Patents

Literature

93 results about "Withdrawal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Withdrawal rate is calculated by taking the amount of funds withdrawn per year and dividing it by the size of the entire portfolio, and is typically expressed as a percentage. SWR and withdrawal rate are not the same thing.

Method and apparatus for providing retirement income benefits

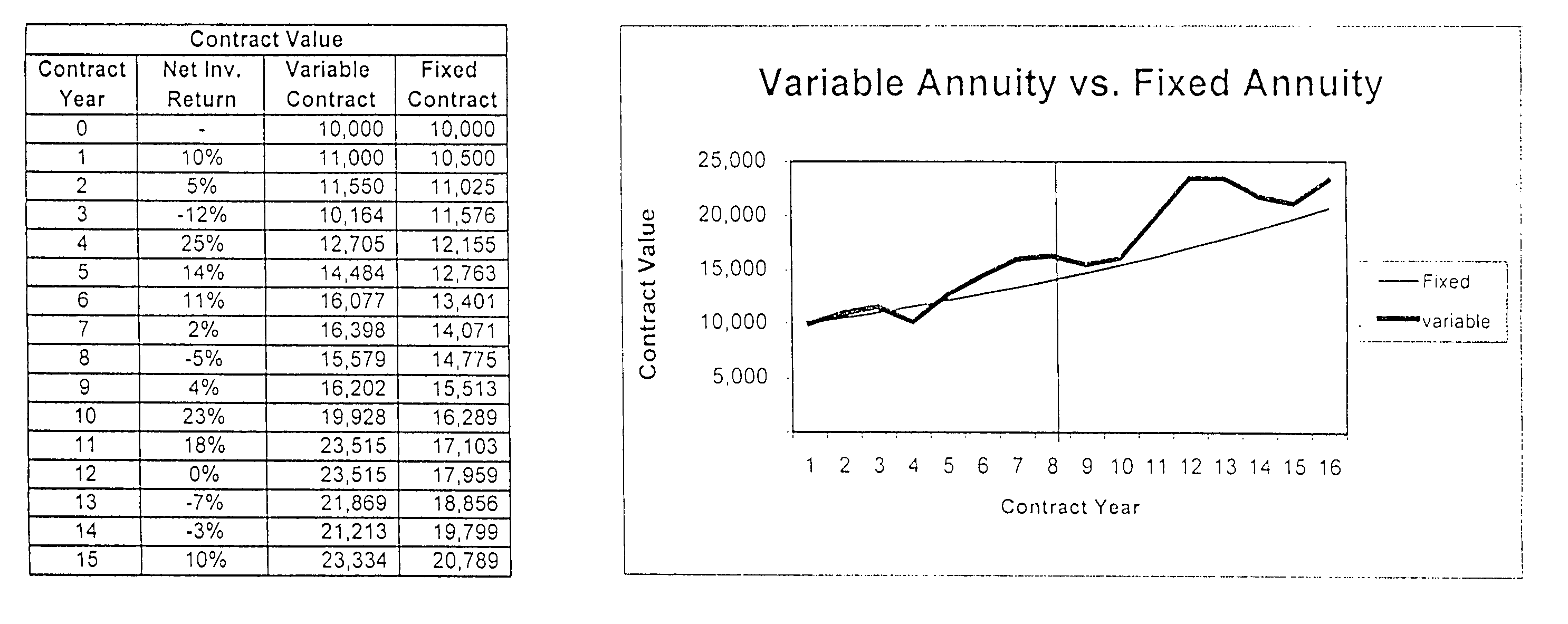

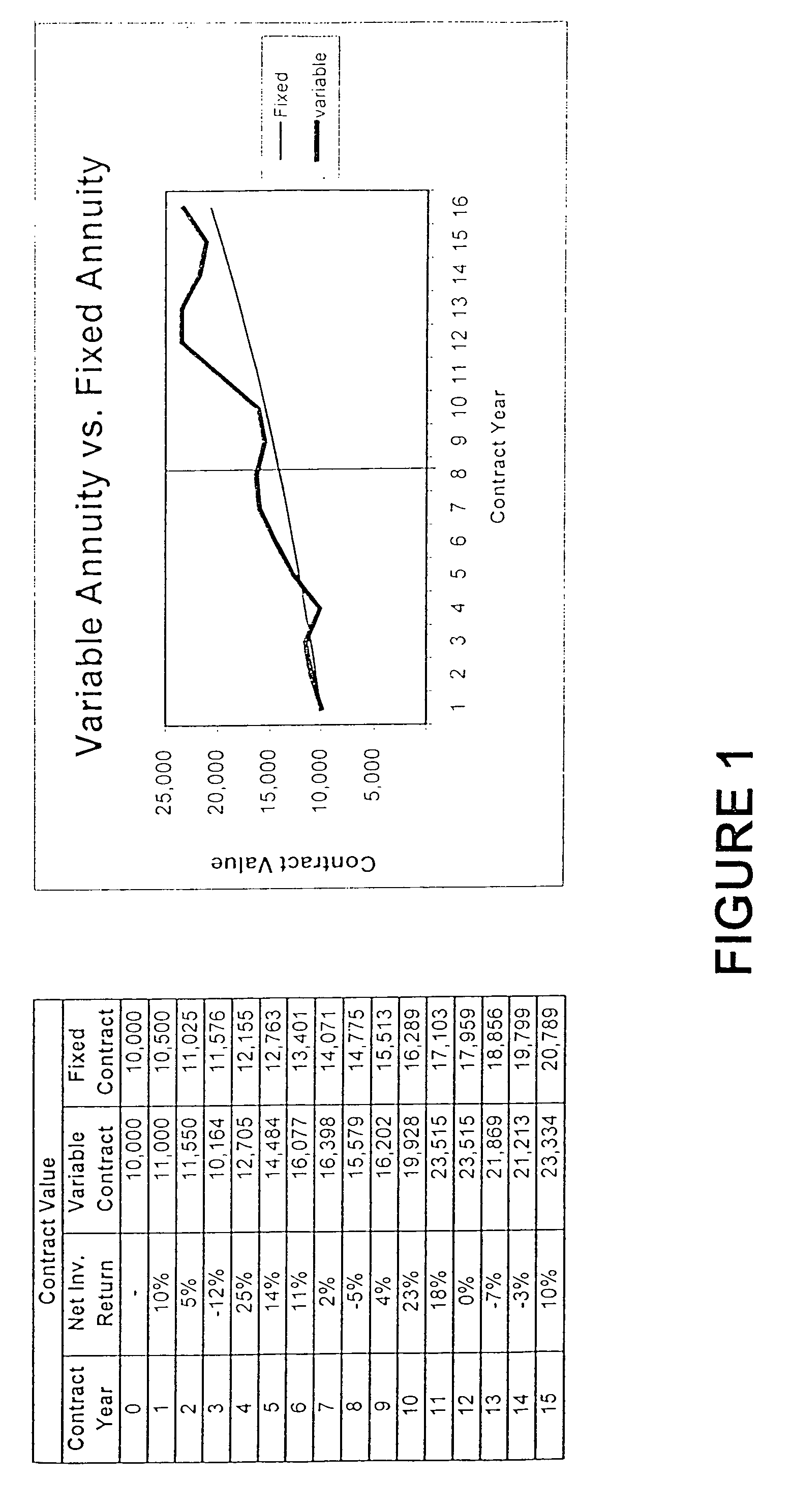

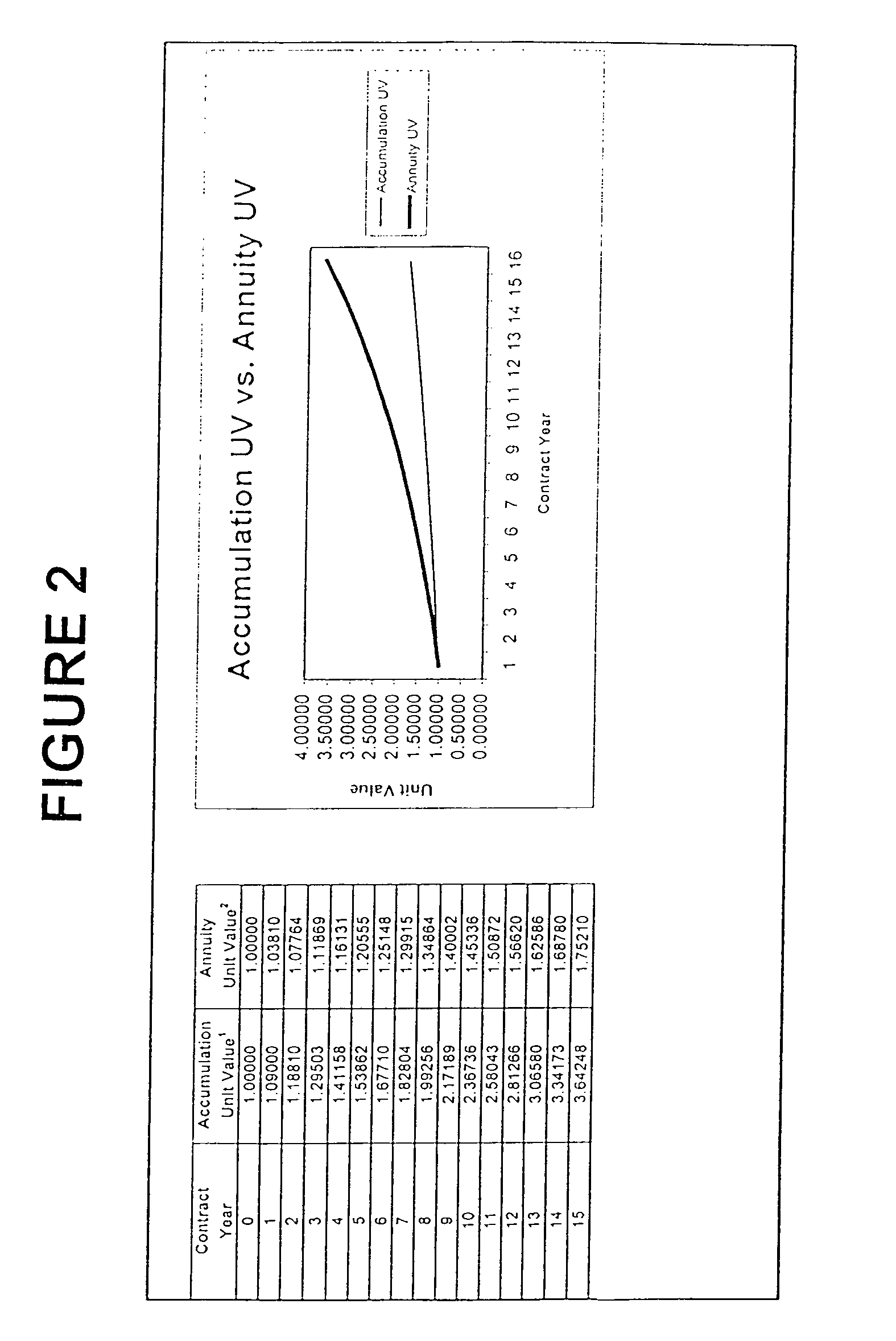

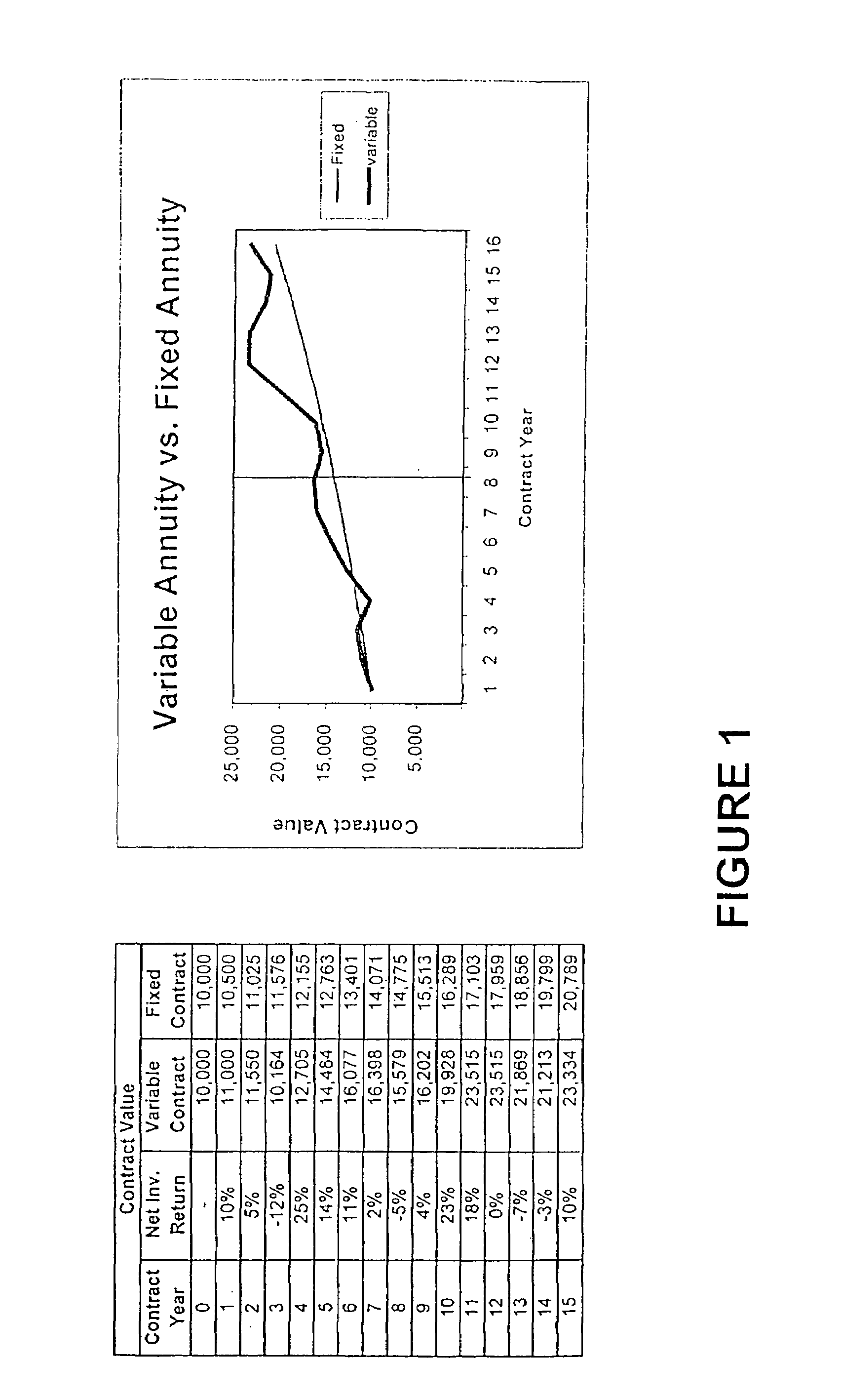

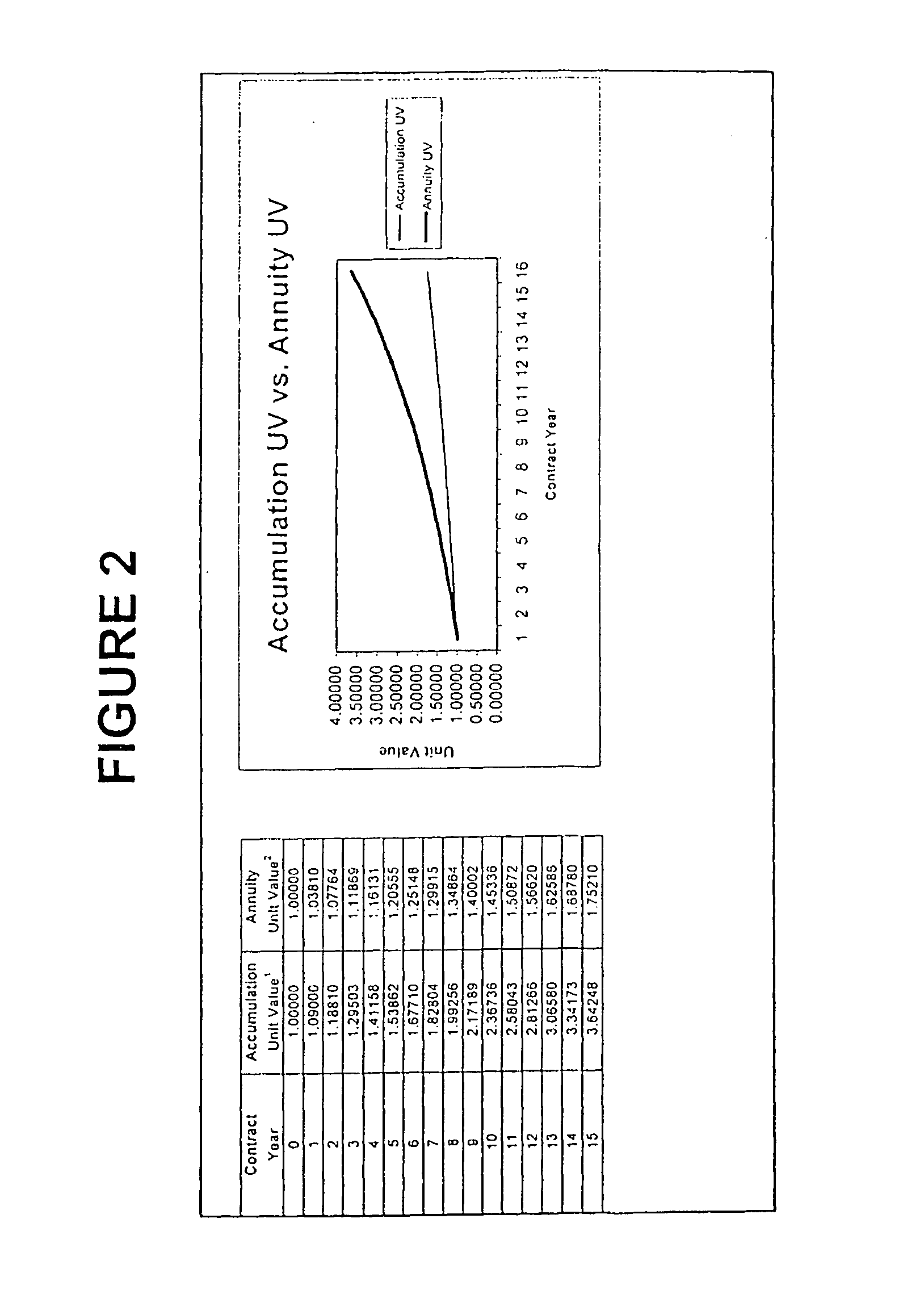

Computerized methods for administering variable annuity plans are disclosed. In certain embodiments, minimum payment features and mechanisms for adjusting current payments in response to cumulative payment totals are provided. Other embodiments provide withdrawal features under which certain guarantees are provided if withdrawals do not exceed predetermined withdrawal rates.

Owner:LINCOLN NAT LIFE INSURANCE

Method and system for providing retirement income benefits

A computerized method of administering an annuity product having a withdrawal feature and a guarantee comprises the steps of establishing an annuity account from which withdrawals can be made, inputting data relating to the annuity account, paying withdrawals to the account owner, and providing a guarantee. Inputted data relating to the account includes a maximum withdrawal rate for a given withdrawal frequency. The guarantee provides that, even if the account value is exhausted before the end of a specified time period, amounts up to the maximum withdrawal will continue to be paid for the specified period, provided that withdrawals before the account value is exhausted do not exceed the maximum rate. The specified time period may be a lifetime period, a period of years or months chosen by the account owner when the account is established, or a period during which withdrawals at least equal a specified percentage of the account value, or a highest account value achieved, as of a specified date. The method may further include the step of establishing a charge to pay for the guarantee.

