Patents

Literature

85results about How to "High permeability coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

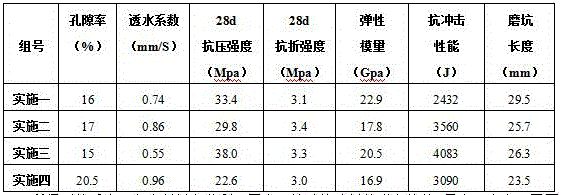

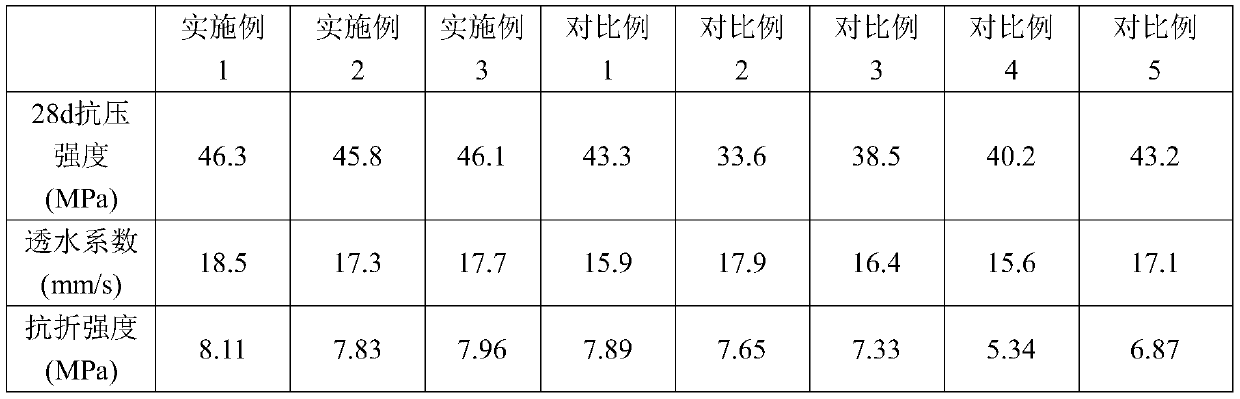

Glue-powder pervious concrete and preparation method thereof

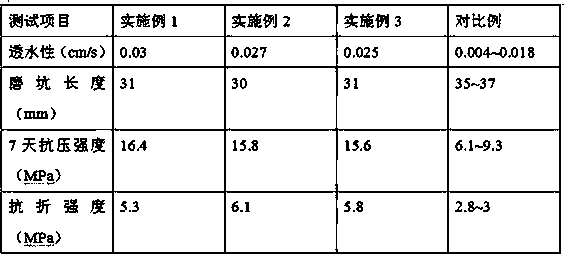

The invention discloses glue-powder pervious concrete and a preparation method thereof. The glue-powder pervious concrete contains the following ingredients in parts by mass: 300-450 parts of cement, 1,300-1,800 parts of coarse aggregates, 2-15 parts of additives, 20-50 parts of mineral admixture, 6-50 parts of waste / used tire rubber powder, 6-12 parts of cementing agent, 0.2-1.0 part of humectant and 100-150 parts of water. According to the glue-powder pervious concrete, the compressive strength, folding strength, porosity, coefficient of water permeability, wear resistance and the like are in line with technical regulations for pervious concrete pavements CJJ / T135-2009; meanwhile, the glue-powder pervious concrete also has the advantages of high toughness, high shock resistance, low elastic modulus, and the like, thereby playing a very good role in promoting the development of high-performance concrete technologies in the construction of sponge cities. The preparation method provided by the invention comprises three steps, i.e., carrying out mortar preparation, carrying out mortar coating treatment and carrying out stirring, thereby obtaining the finished product, and novel equipment is not required to be increased, so that the method is easy and feasible.

Owner:重庆绿恒环保科技有限公司

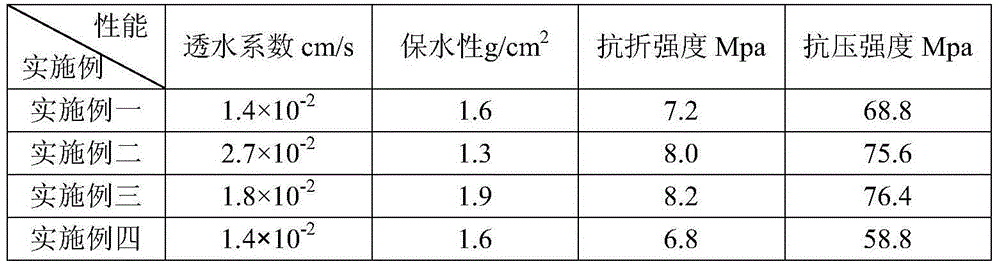

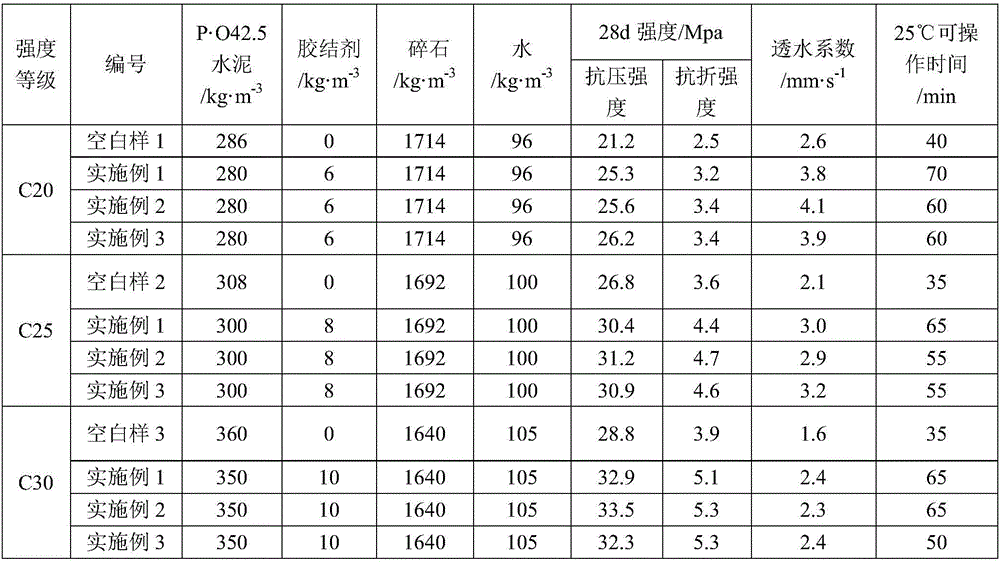

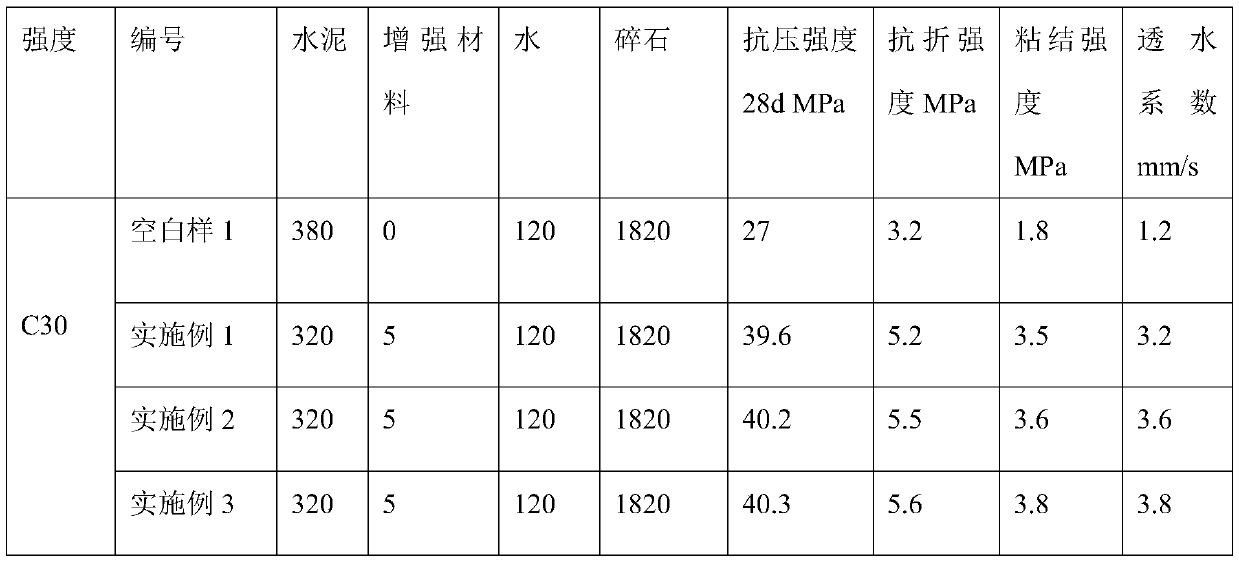

Novel ecological permeable concrete material and preparation method thereof

ActiveCN107098637AIncrease stickinessImprove water retentionIn situ pavingsPaving gutters/kerbsPorosityMaterials science

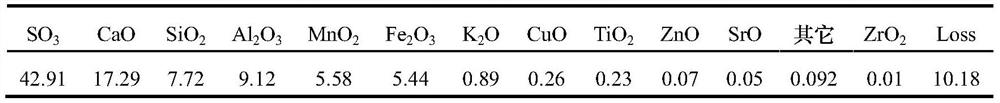

The invention discloses a novel ecological permeable concrete material and a preparation method thereof. The concrete material has the advantages of high strength, high permeable coefficient, adjustable porosity, shorter curing time, simple preparation method and the like, has a very high application value in a sponge city building process, and has important significance to the realization of continuous development of permeable concrete and the maintenance of underground water ecological balance. The novel ecological permeable concrete material is prepared from the following specific components in parts by mass: 400 to 500 parts of natural aggregate, 75 to 92 parts of ordinary Portland cement, 4 to 7 parts of desulfurized gypsum, 4 to 10 parts of silica fume, 0.5 to 1.5 parts of water reducing agent, 22 to 36 parts of water, 4 to 12 parts of adhesive polymer and 0.5 to 1.2 parts of rapid hardening early strength agent.

