Directional solidification apparatus for preparation of porous ceramics based on ice template method and preparation method thereof

A porous ceramic, directional solidification technology, used in ceramic products, other household appliances, household appliances, etc., can solve the problem that the cooling rate cannot reach a linear change in the cooling rate, the control of the pore shape of porous ceramics is limited, and it is difficult to control the growth of ice crystals, etc. problem, to achieve the effect of uniform temperature field, fast cooling rate and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

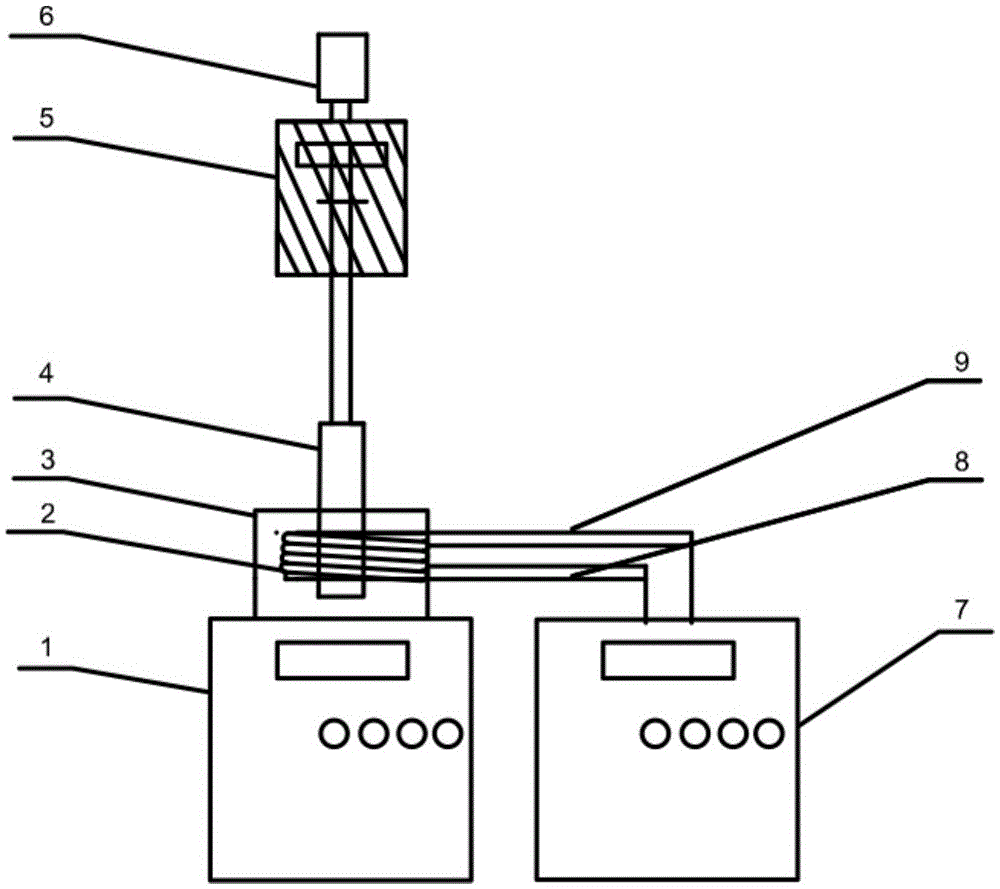

Method used

Image

Examples

Embodiment 1

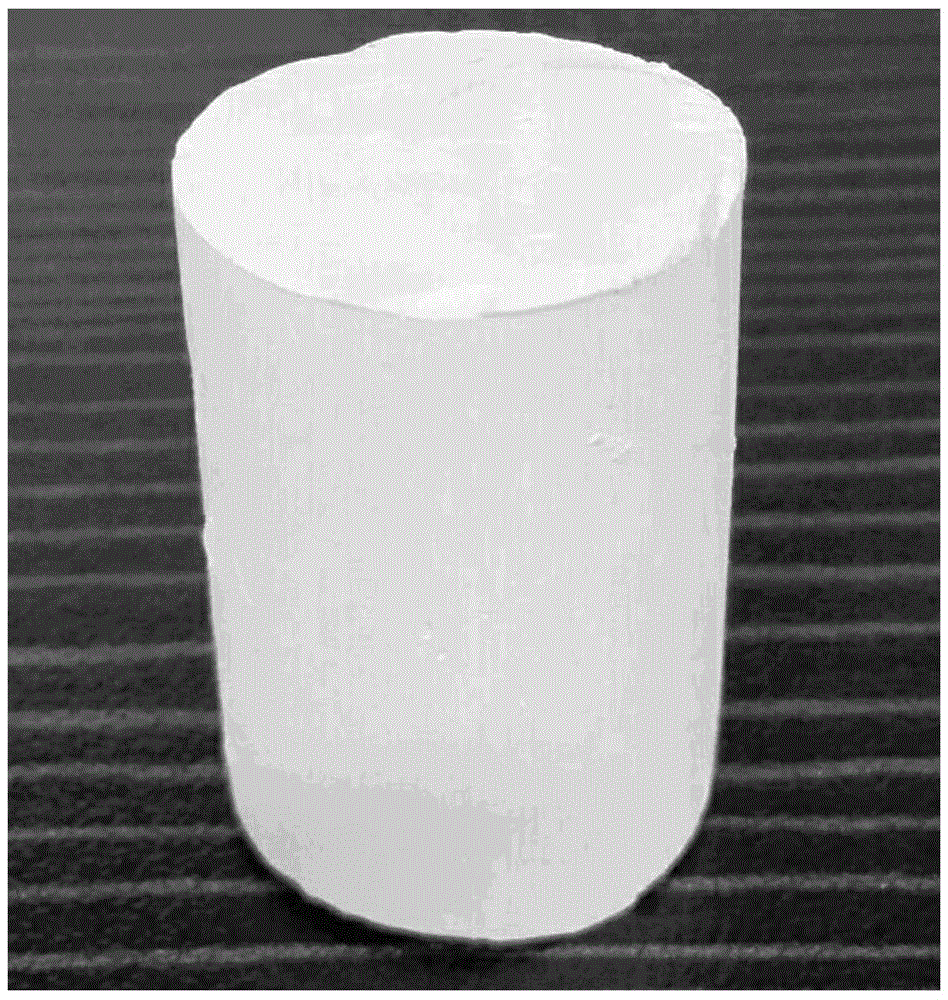

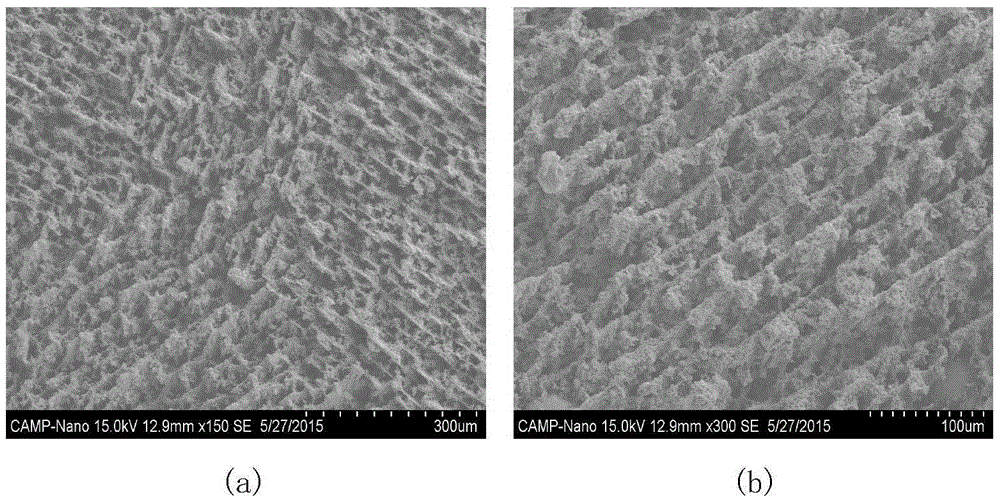

[0027] Embodiment 1: refer to figure 2 , image 3 .

[0028] (1) Preparation of ceramic slurry: Weighing 30g of alumina powder, 0.3g of dispersant, 0.6g of binder PVA, and 70g of deionized water into a stirring container with an average particle size of 200nm respectively, and fully mix Stir for 24h to obtain a stable dispersed slurry;

[0029] (2) Pack the ceramic slurry into a closed container connected to a vacuum pump for degassing, and get rid of the air bubbles generated during the stirring process of the slurry;

[0030] (3) Inject the ceramic slurry into the mold, then place the mold in the directional solidification device, start the power supply, then turn on the low-temperature cycle machine, turn on the water pump cold cycle, set the cooling temperature to -30°C, then start the constant temperature tank, open Water pump heat cycle, set the heating temperature to 80°C, adjust the heat-conducting spiral copper tube and the mold to the set position, start the contro...

Embodiment 2

[0034] Embodiment 2: as Figure 4 shown.

