Patents

Literature

175results about How to "Fast cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device

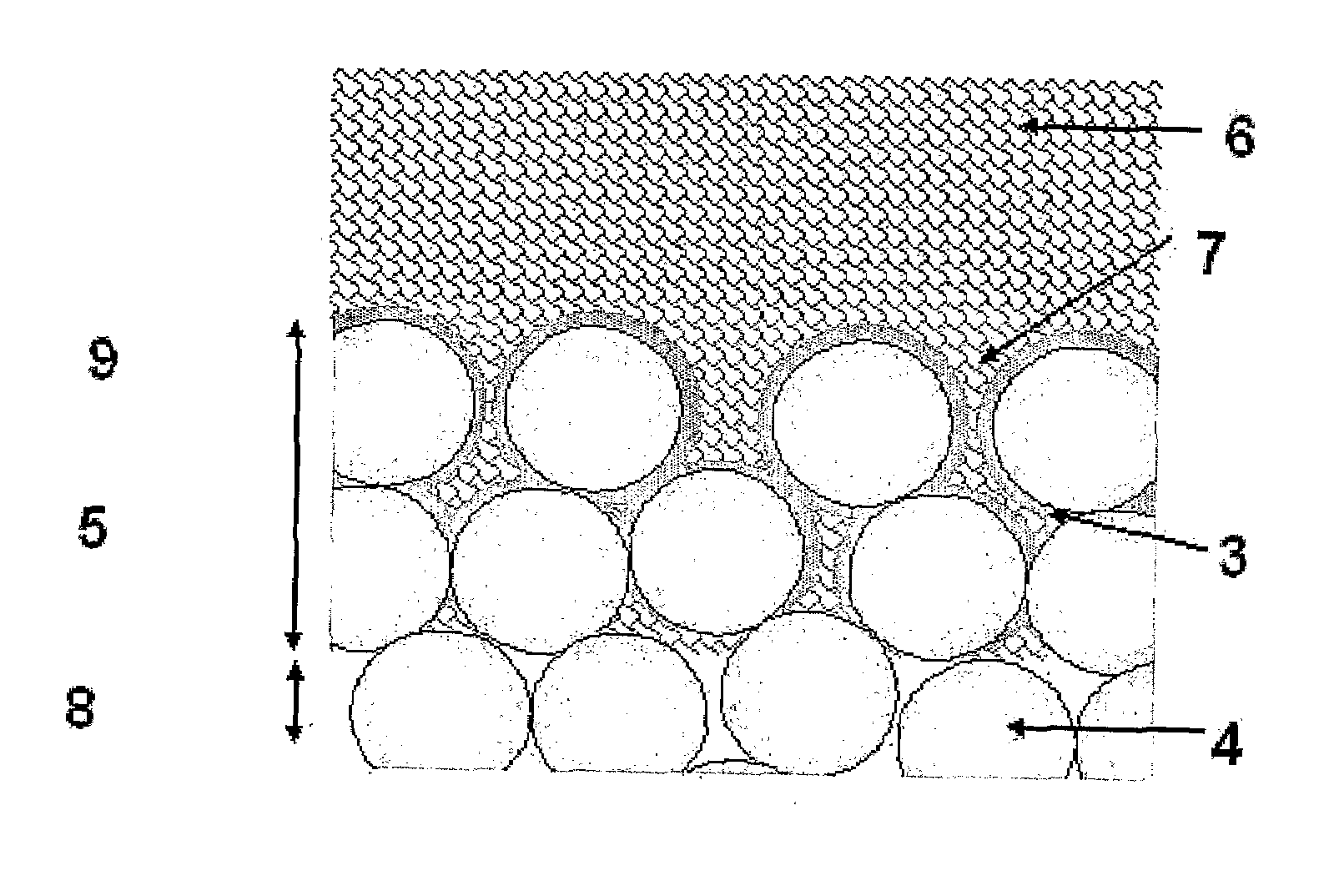

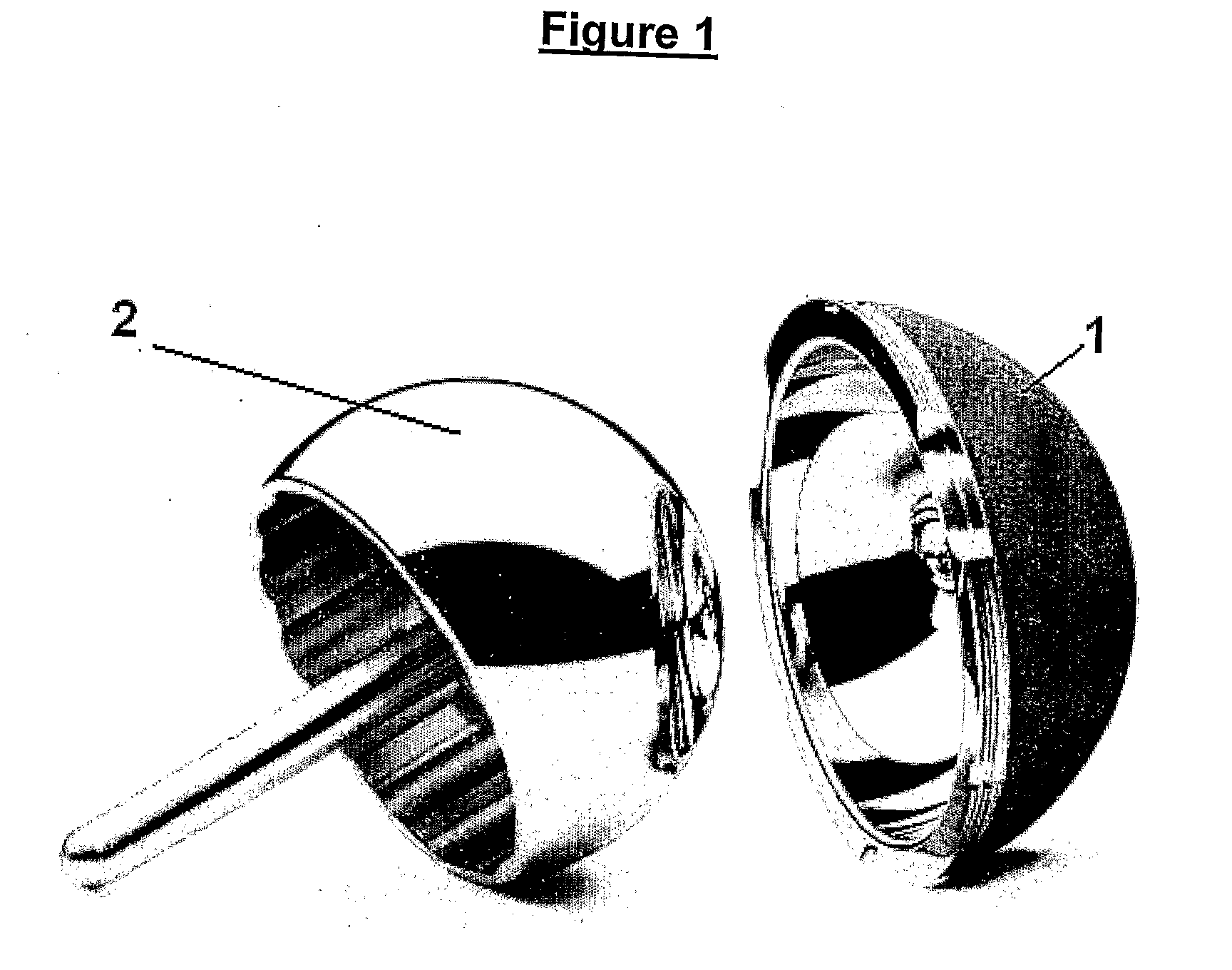

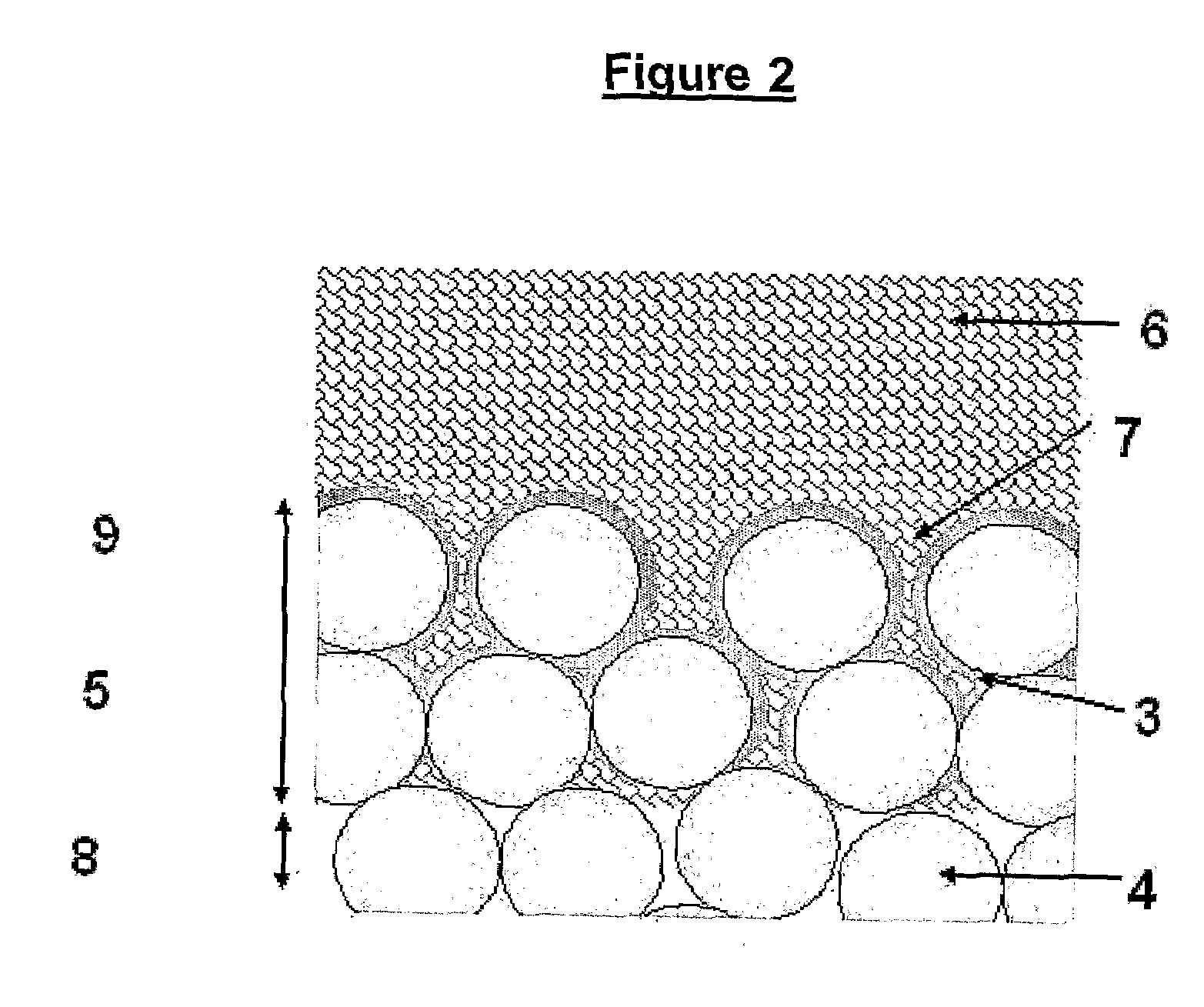

InactiveUS20100094430A1High porositySusceptible to corrosive attackBone implantPretreated surfacesBone replacementMaterials science

An implant for bone replacement and attachment in an animal's body including, a structural portion having an outer porous surface, a ceramic material applied to the porous surface of the structural portion, characterised in that the thickness of the ceramic material as applied utilizing pulsed pressure MOCVD is such that at least some of the pores of the porous surface are not completely closed.