Owner:SHANDONG UNIV

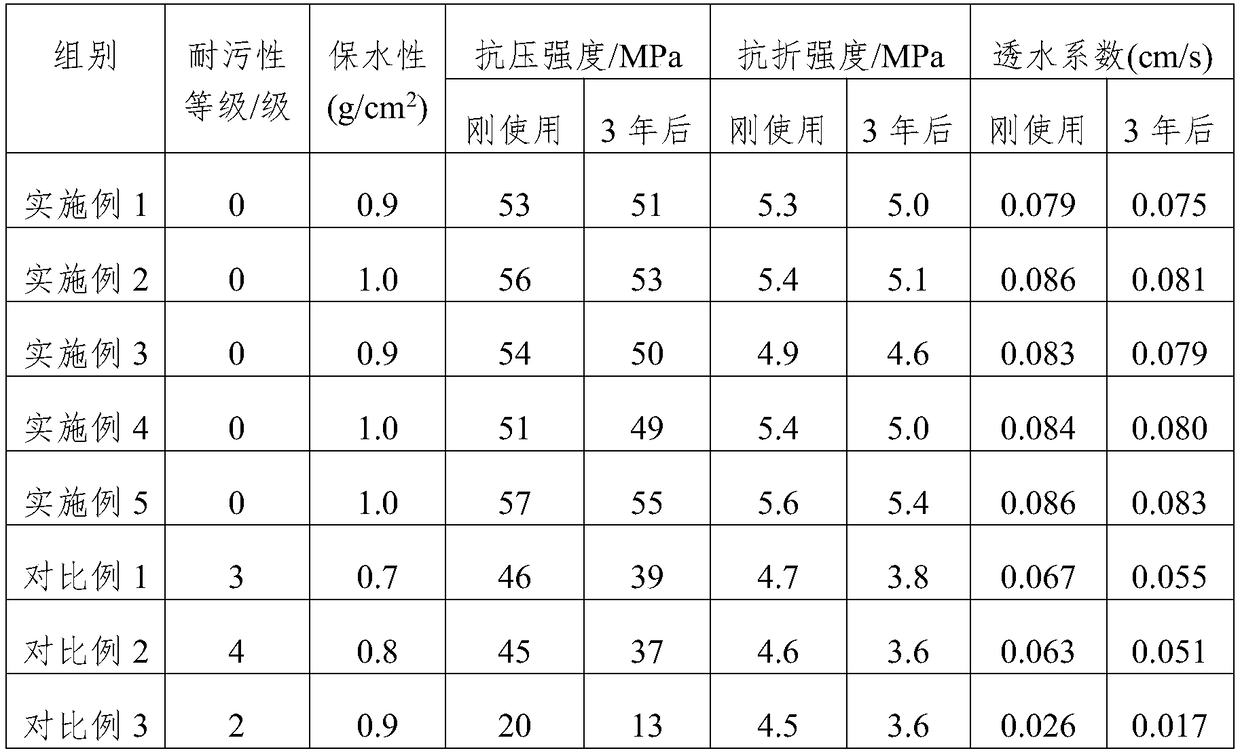

Pervious concrete additive and pervious concrete

InactiveCN107686274AImprove adhesionImprove work performanceCeramicwareCement slurryWork Performances

The invention discloses a pervious concrete additive and pervious concrete prepared from the pervious concrete additive. The pervious concrete additive is prepared from the following raw materials inparts by weight: 25 to 40 parts of re-dispersible latex powder, 15 to 30 parts of hydroxypropyl methylcellulose, 35 to 60 parts of water reducing agents and 20 to 50 parts of modified nanometer silicon dioxide. The pervious concrete additive has the advantages that the bonding force of cement slurry and aggregate can be enhanced; the work performance of the concrete can be effectively improved; the intensity and the pervious coefficient of the concrete can be effectively improved; the service life of the concrete can be prolonged.

Owner:CHINA MCC17 GRP

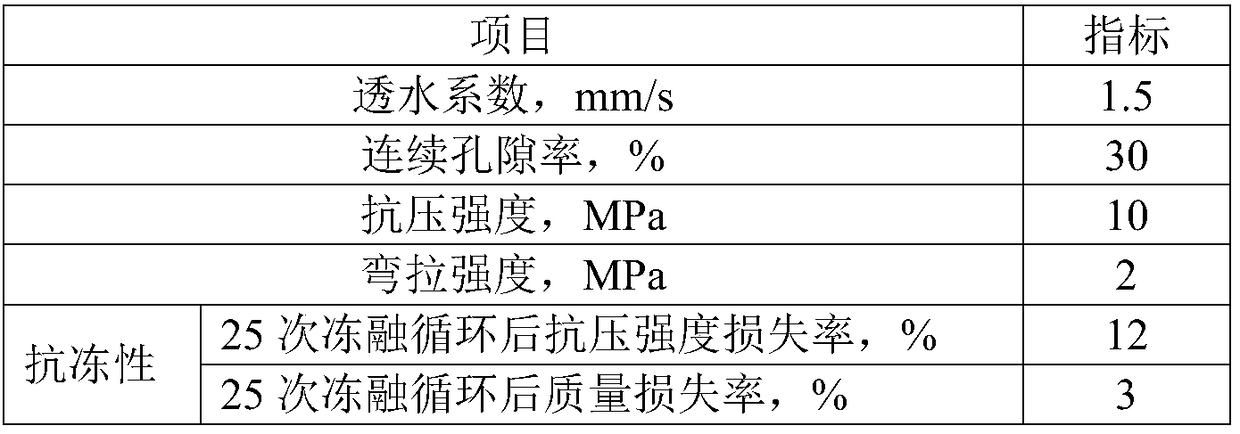

Multi-pore high-strength sintering permeable floor brick

InactiveCN105330318ASolve intractableHigh porosityCeramic materials productionCeramicwarePolyvinyl alcoholSlag

The invention discloses a multi-pore high-strength sintering permeable floor brick. The multi-pore high-strength sintering permeable floor brick is prepared from, by weight, 40-43 parts of sewage plant sludge, 6-7 parts of rice hulls, 4-5 parts of potassium feldspar powder, 10-12 parts of fly ash, 10-12 parts of water glass, 29-31 parts of basalt rubble, 5-6 parts of sawdust, 9-11 parts of mesoporous silica, 0.8-1 part of a silane coupling agent kh560, 3-4 parts of polyvinyl alcohol fibers, 7-9 parts of blast furnace slag and 2-3 parts of chemical waste gypsum powder. According to the multi-pore high-strength sintering permeable floor brick, the mesoporous silica, the sawdust and the polyvinyl alcohol fibers are added in preparation of the brick, and a composite through hole structure can be formed through sintering molding after technological modification; in addition, multiple pores distributed densely are obtained by reasonably regulating the particle size of mixed aggregates; meanwhile, the product is high in compressive strength, firm, durable and high in permeable coefficient.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

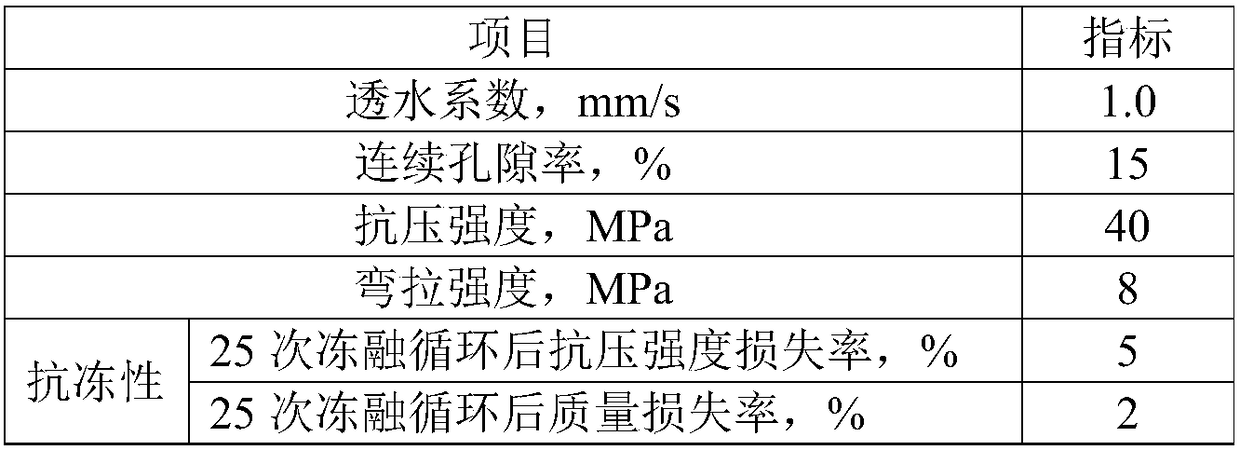

Cement polymer based high-temperature concrete permeable pavement bricks and manufacturing method thereof

The invention provides cement polymer based high-temperature concrete permeable pavement bricks and a manufacturing method thereof and belongs to the field of road surface pavement materials. Each cement polymer based high-temperature concrete permeable pavement brick is prepared from a permeable base layer and a permeable surface layer, wherein the permeable base layer is prepared from 290 to 345 parts of cement A, 0 to 6 parts of ultra-light aggregate A, 1630 to 1765 parts of coarse aggregate, 255 to 290 parts of sand, 0.50 to 0.85 part of polymer emulsion A, 0.35 to 0.50 part of an interface reinforcing agent A and 0 to 0.65 part of a loose soil constriction resisting agent; the permeable surface layer is prepared from 390 to 425 parts of cement B, 0 to 2 parts of ultra-light aggregate B, 0 to 7.5 parts of micro-pore fine aggregate, 1350 to 1400 parts of wear-resisting fine aggregate, 0.65 to 0.85 part of polymer emulsion B, 0.65 to 0.95 part of an interface reinforcing agent B, 8 to 13 parts of a deicer salt scaling resisting and alkali adsorption agent and 15 to 17 parts of pigment. According to the cement polymer based high-temperature concrete permeable pavement bricks, all technological performances of the permeable bricks are comprehensively improved.

