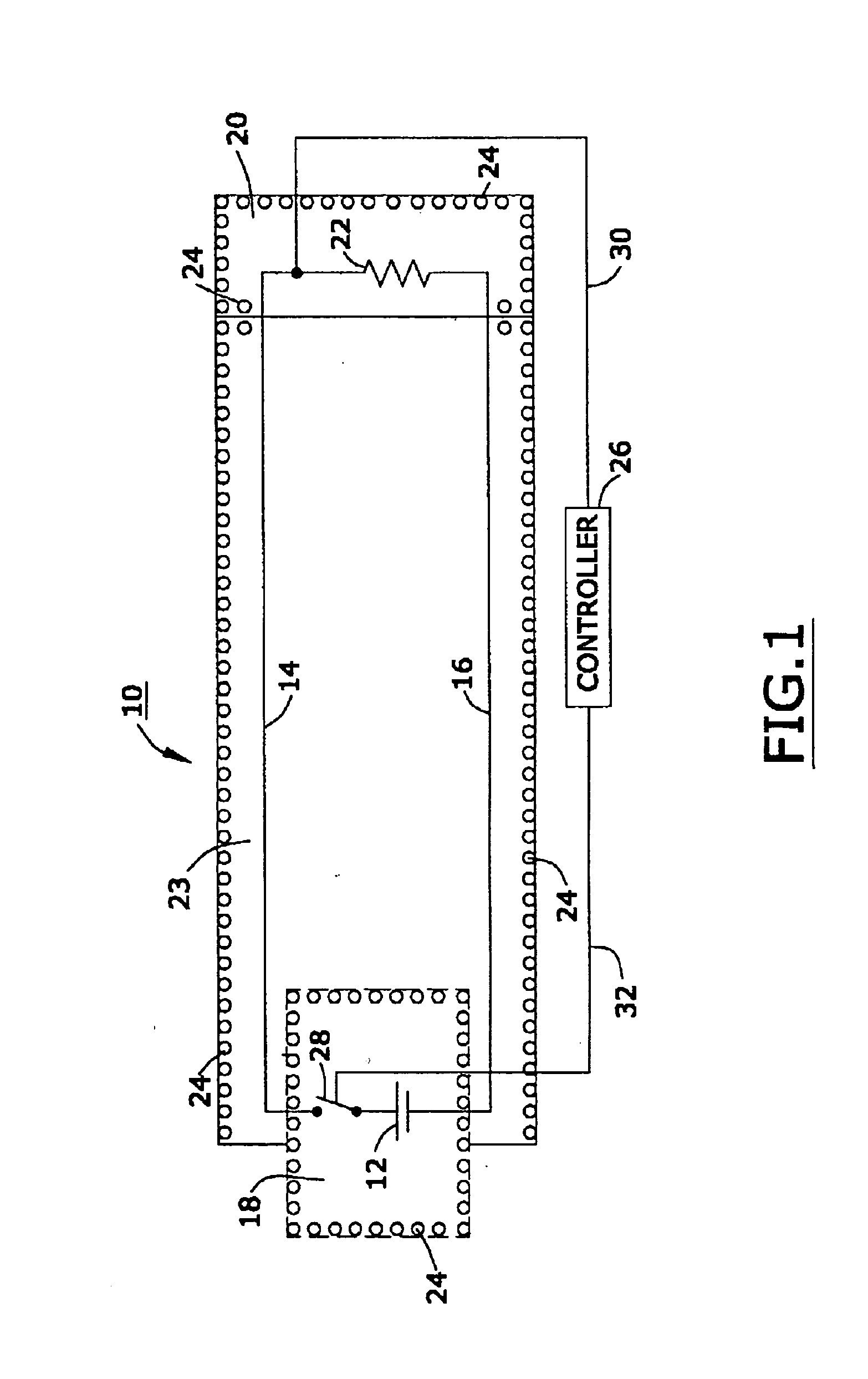

Warm Window System

InactiveUS20060283084A1Sufficient currentOhmic-resistance electrodesLighting and heating apparatusElectricityMetal strips

Disclosed is a warm window system that utilizes individual buss bars that are placed within the space between an inside window pane and an outside window pane and creates sufficient physical force to create an electrical contact on the tin oxide layer on the inside surface of the inside pane of glass. An insulating nonconductive layer can also be used in conjunction with the buss bars. That include metal strips, braided wires, spring loaded indentations, etc. The buss bars have a modulus of elasticity to ensure sufficient electrical contact with the tin oxide layer. The buss bars can be used with either hard coat or soft coat tin oxide coatings on tempered glass or annealed glass. Electrical connections and wires are hidden from the viewing area of the warm window system to enhance the aesthetic value of the warm window system. Retrofit systems allow use of the warm window system in conjunction with an existing installed window system.

Owner:ENERGIZED GLASS

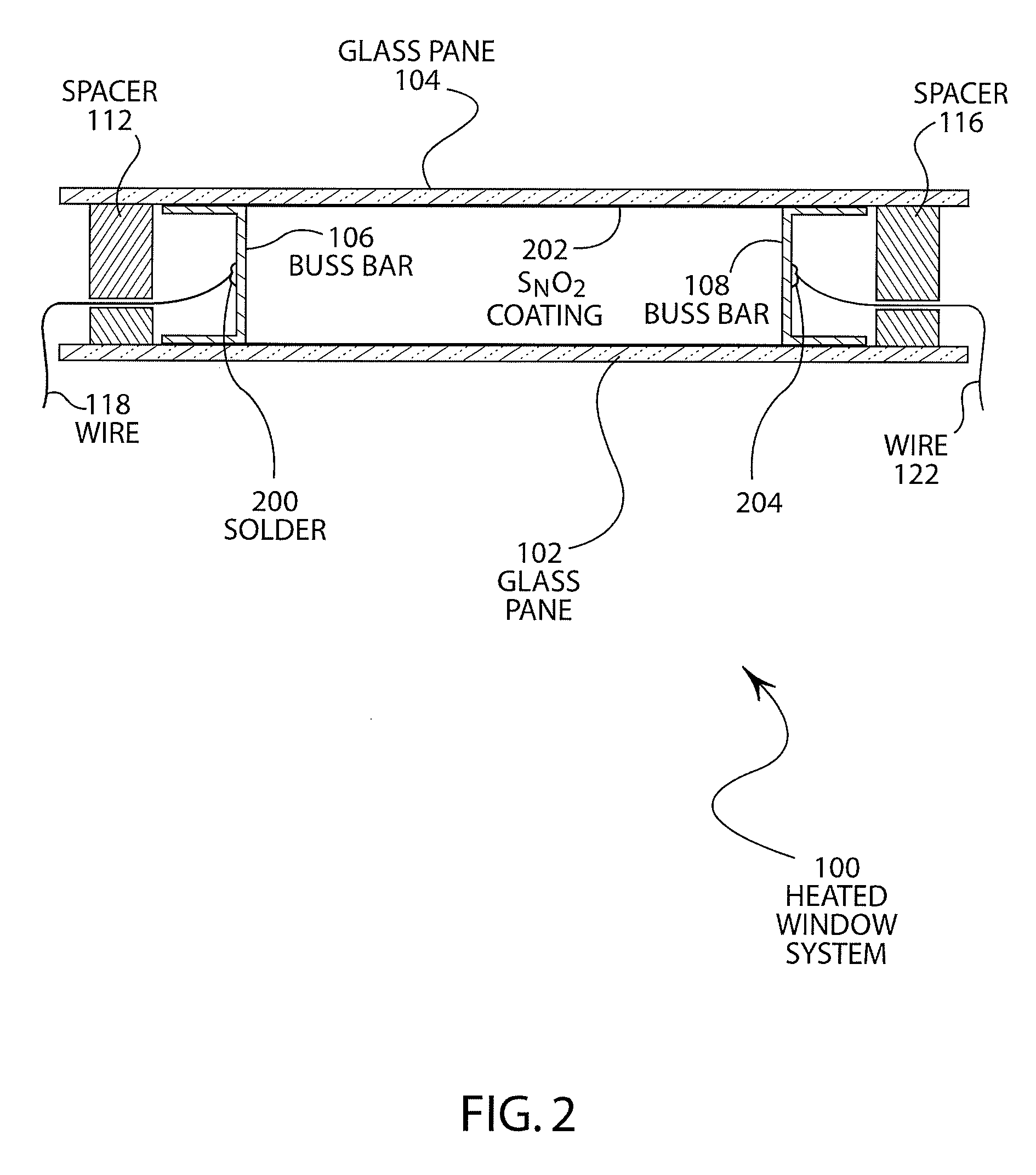

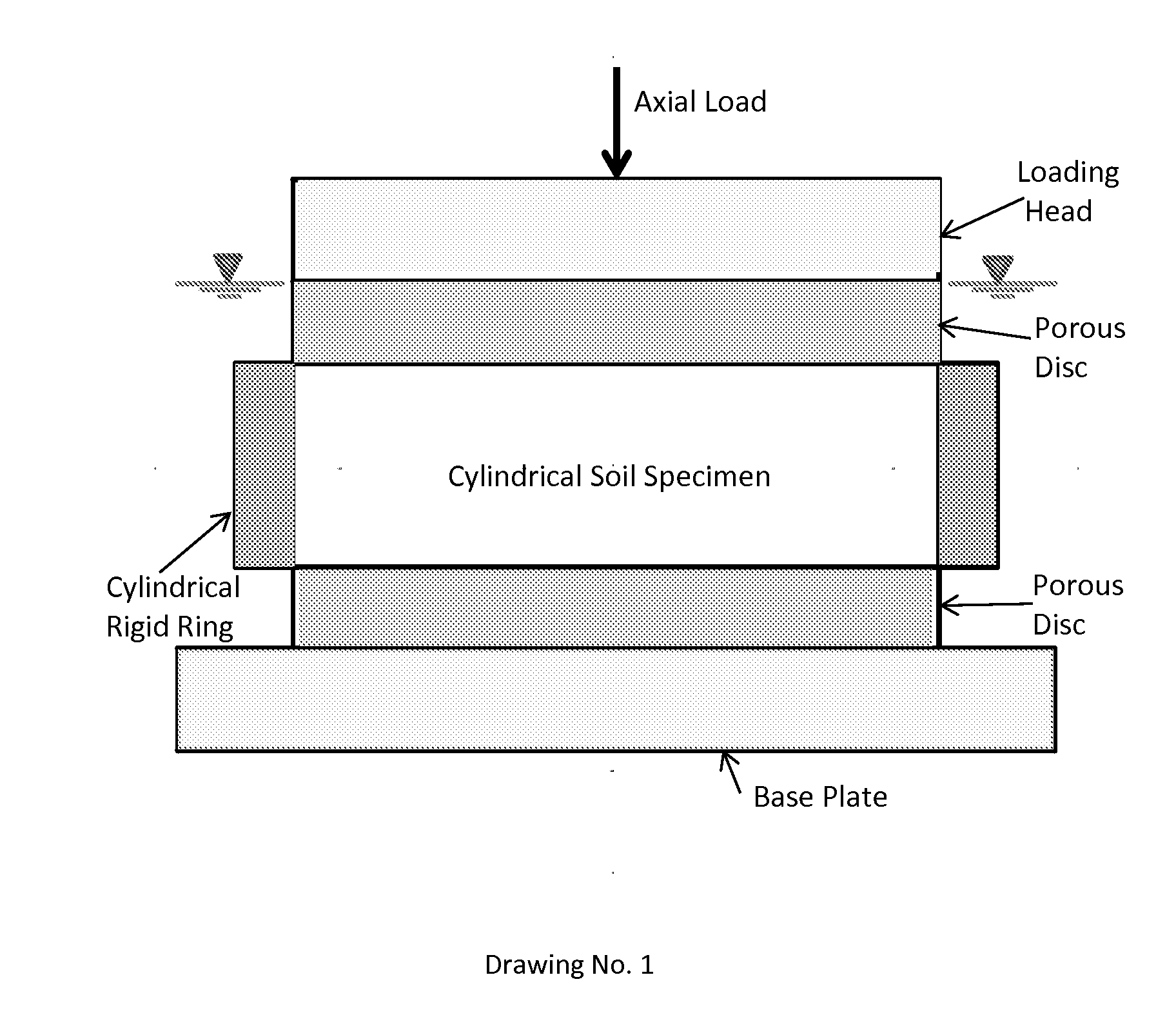

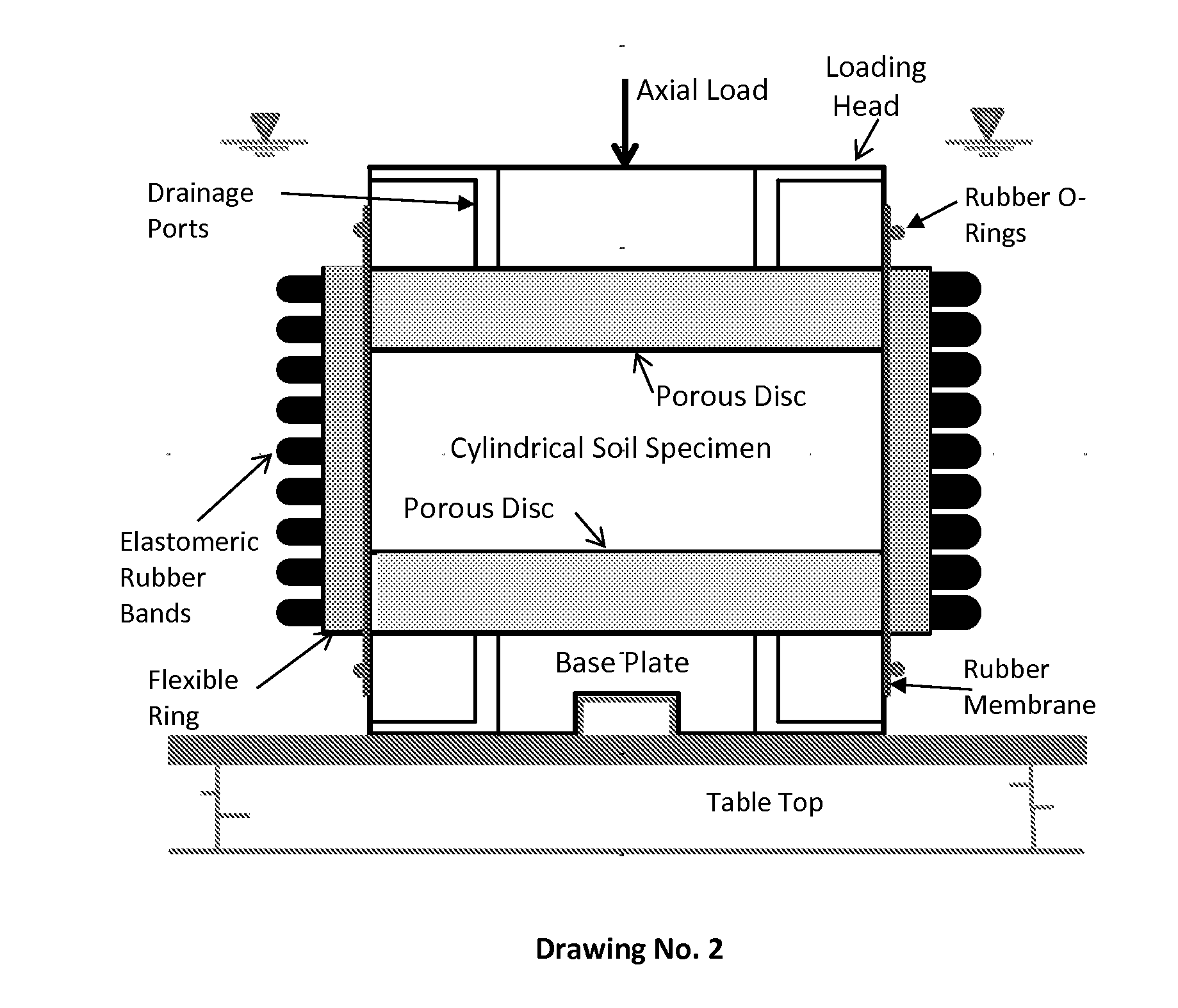

Test Device for Determining Three-Dimensional Consolidation Properties of Soils

InactiveUS20150267370A1Increase lateral resistanceExcessive pressureMaterial strength using tensile/compressive forcesEarth material testingRubber membranePore water pressure

Standard test methods for determining one-dimensional consolidation properties of soils using incremental loading in accordance with ASTM D2435, or AASHTO 216, and of those of other international and organizations, do not accurately predict the values of vertical settlement, coefficients of consolidation in horizontal and vertical directions, and modulus of elasticity in vertical direction, because fixed ring used in these tests do not allow horizontal settlement and dissipation of excess pore-water pressures in horizontal direction, whereas, in field, under application of a vertical load, both horizontal and vertical settlements occur along with dissipation of excess pore-water pressures in both vertical and horizontal directions. To overcome this more than 100 year old problem, the inventor (Dr. Ramesh Chandra Gupta, Ph. D., P.E.) has invented a test device for determining three-dimensional consolidation properties of soils, using a flexible ring which permits development of horizontal and vertical displacements, and dissipation of excess pore-water pressures in both horizontal and vertical directions, along with increased lateral resistance as takes place in field at any depth in a soil deposit when vertical load at the surface is applied.The flexible ring consists of filter fabric around the soil specimen, rubber membrane around the filter fabric, circular segmental metal plates around the membrane and elastomeric rubber bands or spring loaded jacket around the segmental plates, and allows horizontal and vertical displacements, dissipation of pore-water pressures in horizontal and vertical directions to take place with increased lateral resistance with each increment of vertical load like those in the field. Thus new test device simulates field condition to allow accurate determination of three-dimensional consolidation properties of soils (such as settlements, coefficients of consolidation in horizontal and vertical directions, and modulus of elasticity).For this new test device, conventional incremental consolidation frame or triaxial type chamber system either with the triaxial loading system or modified to adapt to incremental consolidation frame, shall be used to perform three-dimensional consolidation tests.

Owner:GUPTA RAMESH CHANDRA

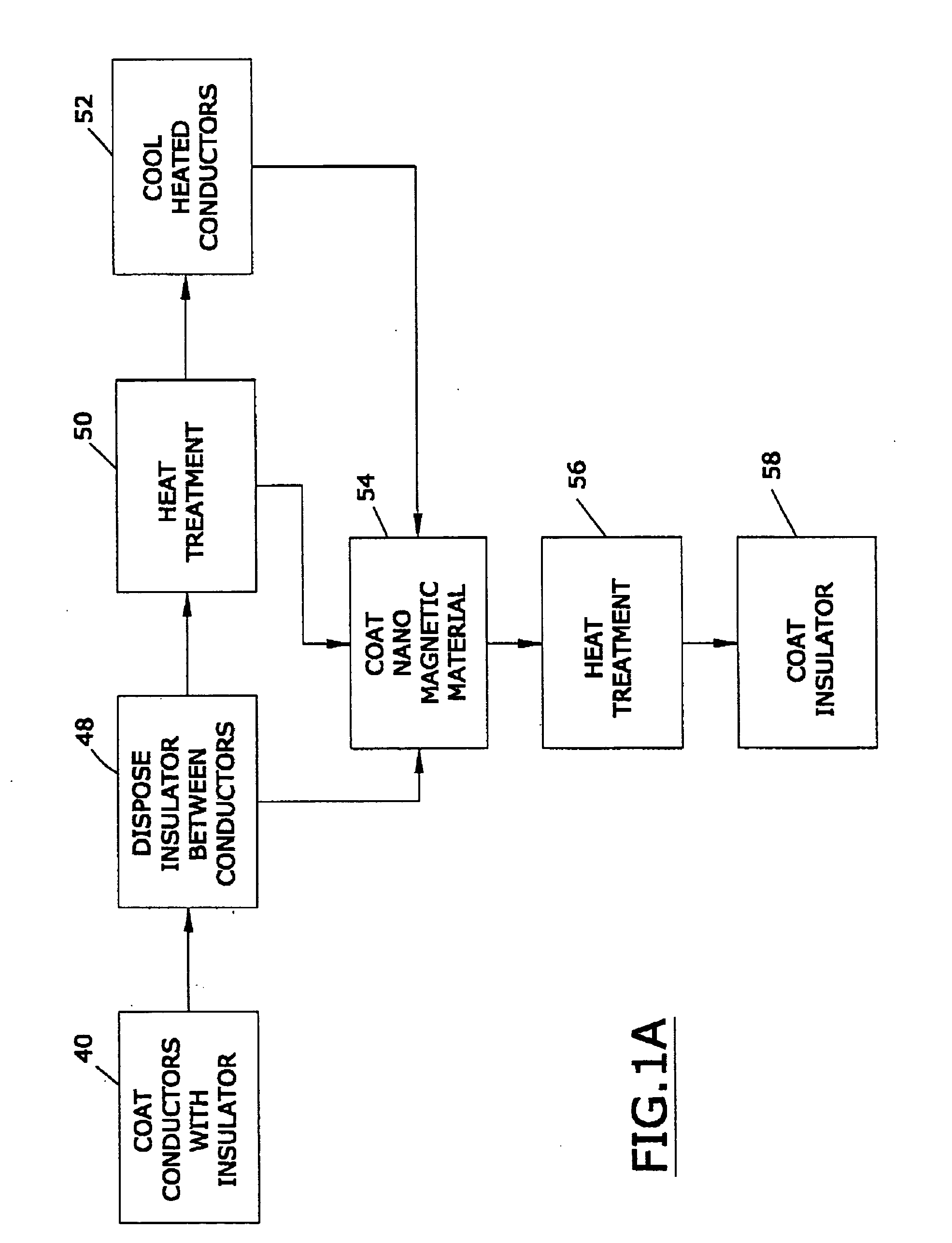

Magnetically shielded conductor

A conductor assembly that contains a flexible conductor and a layer of nanomagnetic material coated onto the conductor. The layer of nanomagnetic material has a tensile modulus of elasticity of at least about 15×106 pounds per square inch, an average particle size of less than 100 nanometers, a saturation magnetization of from about 200 to about 26,000 Gauss, and a thickness of less than about 2 microns.

Owner:BIOPHAN TECH

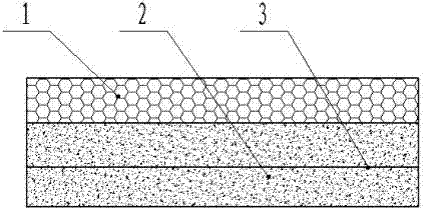

Anti-cracking low-shrinkage-deformation fiber-cement product and production method thereof

InactiveCN102785423AIncreased durabilityExtended service lifeWater-setting substance layered productEngineeringUltimate tensile strength

The invention relates to an anti-cracking low-shrinkage-deformation fiber-cement product and a production method thereof. Concretely, a novel fiber-reinforced cement product with an excellent anti-cracking function and low shrinkage deformation is realized through an ultra-short fiber, low-elasticity-modulus short fiber and high-elasticity-modulus long-fiber composite reinforced-cement base material by simultaneously adopting high-efficiency additives (a high-efficiency water-reducing agent, a thickening agent, an expanding agent and the like). The product comprises a flexible anti-cracking surface layer and a fiber-reinforced cement structural layer, has a simple and resaonable structure, is convenient and easy in production construction and can be applied to projects, such as building external-wall decorative enclosure, indoor engineering construction as well as roads, bridges and the like with higher requirements on the strength and the durability of the cement base material.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

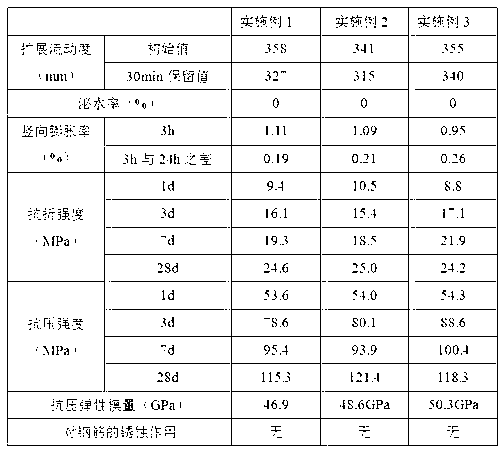

Ultrahigh-strength grouting material based on iron tailing sand and cement and preparation method of grouting material

InactiveCN102992722AGood dispersionImprove liquiditySolid waste managementCompressive strengthUltimate tensile strength

The invention relates to an ultrahigh-strength grouting material based on iron tailing sand and cement and a preparation method of the grouting material. The ultrahigh-strength grouting material is composed of the following components in proportion by weight: 30%-45% of cement, 45%-55% of iron tailing sand, 6%-15% of multielement mineral admixtures, 0.35%-1% of water reducing agent, 0.1%-1% of plastic retaining agent, 0.01%-0.1% of plastic expanding agent, and 2%-6% of shrinkage-compensating expanding agent. The preparation method comprises the steps of uniformly mixing all the components and then uniformly stirring the mixed components in water, wherein the ratio of the water to the materials is 0.09-0.11. The grouting material is good in flowability, is good in stability in a plastic stage, is free from shrinkage in the whole course from the plastic stage to a later hardening stage, and is ultrahigh in early strength, final strength and elasticity modulus, the 1d compressive strength of the material reaches up to 50MPa, the 28d compressive strength of the material can exceed 110MPa, and the 28d elasticity modulus of the material exceeds 45GPa, and therefore, the ultrahigh-strength grouting material is suitable for grouting of various important parts or areas with requirements on high strength and high modulus.