Owner:CANTERPRISE LTD

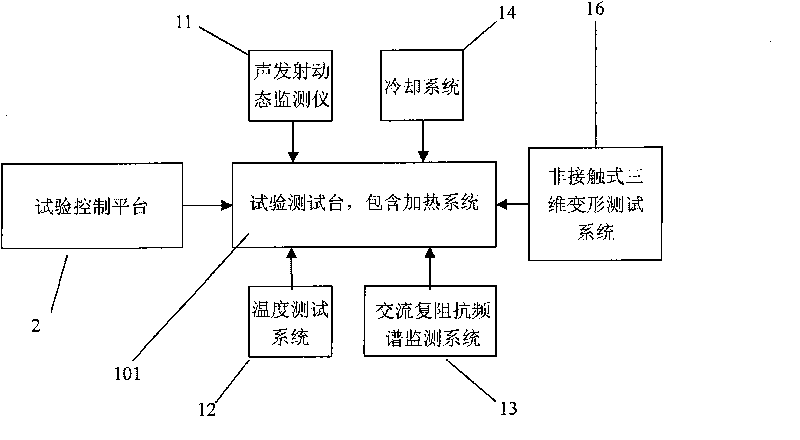

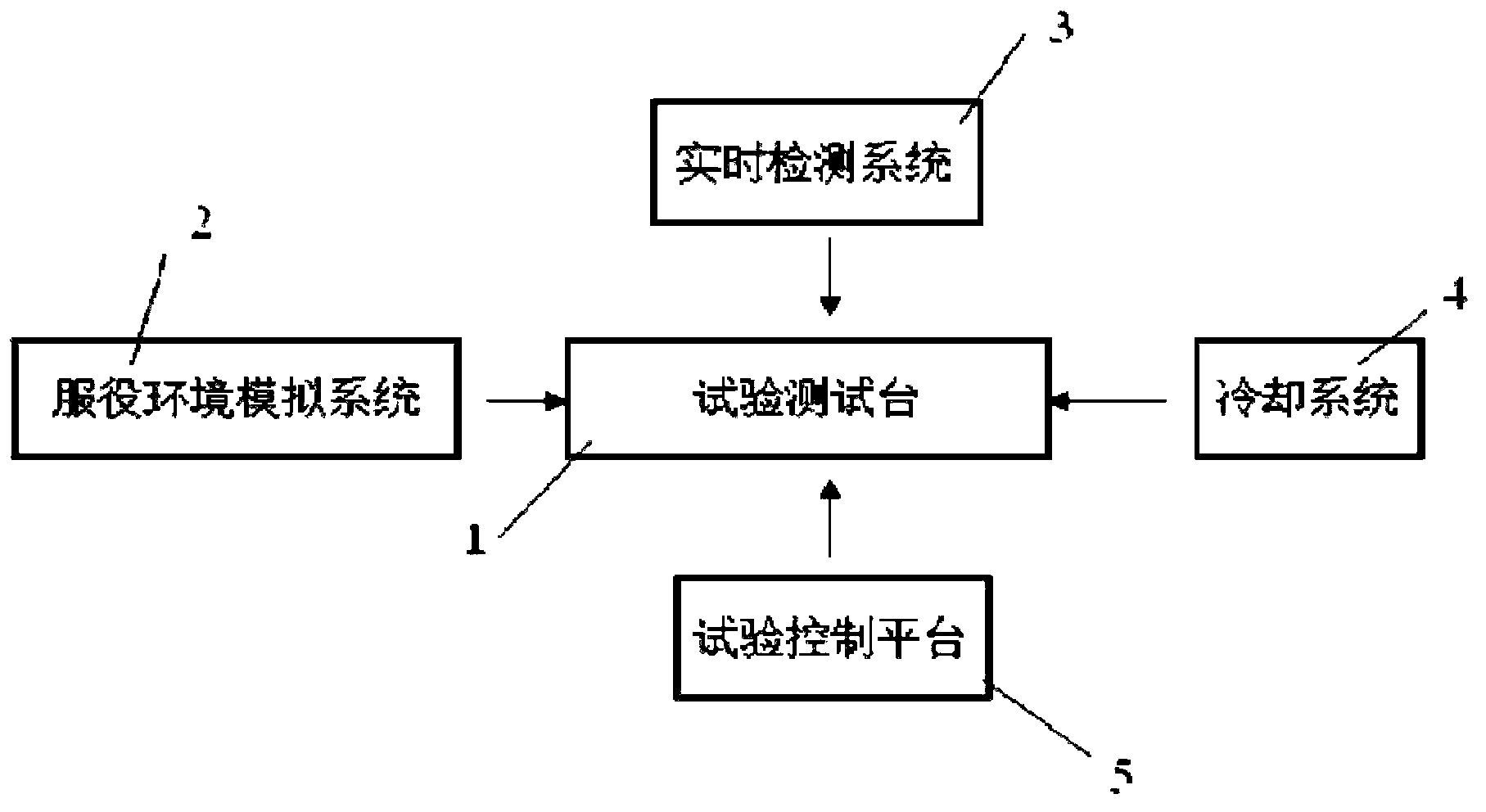

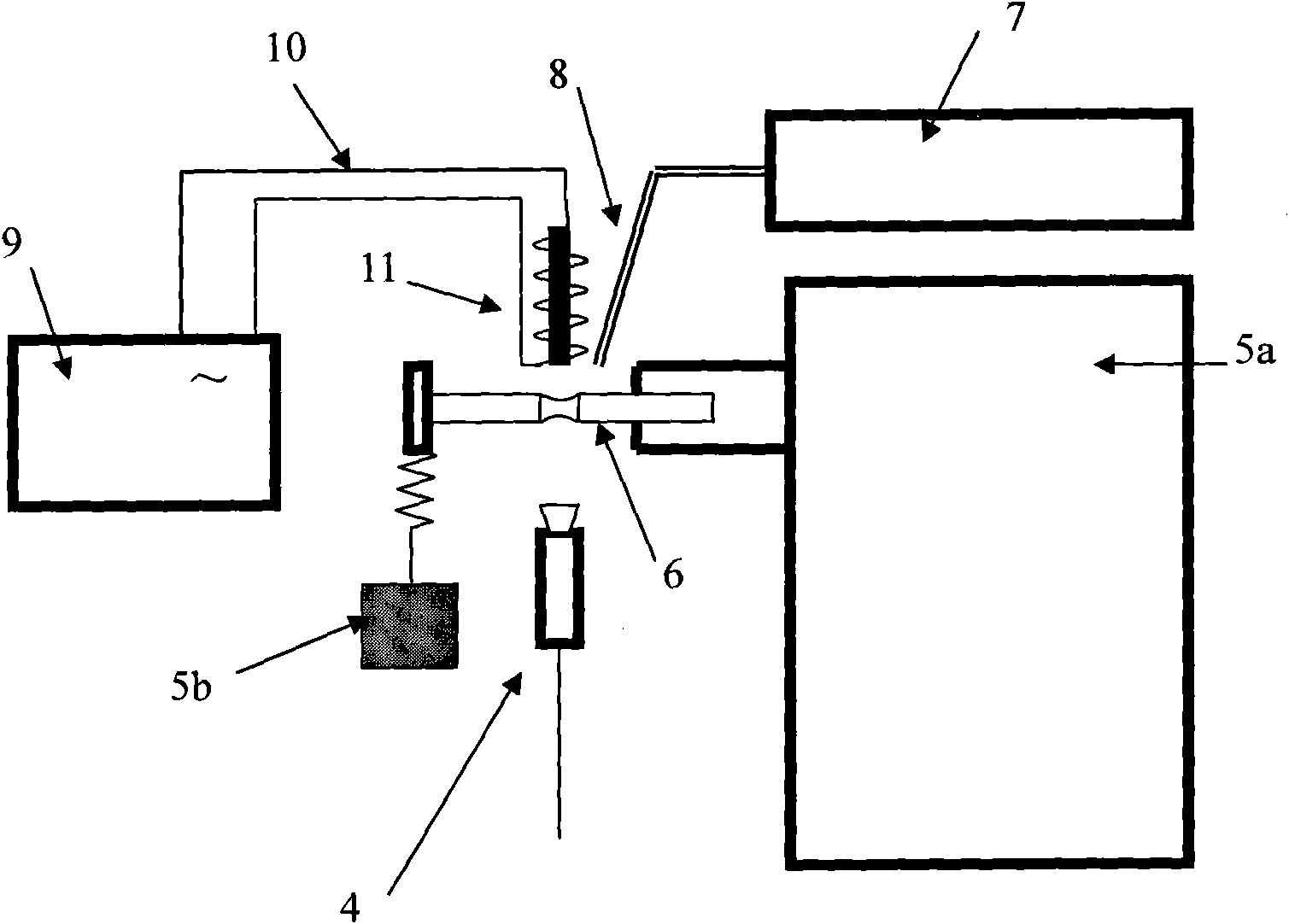

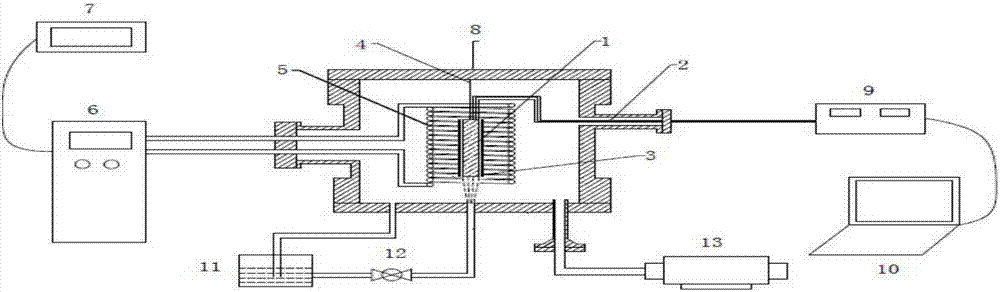

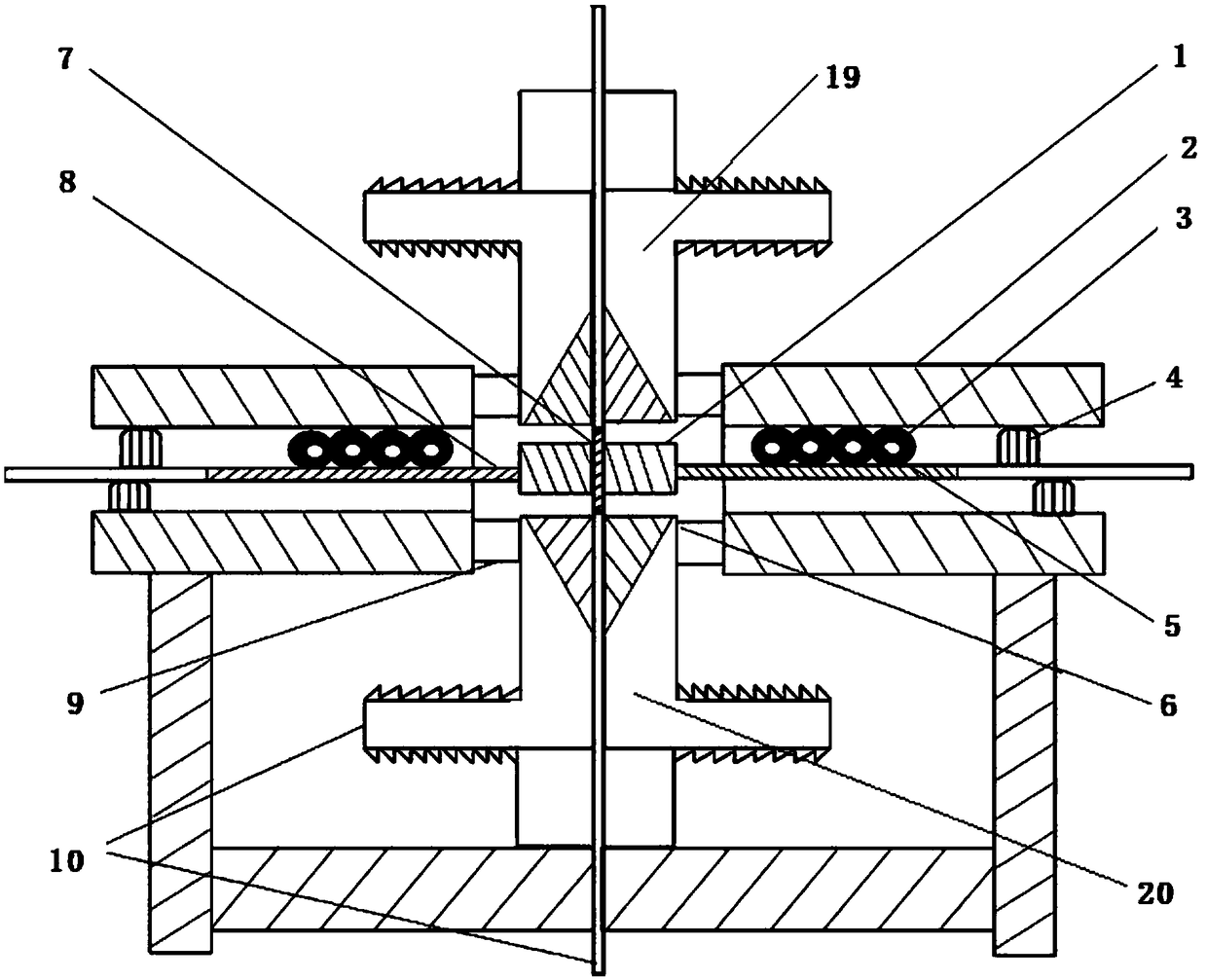

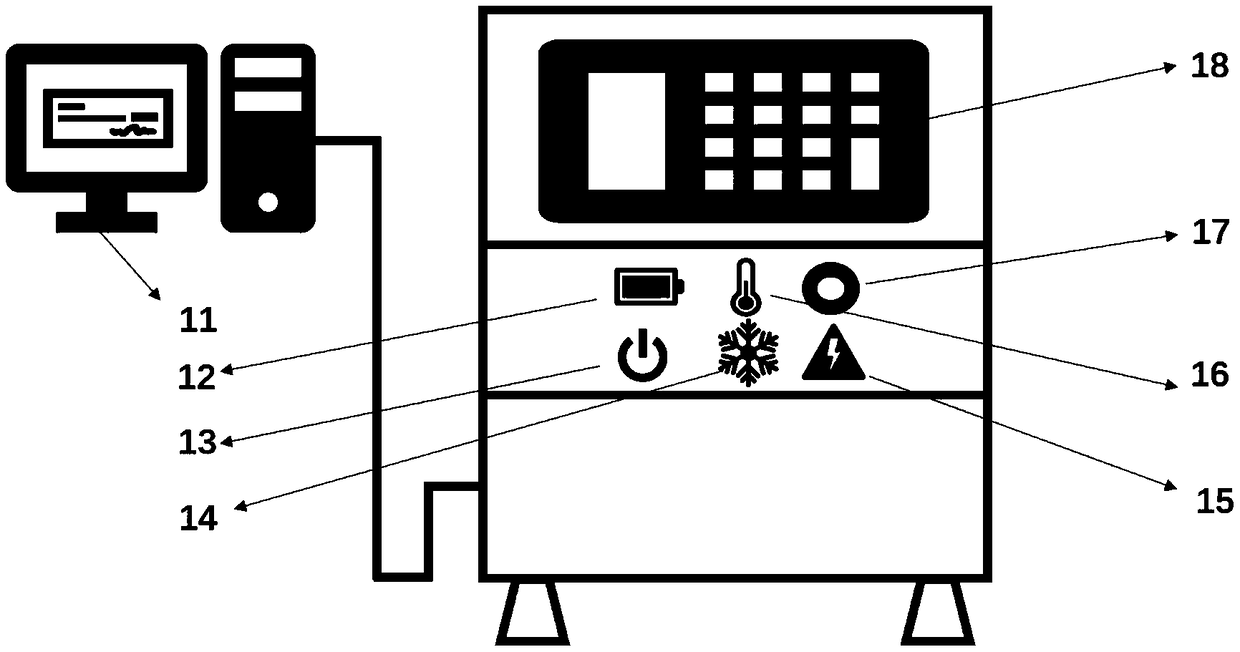

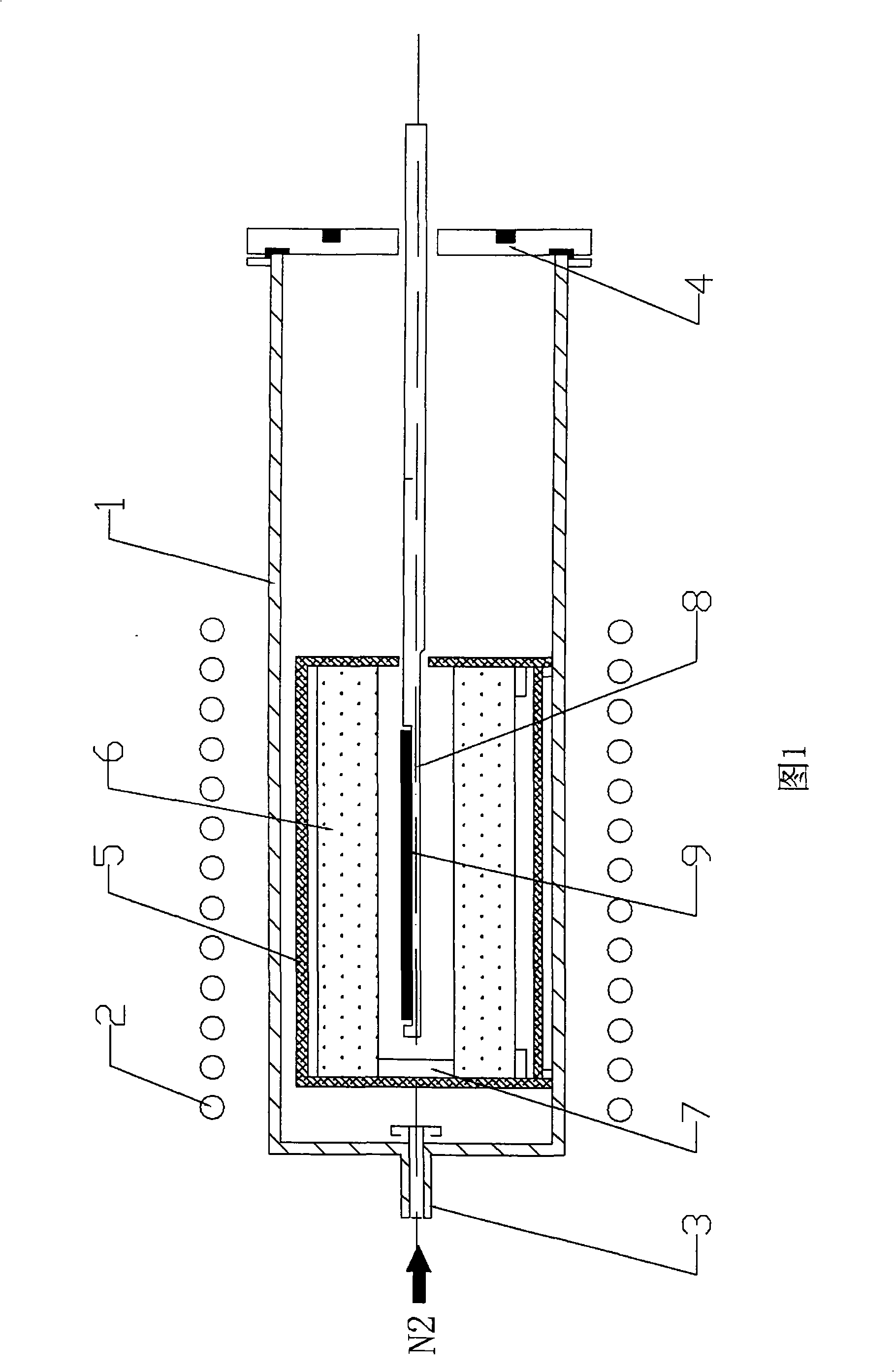

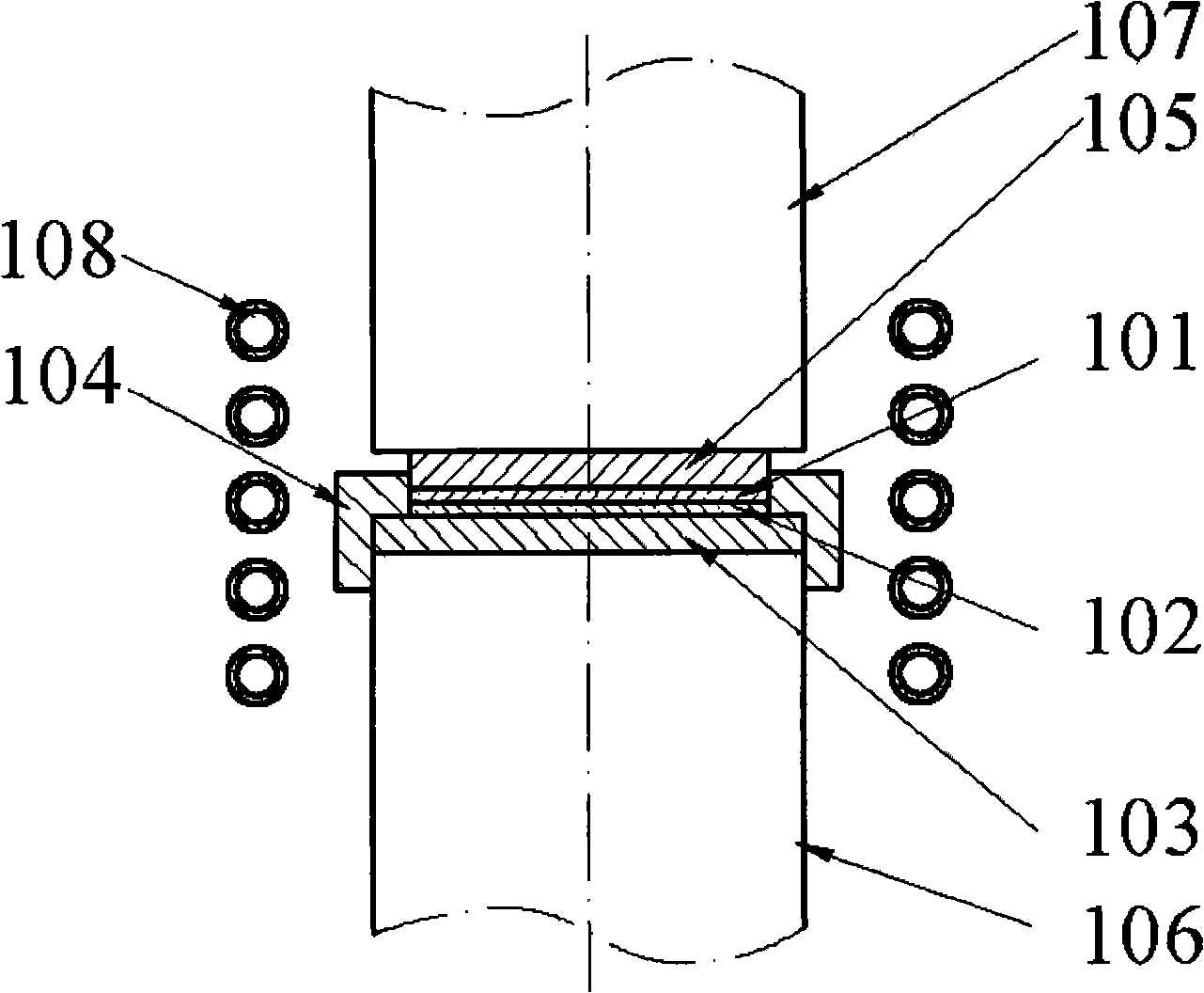

Test device for simulating and testing thermal fatigue failure of high-temperature part in real time

ActiveCN101762452AFast heating and cooling ratesWide temperature rangeWeather/light/corrosion resistanceHeating systemInterfacial oxide

The invention belongs to the field of high-temperature part detecting equipment, in particular to a test device for simulating and testing the thermal fatigue failure of a high-temperature part in real time. The device mainly comprises a high-temperature gas two-way heating system, a real-time temperature testing and collecting system, a cooling system, an ARAMIS non-contact three-dimensional deformation test system, a PCI-2 AE non-destructive detection system, a 1260+1296-type material electric property AC impedance spectroscopy test system, a test control platform and the like. The device can simulate the thermal fatigue work environment of alternating temperature cycle in a high-performance aircraft engine, and synchronously realize the real-time testing and the analysis to the sample temperature, temperature gradient, surface morphology image evolution, three-dimensional deformation field, three-dimensional displacement field, interfacial oxide layer and thickening law, thermal fatigue crack initiation and propagation, cooling gas flow and other data. The device can provide an important experimental platform for effectively evaluating the fatigue failure process and the failure mechanism of the high-temperature part in the high-temperature thermal cycle environment.