Owner:葛兆明 +3

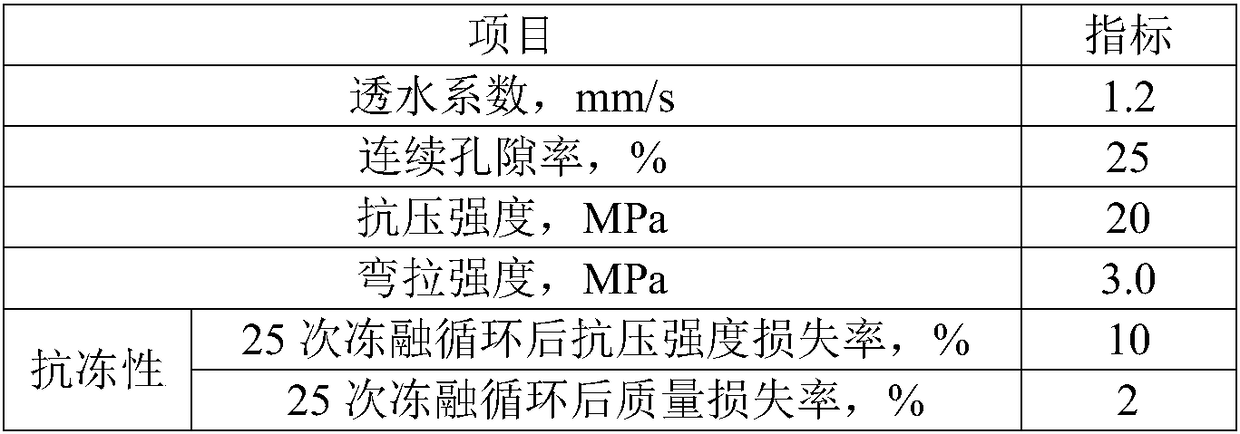

High-performance vegetation pervious concrete

InactiveCN108558336AReduce pore alkalinityHigh connected porosity and permeability coefficientCeramicwareSilica fumeVegetation

The invention discloses high-performance vegetation pervious concrete which is prepared from cement, gypsum, auxiliary binding materials, aggregates, additives, fiber and water. The cement is a mixture of ordinary Portland cement and low-alkalinity sulphoaluminosilicate cement; the auxiliary binding material is a mixture of coal ash, slag and silica fume, and the additives include a mixture of a water reducer, an early strength agent, a redispersible powder and a thickening agent. The high-performance vegetation pervious concrete has the advantages of being high in connection porosity and permeation coefficient, low in pH value, good in mechanical property and durability and the like.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

Energy-saving sintering water-permeable brick adding with coal residues

The invention discloses an energy-saving sintering water-permeable brick adding with coal residues. The energy-saving sintering water-permeable brick adding with the coal residues is prepared from, by weight, 40-43 parts of sludge of sewage treatment plants, 6-7 parts of rice husks, 4-5 parts of potash feldspar powder, 10-12 parts of fly ash, 10-12 parts of water glass, 3-4 parts of calcium fluoride, 5-6 parts of glycerin, 18-20 parts of shale, 14-16 parts of coal residues, 2.5-3.5 parts of coke powder, 1.5-2 parts of paraffin, 9-11 parts of alumina-chrome slags and 5-6 parts of calcium carbonate. According to the energy-saving sintering water-permeable brick adding with the coal residues, treated coal residue and shale mixed coarse aggregate is added, the plasticity index of a brick body can be increased, a green brick is made to be denser, and the strength and durability of the green brick are improved. According to the water-permeable brick prepared through sintering, the combustible feature of the coal residues can be utilized, coal resources are saved, and the brick is friendly to the environment; meanwhile, the energy-saving sintering water-permeable brick adding with the coal residues is good in durability, high in permeation coefficient and capable of saving energy and protecting the environment.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Permeable ceramic brick manufactured from rare earth tailings and manufacturing method thereof

The invention discloses a permeable ceramic brick manufactured from rare earth tailings. The permeable ceramic brick is manufactured by wrapping binding coarse rare-earth tailing particles with a wrapping material. The permeable ceramic brick is manufactured from the following raw materials: 65-80 wt% of coarse rare-earth tailings, 3-10wt% of fine rare-earth tailings, 2-6wt% of clay and 10-20wt% of flux, wherein the mixture of the fine rare-earth tailings, the clay and the flux functions as the wrapping material. In addition, the invention further discloses a manufacturing method of the permeable ceramic brick. The waste rear-earth resources are recycled, and the permeable ceramic brick with good water permeability and water retention and high strength is obtained, thus the purpose of protecting environment can be achieved, and the development of industry, regional economic and urbanization can be promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Recycled aggregate water-permeable brick and production method thereof

ActiveCN110407533AHigh strengthIncrease added valueSolid waste managementCeramicwareBrickCompressive strength

The invention provides a recycled aggregate water-permeable brick and a production method thereof. The recycled aggregate water-permeable brick comprises a base layer, and the base layer comprises, byweight, 95-105 parts of recycled aggregates, 14-16 parts of cement, 14-16 parts of fly ash and 0.22-0.32 part of a water reducer. The production method comprises the following steps: uniformly mixingthe cement, the fly ash and the water reducer, adding water, performing stirring, and adding wetted aggregates; adding the obtained mixture into a mold, and carrying out vibration extrusion molding under 1.5-3 MPa for 15-30 s; and demolding the obtained water-permeable brick, standing the water-permeable brick for 2 h, transferring the water-permeable brick into an autoclave, and curing the water-permeable brick under 0.8-1 MPa at 173-185 DEG C for 6-10 h. The aggregates are recycled aggregates, the use amount of the cement is small, the water-permeable brick has a high compressive strength and a high water permeability, the molding process is quick and simple, and has a low cost, and the environmental pollution can be effectively reduced, so the recycled aggregate water-permeable brick is suitable for large-scale industrial production.

Owner:QINGDAO AGRI UNIV

Inorganic material adhesive and preparation method of same

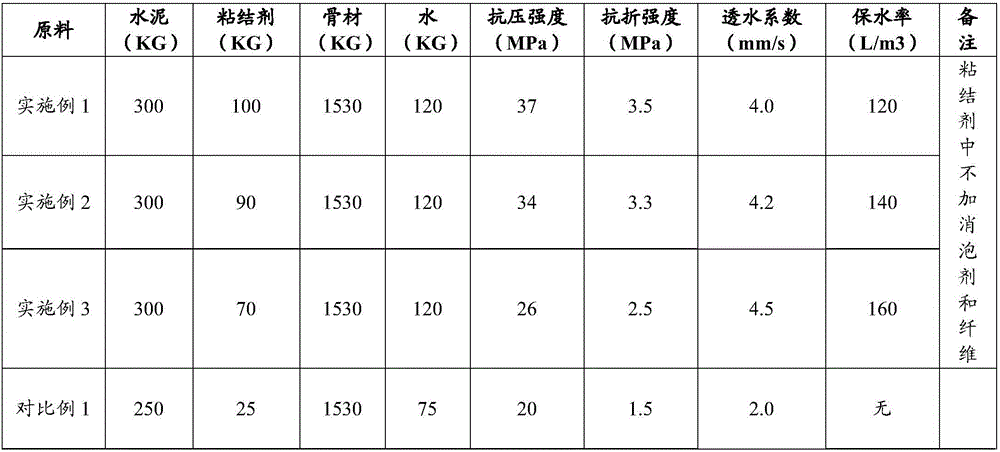

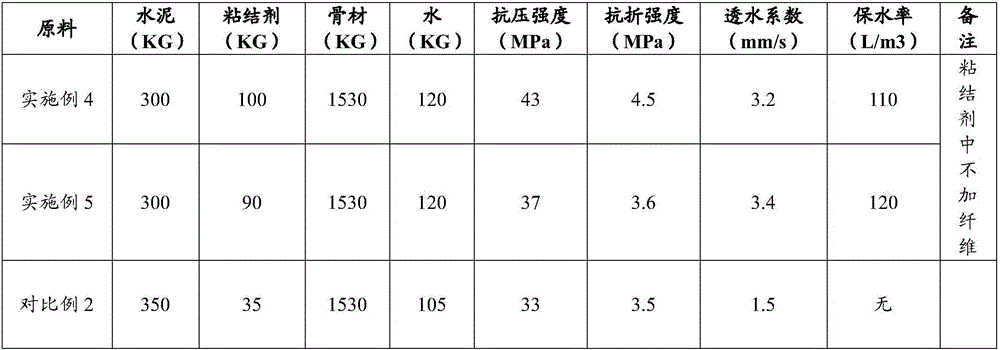

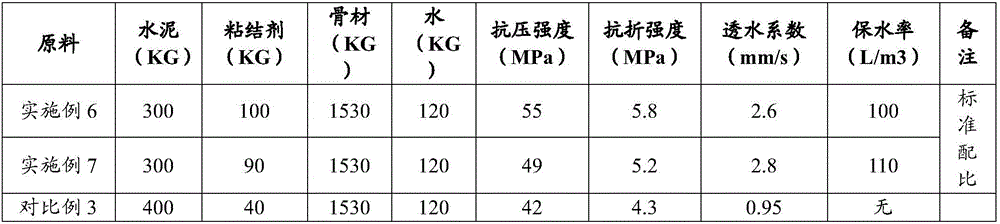

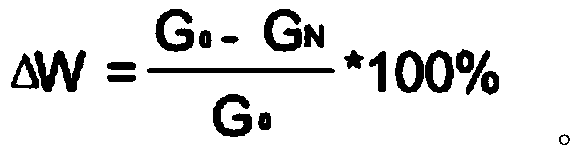

The invention relates to an inorganic material adhesive comprising: a first activator, a second activator, a reduction decreasing agent, an efflorescence prevention agent, an inorganic pigment and fibers. The mass of the first activator is 1-3% of that of the second activator. The mass of the reduction decreasing agent is 0.5-1.5% of that of the second activator. The mass of the efflorescence prevention agent is 3-6% of that of the second activator. The mass of the inorganic pigment is 10-20% of that of the second activator. The mass of the fibers is 1-2.5% of that of the second activator. The invention also relates to a preparation method of the inorganic material adhesive. The inorganic material adhesive, when being used in construction of a water permeable pavement, enables the pavement to have high water permeation coefficient, high water retention, high strength, high durability and no environment pollution, wherein the water permeation coefficient is 2.6-6.3 mm / s, the water retention rate is 100-160 l / m<3>, compressive strength is 20-55 MPa and flexural strength is 2.5-5.8 MPa. The preparation method avoids dust pollution and is lower than 5 mg / Nm<3> in dust emission. The inorganic material adhesive has stable components and is lower than 0.05% in component fluctuation, so that the system has high operation rate being more than 98%.

