Patents

Literature

86 results about "Hexafluoroethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexafluoroethane is a fluorocarbon counterpart to the hydrocarbon ethane. It is a non-flammable gas negligibly soluble in water and slightly soluble in alcohol.

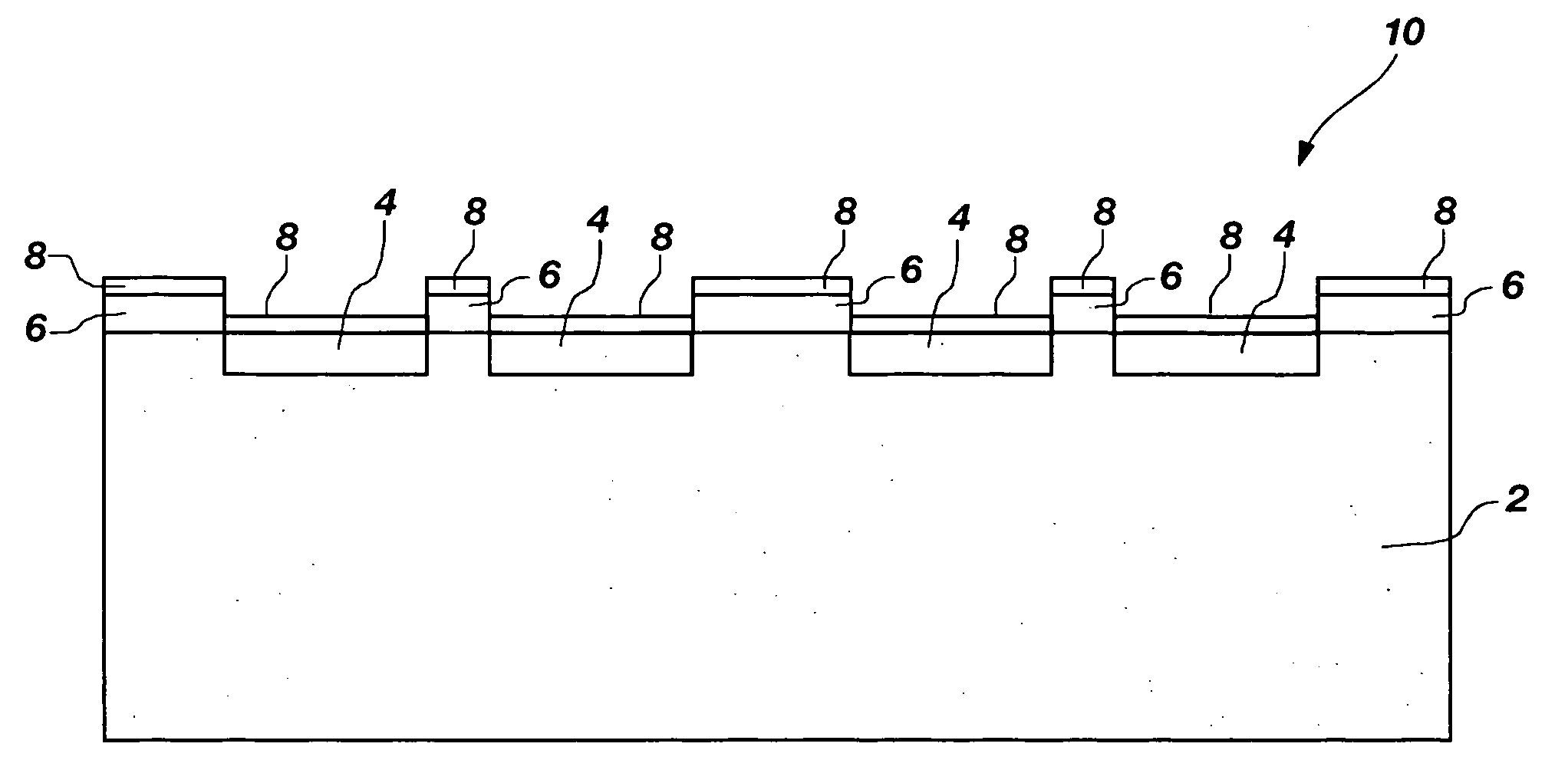

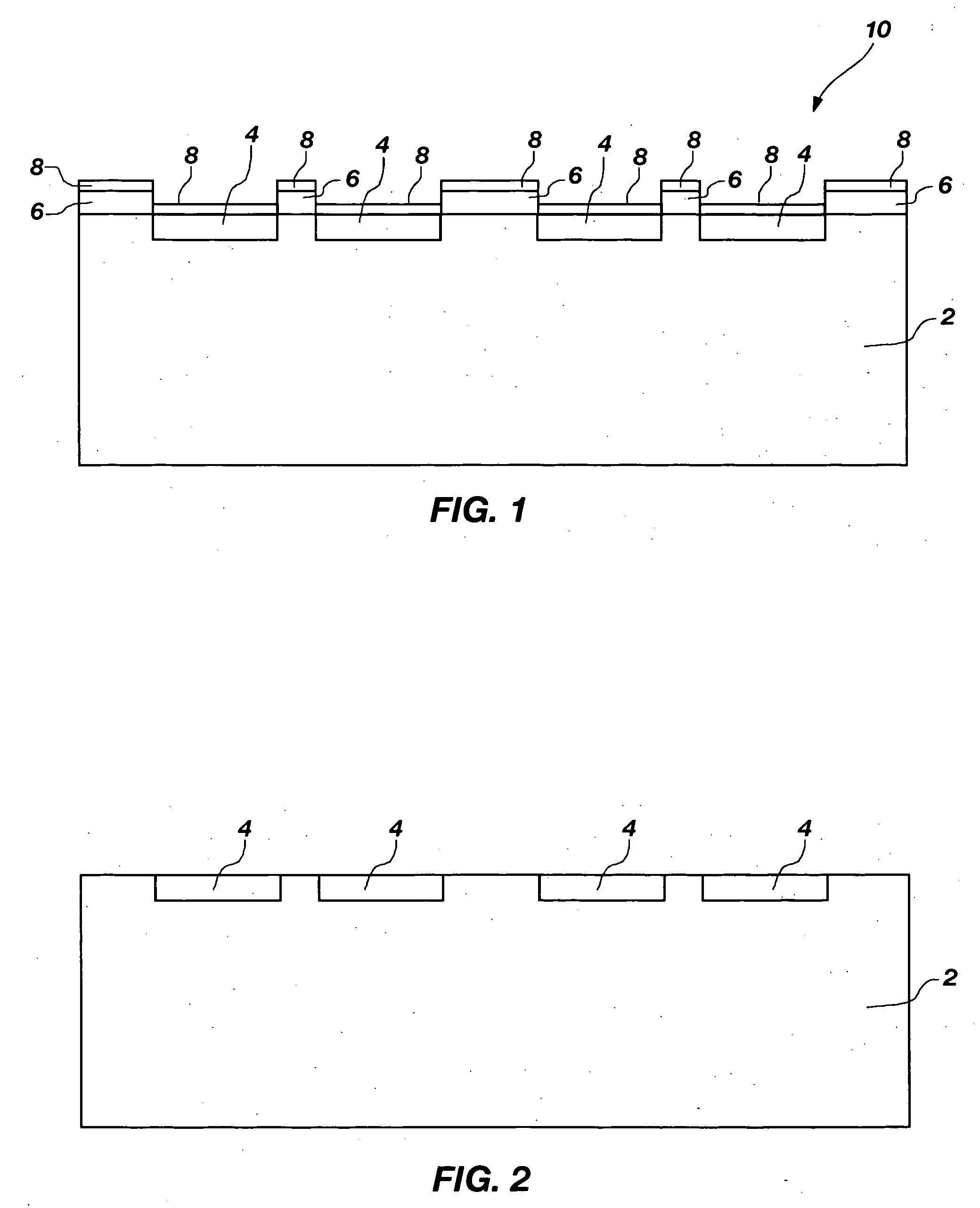

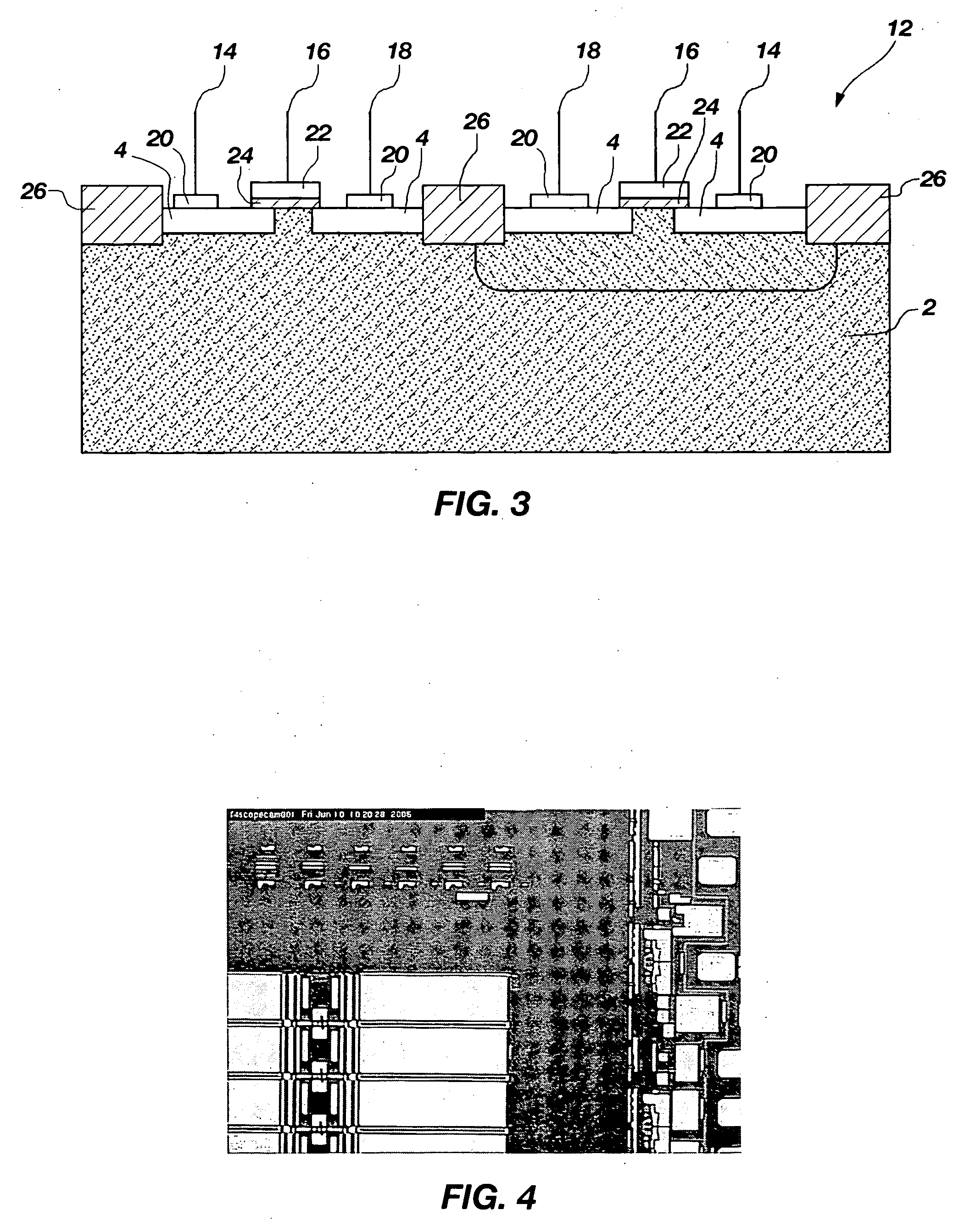

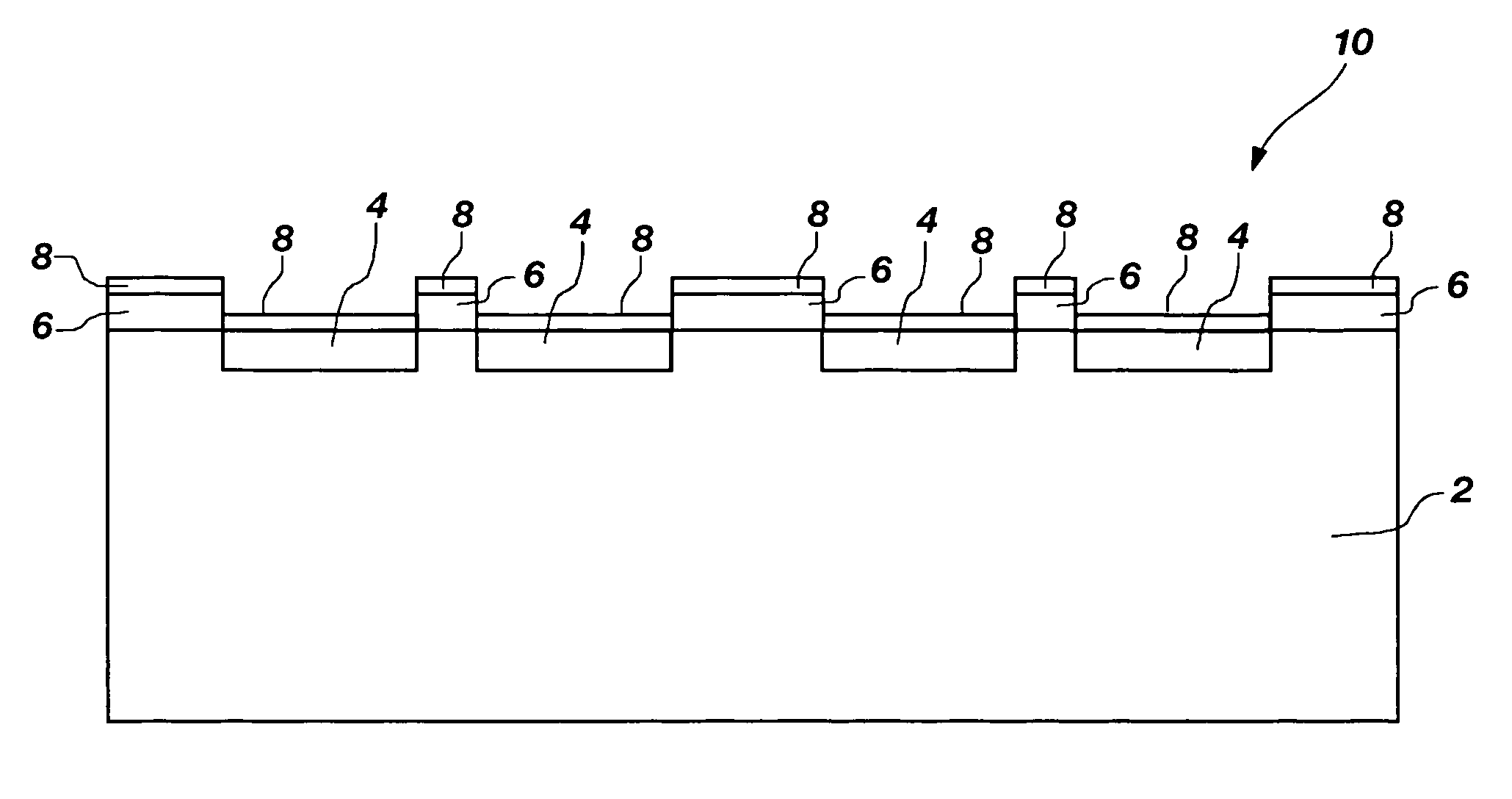

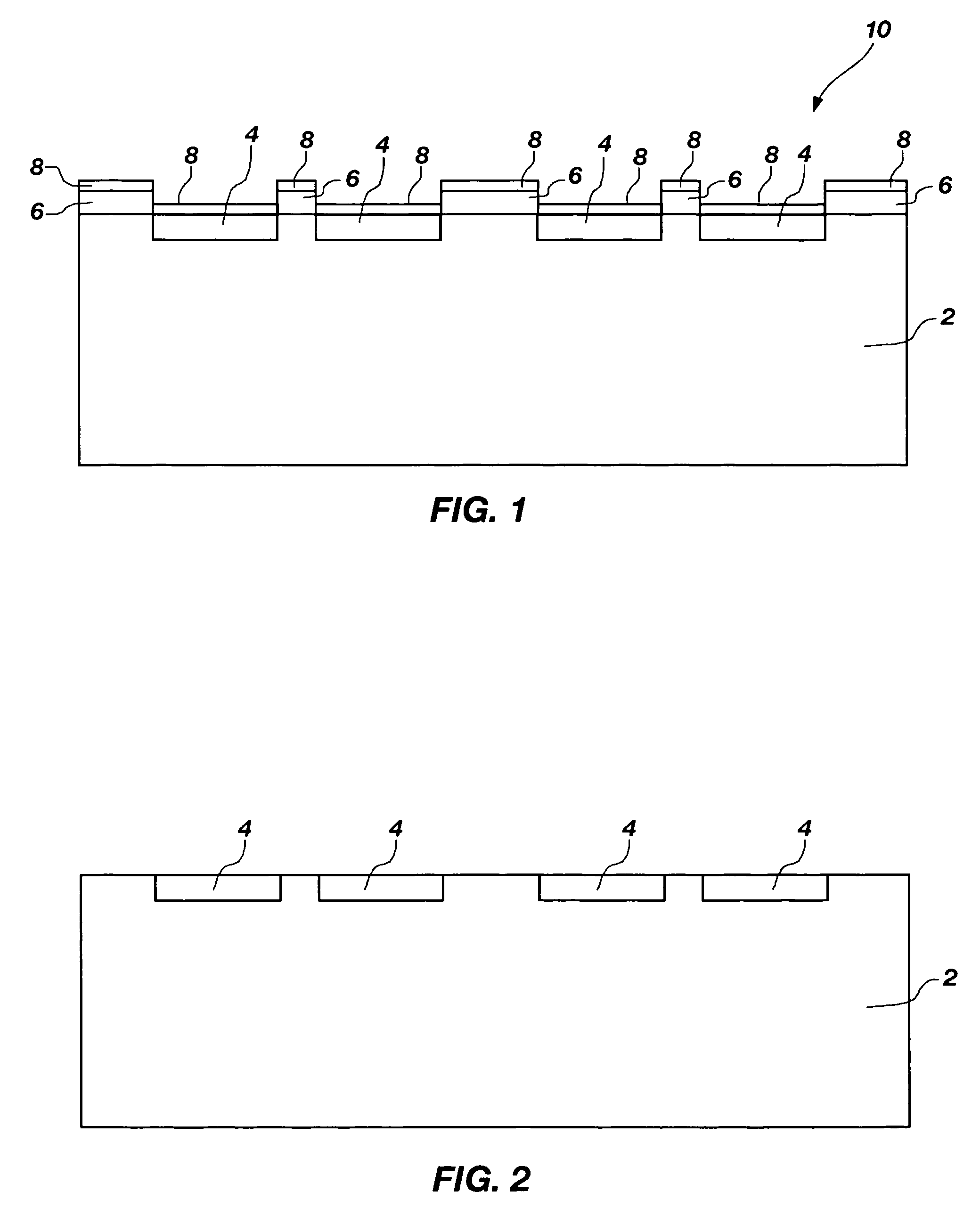

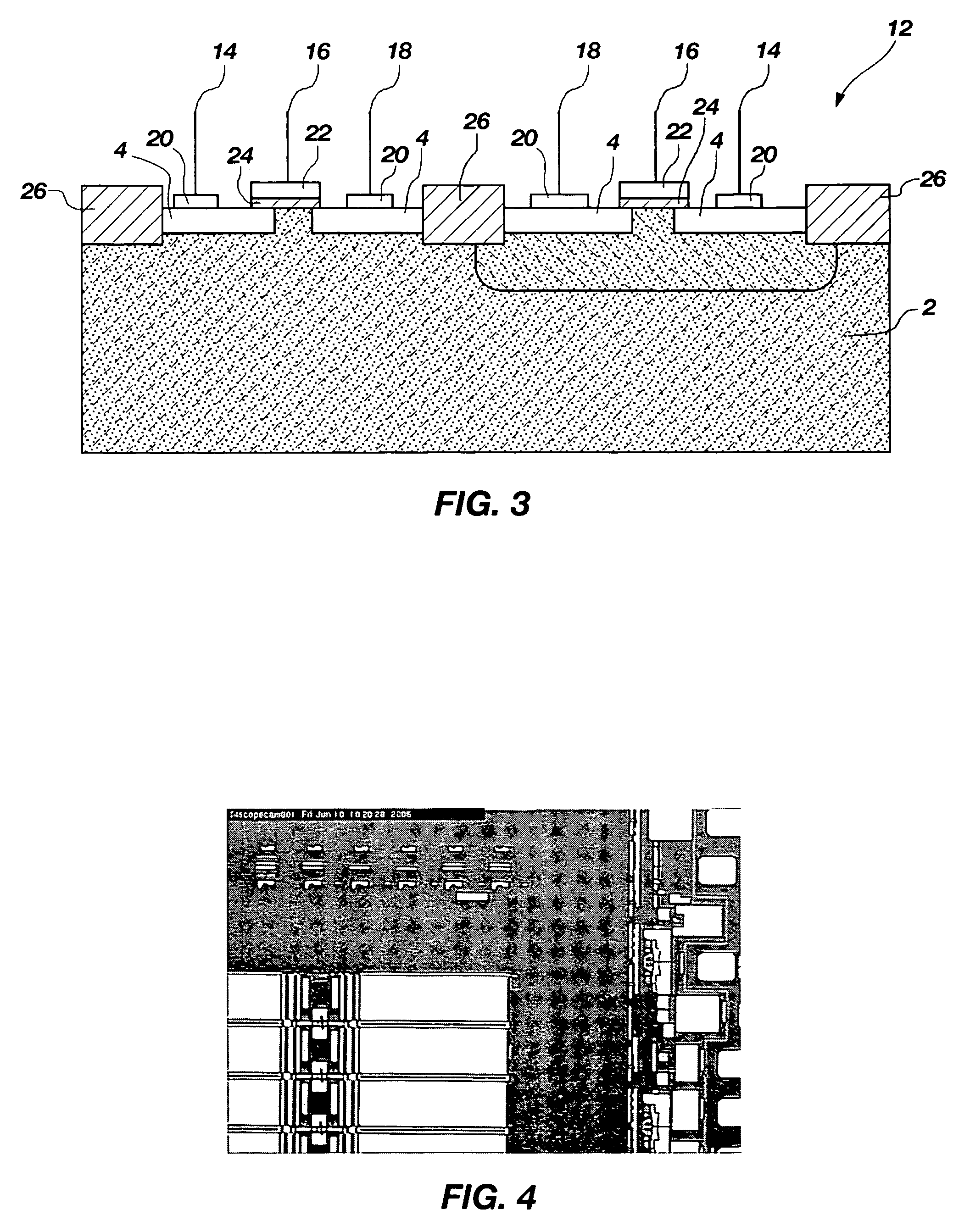

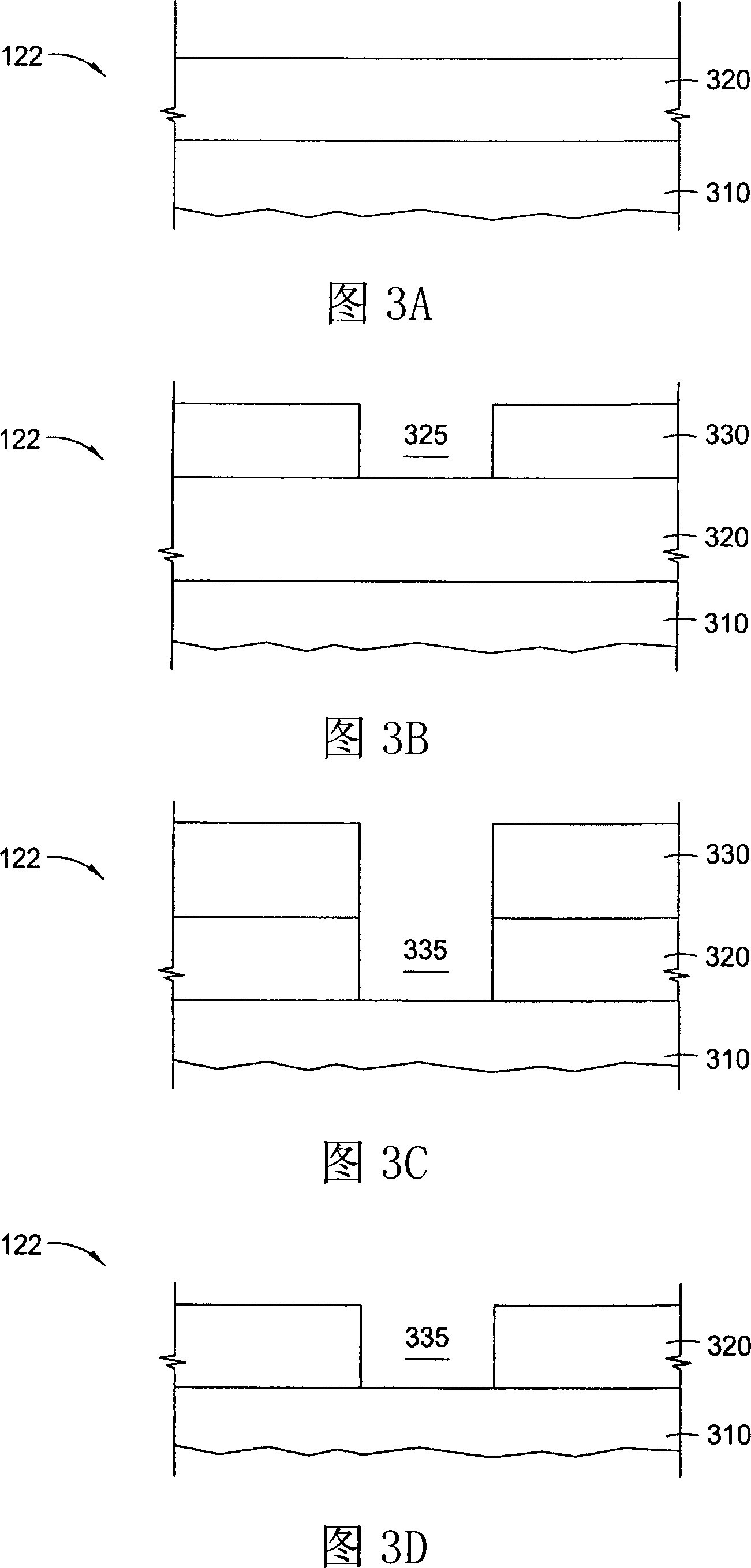

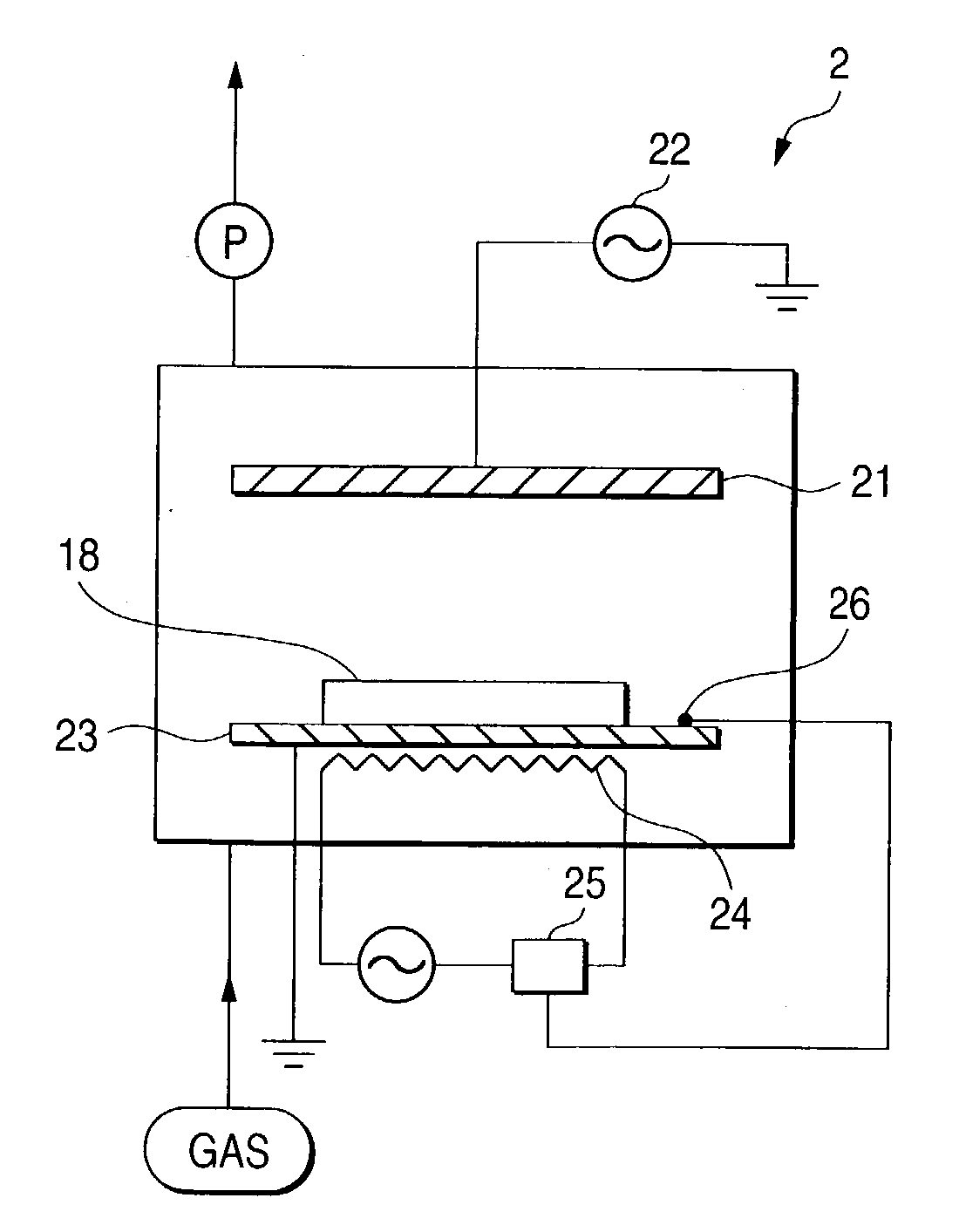

Method of photoresist strip for plasma doping process of semiconductor manufacturing

ActiveUS20070243700A1Sure easySemiconductor/solid-state device manufacturingSemiconductor devicesDopantHexafluoroethane

A method of forming an intermediate semiconductor device is disclosed that comprises providing a semiconductor substrate, forming a photoresist layer on the semiconductor substrate, implanting a dopant into the semiconductor substrate, and removing a dopant-containing layer from the photoresist layer. The dopant-containing layer includes dopant residuals and a carbon-rich crust and may be formed during implantation. The dopant-containing layer may be removed from the photoresist layer by exposing the dopant-containing layer to a water rinse, a chlorinated plasma or to a fluorinated plasma. The water rinse may include deionized water that is maintained at a temperature that ranges from approximately 25° C. to approximately 80° C. The fluorinated plasma may be formed from a gaseous precursor selected from the group consisting of nitrogen trifluoride, carbon tetrafluoride, trifluoromethane, hexafluoroethane, sulfur hexafluoride, and mixtures thereof. A method of forming an ultrashallow junction is also disclosed.

Owner:MICRON TECH INC

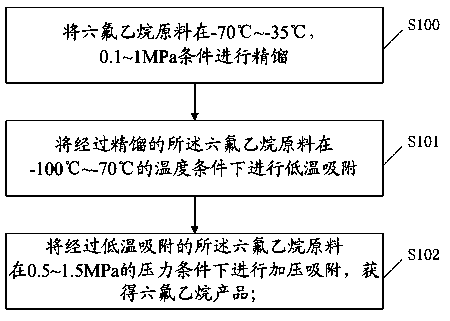

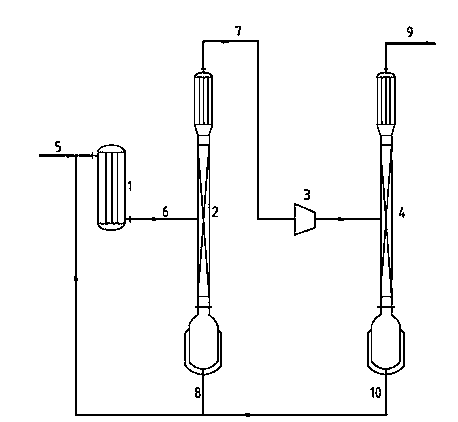

Hexafluoroethane purification method

ActiveCN103664501AHigh puritySolve storage problemsHalogenated hydrocarbon separation/purificationHexafluoroethanePurification methods

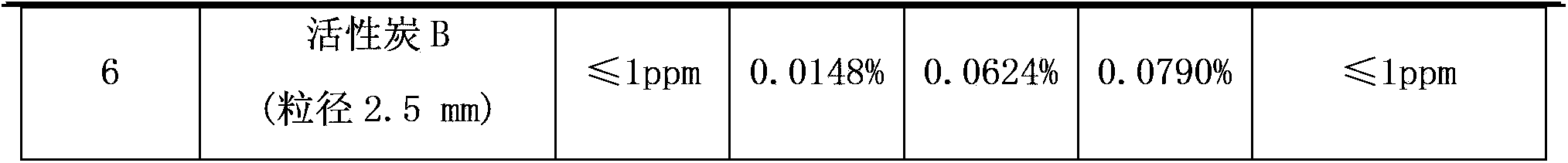

