Tailings-ceramsite light permeable brick and preparation method thereof

A technology of permeable bricks and ceramsite, applied in the field of building materials, can solve the problems of high production cost of permeable bricks, poor anti-thaw performance, etc., and achieve the effect of solving the problem of tailings stockpiling, low cost, and reduced usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The tailings ceramsite lightweight permeable brick and its preparation method in this embodiment comprise the following steps:

[0027] (1) Preparation of tailings ceramsite, including the following steps:

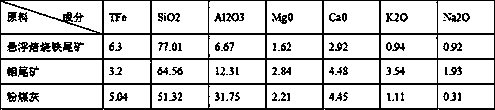

[0028] A. Suspended roasted iron tailings, molybdenum tailings, fly ash, and coal powder by weight percentage: suspend roasted iron tailings 20%, molybdenum tailings 60%, fly ash 15%, coal powder 5%, mix evenly, add water Stir and then granulate to make raw meal balls with a diameter of 5mm~10mm;

[0029] B. Dry the raw pellets at a temperature of 105°C for 2 hours;

[0030] C. Roasting the prepared dry ball at a temperature of 1110° C. for 40 minutes, and cooling naturally to obtain fired tailings ceramsite;

[0031] (2) Preparation of tailings ceramsite lightweight permeable bricks, including the following steps:

[0032] a. Mixing: mix the components according to the parts by weight: 1000 parts of tailings ceramsite, 300 parts of cement, 30 parts of suspended ...

Embodiment 2

[0036] The tailings ceramsite lightweight permeable brick and its preparation method in this embodiment comprise the following steps:

[0037] (1) Preparation of tailings ceramsite, including the following steps:

[0038] A. Suspended roasted iron tailings, molybdenum tailings, fly ash, and coal powder by weight percentage: 25% of suspended roasted iron tailings, 50% of molybdenum tailings, 20% of fly ash, 5% of coal powder, mix evenly, add water Stir and then granulate to make raw meal balls with a diameter of 5mm~10mm;

[0039] B. Dry the raw pellets at a temperature of 105°C for 3 hours;

[0040] C. Roasting the prepared dry ball at a temperature of 1130° C. for 50 minutes, and cooling naturally to obtain fired tailings ceramsite;

[0041] (2) Preparation of tailings ceramsite lightweight permeable bricks, including the following steps:

[0042] a. Mixing: mix the components according to the parts by weight: 1000 parts of tailings ceramsite, 280 parts of cement, 40 parts...

Embodiment 3

[0046] The tailings ceramsite lightweight permeable brick and its preparation method in this embodiment comprise the following steps:

[0047] (1) Preparation of tailings ceramsite, including the following steps:

[0048] A. Suspended roasted iron tailings, molybdenum tailings, fly ash, coal powder by weight percentage: suspended roasted iron tailings 30%, molybdenum tailings 40%, fly ash 25%, coal powder 5%, mix evenly, add water Stir and then granulate to make raw meal balls with a diameter of 5mm~10mm;

[0049] B. Dry the raw pellets at a temperature of 105°C for 4 hours;

[0050] C. Roasting the prepared dry ball at a temperature of 1150° C. for 60 minutes, and cooling naturally to obtain fired tailings ceramsite;

[0051] (2) Preparation of tailings ceramsite lightweight permeable bricks, including the following steps:

[0052] a. Mixing: mix the components according to the parts by weight: 1000 parts of tailings ceramsite, 250 parts of cement, 50 parts of suspended ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com