Owner:上海玖鼎环保科技有限公司

Tailings-ceramsite light permeable brick and preparation method thereof

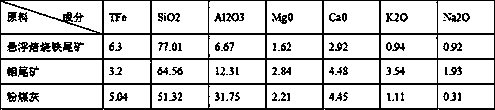

The invention provides a tailings-ceramsite light permeable brick and a preparation method thereof. The method includes preparation of tailings ceramsite and the tailings-ceramsite light permeable brick. The tailings-ceramsite light permeable brick is prepared from, by weight, 1000 parts of the tailings ceramsite, 250-300 parts of cement, 30-50 parts of suspended roasting iron tailings, 0-30 partsof silicon ash, 0-80 parts of coal ash, 2.8-3.0 parts of a water reducer and 100-120 parts of water; the tailings ceramsite comprises, by weight, 20%-30% of the suspended roasting iron tailings, 40%-60% of molybdenum tailings, 15%-25% of the coal ash and 5% of coal dust. The tailings-ceramsite light permeable brick has the advantages of excellent performance, light weight, high strength, high permeable coefficient, low cost and good social and economic benefits.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Surface treatment method for clay brick recycled fine aggregate and cement-based water-permeable brick surface layer

InactiveCN109206037ALow water absorptionHigh compressive strengthSolid waste managementCeramicwareAtherion elymusStearic acid

The invention especially relates to a surface treatment method for clay brick recycled fine aggregate and a cement-based water-permeable brick surface layer, belonging to the field of building materials. The surface treatment method comprises the following steps: vacuum saturation treatment of recycled fine aggregate; a mixing reaction; and washing and drying. According to the method, vacuum saturation treatment is implemented by immersing the recycled fine aggregate in a closed container with a calcium ion solution and then performing vacuumization until a pressure is 10 mbar or below; then the solution is removed through pumping, a catalyst and a mixture of stearic acid / stearate and water are poured, vacuumization is performed again until a pressure is 10 mbar or below, and the pressureis maintained for 2 h; and a temperature is raised to 40-80 DEG C for 1-3 h, then a reaction is performed for 1 to 3 h, and the recycled fine aggregate is taken out for washing and drying. The methodallows a calcium stearate hydrophobic layer to be generated on the surface of the porous recycled fine aggregate and in the pores of the porous recycled fine aggregate in situ through a simple process, so the water absorption rate of the recycled fine aggregate is significantly reduced, and the mechanical performance, water permeability and durability of a recycled cement-based water-permeable brick surface layer material are effectively improved.

