Device comprising a piezoacoustic resonator element, method for producing the same and method for outputting a signal depending on a resonant frequency

A technology of acoustic resonance and resonance frequency, which is applied in the field of manufacturing such devices, can solve problems such as material composition or overall structure limitations of components, and achieve the effects of low additional cost, complete temperature regulation, and reasonable manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

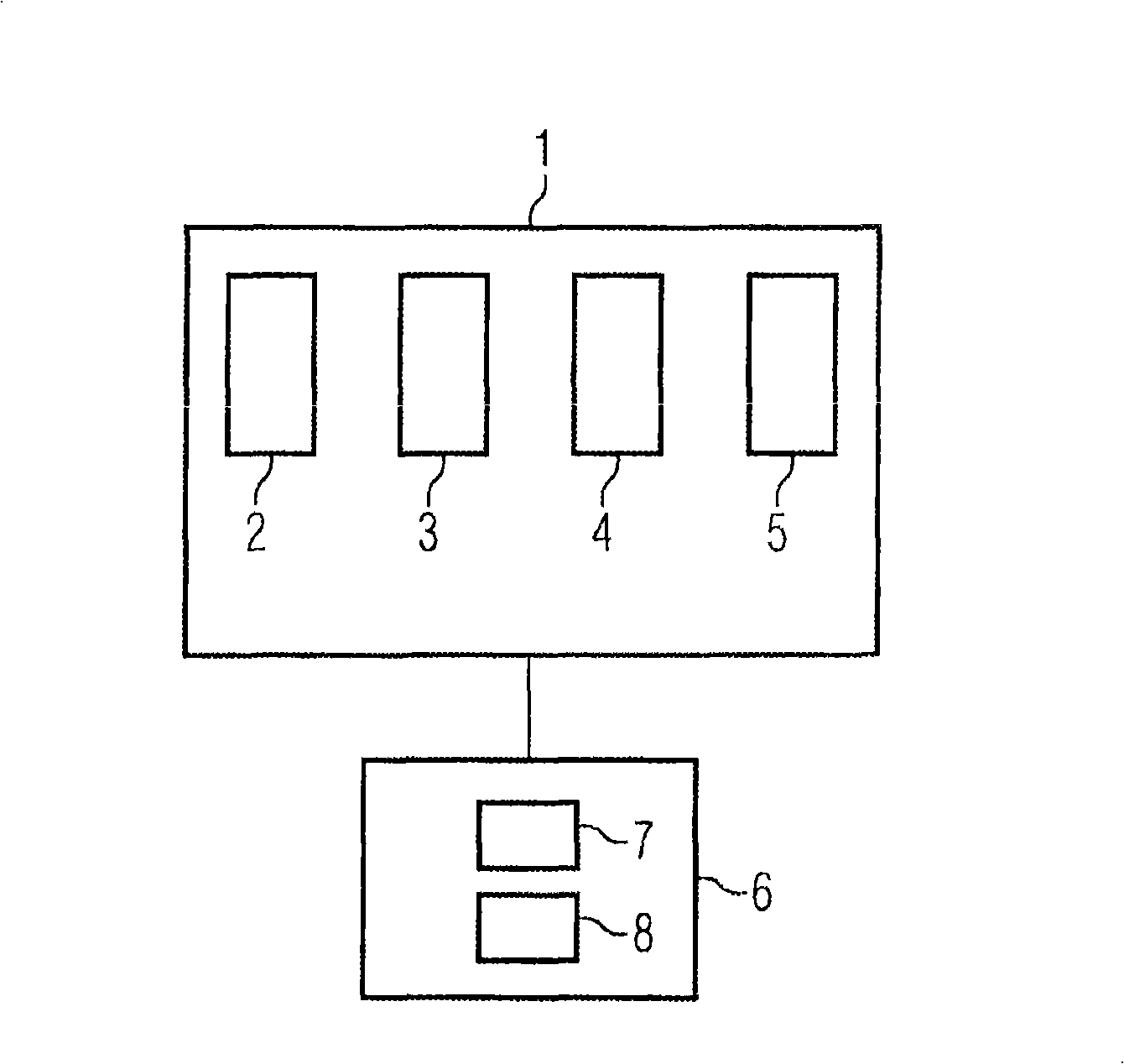

[0071] figure 2 The structure of an embodiment of the device of the present invention is shown. The device 1 according to the invention thus comprises a piezoacoustic resonant element 2 , a temperature acquisition device 3 , an analysis device 4 for determining the resonance frequency of the piezoacoustic resonator element 2 , and for measuring values supplied from the temperature acquisition device 3 Analytical means 5 for determining the temperature. In this embodiment, the measured value is the resistance of the temperature acquisition device 3 . But the present invention is not limited thereto. Instead, any temperature measuring devices or similar devices for measuring temperature disclosed in the prior art may be used as long as they can be integrated with the piezoelectric acoustic resonance element according to the process.

[0072] exist figure 2 The analyzing device 4 for determining the resonance frequency is integrated in the device 1 in the embodiment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com