The invention discloses a hexafluoroethane purification method which comprises the following steps: rectifying a hexafluoroethane raw material under the conditions of (-70)-(-35) DEG C and 0.1-1 MPa; performing low-temperature adsorption on the rectified hexafluoroethane raw material under the temperature conditions of (-100)-(-70) DEG C; and performing pressurized adsorption on the hexafluoroethane raw material after low-temperature adsorption under the pressure conditions of 0.5-1.5 MPa, thus obtaining the hexafluoroethane product, wherein the CO2 volume concentration of the hexafluoroethane product is no more than 0.5 ppm, and the H2O volume concentration is no more than 1 ppm. According to the invention, the problem that potential safety hazard is caused due to insufficient CO2 and H2O removal depth and introduction of anhydrous HCl in hexafluoroethane is solved, the energy consumption is reduced, and the adsorption effect of adsorbent is enhanced; and the purity of the hexafluoroethane product is up to 99.9995% or above, thus meeting the requirements for electronic specific gas in the semiconductor and micro-electronics industry.

Owner:FOSHAN HUATE GASES +1

Method of photoresist strip for plasma doping process of semiconductor manufacturing

ActiveUS7737010B2Semiconductor/solid-state device manufacturingSemiconductor devicesHexafluoroethaneDopant

A method of forming an intermediate semiconductor device is disclosed that comprises providing a semiconductor substrate, forming a photoresist layer on the semiconductor substrate, implanting a dopant into the semiconductor substrate, and removing a dopant-containing layer from the photoresist layer. The dopant-containing layer includes dopant residuals and a carbon-rich crust and may be formed during implantation. The dopant-containing layer may be removed from the photoresist layer by exposing the dopant-containing layer to a water rinse, a chlorinated plasma or to a fluorinated plasma. The water rinse may include deionized water that is maintained at a temperature that ranges from approximately 25° C. to approximately 80° C. The fluorinated plasma may be formed from a gaseous precursor selected from the group consisting of nitrogen trifluoride, carbon tetrafluoride, trifluoromethane, hexafluoroethane, sulfur hexafluoride, and mixtures thereof. A method of forming an ultrashallow junction is also disclosed.

