Purification method of industrial grade hexafluoroethane

A technology for purification of hexafluoroethane, which is applied in the field of purification of industrial-grade hexafluoroethane, can solve the problems of unfavorable industrial production and limited catalyst life, and achieve simple adsorption and regeneration operations, reduced equipment investment, and high adsorption efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

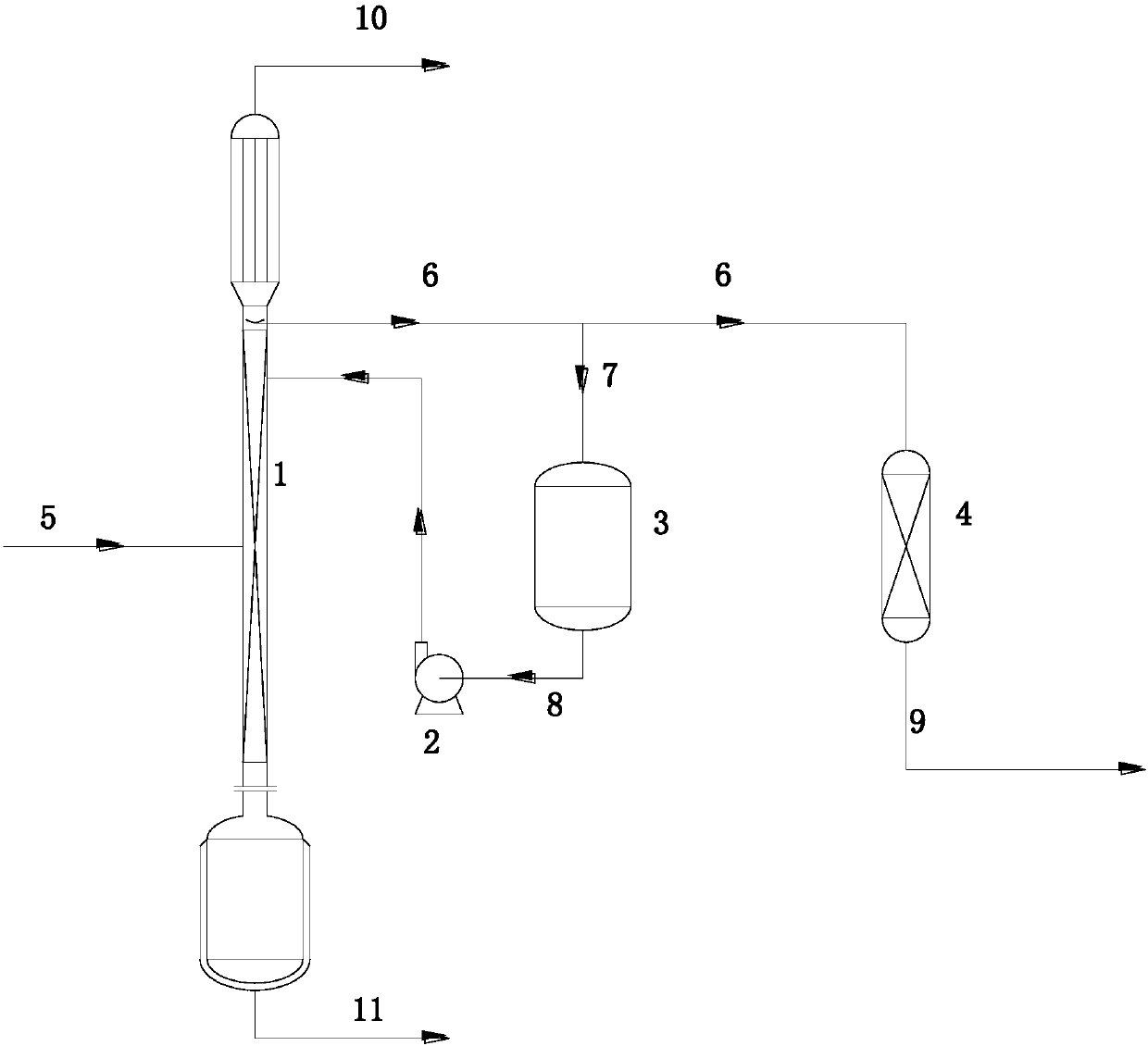

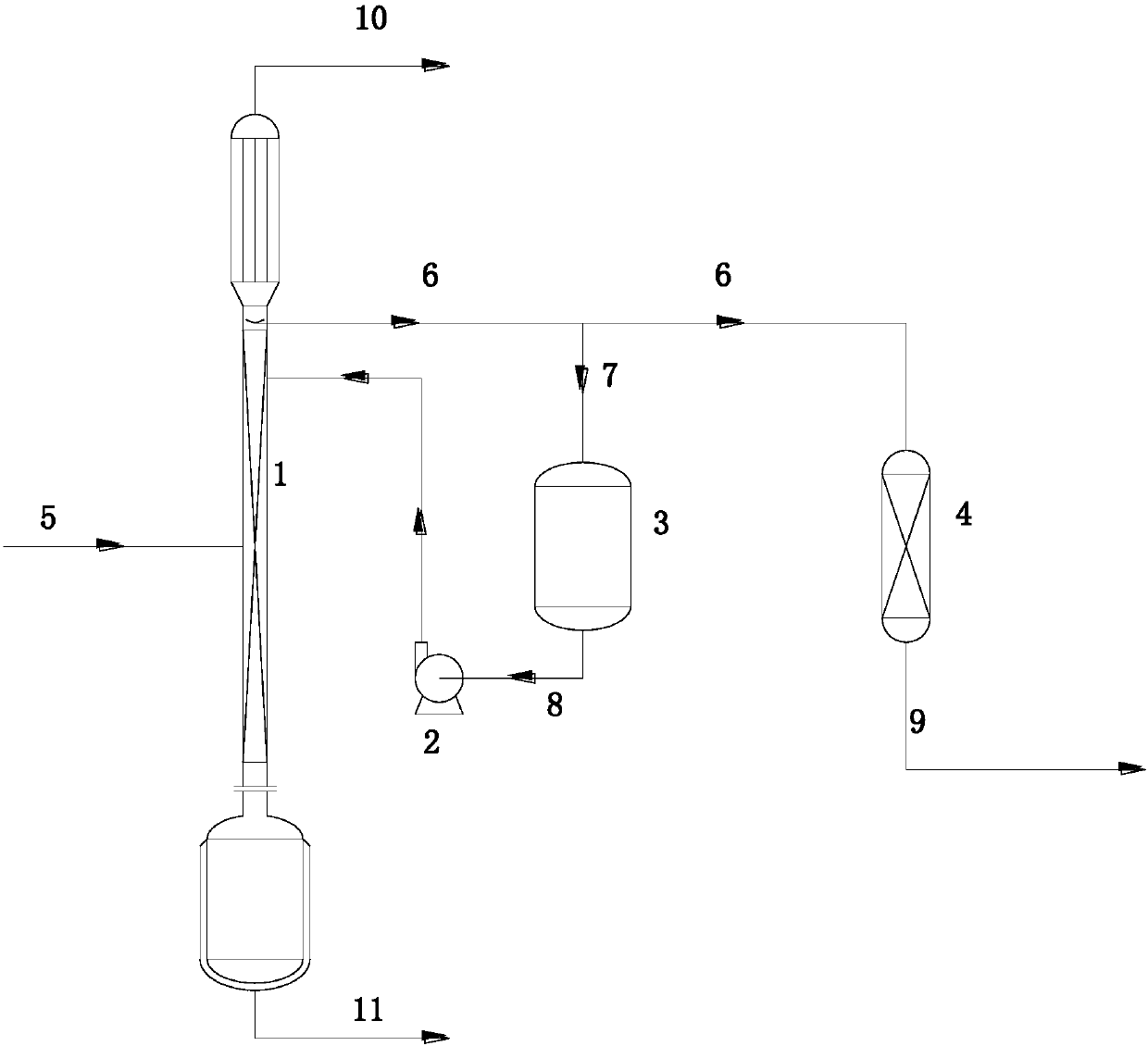

[0042] Feed the raw material stream 5 containing hexafluoroethane and hydrochlorofluorocarbons into the rectification separation tower 1, at a rectification temperature of 36°C, a rectification pressure of 1.5MPa, and an outlet flow rate of the external reflux pump 2 of 2m 3 / h, the liquid level of the external reflux tank 3 is 40% to 60%, and the venting flow rate of the stream 10 containing non-condensable gas and low-boiling hydrochlorofluorocarbons is 1Nm 3 / h conditions for rectification. Pass the rectified hexafluoroethane stream 6 into the adsorber 4, under the conditions of temperature -10°C, pressure 1.5MPa, and molecular sieves mixed with 4A and 5A molecular sieves at a mass ratio of 1:2 as the adsorbent Adsorption under pressure is carried out to obtain the hexafluoroethane product stream 9.

[0043] After analysis, in the hexafluoroethane product stream 9, the purity of the hexafluoroethane product is above 99.95%, and the mass concentration of each impurity is: C...

Embodiment 2