Owner:LINCOLN NAT LIFE INSURANCE

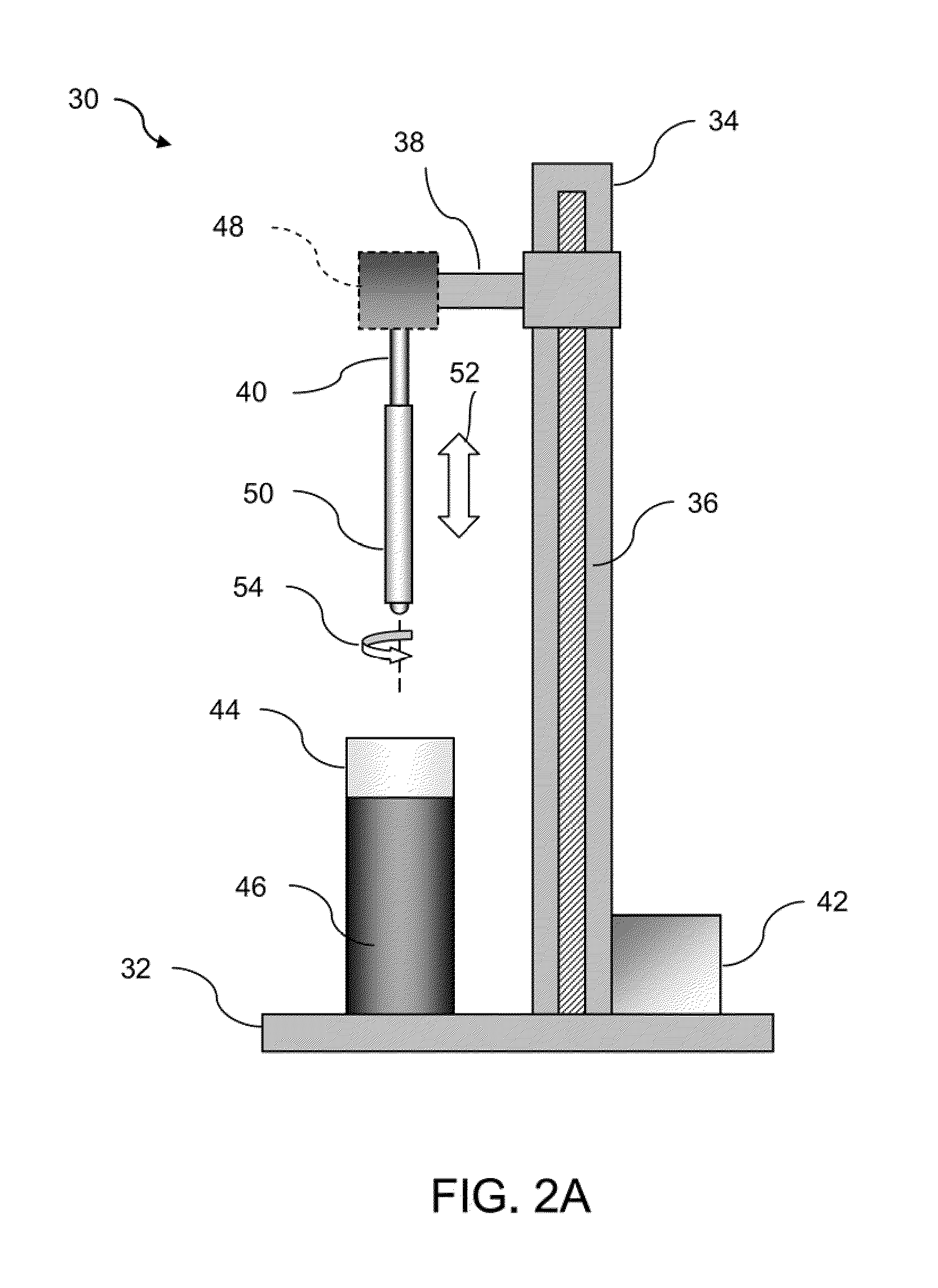

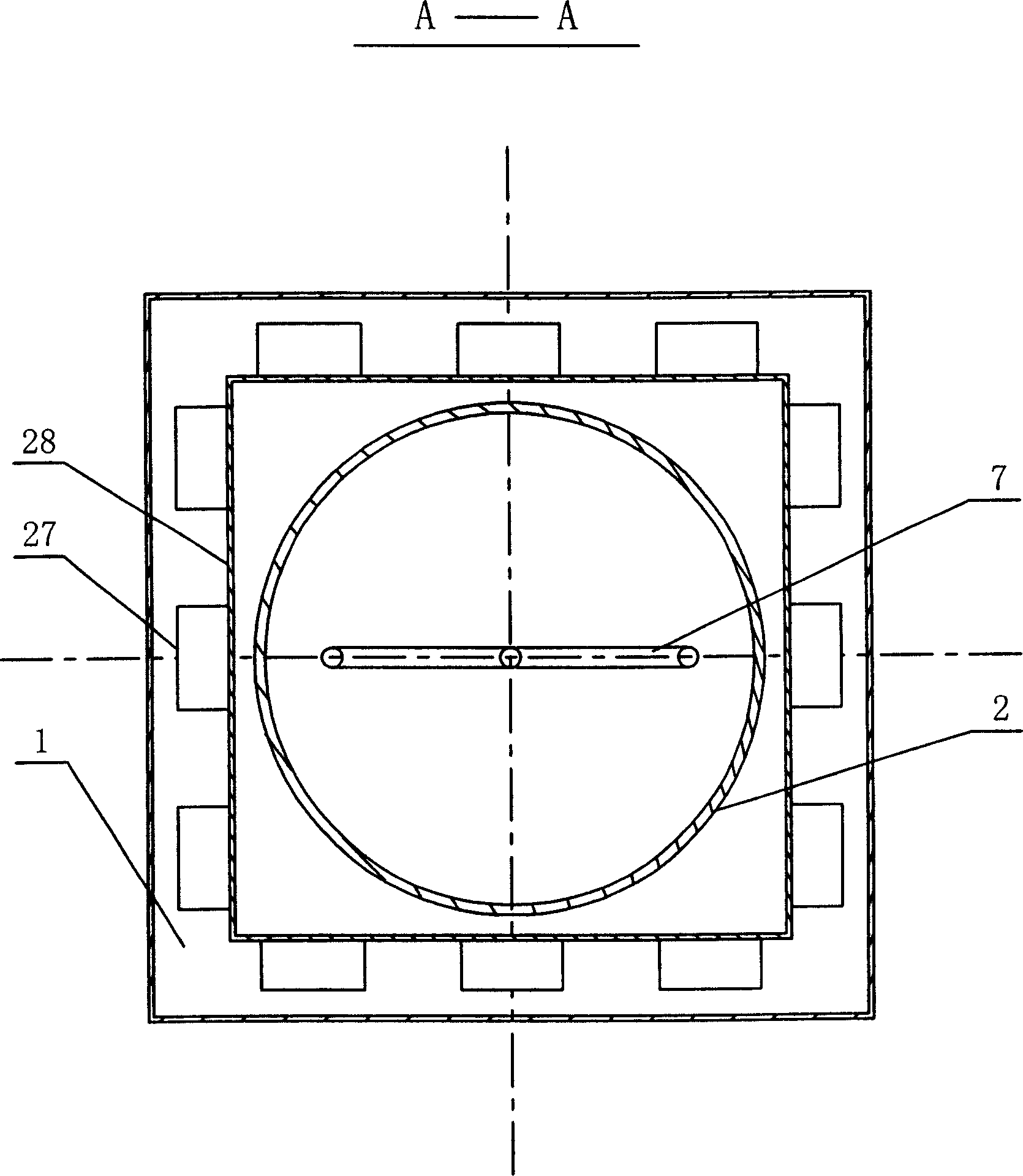