Owner:WUHAN UNIV OF TECH

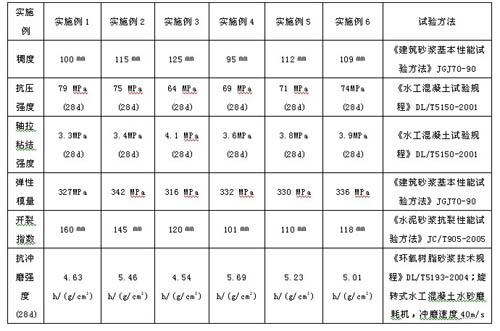

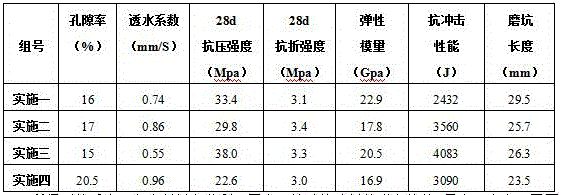

Anti-impact and wear-resistant mortar

The invention discloses an anti-impact and wear-resistant mortar, belonging to the field of a repairing material in water-power engineering. The difficulty that the constructions in the conventional water-power engineering is difficult to repair after being damaged by rushing and abrading with water with sands and stones can be solved. The anti-impact and wear-resistant mortar comprises the following components in parts by weight: 39-48 parts of silicate cement, 45-50 parts of graded hard fine aggregate, 0.05-0.25 parts of water reducing agent, 0.05-0.3 parts of de-foaming agent and 0.05-1.5 parts of nanometer material. The anti-impact and wear-resistant mortar provided by the invention has the advantages of high anti-impact and wear-resistant strength, low elasticity modulus and good anti-crack property, and is a finished product material with a higher application value for repairing through irrigation works.

Owner:POWERCHINA CHENGDU ENG +1

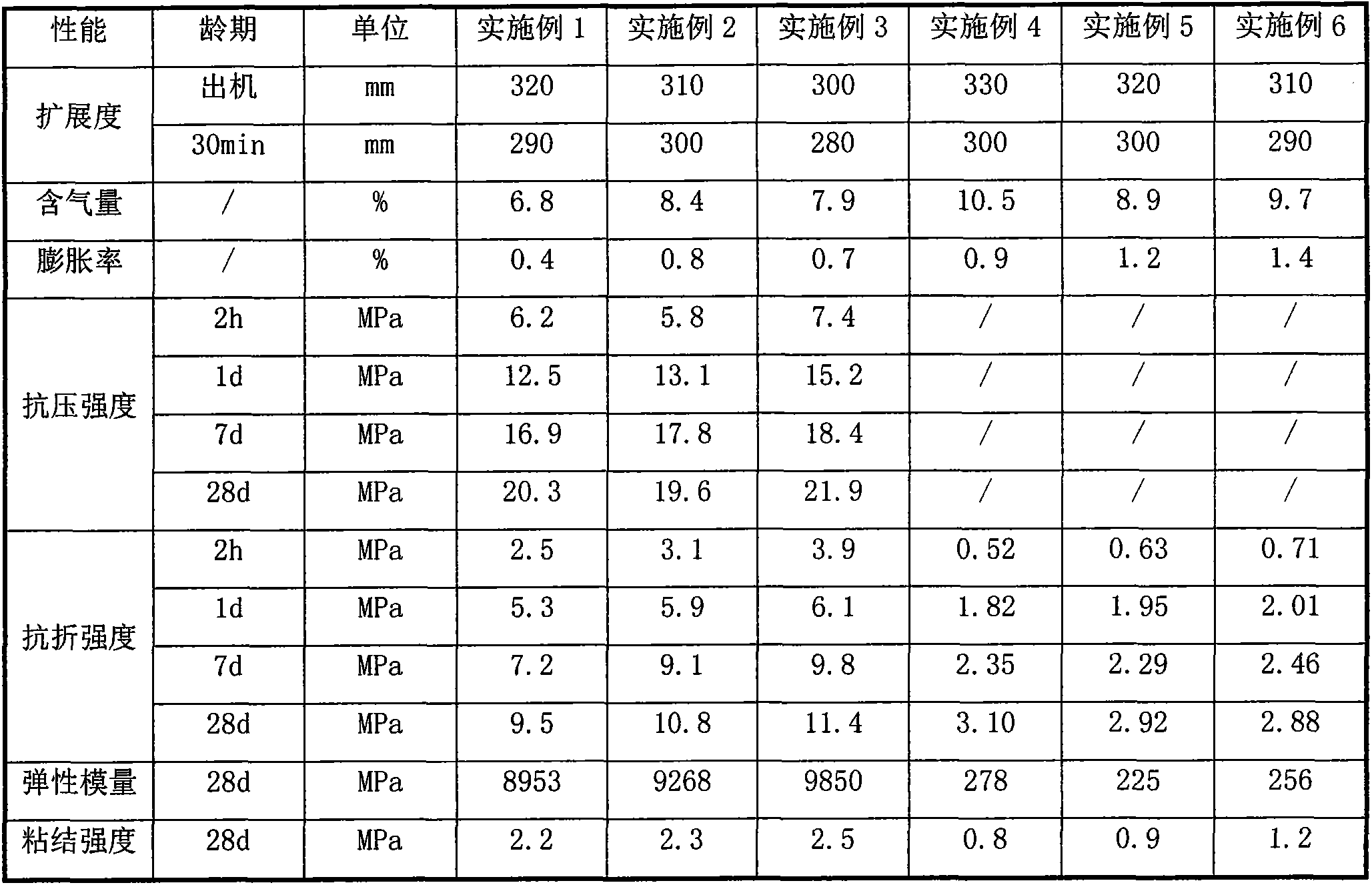

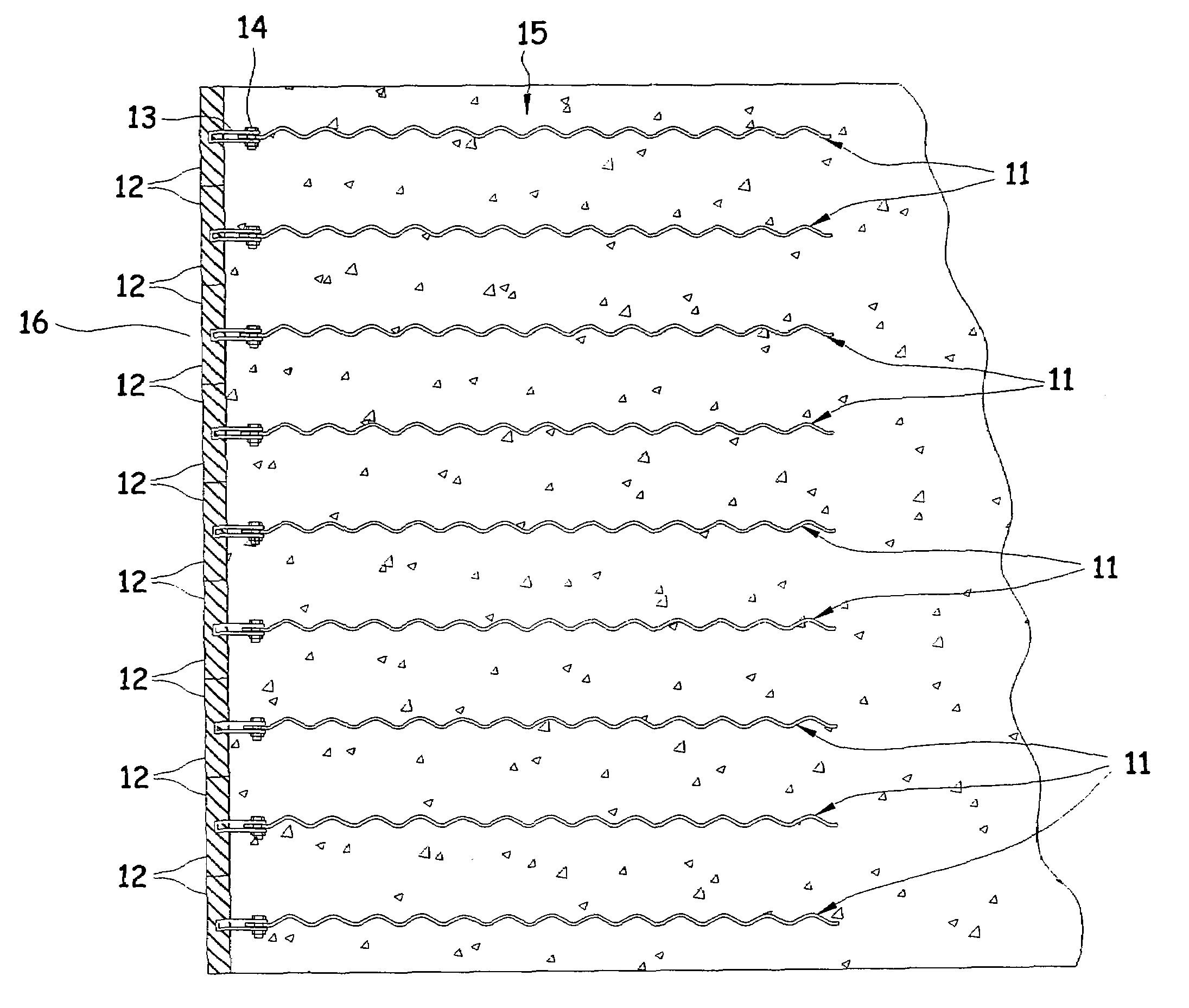

Polymer cement mortar for slab ballastless track of high-speed railway

The invention discloses polymer cement mortar for a slab ballastless track of a high-speed railway. The polymer cement mortar a comprises a dry raw material and a liquid raw material, wherein the dry raw material comprises a binding material component, an elastic adjusting component, an expanding component, an internal curing component, an aggregate component and a coagulation adjusting component; the liquid raw material comprises a polymer emulsion, a water reducing agent, a defoaming agent, an air entraining agent and water; and the weight ratio of the dry raw material to the liquid raw material is 100:(15-25), and the dry raw material and the liquid raw material are uniformly mixed in a proportion to prepare the polymer cement mortar. The polymer cement mortar has the advantages of controllable coagulation time, high adhering strength, adjustable elastic modulus, good elasticity and toughness, high durability and the like, and is capable of replacing cement emulsified asphalt mortar to be applied to a packing material of the slab ballastless track or can be used as a quick repairing material of a filling layer of cement emulsified asphalt mortar.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +1

