Glue-powder pervious concrete and preparation method thereof

A technology of permeable concrete and rubber powder, applied in the field of building materials, can solve problems such as threatening human health, polluting the environment, occupying land resources, etc., and achieve the effect of promoting resource reuse, low elastic modulus, and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

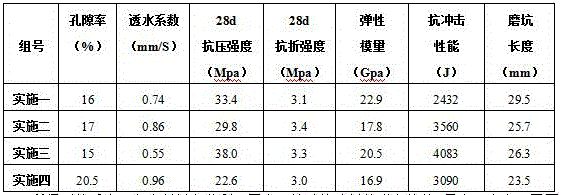

Examples

Embodiment 1

[0029] Use the following components as raw materials to prepare rubber powder permeable concrete: cement 350 kg / m 3 1400 kg / m of coarse aggregate passing through a square hole sieve of 0.085-2.36mm 3 , admixture 7 kg / m 3 (Polycarboxylate superplasticizer accounts for 25 wt%, viscosity modifier accounts for 0.6 wt%; gluconate retarder accounts for 0.4 wt%, and the balance is water), fly ash and silica fume (the mass ratio of the two is 1 : 2) 20 kg / m 3 , waste tire rubber powder 10 kg / m 3 , Styrene-acrylic latex powder 4 kg / m 3 , methyl cellulose ether 0.35 kg / m 3 and water 100 kg / m 3 , the specific steps are:

[0030] 1) Add all cement, fly ash and silica fume, waste tire rubber powder, styrene-acrylic latex powder, methyl cellulose ether, 50% water and 70% admixture into a forced mixer, and stir for 40 s Slurry preparation.

[0031] 2) Then put the coarse aggregate into the slurry prepared in step 1) and continue to stir for 60s to carry out the slurry coating treatme...

Embodiment 2

[0034] The following components are used as raw materials to prepare rubber powder permeable concrete: cement 365 kg / m 3 1500 kg / m of coarse aggregate passing through a square hole sieve of 2.36-4.75mm 3 , Admixture 8.65 kg / m 3 (naphthalene-based water reducer accounts for 15 wt%, viscosity modifier accounts for 0.8 wt%; gluconate retarder accounts for 0.6 wt%, and the balance is water), silica fume 24 kg / m 3 , waste rubber powder 27 kg / m 3 , Acrylic powder 5 kg / m 3 , ethyl cellulose ether 0.4 kg / m 3 and water 120 kg / m 3, the specific steps are:

[0035] 1) Add all cement, silica fume, waste tire rubber powder, acrylate rubber powder, ethyl cellulose ether, 40% water and 80% admixture to a forced mixer, and stir for 30 s to prepare a slurry.

[0036] 2) Then put the coarse aggregate into the slurry prepared in step 1) and continue to stir for 80s to carry out the slurry coating treatment.

[0037] 3) Add the rest of the water and admixture, and continue to stir for 70s ...

Embodiment 3

[0039] Use the following components as raw materials to prepare rubber powder permeable concrete: cement 425 kg / m 3 1750 kg / m of coarse aggregate passing through a round hole sieve of 5-10mm 3 , Admixture 7.9 kg / m 3 (Polycarboxylate superplasticizer accounts for 30 wt%, viscosity modifier accounts for 0.4 wt%; sucrose retarder accounts for 0.8 wt%, and the balance is water), mineral powder and silica fume 30 kg / m 3 (the mass ratio of the two is 1:2), waste rubber powder 20 kg / m 3 , Epoxy resin powder 6 kg / m 3 , hydroxyethyl cellulose ether 0.5 kg / m 3 and water 125 kg / m 3 , the specific steps are:

[0040] 1) Add all cement, mineral powder and silica fume, waste tire rubber powder, epoxy resin powder, hydroxyethyl cellulose ether, 70% water and 60% admixture into a forced mixer, and stir for 25 s for slurry body preparation.

[0041] 2) Put the coarse aggregate into the slurry prepared in step 1) and continue to stir for 100s to carry out the slurry coating treatment.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com