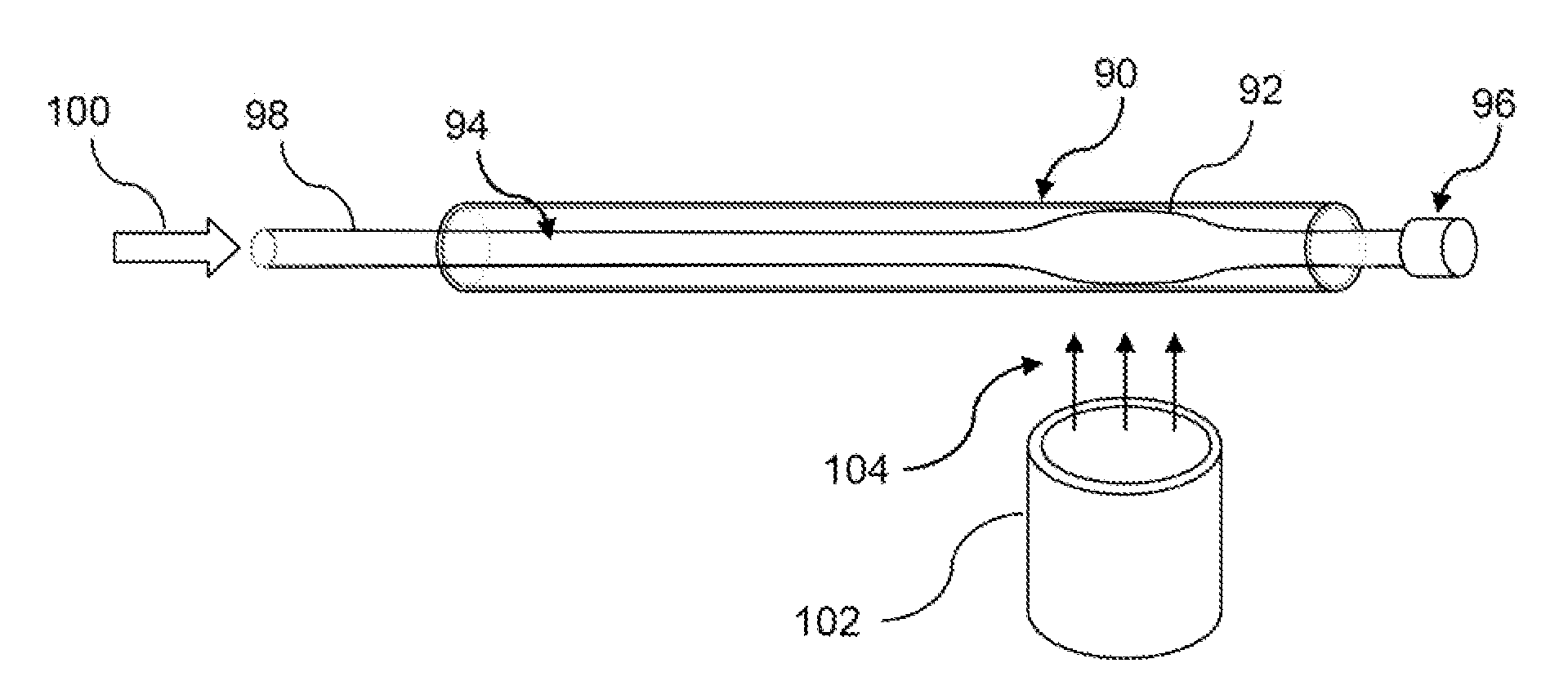

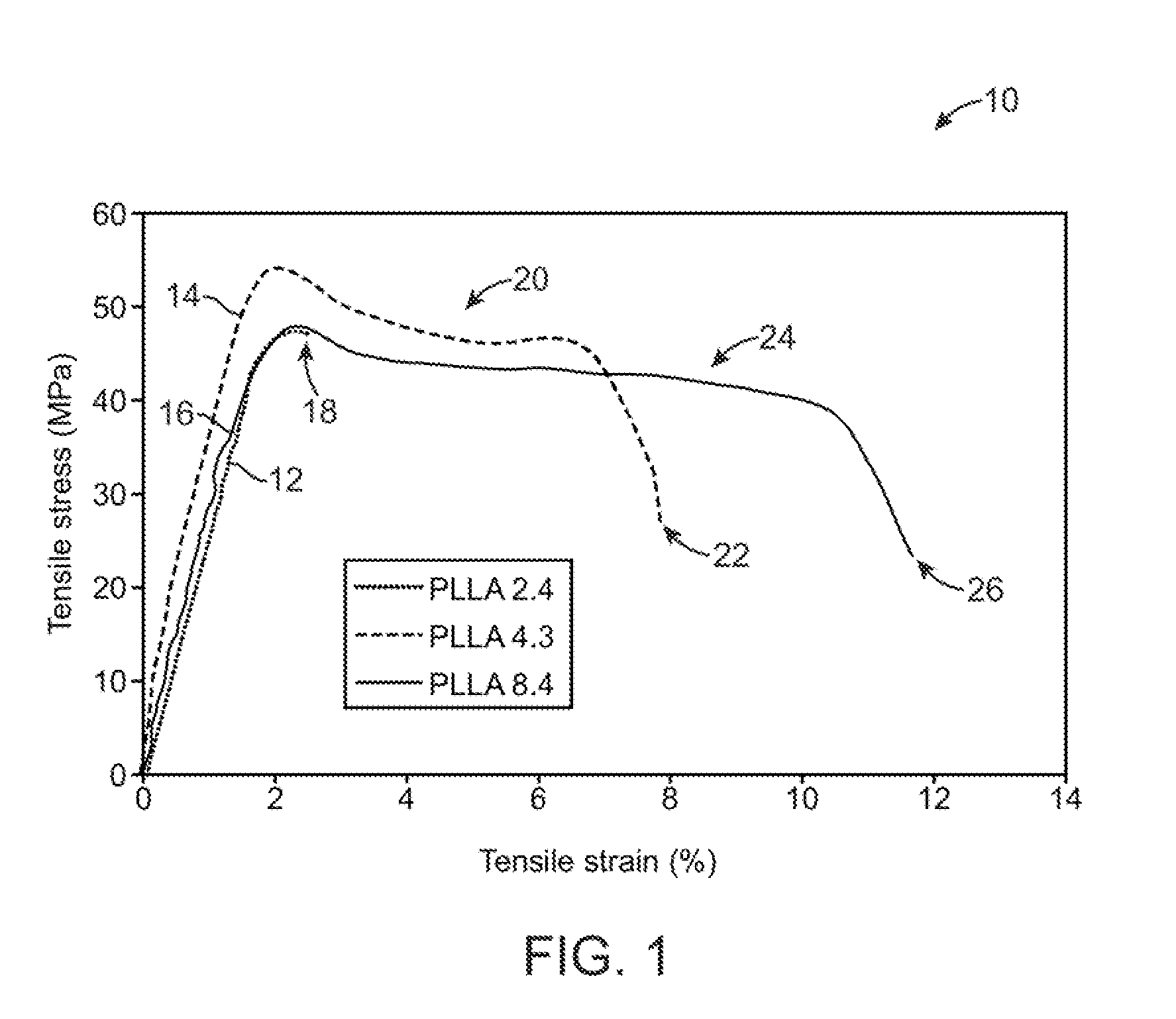