Owner:MICRON TECH INC

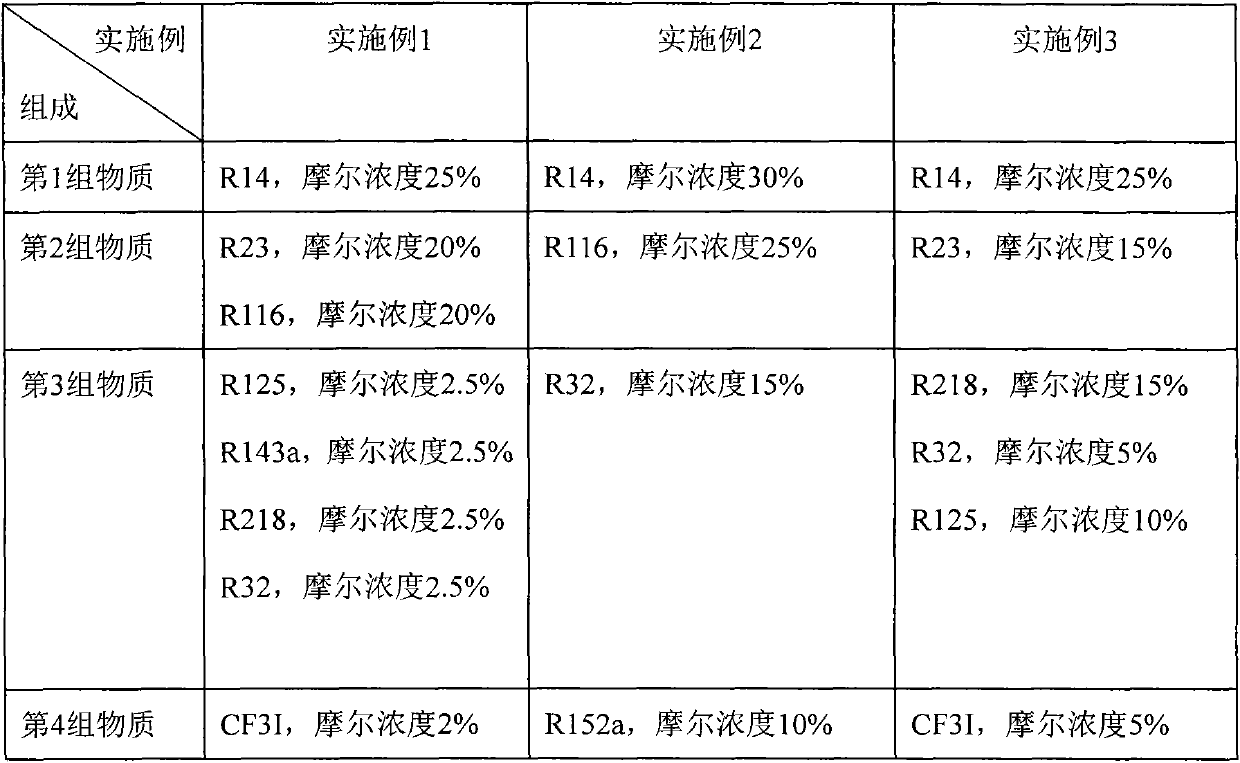

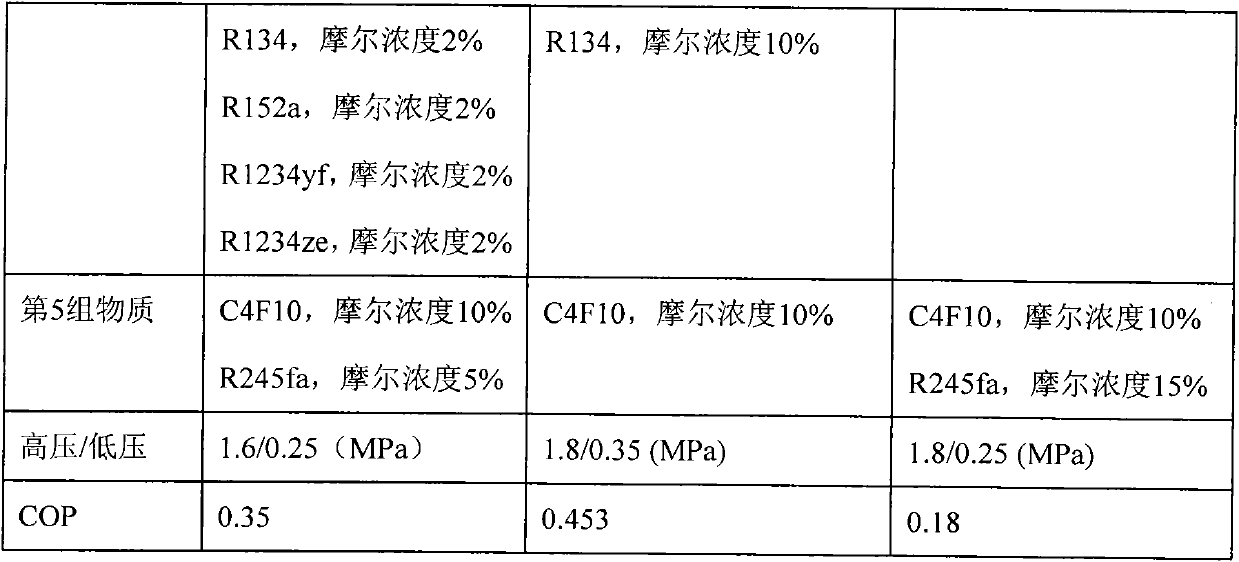

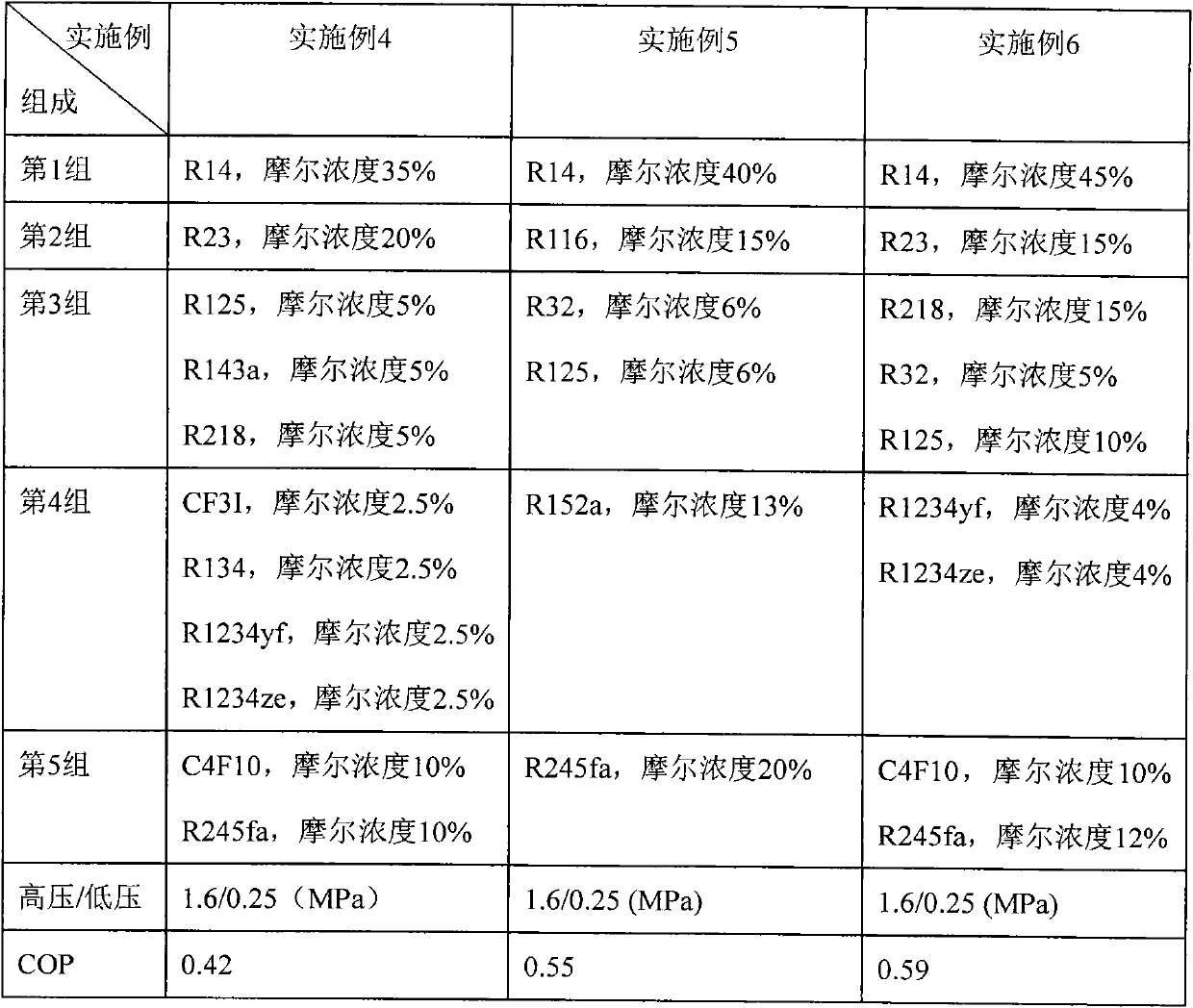

Non-combustible mixing refrigerant suitable for deep refrigeration temperature of minus 80 DEG C to minus 100 DEG C

ActiveCN102559146ANo destructive effectNon-flammableHeat-exchange elementsHexafluoroethanePolymer science

The invention relates to a non-combustible mixing refrigerant suitable for deep refrigeration temperature of minus 80 DEG C to minus 100 DEG C. The non-combustible mixing refrigerant comprises five groups of materials, where the first group of material is tetrafluoromethane; the second group of material is trifluoromethane, hexafluoroethane or a mixture of the trifluoromethane and the hexafluoroethane; the third group of material is pentafluoroethane, trifluoroethane, perfluoropropane, difluoromethane or a mixture of two, three or multiple of the pentafluoroethane, the trifluoroethane, the perfluoropropane and the difluoromethane; the fourth group of material is iodotrifluoromethane, 1, 1, 2, 2-tetrafluoroethane, 1,1-difluoroethane, 2, 3, 3, 3-tetrafluoropropene, 1, 3, 3, 3-tetrafluoropropene or a mixture of two, three or multiple of the iodotrifluoromethane, the 1, 1, 2, 2-tetrafluoroethane, the 1,1-difluoroethane, the 2, 3, 3, 3-tetrafluoropropene and the 1, 3, 3, 3-tetrafluoropropene; the fifth group of material is perfluoro-n-butane, 1, 1, 1, 3, 3-perfluoropropane or a mixture of the perfluoro-n-butane and the 1, 1, 1, 3, 3-perfluoropropane; the molar concentrations of the five groups of materials are respectively 25-50%, 15-40%, 10-30%, 5-20% and 10-25%; and the non-combustible mixing refrigerant is safe in a back-heating type throttling refrigeration system, can realize the refrigeration in the temperature range of minus 80 DEG C to minus 100 DEG C and has low whole green house effect without ozone depletion effect.

Owner:中科赛凌(北京)科技有限公司

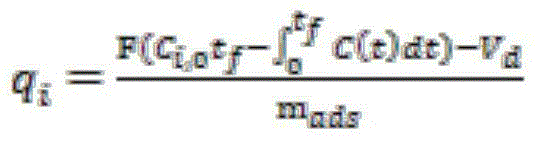

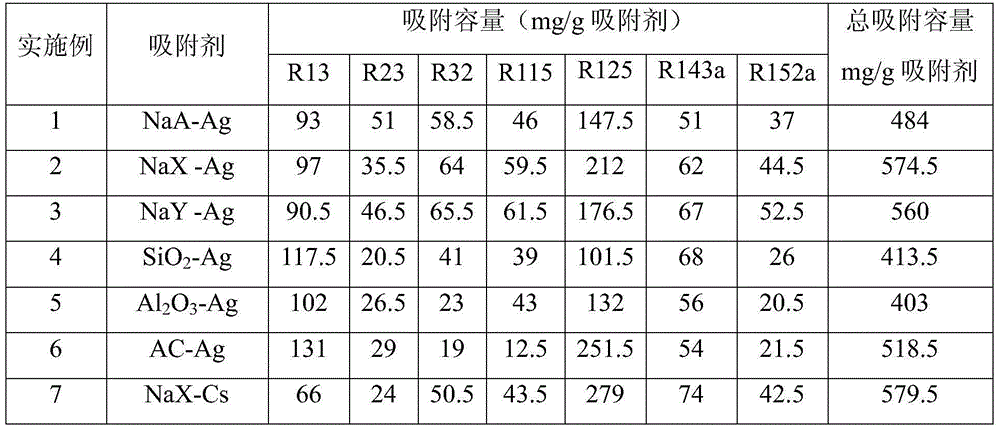

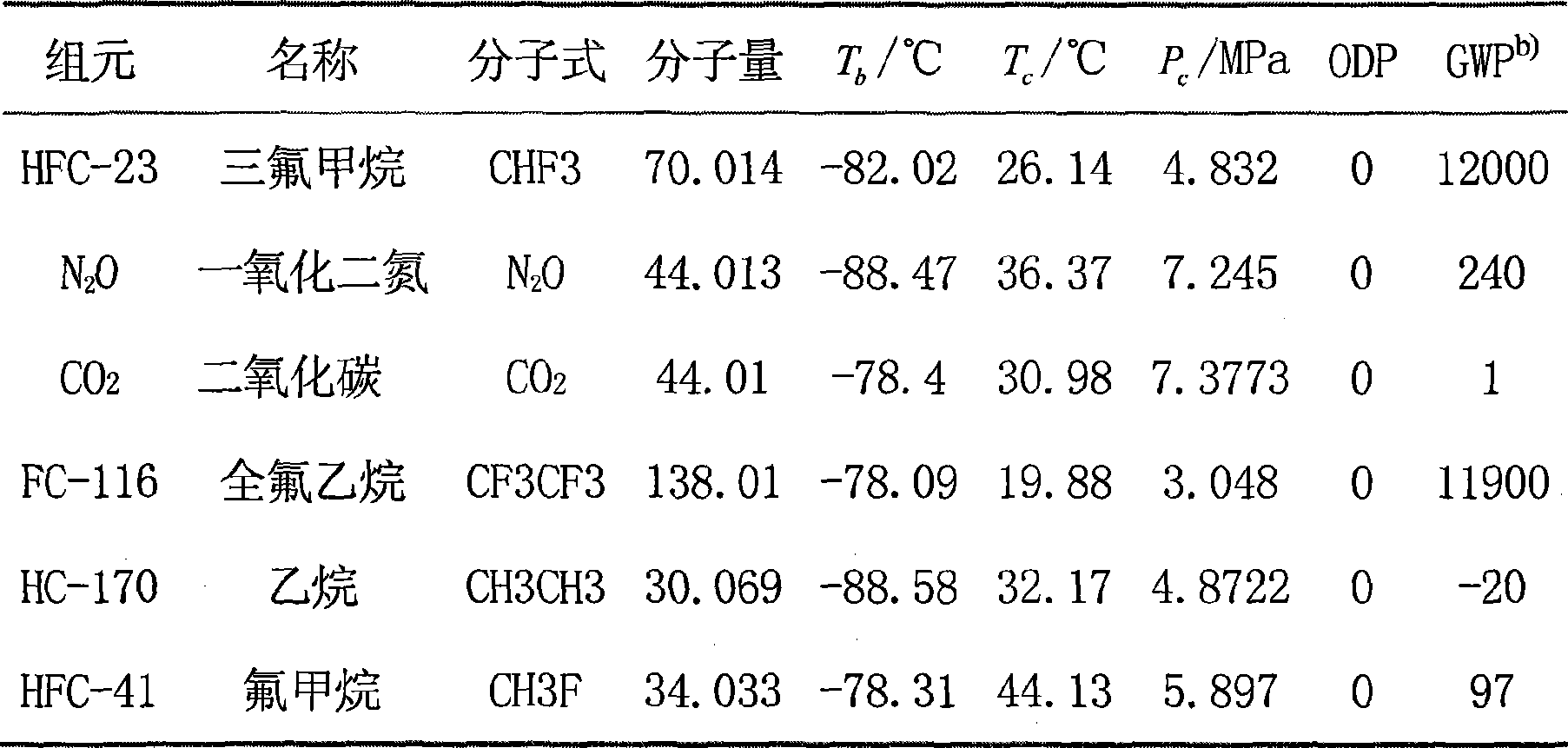

Modified adsorbent and application of same in preparation of ultra-pure hexafluoroethane

InactiveCN105327676AImprove adsorption efficiencyLarge adsorption capacityOther chemical processesSilicon compoundsMolecular sieveHexafluoroethane

The invention discloses an adsorbent modified through an ion exchange method, ball milling method or impregnation method. The adsorbent is selected from a group consisting of an A type molecular sieve, an X type molecular sieve, a Y type molecular sieve, SiO2, Al2O3 and active carbon AC. The modified adsorbent provided by the invention is applicable to removal of organic impurities in a crude hexafluoroethane product and enables an ultra-pure hexafluoroethane product with a purity of no less than 99.999% to be obtained.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +2

Use of alternate refrigerants in optimized cascade process

Methods and systems for liquefying natural gas using nonflammable refrigerants are provided. Methods of liquefaction include cooling a natural gas stream via indirect heat exchange with a first nonflammable refrigerant selected from the group consisting of: difluoromethane, pentafluoromethane, trifluoromethane, hexafluoroethane, tetrafluoroethane, pentafluorethane, trifluoroethane, pentafluoroethane, any derivative thereof, and any combination thereof during a first refrigeration cycle; and cooling the natural gas stream via indirect heat exchange with a second refrigerant during a second refrigeration cycle.

Owner:CONOCOPHILLIPS CO

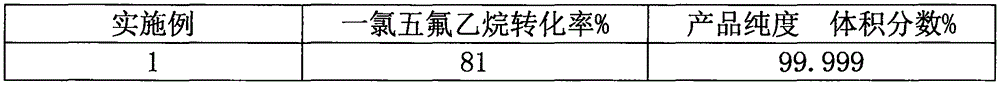

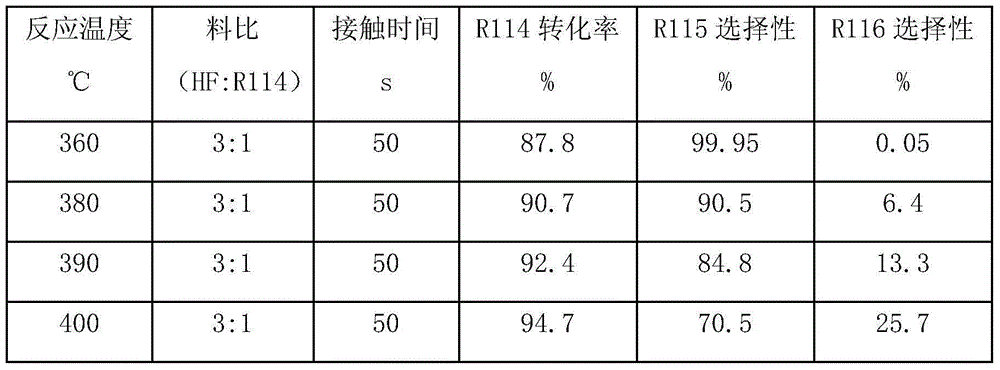

Method for preparing hexafluoroethane

InactiveCN103130607AEasy to industrializeHigh yieldPhysical/chemical process catalystsPreparation by halogen replacementHexafluoroethaneHydrogen fluoride

The invention discloses a method for preparing hexafluoroethane taking chloropentafluoroethane as raw materials. The method comprises the steps: carrying out a gas-phase reaction between a chloropentafluoroethane gas stream and a hydrogen fluoride gas stream under the action of a Cr catalyst or a Cr-Mg catalyst or a Cr-Al catalyst or a Cr-Mg-Al catalyst, and generating the hexafluoroethane. The chloropentafluoroethane gas stream used by the method can contain impurities of lower than 5%. The preparation method has the advantages of being easy and convenient to operate, easy to apply in industrialization, high in selectivity, high in conversion rate and the like.

Owner:SINOCHEM LANTIAN +1

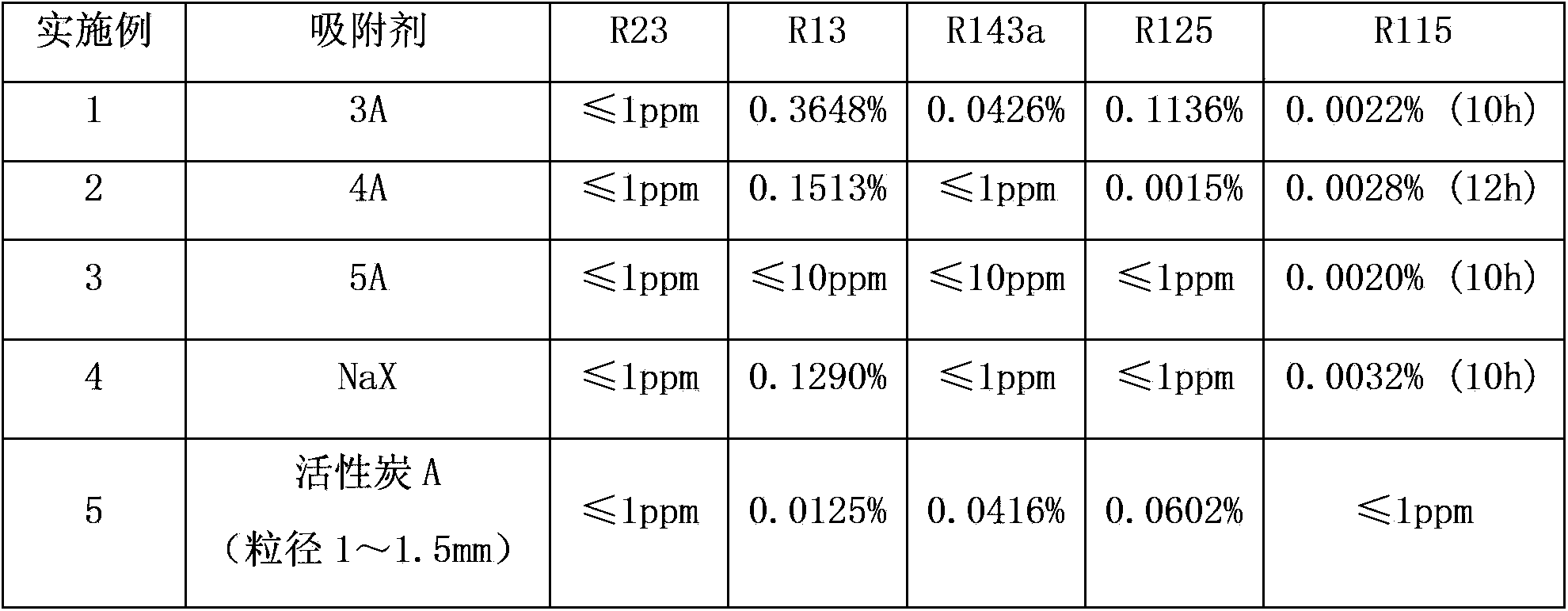

Preparation method of electronic grade hexafluoroethane

ActiveCN106242944AGood effect on adsorption of chloropentafluoroethane gasImprove conversion rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsHexafluoroethaneHydrogen fluoride

The invention relates to a preparation method of electronic grade hexafluoroethane. The preparation method comprises the following steps: a hydrogen fluoride gas and a chloropentafluoroethane gas enter a reactor containing a novel catalyst, and undergo a reaction at 300-500 DEG C at an air speed of 1-5 BV / h to prepare crude hexafluoroethane, wherein a molar ratio of the hydrogen fluoride gas to the chloropentafluoroethane gas is 1-3:1; and the crude hexafluoroethane is rectified, the rectified hexafluoroethane enters an adsorption tower containing an adsorbent and is adsorbed to obtain the highly-pure hexafluoroethane product.

Owner:ZHEJIANG BRITECH CO LTD

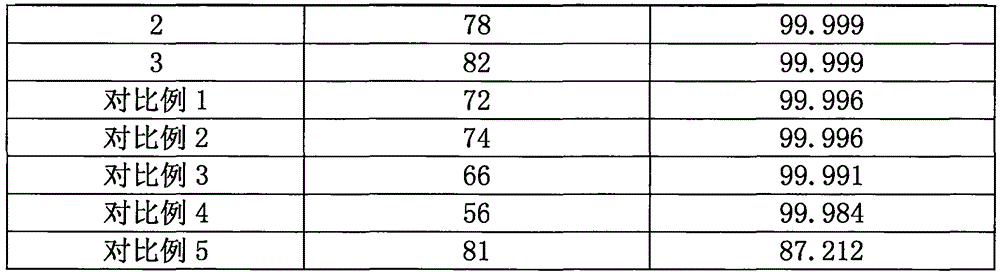

N2O-containing low temperature mixing working substance for cascade refrigeration system

InactiveCN101434831ADestruction will notSmall slip temperatureHeat-exchange elementsHexafluoroethaneBoiling point

The invention relates to a cascade refrigeration system low-temperature mixed refrigerant which is applicable to the temperature area of 180-220K and contains N2O, and a preparation method thereof; the low-temperature mixed refrigerant comprises one or two components of low-boiling point refrigerant N2O(R744A), ethane (R170), fluoromethane (R23), hexafluoroethane (R116), fluoromethane (R41), and CO2 (R744) and is formed by physical mixing at normal temperature. The low-temperature mixed refrigerant damages no ozonosphere, has low greenhouse effect potential, meets the requirement of environmental protection, has suitable thermal parameters and excellent circulation performance, and can optimize and design the new refrigerant system by the existing cascade low-temperature compressor. The mixed refrigerant can be used for replacing the refrigerant in the existing cascade refrigeration low-temperature system.