Owner:XIANGTAN UNIV

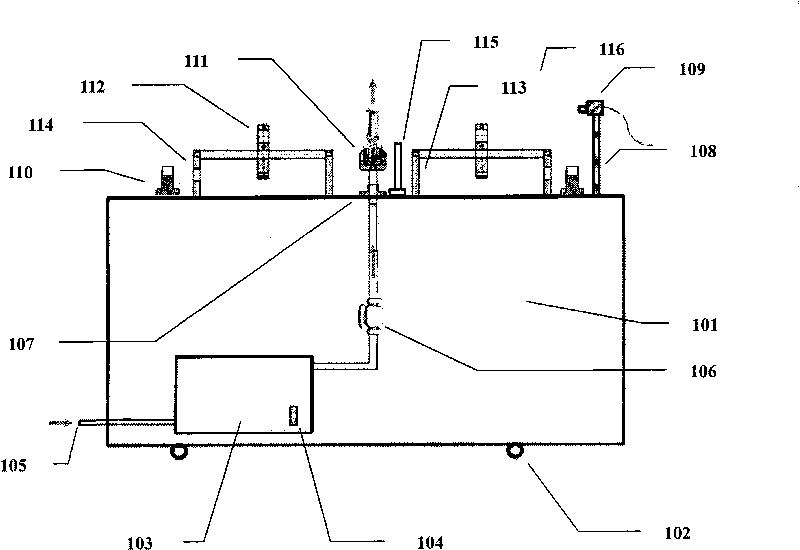

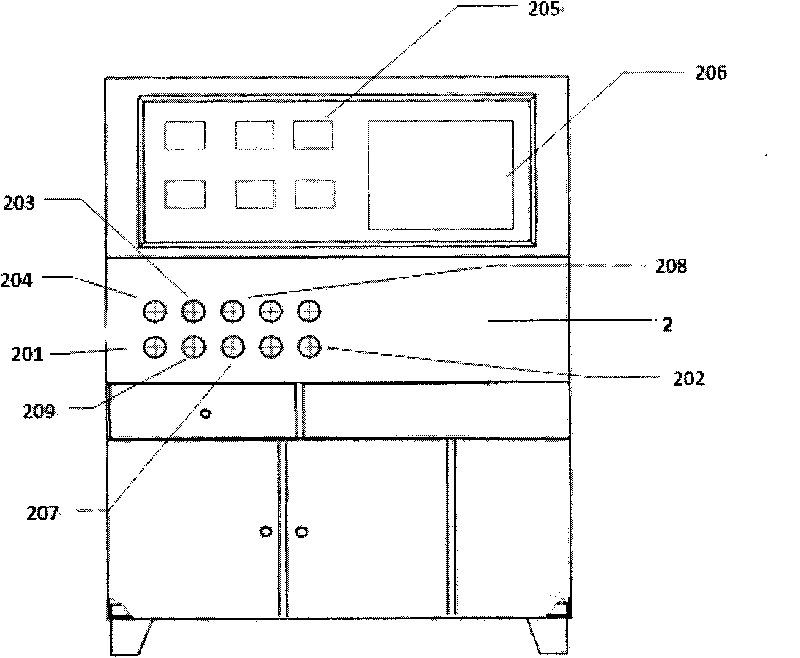

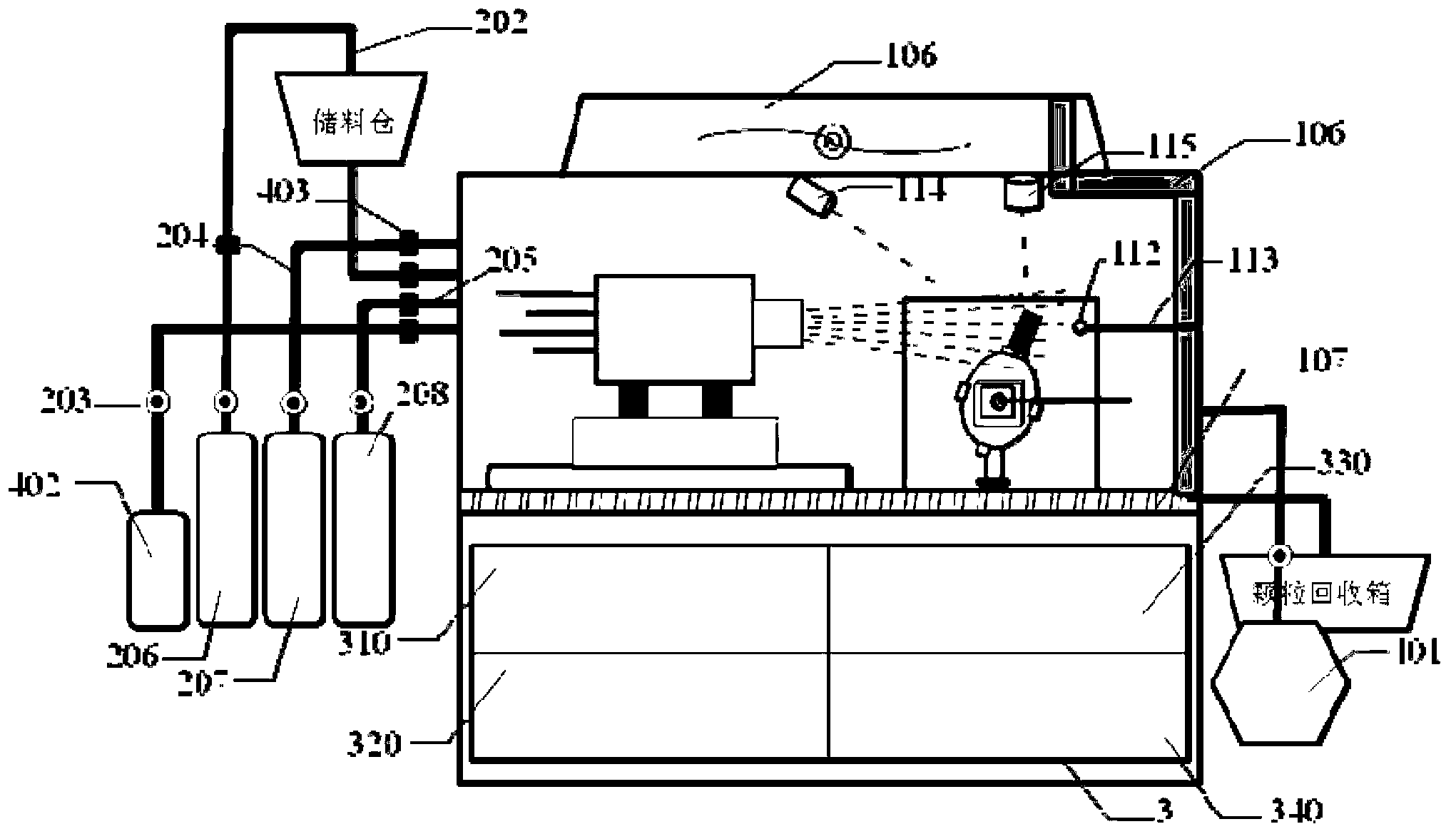

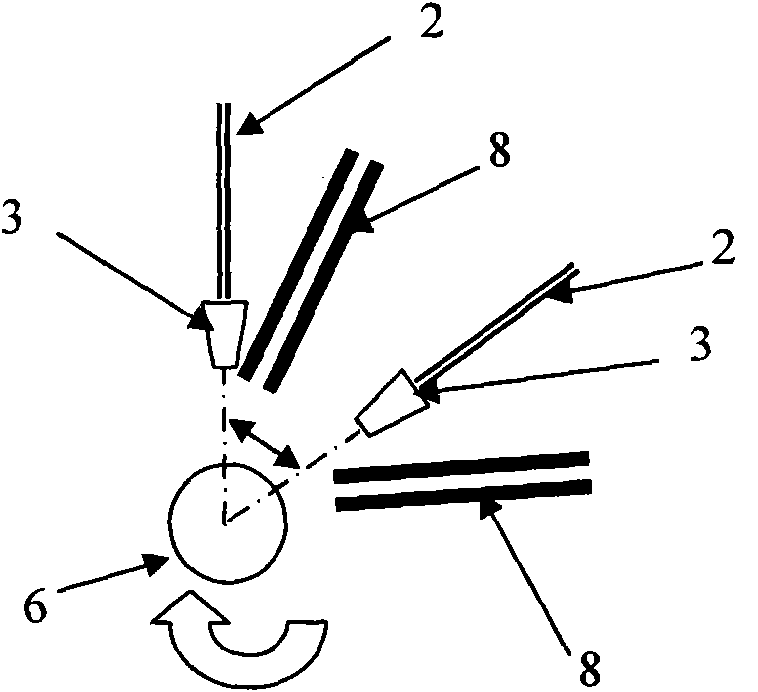

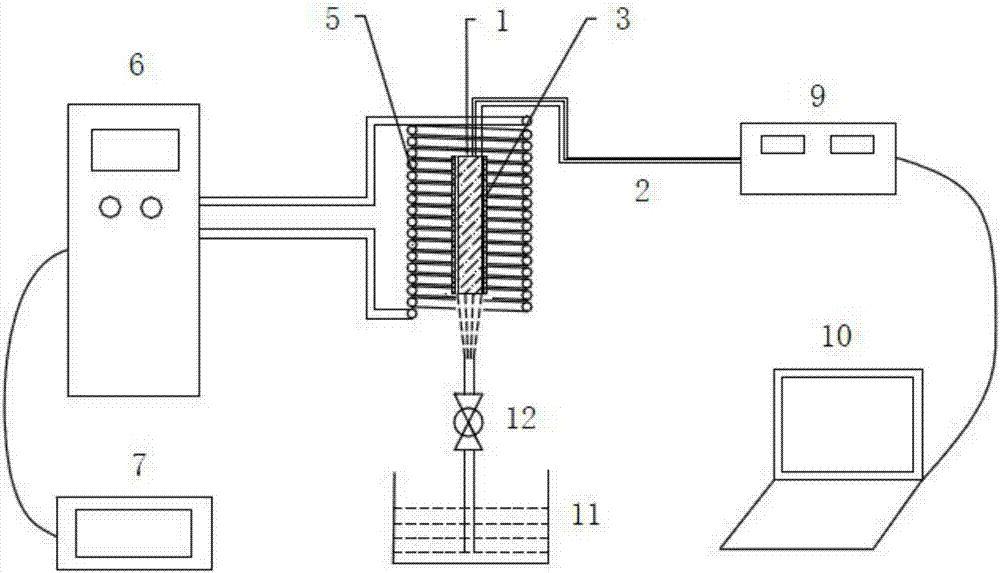

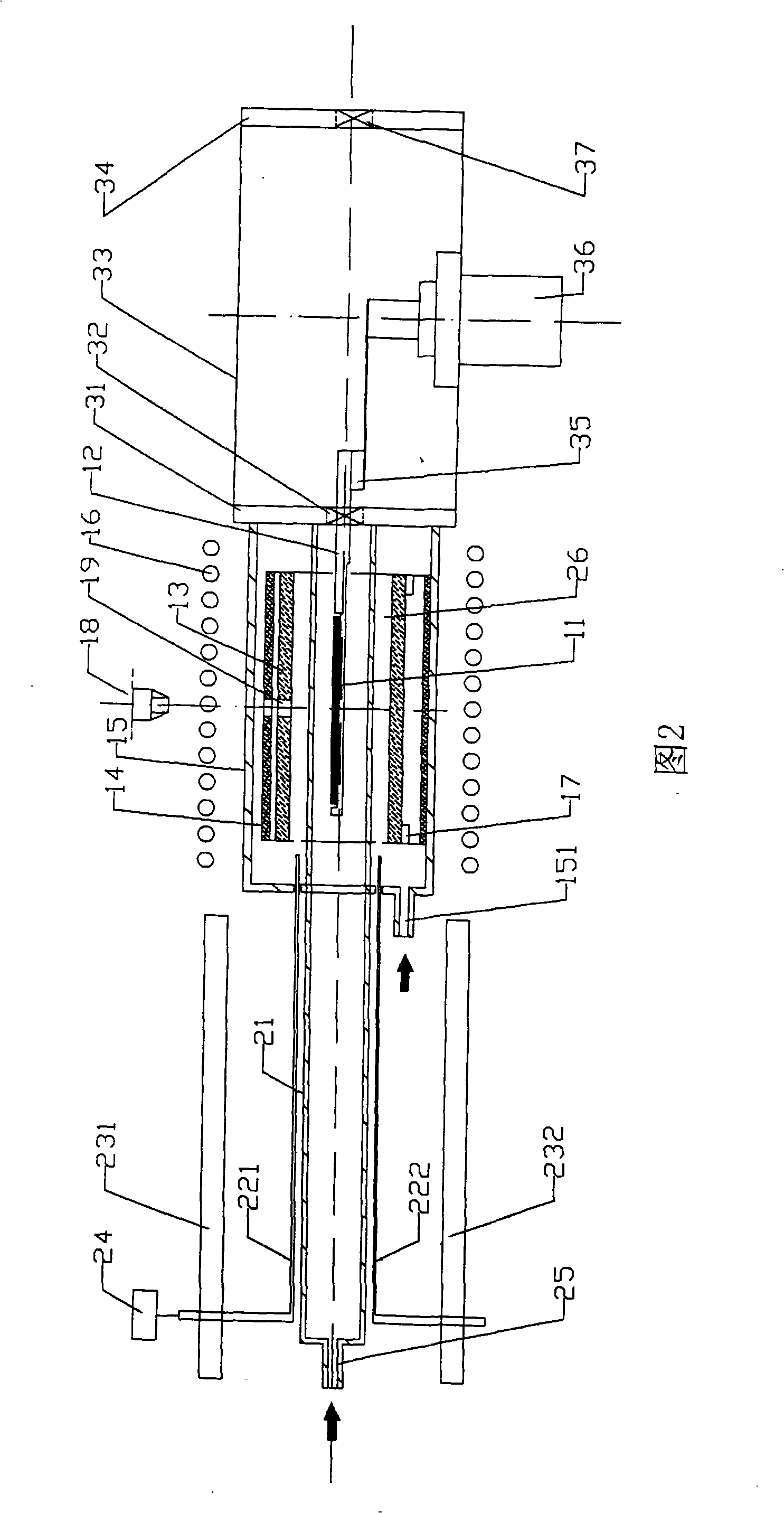

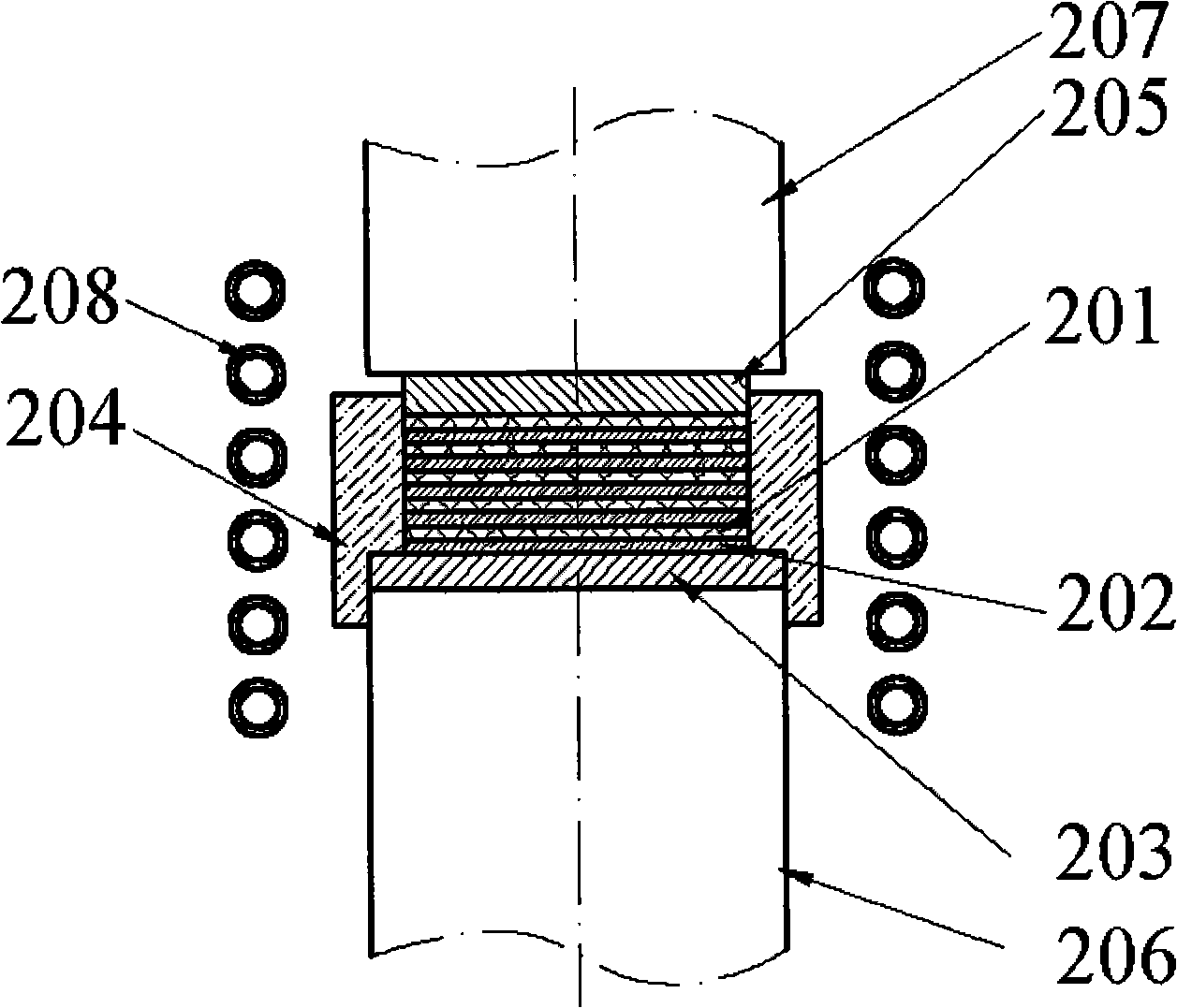

Testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades

ActiveCN103063534AEasy to realize included angleFast heating rateInvestigating abrasion/wear resistanceTest platformTopography

The invention discloses a testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades, belonging to the field of simulation devices in a special service environment. The testing device comprises an erosion particle feeding system, a test testing platform (1), a temperature test system, an acoustic emission nondestructive testing system, a control platform and the like. An erect fixed shaft (101) is arranged on the test testing platform (1) and is connected with a horizontal supporting shaft. The testing device can be used for simulating the erosion service environment in which hard particles in a high-performance aero-engine repeatedly impact thermal barrier coatings of turbine blades due to the driving of airflow. By controlling the parameters such as erosion speed, angle, size and the like of erosion particles, the process that the coatings are eroded by different hard particles in the service process is realized and the real-time test and analysis of data, such as the temperature, the surface topography evolution, the interfacial oxidation of a sample and the like can be synchronously realized. The device can provide an important test platform for effectively assessing the erosion failure process and the failure mechanism of coatings of turbine blades in the special service environment.

Owner:XIANGTAN UNIV

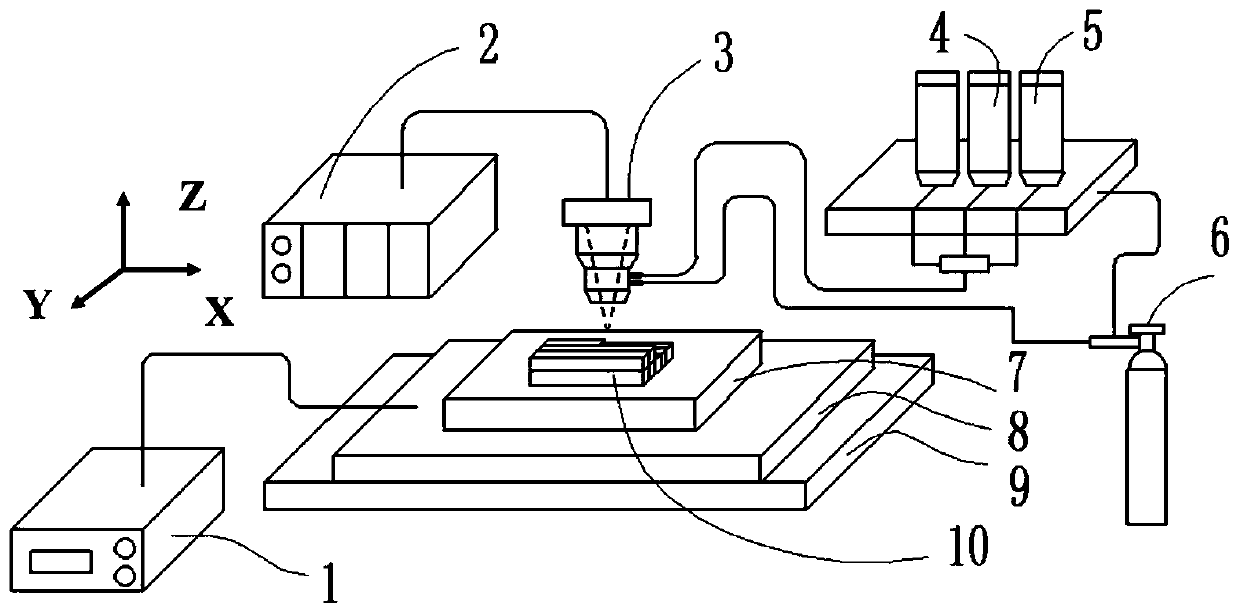

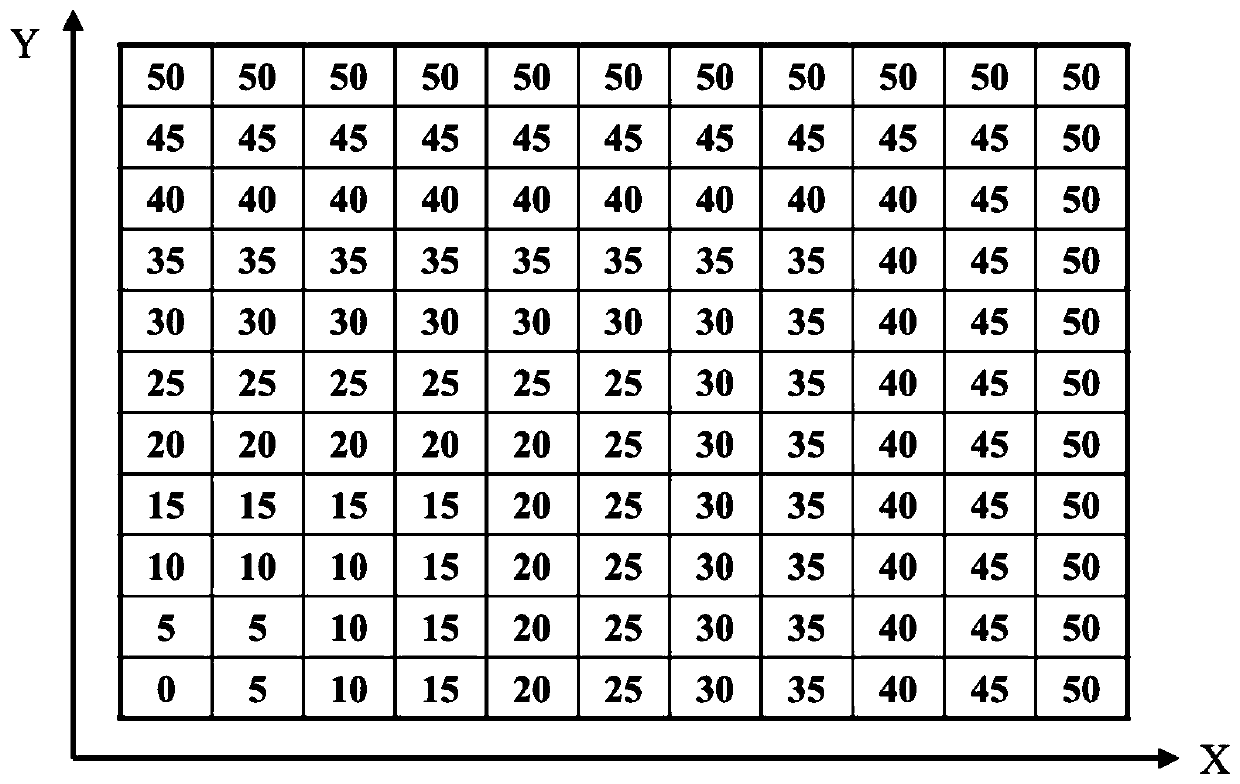

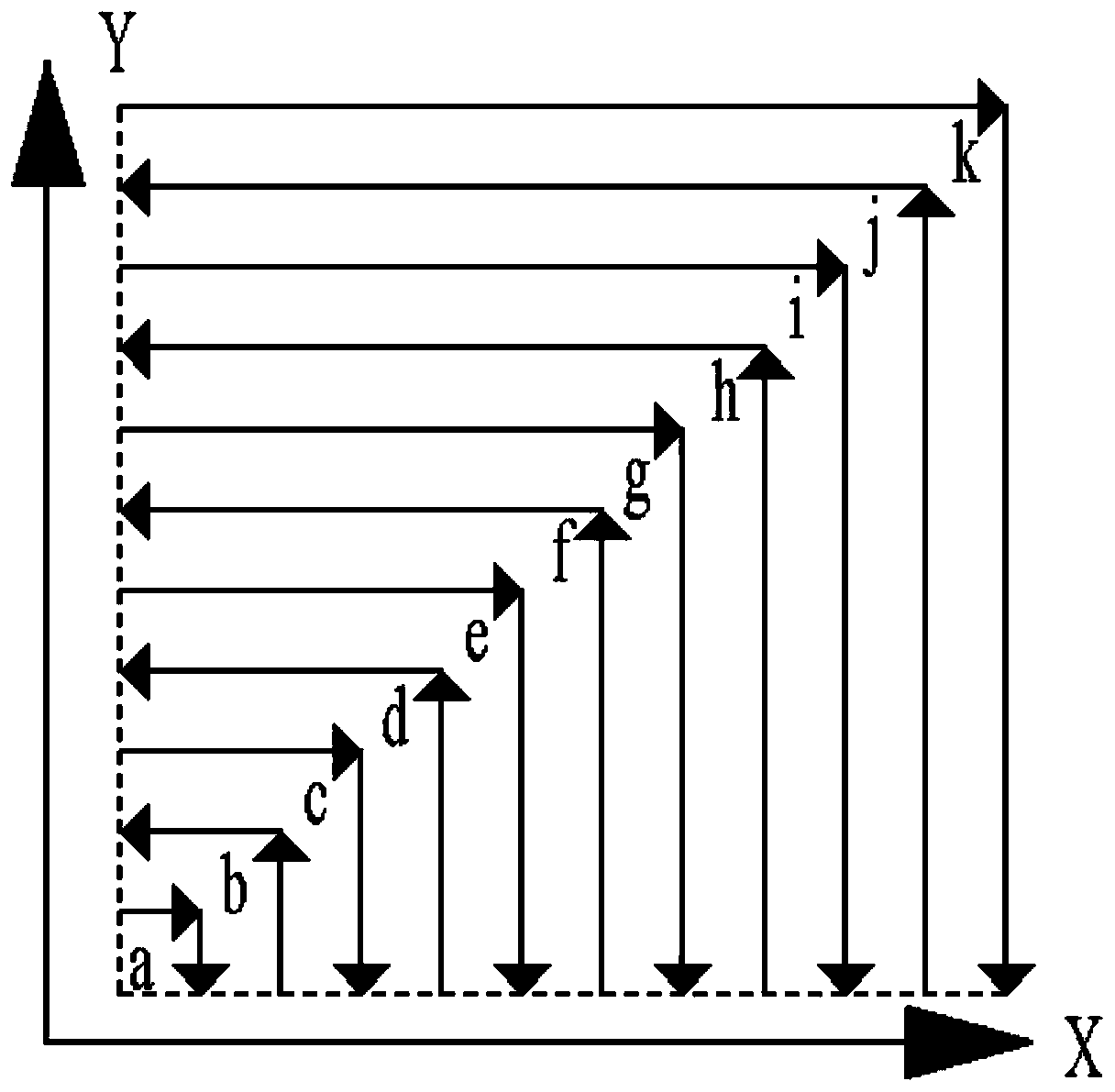

Method for ultrasonic auxiliary laser additive manufacturing of two-dimension titanium-based functional gradient material

ActiveCN111112619AEvenly distributedIncreased heterogeneous nucleation rateAdditive manufacturing apparatusIncreasing energy efficiencyGradient materialMolten bath

The invention discloses a method for ultrasonic auxiliary laser additive manufacturing of a two-dimension titanium-based functional gradient material, and belongs to the technical field of laser additive manufacturing. The two-dimension titanium-based functional gradient material is in one-dimension gradient transition in the XY and YZ plane and is in two-dimension gradient transition in space. According to the preset each-deposition-layer gradient transition form, the area a at the lower left corner is in 7-shaped transition to the area k at the upper right corner, accordingly, bottom ultrasonic is ensured, and sufficient interference is conducted on the molten bath flowing and solidifying process during high-proportion ceramic particle adding. In different gradient areas in the XY and YZplane, optimized direct laser deposition technological parameters and ultrasonic acting parameters are adopted, heat accumulation, the size and content of non-melted ceramic particles and the size ofa thick branch-shaped primary phase are reduced, and accordingly the integral performance of the titanium-based functional gradient material is improved. A laser head conducts scanning according to the 7-shaped path, the number of gradient combined interfaces between adjacent ways is reduced, and the integral performance of the titanium-based functional gradient material can be better improved. By means of the method, uniform distribution of the ceramic particles can be promoted, thick dendritic crystals are crushed, a microcosmic structure is refined, and accordingly the integral performanceof the two-dimension titanium-based functional gradient material is improved.

Owner:DALIAN UNIV OF TECH

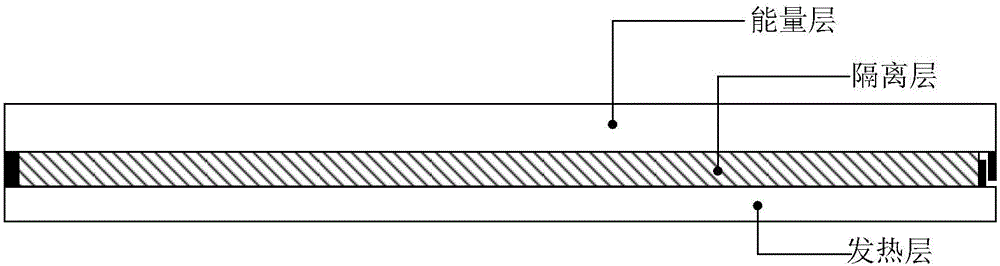

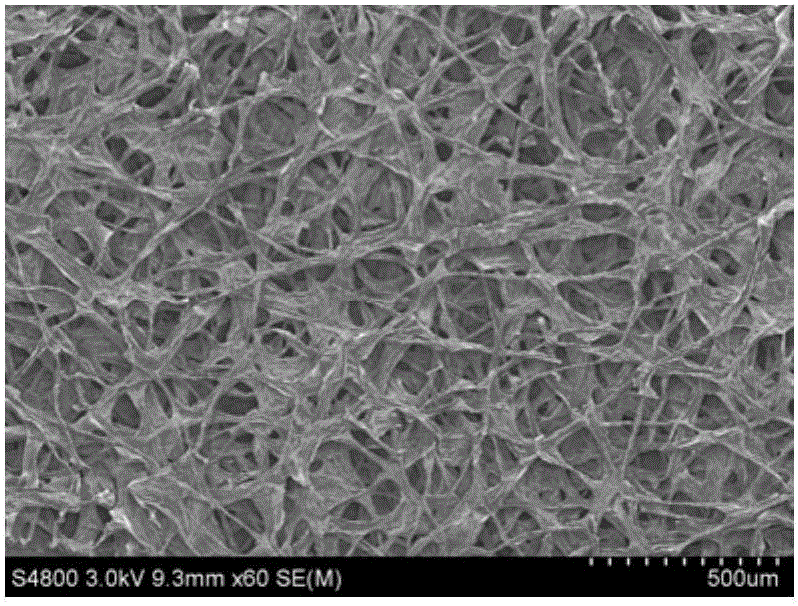

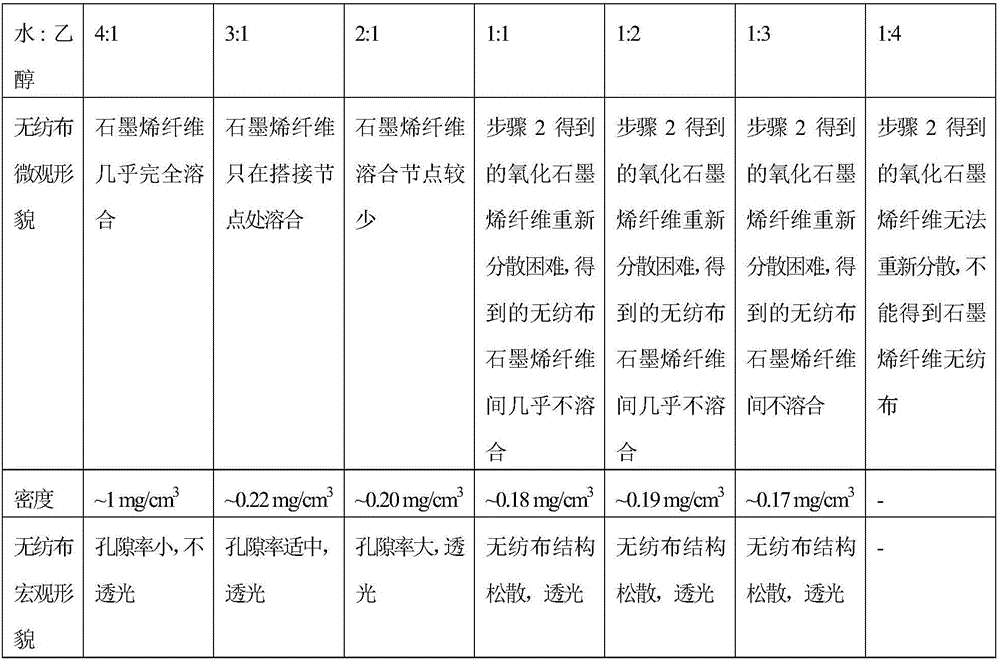

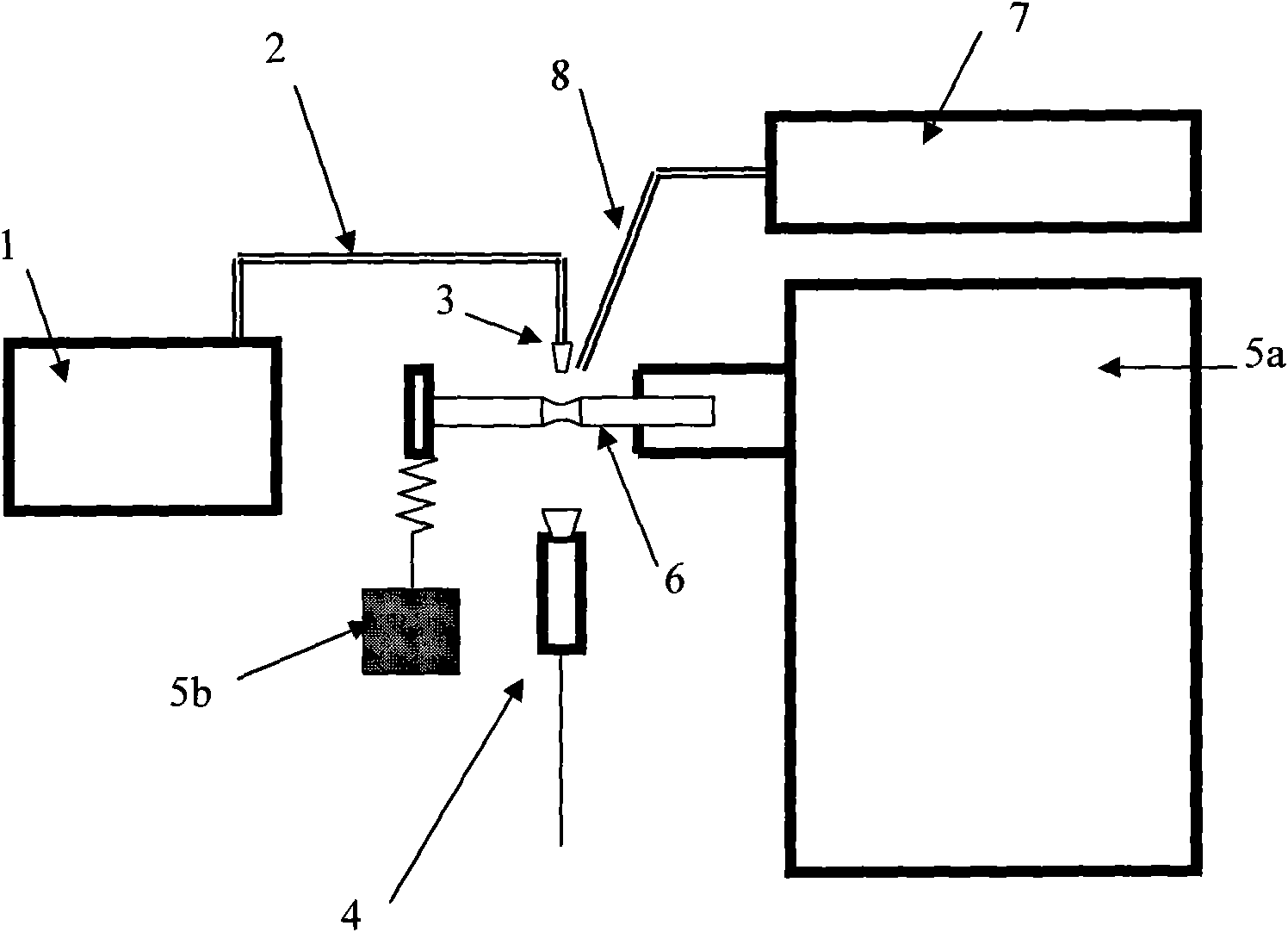

Self-heating film based on graphene fiber nonwovens

ActiveCN106183142AImprove conductivityLow densityLayered productsWet spinning methodsThermal insulationFilm base

The invention discloses a self-heating film based on graphene fiber nonwovens and a preparation method thereof. The self-heating film is provided with voltage and current by a photovoltaic film as an energy layer, and a heating layer is formed by using the electric-induced-heating effect of the graphene fiber nonwovens. The energy layer is separated from the heating layer by a thermal insulation material. As the graphene fiber nonwovens have a high electrical conductivity and a relatively low density, larger heating temperature and higher heating and cooling rates at a relatively low operating voltage can be obtained. Meanwhile, the graphene fiber nonwovens have high flexibility and structural stability, and the self-heating film is still able to show a stable heating behavior at bending state, so the self-heating film based on graphene fiber nonwovens can be used for novel wearable heating device using clean energy.