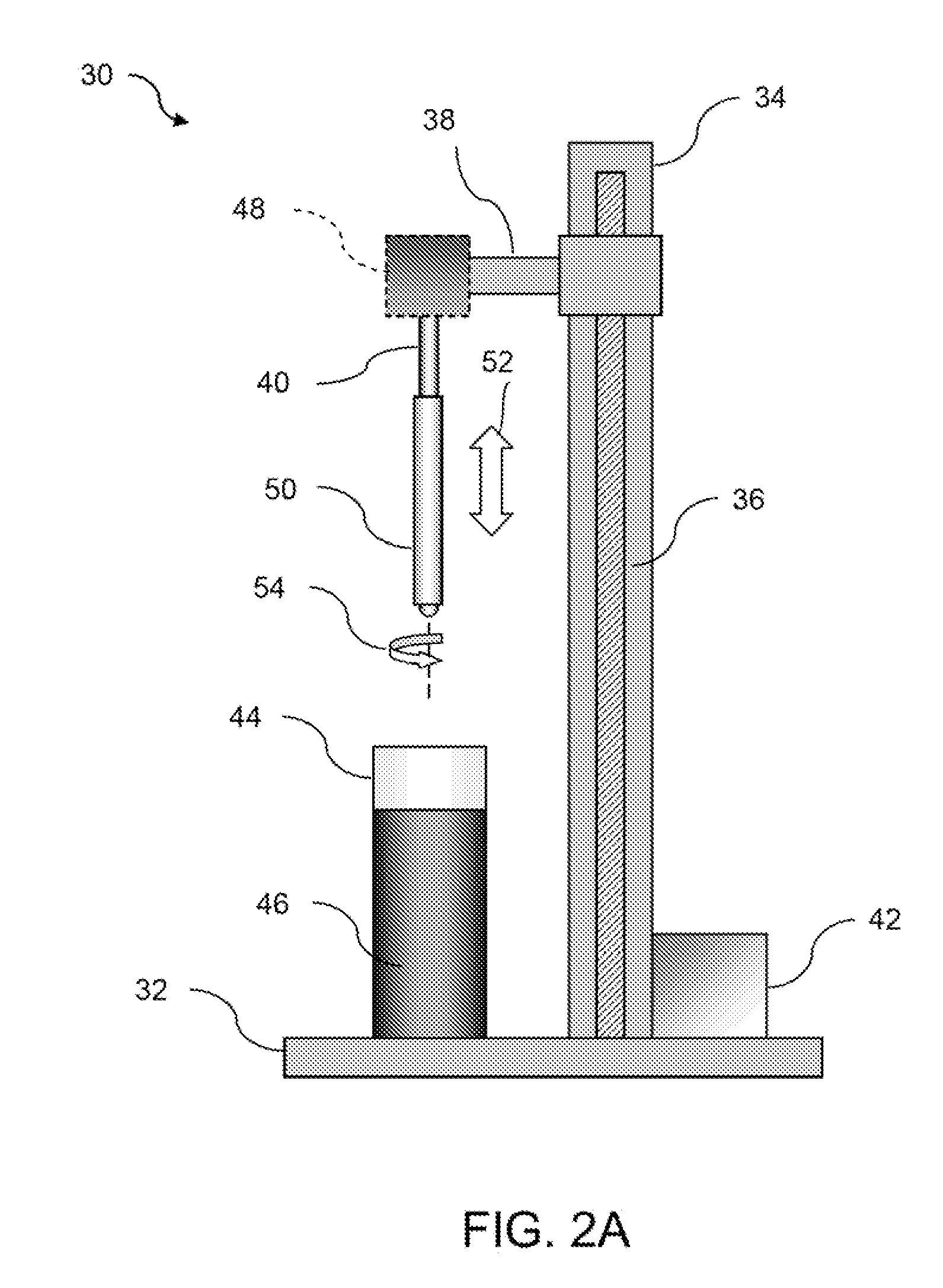

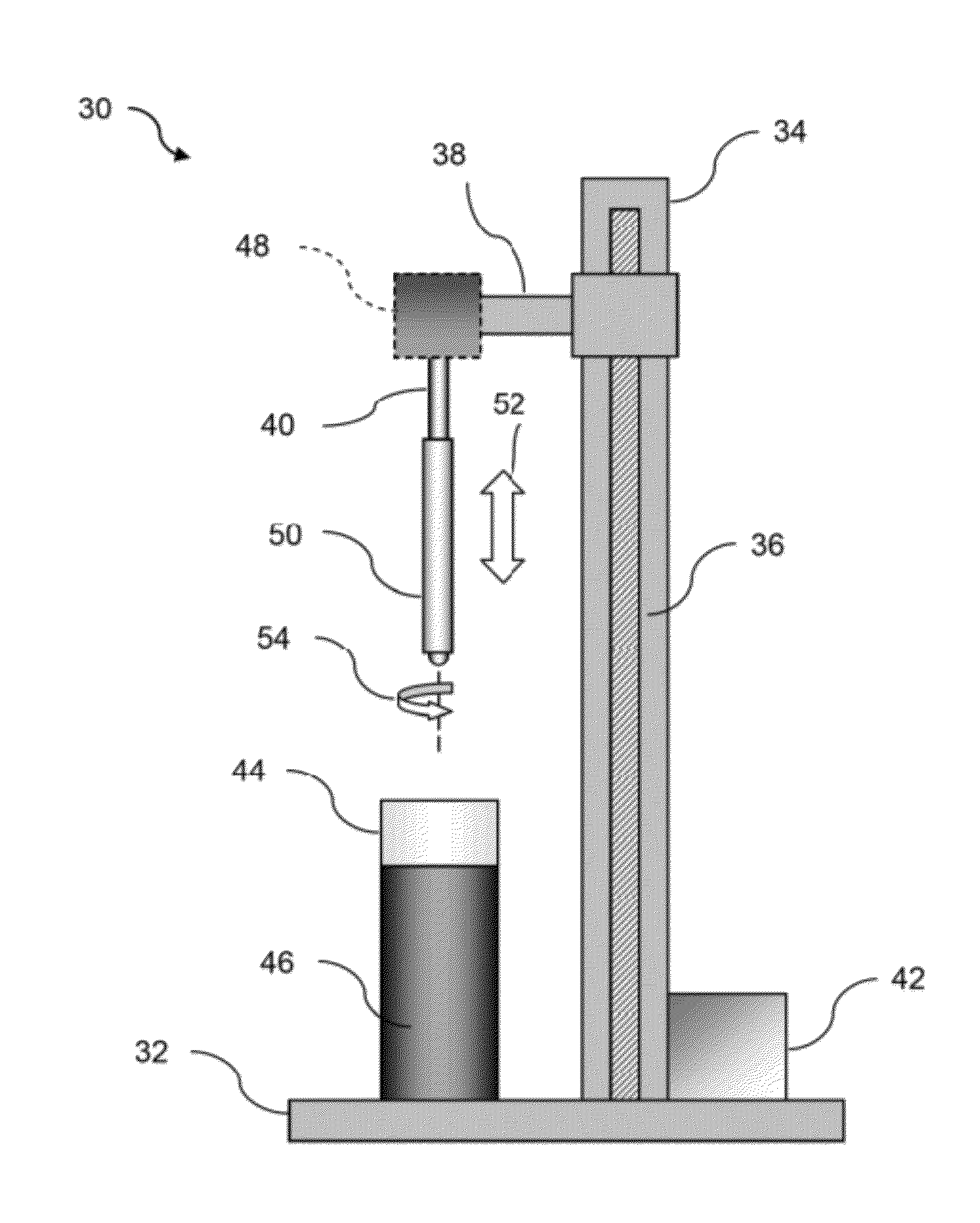