Owner:XI AN JIAOTONG UNIV

Ultra-high purity hexafluoroethane preparation method

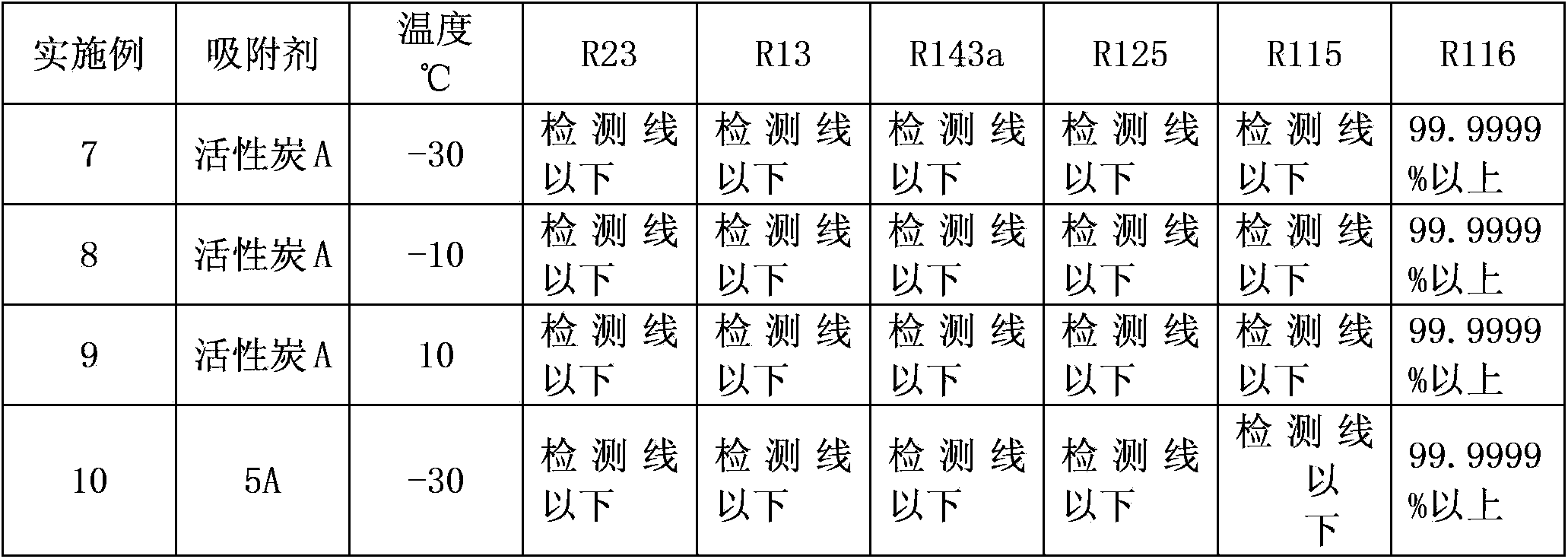

ActiveCN103910599AImprove adsorption efficiencyLarge adsorption capacityHalogenated hydrocarbon preparationHexafluoroethaneMolecular sieve

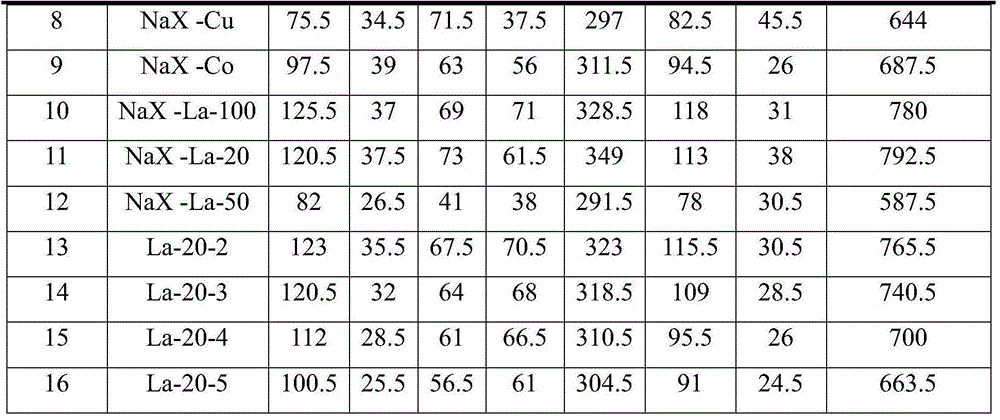

The present invention provides a method for preparing ultra-high purity hexafluoroethane through an absorption method. According to the present invention, an absorption comprising one, two or three materials selected form a 3A type molecular sieve, a 4A type molecular sieve, a 5A type molecular sieve, a NaX type molecular sieve, a CaX type molecular sieve and active carbon is adopted to remove impurities in a hexafluoroethane crude product, wherein the absorption agent is subjected to an activation treatment before absorption, the purity of the prepared hexafluoroethane can achieve 99.999%, even 99.9999% and above, and the prepared ultra-high purity hexafluoroethane can be used as the etching gas / cleaning gas in the semiconductor / electronics industry.

Owner:SINOCHEM LANTIAN +1

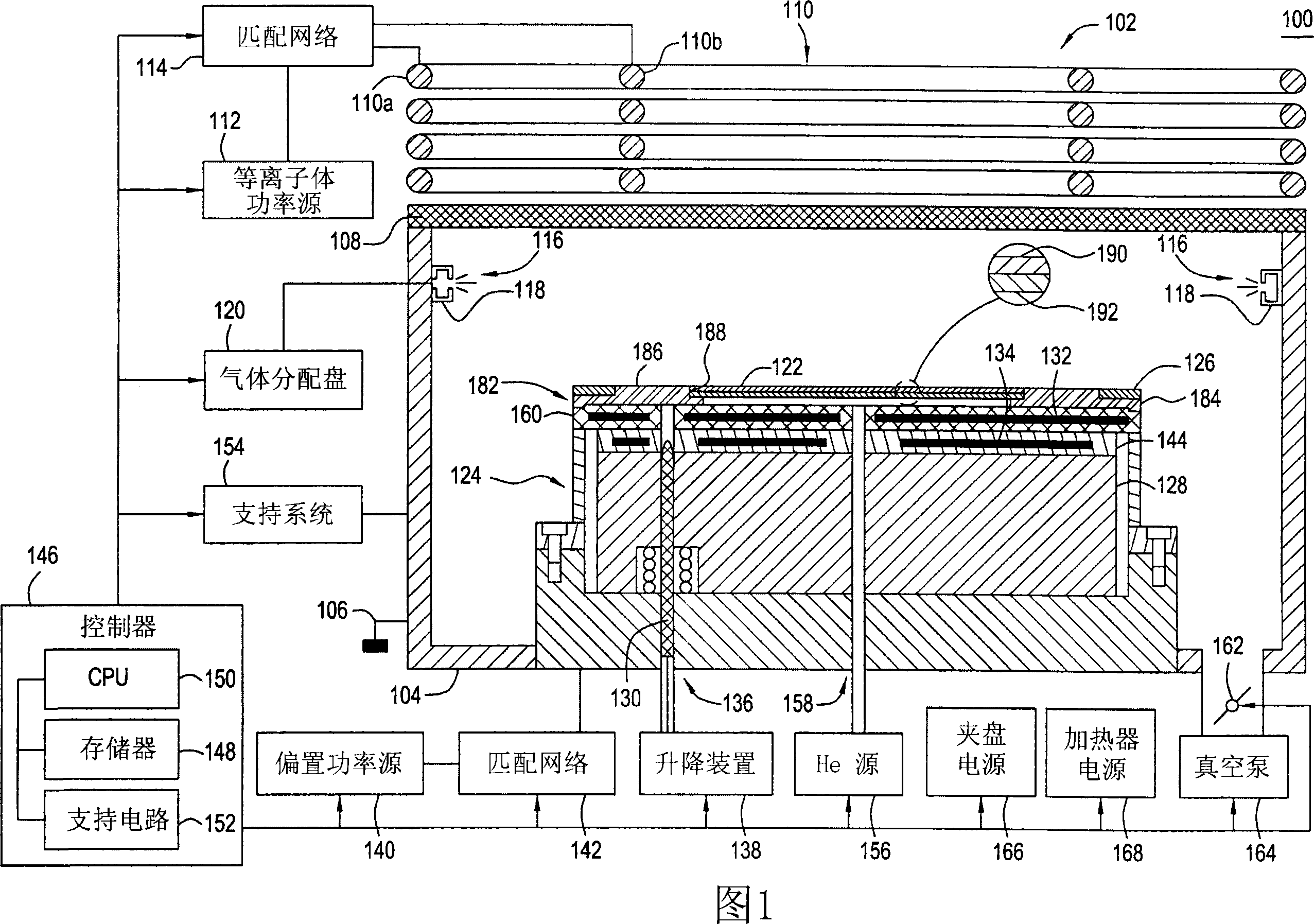

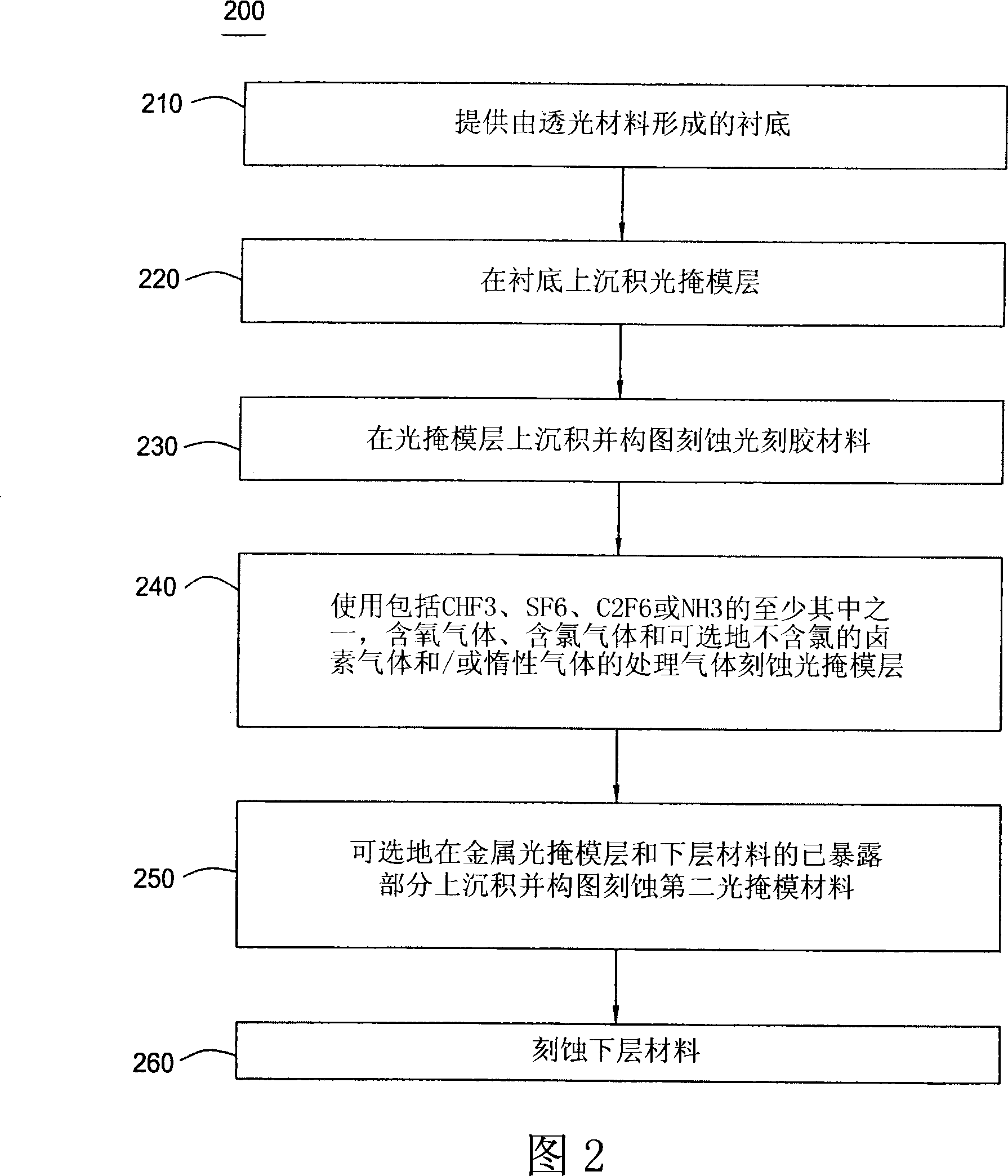

Mask etch process

InactiveCN101174081ASemiconductor/solid-state device manufacturingPhotosensitive material processingHexafluoroethaneSulfur hexafluoride

The present invention provides method and apparatus for etching a metal layer disposed on a substrate, such as a photolithographic reticle, are provided. In one aspect, a method is provided for processing a substrate including positioning a substrate having a metal photomask layer disposed on a optically transparent material in a processing chamber, introducing a processing gas processing gas comprising an oxygen containing gas, a chlorine containing gas, at least one of trifluoromethane (CHF 3 ), sulfur hexafluoride (SF 6 ), hexafluoroethane (C 2 F 6 ) or ammonia (NH 3 ) and optionally a chlorine-free halogen containing gas and / or an inert gas, into the processing chamber, generating a plasma of the processing gas in the processing chamber, and etching exposed portions of the metal layer disposed on the substrate.

Owner:APPLIED MATERIALS INC

Rice-shell board mixture

InactiveCN1853887AHigh strengthImprove water resistanceFlat articlesDomestic articlesHexafluoroethaneHusk

The invention belongs to the formula of synthetic filler for making wooden boards. The ingredients of its rice hull board include wood filler, sodium liquid glass, silicon dioxide and sodium hexafluoroethane silicate. The mixture of rice husk or rice husk and wood chips in any ratio is used as wood filler, and the silica contains artificial silica or various metallurgical production wastes with a SiO2 content of not less than 80% silica powder, and the ingredients are in the following proportions (weight ratio): rice husk: 100, sodium liquid glass added according to dry matter: 25-50, silicon dioxide: 10-70. The wood chipboard has water resistance and high strength (static bending strength = 8-15.0Mpa), and this method can also fully digest and utilize agriculture (rice husk), wood processing (sawdust) and industry (silica powder) production waste.

Owner:INSTITUT KHIMII TVERDOGO TELA I MEKHANOKHIMII SIBIRSKOGO OTDELENIJA ROSSIJSKOJ AKADI NAUK IKHTTM SO RAN +1

Process for the production of fluoroethane and use of the same

InactiveUS20050065385A1Preparation by halogen replacementHalogenated hydrocarbon separation/purificationHexafluoroethaneTetrachloroethylene

A process comprising fluorinating tetrachloroethylene to obtain a crude pentafluoroethane containing impurities and bringing the crude pentafluoroethane containing impurities into contact with oxygen and / or an oxygen-containing compound in the presence of a catalyst. There can be obtained high-purity pentafluoroethane which can be used as a low-temperature refrigerant or an etching gas or as a starting material for the production of high-purity hexafluoroethane.