Owner:杭州德烯科技集团有限公司

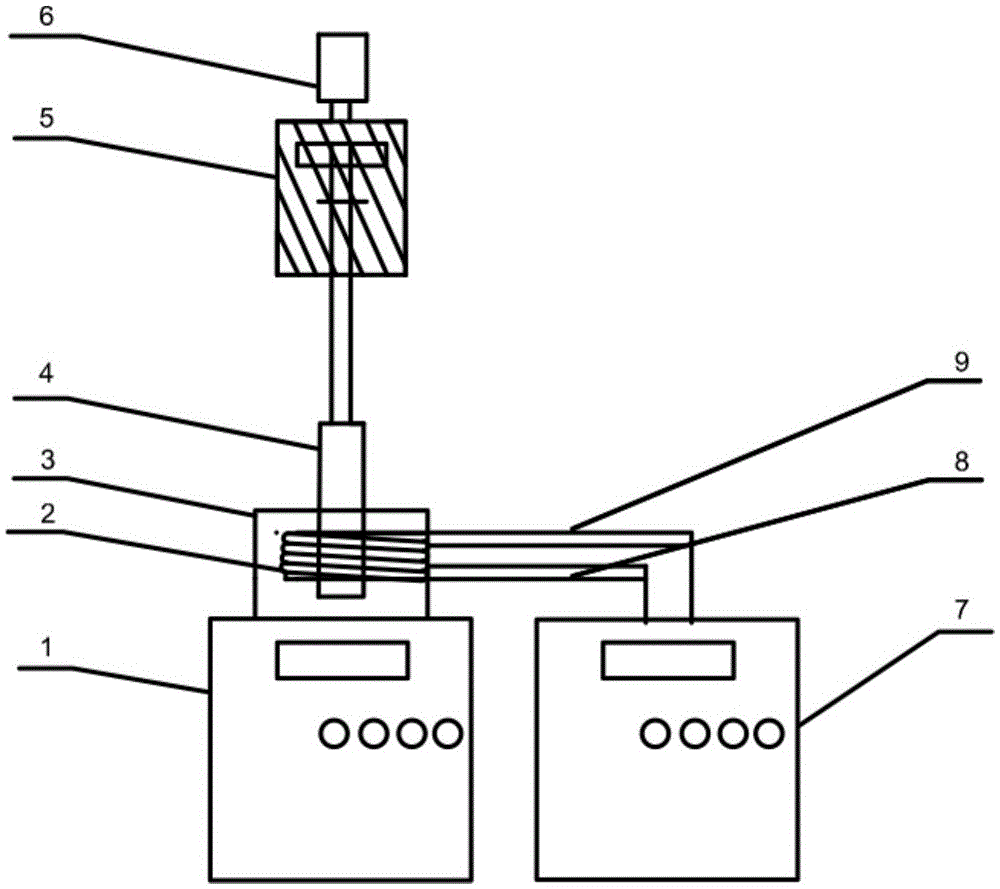

Device and method for testing thermo-mechanical fatigue

InactiveCN101876611AShort heating and cooling cyclesFast heat conductionMaterial strength using repeated/pulsating forcesPhase differenceTemperature waveform

The invention relates to a device and a method for testing thermo-mechanical fatigue. The device comprises a rotary bending fatigue loading device, a heating device for applying a temperature load to a fatigue sample, a sample surface gaseous environment control device and a temperature measurement device. Through the device and the method in combination with the conventional device and the conventional method for rotary bending fatigue and high-speed heating, the temperature load effect of different phase differences on the sample is ensured under the condition of rotary bending fatigue loading. The mechanical load of the fatigue sample is applied and controlled by the rotary bending loading device, while the temperature load is applied and controlled by the heating device and the temperature measurement device; and the phase difference of a temperature waveform and a mechanical load waveform is controlled by the number and the positions of the heating ends of the heating device. The thermo-mechanical fatigue testing device of the invention has the advantages of simple structure, low energy consumption and the capability of realizing rapid temperature rise and drop and accurate phase difference control between the mechanical load waveform and the temperature waveform.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

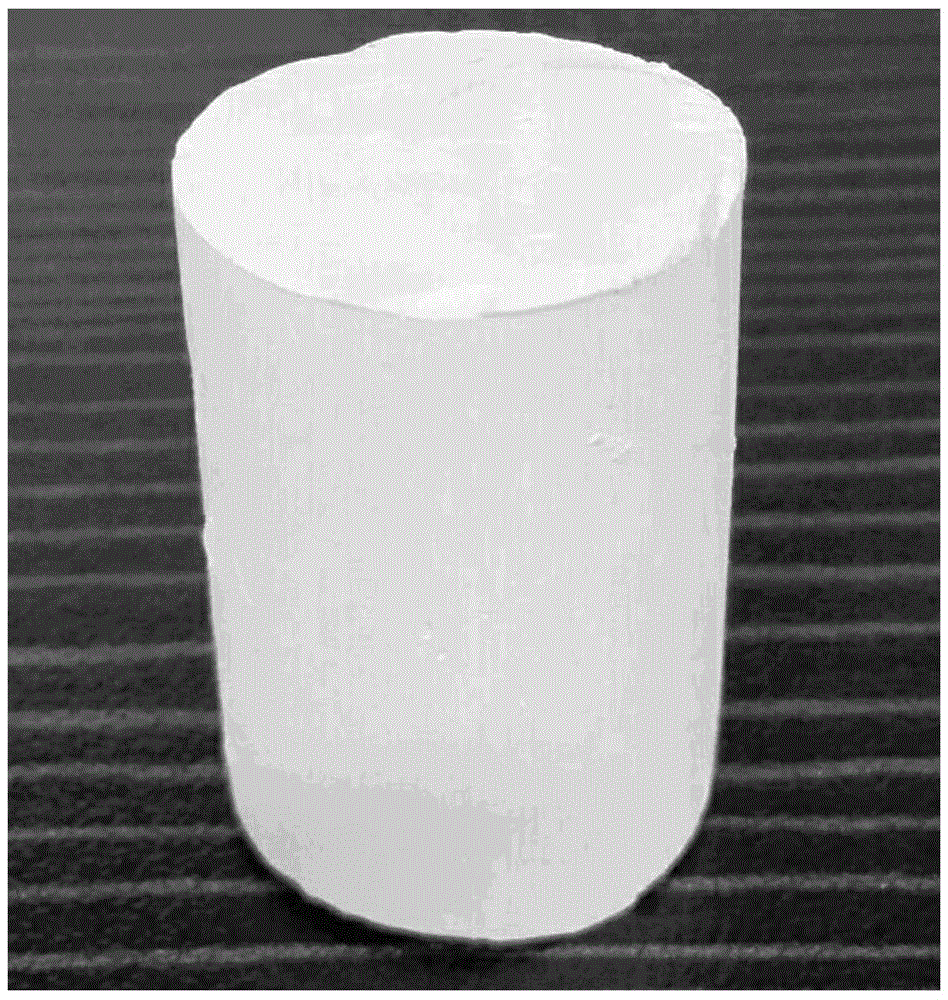

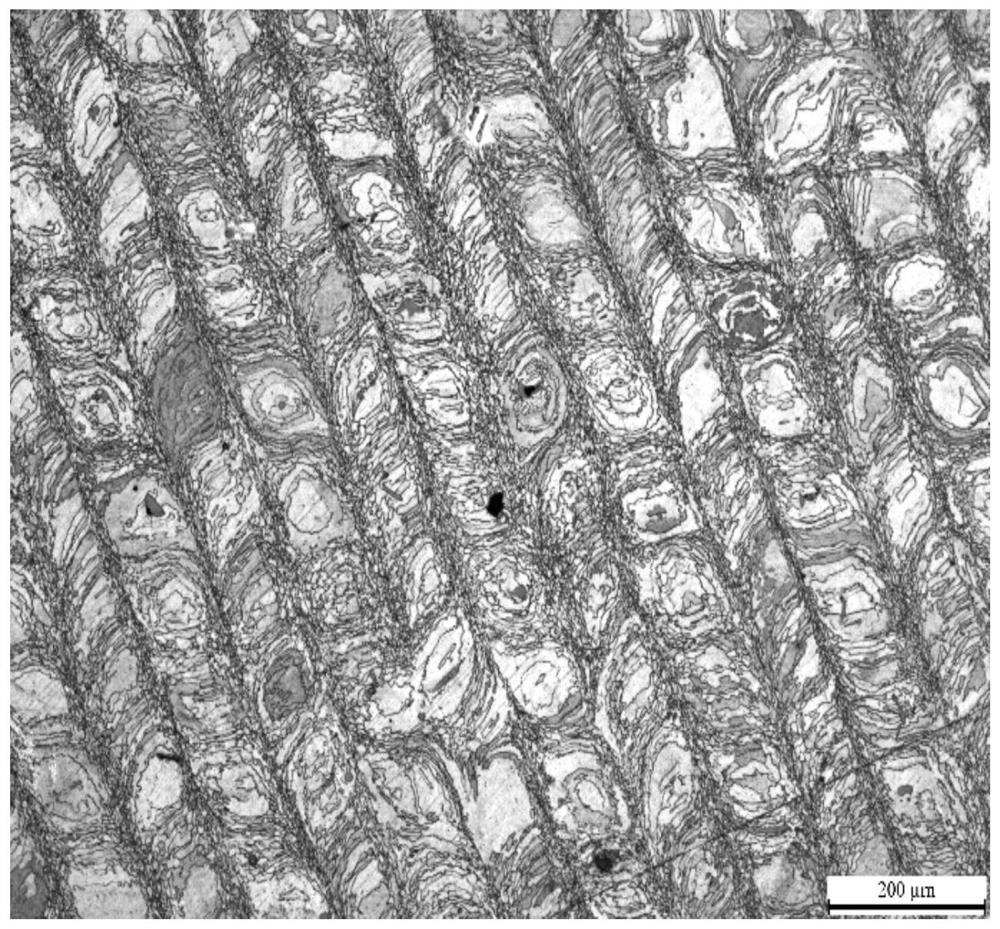

Directional solidification apparatus for preparation of porous ceramics based on ice template method and preparation method thereof

InactiveCN105541369AUniform sizePrecise Control of MorphologyCeramicwareSlurryDirectional solidification

The invention discloses a directional solidification apparatus for preparation of porous ceramics based on an ice template method and a preparation method thereof. The directional solidification apparatus comprises a servo mechanism, a motor, a low temperature circulator, a constant temperature bath and a die. A refrigeration mode with refrigeration at one end and heating at the other end is used for generating a uniform temperature field, the motor and the servo mechanism are controlled for providing a solidification rate which is higher than 500 [mu]m / s, so that a better microscopic structure of the product is provided with better mechanical properties. Two independent technological parameters including temperature gradient and withdrawal rate are regulated separately, so that solidification process of a ceramic slurry is controlled, the regulation and control scope of the withdrawal rate is wide, and the regulated scope is 1-3000 [mu]m / s. A more uniform temperature field is generated by using the high-speed directional solidification method, the cooling rate is higher, the dimension of ice crystal with orientated growth is more uniform, and the porous ceramics with an oriented structure is obtained; form, structure and porosity of the prepared oriented porous ceramic pores are accurately controlled.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

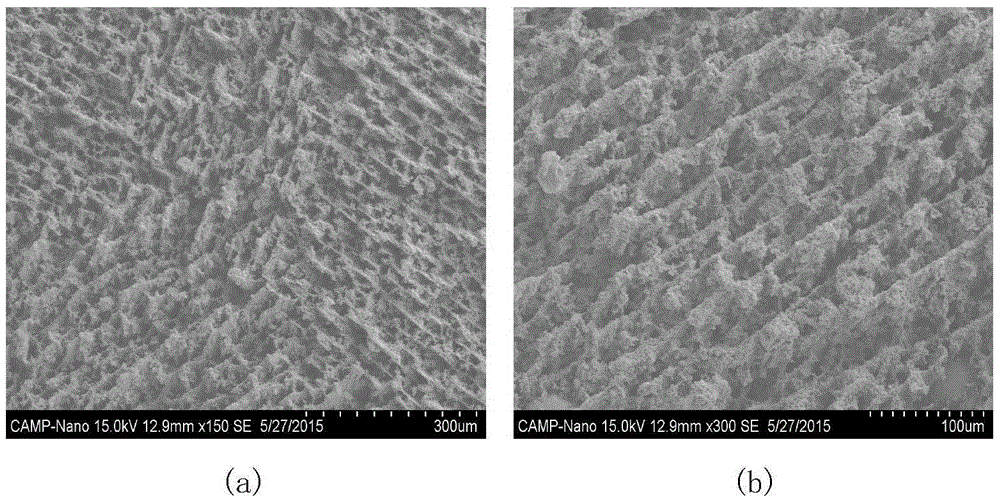

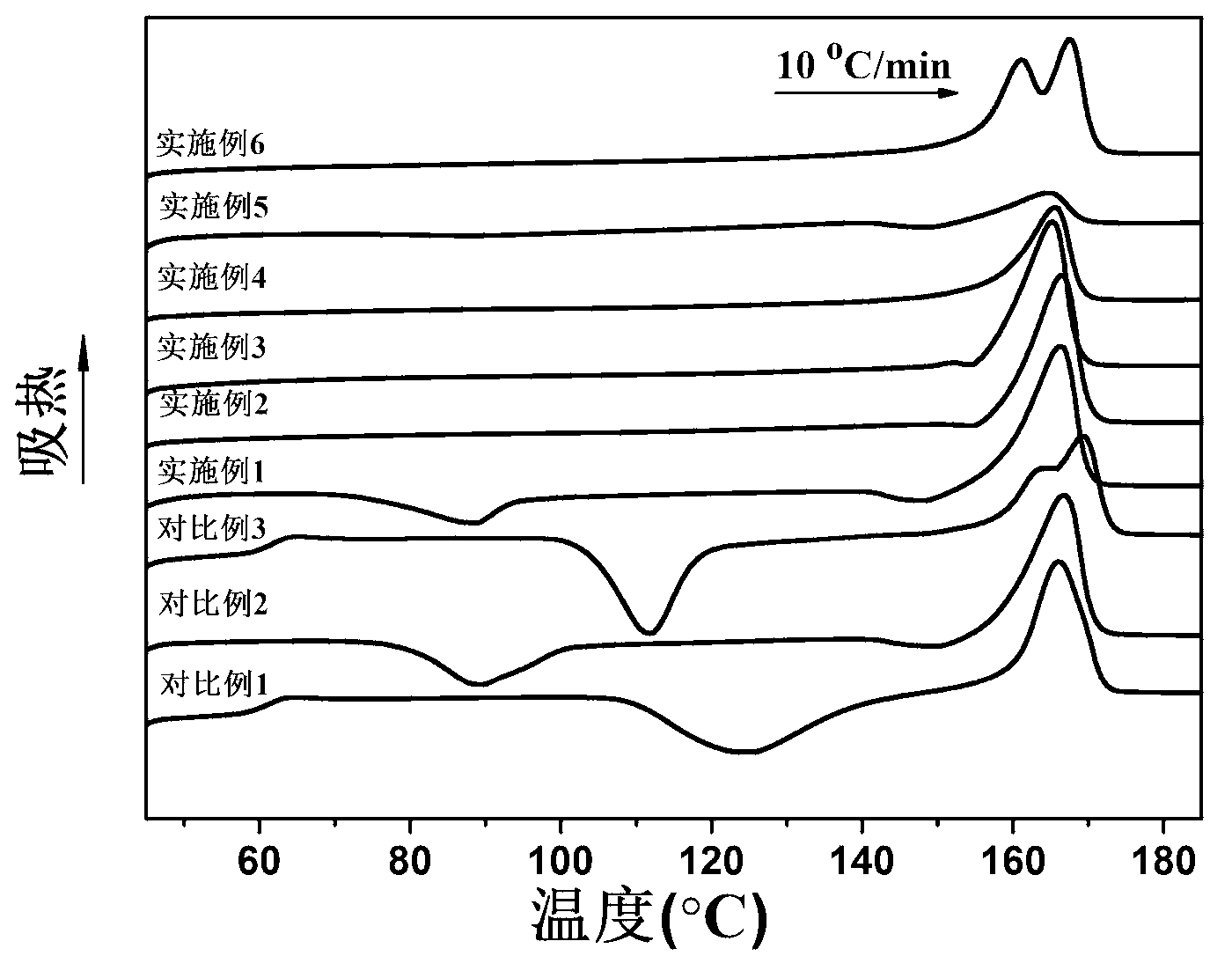

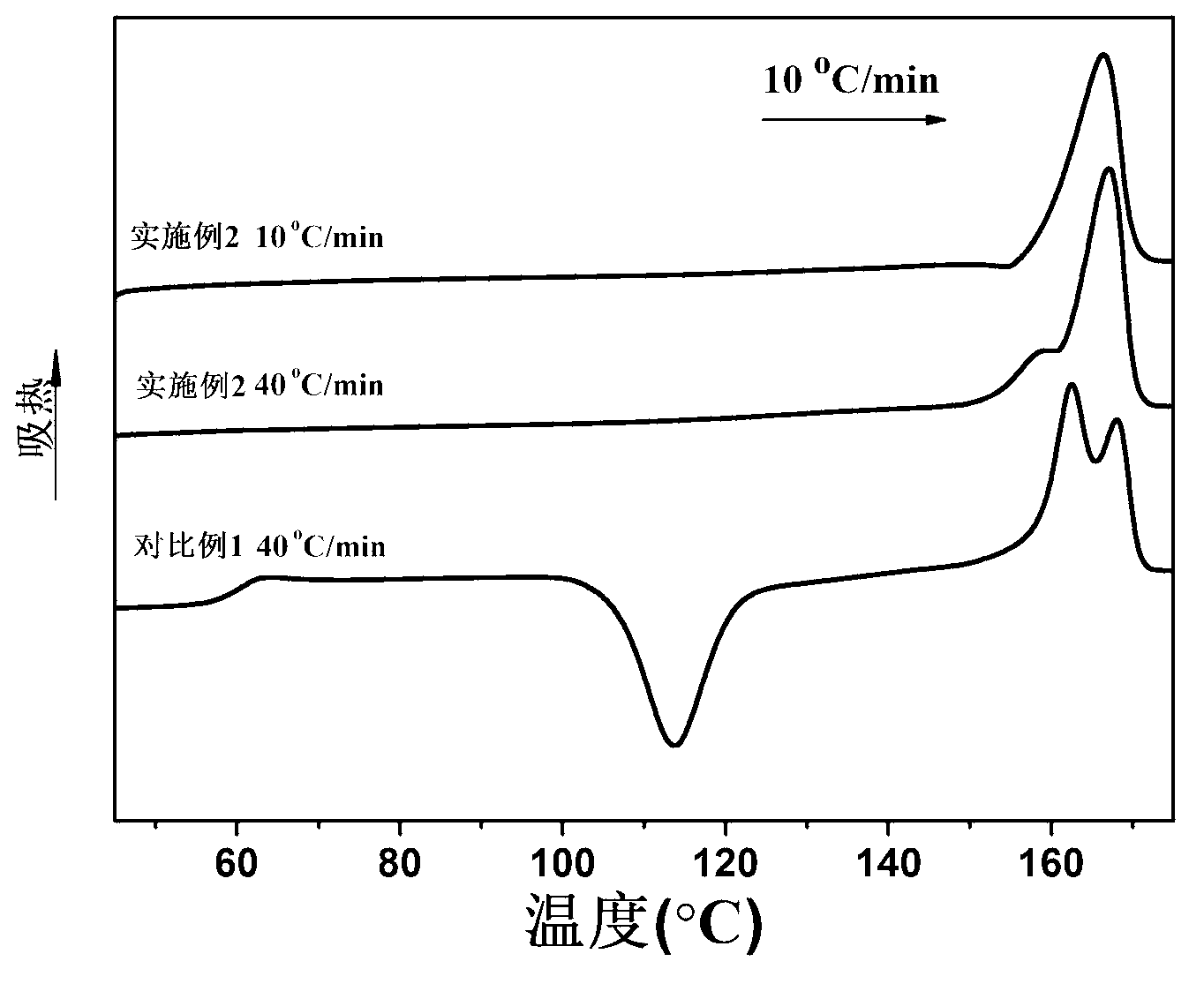

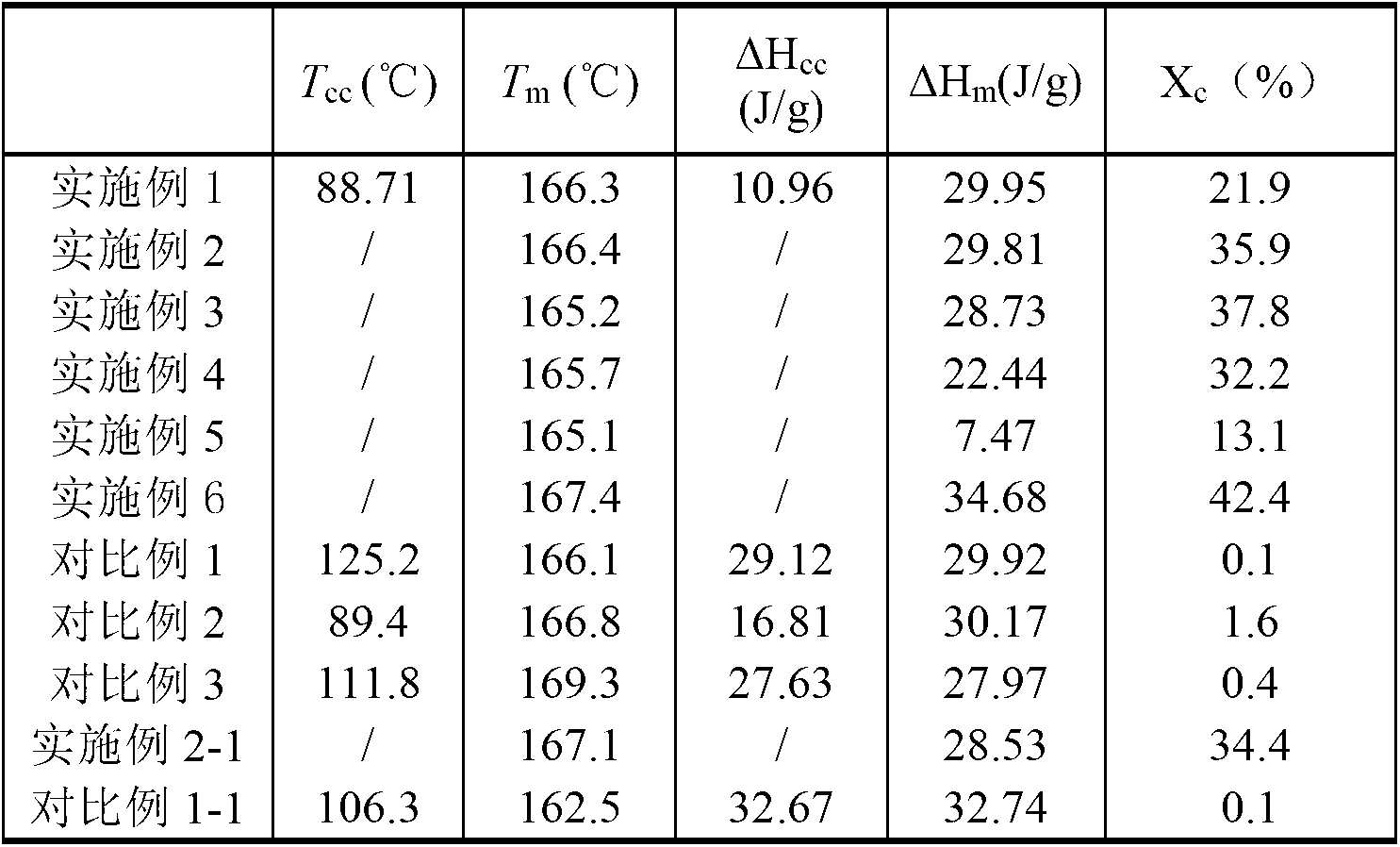

Completely-degradable polylactic acid composite material with high crystallinity and preparation method thereof

The invention discloses a completely-degradable polylactic acid composite material with high crystallinity. A poly-dextrolactic acid / poly-levolactic acid / polyethylene glycol composite material is prepared by the step of adding the polyethylene glycol poly-dextrolactic acid and the polyethylene glycol according to a certain ratio into the poly-levolactic acid in a solution blending way or a melt blending way. A stereo-structure composite crystal and a plasticizer polyethylene glycol which are generated in the blending process of the poly-dextrolactic acid and the poly-levolactic acid jointly accelerate the crystallization of the poly-levolactic acid, so that a polylactic acid sample with high crystallinity can be obtained in a fast cooling process; and all components added in the composite material are biodegradable, i.e., the composite material has high crystallinity and is also completely biodegradable. The preparation technology is simple, easy to operate and low in cost.