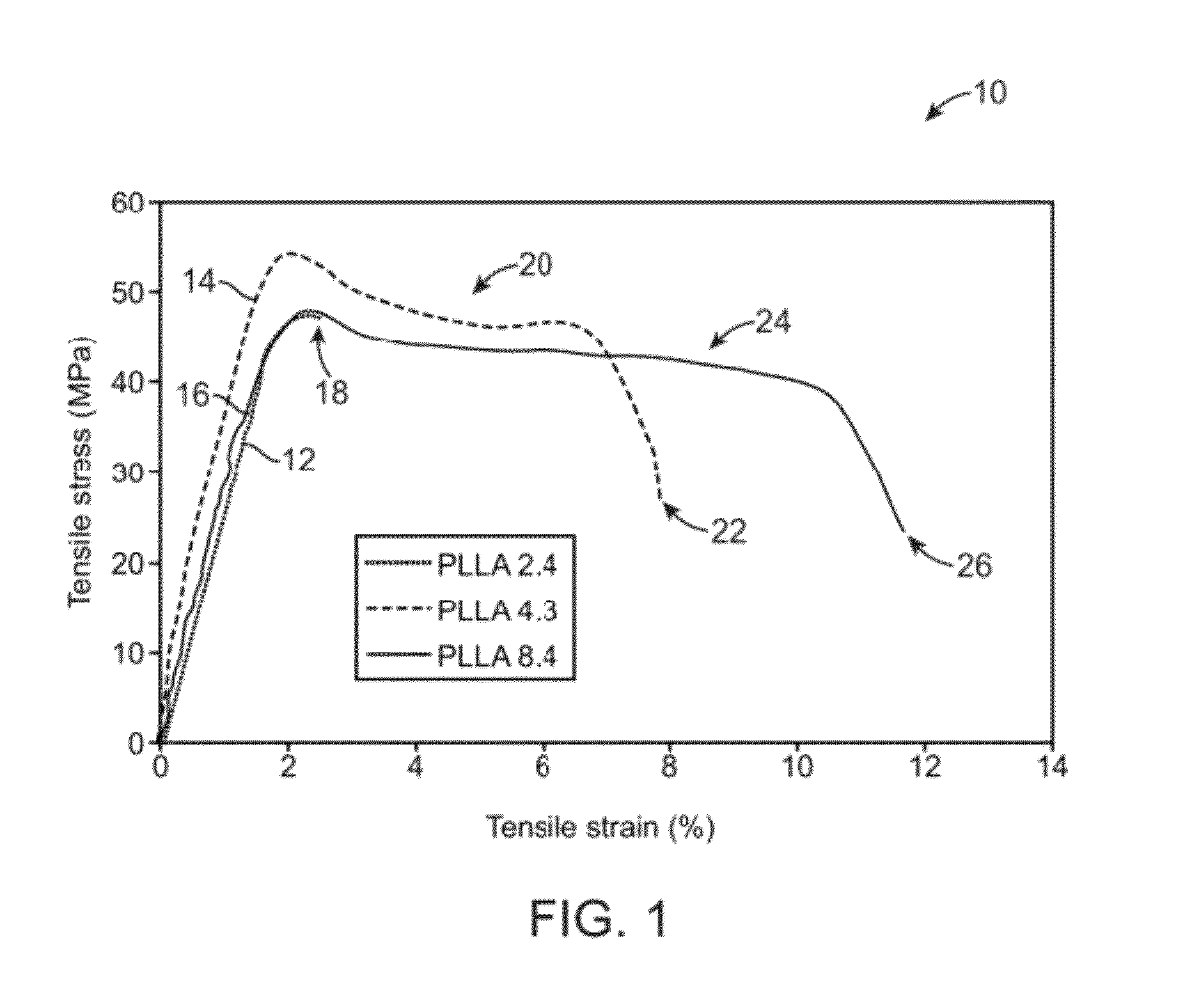

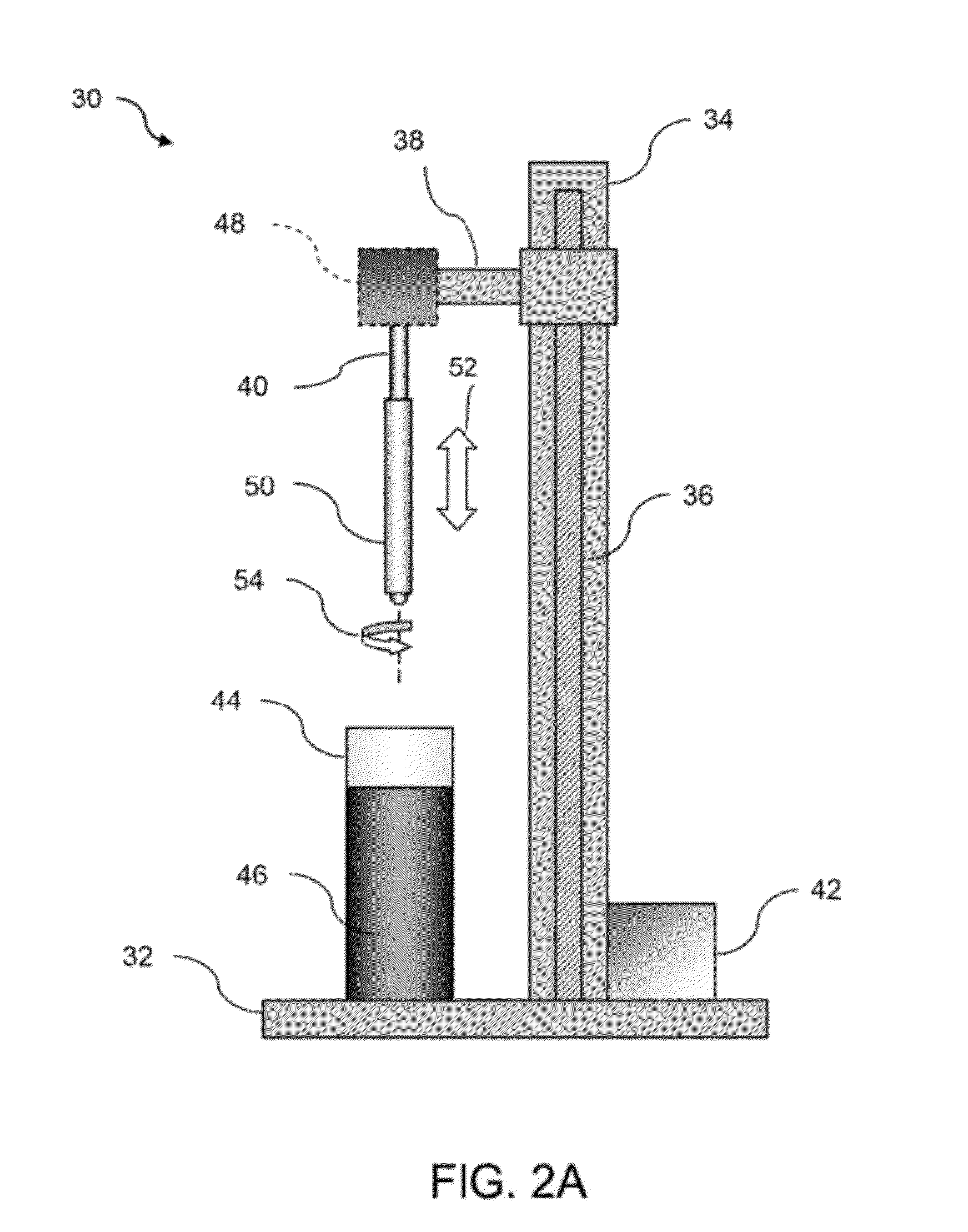

