Boat drive comprising auxiliary drives

A technology of driving equipment and driving device, which is applied in the direction of mechanical gear transmission, ship propulsion, mechanical equipment, etc. It can solve the problems of angular deflection, large modification costs, and the inapplicability of transmission parts to pivotable ship driving equipment, etc., to achieve The effect of maintenance and assembly simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

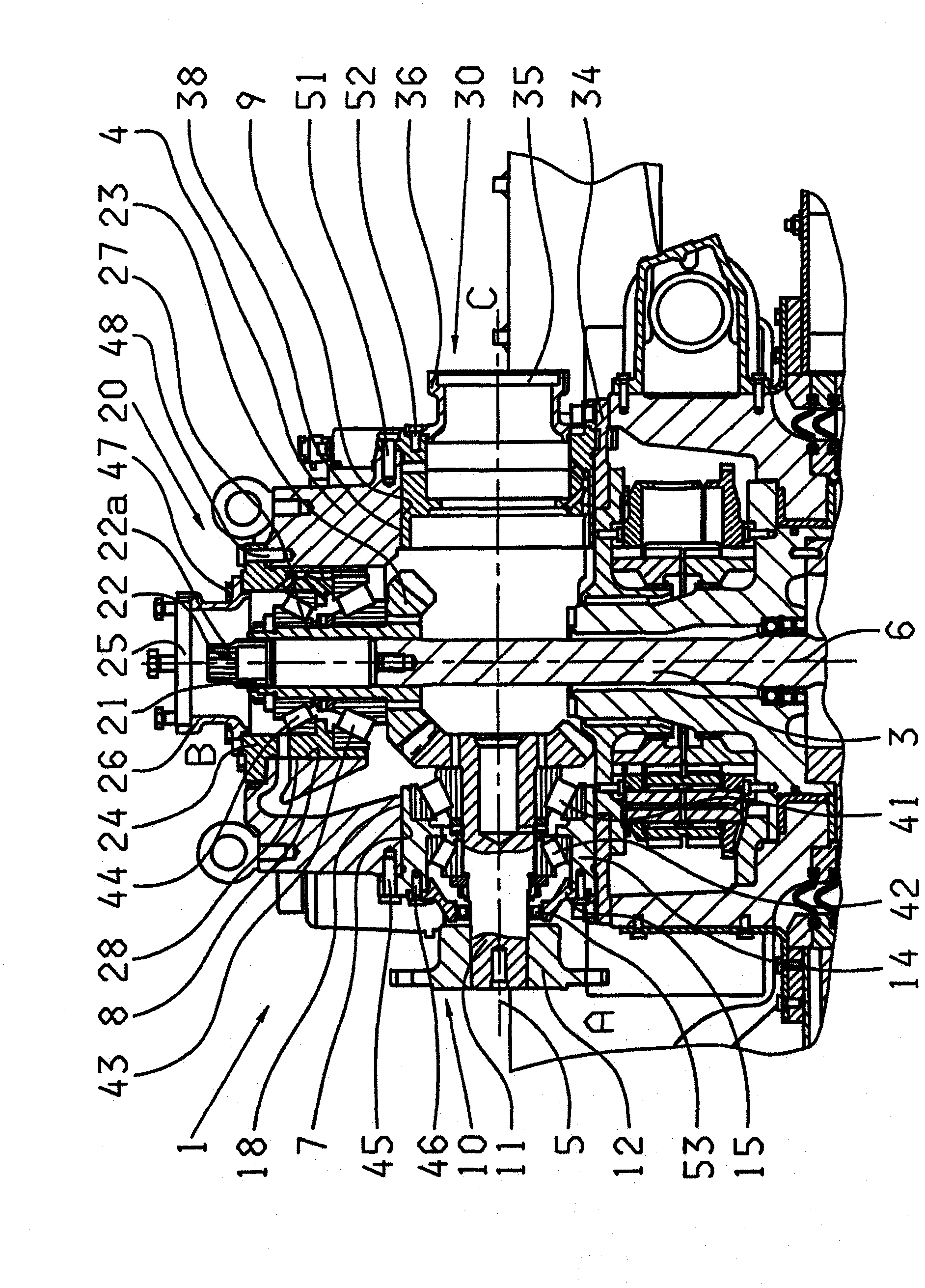

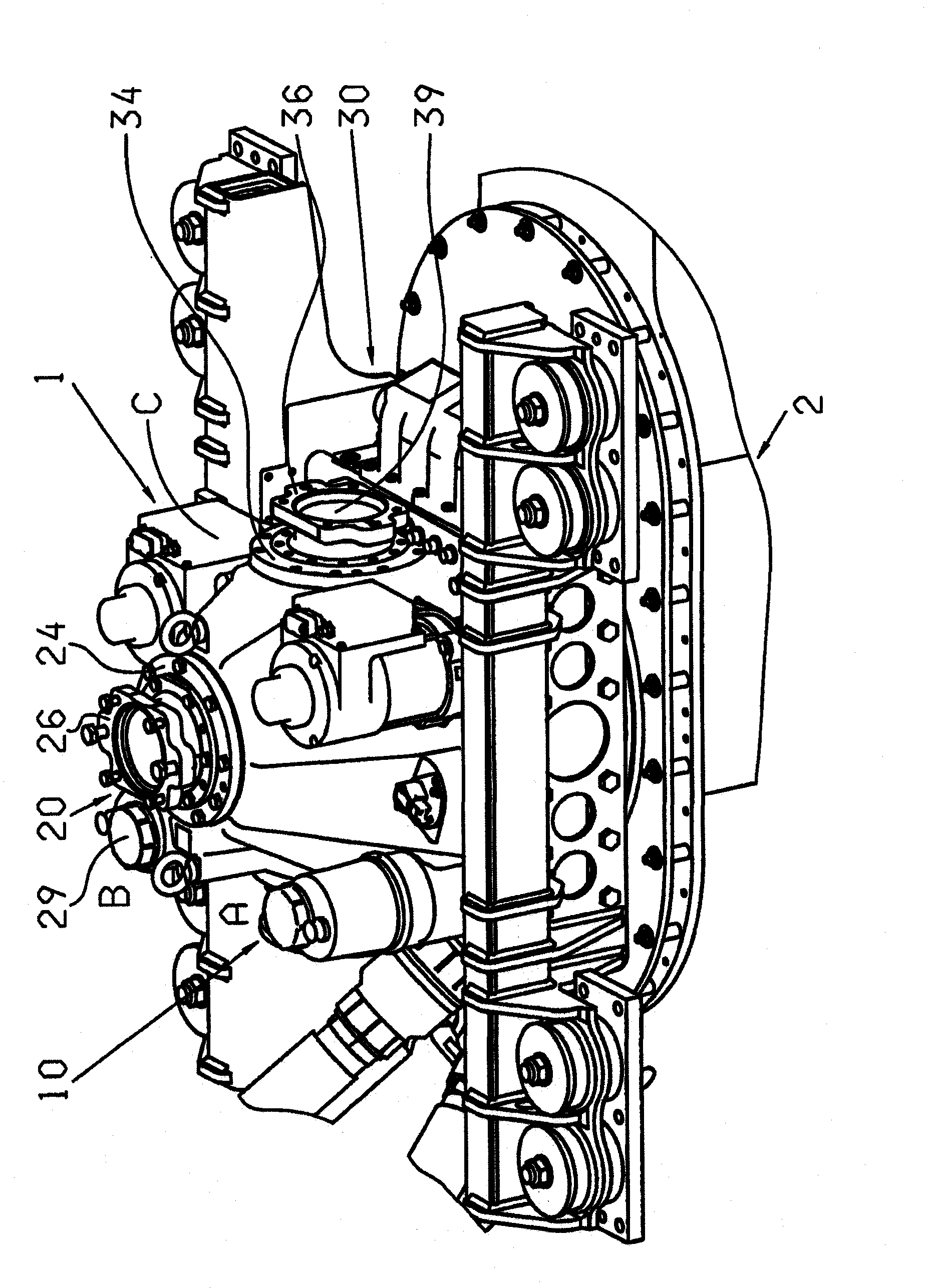

[0023] exist figure 1 A sectional view of the transmission unit 1 is shown in . The sectioning is carried out in a plane spanned by the axis of rotation 5 of the input shaft 11 and the axis of rotation 6 of the output shaft 3 , wherein the axis of rotation 5 lies in the longitudinal direction of the hull and is parallel to the axis of rotation 6 at right angles, and wherein the axis of rotation 6 intersects the axis of rotation 5 perpendicularly. The transmission unit 1 is arranged inside the hull. In the transmission housing 4 of the transmission unit 1, cylindrical inner contours 7, 8 and 9 are respectively formed at the three connecting points A, B and C, wherein the positions of the inner contours 7 and 9 are in relation to the axis of rotation 5 and the position of the inner contour 8 is coaxial with the axis of rotation 6 .

[0024] In the inner contour 7 , at the connection point A, a drive 10 is arranged coaxially to the axis of rotation 5 . In connection point A, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com