Preparation method of electronic grade hexafluoroethane

A hexafluoroethane, electronic-grade technology, applied in the field of preparation of fluorine-containing gas, can solve the problems of small contact area, unfavorable gas passage, influence on reaction efficiency, etc., and achieve the effect of high conversion rate and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

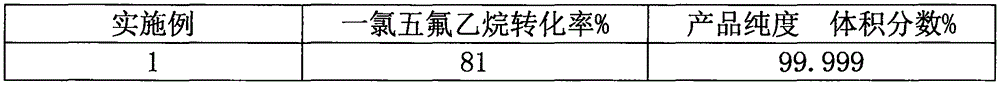

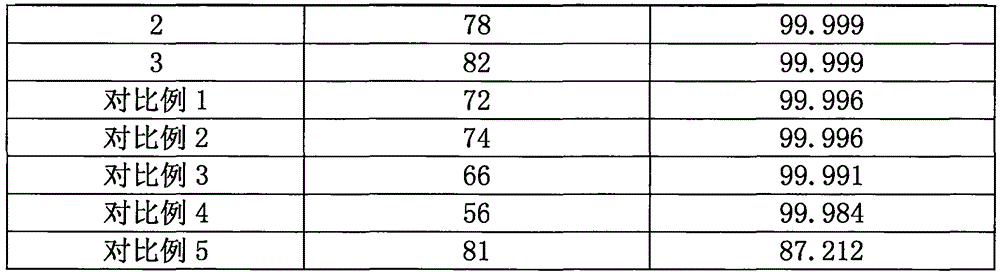

Examples

Embodiment 1

[0023] Step (1): Preparation of Catalyst

[0024] 100Kg of antimony trioxide, 700Kg of water, 20Kg of hydrogen peroxide (mass percentage concentration 40), stirred at 30°C for 4 hours, filtered, and dried to obtain polyantimonic acid; then add 100Kg of activated clay and 2Kg of molecular sieve , stirred at 30°C for 4h, extruded and granulated after the reaction, dried at 300°C for 7h to obtain a catalyst carrier, and then added 2Kg of sodium metaaluminate and 0.3Kg of 1,2-dimethyl-3-hydroxyethylimidazole Tetrafluoroborate, 78Kg hydrogen fluoride pyridine complex, react at 43°C for 6h, and then dry at 150°C for 8h. Get a catalyst.

[0025] Step (2): Synthesis reaction

[0026] Hydrogen fluoride gas and chloropentafluoroethane gas enter the reactor equipped with this catalyst to react, the molar ratio of hydrogen fluoride gas to chloropentafluoroethane is 2:1, the reaction temperature is 400°C, and the space velocity is 3BV / h. Crude hexafluoroethane was obtained.

[0027] St...

Embodiment 2

[0030] Step (1): Preparation of Catalyst

[0031] Mix 100Kg of antimony trioxide, 500Kg of water, and 10Kg of hydrogen peroxide (concentration of 30% by mass), stir at 25°C for 2 hours, filter, and dry to obtain polyantimonic acid; then add 50Kg of activated clay and 1Kg of molecular sieve , stirred at 25°C for 2h, extruded and granulated after the reaction, dried at 200°C for 5h to obtain a catalyst carrier, and then added 1Kg of sodium metaaluminate and 0.1Kg of 1,2-dimethyl-3-hydroxyethylimidazole Tetrafluoroborate, 50Kg hydrogen fluoride pyridine complex, react at 25°C for 5h, and then dry at 100°C for 5h. Get a catalyst.

[0032] Step (2): Synthesis reaction

[0033] Hydrogen fluoride gas and chloropentafluoroethane gas enter the reactor equipped with this catalyst to react, the molar ratio of hydrogen fluoride gas to chloropentafluoroethane is 1:1, the reaction temperature is 400°C, and the space velocity is 1BV / h. Crude hexafluoroethane was obtained.

[0034] Step (...

Embodiment 3

[0037] Step (1): Preparation of Catalyst

[0038] 100Kg of antimony trioxide, 1000Kg of water, 30Kg of hydrogen peroxide (mass percentage concentration 50), stirred at 60°C for 5h, filtered, and dried to obtain polyantimonic acid; then add 200Kg of activated clay and 5Kg of molecular sieve , stirred at 60°C for 5h, extruded and granulated after the reaction was completed, dried at 500°C for 10h to obtain a catalyst carrier, then added 5Kg of sodium metaaluminate, 1Kg of 1,2-dimethyl-3-hydroxyethylimidazole tetra Fluoroborate, 150Kg hydrogen fluoride pyridine complex, react at 60°C for 10h, then dry at 200°C for 10h. Get a catalyst.

[0039] Step (2): Synthesis reaction

[0040] Hydrogen fluoride gas and chloropentafluoroethane gas enter the reactor equipped with this catalyst to react, the molar ratio of hydrogen fluoride gas to chloropentafluoroethane is 3:1, the reaction temperature is 500°C, and the space velocity is 5BV / h. Crude hexafluoroethane was obtained.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com