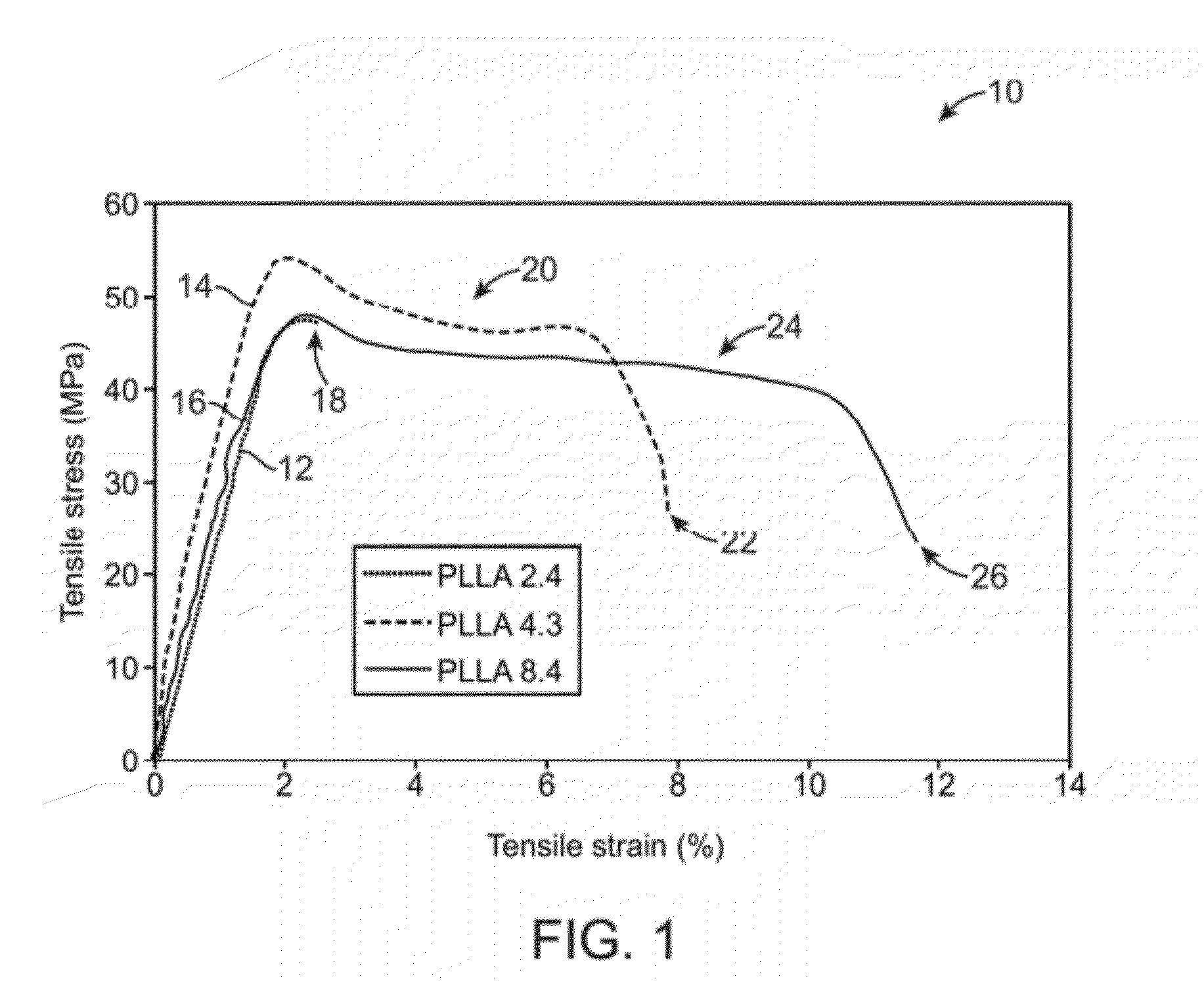

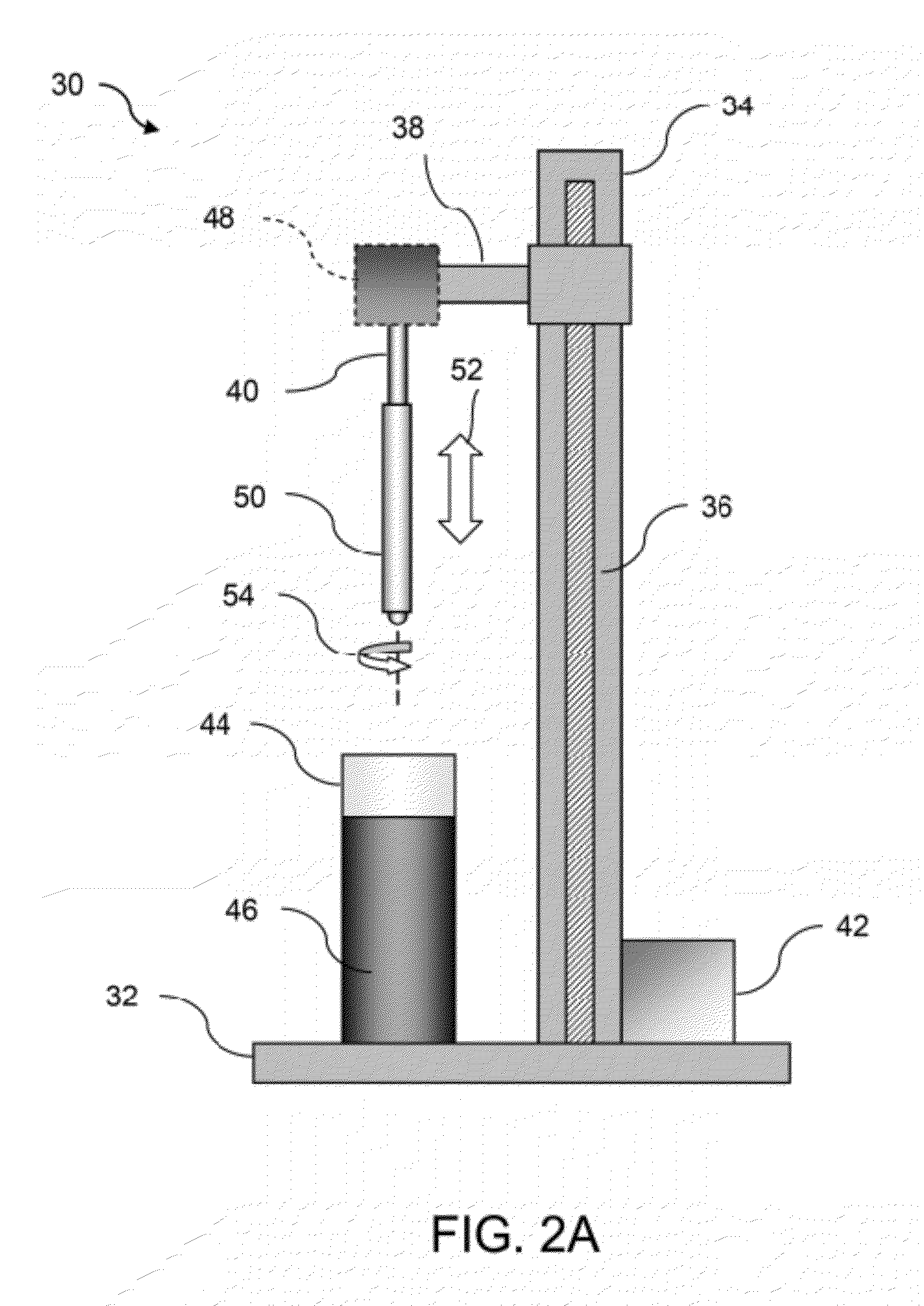

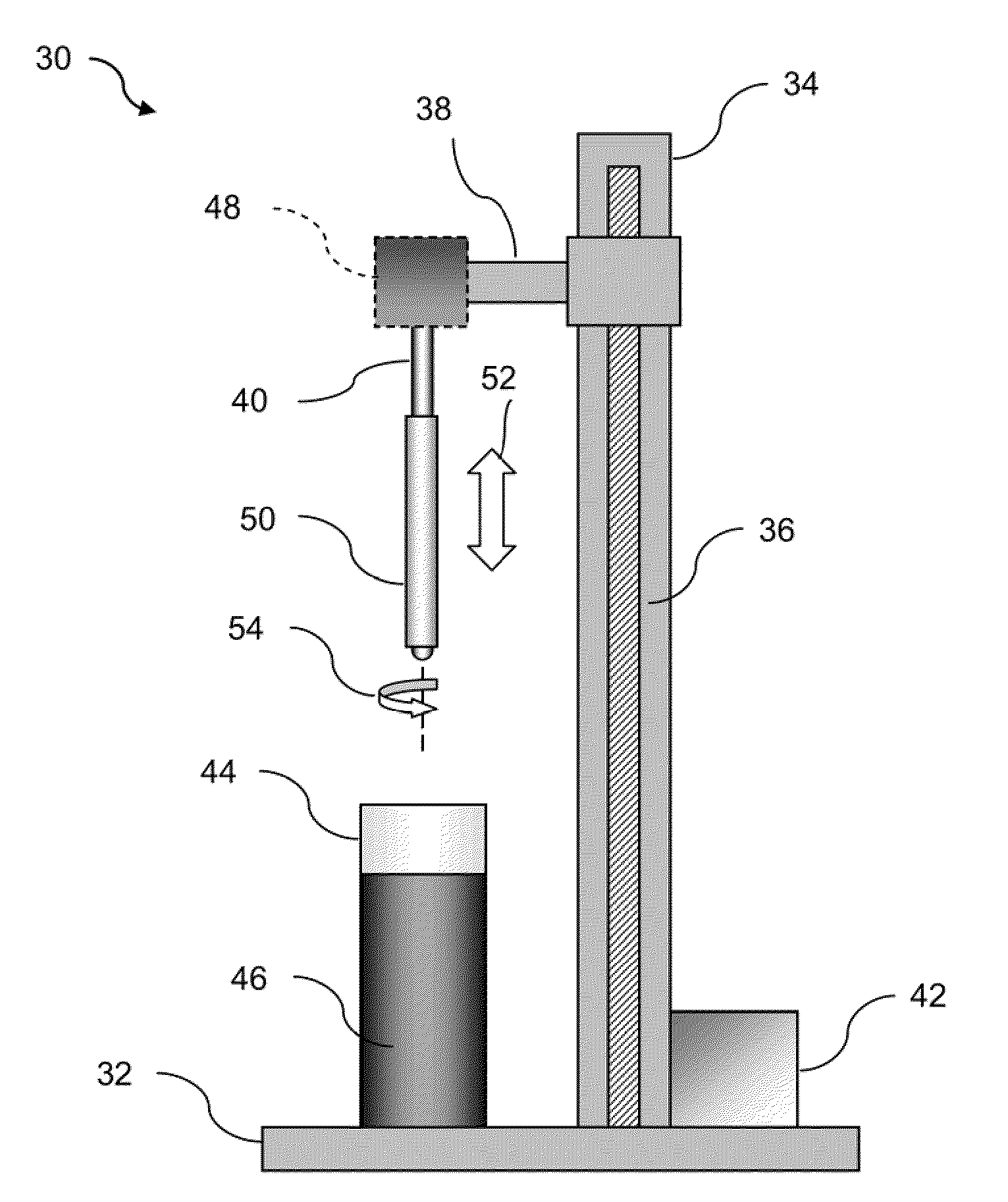