Owner:ZHENJIANG SOBUTE NEW MATERIAL CO LTD +1

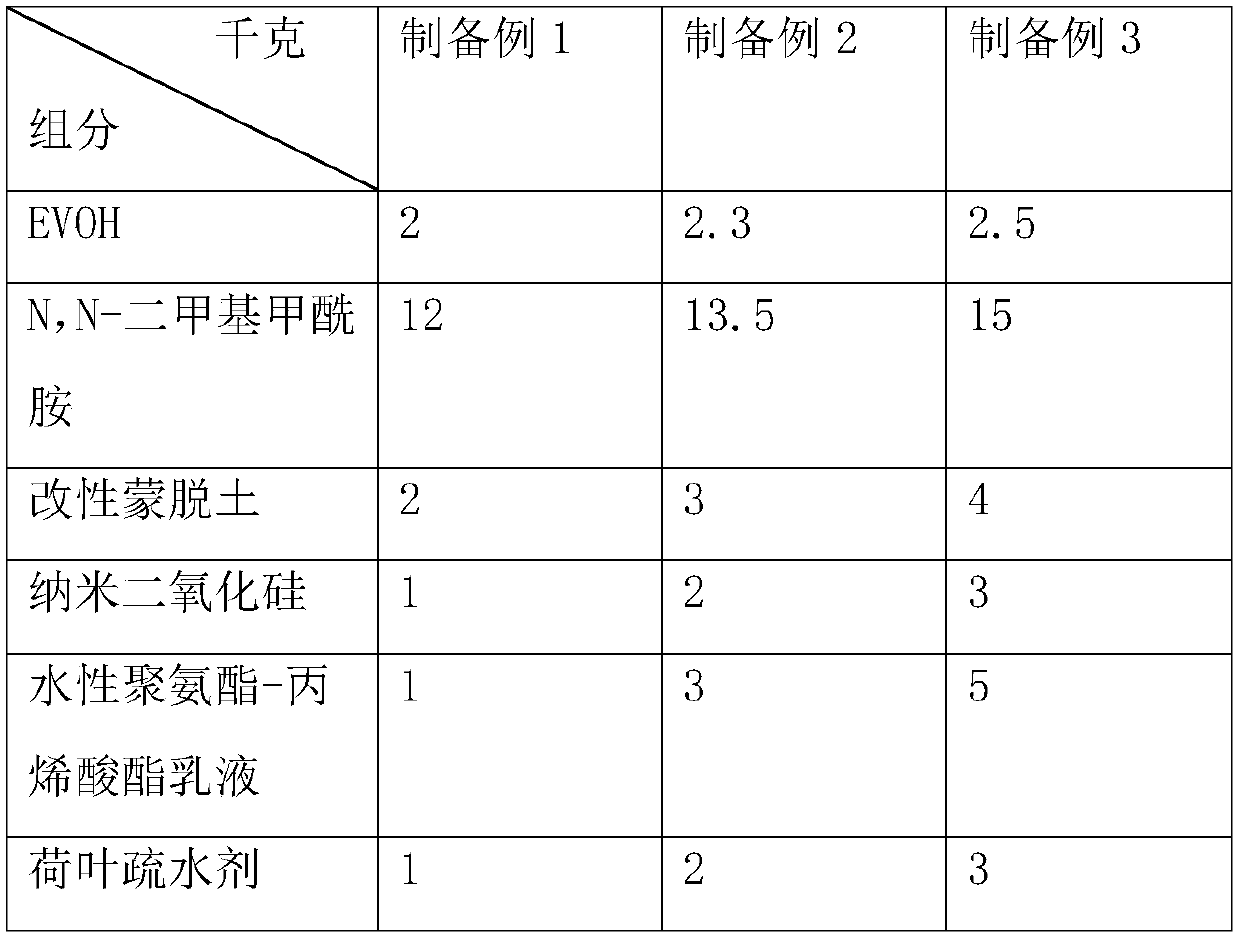

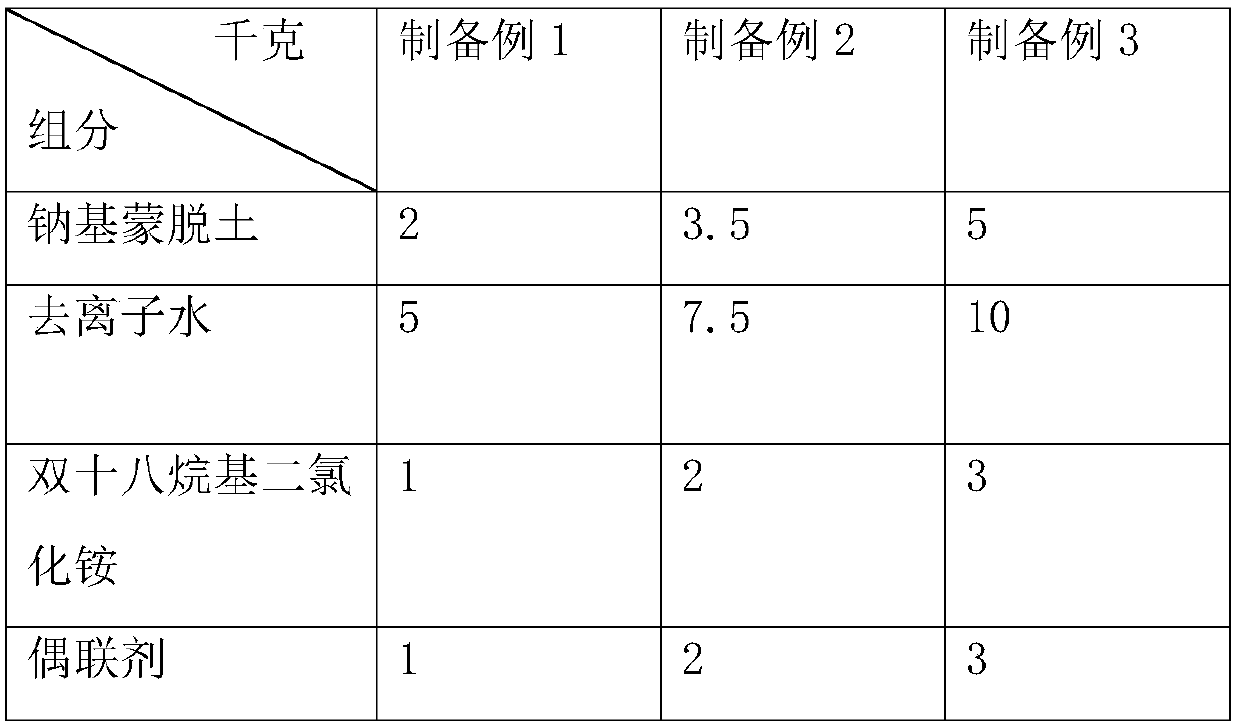

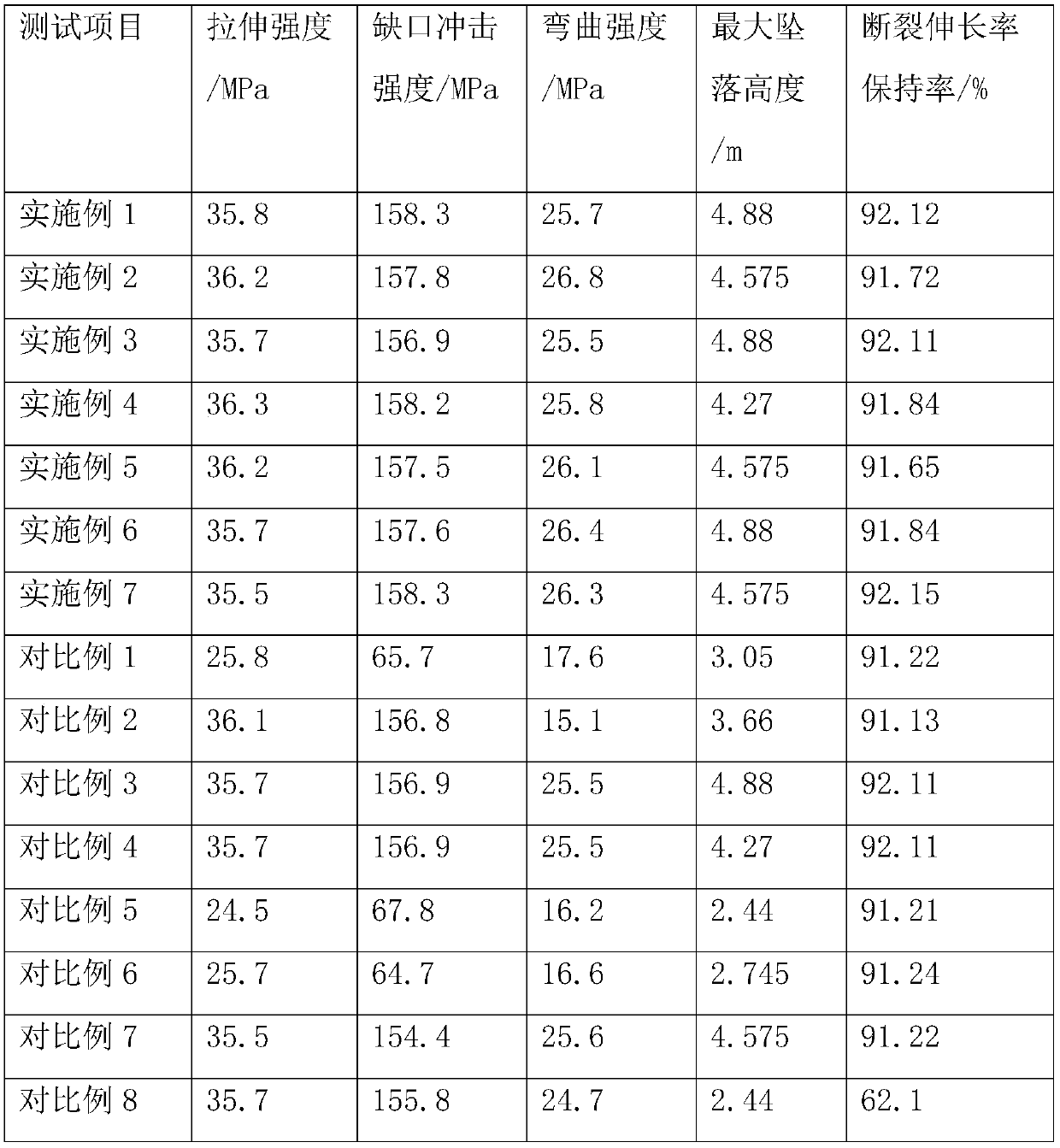

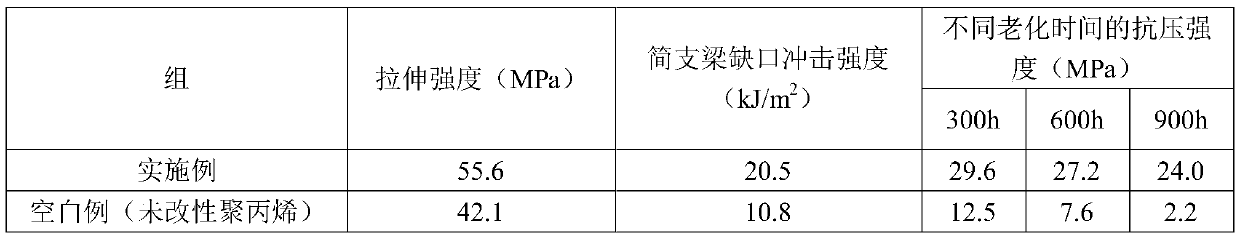

High-barrier-property pesticide packing bottle and preparation method thereof

ActiveCN109575410AImprove permeabilityImprove mechanical propertiesAdhesivesBlow moldingOrganic chemistry

The invention discloses a high-barrier-property pesticide packing bottle and preparation thereof. The high-barrier-property pesticide packing bottle comprises a barrier layer, an adhesion layer and abase layer which adhere to one another successively from inside to outside, the barrier layer and the base layer are separately attached to the two sides of the adhesion layer, and the thickness ratioof the barrier layer, the adhesion layer and the base layer is 1: 0.5-0.8: 2-2.5. The preparation method comprises the following steps: S1, raw material fusing; S2, double-screw extrusion forming; S3, blow molding; and S4, blow molding of the barrier layer. The high-barrier-property pesticide packing bottle has excellent mechanical property and pesticide permeation resistance, and has the advantage of good barrier property. In addition, a pesticide packing bottle prepared by the preparation method is formed integrally, the mechanical property and the pesticide permeation resistance are excellent, and the barrier property is good.