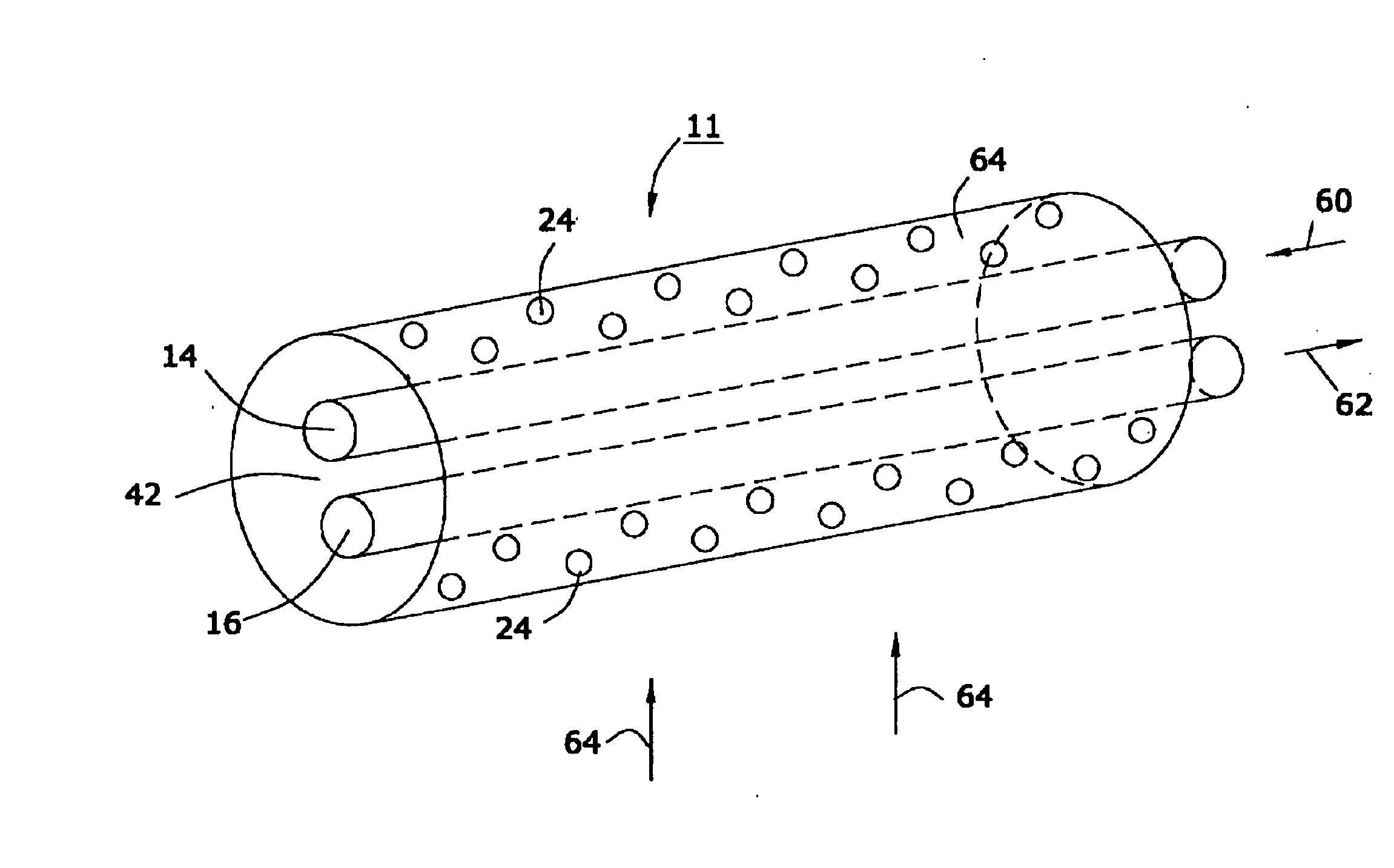

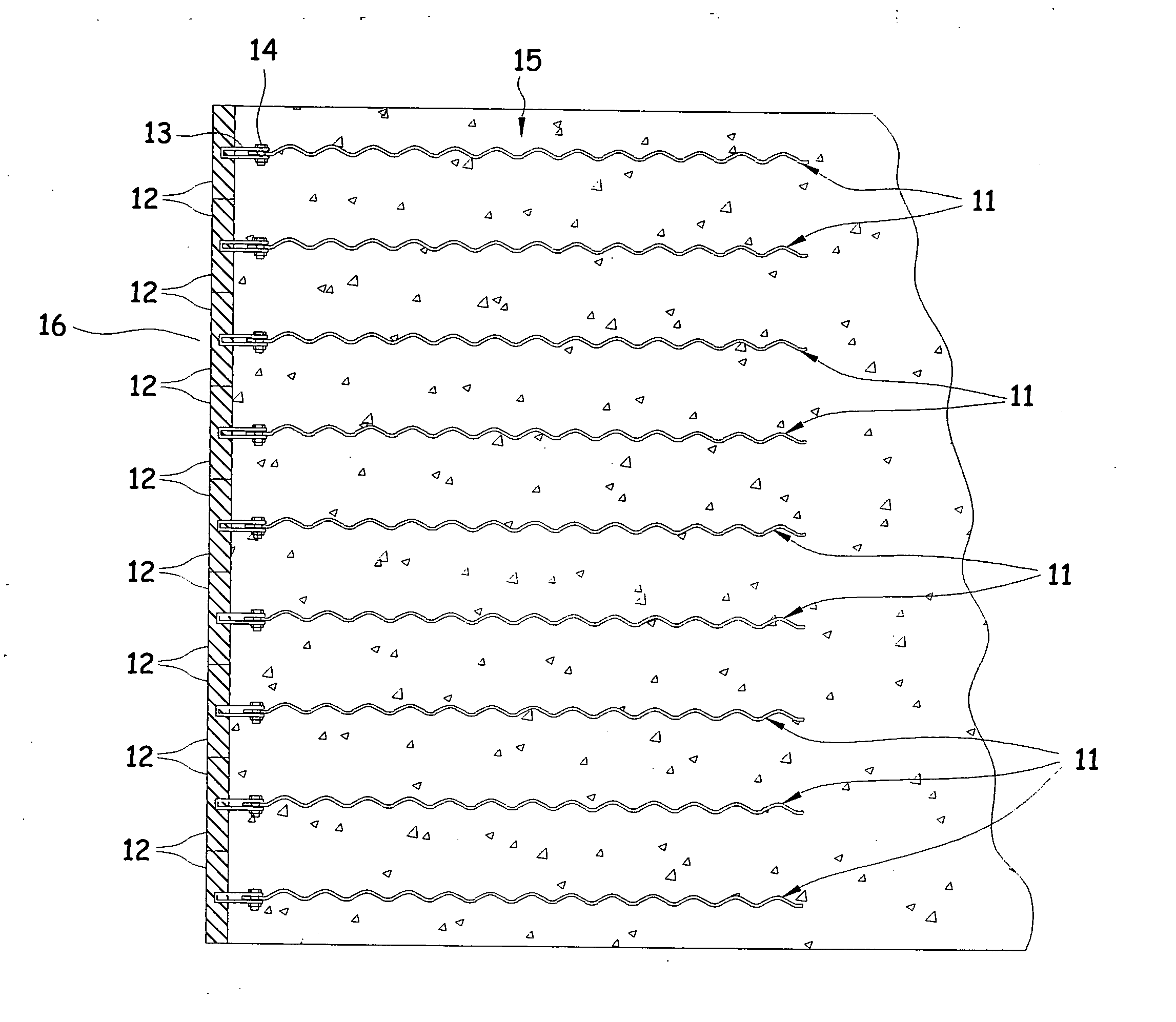

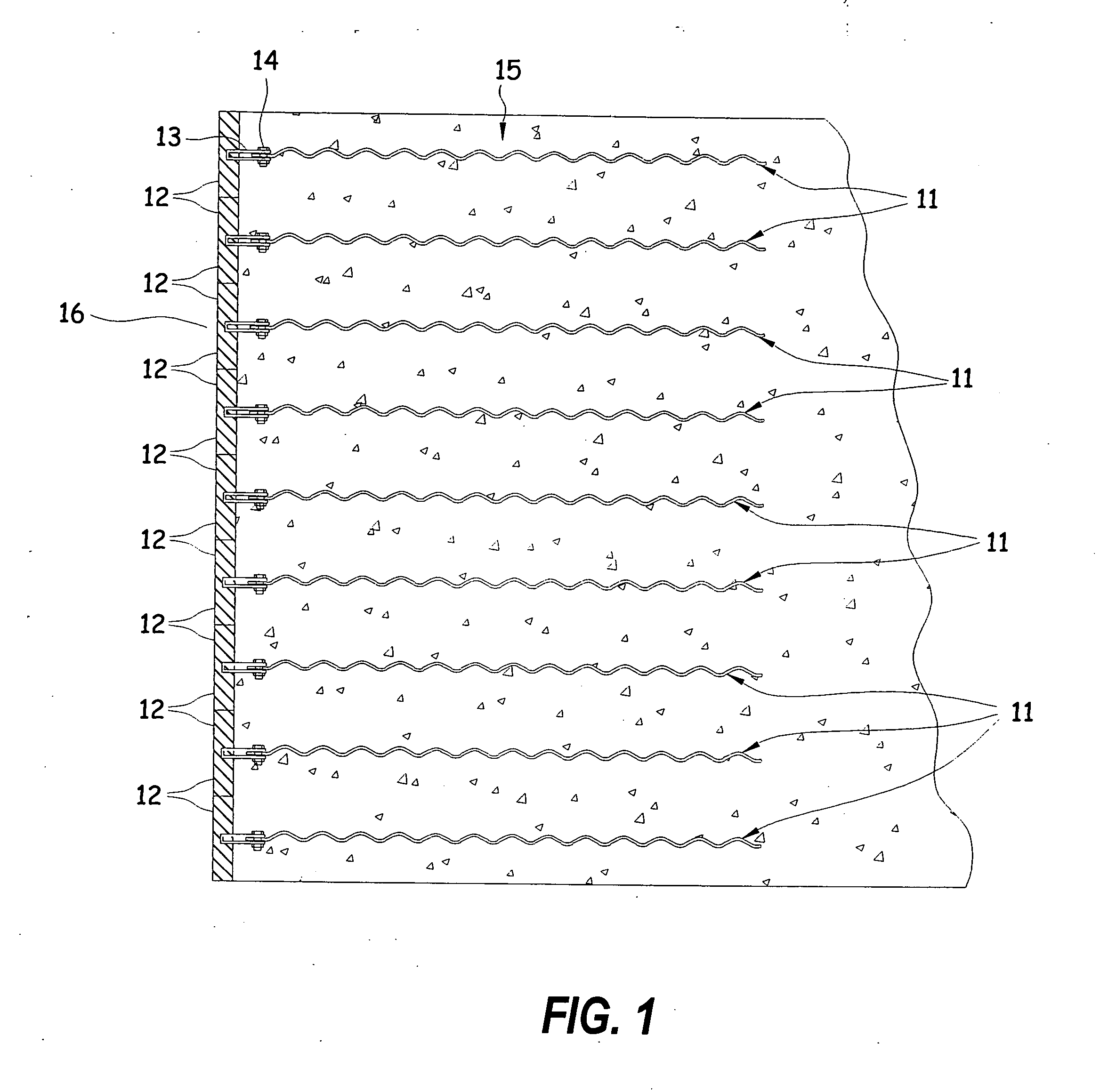

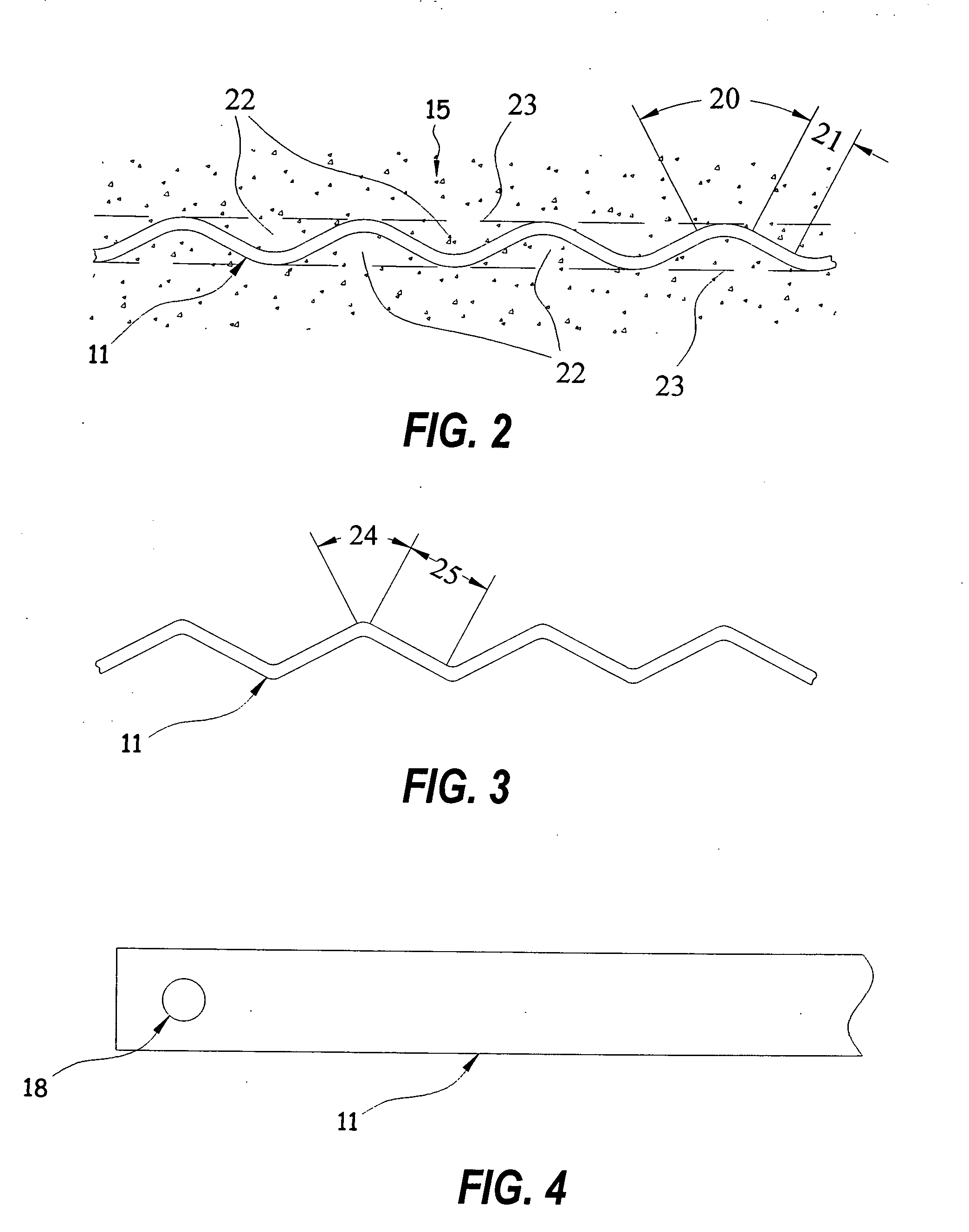

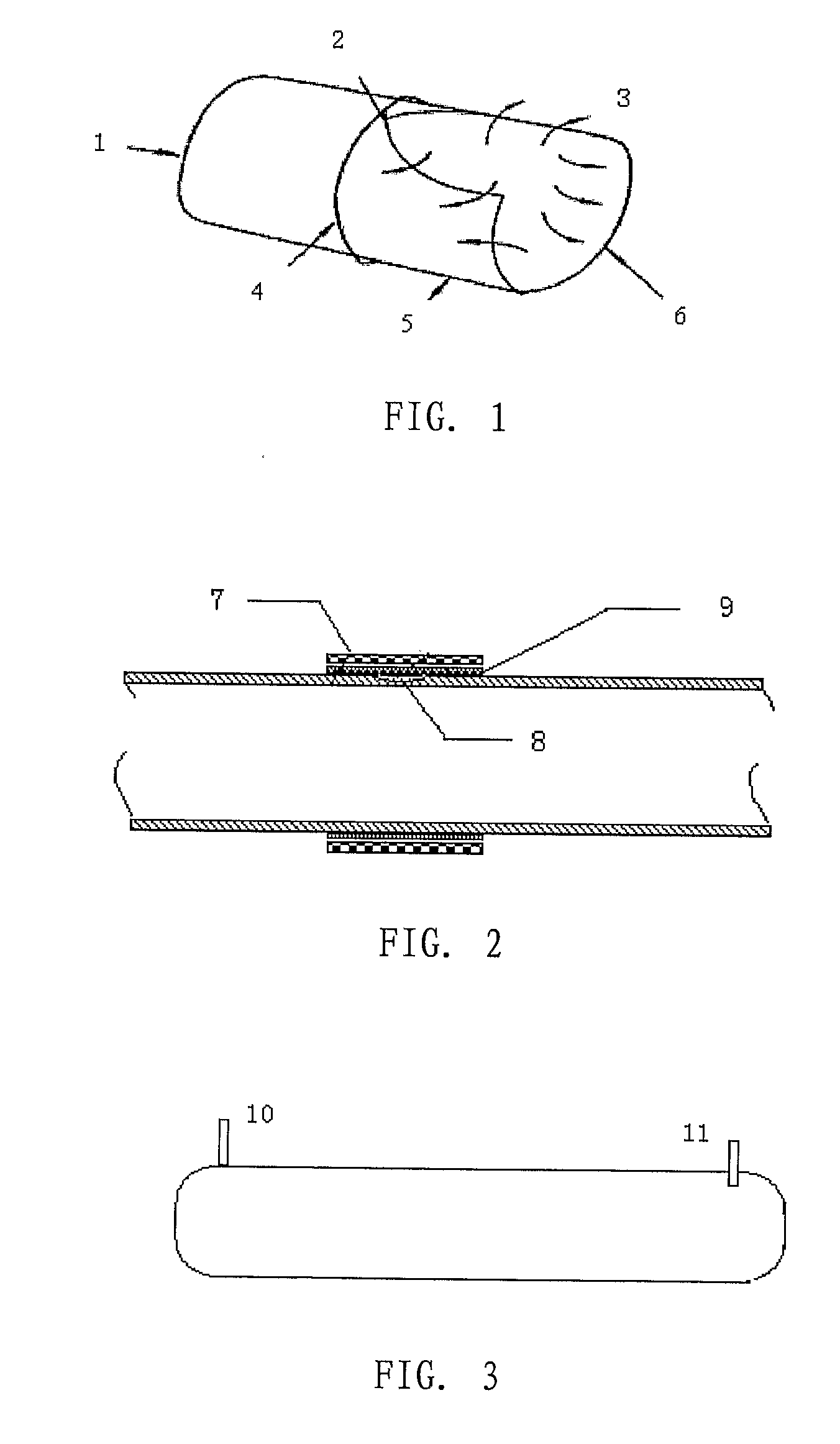

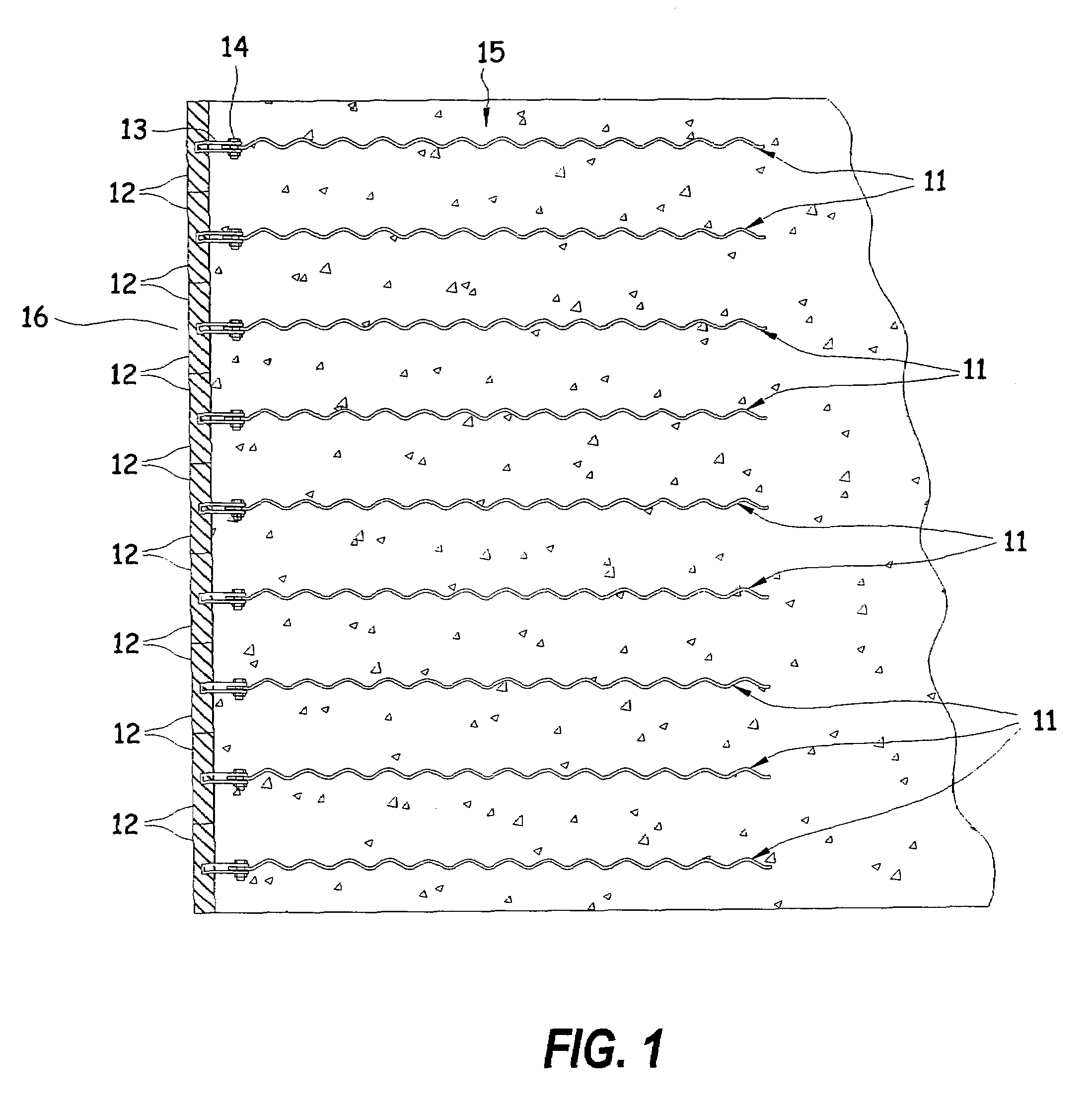

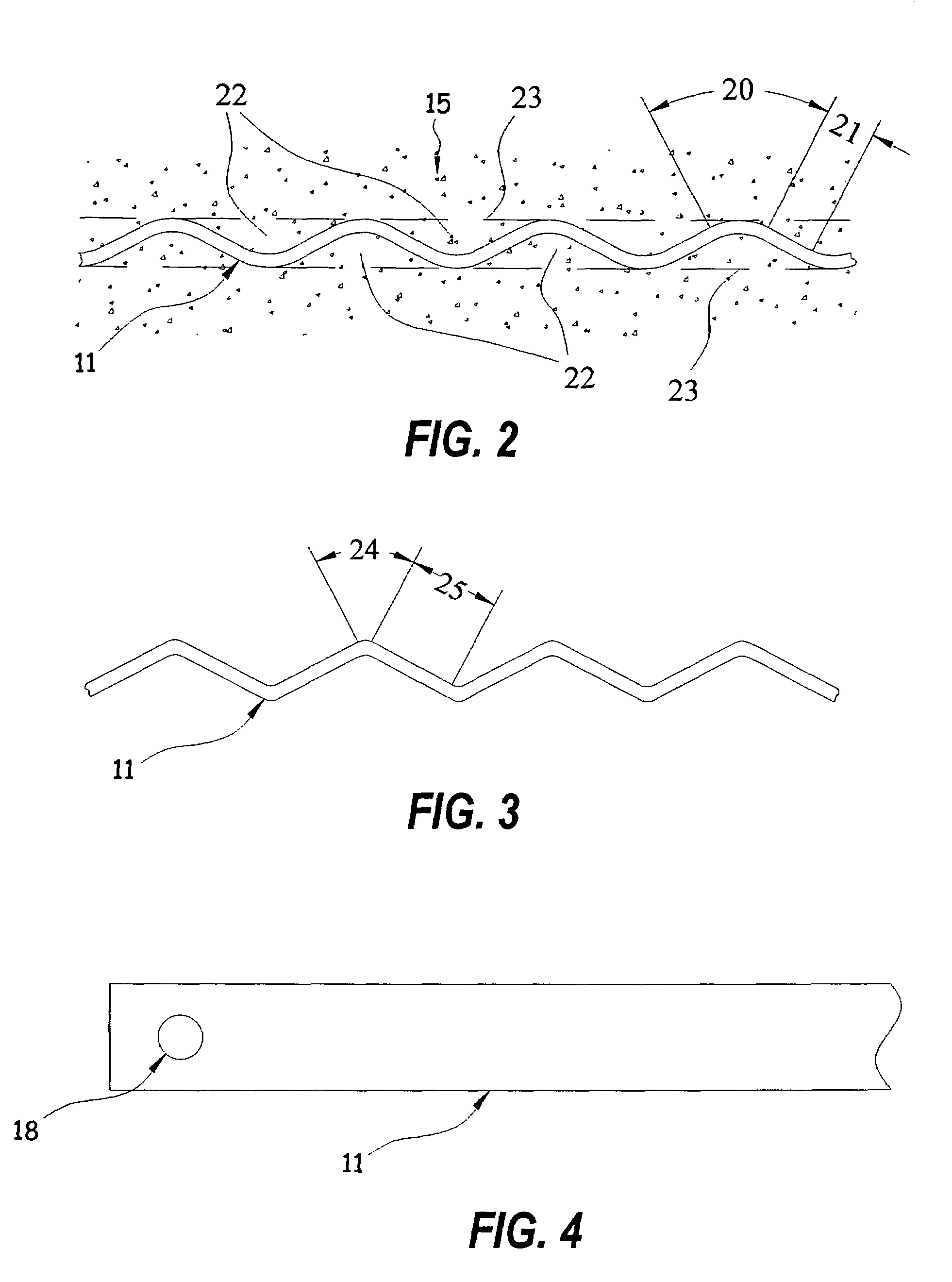

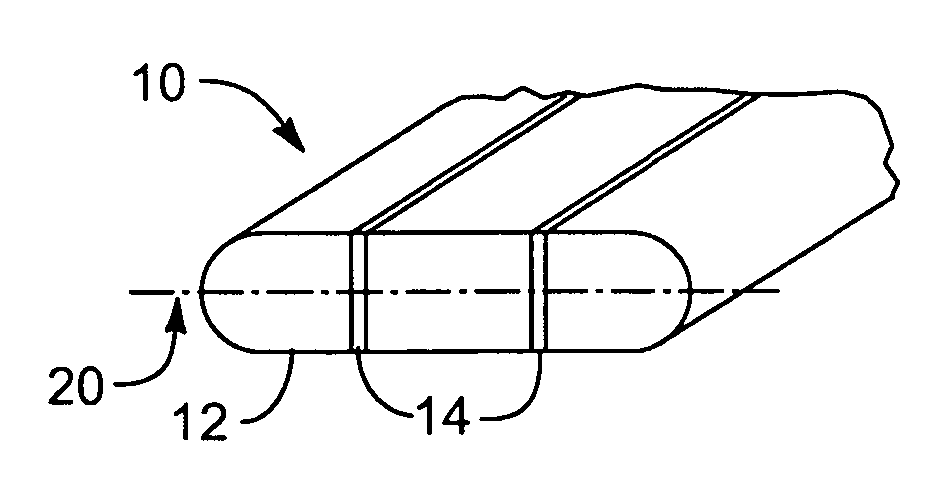

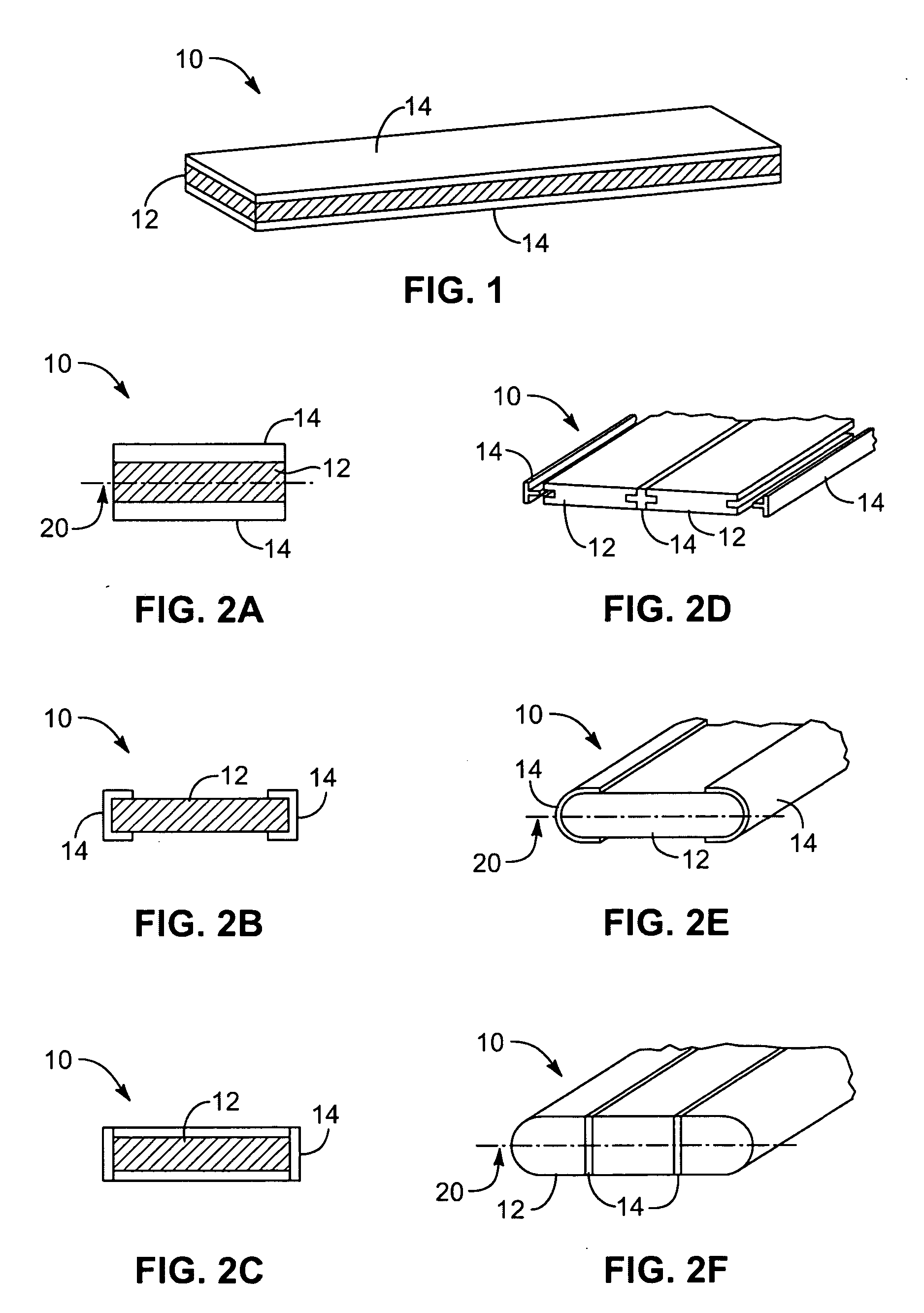

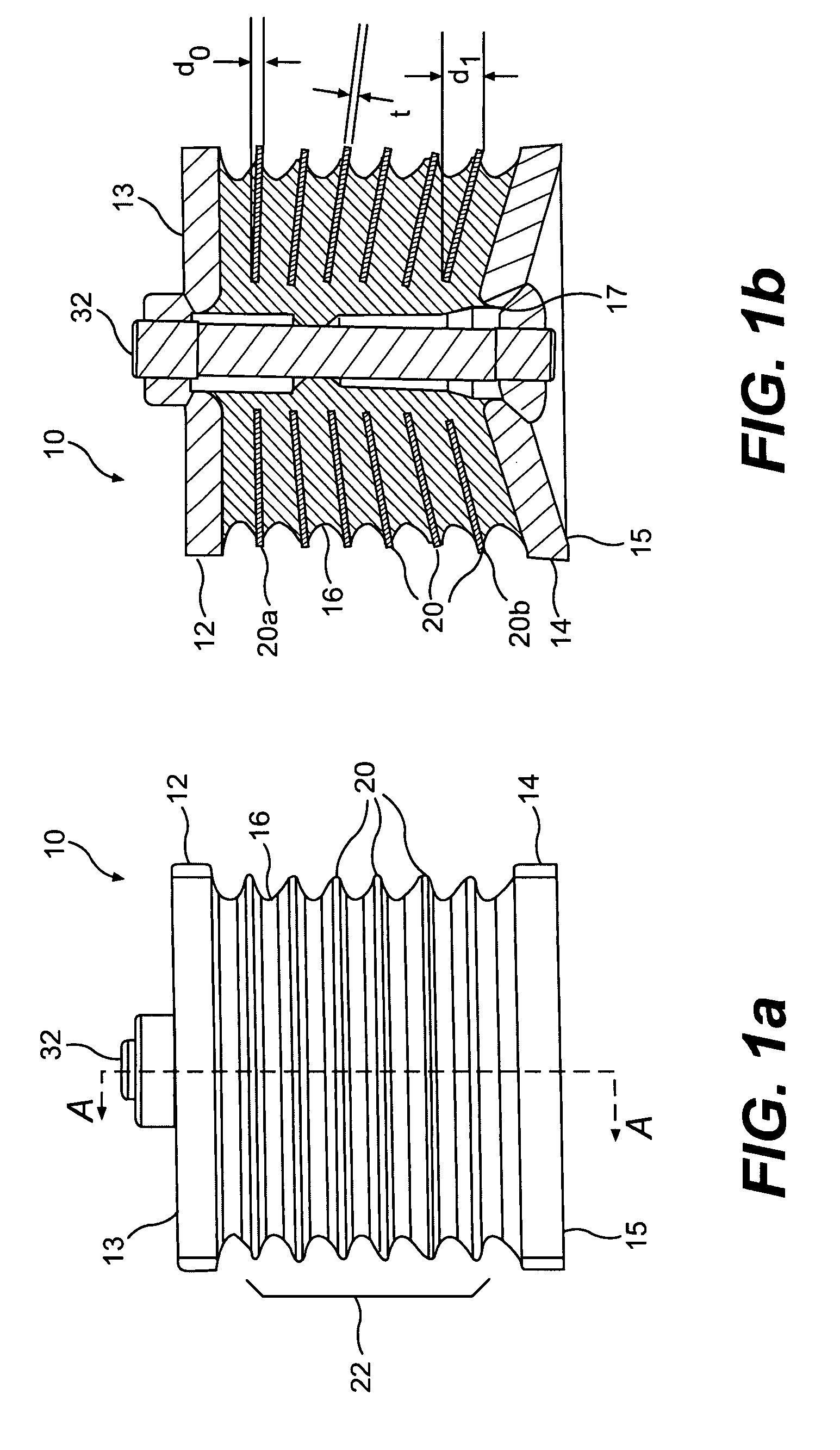

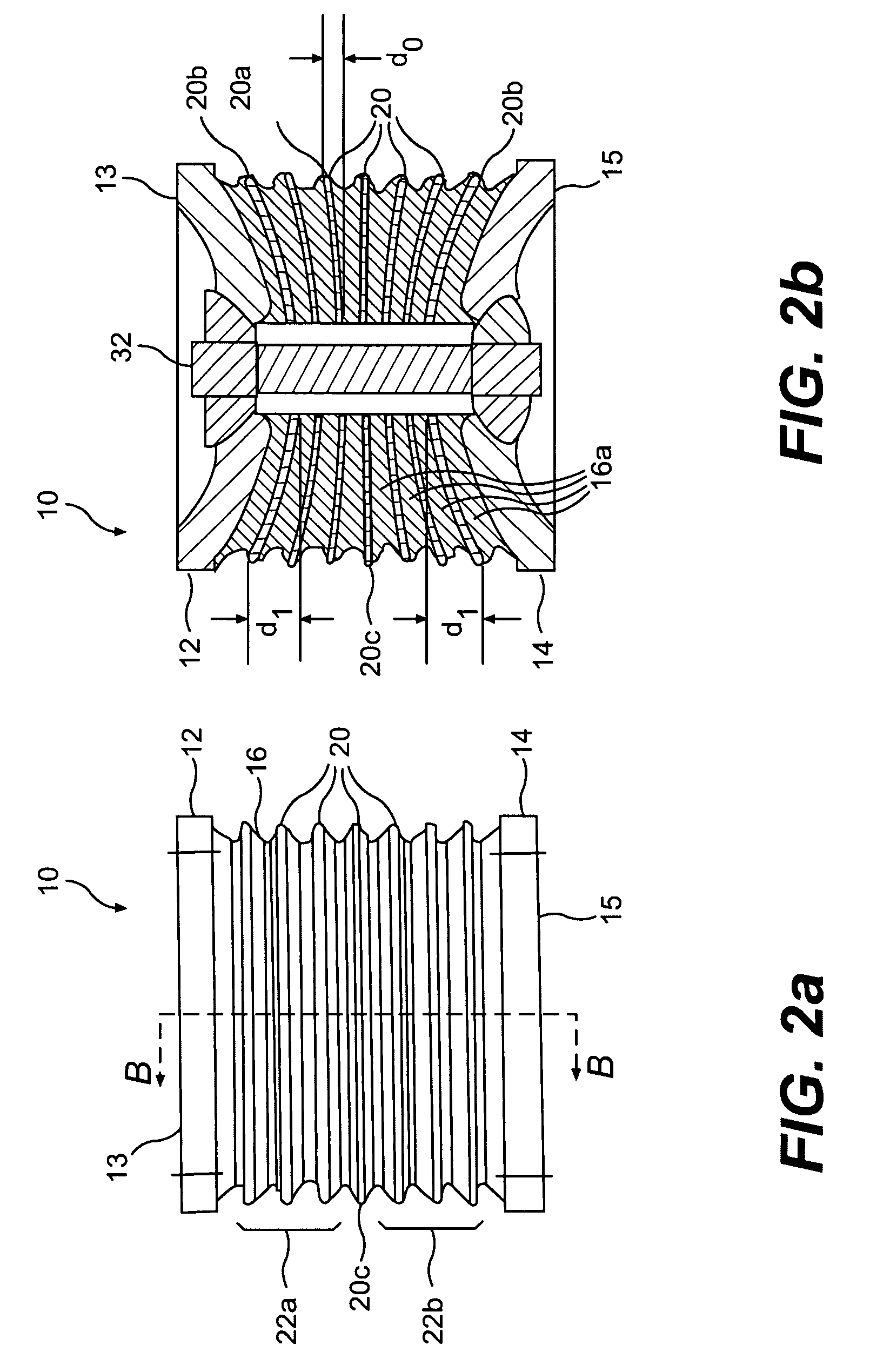

Stabilized earth structure reinforcing elements

ActiveUS20070014638A1Configuration highLow costArtificial islandsExcavationsExtensibilityDesign standard

A stabilizing element in a stabilized material particle structure, particularly an earthen embankment, wherein the material stabilizing elements that are inextensible (material with a higher modulus of elasticity than that of the surrounding particles) in composition nature but made more extensible because of its configuration. This extensibility gives the stabilizing elements the ability to mobilize more of the material shear resistance and adapt to current design standards under extensible type elements. The configuration also enhances the frictional engagement with the adjacent particles. The soil stabilizing elements are attached to facing elements and project into the compacted fill behind the facing. In some structures there may not be a facing element. Additionally, a material coating for metallic stabilizing elements that gives the elements improved corrosion protection, additional service life and / or expands the electrochemical environment in which they can be used