Owner:SICHUAN UNIV

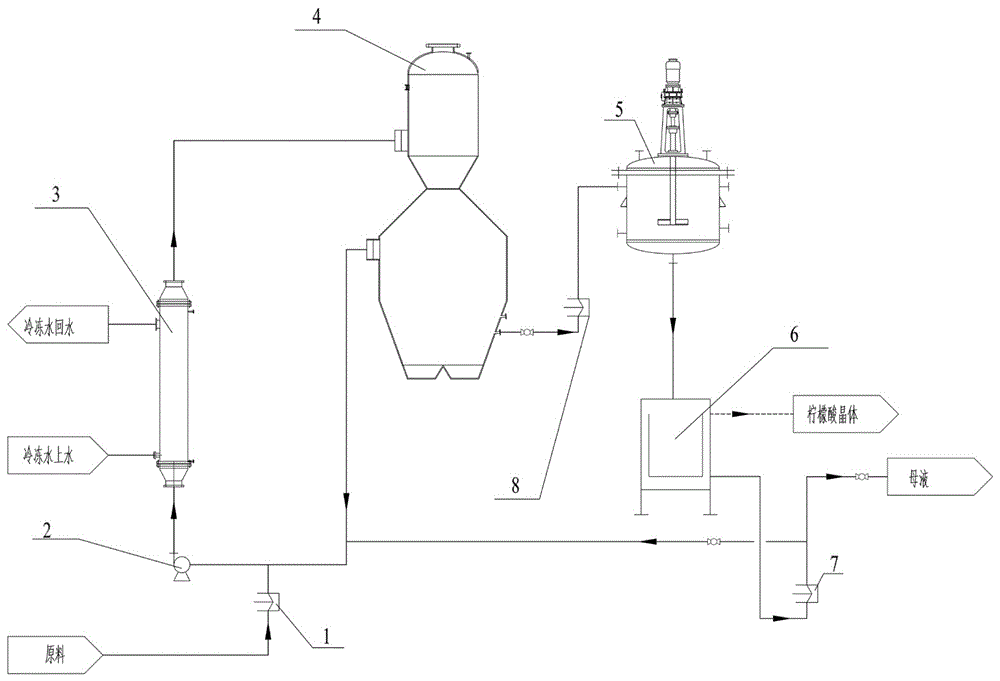

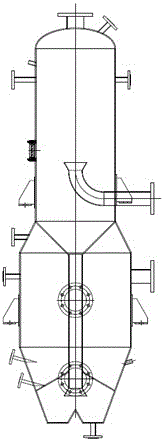

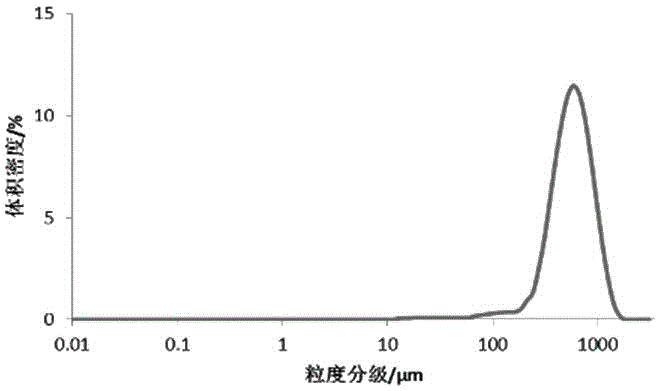

Citric acid continuous cooling crystallization system and method thereof

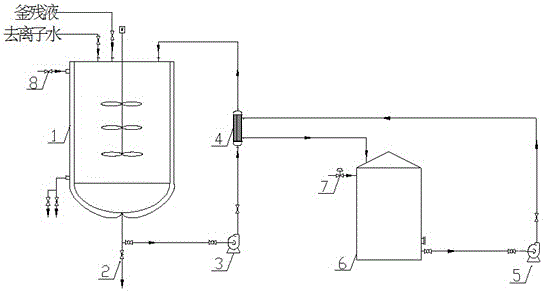

InactiveCN105797422AIncrease productivityStable feeding and dischargingSolution crystallizationHeat exchange cooling cystallizationSlurryCitric Acid Monohydrate

The invention relates to a citric acid continuous cooling crystallization system and a method thereof. In an existing method of producing citric acid monohydrate crystal, intermittent processing equipment is used, product size distribution is uneven, a crystal product is agglutinated seriously, and difference between product batches is large. According to the crystallization method, a citric acid solution is heated and concentrated through two-effect heat exchange, then is input into a circulating pipeline composed of an indirect cooler and a cooling crystallizer through a feed pump and is continuously cooled for cooling crystallization in the circulating pipeline under the action of a circulating pump, and citric acid monohydrate slurry is obtained through cooling crystallization; the citric acid monohydrate slurry is discharged through a discharging pump, conveyed to a crystal slurry buffering tank to be buffered and then input into a centrifugal separation device for solid-liquid separation. According to the continuous cooling crystallization method, intermittent crystallization operation of using a crystallization kettle for feeding and discharging and conducting cooling in the kettle in the past is replaced, the feeding, discharging and cooling flow path is stabilized, continuity and stability of product quality can be effectively ensured, and production efficiency and product quality of citric acid monohydrate are greatly improved.

Owner:西安航天华威化工生物工程有限公司

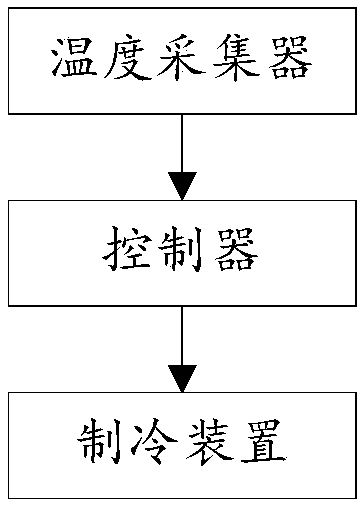

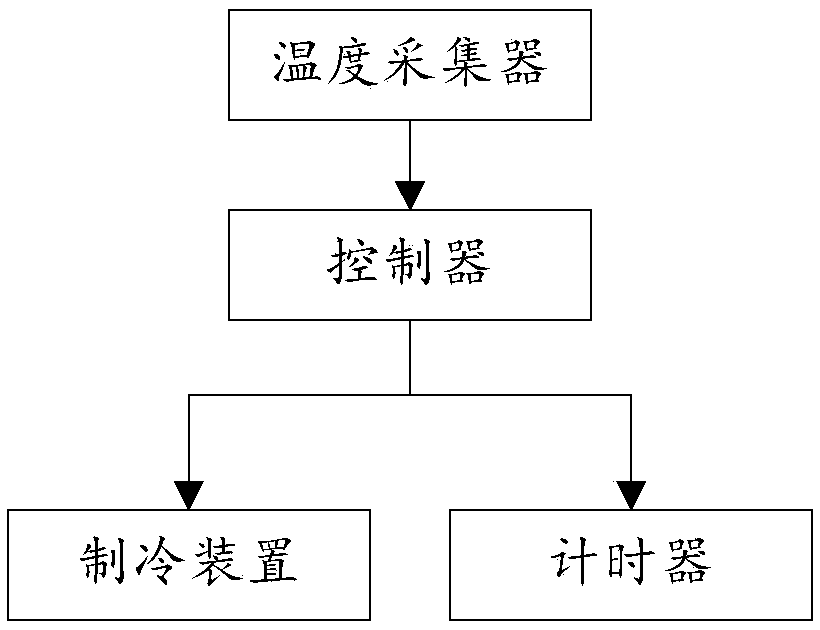

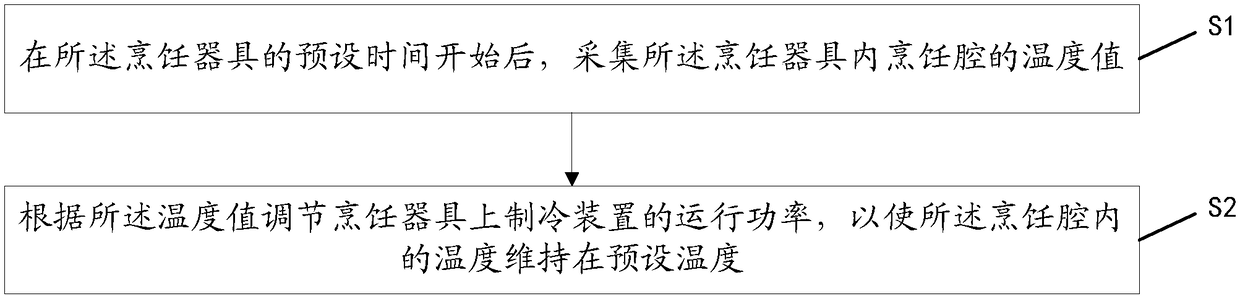

Refrigeration control system and method for cooking utensil and refrigeration cooking utensil

ActiveCN108324115AGuaranteed low temperatureAvoid breedingBeverage vesselsPressure-cookersAppointment timeControl system

The invention relates to a refrigeration control system and method for a cooking utensil and the refrigeration cooking utensil. The refrigeration control system comprises a pot body, a refrigeration device, a temperature collector and a controller, wherein the refrigeration device, the temperature collector and the controller are arranged on the pot body; the temperature collector is used for collecting a temperature value of a cooking cavity in the pot body after appointment time of the cooking utensil is started and sending the collected temperature value to the controller; the controller isused for adjusting the running power of the refrigeration device according to the temperature value, and accordingly the temperature in the cooking cavity is kept within the preset temperature. According to the refrigeration control system, the controller controls the running power of the refrigeration device to adjust the temperature of the cooking cavity in the pot body, it is guaranteed that the cooking utensil is kept in a low temperature state within an appointment time period anytime and bacteria can be prevented from breeding in the cooking utensil within the appointment time.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

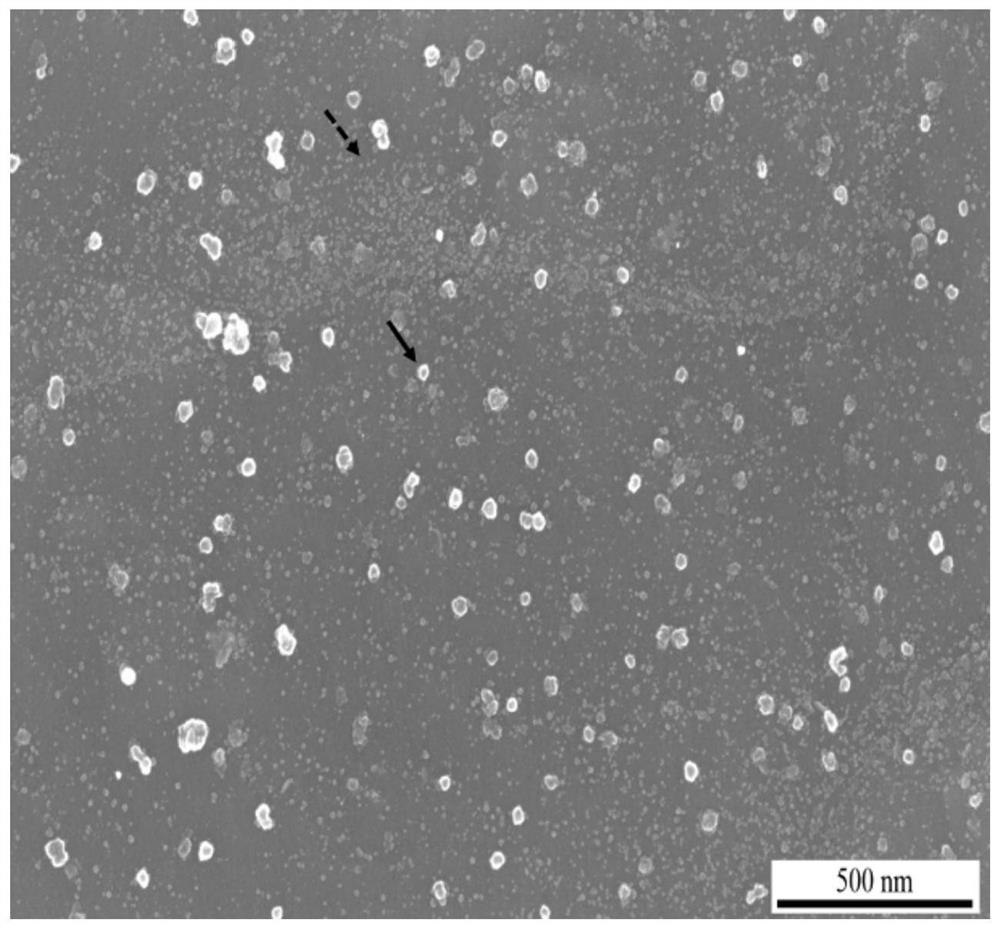

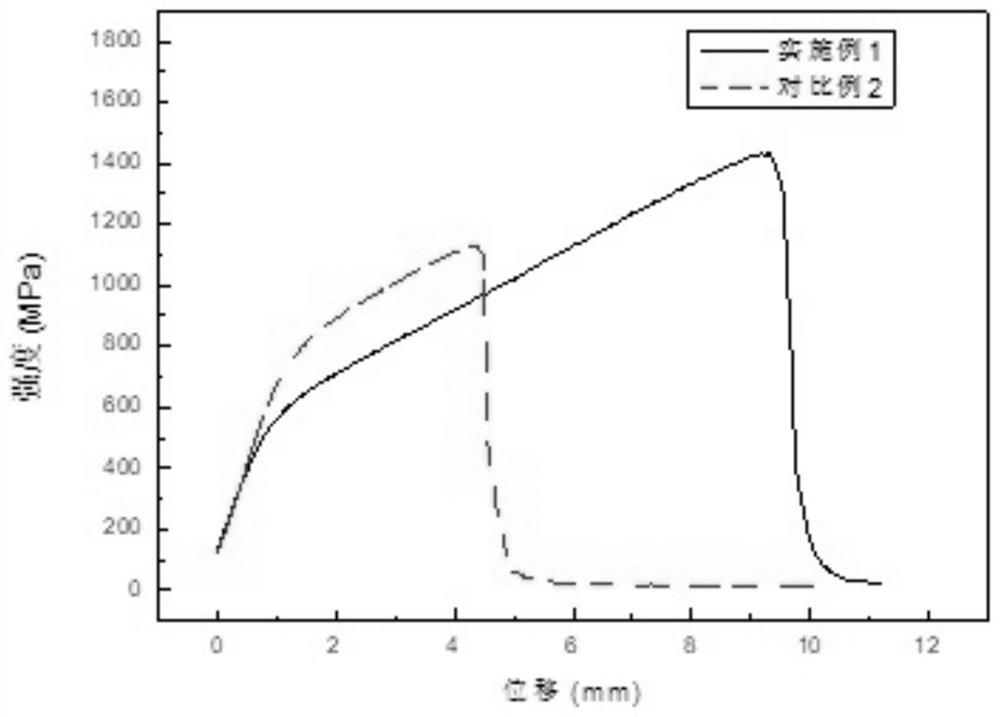

High-strength and high-conductivity Cu-Cr-Nb alloy with double-peak grain size and double-scale nano-phase reinforcing function

ActiveCN112391556AHigh plastic conductivityImprove conductivityAdditive manufacturing apparatusTransportation and packagingElectrically conductiveCopper matrix

The invention provides a high-strength and high-conductivity Cu-Cr-Nb alloy with a double-peak grain size and a double-scale nano-phase reinforcing function, and belongs to the field of additive manufacturing and high-strength and high-conductivity copper alloys. In the designed alloy, the contents of Cr and Nb are 2.0-2.8 at% and 1-1.3 at% correspondingly, the atomic ratio of Cr to Nb is controlled to be slightly greater than 2:1, and a copper matrix is reinforced by nanophases such as a Cr2Nb phase and a Cr phase. According to the alloy, the high-performance Cu-Cr-Nb alloy with the double-peak grain size and the double-scale nano-phase reinforcing function is prepared through the cooperation of selective laser melting and a special heat treatment process. The tensile strength of the prepared Cu-Cr-Nb alloy at room temperature is larger than 800 MPa, the yield strength of the Cu-Cr-Nb alloy is larger than 710 MPa, the microhardness of the Cu-Cr-Nb alloy is not lower than 256 HV, the elongation of the Cu-Cr-Nb alloy is not lower than 25%, and the conductivity of the Cu-Cr-Nb alloy is not lower than 70% IACS. The tensile strength at 700 DEG C is 145-155 MPa.

Owner:CENT SOUTH UNIV

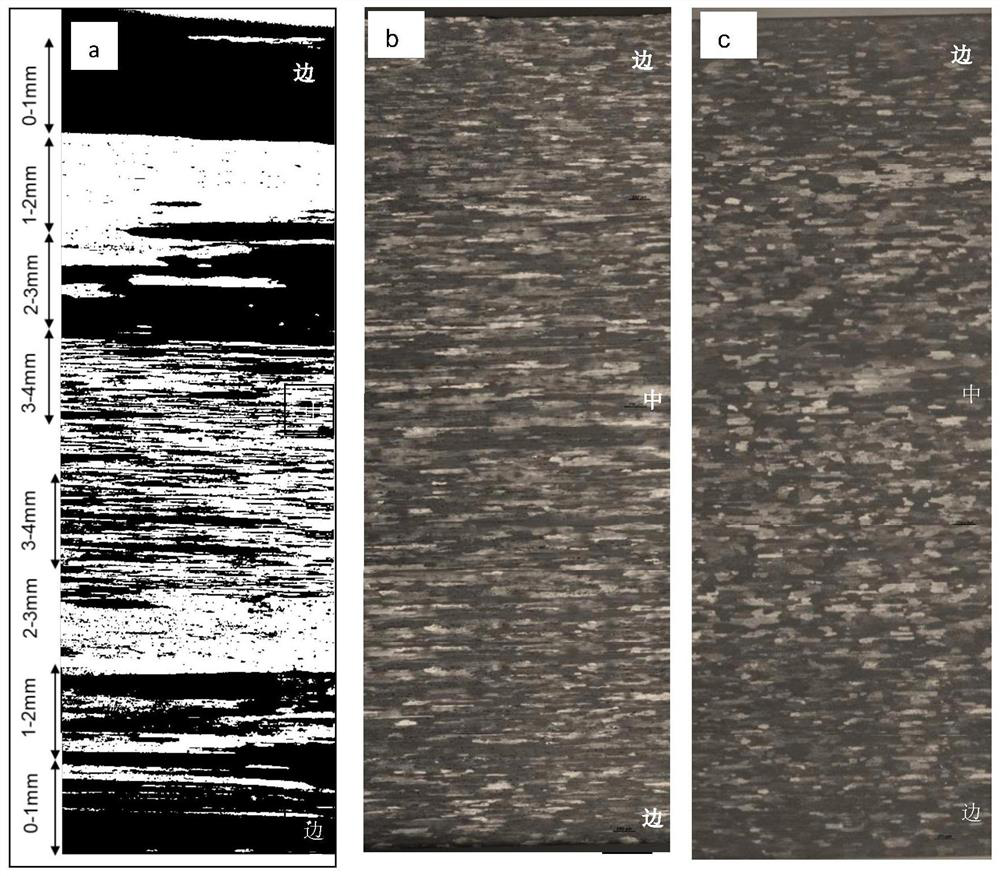

High-throughput preparation method and applications of material, and apparatus for high-throughput preparation of material

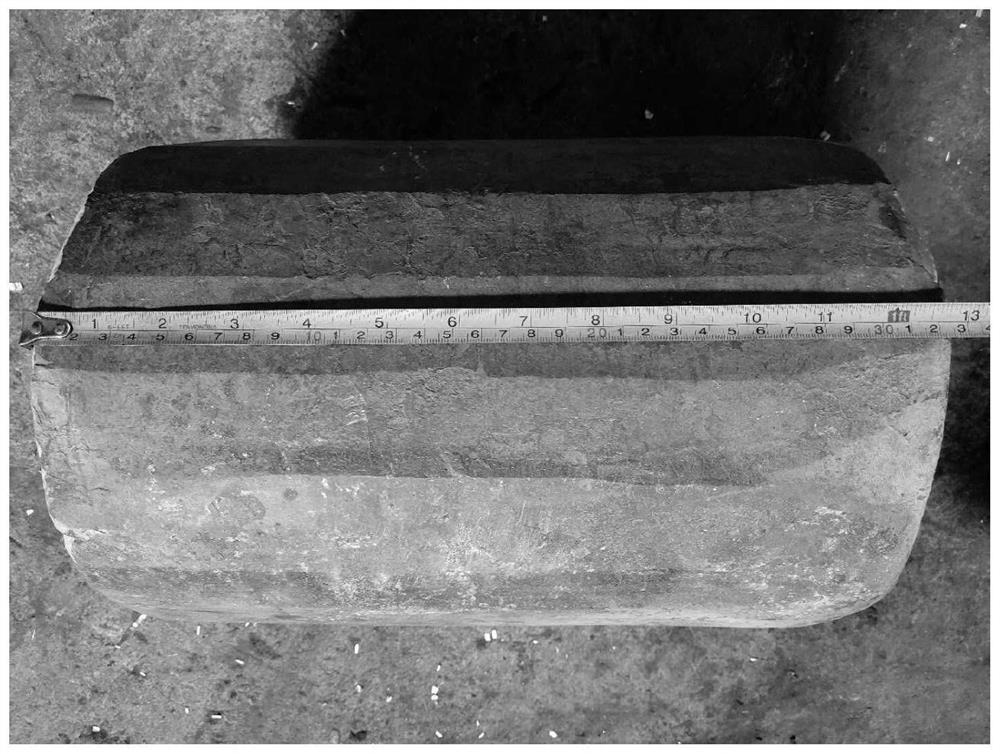

InactiveCN107153025AReduce heat dissipationFast cooling ratePreparing sample for investigationThermal insulationSlow cooling

The present invention provides a high-throughput preparation method of a material, wherein a material sample is heated, the heated material sample is subjected to thermal insulation, and the obtained material sample is maintained at the in situ state while cooling is performed on the obtained material sample from one end. According to the present invention, the material collections having different microstructures and properties are prepared in the high-throughput manner by cooling the material sample from one end, wherein the heat dissipating way of the cooling end is the direct heat exchange between the metal material and the cooling medium, such that the cooling rate is rapid; and the longitudinal surface of the material and the other end surface are subjected to relatively less heat dissipating, the sample is subjected to heat dissipating along the longitudinal direction mainly in the heat conduction manner so as to provide the slow cooling rate, and the cooling rate from the bottom portion to the top portion of the sample is gradually reduced, such that a series of different continuous cooling rates are achieved on the one sample so as to obtain the material collections having different microstructures and properties. The present invention further provides an apparatus for high-throughput preparation of a material, and applications of the material in high-throughput structure characterization and mechanical characterization.

Owner:CENT SOUTH UNIV

Ropivacaine mesylate freeze-dried powder injection

ActiveCN102038651AAvoid the risk of safety accidentsGood freeze-dried appearancePowder deliveryPharmaceutical product form changeFreeze-dryingPhysical chemistry

The invention relates to a ropivacaine mesylate freeze-dried powder injection which consists of ropivacaine mesylate and a PH regulator and is prepared by using the following freeze drying method: (1) a section quick-freezing stage: keeping bulked ropivacaine mesylate solution at the temperature of 0 DEG C for 10-30 minutes, and then keeping the bulked ropivacaine mesylate solution at the temperature of minus 35 DEG C-minus 45 DEG C for 1-2 hours; (2) a lyophilization stage: heating to 0 DEG C under the vacuum degree of 10-20 Pa and at the speed of 2-10 DEG C / h, and then keeping the temperature for 1-3 hours; and (3) a desorption drying stage: heating to 30 DEG C under the vacuum degree of 0-10 Pa and at the speed of 5-10 DEG C / h and keeping the temperature for 2-5 hours. The freeze-dried powder injection provided by the invention has the advantages of high yield, good re-dissolubility, more stable quality and the like.