Owner:SHOWA DENKO KK

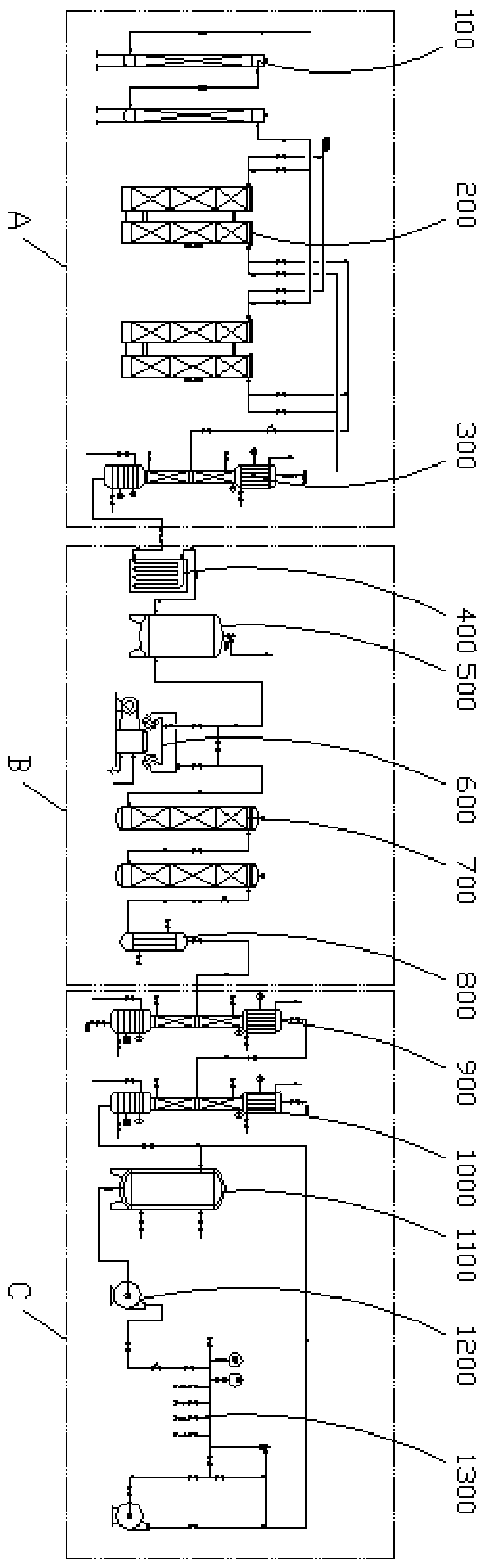

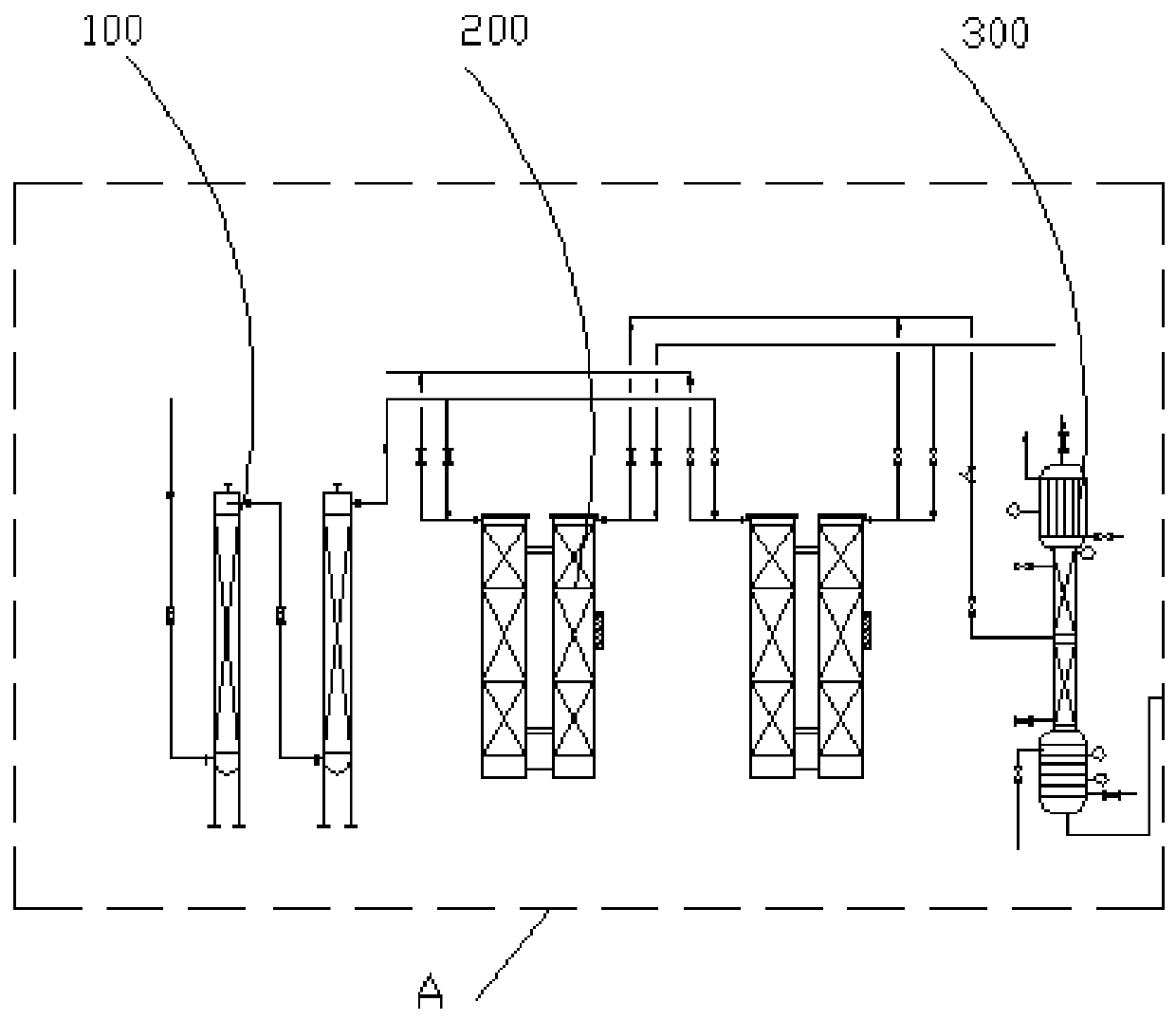

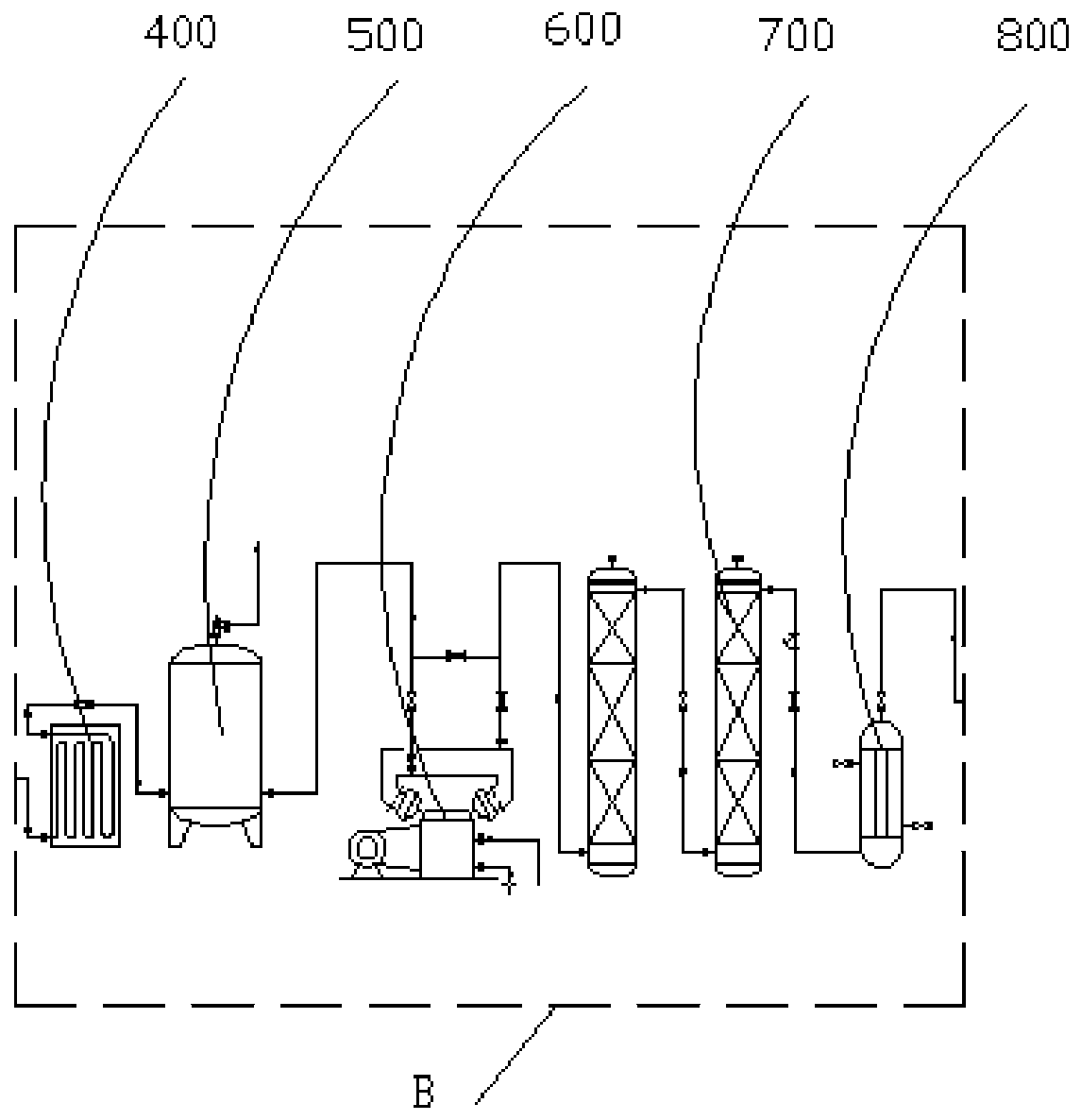

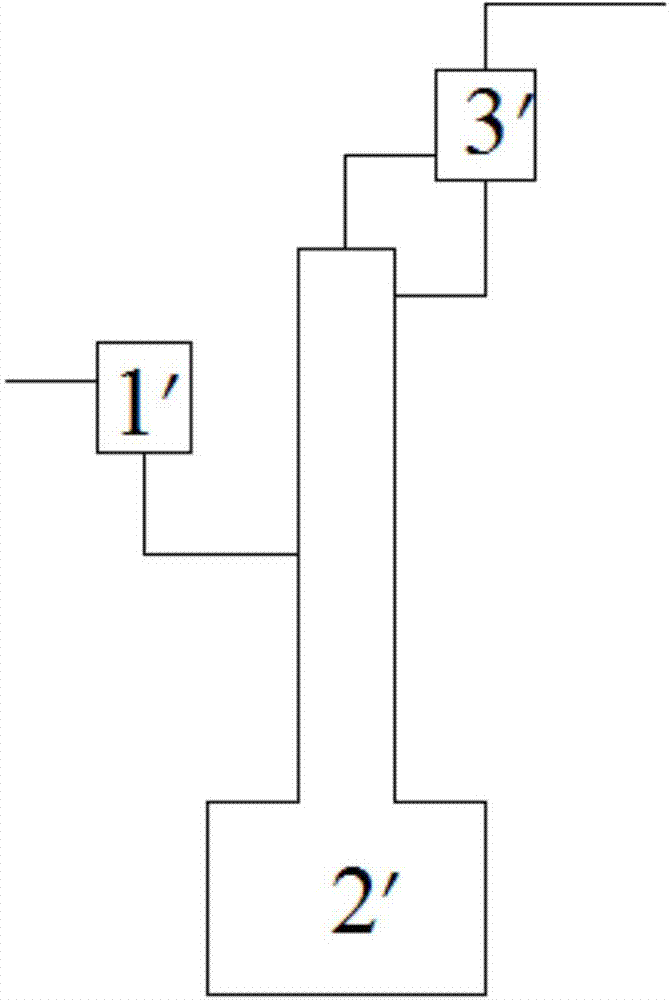

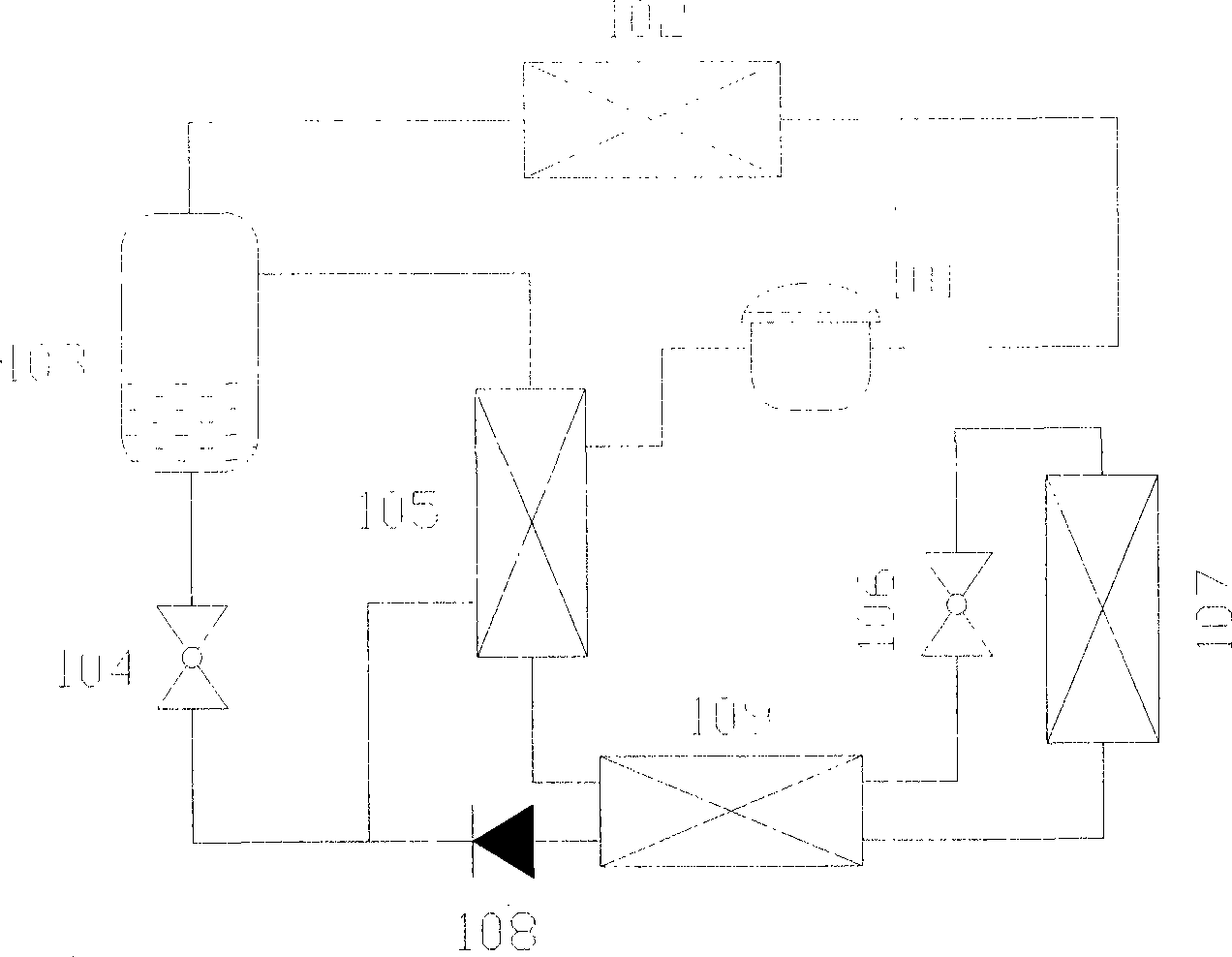

Production method for recovering and purifying electronic-grade hexafluoroethane from carbon tetrafluoride production industrial waste gas

ActiveCN111018662AHigh recovery rateImplement resourcesHalogenated hydrocarbon separation/purificationHexafluoroethaneCarbon monofluoride

The invention discloses a production method for recovering and purifying electronic-grade hexafluoroethane from carbon tetrafluoride production industrial waste gas, and belongs to the field of hexafluoroethane production. The method comprises the following steps: a thermal decomposition purification device and a micro-aerobic adsorption regeneration device are adopted; after precision filtration,a product enters a fractionating device, and carbon tetrafluoride gas generated by the fractionating device returns to a carbon tetrafluoride production line, so that the recovery rate of the carbontetrafluoride is increased; hexafluoroethane containing a small amount of impurities sequentially passes through a vaporizer to be vaporized and then enters a buffer tank; pressurizing is performed byusing a diaphragm type compressor to enable hexafluoroethane in the buffer tank to enter an adsorption tower running under pressure; and after precooling is performed by a precooler, impurities are removed by a high-boiling rectifying tower and a low-boiling rectifying tower in sequence. The recovery rate of carbon tetrafluoride is improved; the technical requirements of the electronic-grade hexafluoroethane are met; the produced electronic-grade hexafluoroethane does not contain a chlorine element which can cause damage to an ozone layer; greenhouse gas emission can be reduced, and industrial waste gas resource utilization, energy conservation and emission reduction can be achieved.

Owner:FUJIAN DEER TECH CORP

Hexafluoroethane production technology

ActiveCN103772136ASimple processLess investmentPreparation by halogen replacementHexafluoroethaneProcess engineering

The invention discloses a hexafluoroethane production technology, and the purity of a hexafluoroethane product can reach more than 99.99% by two-stage separation and purification. The hexafluoroethane production technology simplifies a conventional technological process, saves equipment investment, makes the reaction smooth, and improves the production efficiency.

Owner:SINOCHEM LANTIAN +1

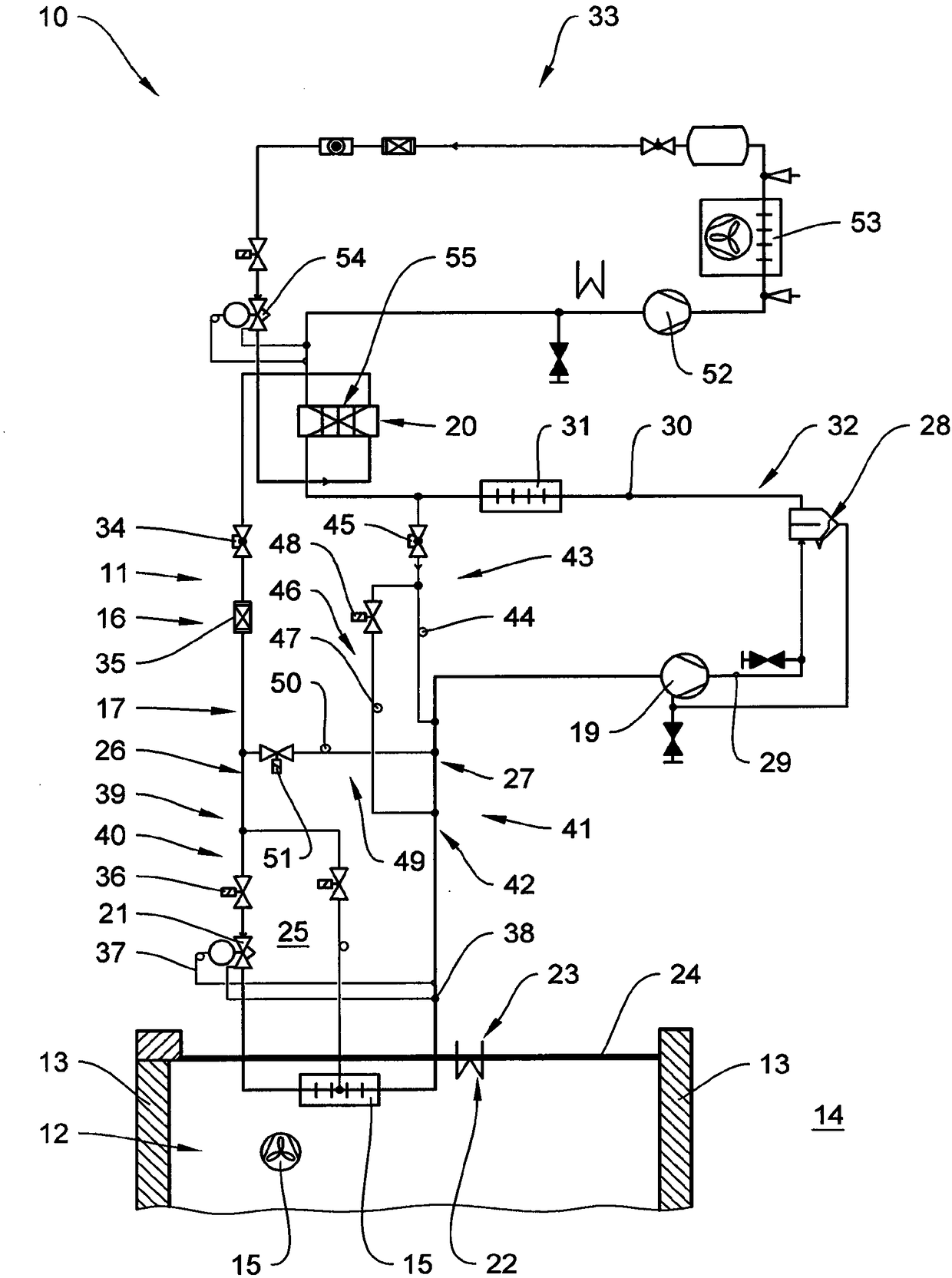

Test chamber

PendingCN108779941AFree from damageMechanical apparatusPreparing sample for investigationHexafluoroethaneEngineering

Owner:WEISS UMWELTTECHNIK GMBH

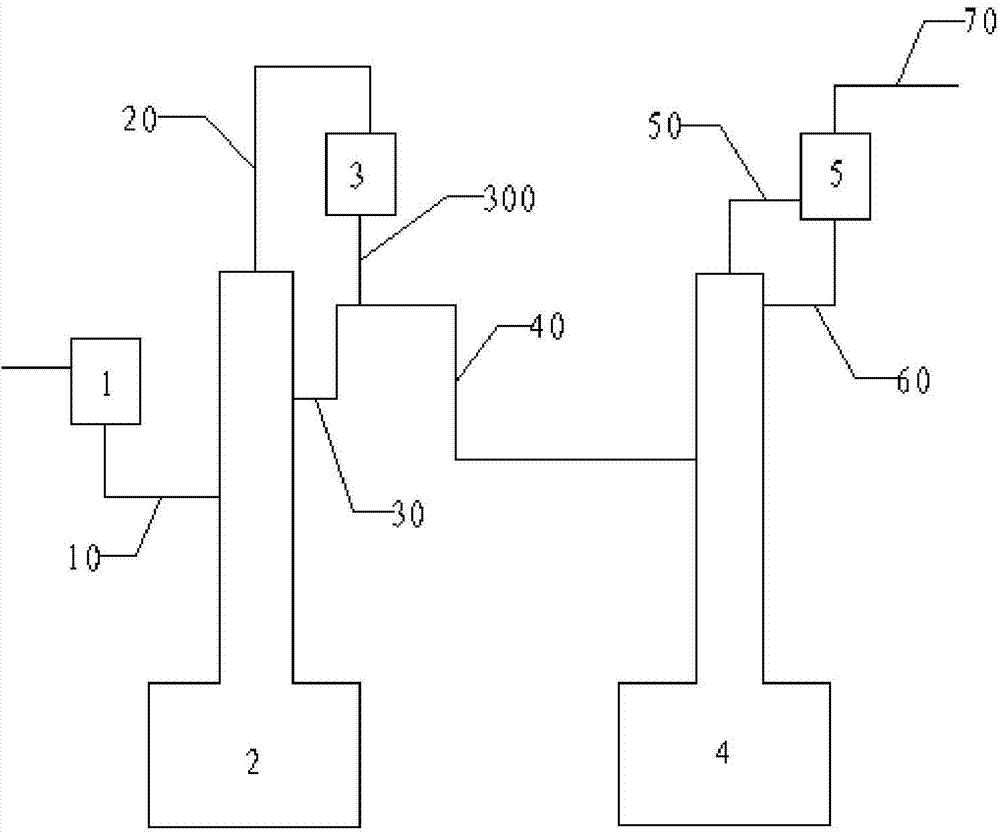

Rectification device and rectification process used for electronic grade sulfur hexafluoride production

ActiveCN103754834AEfficient removalLow costSulfur and halogen compoundsHexafluoroethaneSulfur hexafluoride

The invention relates to a rectification device and a rectification process used for electronic grade sulfur hexafluoride production. Specifically, a rough sulfur hexafluoride gas is pressurized and then sent into a precooler to be converted from gas to liquid under high pressure and low temperature conditions, then gasification, condensation and reflux are carried out in a first rectifying tower and a first condenser to remove high-boiling residue, and then by means of gasification, condensation and reflux in a second rectifying tower and a second condenser, the sulfur hexafluoride is condensed into a liquid state for collection, while low-boiling residue maintains a gas state and escapes from the second condenser. The rectification device and the rectification process provided by the invention can effectively remove high-boiling residue and low-boiling residue impurities from the rough sulfur hexafluoride gas, especially the hexafluoroethane and octafluoropropane impurity gases with a very close boiling point to sulfur hexafluoride under high pressure and low temperature states required by the rectification process. The obtained sulfur hexafluoride fully meets the technical requirements of electronic grade sulfur hexafluoride, also the equipment cost is low, and the production process is simple.

