Anti-cracking low-shrinkage-deformation fiber-cement product and production method thereof

A technology of fiber cement and production methods, which is applied in the direction of chemical instruments and methods, layered products of hydraulically setting substances, layered products, etc., can solve the problems of ineffective control of surface microcracks, difficulty in reinforcing concrete dispersion, and ease of construction. Poor performance and other problems, to prevent separation and bleeding, to achieve dry maintenance, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

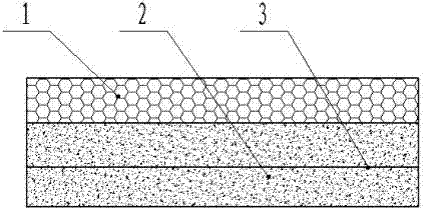

Image

Examples

Embodiment example 1

[0062] 1) Mix 25kg (25%) of cement, 24 kg (24%) of sand, 10kg (10%) of glass debris, 5kg (5%) of powdered pigment, 0.5kg (0.5%) of alumina-based ultra-short fiber, boric acid Aluminum ultra-short fiber 0.5kg (0.5%), PP fiber 2kg (2%), carbon fiber 3kg (3%), soap-free siloxane modified polypropylene emulsion 8kg (8%), water reducing agent naphthalene sulfonate formaldehyde condensation 1kg (1%) of food, 1kg (1%) of early strength agent sulfate, 0.5kg (0.5%) of antifreeze calcium chloride, 0.5kg (0.5%) of thickener hydroxypropyl methylcellulose, and expansion agent sulfur 4kg (4%) of aluminate, 5kg of metakaolin (5%) and 10kg of water (10%) are mixed according to the proportion by weight, and the flexible anti-crack surface layer mortar is made after stirring evenly.

[0063] 2) Make a decorative layer of the prepared surface mortar in the mold by spraying method, and let it cure naturally for 10 minutes;

[0064] 3) Cement 28kg (28%), sand 52kg (52%), PP fiber 1kg (1%), carbon...

Embodiment example 2

[0071] 1) Mix cement 45kg (45%), fine stones 30.5kg (30.5%), ceramic debris 10kg (10%), liquid pigment 3kg (3%), zirconia-based ultra-short fiber 0.3kg (0.3%), boric acid Magnesium-based ultra-short fiber 0.2kg (0.2%), PVA fiber 1kg (1%), glass fiber 2kg (2%), soap-free siloxane modified styrene-acrylic emulsion 5kg (5%), water reducing agent sulfonated melamine Formaldehyde condensate 0.5kg (0.5%), accelerator nitrite 0.5kg (0.5%), antifreeze agent potassium carbonate 0.5kg (0.5%), crystal expansion agent 1.5kg (1.5%), of which calcium: magnesium: silicon aluminum =2:5:3), 3kg of fly ash (3%), and 20kg of water (20%) are mixed according to the proportion of weight percentage, and the flexible anti-crack surface layer mortar is made after stirring evenly;

[0072] 2) Make a decorative layer in the mold with the prepared surface mortar by brushing method, and let it cure naturally for 20 minutes;

[0073] 3) Mix 34kg (34%) of cement, 46kg (46%) of sand, 2kg (2%) of glass fiber...

Embodiment example 3

[0080] 1) Mix 28kg (28%) of cement, 30kg (30%) of sand, 25kg (25%) of metal debris, 1kg (1%) of polycarboxylate (1%) of water reducing agent, 1kg (1%) of triethanolamine (1%) of early strength agent, antifreeze Sodium nitrite 0.5kg (0.5%), thickener hydroxyethyl cellulose 0.5kg (0.5%), expansion agent magnesia 1kg (1%) and water 13kg are mixed according to the following weight percentages, and stirred evenly Finally, it is made into flexible anti-crack surface mortar;

[0081] 2) Make a decorative layer in the mold with the prepared surface mortar by laying vibration method, and let it cure naturally for 30 minutes;

[0082] 3) Mix cement 30kg (30%), sand 46kg (46%), PVA fiber 2kg (2%), steel fiber 3kg (3%), glass fiber 2kg (2%), soap-free siloxane modified styrene-acrylic Emulsion 1.5kg (1.5%), water reducer sulfonated melamine formaldehyde condensate 0.5kg (0.5%), early strength agent nitrite 0.5kg (0.5%), antifreeze agent potassium carbonate 0.5kg (0.5%), expansion agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com