Mixed working substance containing N*O in auto-cascade circulatory system

A technology of circulation system and mixed working fluid, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of increasing exhaust gas temperature, increasing system pressure ratio, and low reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

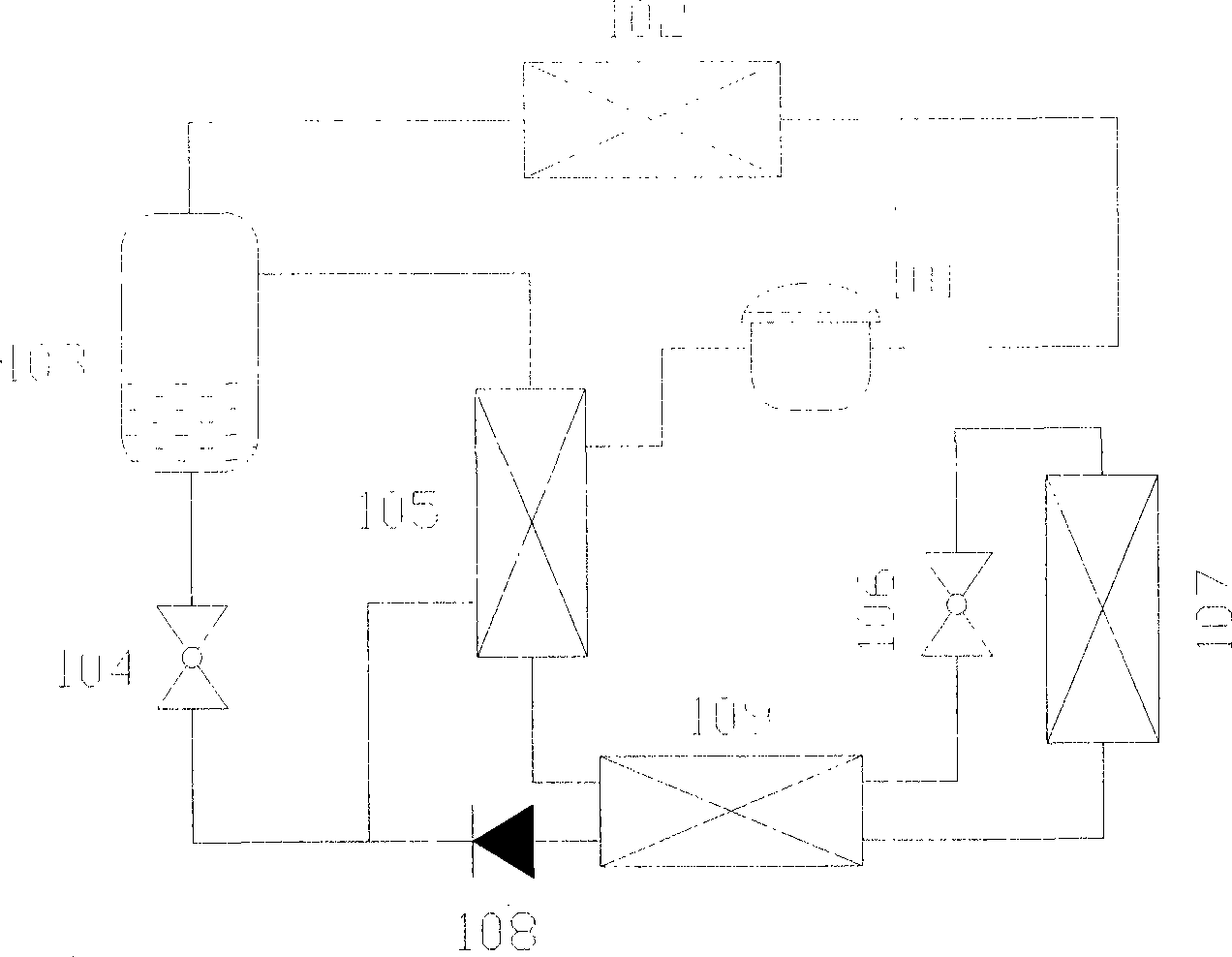

[0014] Embodiment 1-Example 4: Suitable for 200K temperature zone self-cascading circulation system containing N 2 The mixed working fluid of O(R744A), the ambient temperature is 300K, and the refrigeration cycle is figure 1 As shown, the working substance concentration and properties are shown in the following table 1:

[0015] Table 1

[0016] project Example 1 Example 2 Example 3 Example 4 Group 1

substance

45%

(N 2 O 35%,

Ethane 10%)

40%N 2 o

50%

(N 2 O 15%, three

Fluoromethane 35%) 40%

(N 2 O 30%, B

ene 10%)

Group 2

substance

55% butane

60%

(butane 50%,

1,1,1,3,3,3 Hexafluoro

Propane 10%)

50%

(butane 35%,

trans-2-butene

5%, 1-butene

5%, perfluorobutane

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com