Owner:FUJIAN YONGJING TECH CO LTD

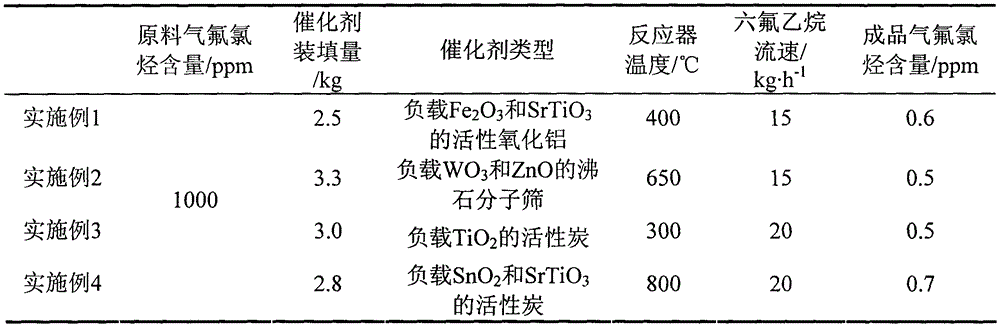

Hexafluoroethane purifying method

ActiveCN104529692AExtended service lifeWill not affect subsequent processesHalogenated hydrocarbon separation/purificationHexafluoroethaneMolecular sieve

The invention discloses a hexafluoroethane purifying method which includes the following steps that crude hexafluoroethane is sequentially introduced into a water washing tower and an alkaline washing tower, acid gas in the hexafluoroethane is washed way, the washed gas enters a reactor which is filled with a metal catalyst, reaction temperature is controlled between 300 DEG C and 8000 DEG C, the flow rate of the hexafluoroethane is 15-30kg / h, then the gas sequentially adsorbs CO2, H2O and HF through an adsorption tower, impurities such as H2, O2, N2, CH4, CF4, SF6 and C3F8 are removed through rectification in a rectifying tower, and hexafluoroethane gas with the purity of 99.999% can be obtained. The metal catalyst is supported, a carrier is one of active aluminum oxide, a zeolite molecular sieve and active carbon, and a body is one or more of TiO2, ZnO, WO3, SnO2, Fe2O3 or SrTiO3. By means of the method, the content of hydrochlorofluorocarbons in the hexafluoroethane can be removed to be under 1ppmv.

Owner:昊华气体有限公司

Preparation process of polyvinylidene fluoride with thermal stability

The invention discloses a preparation process of polyvinylidene fluoride with thermal stability. The preparation process comprises the following steps of (1) adding 0.6 part by weight of hydrogen peroxide and 0.9 part by weight of an inorganic alkali solution into a reaction kettle, uniformly mixing, then, adding 15.2 parts by weight of a hexafluoroethane solvent and 0.4 part by weight of an acryloyl chloride solution, and reacting at the temperature of 8.5 DEG C below zero for 36 minutes by stirring; (2) introducing 9.3 parts by weight of a polyacrylic acid solution, 68 parts by weight of vinylidene fluoride monomers and 3.8 parts by weight of chlorocyclopentante, reacting at the temperature of 34 DEG C by stirring, and stopping reacting when the pressure is reduced to be smaller than 0.26MPa; and (3) filtering, washing and drying to obtain powdery polyvinylidene fluoride. Polyvinylidene fluoride prepared by using the preparation method is favorable in thermal stability and processibility and capable of meeting the requirements of production processes such as injection molding, extruding and film drawing.

Owner:CHANGSHU LIYUAN MEMBRANE TECH

Mixed working substance containing N*O in auto-cascade circulatory system

InactiveCN101445718AAchieve refrigerationConsumption potential zeroHeat-exchange elementsHexafluoroethaneSubstance use

The invention discloses a mixed working substance containing N2O in an auto-cascade circulatory system. The working substance consists of 15-50% of a first group substance by mass fraction and a second group substance in balancing amount, wherein, the first group substance is N2O or a compound formed by N2O and one or more of ethane, trifluoromethane, hexafluoroethane, fluoromethane, carbon dioxide and ethylene. Compared with the prior working substance used for the auto-cascade circulatory system, the mixed working substance provided by the invention has the following advantages: the mixed working substance provided by the invention can effectively realize the refrigeration of a temperature range of 200-240K; the ozone depletion potential (ODP) of N2O (R744A) equals to zero, and the global warming potential (GWP) thereof is relatively low; and as N2O is a natural substance which can be easily obtained, and other refrigerants matched with N2O are reasonably priced, the use of the mixed refrigerant can reduce the cost for companies.

Owner:HENAN XINFEI ELECTRICAL EQUIP +1

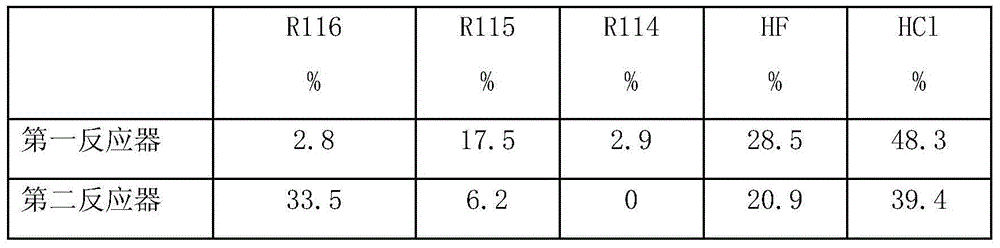

Production method of hexafluoroethane

The invention discloses a production method of hexafluoroethane. Dichlorotetrafluoroethane is taken as a raw material and two-stage circulation technology is adopted. Chloropentafluoroethane is generated in a first-stage reaction, and hexafluoroethane is generated in a second-stage reaction. According to the production method provided in the invention, a hexafluoroethane product with purity more than 99.9% is obtained.

Owner:陕西中化蓝天化工新材料有限公司 +1

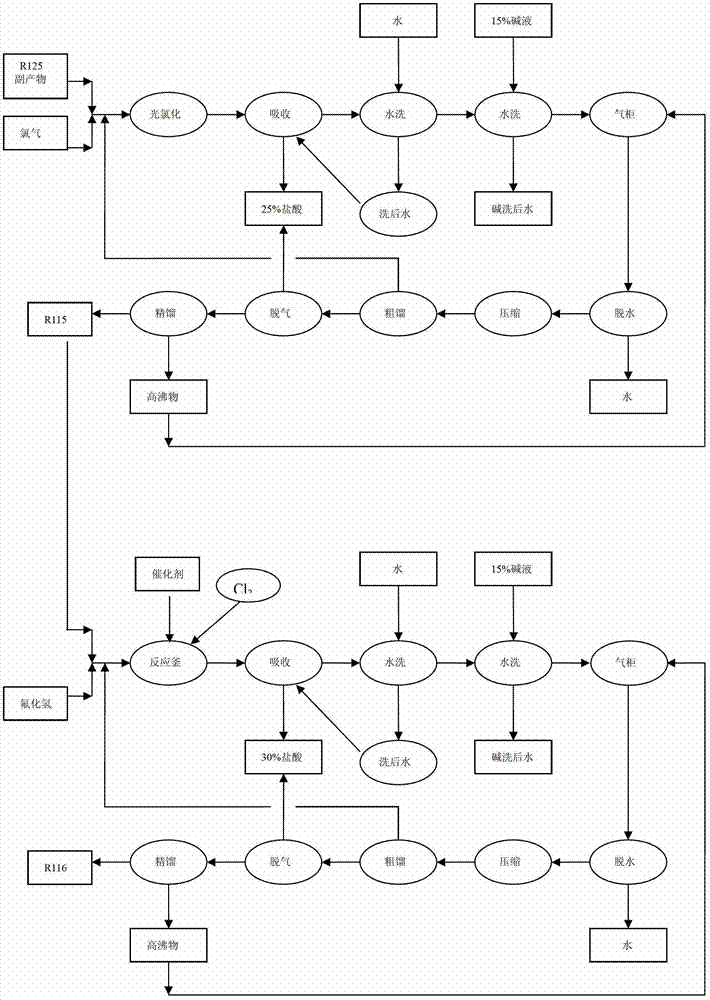

Preparation method of hexafluoroethane

InactiveCN102766015AImprove conversion rateSolution to short lifePreparation by halogen replacementHexafluoroethaneHydrogen fluoride

The invention relates to a preparation method of hexafluoroethane, belonging to the technical field of fluoride industry. The preparation method is characterized by comprising the following steps: 1, enabling a pentafluoroethane by-product to contact and react with mixed chlorine gas in a photochemical tower; and 2, enabling chloropentafluoroethane which is a product obtained in the step 1 to contact and react with mixed hydrogen fluoride liquid in a reactor containing a catalysis which is an antimonial fluoride. The preparation method is simple in process, high in product yield and is easy for large-scale industrial production, and meanwhile, the process has the advantages of little three waste pollution, easiness in reaction control, long service life of the catalyst, low reaction energy consumption and the like; moreover, the byproduct generated during the production process of pentafluoroethane can be effectively treated, the production cost is lowered, the energy consumption is reduced, the conversion rate of raw materials is high, and market demand on hexafluoroethane can be relieved at the same time.

Owner:SHANDONG HUAAN NEW MATERIAL

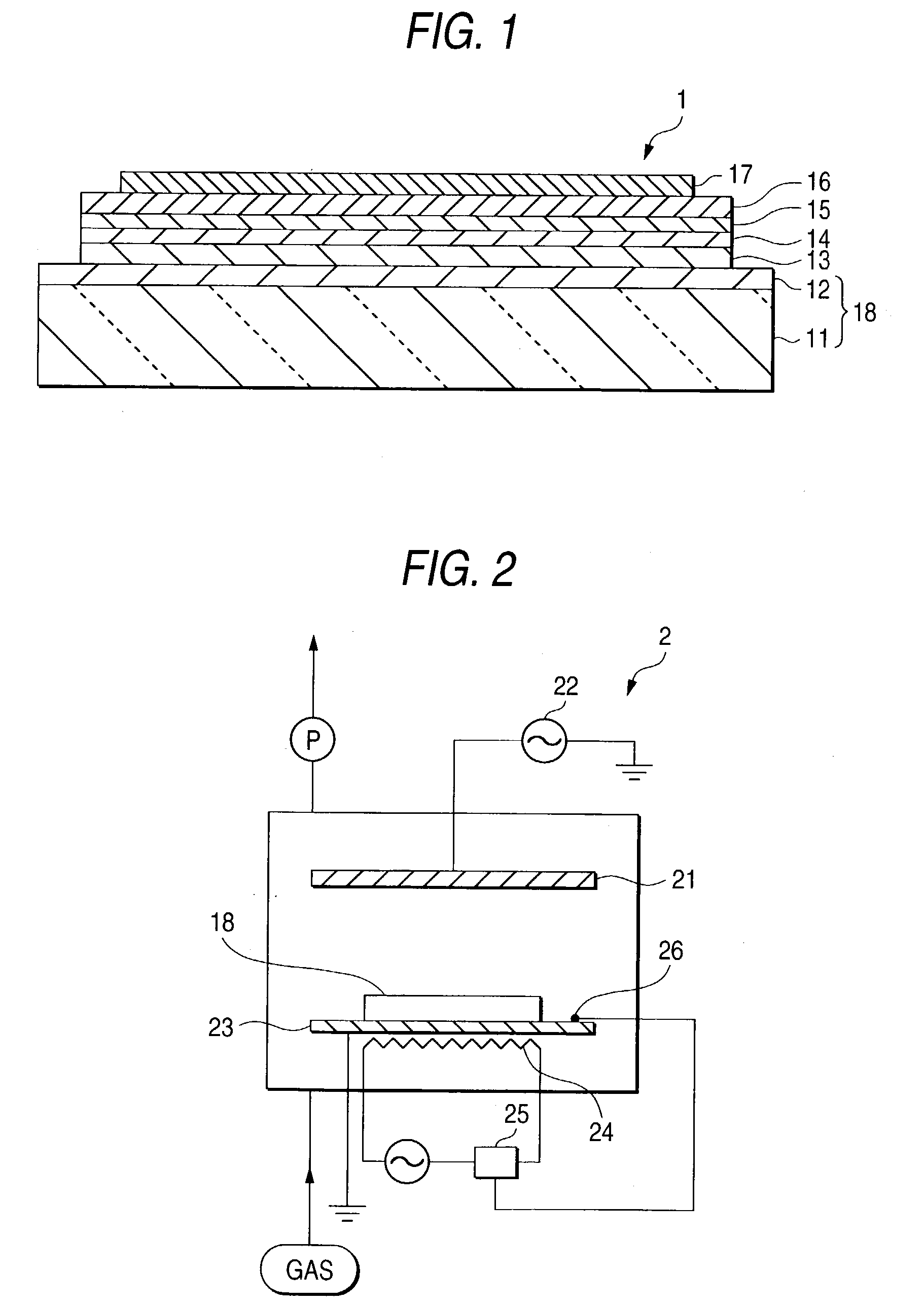

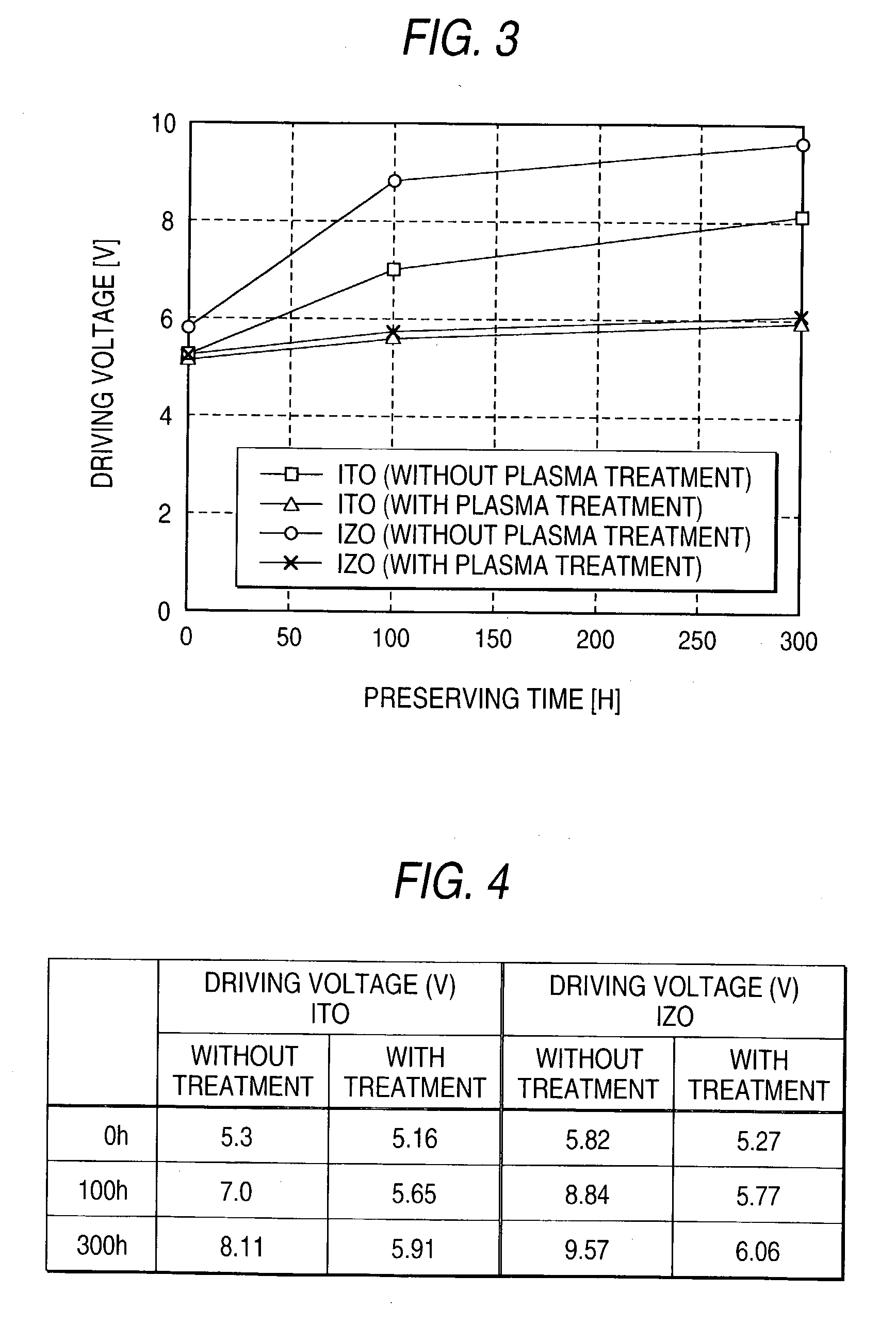

Manufacturing method of organic electroluminescent element

InactiveUS20030211233A1Low heat resistanceAvoid etchingElectroluminescent light sourcesSolid-state devicesHexafluoroethaneOctafluorocyclobutane

An electrode-equipped substrate includes a substrate portion of synthetic resin and a transparent electrode. The electrode-equipped substrate is subjected to heat treatment at a temperature of 200° C. or less as well as plasma treatment before organic layers are deposited. The plasma treatment is carried out within atmosphere of (A) a mixed gas of oxygen and any one of nitrogen, argon, helium, neon and xenon, with an oxygen density of 5% or less; (B) a mixed gas of oxygen and any one of carbon tetrafluoride, hexafluoroethane, octafluoropropane and octafluorocyclobutane; or (C) a sole gas of nitrogen, argon, helium, neon, xenon, carbon monoxide, carbon dioxide, nitrogen monoxide or nitrous oxide.