Owner:ASHGROVE HLDG LLC

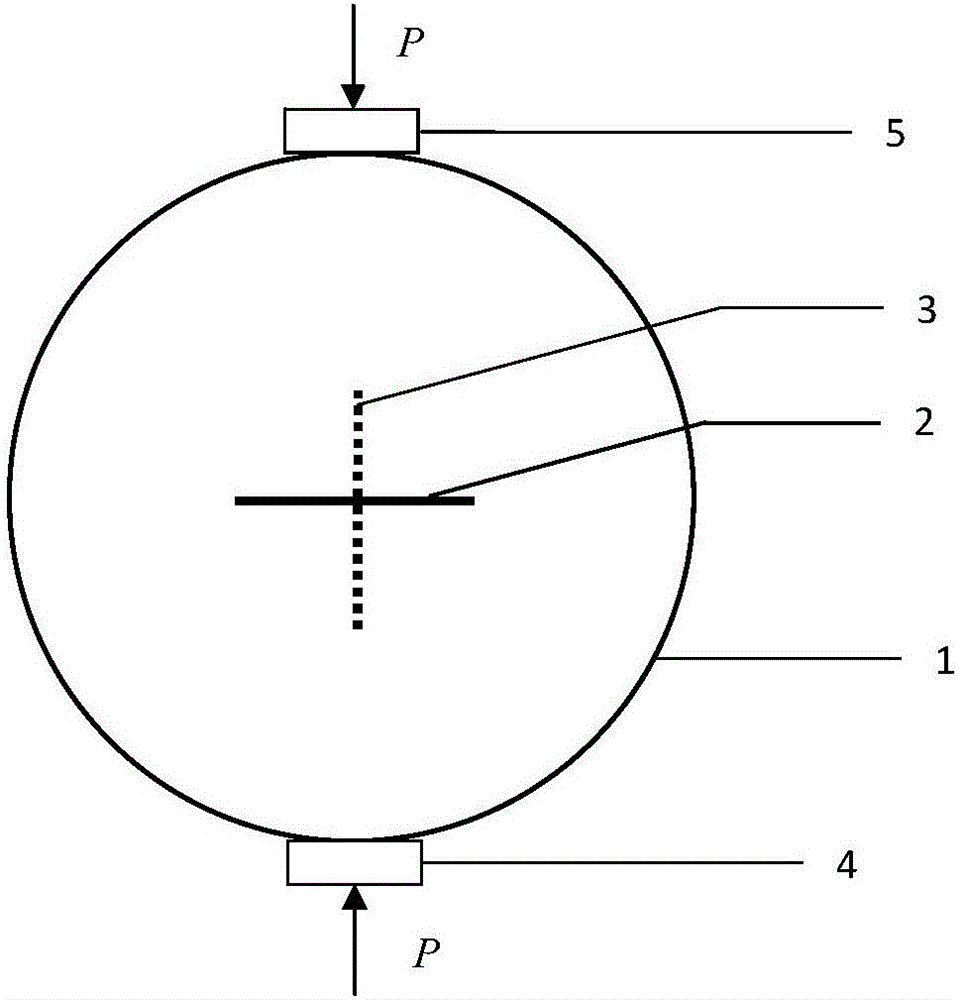

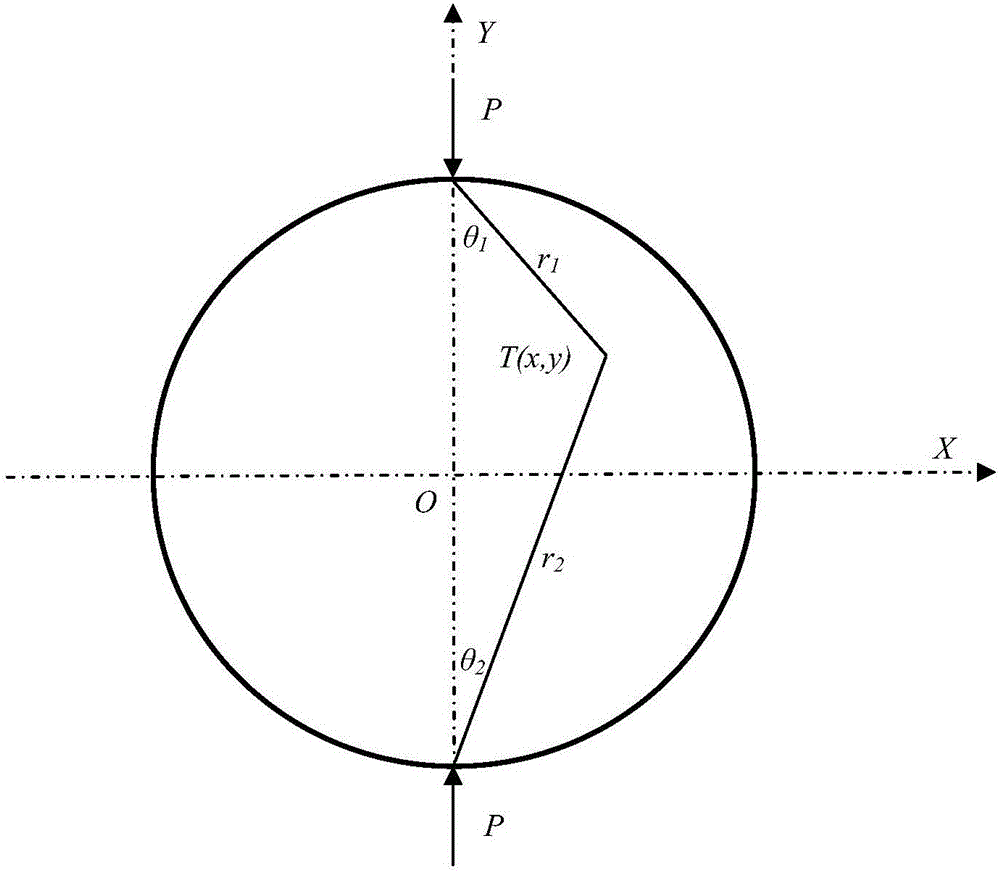

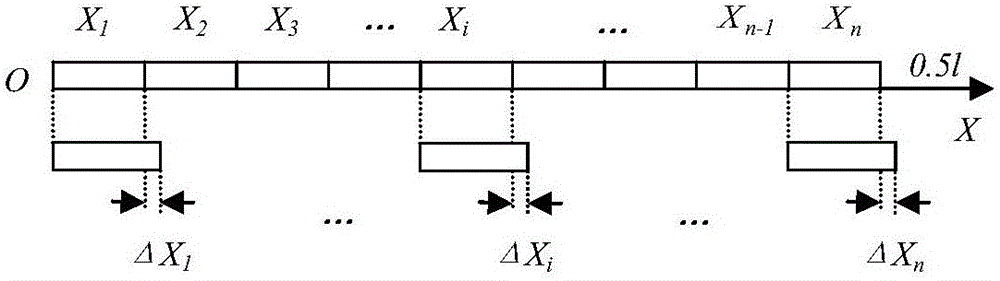

Method and device for synchronously testing tension, compression and split resilience moduli of pavement material

ActiveCN106706422AHigh precisionGuide engineering practice wellMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesTest efficiencyElectrical resistance and conductance

The invention discloses a method and device for synchronously testing tension, compression and split resilience moduli of a pavement material. The method comprises the following steps: performing a split loading test on a test sample through an MTS multifunctional material testing system, and deducing computing formulae for the tension modulus and the compression modulus of the pavement material test sample during split loading; and respectively pasting resistance strain gages on horizontal radial and vertical radial centers in the front and back parts of the test sample, measuring the average tension strain and the average compression strain of the center positions of the test sample, measuring the horizontal radial deformation of the test sample through a displacement sensor, and substituting in the formulae to obtain the testing results of the split modulus, the tension modulus and the compression modulus of the material. According to the invention, the three moduli of the material can be simultaneously measured through a single test, thereby improving the modulus testing precision and test efficiency of the pavement material and lowering the indoor test and testing cost; and accurate design parameters can be provided for scientific design of a durable pavement considering the difference in the tension and compression moduli of the material.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

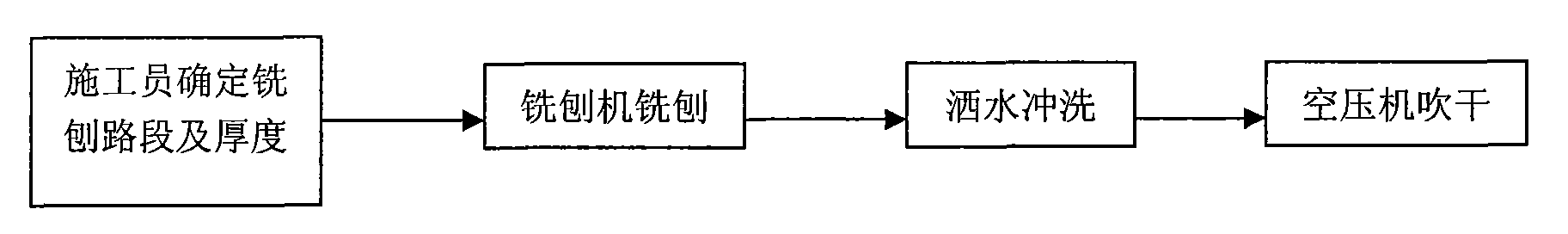

Asphalt stabilized macadam overlay reforming method for old road and structure thereof

An asphalt stabilized macadam overlay reforming method for old road comprises determining equivalent resilient modulus of original road surface, performing construction by using one of the following three treating schemes or combination, aiming at different damage conditions of road surface, wherein scheme A is to overlay asphalt concrete layer on original road surface which is not seriously damaged; scheme B is to excavate partly a layer of original road surface which is locally damaged, such as spongy surface, track, looseness, crack and the like, back patch asphalt stabilized macadam, overlay an asphalt concrete layer thereon; scheme C is to excavate fully an oil surface layer of the original road surface which is seriously damaged, has a track depth larger than 3cm, local net-shaped cracking, depression and deformation, not scratch the base layer, overlay an asphalt concrete layer thereon after performing priming oil treatment and back patching two layers of asphalt stabilized macadam.

Owner:JIANGXI GANYUE EXPRESSWAY

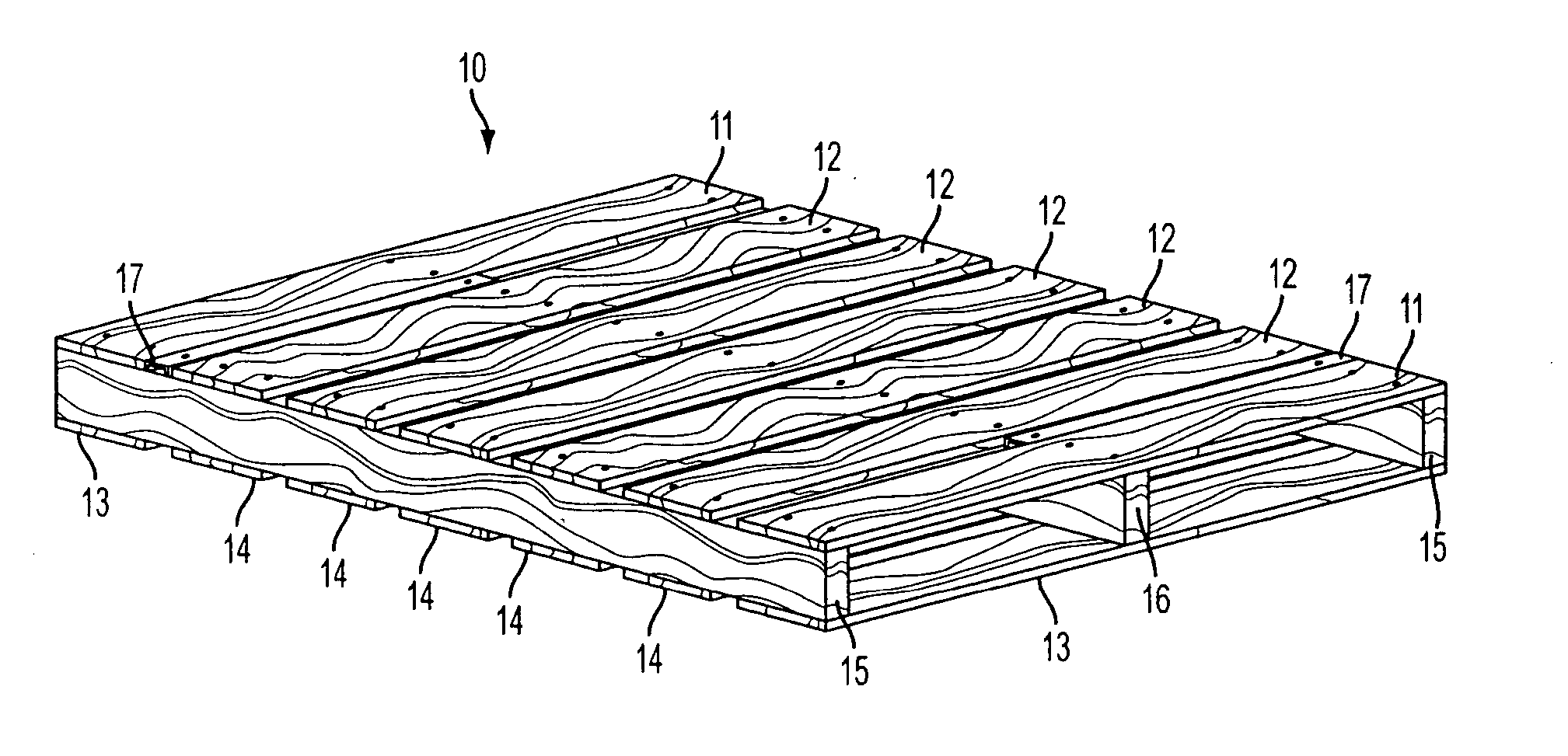

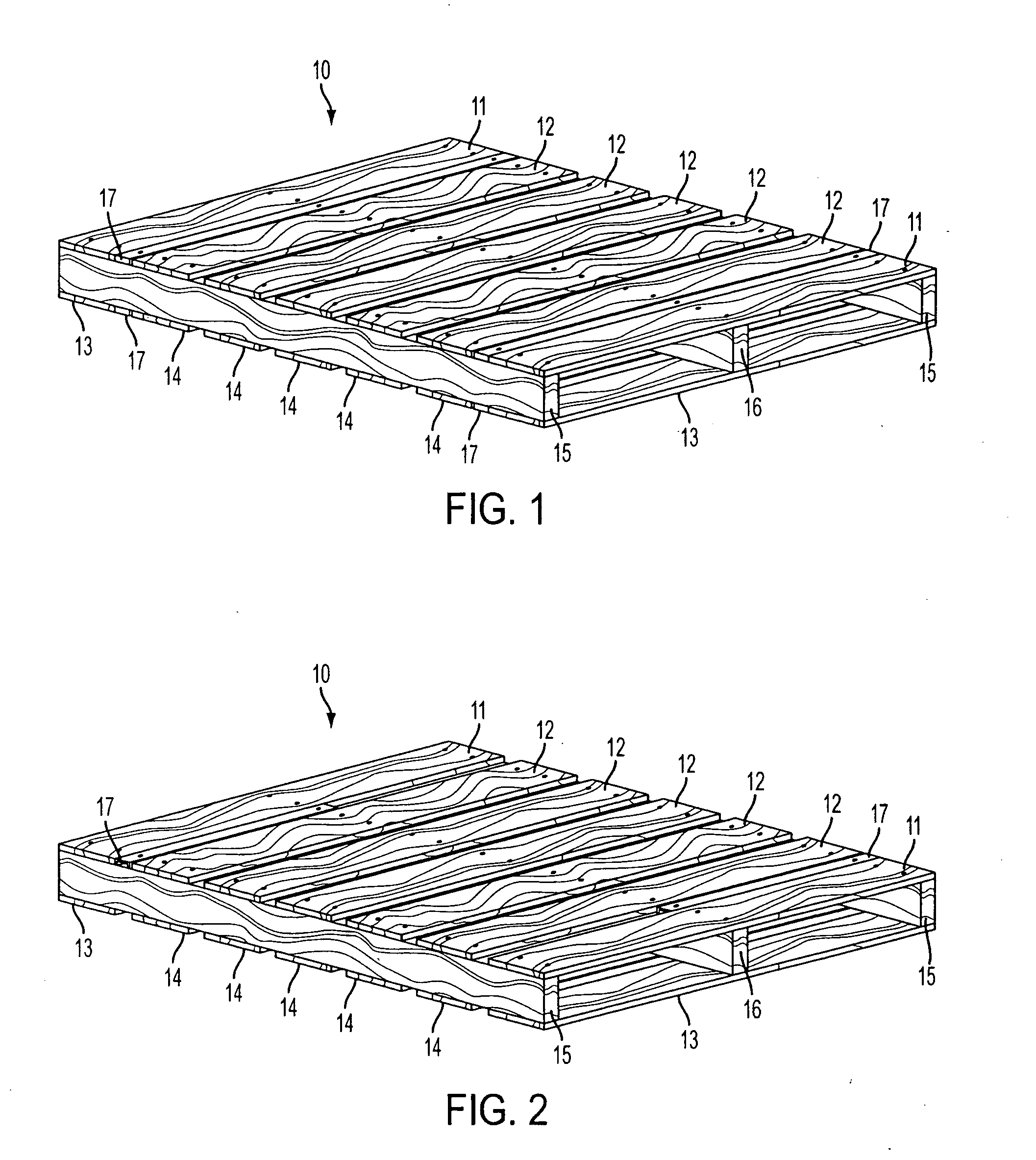

Shipping pallet equipped with a non-structural member carrying a readable device

ActiveUS20060254474A1Protection from damageContainer decorationsLevel indicationsEngineeringResilient modulus

A shipping pallet comprised of at least one layer of substantially parallel, structural deck boards attached to a plurality of stringers is disclosed. The layer of deck boards defines a three-dimensional, substantially rectilinear deck zone that is defined by a top plane, a bottom plane, and four side-edge planes. The pallet includes at least one non-structural member that carries a readable device within the deck zone of a pallet, in the space between two structural deck boards. The non-structural member has a Modulus of Elasticity and Modulus of Rupture that are both below that of the strongest deck board in the deck zone in which the non-structural member is mounted.