Owner:鲁南新时代生物技术有限公司

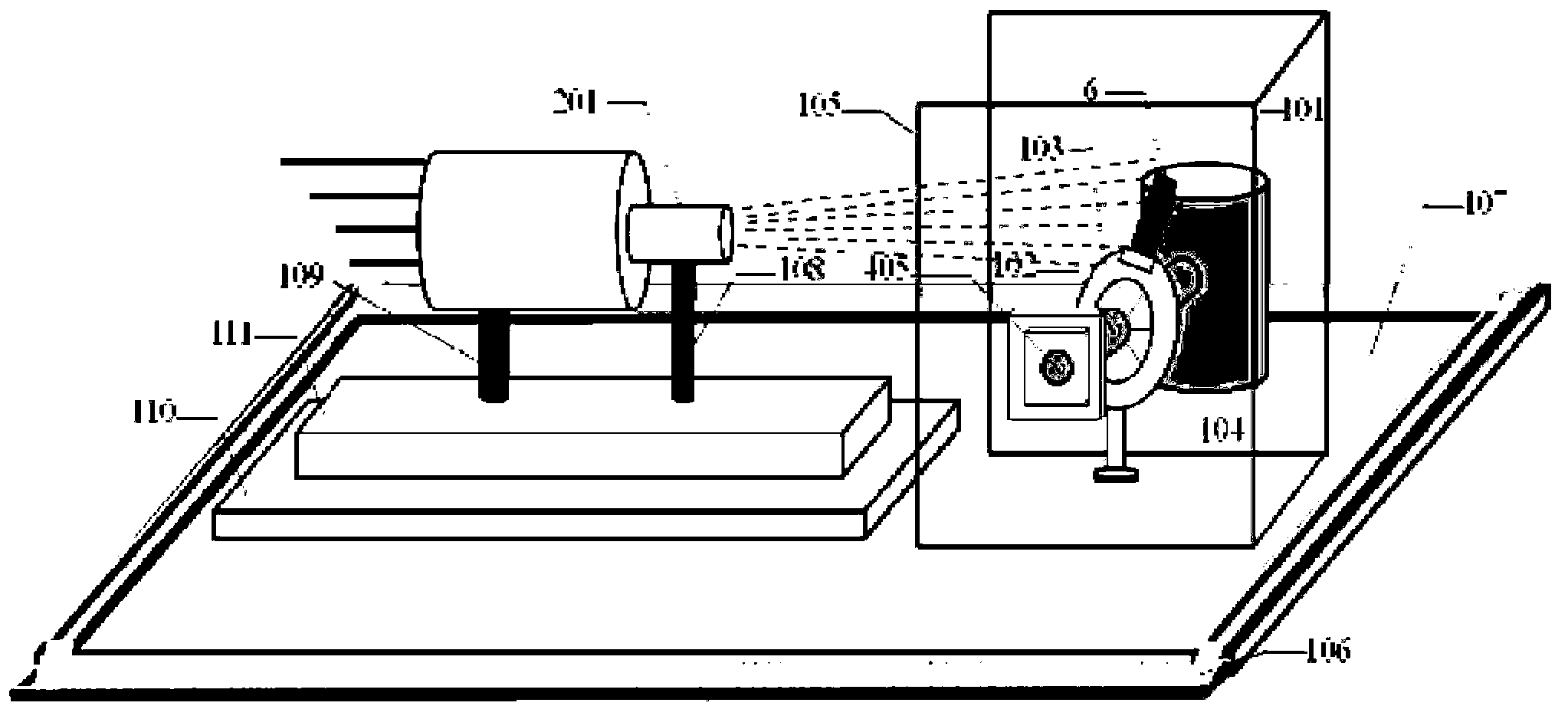

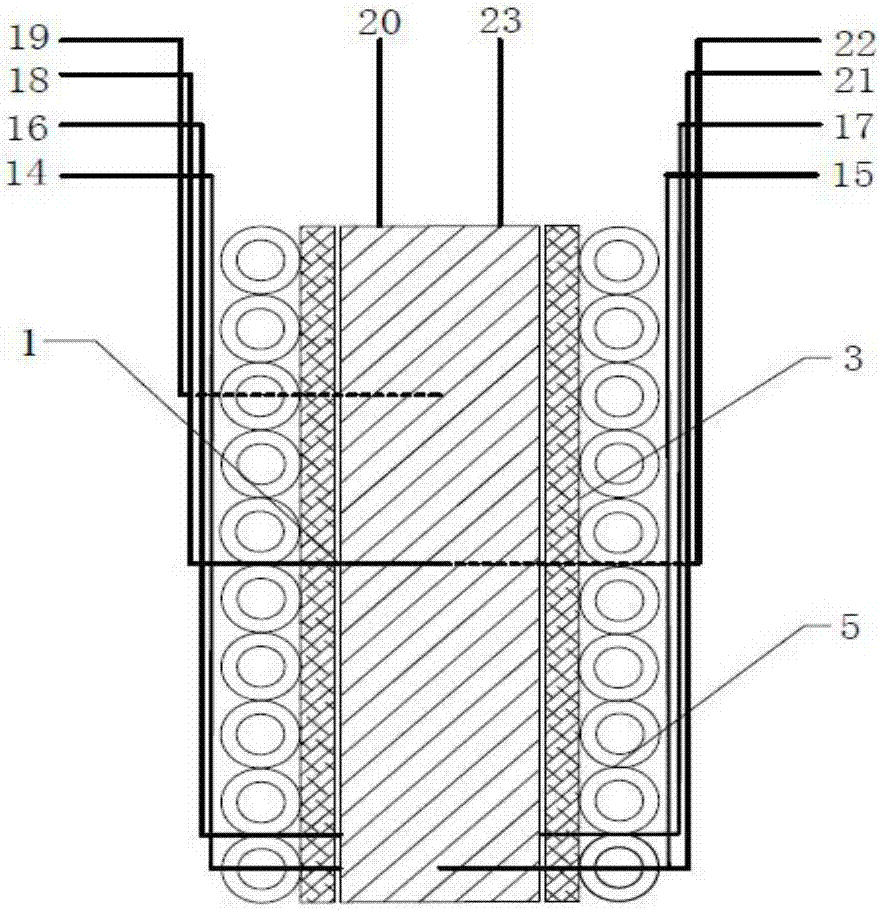

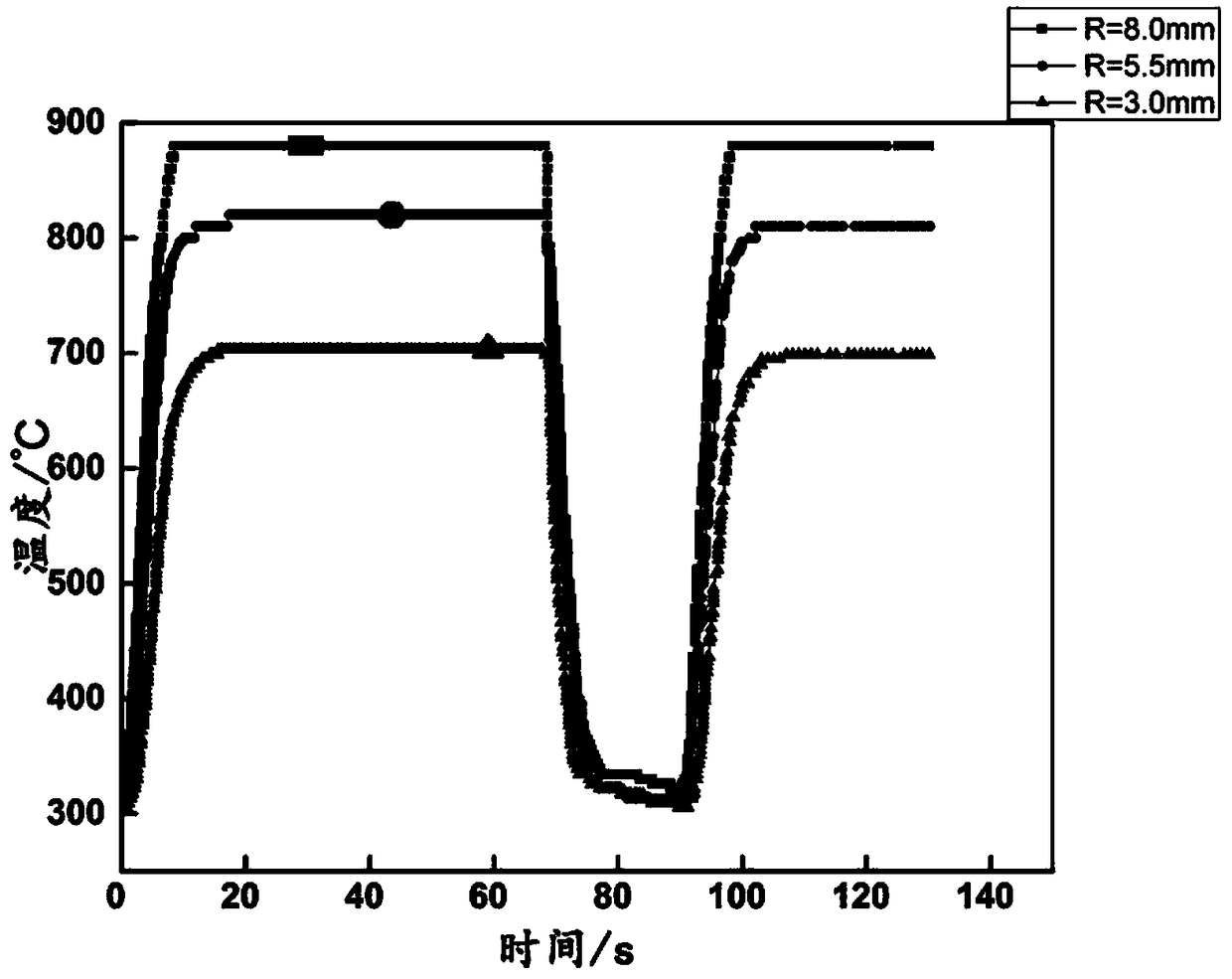

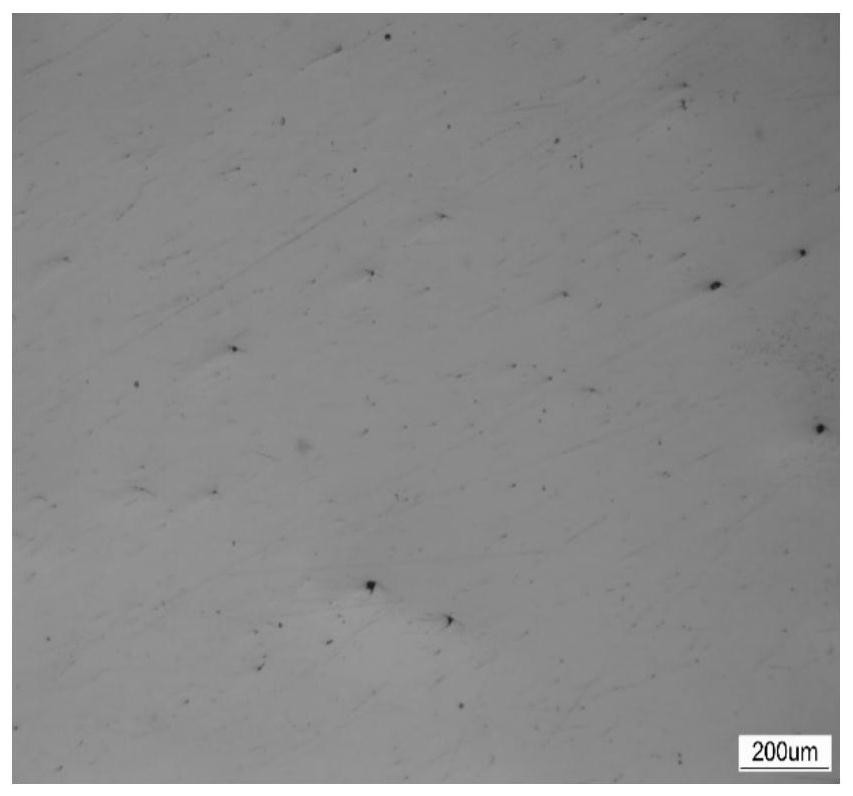

Experimental device used for thermal fatigue of turbine blade material

The invention discloses an experimental device used for the thermal fatigue of a turbine blade material. The device comprises an experiment test bench, an induction coil heating system, a temperaturetesting and collecting system, a cooling system and an experiment control platform, wherein the induction coil heating system, the temperature testing and collecting system, the cooling system and theexperiment control platform are independently connected with the experiment test bench; a specimen is fixed on a fixture; cooling gas passes through a first cooling gas channel and a second cooling gas channel to cool the surface, the end part and the inner side of the specimen; a thermocouple is independently arranged on a position with a surface radius of 3.5mm, a position with a surface radiusof 6.5mm, a position with a surface radius of 8.5mm and a specimen inner ring; the thermocouple is connected with a temperature display instrument and a computer host; and the inner ring of the induction coil is provided with an induction coil cooling water channel, cooling water flows in from one side of the induction coil and flows out from the other side. The device has the advantages that thermal fatigue working environment, where the turbine blade is positioned, with alternating circulation under different working states can be simulated, and in addition, important experiment data can beprovided for the thermal fatigue failure mechanism and the reliability of the turbine blade material.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for improving strength and conductivity of Cu-Cr-Nb alloy

ActiveCN112317755AIncrease solid solutionInhibit growthAdditive manufacturing apparatusConductive materialHydrogen contentElectro conductivity

The invention provides a method for improving strength and conductivity of a Cu-Cr-Nb alloy. According to the method, Cu-Cr-Nb alloy powder with high sphericity degree and less satellite powder is prepared through argon atomization, nitrogen low-temperature winnowing powder screening is adopted, and packaging is conducted in the reducing atmosphere; SLM forming is conducted in the atmosphere withthe hydrogen content being 1-3% and the balance of argon gas, so that oxygen content in the alloy is effectively reduced, and conductivity of the alloy is improved; and finally, a formed part is placed in a reducing atmosphere to be subjected to two-stage aging treatment, and the Cu-Cr-Nb alloy with high strength, high plasticity and high conductivity is obtained. The room-temperature tensile strength of the Cu-Cr-Nb alloy prepared through the method is not lower than 623 MPa, the elongation is not lower than 27%, the microhardness is not lower than 217 HV, the electric conductivity reaches 84% IACS, and the 700 DEG C high-temperature tensile strength is not lower than 140 MPa. The method has important application value in the field of high-strength and high-conductivity copper alloys.

Owner:CENT SOUTH UNIV

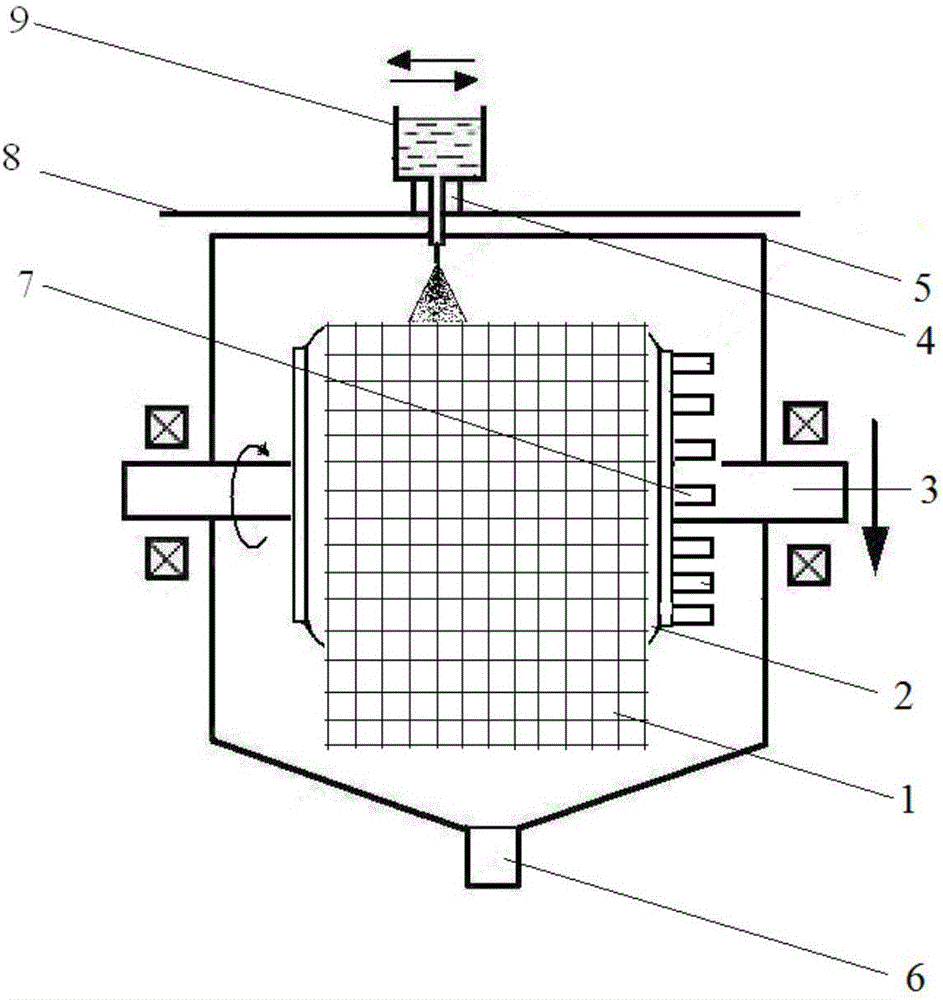

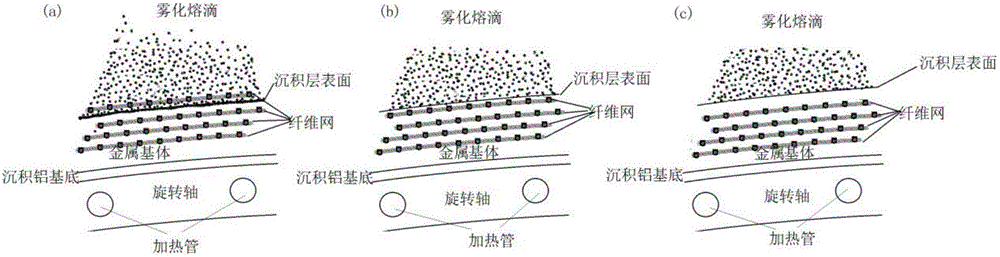

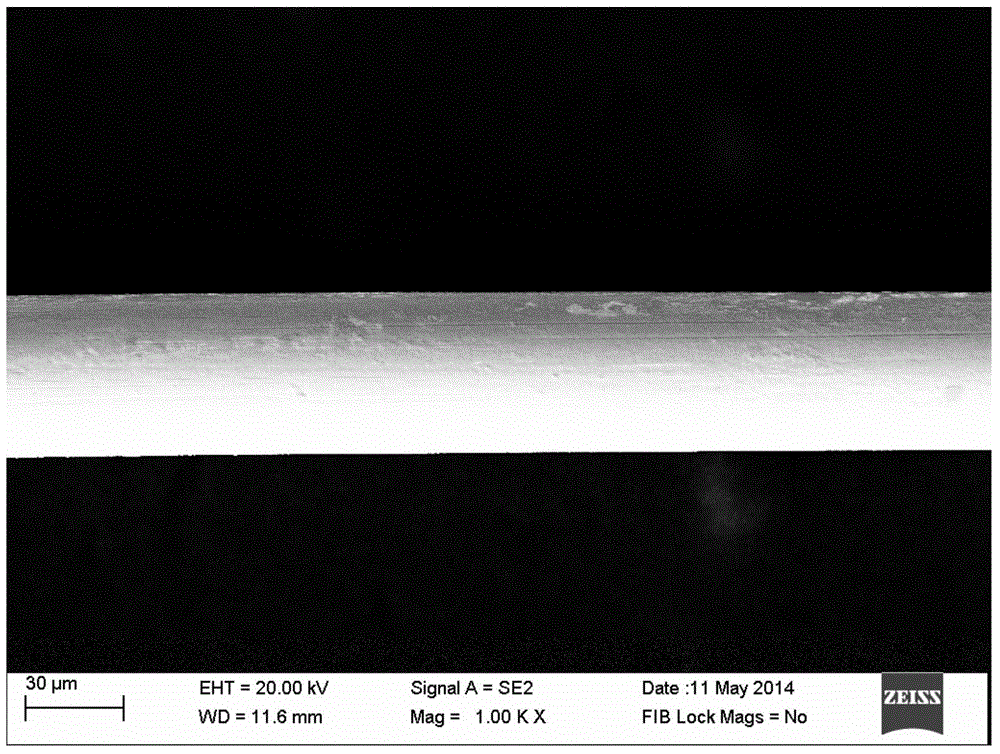

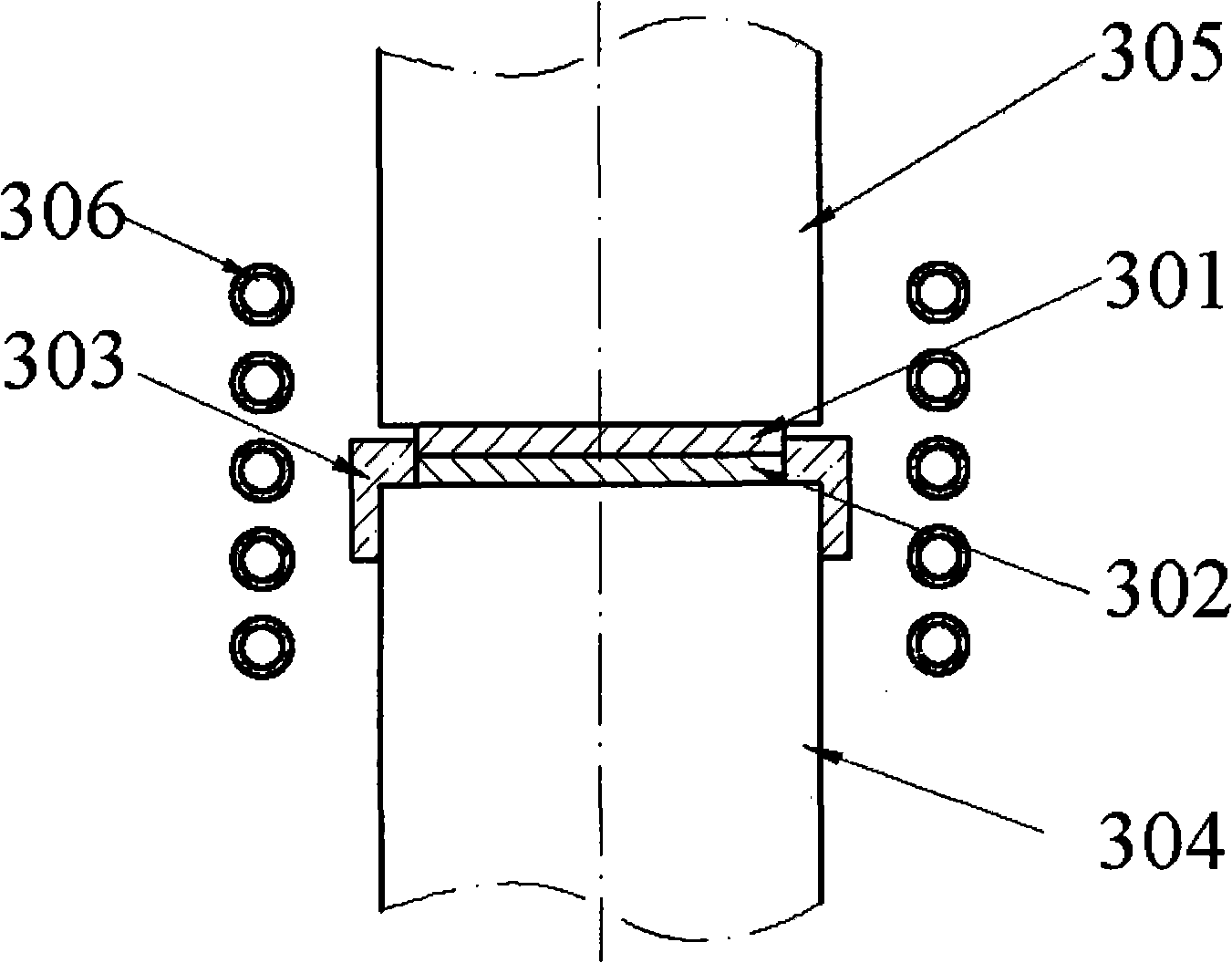

Preparation method and device for fiber reinforced metal matrix composite

The invention provides a preparation method for a fiber reinforced metal matrix composite. Good bonding between a matrix alloy and a fiber mesh and between the matrix alloy and a settled layer is realized by adopting the preparation method. The invention further provides a preparation device for realizing the preparation method and application of the preparation device. The preparation device can realize thickness control over a metal matrix layer between fiber layers and uniform distribution of fibers or enhancement of graded fibers. The preparation device can be used for preparing molten-state metal alloys of an aluminium alloy, a tin alloy, a lead alloy, a copper alloy, an iron alloy and a titanium alloy, and tubular bases made of an aluminium-base alloy, a copper-base alloy, an iron-base alloy, a tin-base alloy and a lead-base alloy. The preparation method and device can realize regulation of the thickness of the metal matrix layer between the fiber layers; the shorter the rotation interval time of a matrix rotating shaft is, the smaller the thickness of the metal matrix layer is, and otherwise, the larger the thickness of the metal matrix layer is; and progressive regulation of the rotation interval time can be realized by a controller, and enhancement of the graded fibers is conveniently realized.

Owner:HUAIHAI INST OF TECH

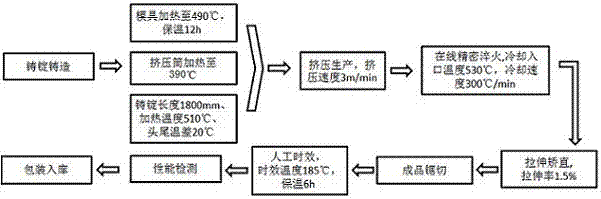

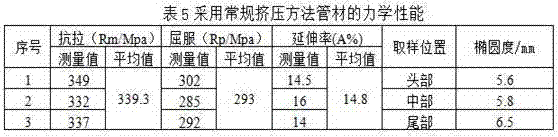

Preparation method of large-sized Al-Mg-Si-Mn alloy tube for textile equipment

InactiveCN107099704AGuaranteed performanceEnsure stabilityExtrusion control devicesIngot castingWater spray

The invention relates to the technical field of alloy profile preparation, in particular to a preparation method of a large-sized Al-Mg-Si-Mn alloy tube for textile equipment. The specific steps include casting and ingot casting, die heating, extrusion container heating, ingot casting heating, extrusion production, in-line precision quenching, stretching and straightening, finished product cutting, artificial seasoning, performance detecting and packaging and warehousing. The large-sized Al-Mg-Si-Mn alloy tube comprises the following components, by weight: 0.7-1.1% of Mg, 0.8-1.2% of Si, 0.4-0.5% of Mn and no more than 0.5% of Fe, further comprises at least one of the following elements: no more than 0.10% of Cr, no more than 0.05% of Zn, no more than 0.05% of Cu, no more than 0.05% of Ti, and no more than 0.03% of V, and the balance Al. Compared with traditional extrusion methods, according to the preparation method of the large-sized Al-Mg-Si-Mn alloy tube for the textile equipment, the components of Al-Mg-Si-Mn alloy and technology ranges of all extrusion processes are adjusted, the technology control process is more refined, the production stability is guaranteed, at the same time, precise in-line water spray quenching is adopted, so that mechanical properties are much better, good uniformity of the tube after being extruded can be guaranteed, and the production efficiency is improved greatly.