Owner:PIONEER CORP

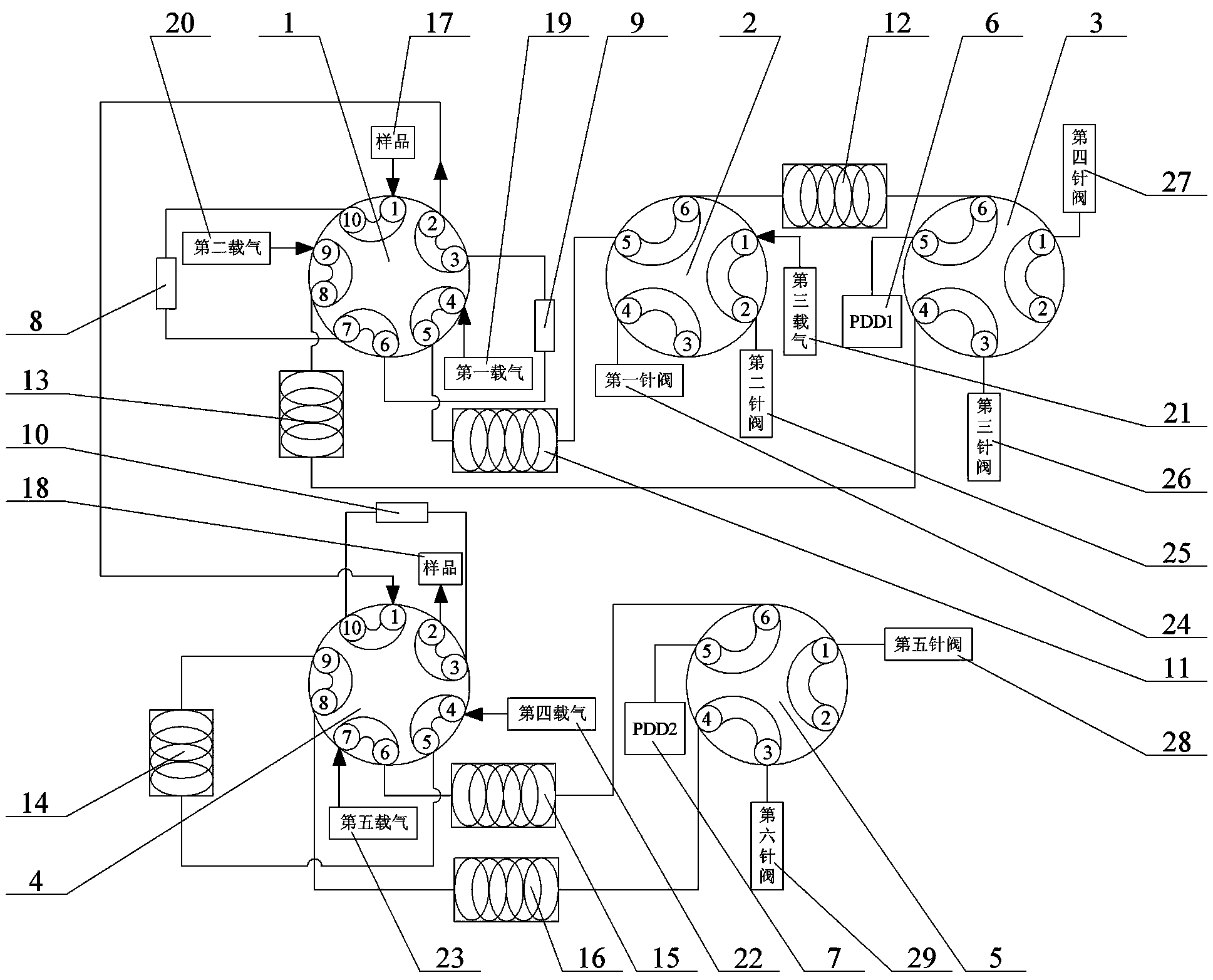

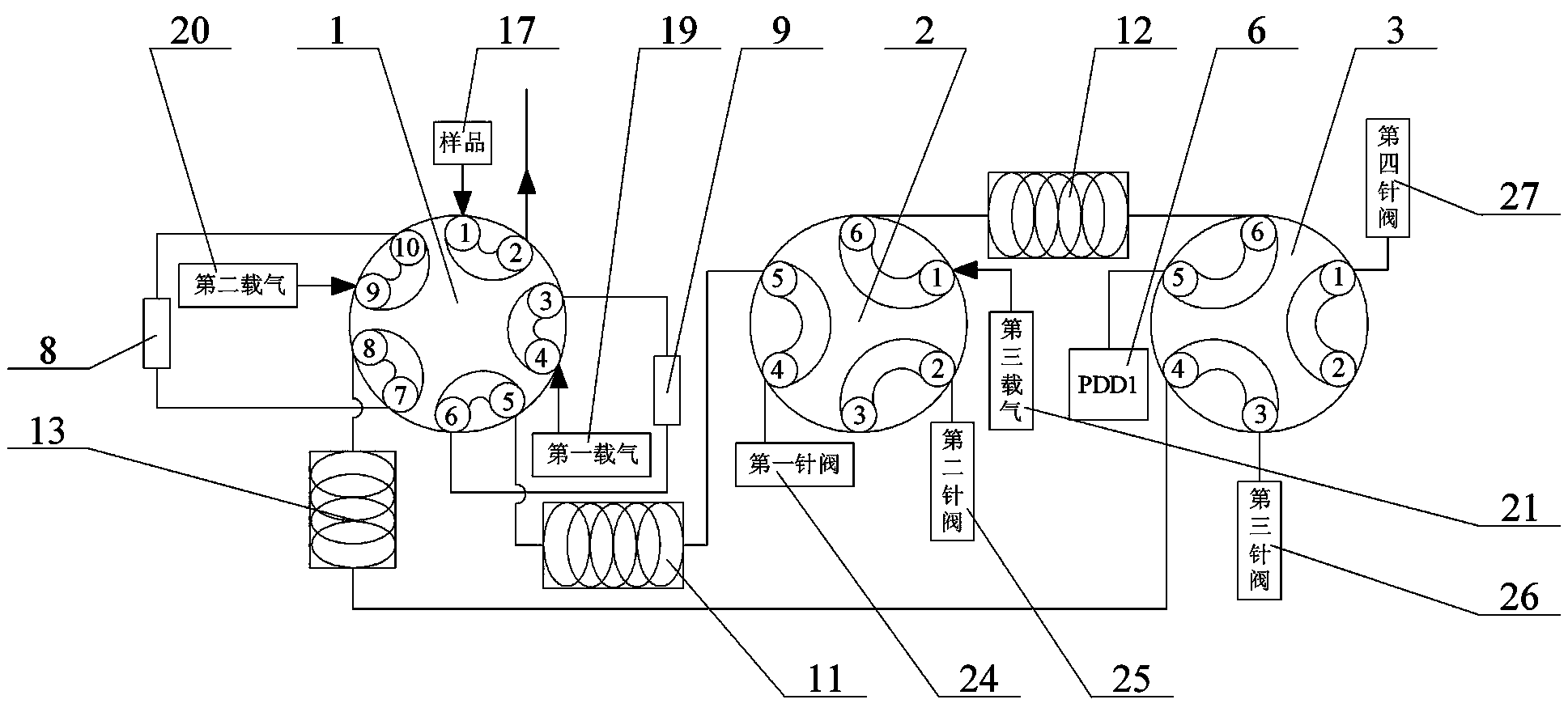

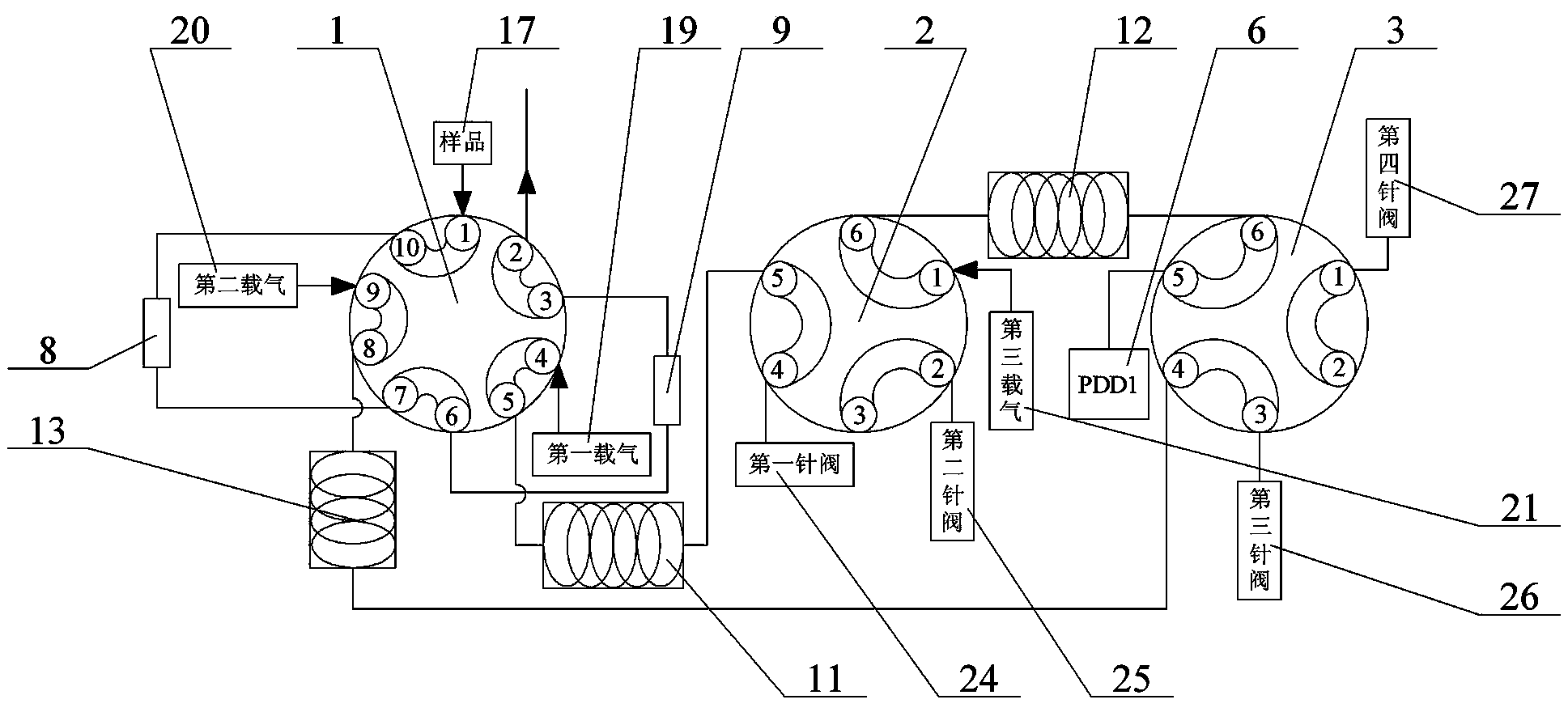

Gas chromatograph for analyzing trace impurities in electronic grade hexafluoroethane

The invention relates to a gas chromatograph for analyzing trace impurities in electronic grade hexafluoroethane. The structure of the gas chromatograph comprises a sample feed system, a transfer valve, a chromatographic column, a discharge needle valve and a detector. The gas chromatograph is characterized in that the sample feed system comprises a sample inlet, a sample outlet, a first quantitative pipe, a second quantitative pipe and a third quantitative pipe; the transfer valve comprises a first transfer valve, a second transfer valve, a third transfer valve, a fourth transfer valve and a fifth transfer valve; the chromatographic column comprises a first chromatographic column, a second chromatographic column, a third chromatographic column, a fourth chromatographic column, a fifth chromatographic column and a sixth chromatographic column; the discharge needle valve comprises a first needle valve, a second needle valve, a third needle valve, a fourth needle valve, a fifth needle valve and a sixth needle valve; the detector comprises a helium ionized first detector PDD1 and a second detector PDD2. According to the invention, samples are fed once, the chromatographic analysis for each inorganic impurity in the electronic grade hexafluoroethane is completed, the sensitivity is high, the repeatability is good, and the chromatographic analysis conforms to the standard.

Owner:SHANGHAI HUAAI CHROMATOGRAPHIC ANALYSIS

Catalyst for fluorinating of chloropenta fluoroethane to convert into hexafluoroethane, a preparation method and application in purifying pentafluoroethane

ActiveCN107243351AEfficient use ofAvoid churnPhysical/chemical process catalystsPreparation by halogen replacementHexafluoroethaneAluminum fluoride

The invention relates to a catalyst for fluorinating of chloropenta fluoroethane to convert into hexafluoroethane, a preparation method and application in purifying pentafluoroethane. The preparation method comprises the following steps of using antimony pentoxide and aluminium oxide as raw materials, mixing, grinding, enabling the antimony pentoxide and the aluminium oxide to fully mix and touch, and roasting, so as to obtain a precursor; leading hydrogen fluoride gas to fluorinate the precursor, and enabling antimony (V) and aluminum to easily form an antimony (V)-fluorine-aluminum bonding structure. The preparation method has the advantages that by adopting the bonding structure, the fluorine and chloride compounds of the antimony (V) can be effectively fixed and uniformly distributed at the surface of aluminum oxide and aluminum fluoride, so that the dispersivity of the active component (antimony) is improved, the loss of the active component (antimony) is avoided, the high-efficiency utilization of the antimony as the solid catalyst for gas-phase catalyzing is guaranteed, and the antimony can effectively play functions; the fluorine and chloride exchange ability of the antimony is further improved by the high acidity of the aluminum, so that the obtained antimony-aluminum catalyst has high fluorine and chloride exchange ability and strong catalysis activity.

Owner:SHANDONG DONGYUE CHEM

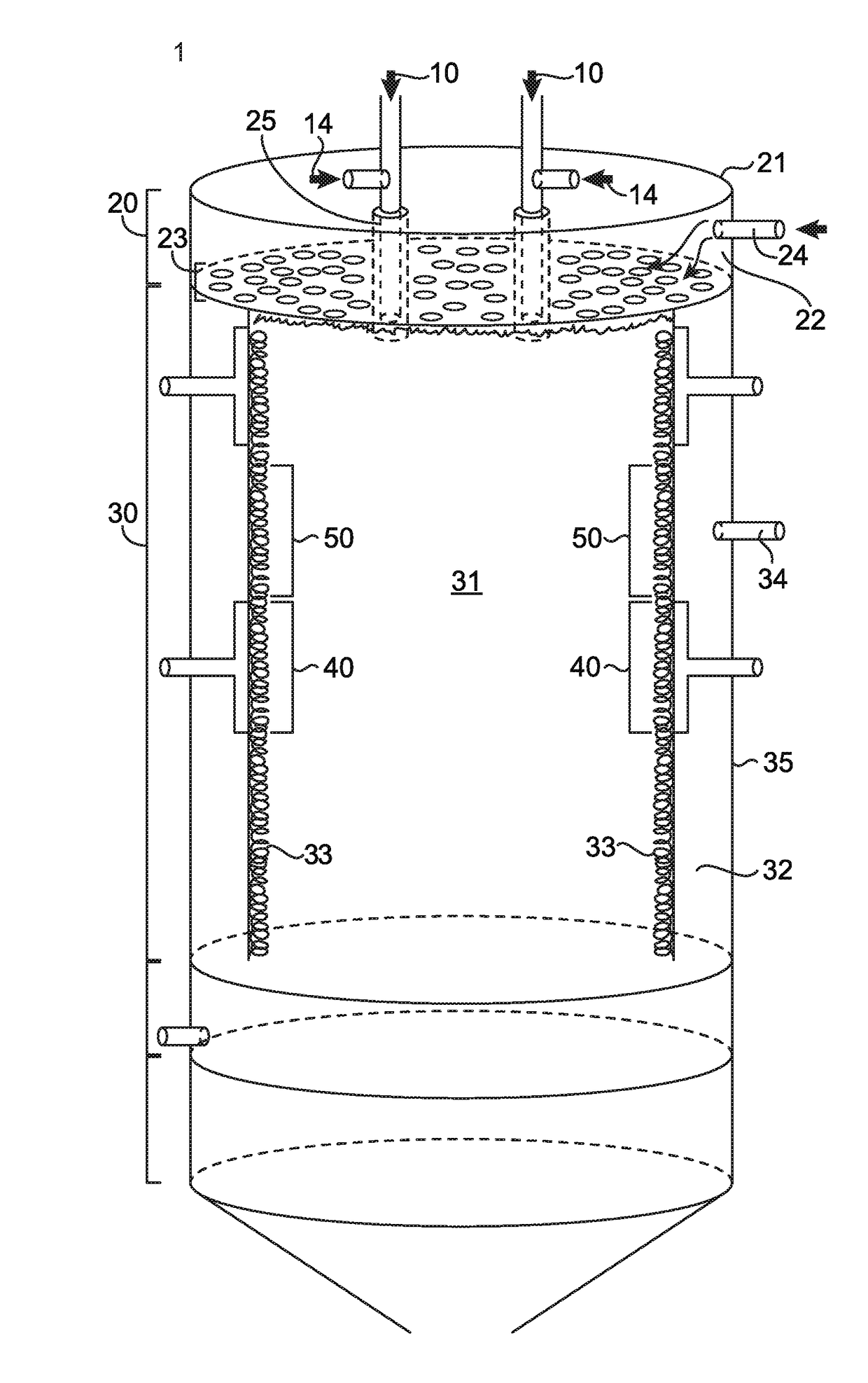

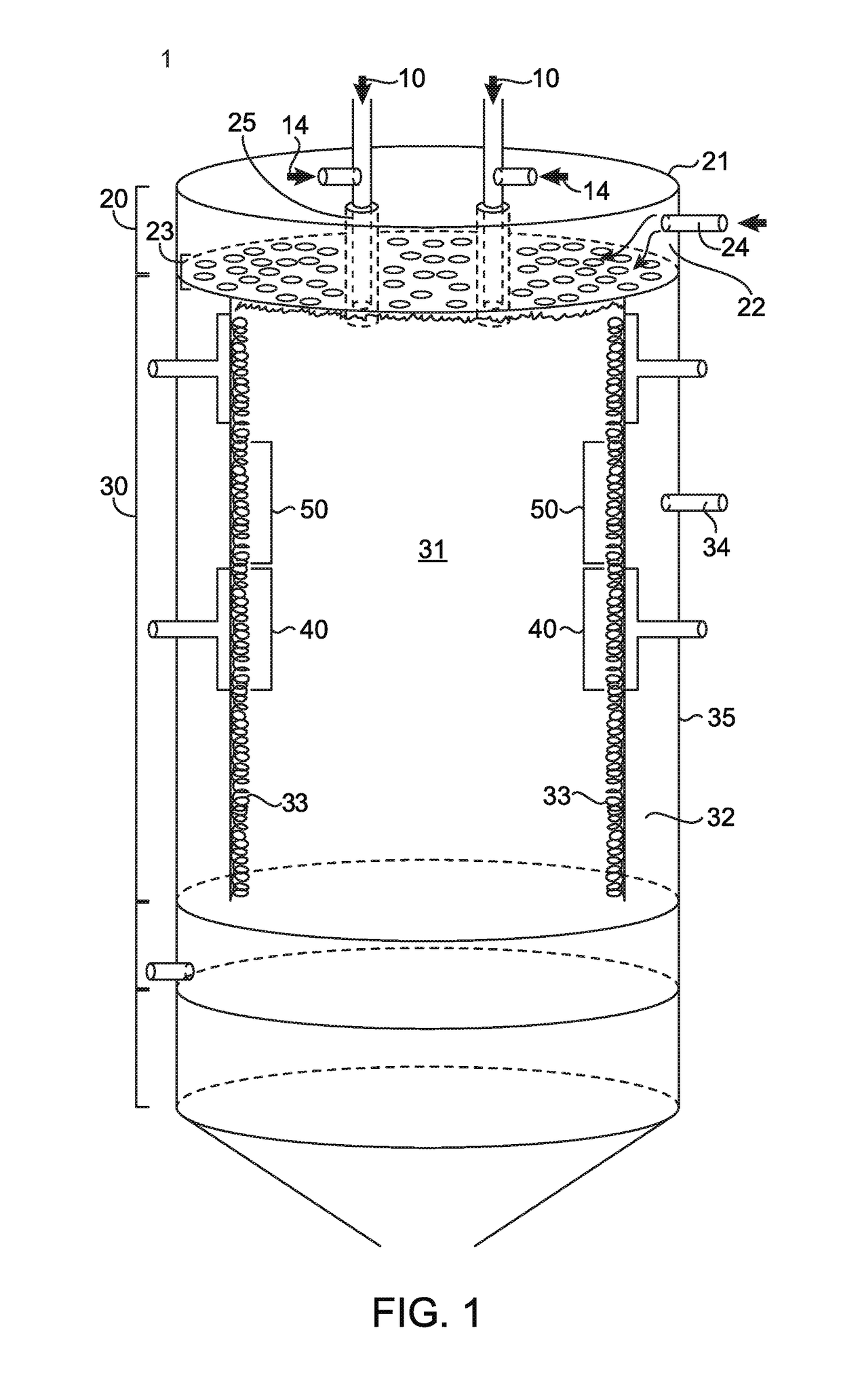

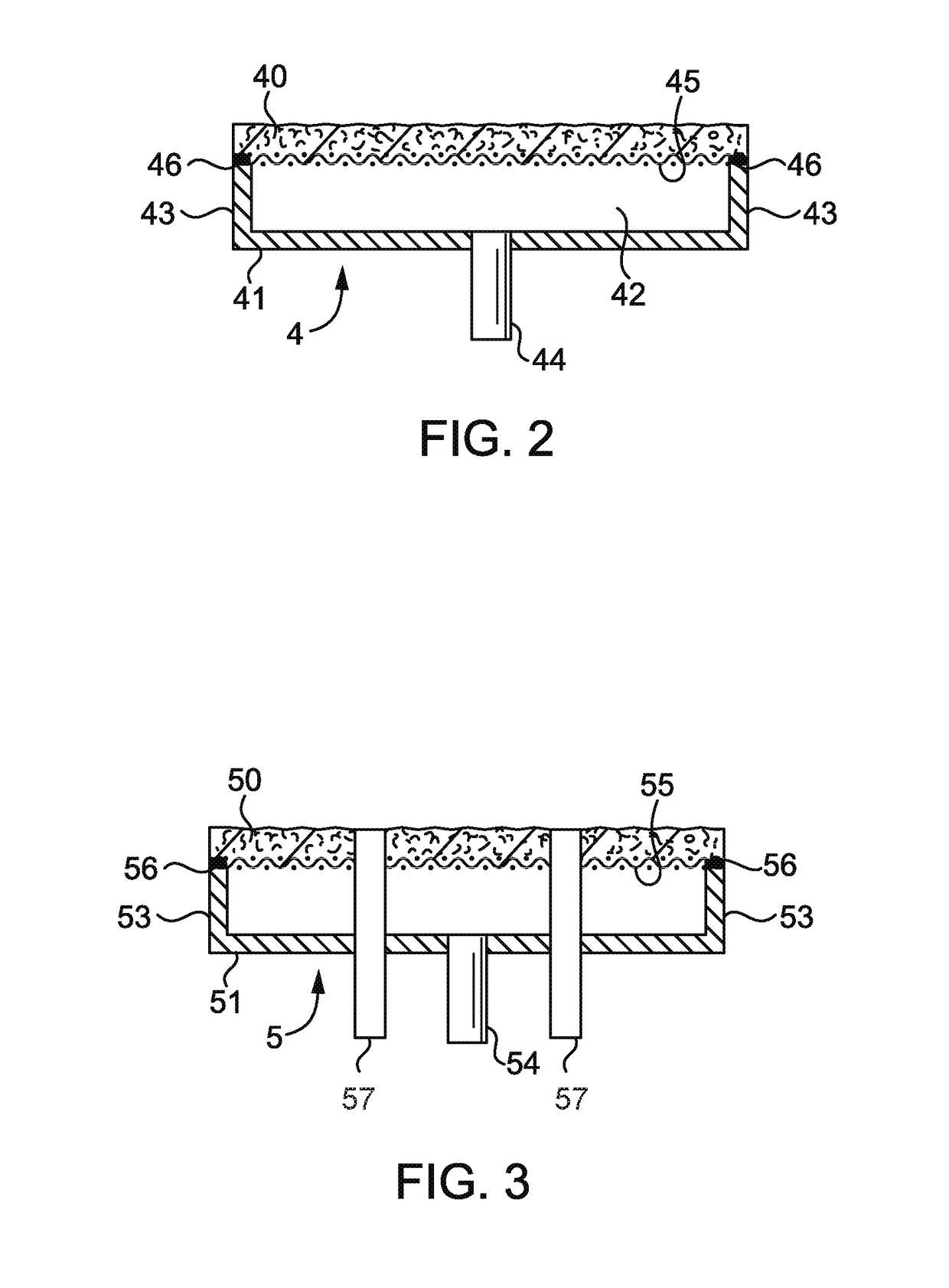

Systems and methods for improved waste gas abatement

ActiveUS20180259182A1Reduce accumulationLong lastingGas treatmentDispersed particle separationParticulatesHexafluoroethane

The present disclosure generally relates to systems and methods for the combustive abatement of waste gas formed during the manufacture of semiconductor wafers. In particular, the systems described herein are capable of combusting air-polluting perfluorocarbons, including those having high greenhouse gas indexes such as hexafluoroethane (C2F6) and tetrafluoromethane (CF4), as well as particulate-forming silicon dioxide precursors, such as silane (SiH4) and tetraethoxysilane (Si(OC2H5)4, abbreviated TEOS), with greater efficiency and lower energy usage than prior abatement systems. More particularly, and in one preferred embodiment, the present disclosure is directed to a waste gas abatement system that utilizes a combination of non-combustible and combustible gases (or gas mixtures) for thermal combustion, which are directed through multiple permeable interior surfaces of a reaction chamber, efficiently combusting waste gas and preventing undesirable accumulation of solid particulate matter on the chamber surfaces.