Owner:杭州普信塑料包装有限公司

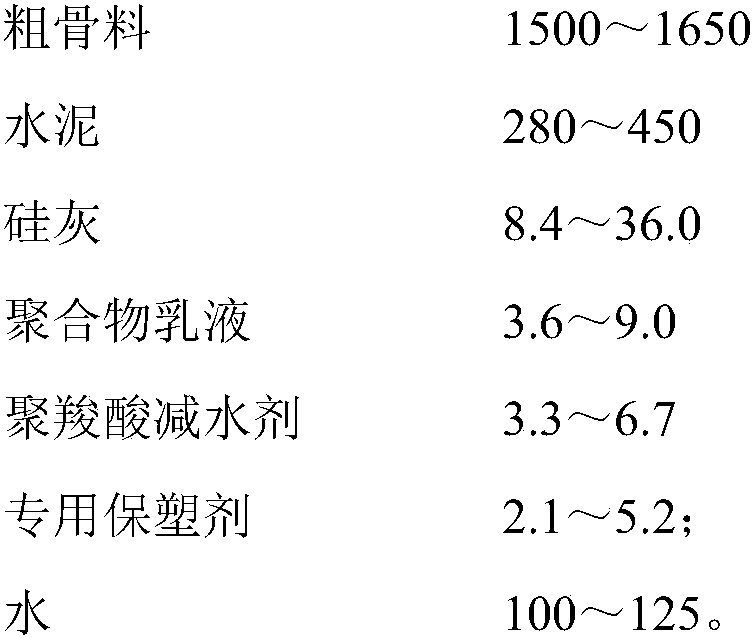

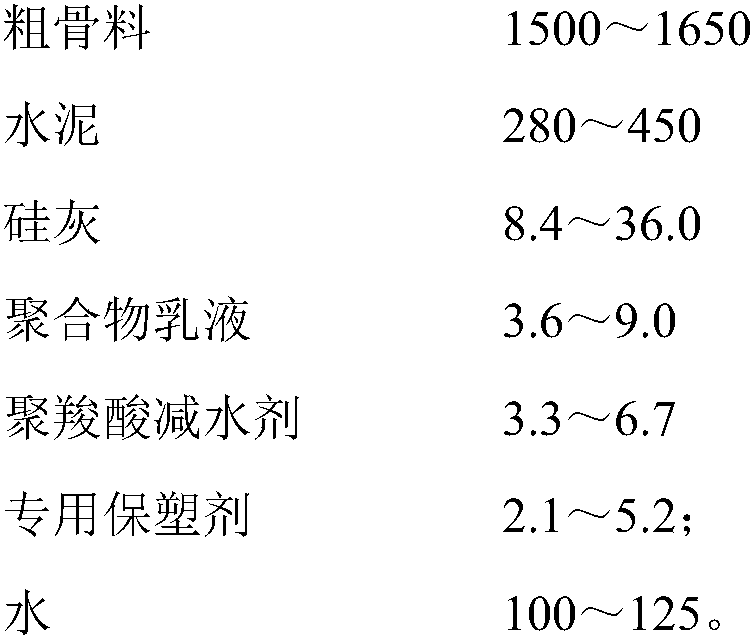

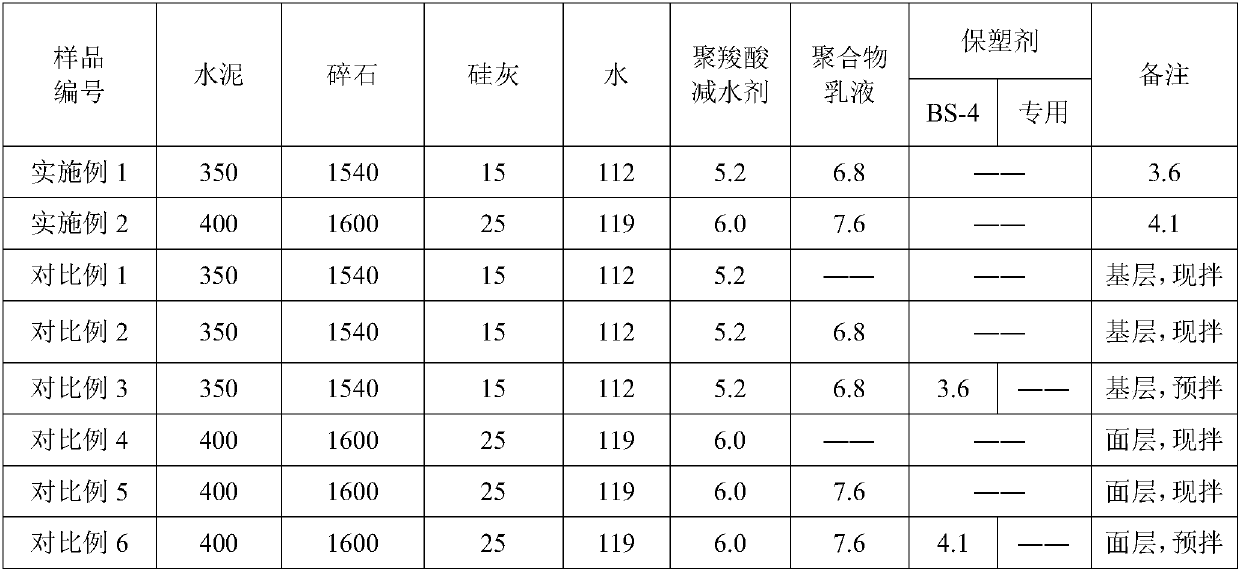

Premixed pervious concrete, preparation method and application thereof

ActiveCN109534748AGuaranteed water permeabilityImprove mobilityIn situ pavingsPaving gutters/kerbsBenzoyl peroxideSuperplasticizer

The invention discloses a premixed pervious concrete, a preparation method and an application thereof and belongs to the technical field of building material concrete. The premixed pervious concrete disclosed by the invention contains cement, coarse aggregate, silica fume, polymer emulsion, special plastic retaining agent, polycarboxylate superplasticizer and water, wherein the special plastic retaining agent is formed by taking macro-monomer ethylene glycol monovinyl polyethylene glycol ether, ethyl acrylate, sodium allysulfonate and hydroxyalkyl acrylate as unsaturated monomers, benzoyl peroxide as an initiator and 3-thiohydracrylic acid as a chain transfer agent and then compounding. According to the technical scheme of the invention, the premixed pervious concrete is capable of meetingthe demand of large-scale application in pervious concrete market, and meanwhile, the use performance of the premixed pervious concrete can be effectively guaranteed so as to guarantee the stabilityof engineering construction quality.

Owner:CHINA MCC17 GRP

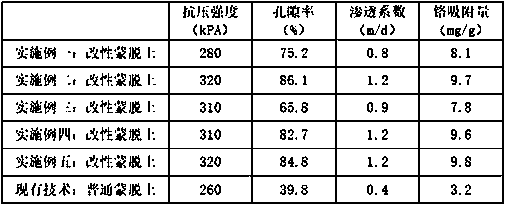

Biochar modified montmorillonite and preparation method thereof

ActiveCN109529760AHigh strengthHigh porosityOther chemical processesWater contaminantsPorosityRed mud

The invention relates to biochar modified montmorillonite and a preparation method thereof. Through being metered in parts by mass, the modified montmorillonite is prepared from the following ingredients including 70 to 90 parts of ordinary montmorillonite, 5 to 10 parts of modified calcium oxide, 2 to 5 parts of modified red mud, 2 to 6 parts of sodium carboxymethylcellulose, 2 to 4 parts of bauxite, 3 to 6 parts of polyacrylate and 2 to 4 parts of reinforced modifying agents; the reinforced modifying agents are prepared from 40 to 55 parts of biochar, 15 to 20 parts of white carbon black, 15to 20 parts of hollow glass microspheres and 15 to 20 parts of mica powder. Through the modification on ordinary montmorillonite, the prepared modified montmorillonite has the characteristics of higher intensity, larger pore rate and higher water permeation coefficient than the ordinary montmorillonite, and can be widely applied to the field of heavy metal adsorption or other polluted soil body restoration; the service life of the montmorillonite is greatly prolonged; the economic benefits are increased.

Owner:TAIYUAN UNIV OF TECH

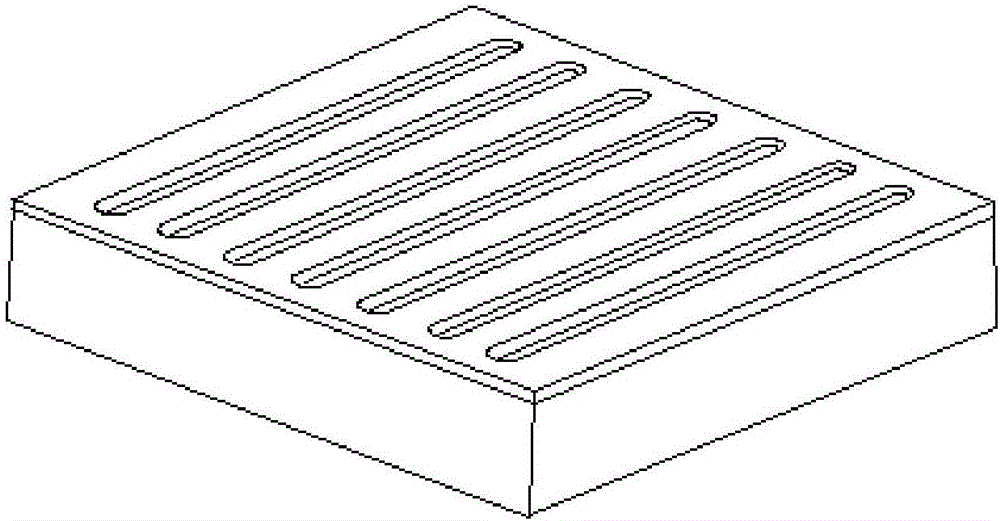

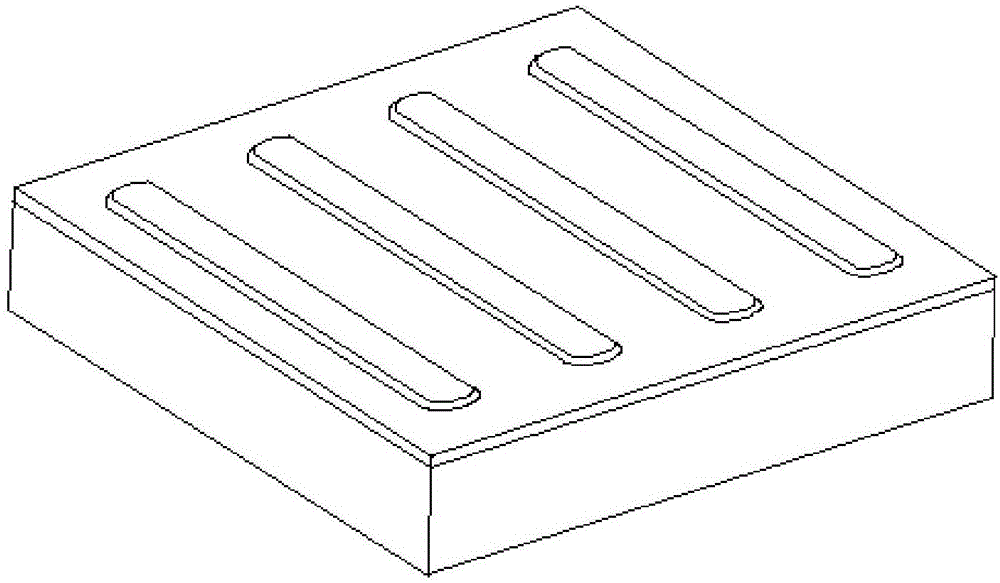

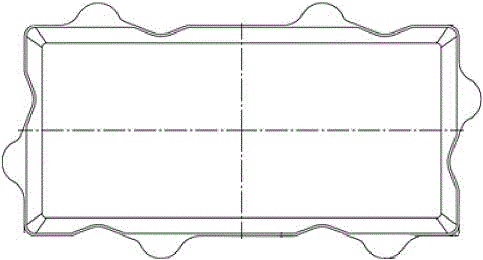

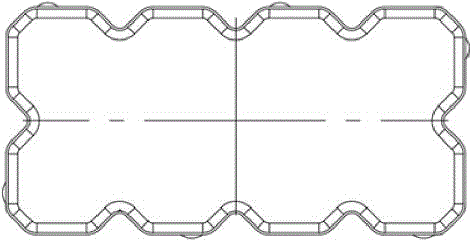

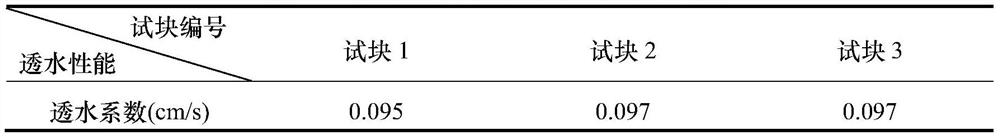

Concrete pavement brick capable of achieving gap water permeation and self water permeation

InactiveCN105401504AHigh permeability coefficientGood water permeabilityPaving gutters/kerbsBrickSurface layer

The invention relates to a concrete pavement brick capable of achieving gap water permeation and self water permeation. The integral body of the concrete pavement brick is a rectangular building brick, wherein the four corners of the building brick adopt rounding corners; the building brick comprises a bearing base layer and an ornamental surface layer arranged on the base layer; the four sides of the surface layer and the base layer are arranged as approximately serrate concave-convex edges; one or more U-shaped or V-shaped bumps and grooves are arranged on the concave-convex edges; and blank holders with the size of 1-10 mm are arranged on the four sides of the surface layer. A base material and a surface material are respectively adopted for preparing the bearing base layer and the ornamental surface layer of the water permeation concrete pavement brick, and the concrete pavement brick not only has the color and texture of an archaistic sintered brick and but also has shock resistance and high load carrying performances and good water permeation performance; and the brick is convenient and quick to pave, adjacent bricks are interlocked firmly and reliably, and the paved water permeation pavement truly has double effects of functionality and ecological landscape.

