Heat preservation control system and method for cooking utensil and cooking utensil

A technology of cooking utensils and control systems, which is applied in the field of heat preservation control systems of cooking utensils, and can solve the problems of single heat preservation methods for electric cookers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

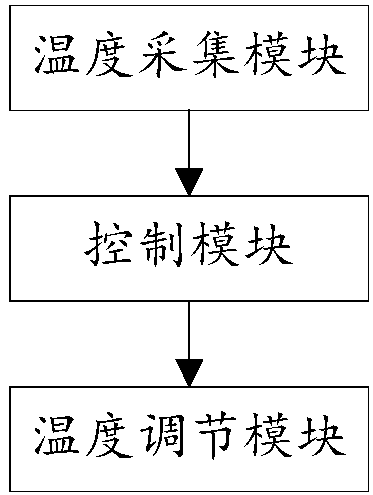

[0075] Such as Figure 1-Figure 3 As shown, a heat preservation control system of a cooking appliance in this embodiment includes a temperature adjustment module, a temperature acquisition module and a control module;

[0076] The temperature collection module is used to collect the temperature value in the cooking cavity of the cooking appliance when the cooking appliance enters the heat preservation stage, and send the temperature value to the control module;

[0077] The control module is configured to compare the remaining time of heat preservation with the first preset time in real time after the cooking appliance enters the heat preservation stage, generate a control instruction according to the comparison result, and send the control instruction to the temperature adjustment module;

[0078] The temperature adjustment module is configured to adjust the temperature according to the control instruction, and maintain the temperature value within a preset temperature range...

Embodiment approach 1

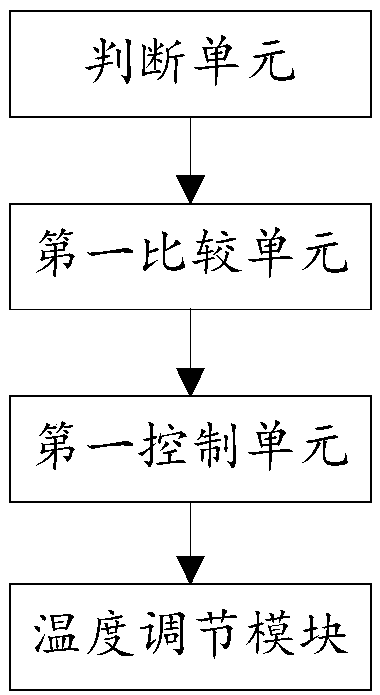

[0085] Such as figure 2 As shown, in this embodiment, the control module in the first heat preservation stage includes a first control unit, a judgment unit and a first comparison unit;

[0086] The judging unit is configured to judge whether the remaining time of the heat preservation is less than the first preset time;

[0087] The first comparison unit is configured to compare the temperature value with the upper temperature limit and the lower temperature limit of the first preset temperature range when the remaining time of the heat preservation is greater than or equal to the first preset time;

[0088] The first control unit is configured to send a control command to the temperature adjustment module according to the comparison result to maintain the temperature within the first preset temperature range.

[0089] The first control unit is specifically configured to send a refrigeration control command to the temperature adjustment module when the temperature value is ...

Embodiment approach 2

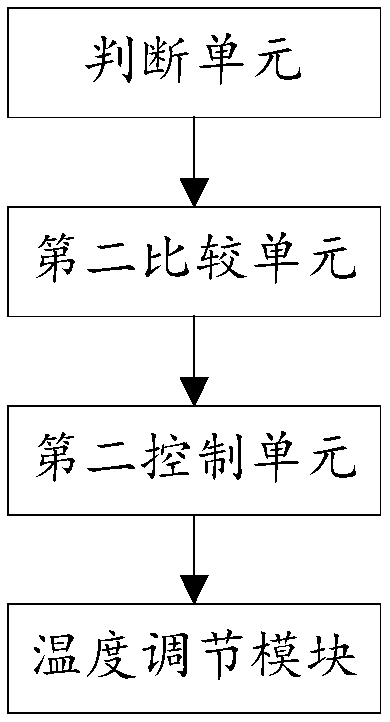

[0105] Such as image 3 As shown, in this embodiment, the control module includes:

[0106] A judging unit, configured to judge whether the remaining time of the heat preservation is less than the first preset time;

[0107] A second comparison unit, configured to compare the temperature value with the upper temperature limit and the lower temperature limit of the second preset temperature range when the remaining time of the heat preservation is less than the first preset time;

[0108] The second control unit is configured to send a control command to the temperature adjustment module according to the comparison result to maintain the temperature within the second preset temperature range.

[0109] The second control unit is configured to send a cooling control command to the temperature adjustment module when the temperature value is greater than the upper temperature limit of the second preset temperature range; When the temperature lower limit of the temperature range i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com