[0035] (1) Preparation of ceramic slurry: Weighing 75g of alumina powder with an average particle diameter of 200nm, 0.75g of dispersant, 1.5g of binder PVA, and 75g of deionized water into a stirring container, fully mixed Stir for 24h to obtain a stable dispersed slurry;

[0036] (2) Pack the ceramic slurry into a closed container connected to a vacuum pump for degassing, and get rid of the air bubbles generated during the stirring process of the slurry;

[0037] (3) Inject the ceramic slurry into the mold, then place the mold in the directional solidification device, start the power supply, then turn on the low temperature cycle machine, turn on the water pump cold cycle, set the cooling temperature to -30°C, and then start the constant temperature bath , turn on the heat cycle of the water pump, set the heating temperature to 80°C, adjust the heat-conducting spiral copper tube and the mold to the set position, and finally start ...

Embodiment 3

[0041] Embodiment 3: as Figure 5 shown.

[0042] (1) Preparation of ceramic slurry: Weigh 70g of alumina powder with a particle size of 200nm, 0.7g of dispersant, 1.4g of binder PVA, and 30g of deionized water into a stirring container, fully mix and stir 24h, obtain the slurry of stable dispersion;

[0043] (2) Pack the ceramic slurry into a closed container connected to a vacuum pump for degassing, and get rid of the air bubbles generated during the stirring process of the slurry;

[0044] (3) Inject the ceramic slurry into the mold, then place the mold in the directional solidification device, start the power supply, then turn on the low-temperature cycle machine, turn on the water pump cold cycle, set the cooling temperature to -30°C, then start the constant temperature tank, open Water pump heat cycle, set the heating temperature to 80°C, adjust the heat-conducting spiral copper tube and the mold to the set position, and finally start the control motor to adjust the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com