Owner:YANCHENG RONGLI NEW BUILDING MATERIAL

Resin-cement composite non-sintered water-permeable floor tile

InactiveCN105330230AImprove the disadvantage that large holes are easily blocked by mudHigh strengthSolid waste managementCeramicwarePorositySilanes

The invention discloses a resin-cement composite non-sintered water-permeable floor tile. The resin-cement composite non-sintered water-permeable floor tile is prepared from, by weight, 50-53 parts of desert sand, 4-5 parts of thermoplasticity phenolic resin, 0.6-0.7 part of urotropin, 0.2-0.22 part of calcium stearate, an adequate amount of water, 42-45 parts of portland cement of which the mark number is 42.5, 155-160 parts of municipal waste incineration residues, 20-22 parts of black corundum, 1-1.2 parts of gamma-aminopropyl triethoxy silane, 5-6 parts of wood sawdust, 3-3.5 parts of waterborne polyurethane emulsion, 5-6 parts of flyash and 0.7-0.8 part of polycarboxylate superplasticizer. According to the resin-cement composite non-sintered water-permeable floor tile, the wood sawdust is added in surface materials, a porous structure is obtained through carbonization, the porosity of the surface materials is further increased, and the effects of sound absorption and noise reduction are improved; the water-permeable floor tile is made by adopting a sintering-free forming process, energy saving and consumption reducing are achieved, and the product is high in stability, compressive strength and coefficient of water permeability.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

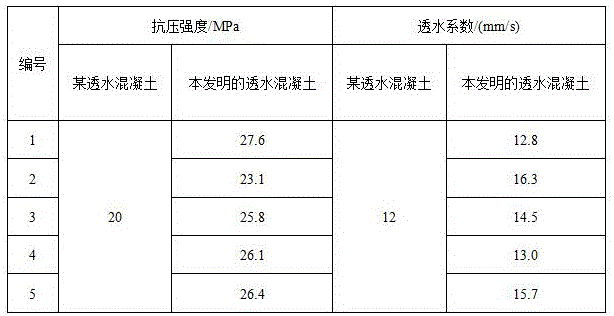

Water-permeable concrete and preparation method thereof

InactiveCN108191341AHigh permeability coefficientHigh compressive strengthCeramicwareRoad surfaceHigh intensity

The invention discloses water-permeable concrete, which is prepared from the following components in parts by mass: 300 to 500 parts of cement, 1,500 to 1,700 parts of aggregate, 9 to 15 parts of water reducing agent, 15 to 50 parts of enhancer and 90 to 125 pars of water, wherein the enhancer is prepared from silica fume, ultrafine powder and a nano material TiO2; in percentage by mass, in the enhancer, alumina accounts for 0.92 percent, calcia accounts for 0.14 percent, iron oxide accounts for 0.27 percent, magnesia accounts for 1.59 percent and silica accounts for 93.11 percent; the iglossis 3.18 percent. The water-permeable concrete prepared by the preparation method is high in water permeability coefficient and high in compressive strength, and meets a high-strength requirement of the construction of a road surface.

Owner:珠海市昂科装饰工程有限公司岳阳分公司

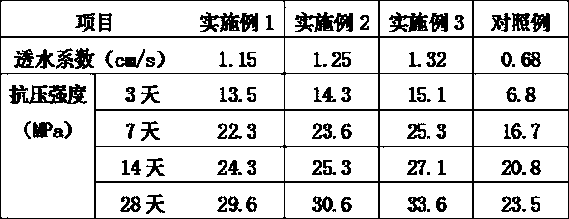

High-property water permeation concrete cementing agent and application thereof

InactiveCN106746880AExtend construction operation timeHigh compressive strengthBreaking strengthSilicon oxide

The invention discloses a high-property water permeation concrete cementing agent. The high-property water permeation concrete cementing agent is prepared from the following raw materials in percentage by mass: 68 to 72% of activated silicon dioxide powder, 18 to 22% of interface modifier, 7 to 10% of water reducing agent, 2 to 4% of thickening time control agent, and 0 to 2% of thickener. The high-property water permeation concrete cementing agent has the advantages that by blending the cementing agent into water permeation concrete, the construction operation time can be obviously prolonged; the compressive and break strengths are improved, and the water permeation coefficient is increased.

Owner:中建西部建设西南有限公司 +1

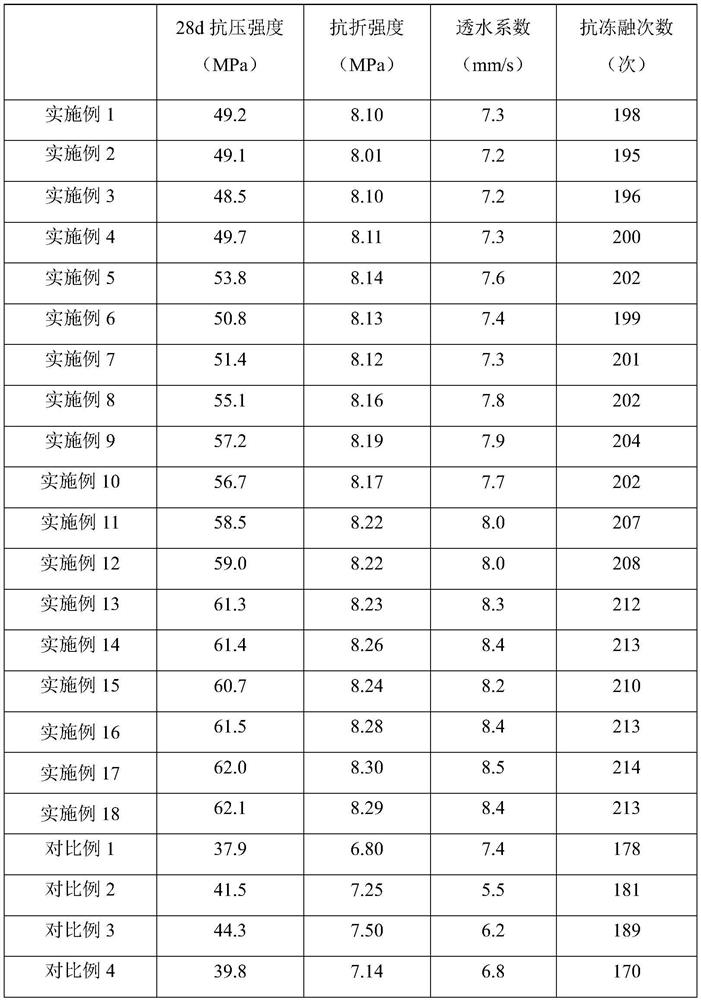

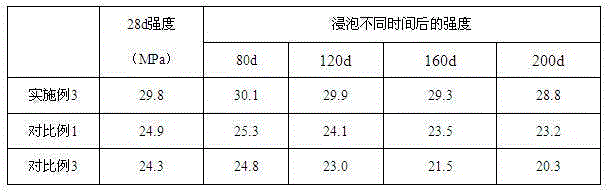

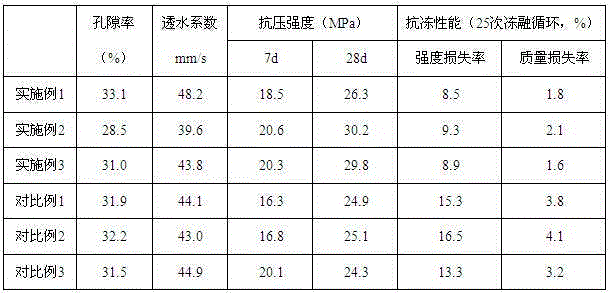

Pervious concrete and preparation method thereof

The invention relates to the technical field of concrete, in particular to pervious concrete which is prepared from the following raw materials in parts by weight: 40-60 parts of water, 90-130 parts of cement, 450-550 parts of basalt, 70-90 parts of an admixture, 1.5-2.7 parts of a water reducing agent, 0.5-1.7 parts of an air entraining agent, 35-55 parts of epoxy resin, 8-28 parts of a curing agent, 8-20 parts of modified fibers and 8-12 parts of an epoxy silane coupling agent. The modified fiber comprises the following components in parts by weight: 5-13 parts of modified basalt fiber and 3-7 parts of plant fiber; the modified basalt fiber is formed by processing basalt and attapulgite according to the weight ratio of (10-14): (2-5). According to the invention, the pervious concrete has a good water permeability coefficient, and the compressive strength, the breaking strength and the freeze-thaw resistance frequency are also improved.