Owner:ALZETA

Purification method of industrial grade hexafluoroethane

InactiveCN109970509AHigh puritySimple processHalogenated hydrocarbon separation/purificationHexafluoroethaneMolecular sieve

The invention discloses a purification method of industrial grade hexafluoroethane. The method comprises the two steps of rectification separation and pressure adsorption, wherein the pressure adsorption step uses a molecular sieve adsorbent to remove impurities. The method provided by the invention has the advantages of short flow, convenient operation, low energy consumption and strong treatmentcapability.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

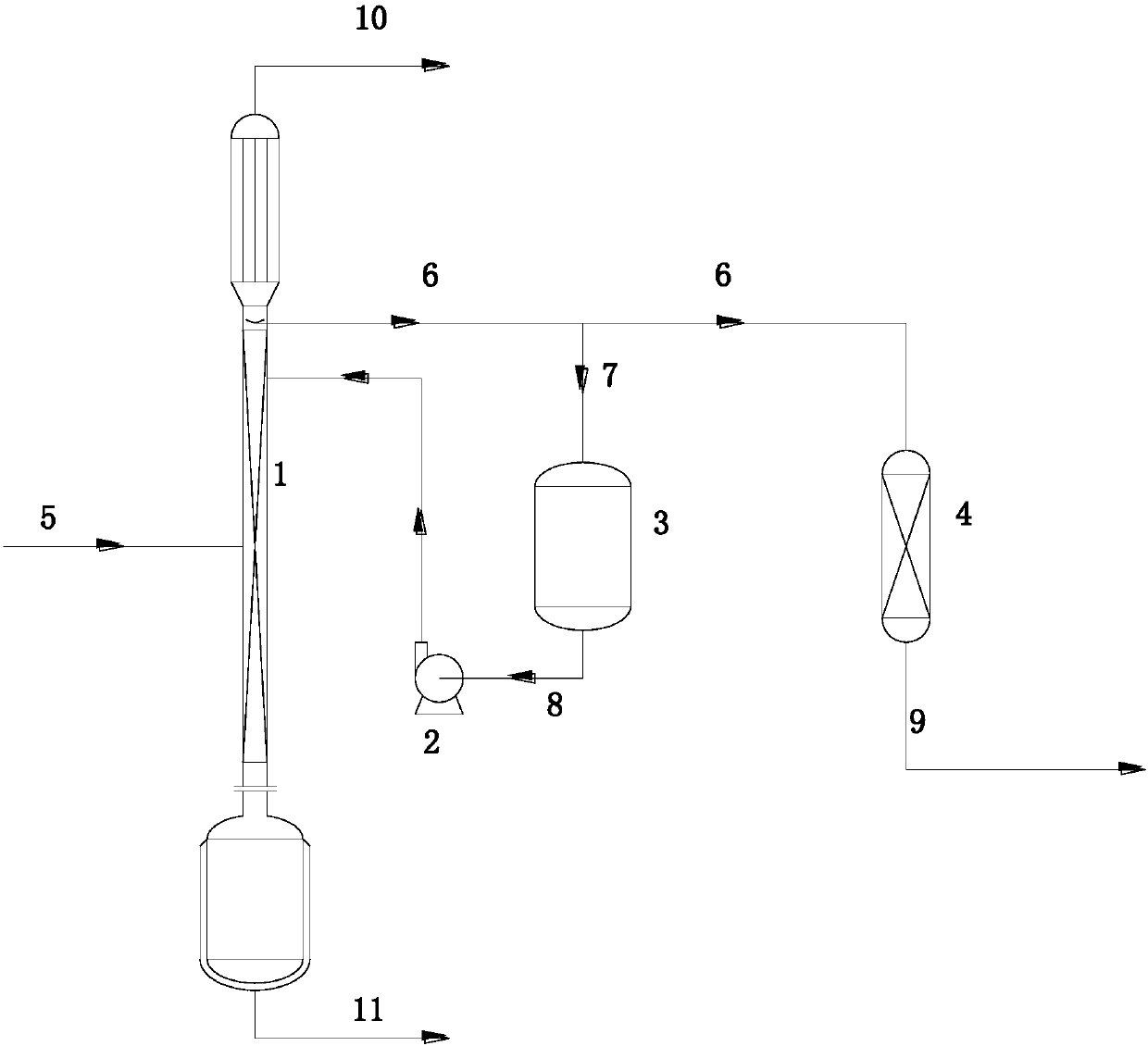

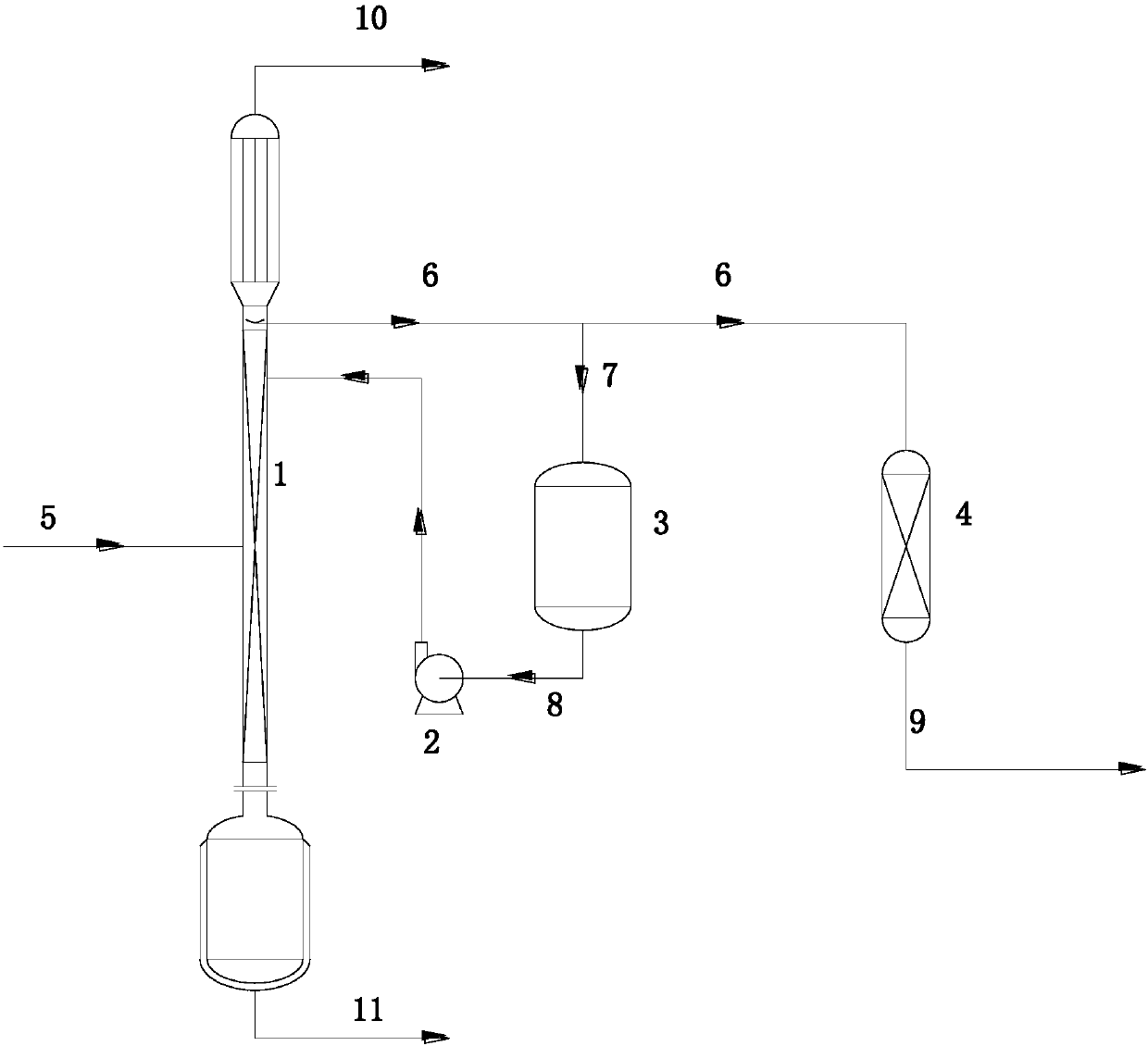

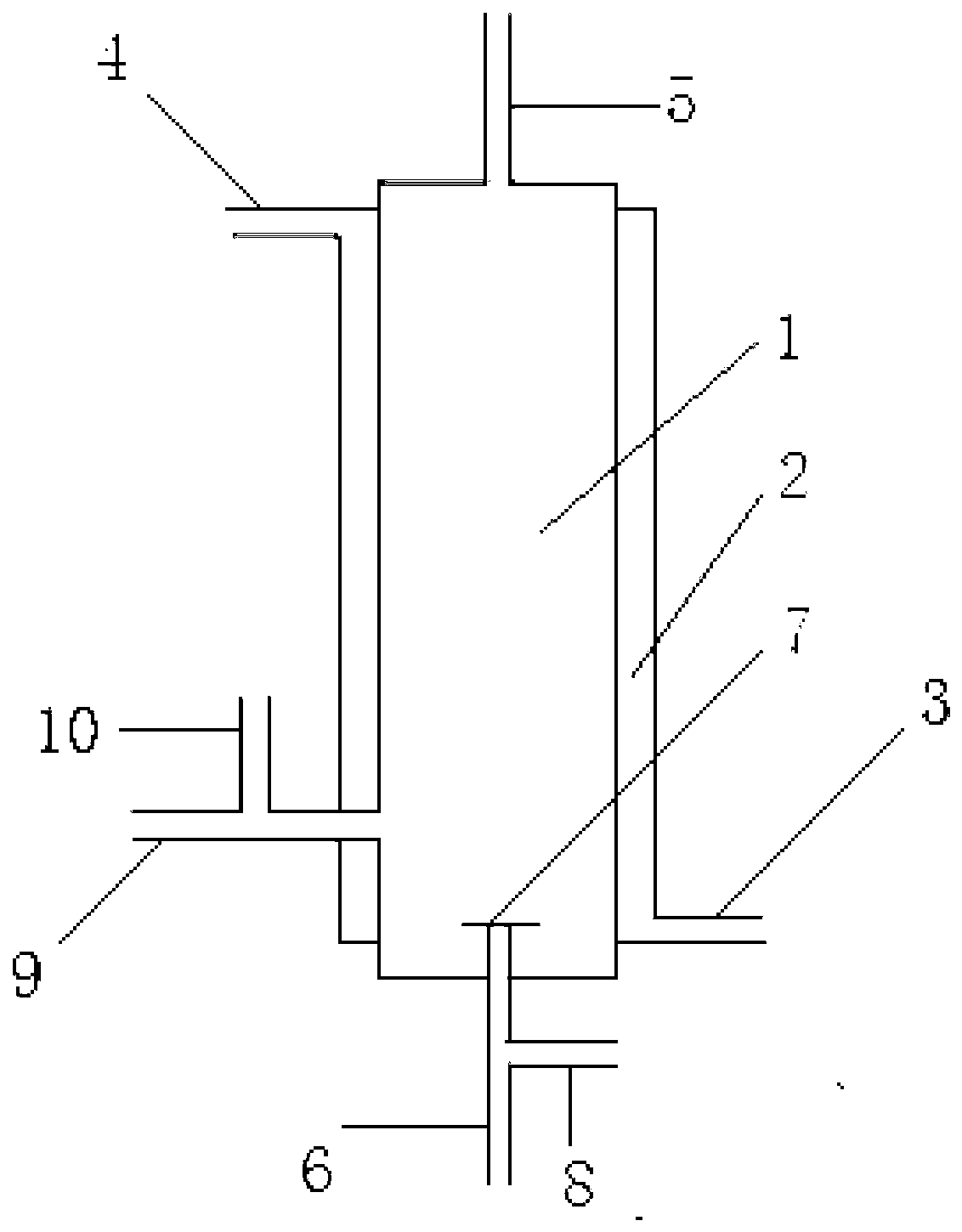

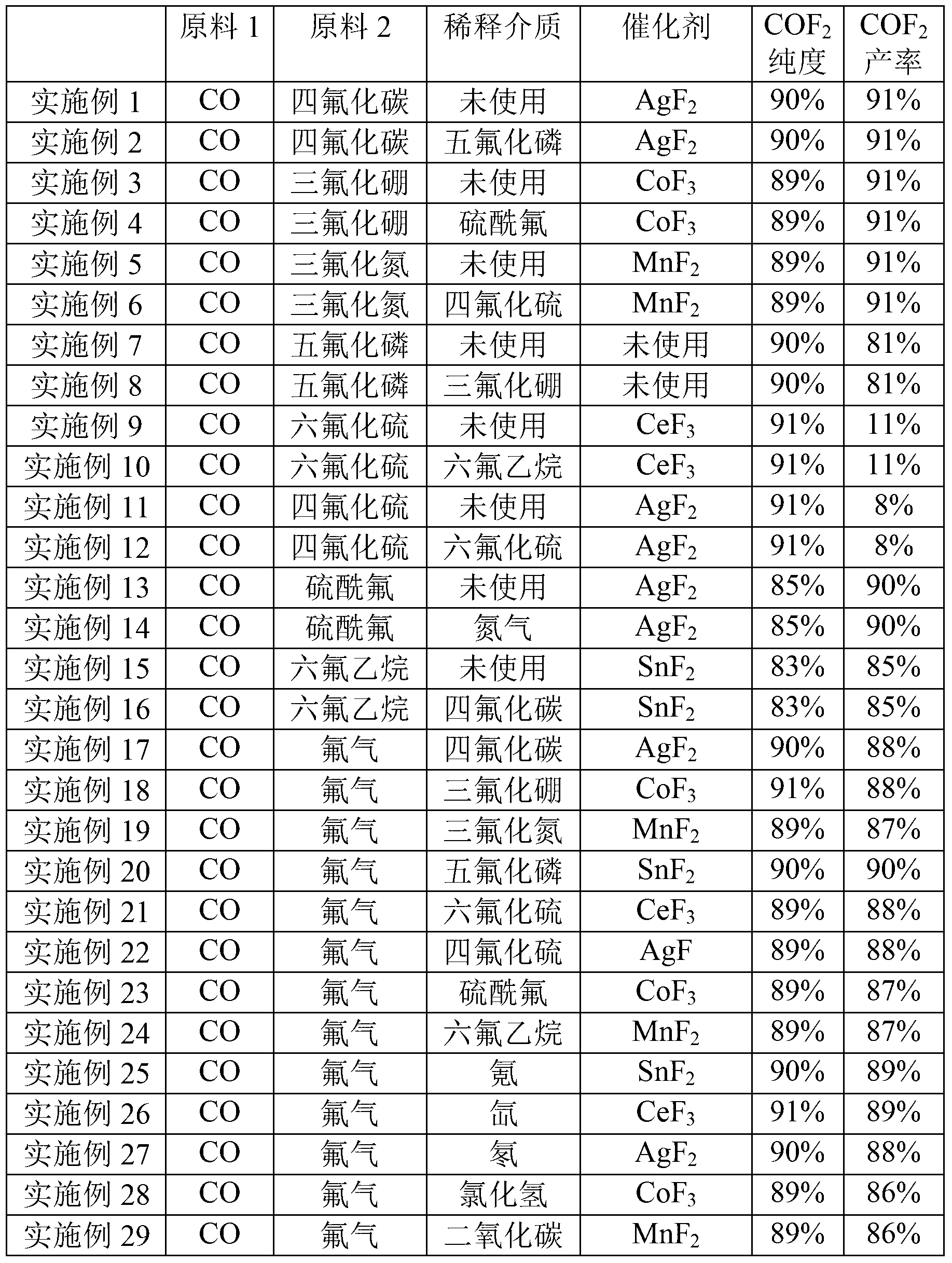

Preparation method of carbonyl fluoride

ActiveCN103213965ASafe preparationEconomical and efficient to prepareCarbon compoundsHexafluoroethanePhosphorus trifluoride

The invention relates to a preparation method of carbonyl fluoride and belongs to the fluorine chemical field and the field of electronic industrial gas. The preparation method is used for preparing carbonyl fluoride through the reaction of carbon monoxide and fluorine-containing substance, wherein the fluorine-containing substance is at least one of carbon tetrafluoride, boron trifluoride, nitrogen trifluoride, sulfur tetrafluoride, sulfur hexafluoride, phosphorus trifluoride, phosphorus pentafluoride, sulfuryl fluoride or hexafluoroethane; the favourable conditions including temperature, pressure, a proportion of fluorine-containing substance to carbon monoxide and gas supply flow rate of the fluorine-containing substance are selected; dilution medium is further added in the method for diluting or carrying out catalytic reaction by virtue of catalyst. The preparation method of the carbonyl fluoride is free of fluorine gas, capable of lowering the corrosion to a reactor, reaction heat, reaction intensity, potential explosive risk and yield drop caused by side reaction, and capable of safely, economically and effectively preparing the carbonyl fluoride. The invention further provides dilution medium which is used in the preparation of the carbonyl fluoride through the reaction of carbon monoxide and fluorine gas.

Owner:PERIC SPECIAL GASES CO LTD

A method of preparing hexafluoroethane at high temperature

ActiveCN105461507AAvoid problemsEasily brokenHalogenated hydrocarbon preparationHexafluoroethaneCobalt(II) fluoride

The invention relates to a method of preparing hexafluoroethane at high temperature and belongs to the technical field of fluorine chemical engineering. The method includes adding cobaltous fluoride into a reactor, controlling the temperature of the reactor to be 350-450 DEG C and pressure of the reactor to be 0.1-0.15 MPa, adding a gas mixture of nitrogen trifluoride and nitrogen and pentafluoroethane, with the gas space velocity in a cobaltous oxide bed layer being 0.2-5 / min, and discharging a reaction product from the reactor to obtain the hexafluoroethane. Raw materials used in the method are safe. The method is safe in operation, high in product yield and suitable for large-scale industrial production.

Owner:PERIC SPECIAL GASES CO LTD

Process for ashing organic materials from substrates

InactiveCN1289452ASemiconductor/solid-state device manufacturingPhotosensitive material processingOrganic filmHexafluoroethane

Ashing of an organic film from a substrate is carried out by providing a plasma comprising a gas or gas mixture selected from the following groups: (a) sulfur trioxide alone; (b) sulfur trioxide plus one supplemental gas; and (c) sulfur trioxide plus at least two supplemental gases. Any of the following gases may be employed as the supplemental gas: water vapor, ozone, hydrogen, nitrogen, nitrogen oxides, or a halogenide such as tetrafluoromethane, chlorine, nitrogen trifluoride, hexafluoroethane, or methyltrifluoride.

Owner:安农股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com