Owner:广西南南铝加工有限公司

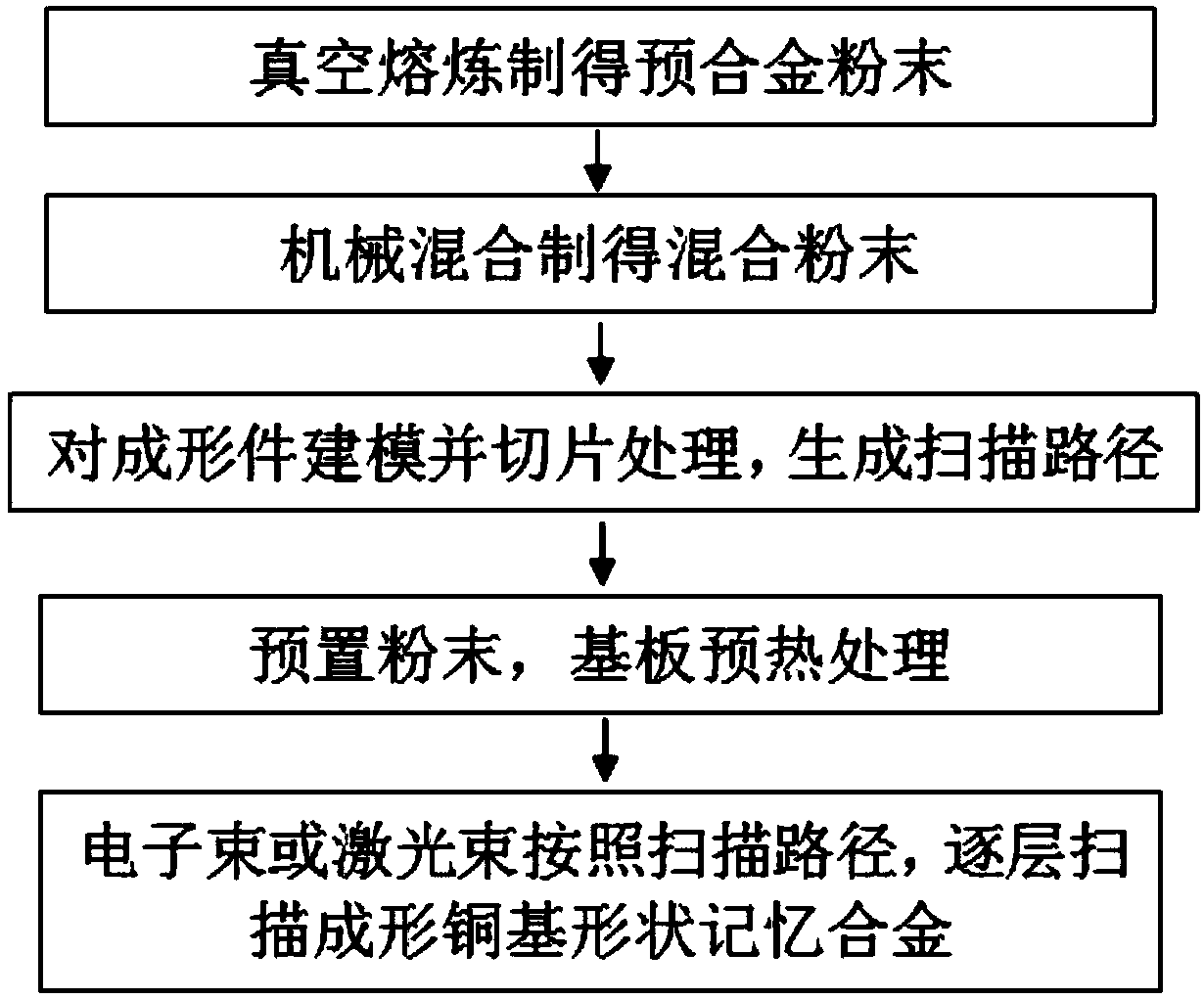

Method for in-situ preparation of copper-based shape memory alloy through additive manufacturing

InactiveCN109648091AGuaranteed uniformityRaise the remelting zoneAdditive manufacturing apparatusIncreasing energy efficiencyIn situ reactionHigh density

The invention belongs to the field of preparation of copper-based shape memory alloys, and discloses a method for the in-situ preparation of any copper-based shape memory alloy through additive manufacturing. The method includes the following steps that (a) mixed powder needed by the element in a part is prepared and used as a raw material, and (b) the copper alloy is used as a forming substrate,electron beams or laser beams are used for conducting the selection melting technology to prepare the required copper-based memory alloy part, in the process, all the components in the mixed powder are instantly heated above melting points of the components and melted into a liquid phase without difference, the in-situ reaction diffusion is conducted under the liquid phase, the atomic reaction isfast, the diffusion time is short, and the composition segregation is avoided; and in addition, the parent phase formed by the main elements is not dissolved to form brittle gamma 2 phase but to formthe martensite phase, and the memory performance and hyperelasticity of the desired product are improved. By means of the method for the in-situ preparation of the copper-based shape memory alloy through the additive manufacturing, the product with any shape, high density, memory performance, super elasticity and high toughness are quickly prepared.

Owner:HUAZHONG UNIV OF SCI & TECH

Production method of alloy spring steel wire with excellent drawing performance

ActiveCN112845578AIncreased substructure densityImprove stabilityRollsMetal rolling arrangementsSpinsAlloy

The invention belongs to the technical field of rolling, and particularly relates to a production method of an alloy spring steel wire with excellent drawing performance, which comprises the working procedures of cogging, heating, rolling and cooling, the temperature of a second heating section and a soaking section of a casting blank is 1200-1250 DEG C, cogging is carried out after the heat preservation time is 3-6 hours, an intermediate blank is heated for 100-300 minutes, the temperature of the second heating section and the soaking section is 900-1050 DEG C, and the second heating section and the soaking section do not exceed 100 minutes; the temperature in / out of a finishing mill is 750-850 DEG C, and the deformation is 60-90%; and the spinning temperature is 750-800 DEG C, the Stelmor controlled cooling time is 600-1200 seconds, the cooling rate is 0.10-0.20 DEG C / s, and air cooling is carried out in a manner of avoiding wind after discharging from a cover. A 100% ferrite F + pearlite P structure is obtained, the grain size is more than 9 grade, the plastic deformation performance is excellent, and the method can be directly used for large-deformation cold drawing processing without annealing, and has the characteristics of energy conservation, consumption reduction, greenness, environmental protection and the like.

Owner:ZENITH STEEL GROUP CORP +1

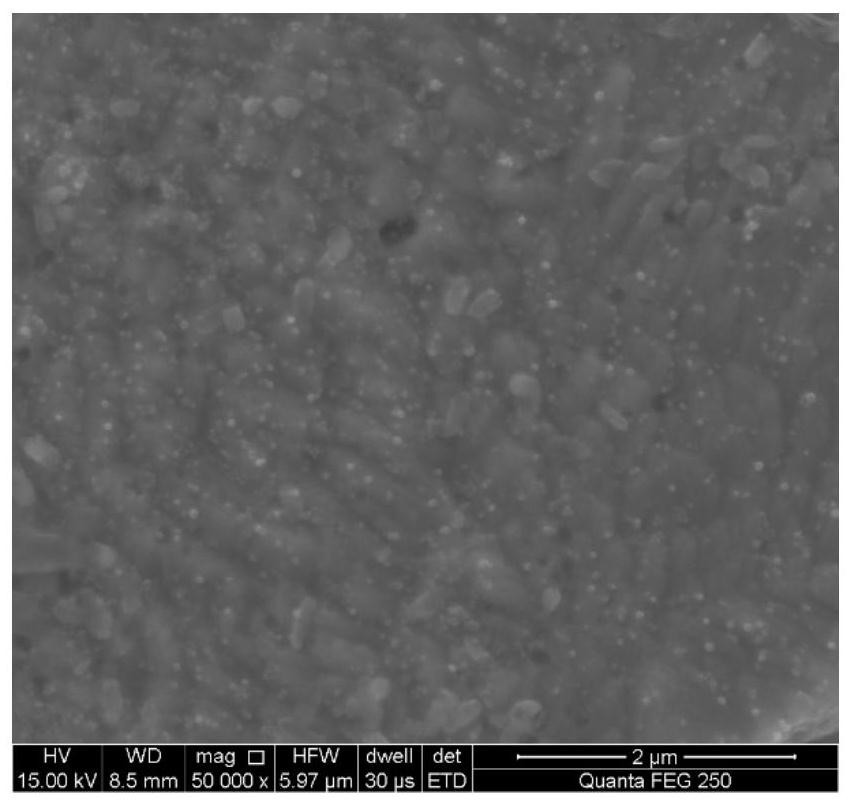

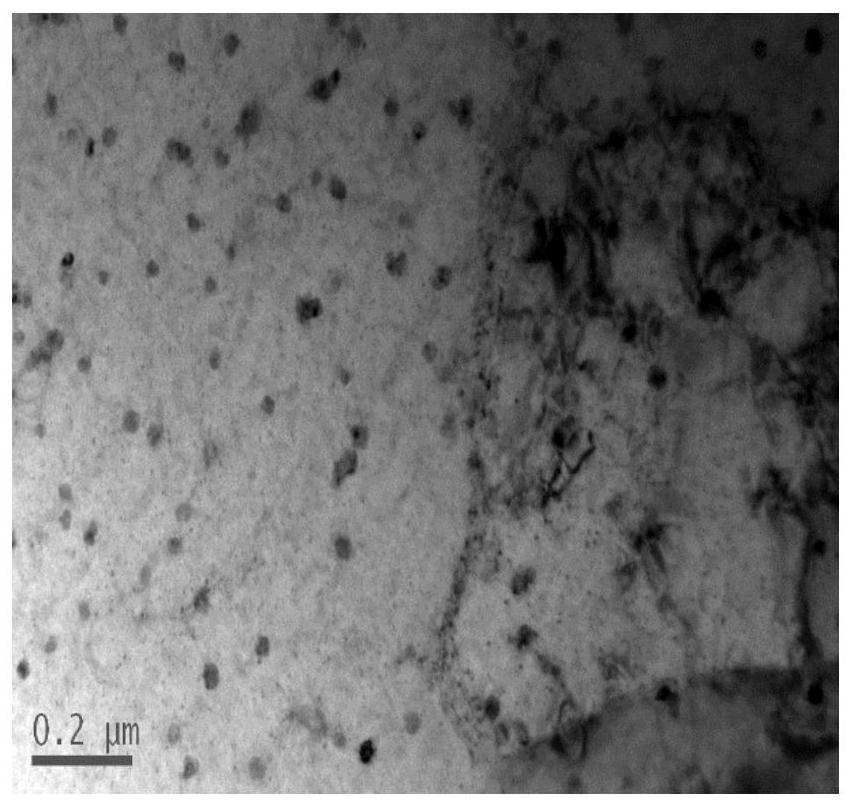

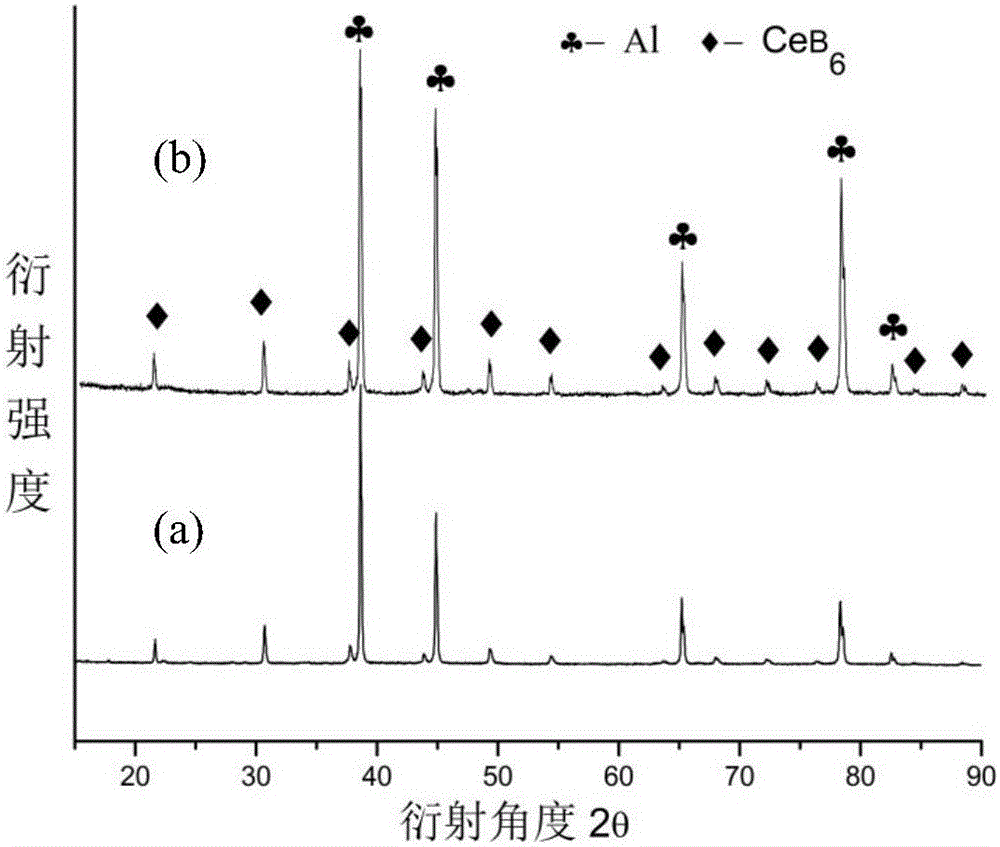

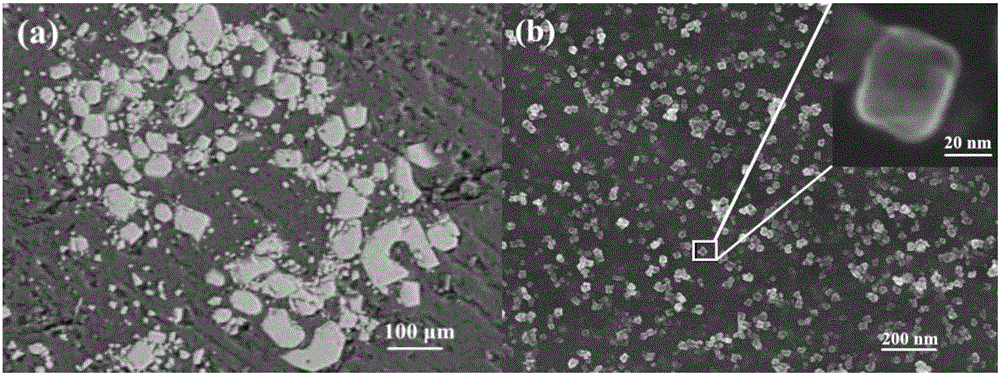

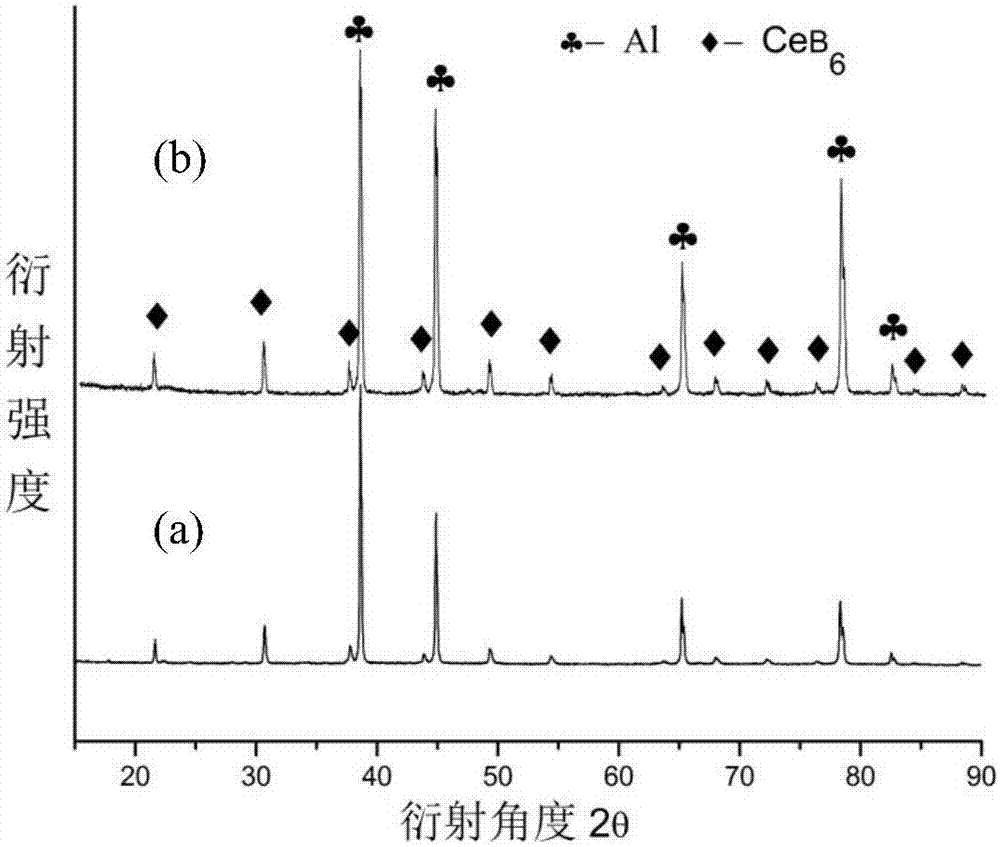

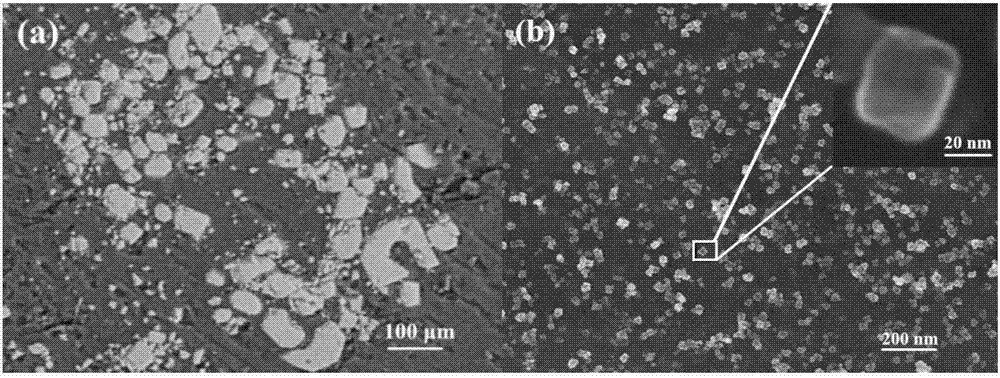

Preparing method of in-situ synthesized aluminum matrix composite inoculant

ActiveCN105950921AHighlight substantive featuresGood refinement effectCrucibleAluminum matrix composites

The invention provides a preparing method of an in-situ synthesized aluminum matrix composite inoculant and relates to an aluminum-based alloy. The preparing method is a method for making an ribbon-shaped CeB6 / Al nanometer in-situ aluminum matrix composite inoculant by adopting an in-situ synthesis reaction process and a rapid solidification technology. The method comprises the following steps: weighing required quantities of commercial Al-2.8%B intermediate alloy and commercial Al-20.2%Ce intermediate alloy, and mixing the materials according to a ratio that the ratio by weight of the Al-2.8%B intermediate alloy to the Al-20.2%Ce intermediate alloy is 22:7; putting all of the materials into a crucible of a high-vacuum induction melting furnace and smelting the materials so as to make a blocky Al-B-Ce intermediate alloy; and carrying out rapid solidification treatment so as to make an in-situ synthesized ribbon-shaped CeB6 / Al nanometer in-situ aluminum matrix composite inoculant. The method overcomes defects in the prior art that reinforced particles in the inoculant cannot be distributed on a matrix in a dispersion manner or the dispersion degree is not ideal, the particles are precipitated in melt in an aggregation manner and the sizes of the particles are large.

Owner:HEBEI UNIV OF TECH

A kind of preparation method of in-situ self-generated aluminum-based composite material inoculant

ActiveCN105950921BHighlight substantive featuresGood refinement effectCrucibleAluminum matrix composites

The invention provides a preparing method of an in-situ synthesized aluminum matrix composite inoculant and relates to an aluminum-based alloy. The preparing method is a method for making an ribbon-shaped CeB6 / Al nanometer in-situ aluminum matrix composite inoculant by adopting an in-situ synthesis reaction process and a rapid solidification technology. The method comprises the following steps: weighing required quantities of commercial Al-2.8%B intermediate alloy and commercial Al-20.2%Ce intermediate alloy, and mixing the materials according to a ratio that the ratio by weight of the Al-2.8%B intermediate alloy to the Al-20.2%Ce intermediate alloy is 22:7; putting all of the materials into a crucible of a high-vacuum induction melting furnace and smelting the materials so as to make a blocky Al-B-Ce intermediate alloy; and carrying out rapid solidification treatment so as to make an in-situ synthesized ribbon-shaped CeB6 / Al nanometer in-situ aluminum matrix composite inoculant. The method overcomes defects in the prior art that reinforced particles in the inoculant cannot be distributed on a matrix in a dispersion manner or the dispersion degree is not ideal, the particles are precipitated in melt in an aggregation manner and the sizes of the particles are large.