Owner:HUNTER PAINE ENTERPRISES

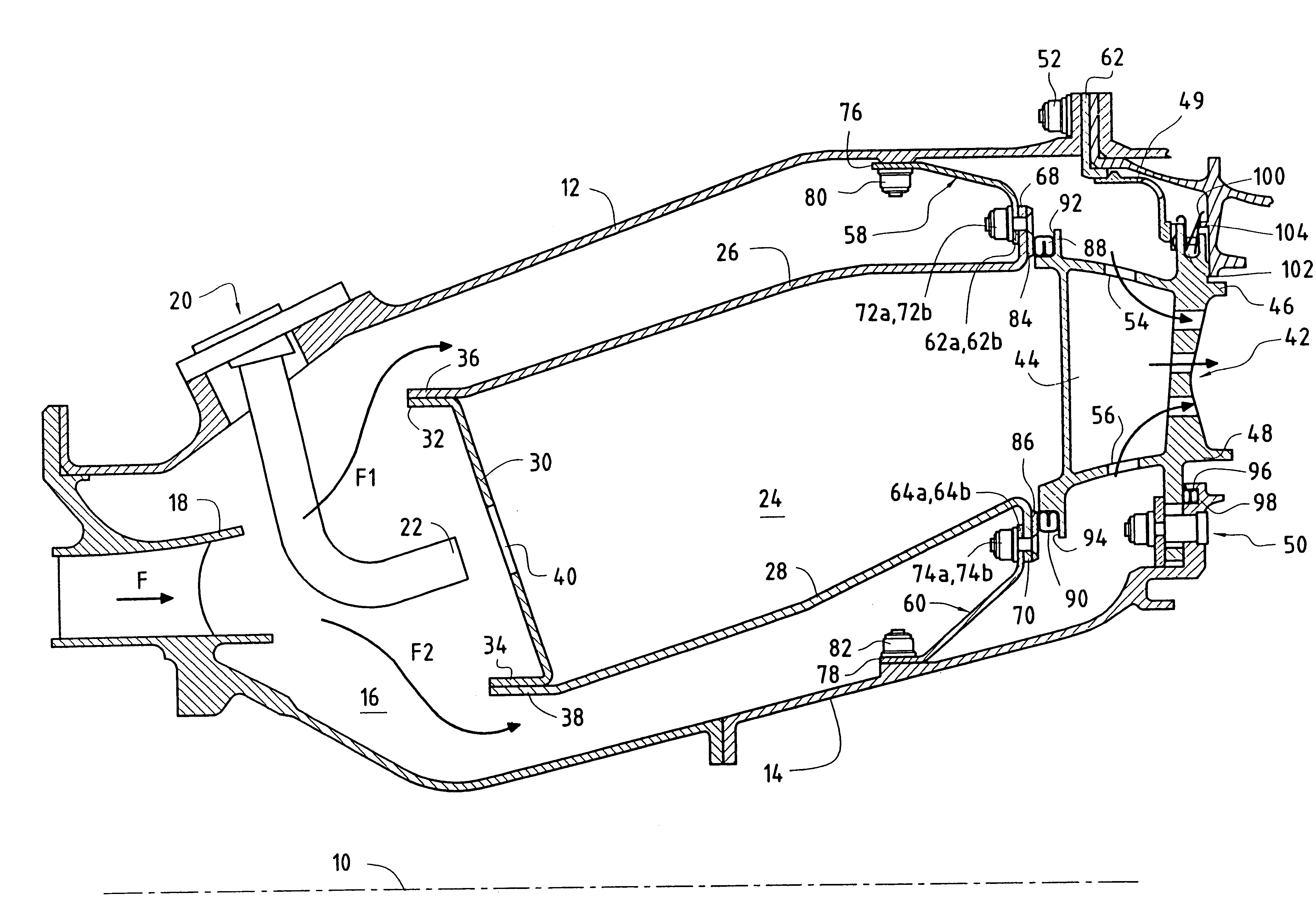

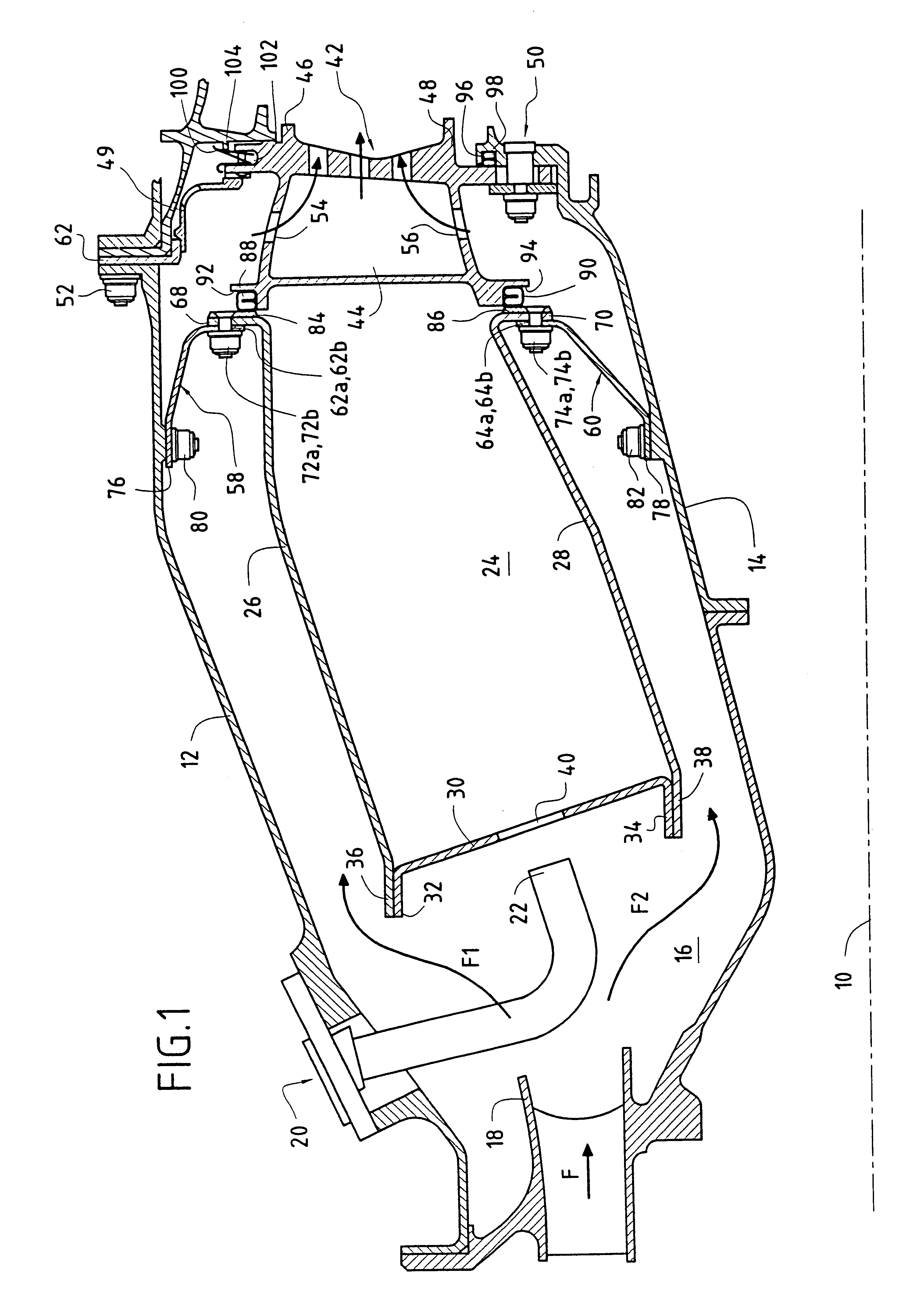

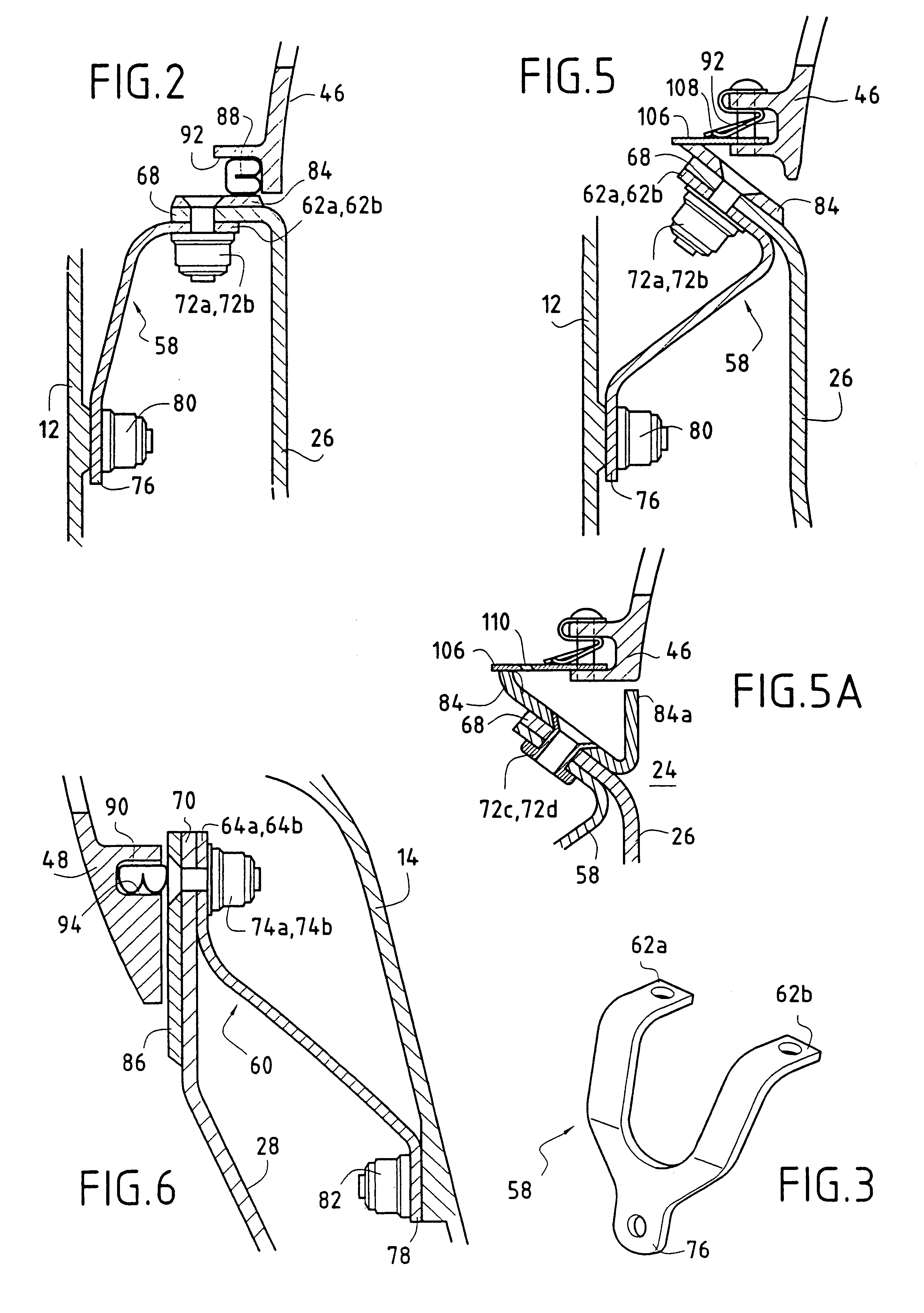

Resilient mount for a CMC combustion chamber of a turbomachine in a metal casing

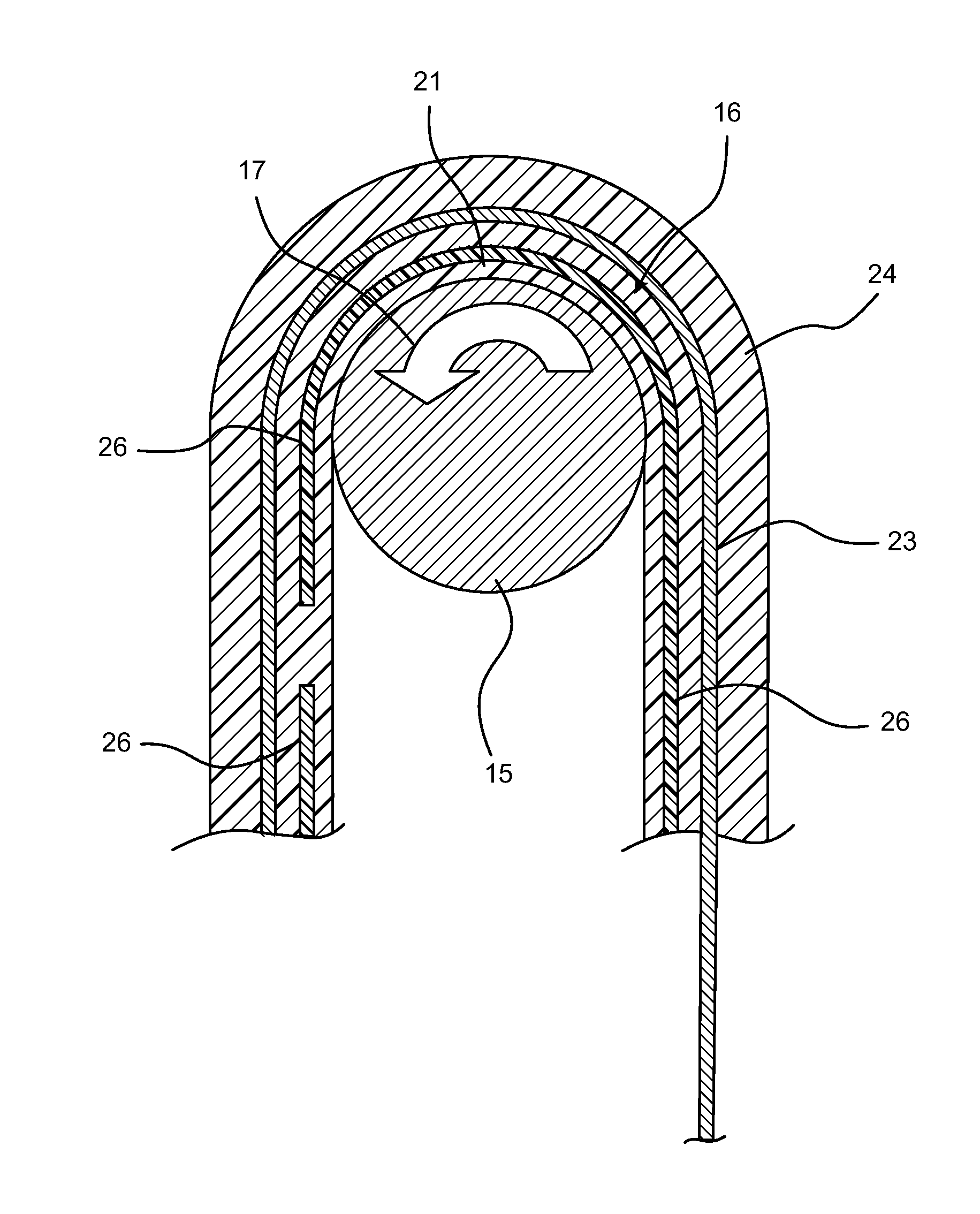

InactiveUS6732532B2Mitigate such drawbackEasy to manufactureContinuous combustion chamberEngine manufactureCombustion chamberMetallic materials

In a turbomachine comprising an annular shell of metal material containing in a gas flow direction F: a fuel injection assembly; an annular combustion chamber of composite material; and an annular nozzle of metal material forming the inlet stage with fixed blades of a high pressure turbine, provision is made for the combustion chamber to be held in position inside the annular metal shell by a plurality of flexible metal tongues each comprising three branches connected together in a star configuration, the ends of two of these three branches being fixed securely to a downstream end of the combustion chamber via respective first and second fixing means, and the end of the third branch being fixed securely to the annular shell via third fixing means.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

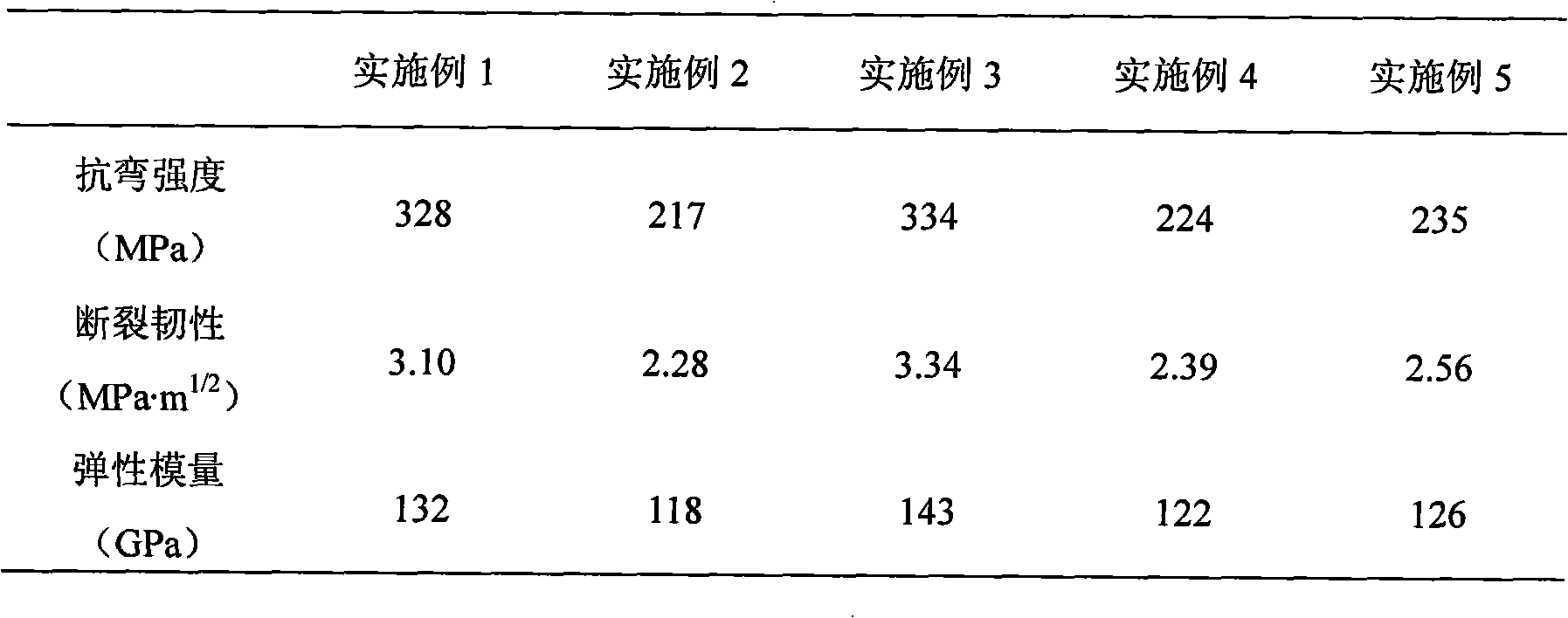

Rare earth-mixing high strength lithium bisilicate sitall material and preparation method thereof

The invention relates to a rare earth-mixing high strength lithium bisilicate sitall material and a preparation method thereof. Parent glass of the invention includes the following components according to molar percentage: 61.2 to 66.0 percent of SiO2, 0 to 2.5 percent of B2O3, 0 to 1.6 percent of Al2O3, 1.0 to 3.7 percent of P2O5, 0 to 2.3 percent of ZrO2, 1.0 to 1.8 percent of K2O, 24.2 to 31.8 percent of Li2O, 0 to 2.0 percent of MgO, 0 to 2.0 percent of CaO, and 0.5 to 4.2 percent of La2O3+Y2O3. A corresponding raw material prepared from the oxidates is processed by the steps of ball milling, 80 mesh sieve sieving and uniform mixing to obtain a batch; the batch is led into a copple to be melted after the temperature from 1480 to 1520 DEG C is maintained for 2 to 3 hours, and the melted batch is cast into a stainless steel mould to be molded and then is annealed at 500 DEG C for 0.5 hour; and the step of coring is carried out in a resistance furnace at the temperature from 500 to 550 DEG C for 1 hour, and the step of crystallization is carried out at the temperature from 600 to 850 DEG C for 2 hours. The crystallization degree of the sitall is as high as 60 to 70 percent, the flexural strength is 100 MPa or more higher than the sitall to which the rare earth oxides are not added, the highest flexural strength reaches 334 MPa, the maximum elastic modulus reaches 143 GPa, and the highest fracture toughness reaches 3.34 MPa-m. The sitall of the invention has favorable stability, and the heat treatment temperature is lower and is easy to control.

Owner:CENT SOUTH UNIV

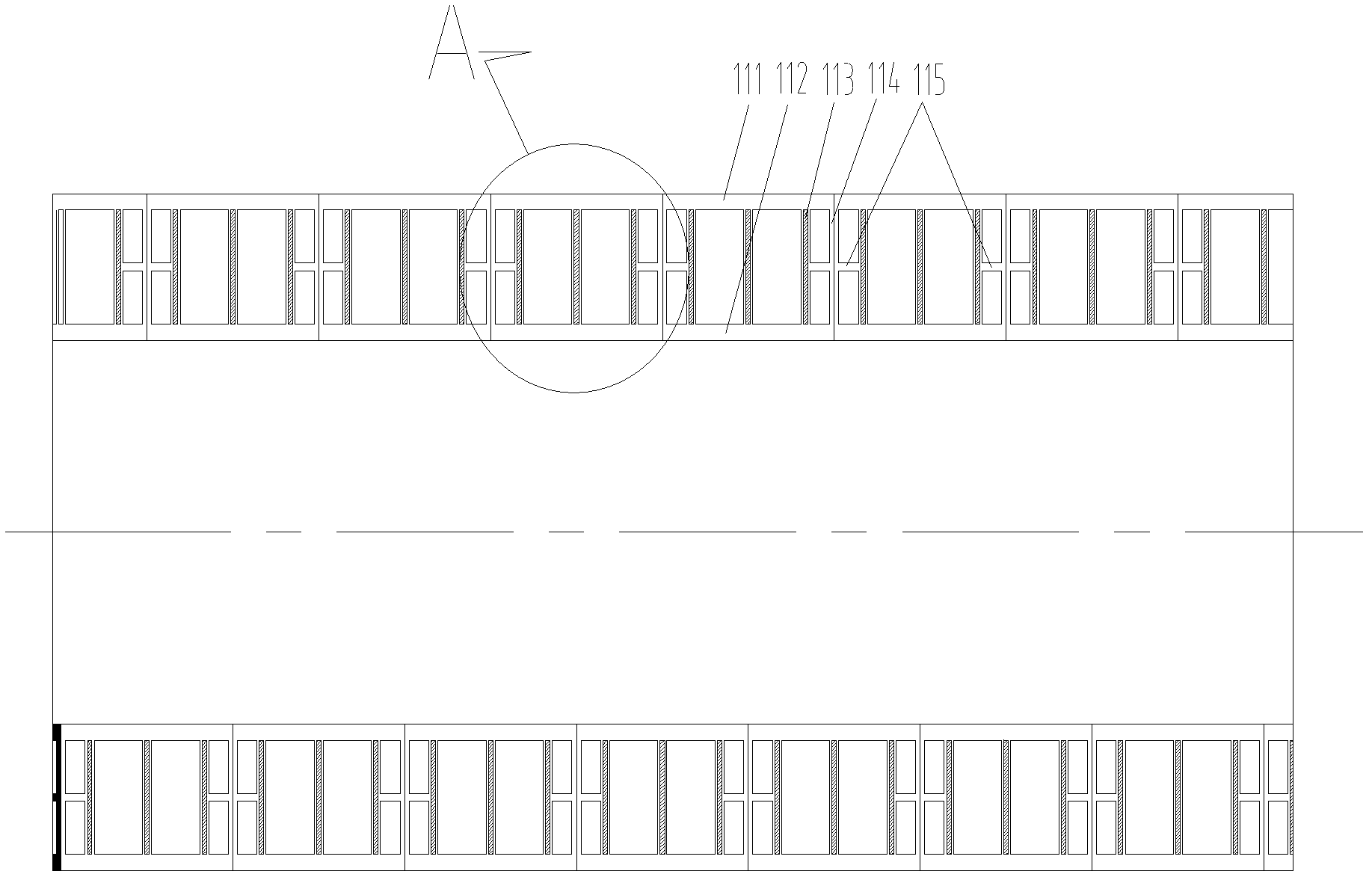

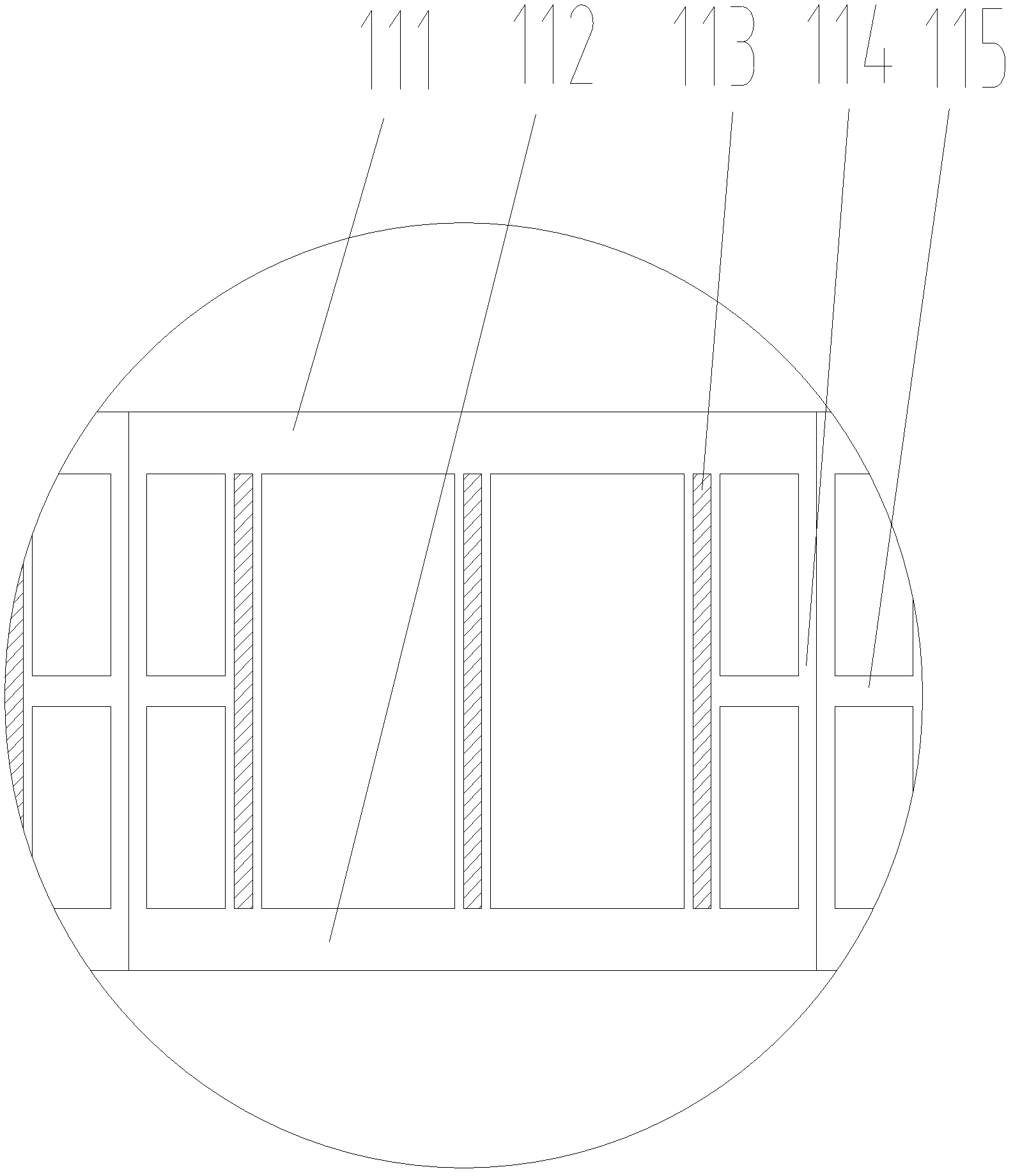

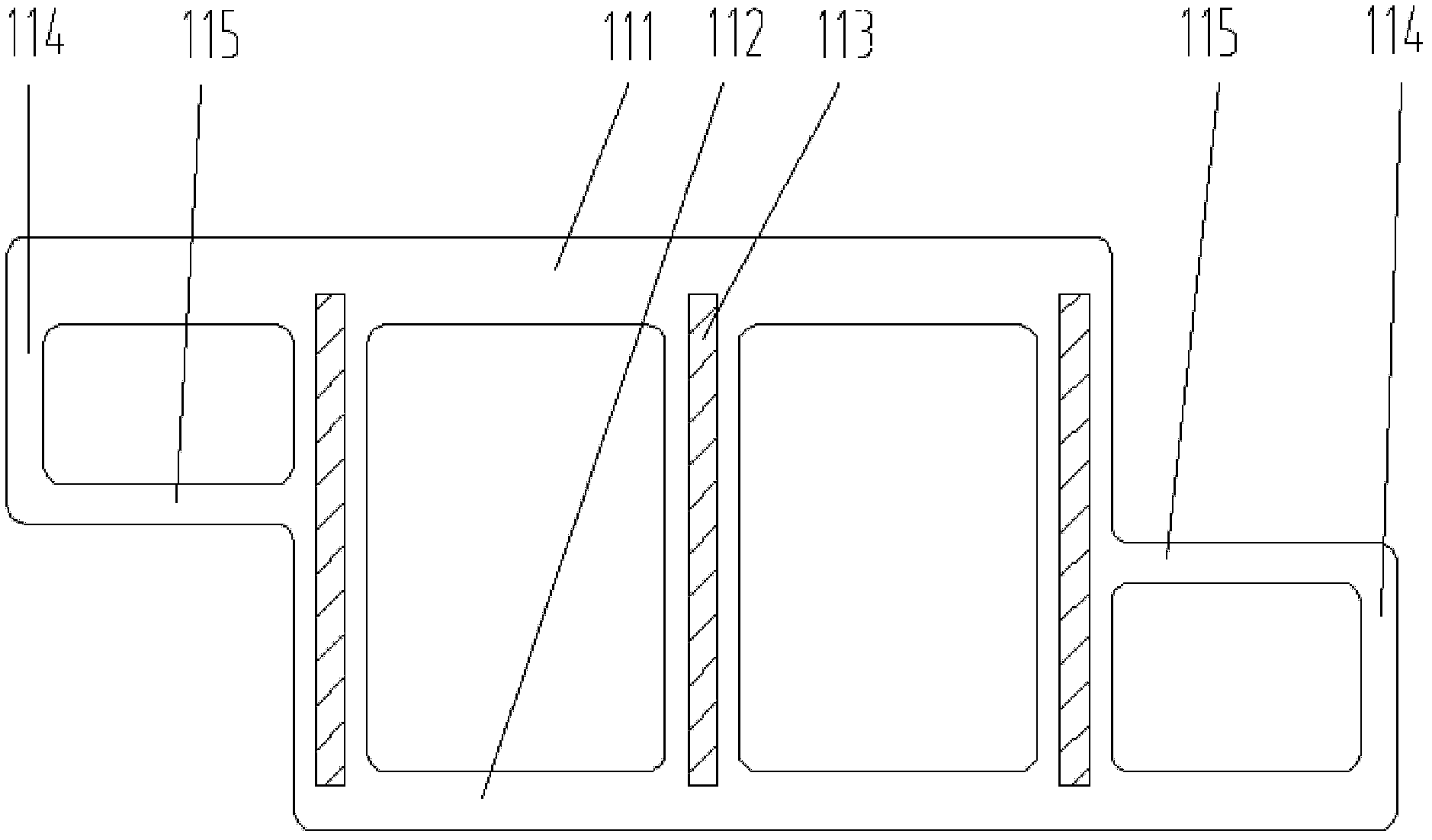

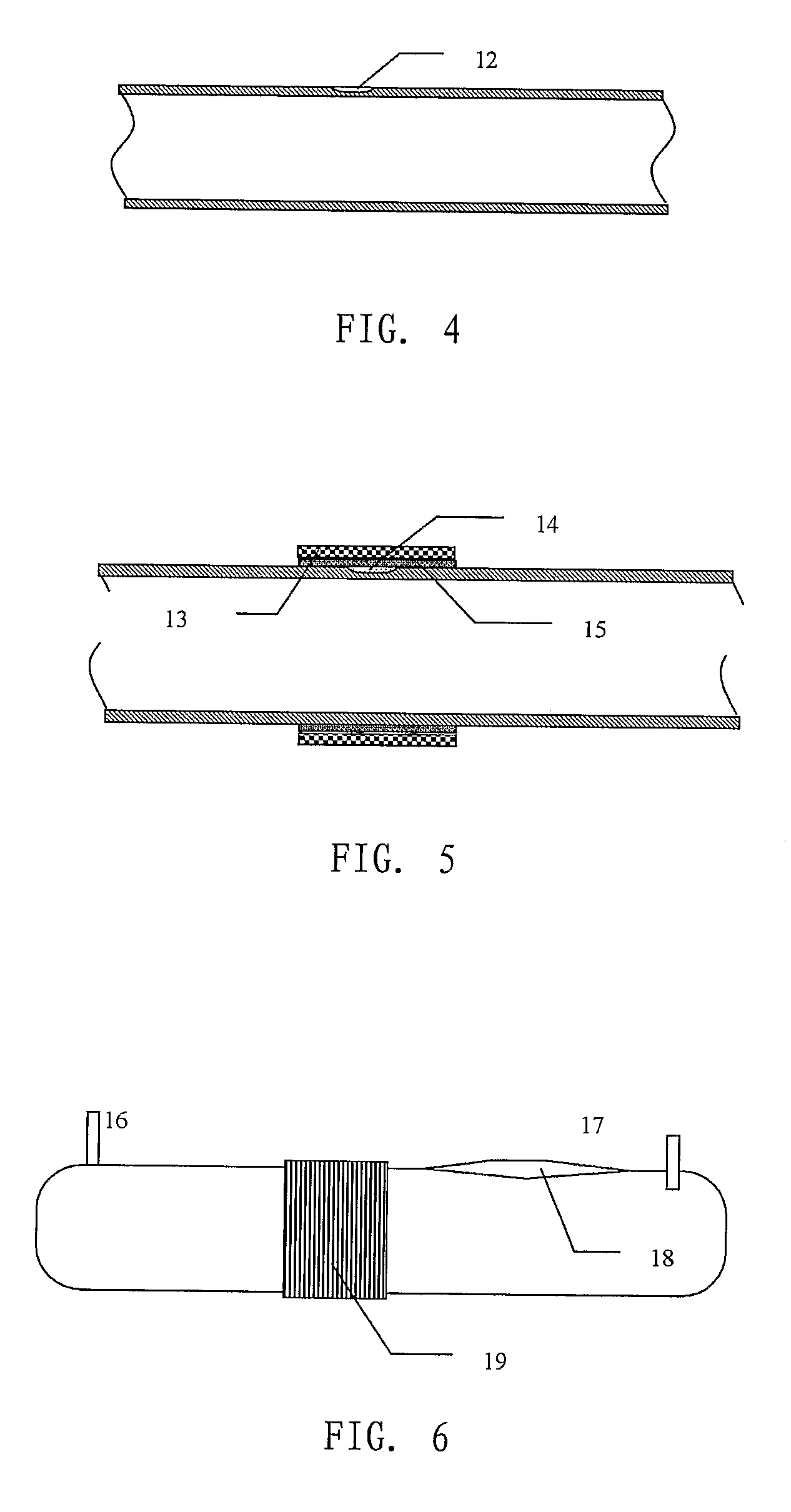

Reinforced thermoplastic composite wall pipe, strip and its complete production equipment

The invention discloses a strip material for a reinforced thermoplastic composite structure wall pipe, which comprises an upper base plate, a lower base plate and at least one reinforcing rib, wherein the reinforcing rib is vertically connected with the upper base plate and the lower base plate into a whole, and a reinforcing sectional material is at least positioned in the reinforcing rib. The composite elastic modulus in a strip material of the reinforced thermoplastic composite structure wall pipe is greater than that of the reinforcing sectional material of a thermoplastic material layer, the ring stiffness of the pipe material can be obviously improved, and in addition, the consumption of raw materials can be obviously reduced. The invention also discloses a pipe material for the reinforced thermoplastic composite structure wall pipe made of a strip material of the reinforced thermoplastic composite structure wall pipe, the pipe material has smooth and flat inner walls and outer walls, and in addition, a plurality of hollow structures are arranged between the inner walls and the outer walls. The invention also discloses a reinforced thermoplastic composite structure wall pipe set production device for producing the pipe material of the reinforced thermoplastic composite structure wall pipe, the production device can synchronously realize the continuous production of the strip material for the reinforced thermoplastic composite structure wall pipe and the pipe material for the reinforced thermoplastic composite structure wall pipe, and the production efficiency is improved.