Owner:福建省闽宏建材实业有限公司

Pervious concrete for highway engineering

ActiveCN105084838AHigh permeability coefficientHigh compressive strengthSolid waste managementSoil scienceSlag

The invention relates to anti-corrosion pervious concrete for highway engineering, and belongs to the technical field of building materials. The pervious concrete for highway engineering consists of the following materials in percentage by weight: 20-25% of gelled materials, 1.0-1.2% of calcium-rich powder, 5.0-6.0% of slag aggregate, 20-25% of steel slag aggregates, 2.5-3.2% of additives and the balanced coarse aggregates. On the premise that porosity and permeation coefficient of the anti-corrosion pervious concrete are obviously higher than those of the conventional pervious concrete, and compressive strength of the anti-corrosion pervious concrete is still higher than that of the conventional pervious concrete. Anti-corrosion performance is high, and the service life is prolonged obviously.

Owner:安萍

Water-permeable concrete

The invention discloses water-permeable concrete. The water-permeable concrete comprises the following components, in parts by weight: 100-110 parts of coarse aggregate, 12-17 parts of cement, 11-12 parts of water, 2-3 parts of gypsum powder, 1.5 parts of mineral slag, 1-3 parts of Dura fibers, and 4-6 parts of modified polypropylene particles, wherein the modified polypropylene particles are SEBSmodified particles. The water-permeable concrete provided by the invention has better freeze-thaw resistance, strong water permeability and excellent mechanical properties.

Owner:济南长兴建设商砼有限公司

Recovered construction waste regenerative water permeable brick and preparation method thereof

ActiveCN109455990ASolve the problem of low resource utilizationReduce miningAuxillary shaping apparatusBrickSludge

The invention discloses a recovered construction waste regenerative water permeable brick. The recovered construction waste regenerative water permeable brick is prepared from the following raw materials in parts by weight: 1800-1900 parts of construction waste, 850-950 parts of municipal sludge, 300-350 parts of cement, 400-500 parts of biogas residue, 350-450 parts of industrial waste residue, 350-450 parts of solid waste incineration slag, and 150-200 parts of water, wherein the industrial waste residue is one or more of fly ash, slag and coal residue. Solid waste of construction, industry,life and the like substitutes the natural raw materials to be processed into the water permeable brick, mining for natural resources is reduced, and energy is saved; and city waste can be subjected to harmless and resourceful treatment simultaneously, the pressure of the waste to cities is lowered, the problem that resourceful utilization of the waste of construction, industry and life is low issolved, and the purposes of turning the waste into treasure and protecting the environment are achieved.

Owner:双峰县梓门金峰环保砖厂

Novel anti-crack sinter-free energy-saving type water-permeable tile

InactiveCN105367020AImprove the disadvantage that large holes are easily blocked by mudHigh strengthFiberCellulose

The invention discloses a novel anti-crack sinter-free energy-saving type water-permeable tile. The tile is prepared from, by weight, 50-53 parts of desert sand, 4-5 parts of thermoplastic phenolic resin, 0.6-0.7 part of urotropin, 0.2-0.22 part of calcium stearate, an appropriate volume of water, 42-45 parts of Portland cement with the mark number of 42.5, 5-6 parts of coal ash, 2-3 parts of natural rubber paste, 2-2.5 parts of carboxymethylcellulose, 43-47 parts of vanadiumore tailings, 3-4 parts of glass fiber, 1-1.2 parts of Twain 80, 22-24 parts of anti-crack fiber, 88-93 parts of lightweight shale ceramsite, 22-25 parts of kaolin and 0.7-0.8 part of cellulose ether. Anti-crack fiber is added to the surface layer material and the bottom layer material; with the aid of the scientific and reasonable component proportion, the water-permeable tile prepared through the sinter-free process has excellent anti-crack performance, is firm, durable and high in water-permeable coefficient, and is environmentally friendly, free of pollution and capable of saving energy in the production process.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Water-permeable concrete cementing material and preparation method thereof

The invention belongs to the field of concrete and in particular discloses a water-permeable concrete cementing material and a preparation method thereof. A formula of the cementing material comprisesthe following components in parts by weight: 40 to 60 parts of ordinary portland cement, 10 to 25 parts of activated silicon dioxide powder, 5 to 8 parts of epoxy resin, 3 to 5 parts of sodium gluconate, 4 to 6 parts of stearate, 1 to 3 parts of a flocculating agent and 0.5 to 1.5 parts of a polycarboxylic acid water reducer. The formula of the cementing material, provided by the invention, is scientific and reasonable and all the components are complementary to each other, so that the wear resistance of water-permeable concrete can be improved, the continuous porosity is reduced, and the 3dcompression strength, 28d compression strength and water-permeable coefficient are remarkably improved.

Owner:湖南三恒建设园林工程有限公司

A water-based liquid reinforcing material for high-performance water-permeable concrete and a preparation method thereof

A water-based liquid reinforcing material for high-performance water-permeable concrete is disclosed. Raw materials of the water-based liquid reinforcing material include, by weight, 5-20 parts of powder reinforcing polymer, 35-50 parts of nanometer silica fume, 10-20 parts of a water reducing agent, 3-5 parts of a viscosity adjusting agent, 0.2-2 parts of a defoamer, 0.1-2 parts of a retarder, 0.5-1 part of a rheological agent and 10-15 parts of an early strength agent. A preparation method of the water-based liquid reinforcing material is also disclosed.

Owner:四川珠峰飞越科技有限责任公司

Pervious concrete

InactiveCN106587848AGood water hardnessHigh activitySolid waste managementMaterials scienceReducing agent

The invention discloses pervious concrete. The pervious concrete is prepared from the following raw materials according to weight: 320kg / m<3>-460kg / m<3> of cement, 80kg / m<3>-220kg / m<3> of desulphurization ash, 1170kg / m<3>-1300kg / m<3> of pebbles, 0kg / m<3>-100kg / m<3> of sand, 152kg / m<3>-190kg / m<3> of water and 1.5kg / m<3>-1.7 kg / m<3> of a water reducing agent. The pervious concrete has the beneficial effects that as lots of desulphurization ash is used, the problem that lots of land is occupied by accumulated desulphurization ash is solved; the pervious concrete has excellent performance and low cost; and the resource comprehensive utilization of the desulphurization ash is realized.

Owner:JIAHUA SPECIAL CEMENT

Method for preparing water permeable bricks based on coal gangue

The invention discloses a method for preparing water permeable bricks based on coal gangue, belonging to the field of water permeable bricks. According to the method, the coal gangue having adhesive property is melted at the high temperature in the carbon dioxide atmosphere; under the action of high temperature, the formed sodium metaaluminate reacts with carbon dioxide, so that sodium hydrogen carbonate is produced; sodium hydrogen carbonate is further decomposed by heat so as to produce sodium carbonate, and pore-forming is carried out, so that the porosity is increased; furthermore, the adsorbed lignin, cellulose and the like are thermally decomposed, so that the pores are protected; then, particles and cryolite powder are added, mixed and calcined, and the melting point of the mixtureis lowered by means of the cryolite powder; in a calcining process, a serpentine structure is destroyed, and magnesium-like olivine is formed, so that the porosity is increased, and the strength is improved; furthermore, silica in the calcined product reacts with the sodium carbonate so as to form sodium silicate, so that the bonding strength between the substances is improved, and the compressionresistance and the breaking strength are improved. The method solves the problems of high production cost and low compressive strength of the existing water permeable bricks.

Owner:方建波

Compressive permeable brick of basalt fiber composite polyvinyl chloride with improved sound absorption effect

The invention discloses a compressive permeable brick of basalt fiber composite polyvinyl chloride with an improved sound absorption effect. The compressive permeable brick is prepared from the following raw materials in parts by weight: 40-43 parts of granite edge scraps, 30-32 parts of waste concrete, 20-22 parts of 42.5-grade ordinary portland cement, 2-2.5 parts of polyester-cotton fabric leftover materials, 0.1-0.12 part of dimethylamine-epichlorohydrin polymer, 0.3-0.4 part of an early-strength polycarboxylate superplasticizer, a proper amount of water, 4-5 parts of polyvinyl chloride paste resin, 7.5-9 parts of basalt fiber, a proper amount of 5wt% sodium hydroxide solution, a proper amount of 10wt% acetate solution, a proper amount of deionized water, 1-1.2 parts of a silane coupling agent KH550, 2-3 parts of tributylcitrate an 0.5-0.6 part of calcium stearate. The prepared green brick has good plasticity, tenacity, compressive strength and abrasive resistance, has developed through holes, is high in permeation coefficient and has a noise absorption function.

Owner:岳承华

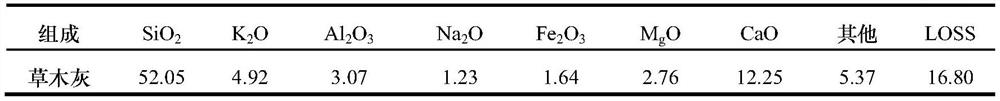

Water-permeable brick and method for preparing sintered water-permeable brick from manganese dioxide slag and plant ash

ActiveCN112341239AGuaranteed compressive strengthGuaranteed wear resistanceCeramic materials productionCeramicwareCompression moldingBrick

The invention discloses a water permeable brick and a method for preparing the sintered water permeable brick from manganese dioxide slag and plant ash. In the method for preparing the sintered water-permeable brick from the manganese dioxide slag and the plant ash, raw materials are composed of water and the following powder in parts by weight: 52-56 parts of electrolytic manganese dioxide slag,20-25 parts of plant ash of a biological power plant, 20-24 parts of quartz powder, 2.5-3 parts of sodium silicate and 18-22 parts of limestone powder with the fineness of 0.3 mm. The preparation process comprises four steps of preparation of a green body wet material, compression molding of the wet material, green body drying and sintering. A sintered microcrystalline ceramic structure taking pyroxene and wollastonite as main crystalline phases is formed in the water-permeable brick sintered by the method, so that the compressive strength and the wear resistance of the water-permeable brick are guaranteed, and the prepared water-permeable brick also has an obviously higher water permeability coefficient than a traditional water permeable brick, and is more ideal in comprehensive performance, and a new alternative way is provided for resource utilization of electrolytic manganese dioxide and biomass power generation waste residues.

Owner:HUNAN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com