Owner:HEBEI UNIV OF TECH

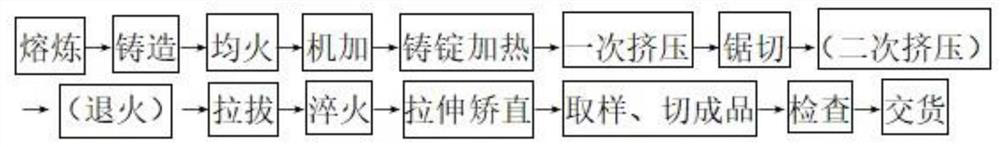

Processing method of 2xxx series aluminum alloy bars and wires for fasteners

ActiveCN113293273AExcellent formabilityExcellent matching plasticityFurnace typesHeat treatment furnacesWire rodTemperature control

The invention discloses a processing method of 2xxx series aluminum alloy bars and wires for fasteners, which comprises the following steps: adding an intermediate alloy into an aluminum ingot, smelting in a smelting furnace, and then carrying out semi-continuous casting to obtain an industrial cast ingot; carrying out homogenization treatment on the cast ingot added with the alloy, increasing the temperature of the cast ingot to 480-505 DEG C from the room temperature in a one-stage or multi-stage heating mode, and conducting out heat preservation for 10-60 h; extruding the obtained cast ingot into a bar, controlling the extrusion outlet speed of the profile to be 0.1-4 mm / s, and controlling the extrusion temperature to be 360-470 DEG C; carrying out annealing heat treatment on the extruded bar blank, the annealing process parameters are as follows: the temperature is 250-450 DEG C, the annealing time is 0.5-3 h, the bar blank is discharged from a furnace and cooled in air, and an annealed bar is obtained; carrying out cold drawing on the extruded bar or the extruded and annealed bar; carrying out solid solution quenching on the cold-drawn bars and wires; and pre-stretching the bars and the wires, and controlling the pre-stretching amount to be 0.1%-3%;.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

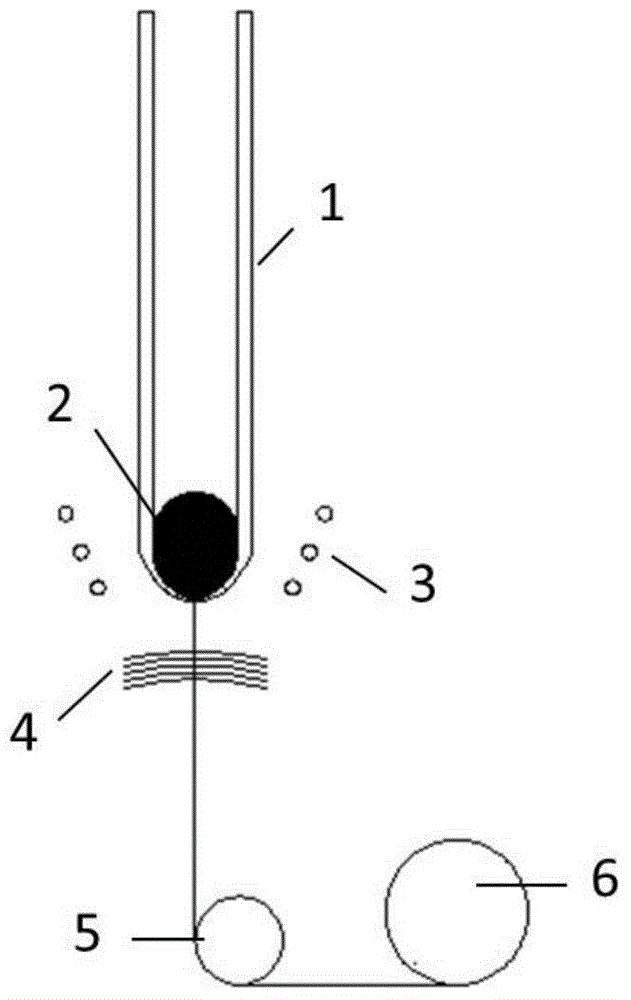

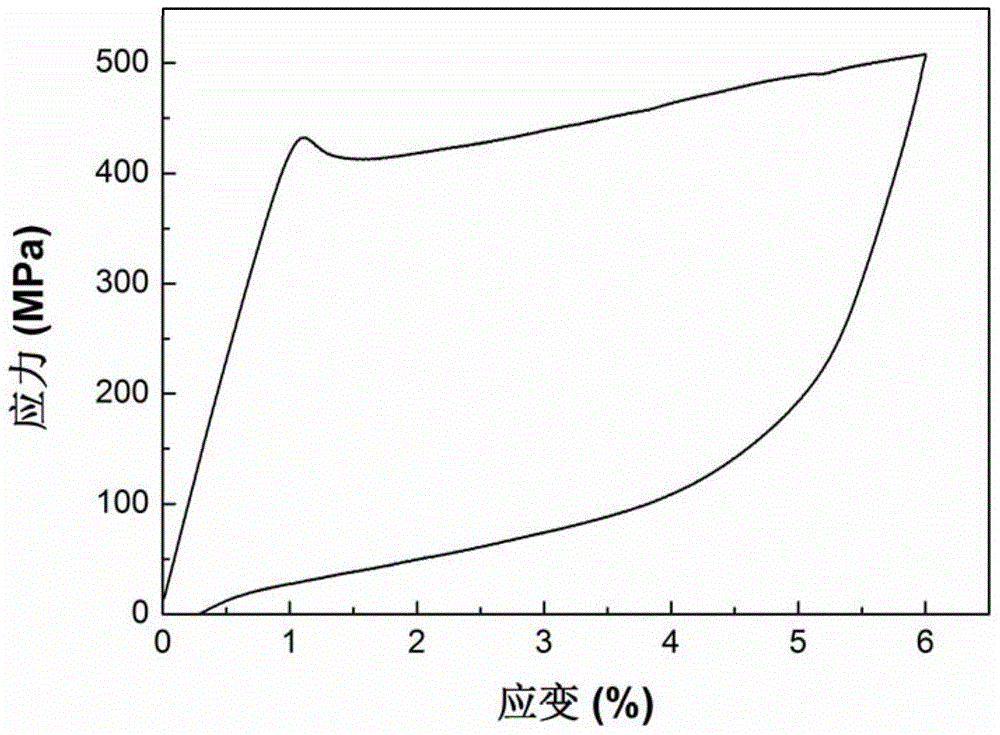

Copper-based hyperelastic shape memory alloy wire and preparation method thereof

The invention relates to a copper-based hyperelastic shape memory alloy wire and a preparation method thereof. The molecular formula of the alloy is Cu100-xSnx, wherein the x equals to 14-17. The preparation method adopts the method of wrapping spin with glass, and comprises the following steps: alloy ingots are gradually fused through a high frequency induction device within the range of 200-600A, and when the bottom glass tube is softened, the fused alloy liquid and the bottom glass tube form a micro melting bath; a glass-coated alloy material is pulled out from the softened glass tube bottom with a glass rod provided with a tip; the glass-coated alloy material is winded on a wire winding wheel after being cooled by sprayed water; the glass on the surface of a prepared micro wire is peeled off to obtain a bare copper-stannum hyperelastic shape memory alloy wire. The shape memory alloy wire is formed by one step, and simple in working procedures; the diameter of the prepared micro wire is 3-200 micron, can be wildly applicable to sensors and drives, is an intelligent material combining perception and drive, and has important significance for promoting the micromation of intelligent elements.

Owner:UNIV OF SCI & TECH BEIJING

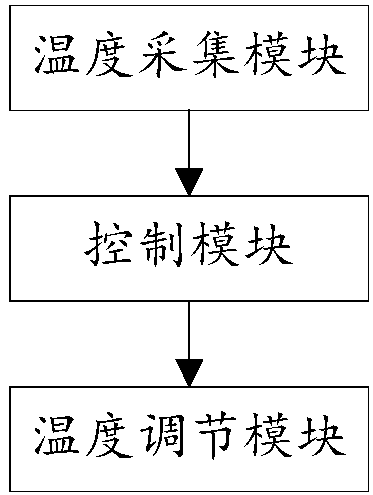

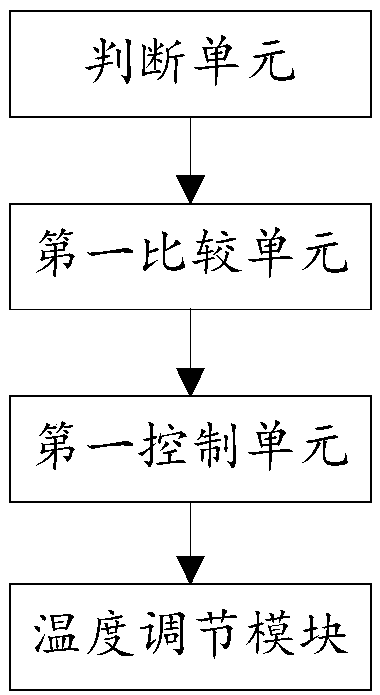

Heat preservation control system and method for cooking utensil and cooking utensil

ActiveCN108324084AAppropriate serving temperatureRealize temperature regulationCooking vesselsBeverage vesselsControl systemComputer module

The invention relates to a heat preservation control system and method for a cooking utensil and the cooking utensil. The heat preservation control system comprises a temperature adjustment module, atemperature collection module and a control module; the temperature collection module is used for collecting a temperature value of a cooking cavity in the cooking utensil when the cooking utensil enters a heat preservation stage and sending the temperature value to the control module; the control module is used for comparing heat preservation remaining time with first preset time in real time after the cooking utensil enters the heat preservation stage, generating a control command according to a comparison result and sending the control command to the temperature adjustment module; the temperature adjustment module is used for adjusting the temperature according to the control command and keeping the temperature value within a preset temperature range. By arranging the heat preservationcontrol system, a user can control the temperature in the cooking cavity and keep the temperature in different temperature ranges according to the length of the heat preservation remaining time, and when the heat preservation remaining time is up, the temperature of rice reaches the proper eating temperature.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Infrared rapid heat-treatment cavity for semiconductor chip with movable heat baffle

InactiveCN101409228AWide heating temperature rangeFastSemiconductor/solid-state device manufacturingInfraredProcess equipment

The invention relates to a semiconductor plate infrared fast heat treatment cavity with a movable thermal baffle, belonging to the technical field of the technological device for manufacturing an ultra large scale integrated circuit and a semiconductor. The heat treatment cavity comprises a flat rectangular double-layer quartz cavity, and an infrared heating cavity and an infrared reflection plate which are fixed between an inner quartz cavity and an outer quartz cavity. The front end of the inner quartz cavity extends into the outer quartz cavity. The front ends of the inner quartz cavity and the outer quartz cavity are provided with a sealing cavity cover and a sealing valve thereof. The heat treatment cavity also comprises a mechanical hand which is provided with a quartz plate support fixedly, and a drive mechanism. The movable thermal baffle is also arranged outside the double-layer quartz cavity. The thermal baffle can extend into a gap between the external wall of the inner quartz cavity and the internal wall of a flat rectangular infrared heating cavity from the back end of the double-layer quartz cavity along the direction of axis of the double-layer quartz cavity. The heat treatment cavity of the invention can ensure that a semiconductor plate is heated or cooled fast and realize actual spike annealing. The heat treatment cavity heats the semiconductor plate with uniform temperature within wide range; the heated semiconductor plate has high heating rate and cooling rate; and the semiconductor plate has any size and high production efficiency.

Owner:中国电子信息产业集团有限公司 +2

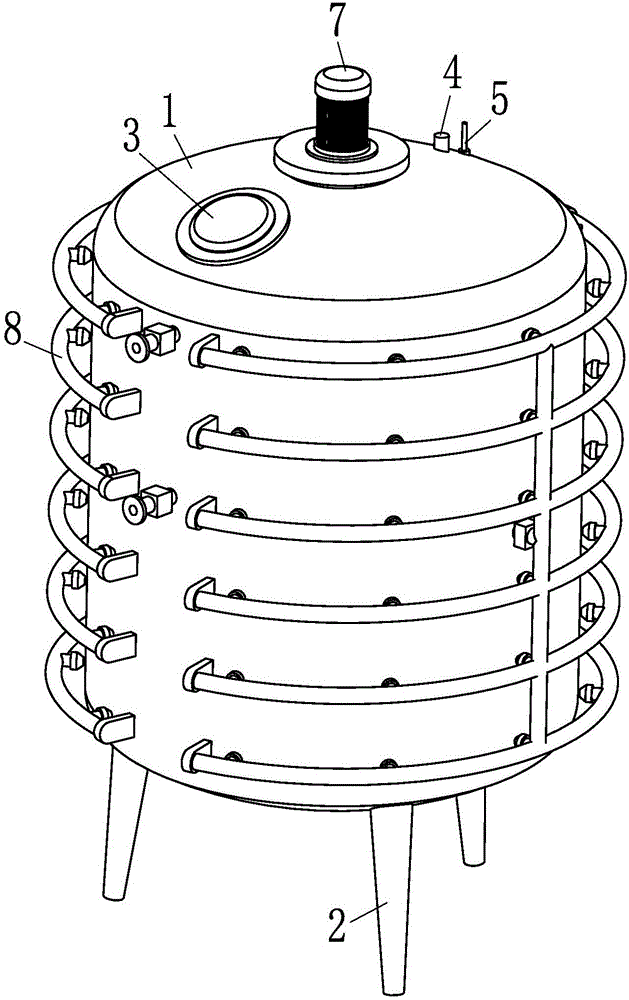

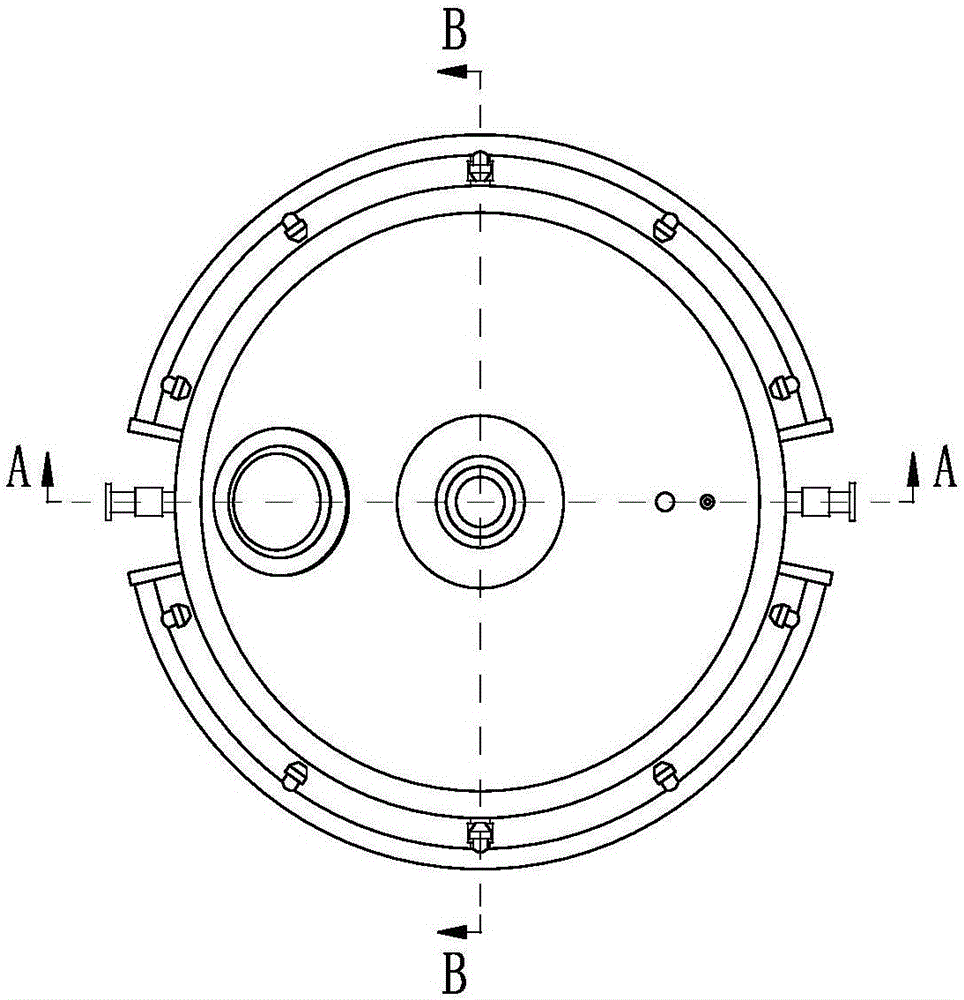

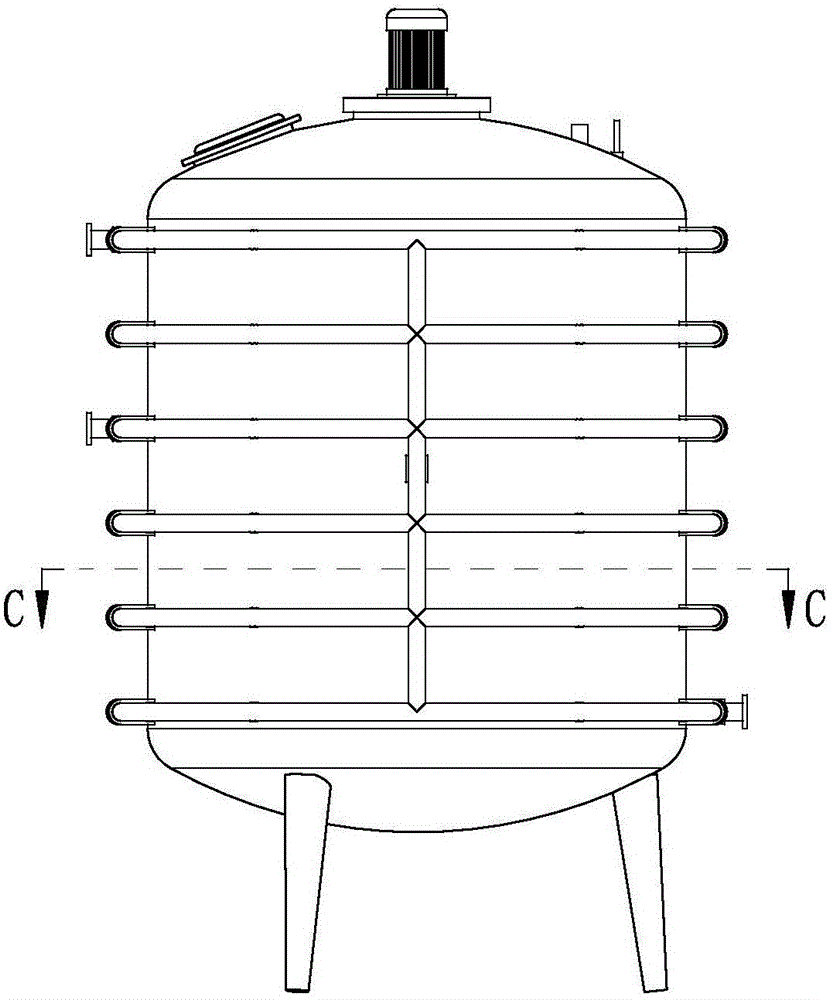

Self-cooling alcohol storage tank

The invention relates to the field of alcohol production equipment and in particular discloses a self-cooling alcohol storage tank. The self-cooling alcohol storage tank comprises a tank body, supporting legs, an access hole and a pressure discharge port, and also comprises a water temperature sensor, an internal cooling device, a stirring device and an external cooling device, wherein the stirring device is positioned in the middle of the tank body; the internal cooling device is wound around the stirring device; the external cooling device is wound around the tank body; the internal cooling device comprises six cooling pipe groups, four connecting vertical pipes, a water inlet pipe and a water outlet pipe; the external cooling device comprises two external cooling units; each of the two external cooling units comprises an external cooling main pipe, an external cooling vertical pipe, an external cooling ring pipe, a nozzle and a support; the stirring device comprises a stirring motor, a stirring main rod and a stirring side rod. According to the self-cooling alcohol storage tank disclosed by the invention, alcohol liquid in the alcohol storage tank can be efficiently and uniformly cooled, and danger of alcohol caused by high temperature and volatilization of alcohol can be reduced.

Owner:ANHUI ANTE FOOD

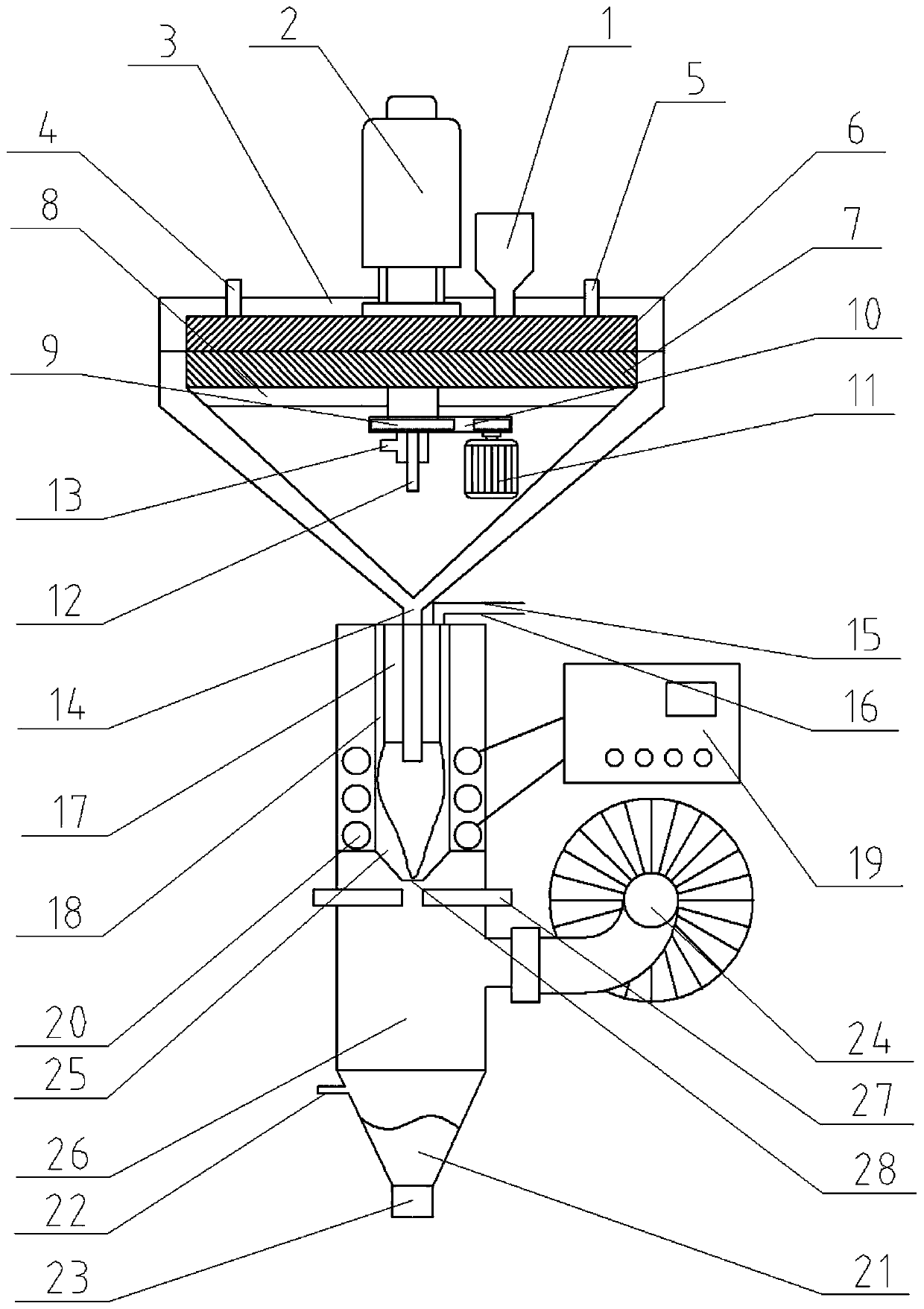

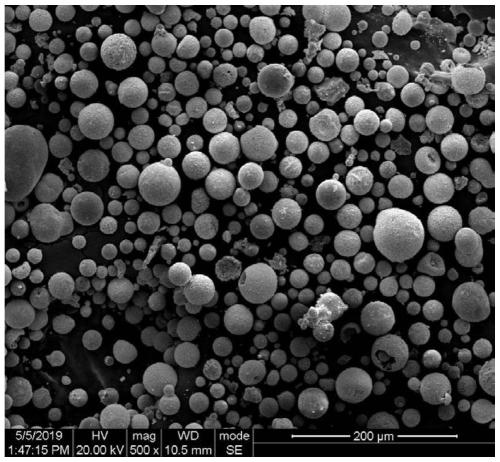

Preparation device and preparation technology for polymer-based spherical powder

ActiveCN111036342ARealize mass productionImprove grinding effectAdditive manufacturing apparatusCocoaPhysical chemistryPolymer chemistry

The invention provides a preparation device and preparation technology for polymer-based spherical powder. The preparation device comprises a grinding disc grinding system and an inductive coupling plasma powder nodulizing system, and the grinding disc grinding system of the preparation device achieves material ultrafine grinding under the room temperature condition by exerting strong extruding stress, cutting stress and circumferential stress to materials; and the inductive coupling plasma powder nodulizing system takes high-temperature plasmas as a high-temperature heat source, polymer powder is heated uniformly, the melting and cooling rate is high, and nodulizing treatment can be completed in an ultrashort time. According to the preparation device, the preparation process of the polymer-based spherical powder is integrated and achieves continuous production, the preparation technology is significantly improved, therefore, the polymer-based spherical powder material which has the excellent performance and can be applied to the SLS field is prepared, and large-scale batch production can be achieved.

Owner:SICHUAN UNIV

Magnesium alloy forged piece and manufacturing method thereof

ActiveCN112589024ASmall mechanical propertiesLow ductilityMetal-working apparatusRare-earth elementMagnesium alloy

Magnesium alloy comprises, by mass percentage, 3.5%-5.0% of Al, 2.0%-3.5% of Zn, 0.1%-0.8% of Mn, 0.01%-0.80% of RE, 0.001%-0.090% of Ca, other inevitable impurity elements and the balance magnesium,wherein the sum of the content of Al and the content of Zn is larger than or equal to 6% and smaller than or equal to 8%, and RE is a rare earth element. A forging technology is developed, a high-ductility medium-strength magnesium alloy large forged piece is successfully manufactured, and the wider application of large-specification magnesium alloy bearing structural parts is promoted.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Crystallization process of di-trimethylolpropane

ActiveCN105732335AAvoid destructionReduce cooling rateEther separation/purificationSolution crystallizationTemperature controlChilled water

The invention relates to a crystallization process of di-trimethylolpropane.Kettle raffinate containing di-trimethylolpropane and water are added into a crystallization stirring kettle to be prepared into a solution with the mass fraction of 60% to 65%; crystallization and condensation are carried out, then a cooling water circulating pump, an outer liquid circulating pump and a program temperature control system are started, liquid is slowly cooled, and then a proper amont of di-trimethylolpropane is added as seed crystals; then stepping cooling is continued according to setting of the program temperature control system, a valve in front of the outer liquid circulating pump is switched off, pumping continues to be carried out for 3 min, cooling water leading to a jacket of the crystallization stirring kettle is switched to be connected, and stepping cooling is continued according to the setting of the program temperature control system; finally, a discharging valve at the bottom of the crystallization stirring kettle is switched on, and liquid containing a large number of crystals is discharged into a sealing-tape machine or centrifugal machine for solid-liquid separation.The crystallization process has the advantages that products with coarse crystal grains can be obtained, and subsequent filtering and washing can be completed easily.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

Press welding method for semiconductor extension film

InactiveCN101267012AFast heating rateFast heating rate or cooling rateSemiconductor devicesProduction rateEngineering

The invention discloses a semiconductor epitaxial wafer press-welding method, the method does not need to heat the press-welding method through the way of thermal resistance heating, thus preventing the press-welding method in the way of thermal resistance heating from effecting ohmic contact performance of the epitaxial wafer because of thermal diffusion. The method avoids farthest deterioration of quality of epitaxial wafer caused by the way of thermal resistance heating. The invention comprises the following steps: location steps: placing welding epitaxial wafer and substrate on a worktable of folder device, causing welded surface of the epitaxial wafer and the substrate location-docking through a location device; electromagnetic-welding steps: connecting electromagnetic coil, imposing folder pressure on the epitaxial wafer and the substrate through the folder device of welding body, heating the press-welding method of the epitaxial wafer or the substrate through electromagnetic wave which is sent out by electromagnetic coil, thus causing the epitaxial wafer and the substrate press-welding together. The invention can increase the production rate because of fast heating rate and cooling rate obviously.

Owner:LATTICE POWER (JIANGXI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com