Mask etch process

A technology of mask plate and mask layer, which is applied in the photoplate making process of patterned surface, photosensitive material processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

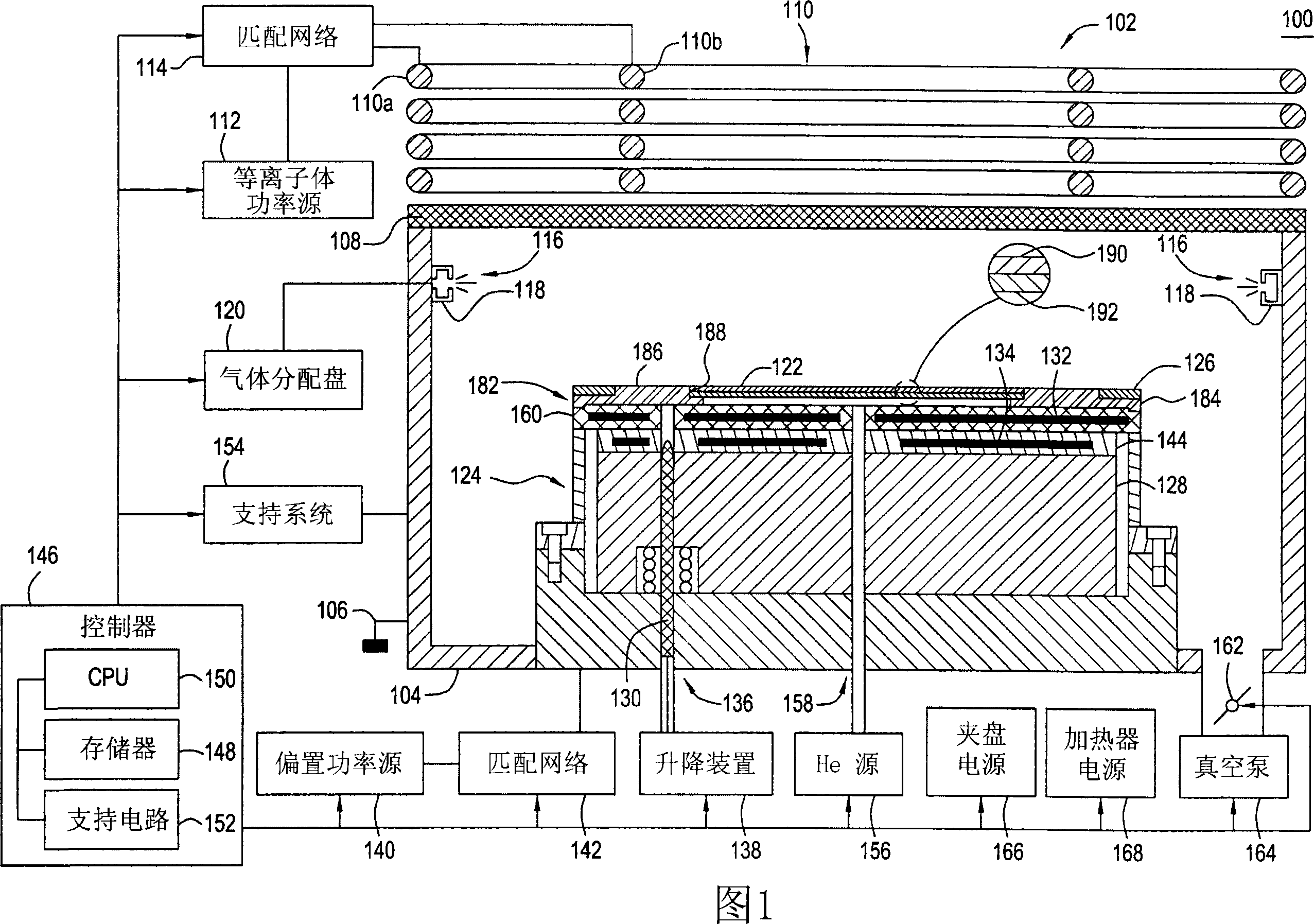

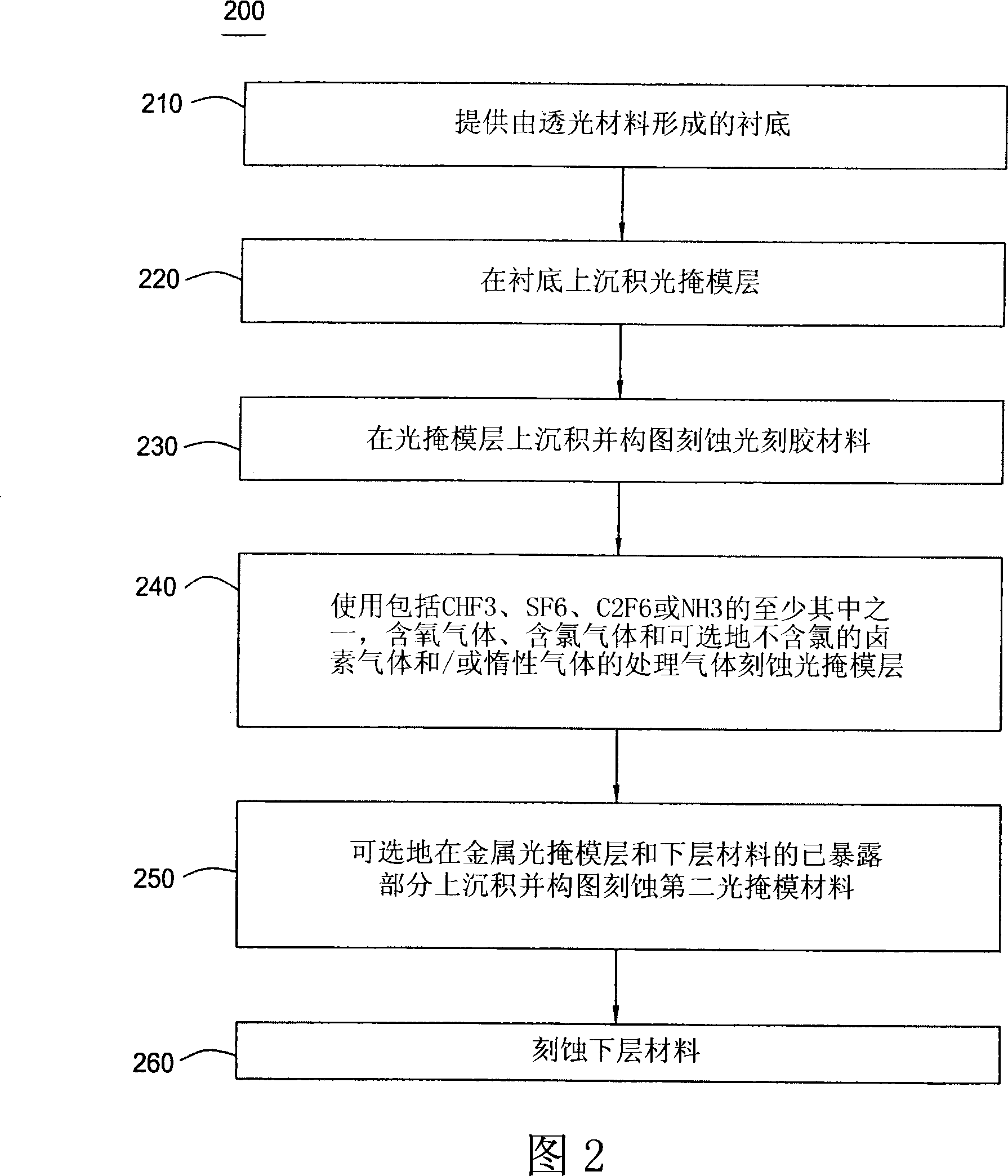

[0071] A photolithographic mask including a substrate formed of a light transmissive material such as optical quality quartz, fused silicon material, molybdenum silicide is introduced into a processing chamber for resist deposition (MoSi), molybdenum silicon oxynitride (MoSi X N Y o Z ), calcium fluoride, alumina, sapphire, or combinations thereof, a chrome photomask layer deposited on the substrate to a thickness, for example, between about 70 nanometers (nm) and about 100 nm. An optional ARC layer of chromium oxynitride may be formed, which may comprise up to about 25% of the overall chromium thickness.

[0072] A resist, such as the resist material ZEP commercially available from Tokyo-Oka, Japan, or chemical Reinforced resist or CAR resist also commercially available from Tokyo-Oka, Japan. The resist is deposited on the substrate to a thickness between about 200 nm and about 600 nm, eg, about 300 nm to about 400 nm, but can be any thickness desired.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com