Owner:华瀚管道系统科技有限公司

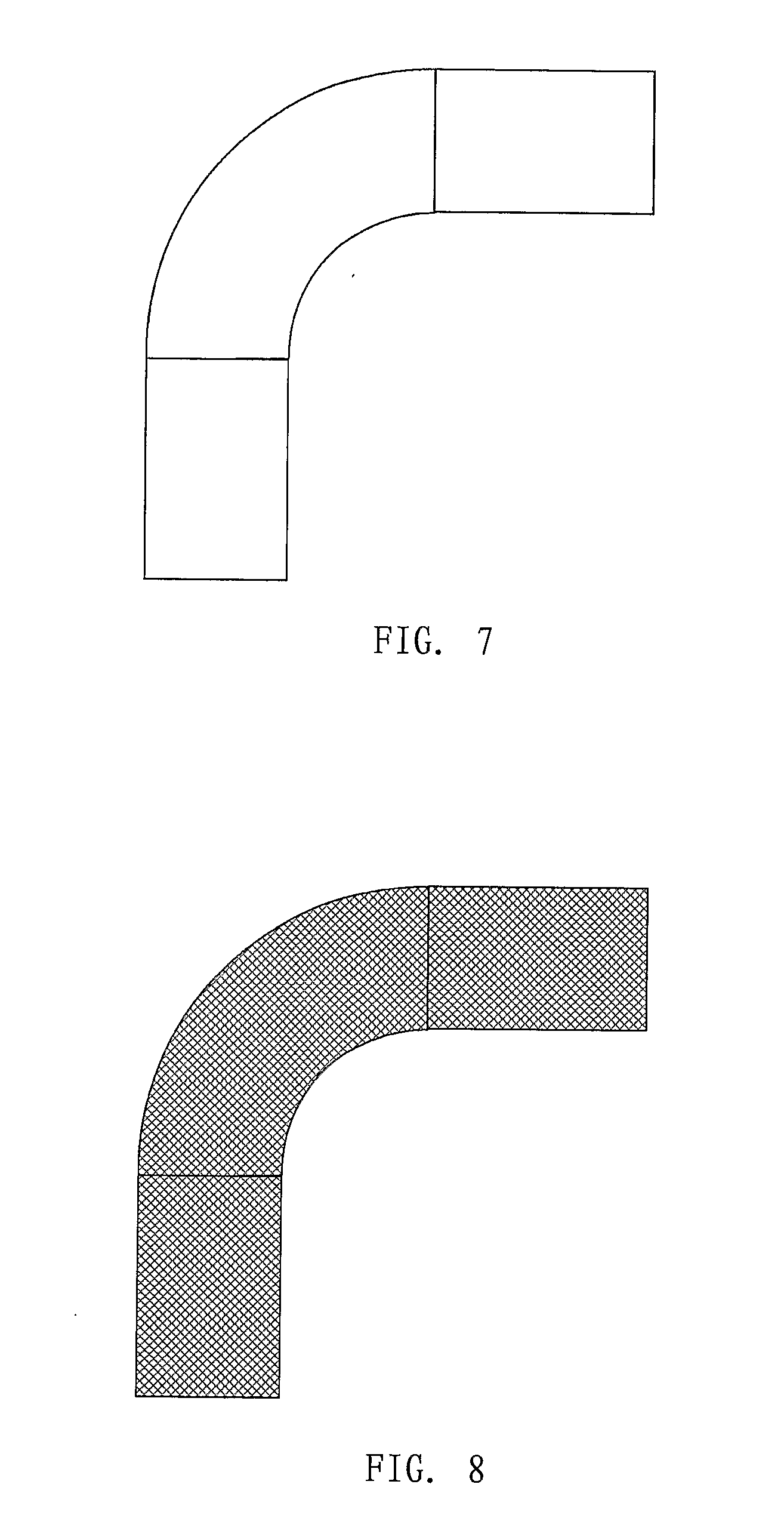

Technique for repairing, strengthening and crack arrest of pipe

InactiveUS20100147409A1High strengthLow costThermal insulationLayered productsFiberInternal pressure

A method for repairing / strengthening and crack arrest of pipe, especially metal pipe, in which, first, to cover an insulated material on the position needing repairing / strengthening and crack arrest, then to lay a high strength fiber composite material. The modulus of elasticity of the material used in the invention is close to the metal pipe's, it can be integrated with the pipe and bear the internal pressure with the pipe, thus the final composite pipe reaches required bear capacity, such as, the original most operation pressure of pipe can be recovered; and it can take effect for crack arrest of pipes when pipes happen burst accident. Otherwise, because of the insulated material is used on the bottom layer, it prevent thoroughly from galvanic corrosion between pipe and strengthening material. The method can be implemented simply and without fire, it is advantageous to tight joint between strengthening material and pipe, and between strengthening layers, and it can be used to repair and enhance the pipeline in use.

Owner:BEIJING SAFETECH PIPELINE

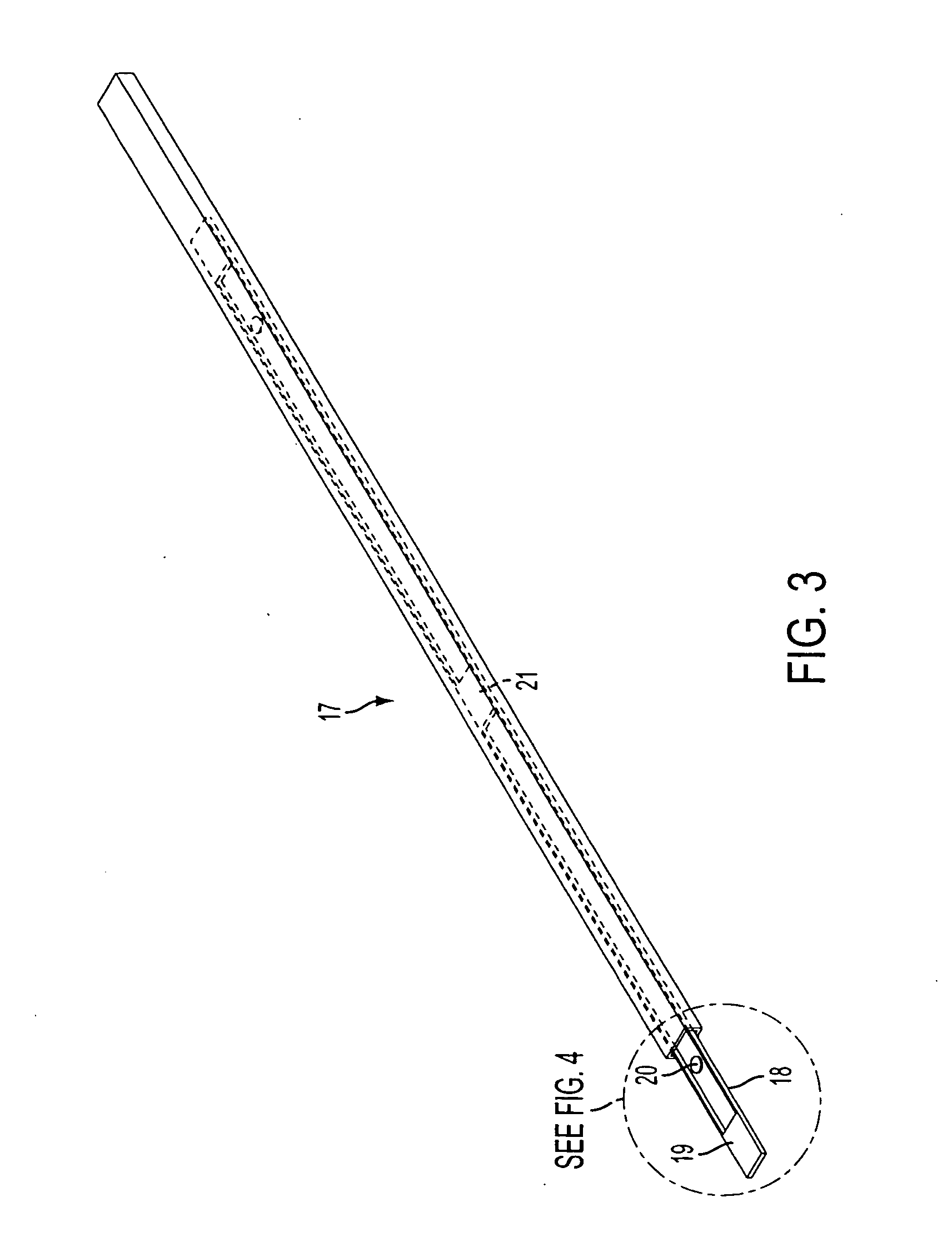

Stabilized earth structure reinforcing elements

ActiveUS7270502B2Configuration highLow costArtificial islandsExcavationsExtensibilityDesign standard

A stabilizing element in a stabilized material particle structure, particularly an earthen embankment, wherein the material stabilizing elements that are inextensible (material with a higher modulus of elasticity than that of the surrounding particles) in composition nature but made more extensible because of its configuration. This extensibility gives the stabilizing elements the ability to mobilize more of the material shear resistance and adapt to current design standards under extensible type elements. The configuration also enhances the frictional engagement with the adjacent particles. The soil stabilizing elements are attached to facing elements and project into the compacted fill behind the facing. In some structures there may not be a facing element. Additionally, a material coating for metallic stabilizing elements that gives the elements improved corrosion protection, additional service life and / or expands the electrochemical environment in which they can be used.

Owner:ASHGROVE HLDG LLC

High-modulus modifier composite of bituminous mixture and preparation method thereof

ActiveCN101921419AHigh modulus of elasticityImprove adhesionBuilding insulationsRoad surfacePolypropylene

The invention discloses a high-modulus modifier composite of a bituminous mixture and a preparation method thereof. The high-modulus modifier composite of the bituminous mixture comprises the following components in parts by weight: silica powder, thermoplastic butadiene styrene rubber, modified polyethylene, polyethylene, modified polypropylene, polypropylene, ethylene-vinyl acetate polymers, antiagers and bitumen. The preparation method of the high-modulus modifier composite of the bituminous mixture comprises the following steps of: weighing the components in the parts by weight according to a proportion; stirring the components, and raising temperature at the same time; then adding the silica powder, the antiagers and the bitumen to a molten mass, and stirring for uniformly mixing at 160-200 DEG C and under certain rotating speed; extruding through a screw extruder, cooling with normal temperature water, and cutting so as to obtain granular finished products. The invention enhances the elastic modulus, improves the adhesive property, enhances the high-temperature anti-rutting property, the water stable property and the ageing-resistant performance, obviously reduces the damages, i.e. rutting, process, bumps, cracks, pits, looseness, and the like, of bituminous pavements, has the advantages of simple processing process, prolonged service life and convenient use, omits a process link of modifying the bitumen and can be widely used for paving the bituminous pavements of roads.

Owner:XIAN ZHONGLI ASPHALT CO LTD

Stiffened parts for window covering and methods for making the same

InactiveUS20060113046A1Improve rigidityIncrease stiffnessDoor/window protective devicesWing framesEngineeringResilient modulus

A window covering component comprising a substrate having a modulus of elasticity and a stiffener having a higher modulus of elasticity than the substrate and positioned substantially away from the plane in which the substrate would otherwise tend to deform.

Owner:PRINCE KENDALL W +2

Glue-powder pervious concrete and preparation method thereof

The invention discloses glue-powder pervious concrete and a preparation method thereof. The glue-powder pervious concrete contains the following ingredients in parts by mass: 300-450 parts of cement, 1,300-1,800 parts of coarse aggregates, 2-15 parts of additives, 20-50 parts of mineral admixture, 6-50 parts of waste / used tire rubber powder, 6-12 parts of cementing agent, 0.2-1.0 part of humectant and 100-150 parts of water. According to the glue-powder pervious concrete, the compressive strength, folding strength, porosity, coefficient of water permeability, wear resistance and the like are in line with technical regulations for pervious concrete pavements CJJ / T135-2009; meanwhile, the glue-powder pervious concrete also has the advantages of high toughness, high shock resistance, low elastic modulus, and the like, thereby playing a very good role in promoting the development of high-performance concrete technologies in the construction of sponge cities. The preparation method provided by the invention comprises three steps, i.e., carrying out mortar preparation, carrying out mortar coating treatment and carrying out stirring, thereby obtaining the finished product, and novel equipment is not required to be increased, so that the method is easy and feasible.

Owner:重庆绿恒环保科技有限公司

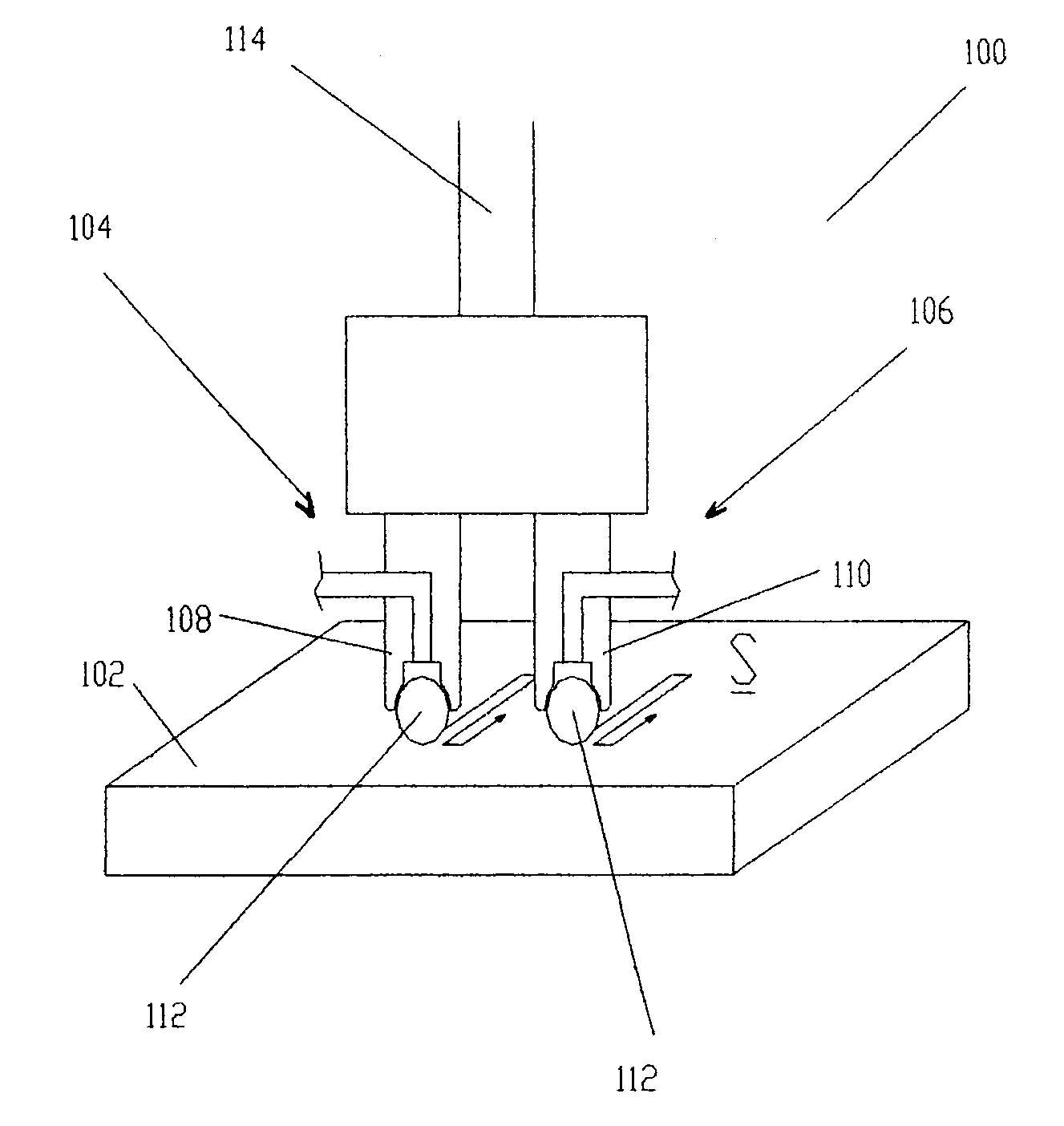

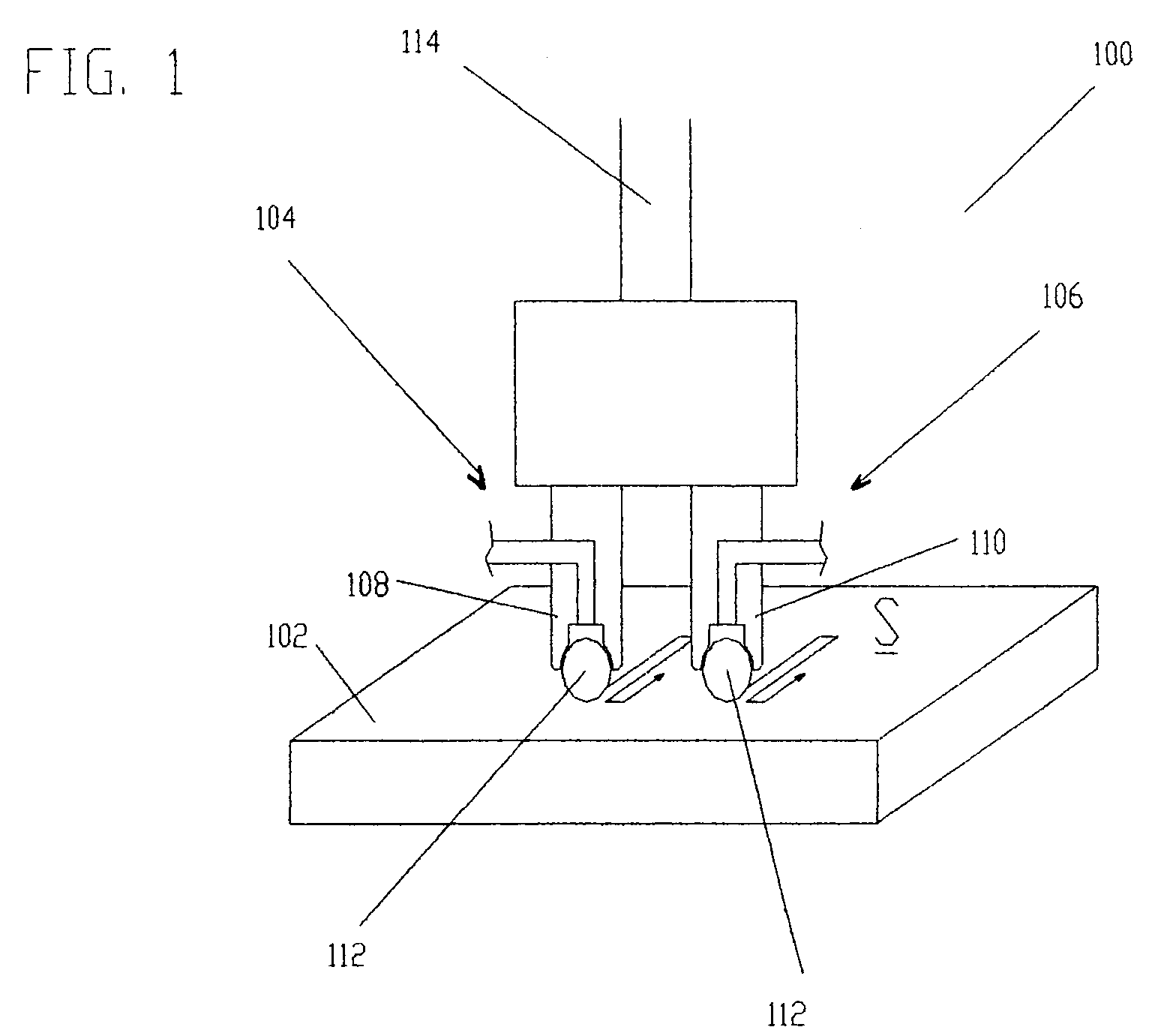

Method for improving the magnitude of compressive stress developed in the surface of a part

This invention relates to a method and an apparatus for performing the method of inducing compressive residual stress along the surface of a part. In the preferred embodiment of the invention, the method includes burnishing or deep rolling a surface using a first and a second roller or ball burnishing members, whereby the first and second burnishing members may have a different diameter and / or modulus of elasticity. In another preferred embodiment of the invention, the burnishing operations may be performed while the surface of the part is at different temperatures.

Owner:SURFACE TECH HLDG

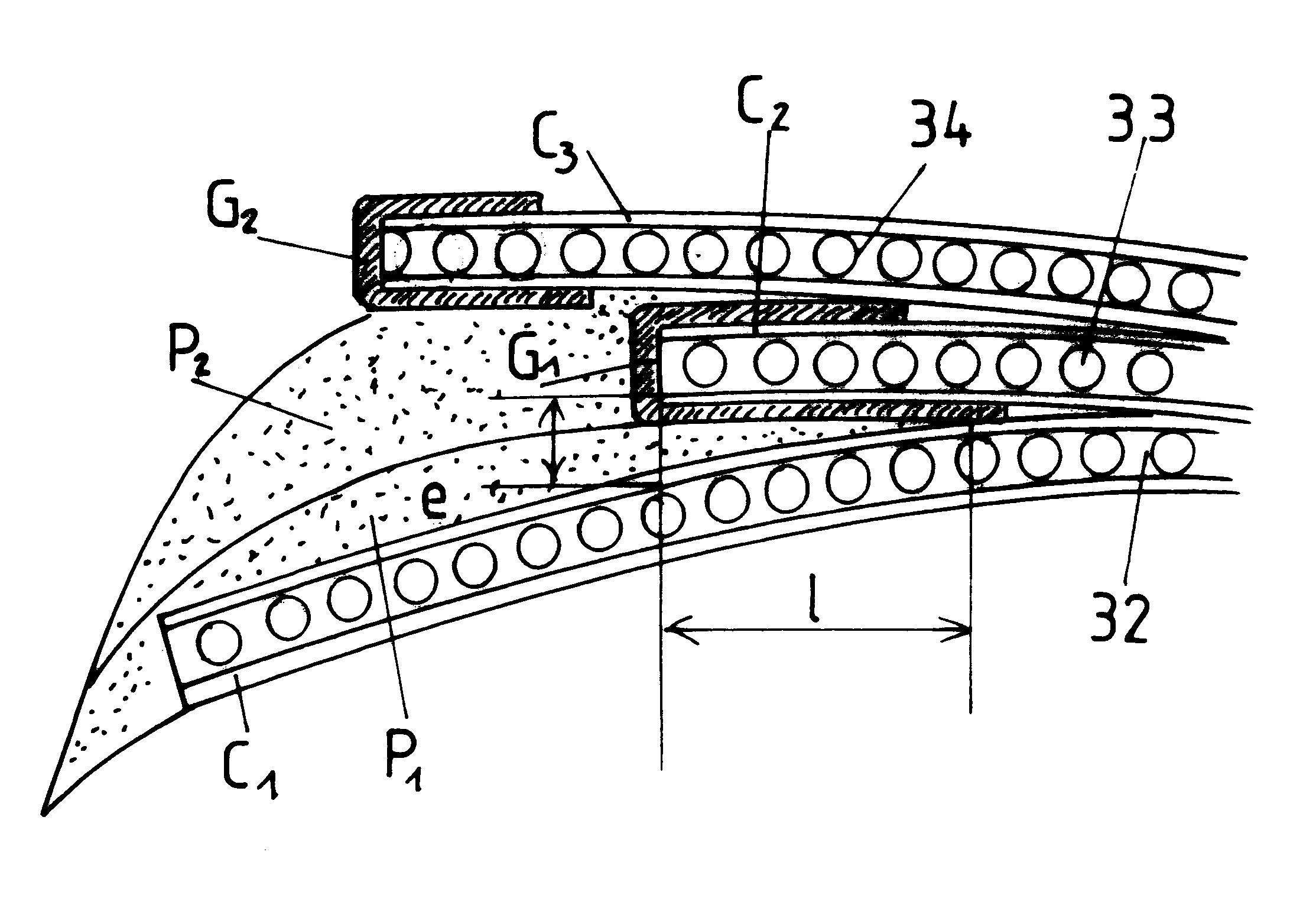

Tire having crown reinforcement with profiled element and edging rubber

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

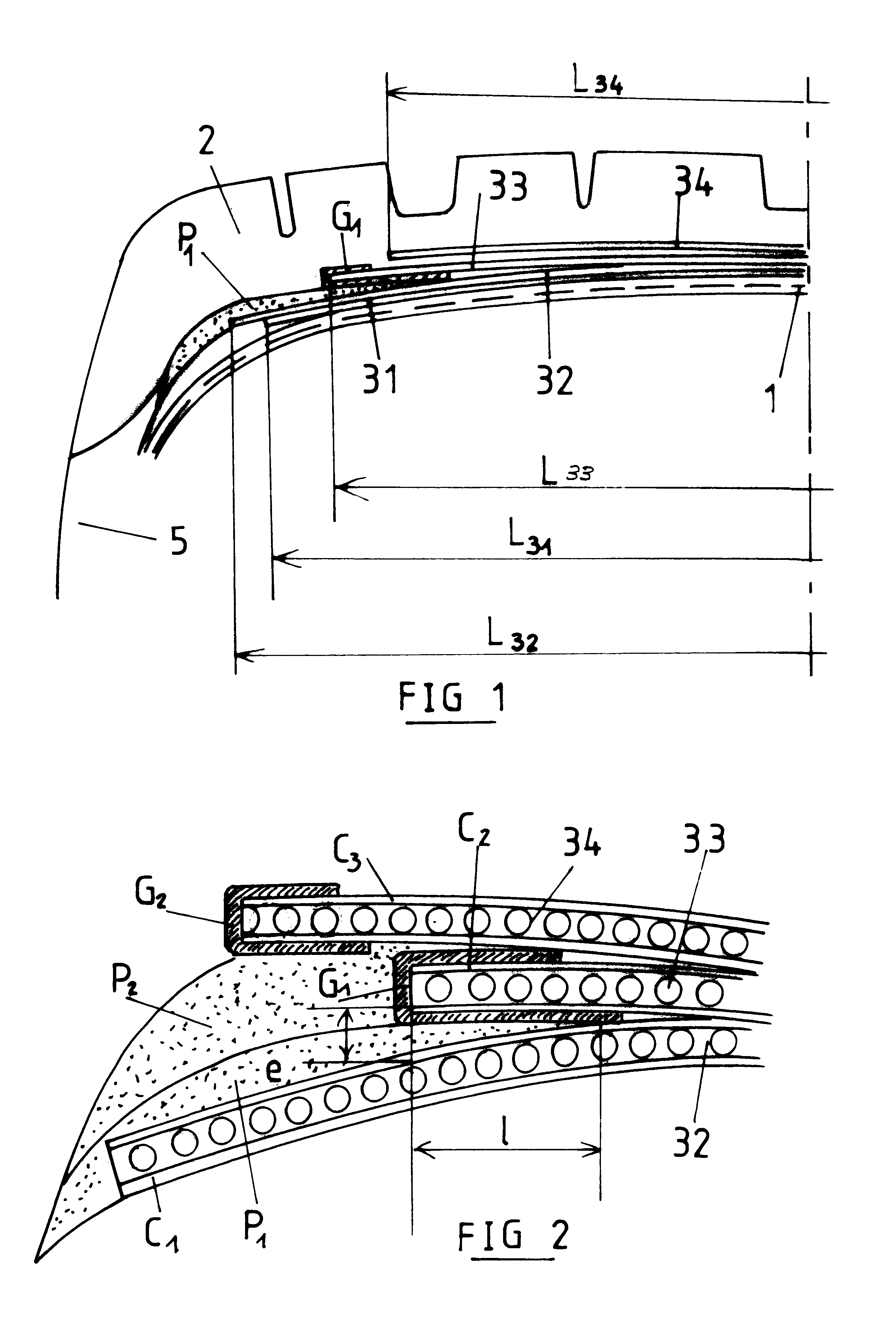

Heat conjunction metal board laser forming method

InactiveCN101204756AImprove forming efficiencyIncrease the amount of deformationLaser beam welding apparatusAviationNumerical control