[0046] Feed the raw material stream 5 containing hexafluoroethane and hydrochlorofluorocarbons into the rectification separation tower 1, at a rectification temperature of 40°C, a rectification pressure of 2.0MPa, and an outlet flow rate of the external reflux pump 2 of 1.8m 3 / h, the liquid level of the external reflux tank 3 is 50% to 60%, and the venting flow rate of the stream 10 containing non-condensable gas and low-boiling hydrochlorofluorocarbons is 0.6Nm 3 / h conditions for rectification. Pass the rectified hexafluoroethane stream 6 into the adsorber 4, under the conditions of temperature -15°C, pressure 1.6MPa, and molecular sieve mixed with 5A and NaX molecular sieve at a mass ratio of 2:1 as the adsorbent Adsorption under pressure is carried out to obtain the hexafluoroethane product stream 9.

[0047] After analysis, in the hexafluoroethane product stream 9, the purity of the hexafluoroethane product is above 99.9995%, and the mass concentration of each impurity ...

Embodiment 3

[0050] Feed the raw material stream 5 containing hexafluoroethane and hydrochlorofluorocarbons into the rectification separation tower 1, at a rectification temperature of 42.5°C, a rectification pressure of 2.05MPa, and an outlet flow rate of the external reflux pump 2 of 1.85m 3 / h, the liquid level of the external reflux tank 3 is 50% to 60%, and the venting flow rate of the stream 10 containing non-condensable gas and low-boiling hydrochlorofluorocarbons is 0.5Nm 3 / h conditions for rectification. Pass the rectified hexafluoroethane stream 6 into the adsorber 4, under the conditions of temperature -16°C, pressure 1.8MPa, and molecular sieve mixed with 5A and 13X molecular sieve at a mass ratio of 3:2 as the adsorbent Adsorption under pressure is carried out to obtain the hexafluoroethane product stream 9.

[0051] After analysis, in the hexafluoroethane product stream 9, the purity of the hexafluoroethane product is above 99.9995%, and the mass concentration of each impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com