Method for ultrasonic auxiliary laser additive manufacturing of two-dimension titanium-based functional gradient material

A functionally graded material, laser additive technology, applied in additive manufacturing, additive processing, energy efficiency improvement, etc., can solve the problem of uneven distribution and coarse ceramic particles, and achieve the effect of benefiting microstructure and promoting uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

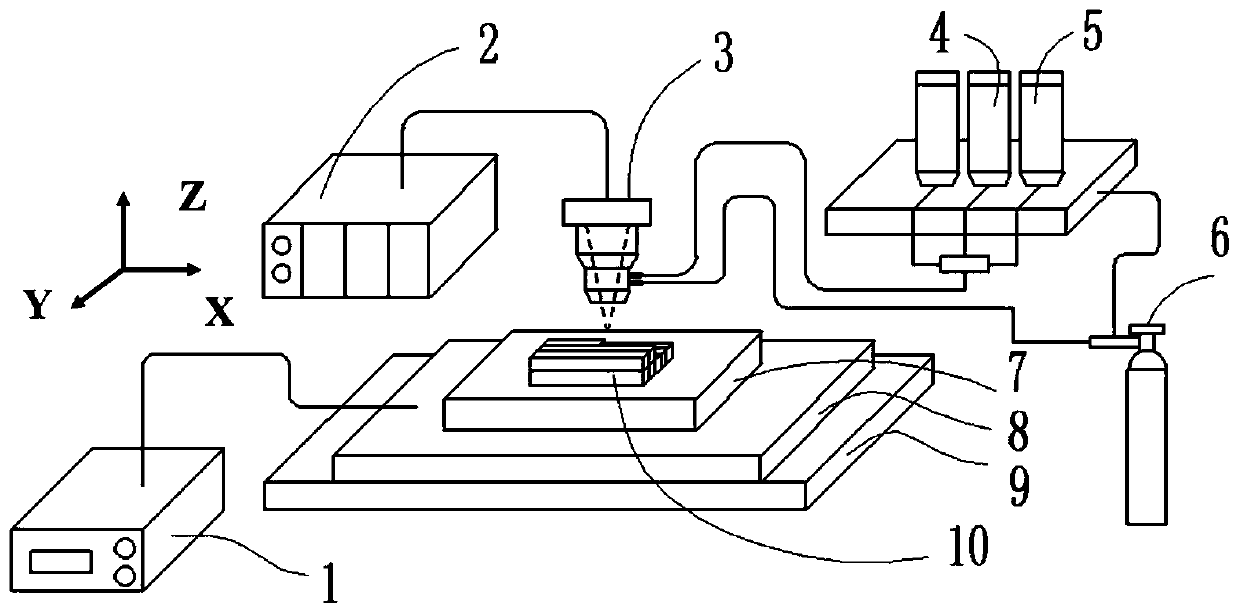

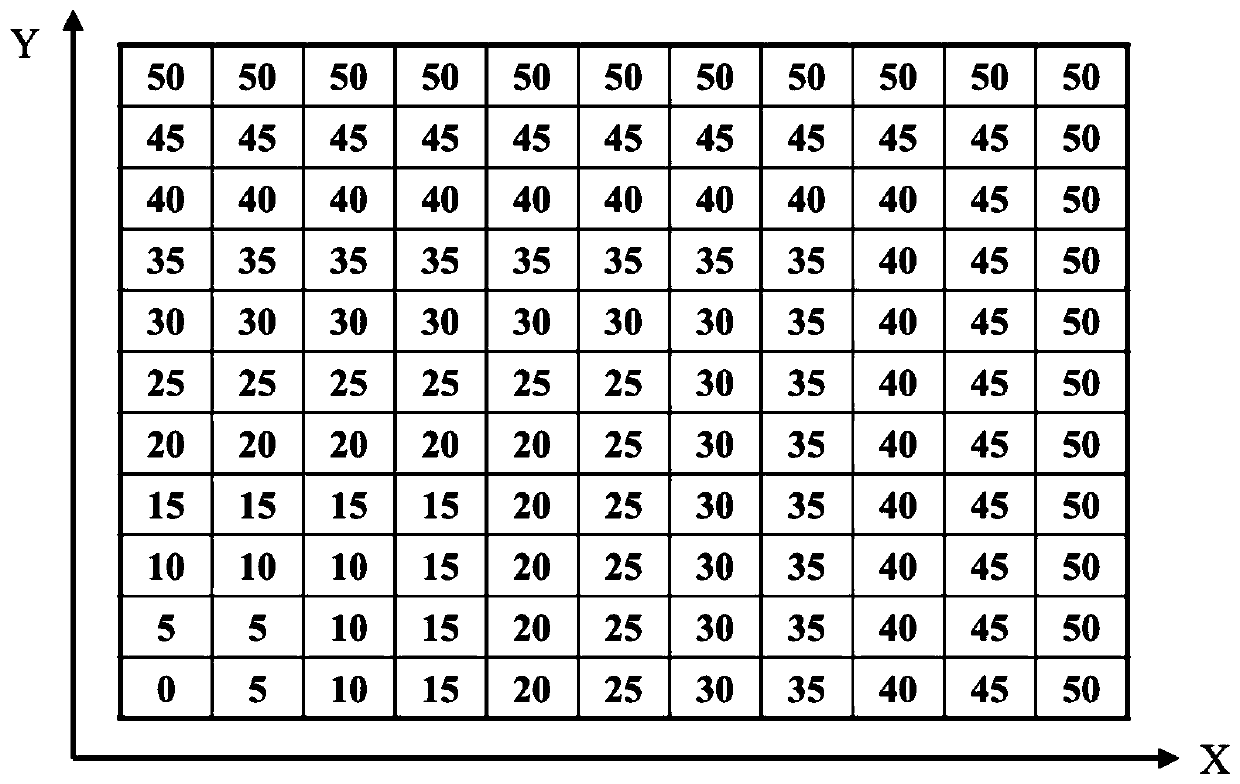

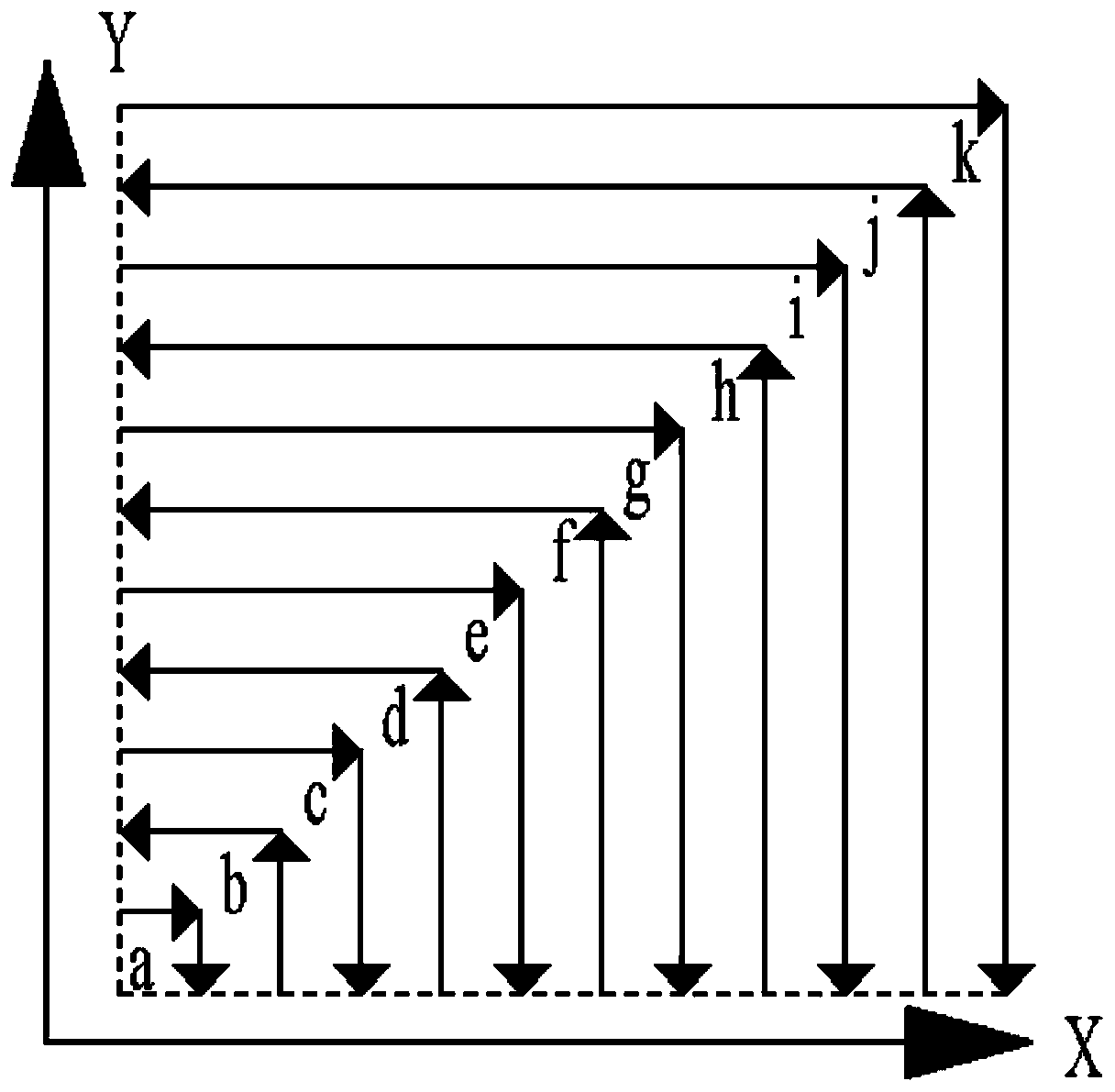

[0032] The present invention will be further described below with reference to the accompanying drawings. Taking ultrasonic-assisted direct laser deposition of TiC (titanium carbide) reinforced Ti6Al4V (TC4 titanium alloy) two-dimensional titanium-based functionally graded material as an example, specific implementation methods are given:

[0033]A method for ultrasonic-assisted laser additive manufacturing of two-dimensional titanium-based functionally graded materials. The device for manufacturing two-dimensional titanium-based functionally graded materials for ultrasonic-assisted laser additive manufacturing of the method includes an ultrasonic generator 1, a laser 2, and a laser head 3. Powder feeding cylinder 4, powder feeding cylinder 5, high-purity argon gas 6, titanium alloy substrate 7, ultrasonic vibration platform 8, machine tool motion platform 9. The titanium alloy substrate 7 is horizontally fixed on the ultrasonic vibration platform 8, and is directly below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com