The invention relates to a laser forming method for a thermally combined metal plank. A work-piece is arranged on a three dimensional numerical control platform and one end is fixed. A continuous laser bean heats the surface of the metal plank at a certain scanning speed along a given moving track and force is applied at the location of about 1 to 3 spot diameters after the laser bean. As an elasticity modulus and an off set limit of the metal plank is greatly descended under a thermal state, the uneven heat stress caused by heating part of the work-piece by the laser bean is combined with a crushing stress to lead the plank to generate a larger elasticity modulus; thereby improving the forming efficiency of the plank. The method is not only suitable for the normal metal plank, but also can be applied to the forming of high-hard brittle difficult-deforming materials; the invention has a promising application in the manufacturing field of aerospace, micro-electronics and ships.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

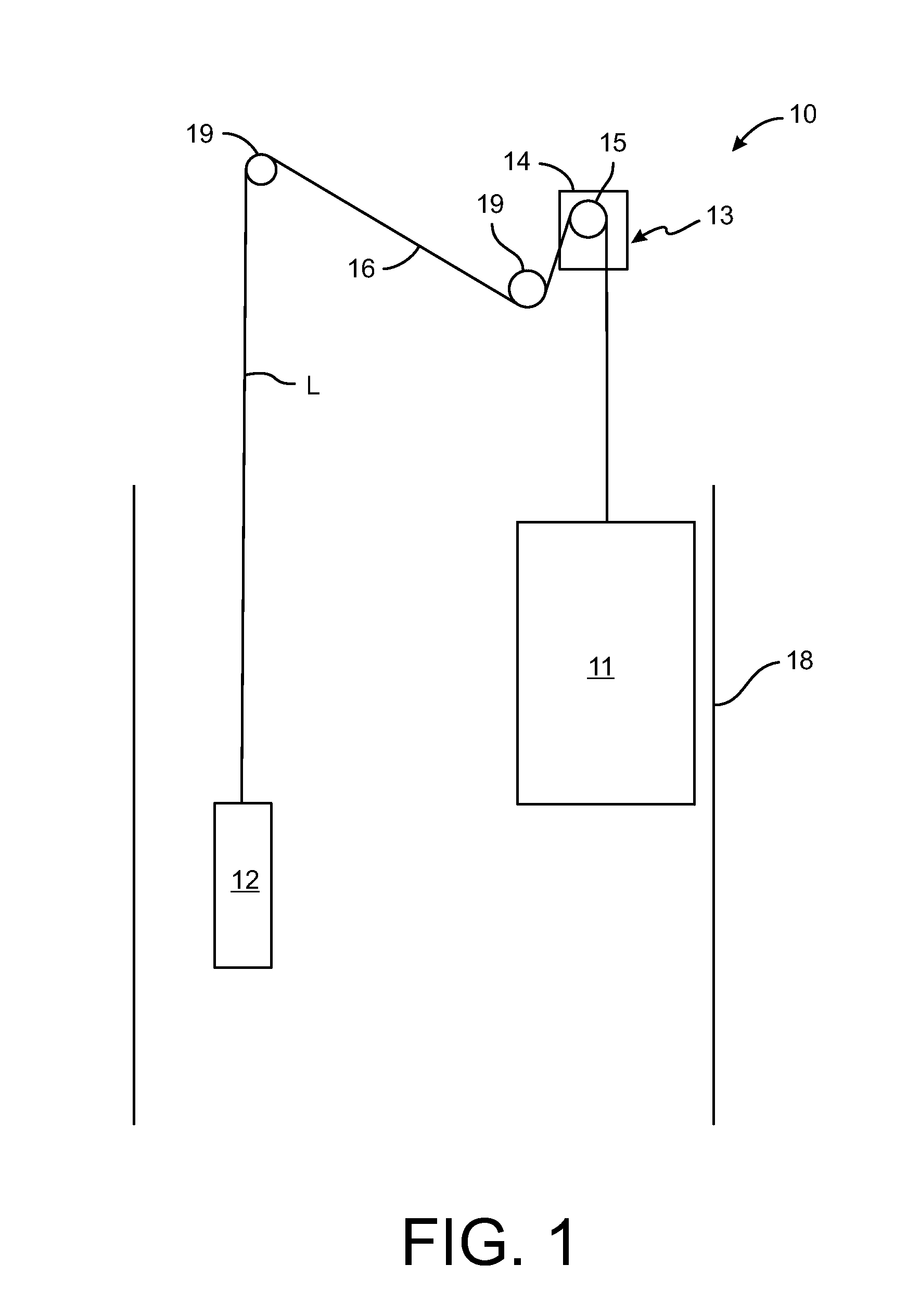

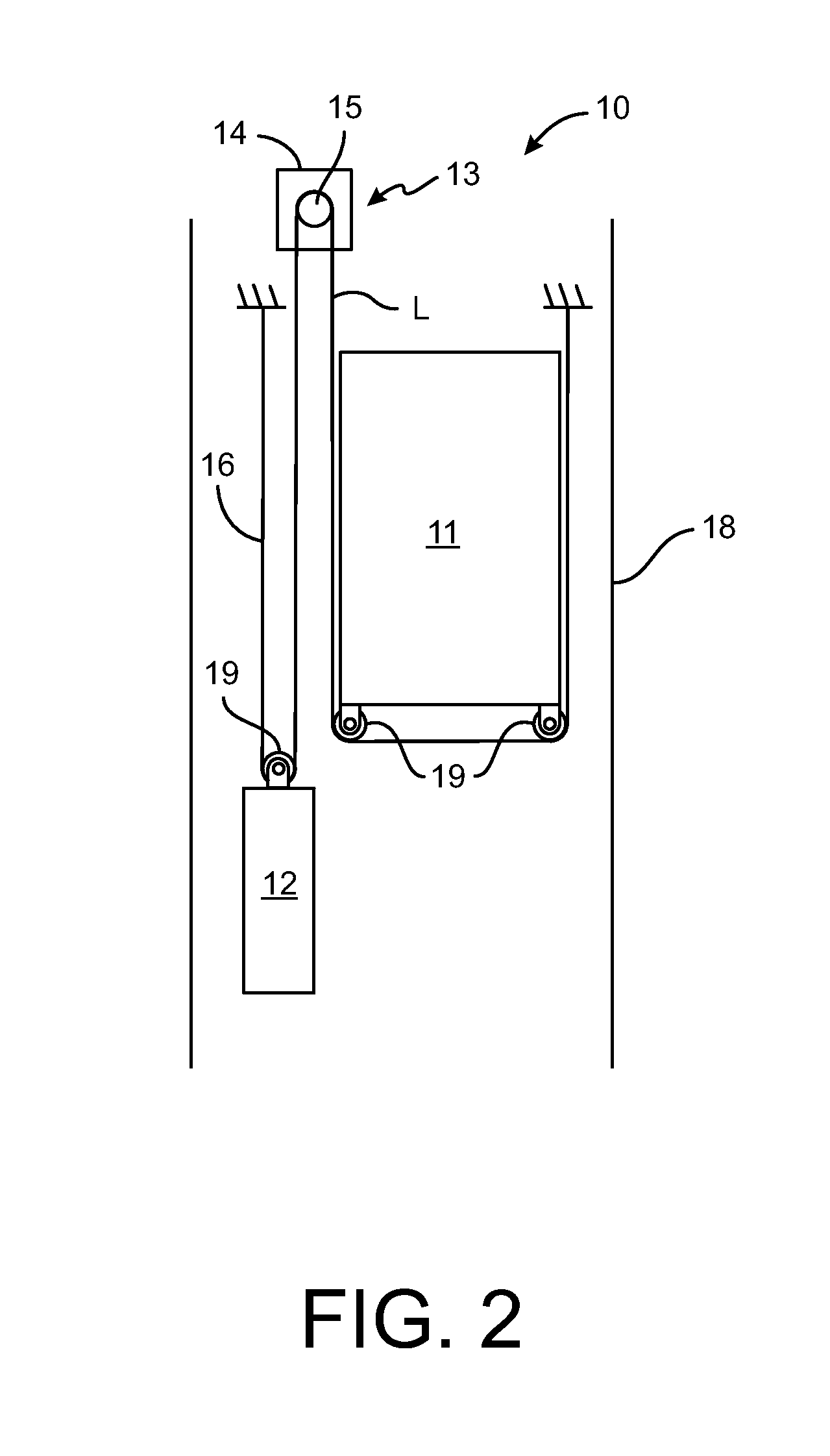

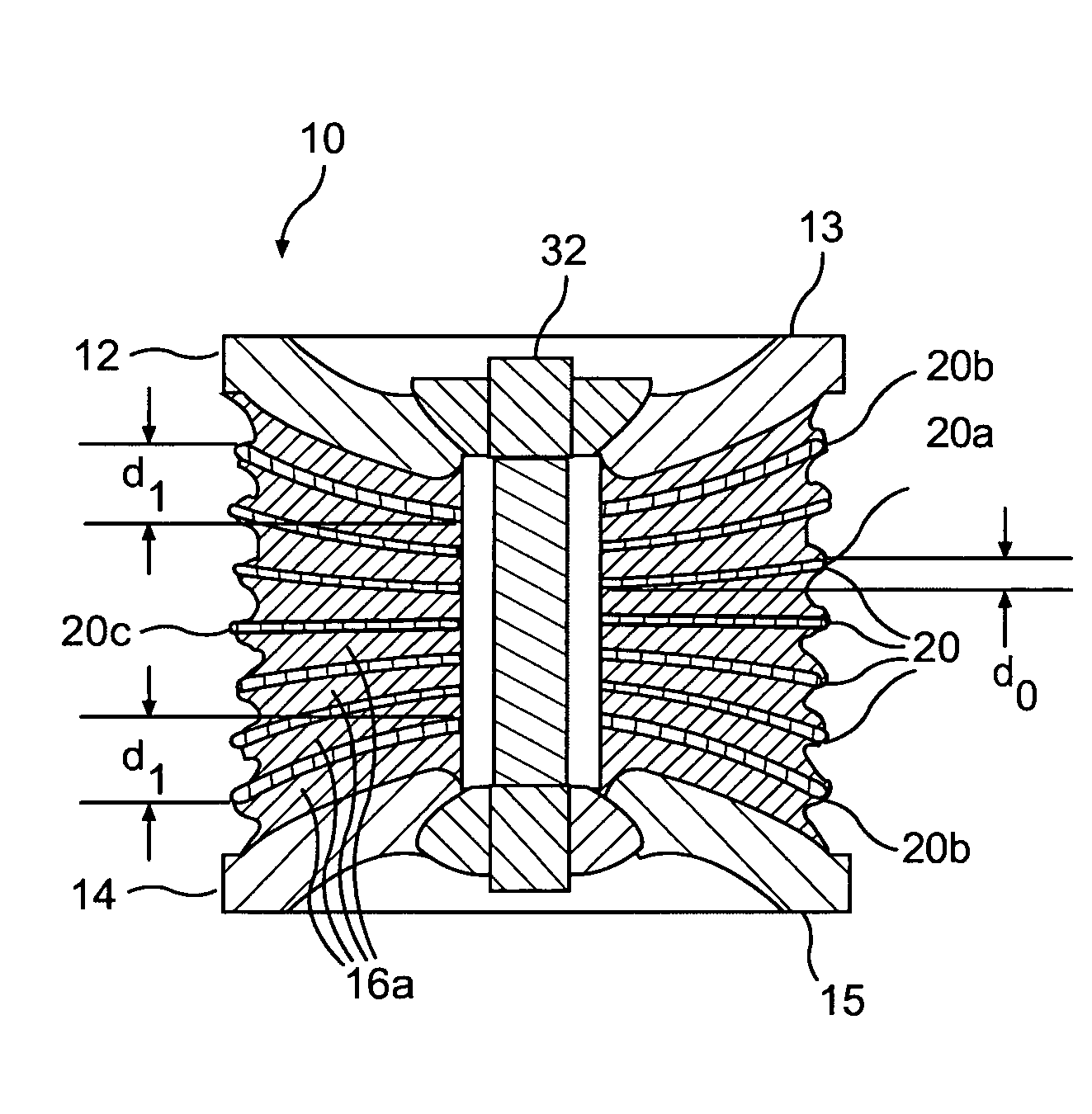

Elevator Tension Member

Elevator tension members are disclosed. The disclosed tension member longitudinally extends along a longitudinal axis and includes a plurality of fibers formed into one or more primary strands or cords extending parallel to the longitudinal axis and a plurality of fibers formed into one or more secondary strands or cords extending parallel to the longitudinal axis and through less than the full length of the belt, and a jacket retaining the primary and secondary strands or cords. The secondary strands or cords have a tensile modulus greater than a tensile modulus of the jacket and less than a tensile modulus of the primary strands or cords. Methods of making the tension member are also disclosed.

Owner:OTIS ELEVATOR CO

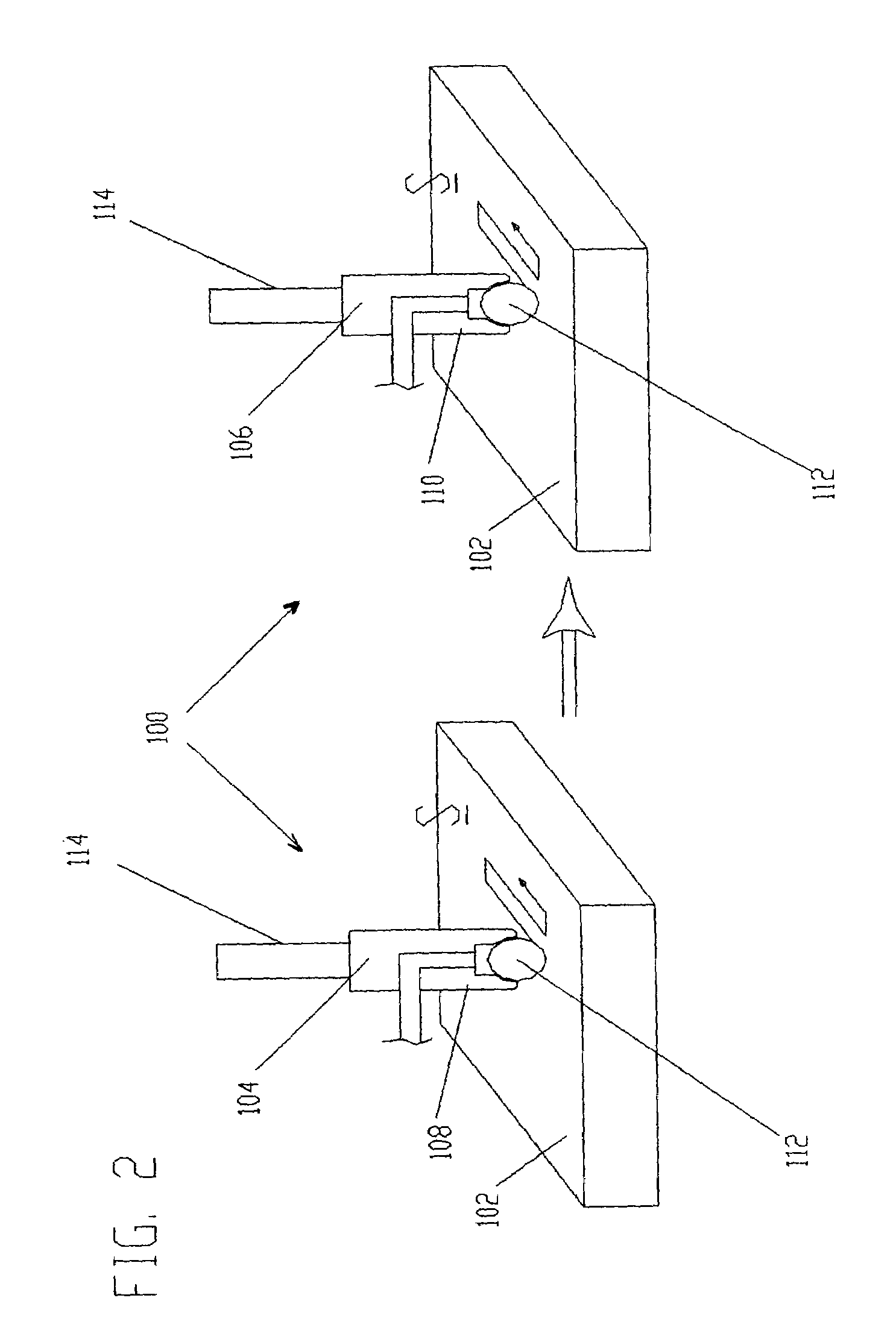

Load-bearing resilient mount

ActiveUS8070143B2Control deformationPortable framesSprings/dampers functional characteristicsEngineeringMechanical engineering

A resilient mount including a first mounting member and a second mounting member is provided. The mount includes a first plurality of stiffening elements located between the first and second mounting members. At least a first stiffening element of the first plurality of stiffening elements is non-parallel to a second stiffening element of the first plurality of stiffening elements. Each of the first plurality of stiffening elements has a material thickness and an out-of-plane dimension that is greater than the material thickness. Each stiffening element of the first plurality of stiffening elements is substantially rigid so as to substantially limit the deformation of the stiffening element under load. The mount may also include a resilient material located between and coupled to adjacent stiffening elements of the first plurality of stiffening elements.

Owner:CATERPILLAR INC

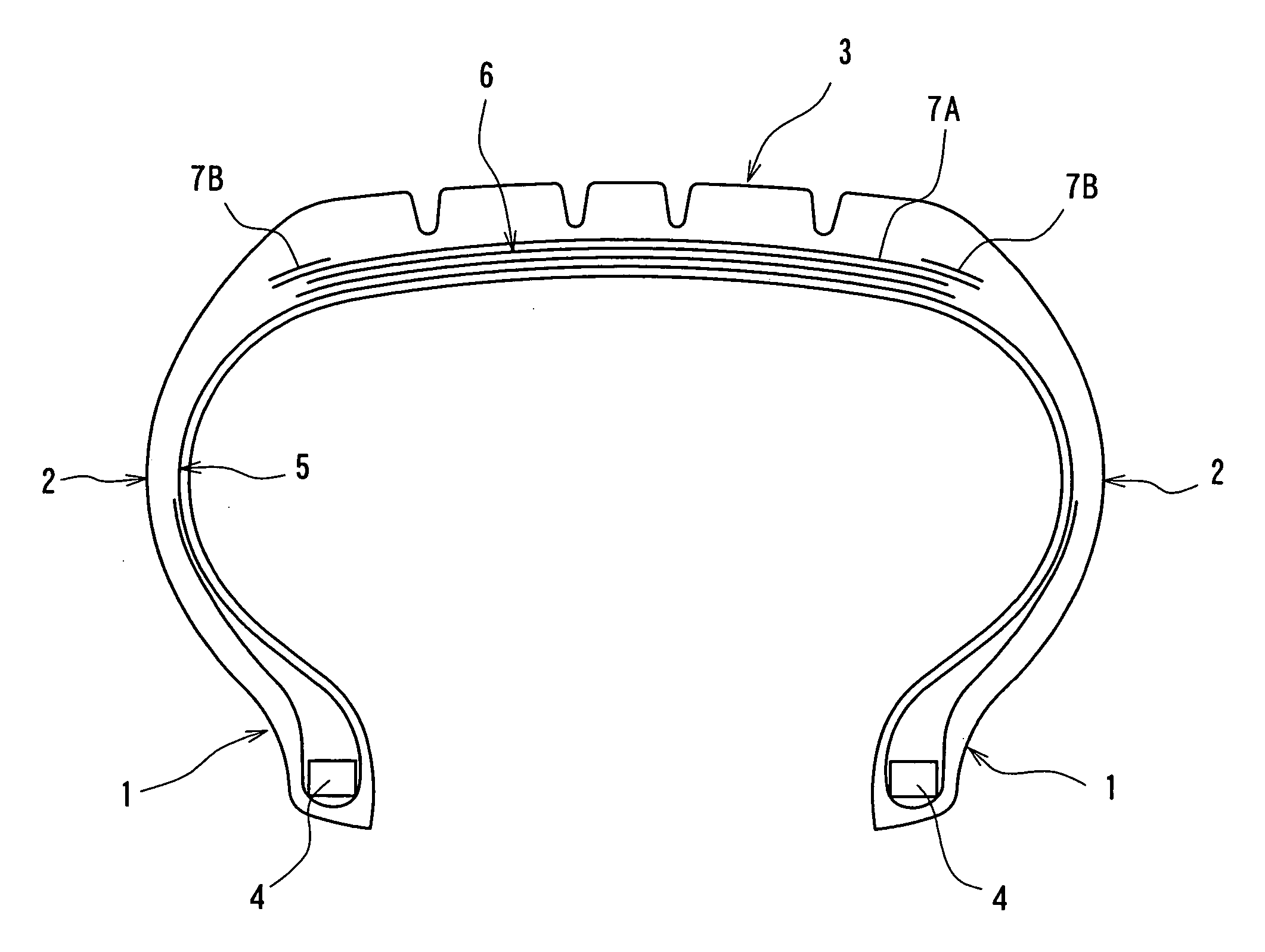

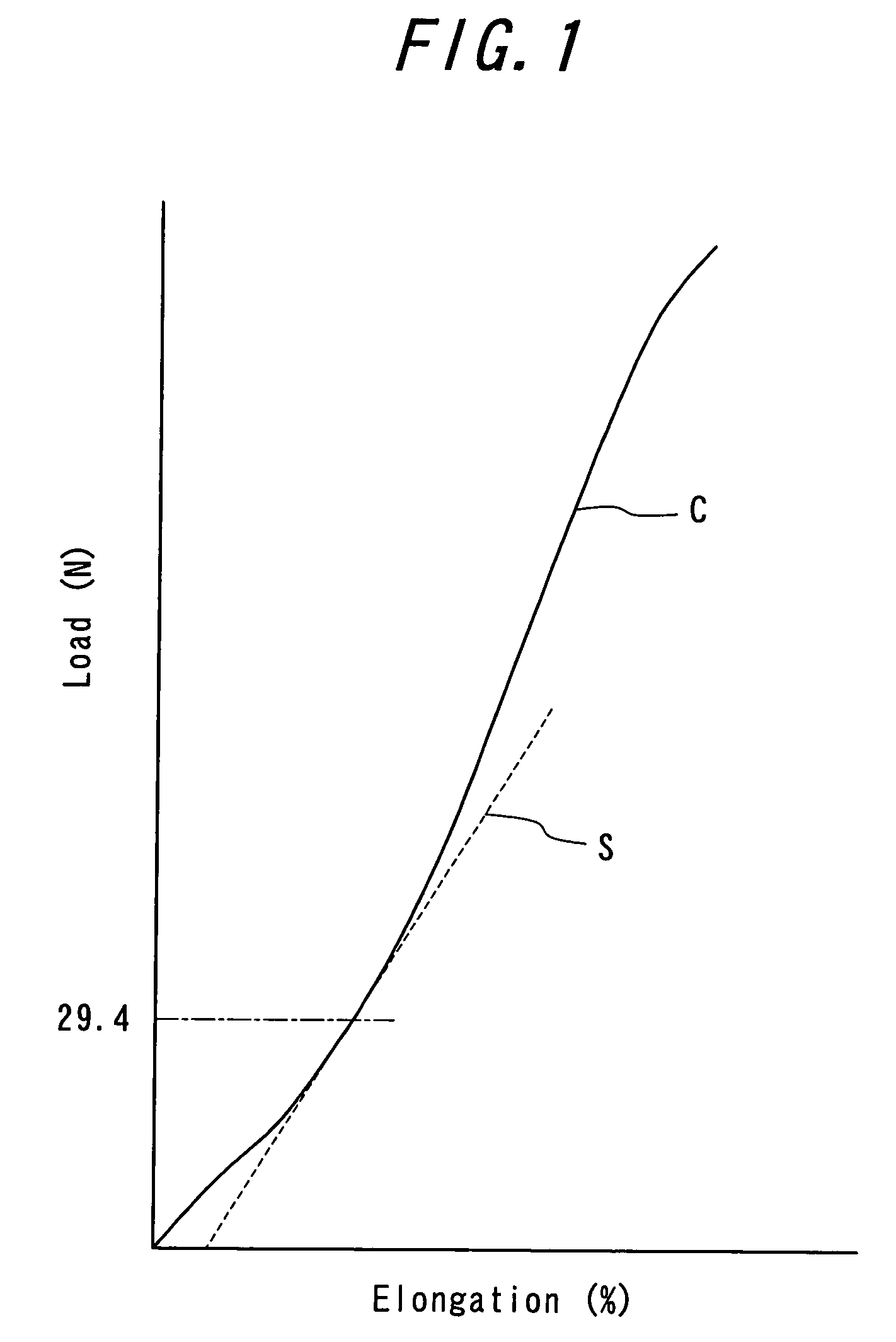

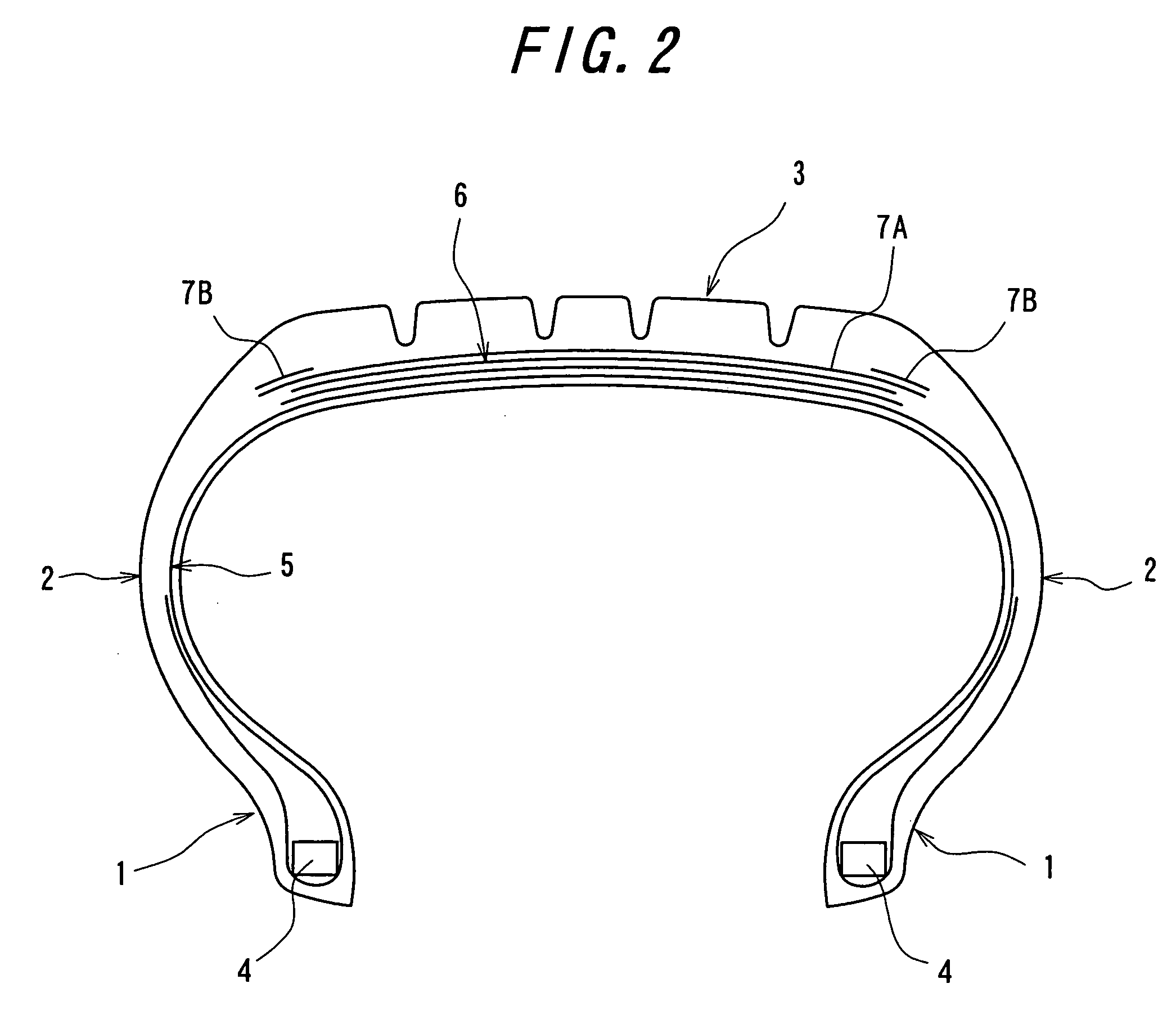

Pneumatic radial tire

ActiveUS20070006957A1Improved high-speed durabilityRelieve pressureNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyethylene terephthalateEngineering

This invention relates to a pneumatic radial tire having low road noise and flat spot and a high high-speed durability, and more particularly to a pneumatic radial tire comprising a radial carcass (5), a belt (6) disposed outside a crown portion of the carcass in a radial direction and comprised of at least two belt layers, and a belt reinforcing layer (7A, 7B) disposed outside the belt in the radial direction, characterized in that the belt reinforcing layer 7A, 7B is formed by continuously and spirally winding a polyethylene terephthalate cord(s) in a circumferential direction of the tire, and this cord has an elastic modulus of not less than 2.5 mN / dtex·% under a load of 29.4 N measured at 160° C.

Owner:BRIDGESTONE CORP

Conformable multi-layer sheet materials

InactiveUS6869496B1Easy to operatePromote softeningStampsLamination ancillary operationsPolyesterPhysical property

A multi-layer sheet material comprises a film, and adhesive layer and an optional release liner. The film is a polyester blend comprising first and second polyesters that are substantially amorphous and possess certain physical properties including softening temperature, E-modulus, elongation and residual stress.

Owner:3M INNOVATIVE PROPERTIES CO

Geopolymer/ waste rubber powder composite material and preparation method thereof

The invention discloses a geopolymer / waste rubber powder composite material and a preparation method thereof. The geopolymer / waste rubber powder composite material comprises the following raw material components in parts by weight: 35-70 parts of geopolymer alkali activated material and 30-65 parts of waste rubber powder / modified water glass mixed slurry; the waste rubber powder / modified water glass mixed slurry is prepared from the following components in parts by mass: 5-50 parts of waste rubber powder and 50-95 parts of modified water glass. The prepared composite material adopts cast molding; and after the composite material is cured, the compressive strength is between 15MPa and 96MPa, and the elasticity modulus is between 92MPa and 400MPa. The composite material disclosed by the invention not only solves the problem of utilization of waste rubber, but also solves the technical problems of high brittleness and insufficient toughness of geopolymer materials. The composite material can be applied in the engineering fields of buildings, traffic, military affairs and the like.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

Biodegradable macromolecule composite material with shape memory function and its preparation method and use

InactiveCN101240116AGood magnetic responseHigh elastic modulusStentsSurgeryPolypyrroleMechanical property

The invention relates to a biodegradable polymer composite material having shape memory function, comprising a biodegradable polymer material, which is characterized in that the molecular weight of the biodegradable polymer material is 20000 to 1500000, 1 to 20 parts of nano-scopic or micron-sized organic conductive particles and / or inorganic magnetic particles are added in the 100 parts by weight of the polymer, wherein, the organic conductive particles is one of polypyrrole, polyaniline, poly3,4-dioxane ethyl thiophene or the mixture of them, the inorganic magnetic particles is one of ferroferric oxide and ferric oxide magnetic particles or the mixture of them. The mechanical property and mechanical property of the materials, with good elasticity modulus, well elasticity, high shape recovery rate, easy shape memory and changing operation and fast shape recovery speed.

Owner:SOUTHWEST JIAOTONG UNIV

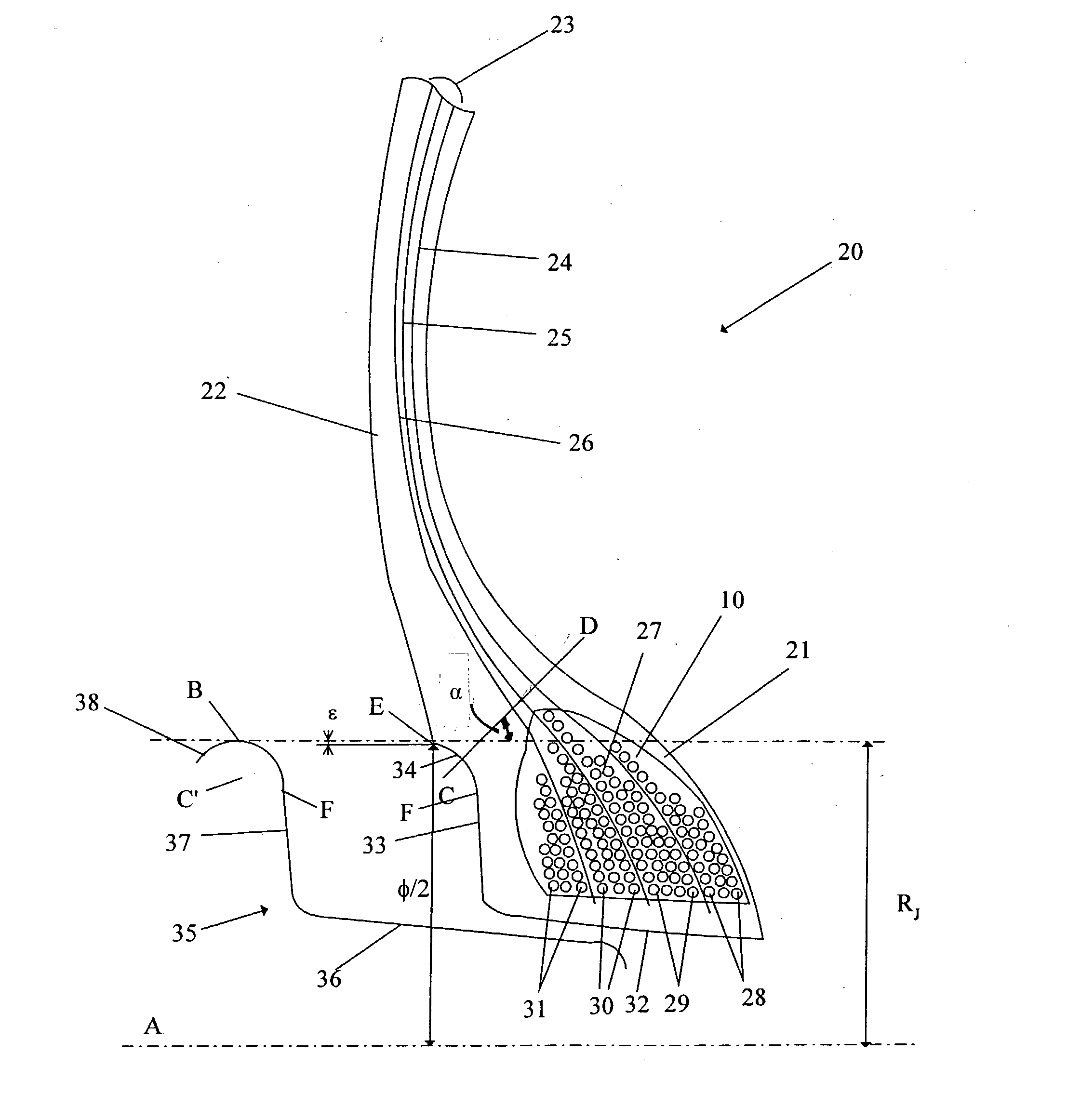

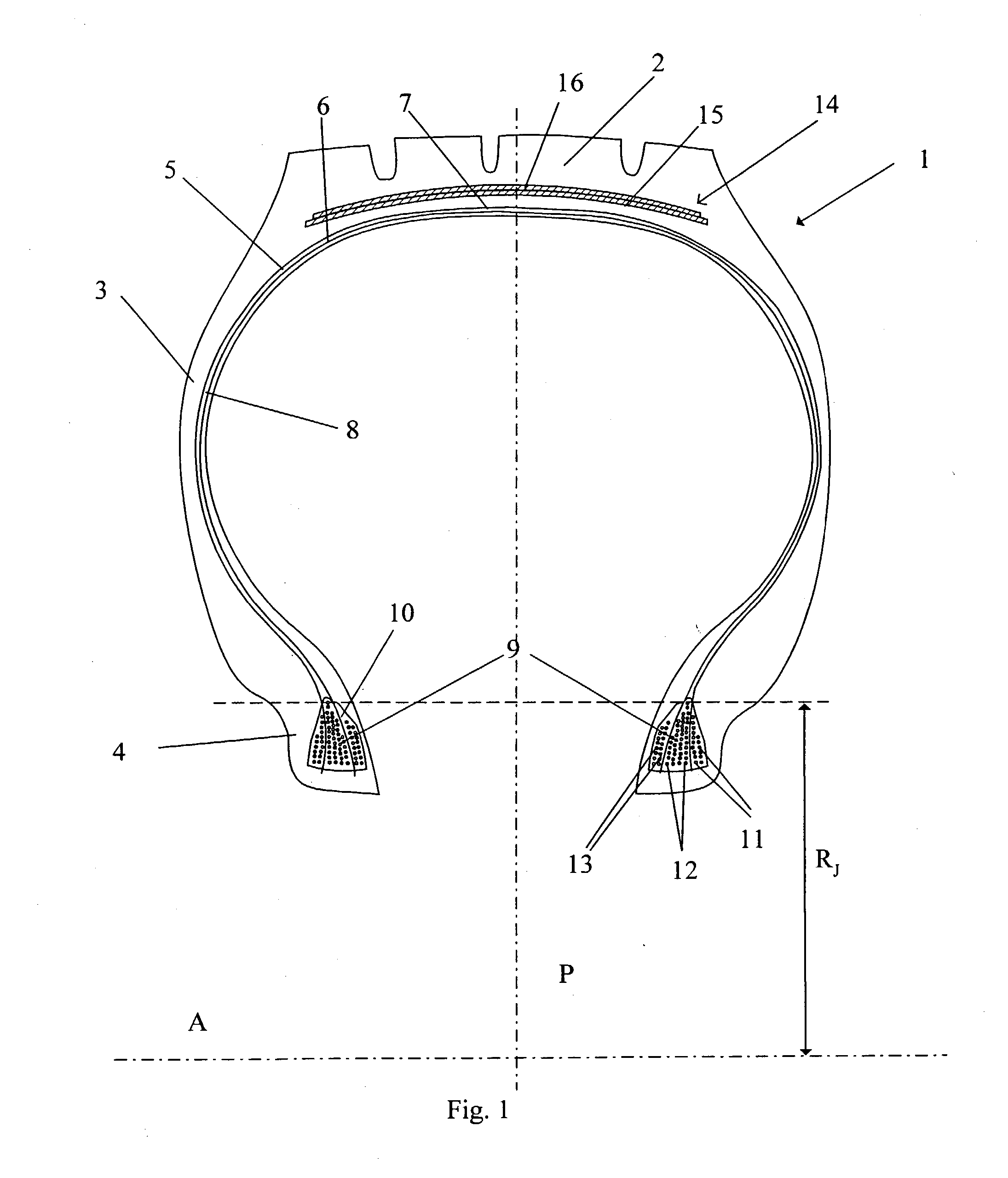

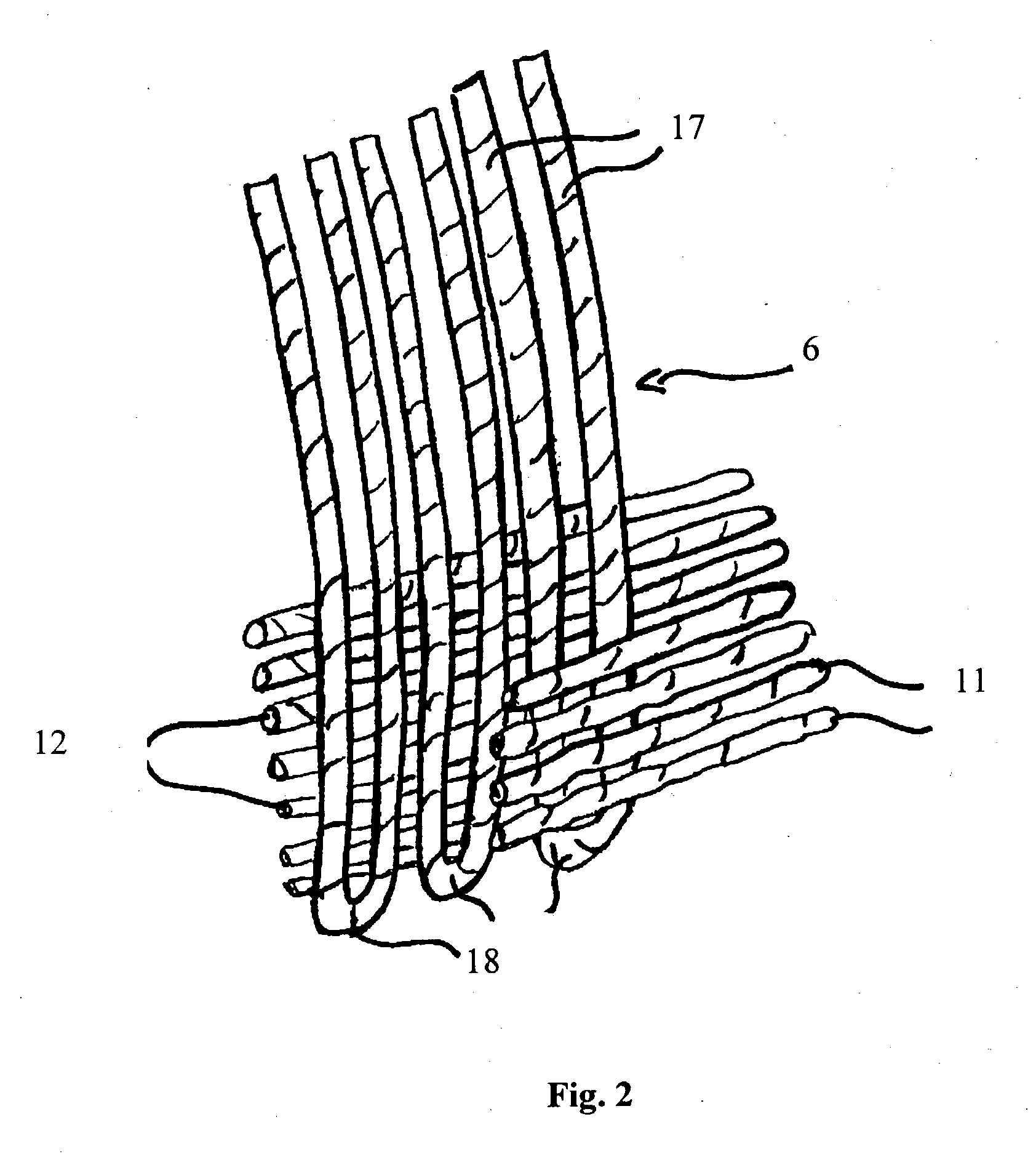

Tire having an improved carcass reinforcement anchoring structure

InactiveUS20030150541A1High densityHigh modulusPneumatic tyre reinforcementsTyre beadsEngineeringResilient modulus

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

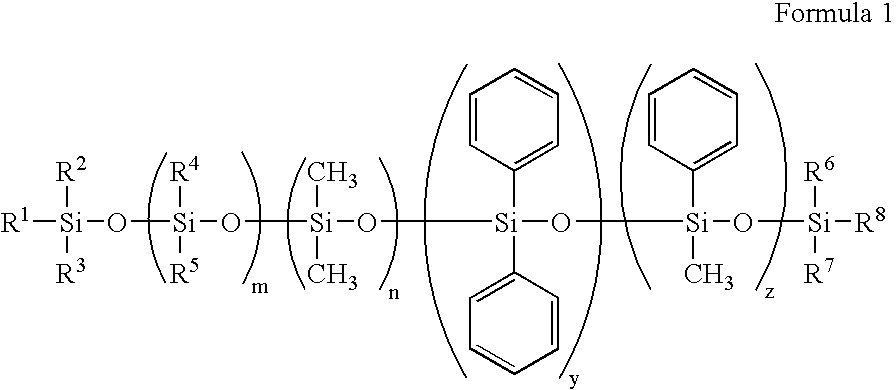

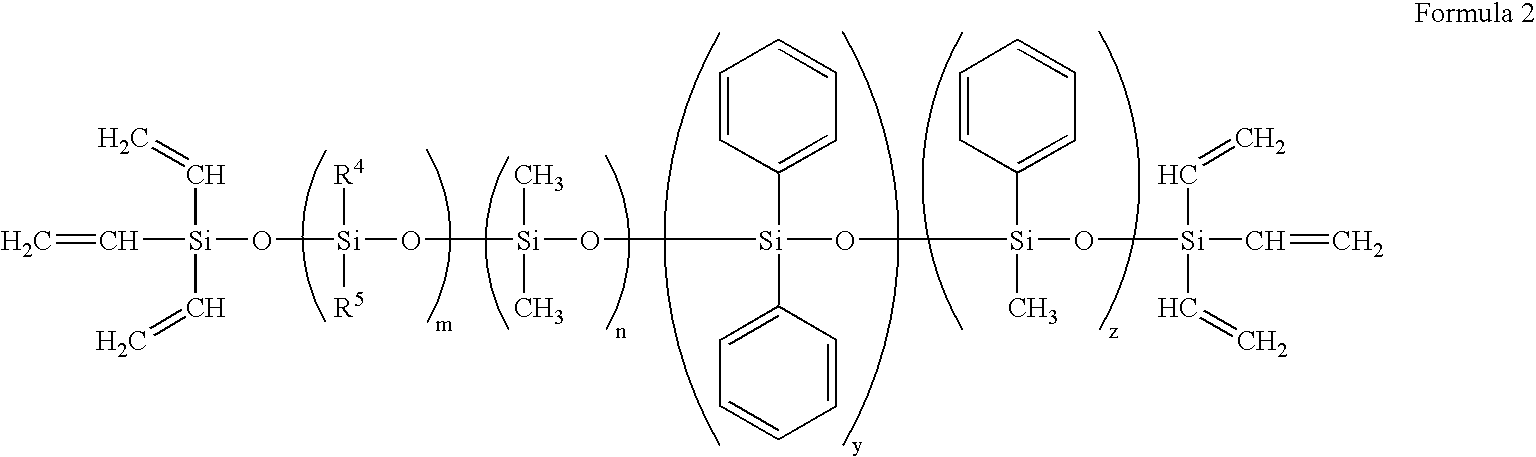

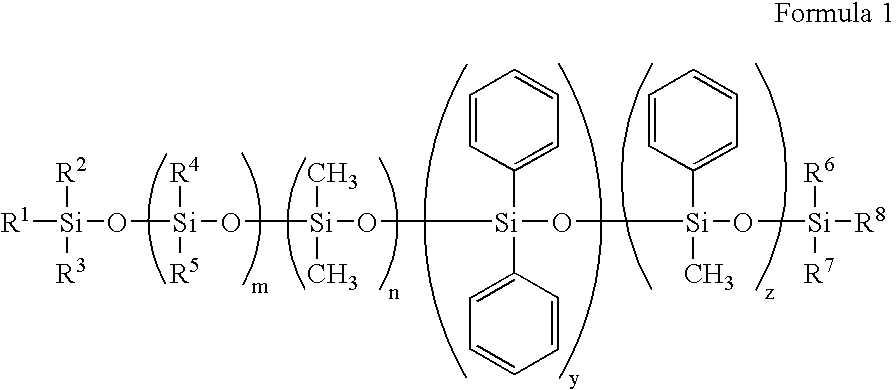

Silicone containing polymeric materials

ActiveUS20090163602A1Reduce the degree of polymerizationCosmetic preparationsMammary implantsBreast implantEye lens

A polymeric material with a variable modulus of elasticity is described herein. The polymeric material described herein is useful for forming implantable medical devices (e.g. ophthalmic lenses, breast implants, and body augmentation devices). In addition, medical devices formed from the polymer material can be used to controllably release a therapeutic agent. Also, the polymeric material may be used to prepare topical compositions or other applications or devices where control of a mechanical property such as material modulus is important.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com