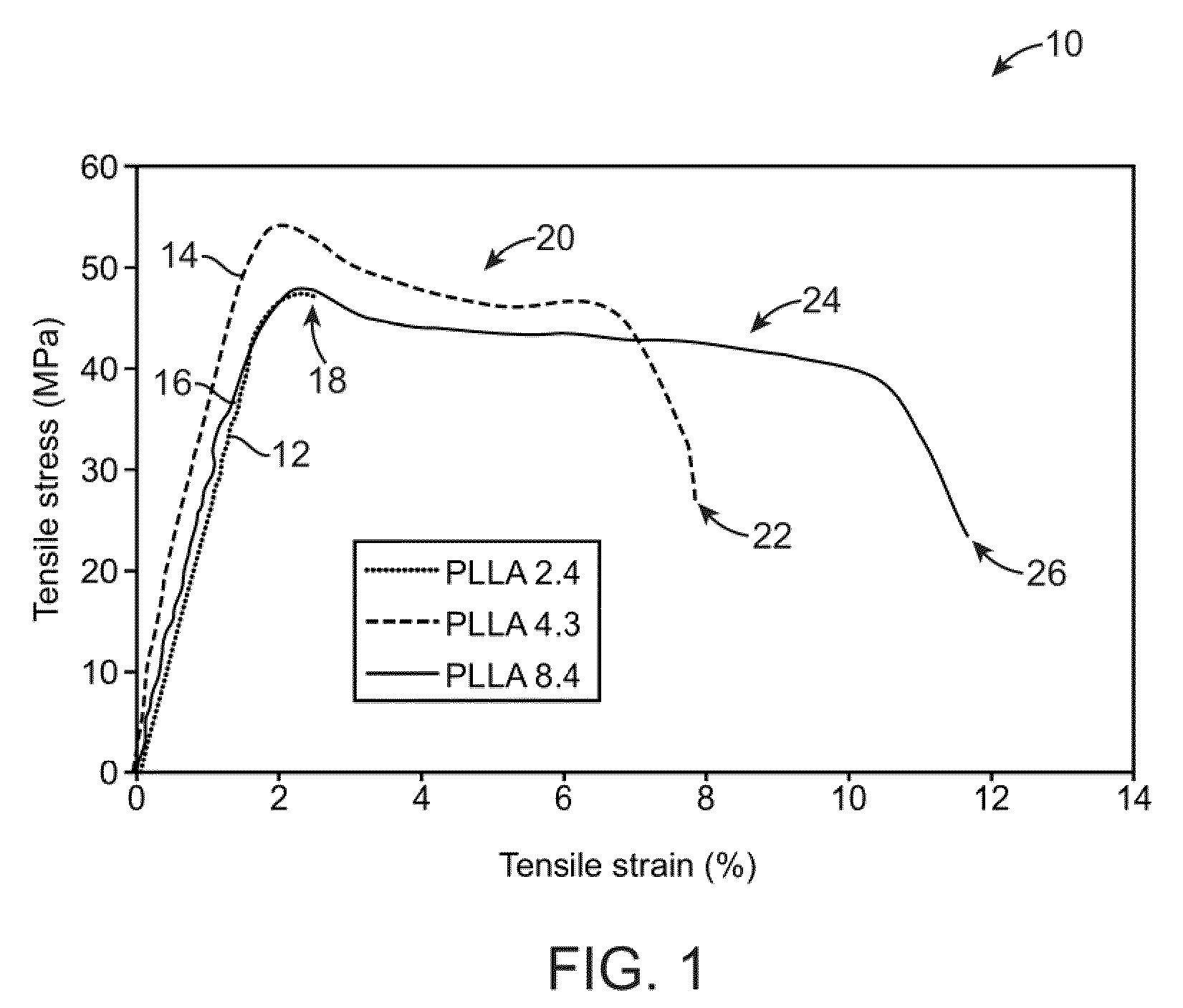

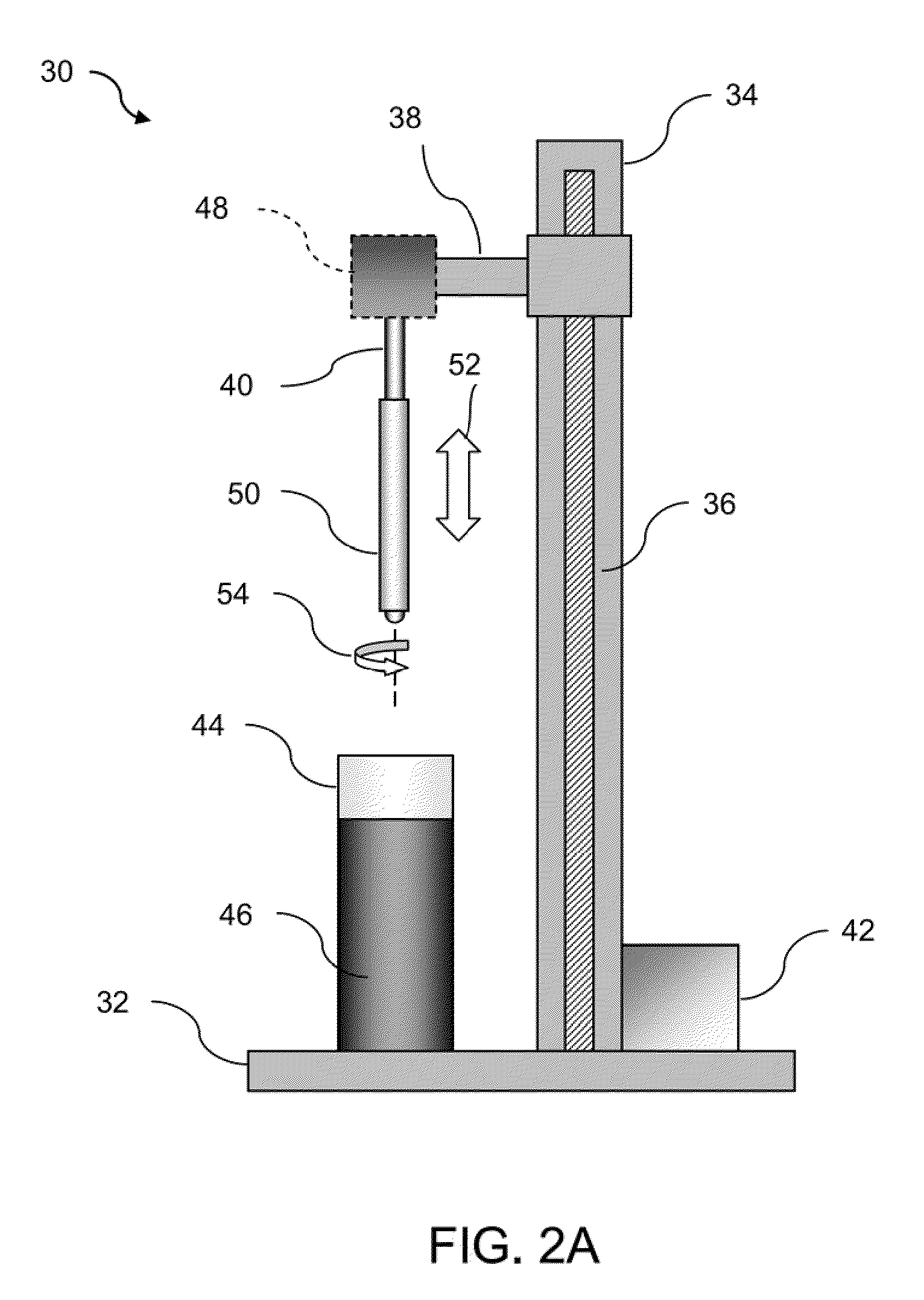

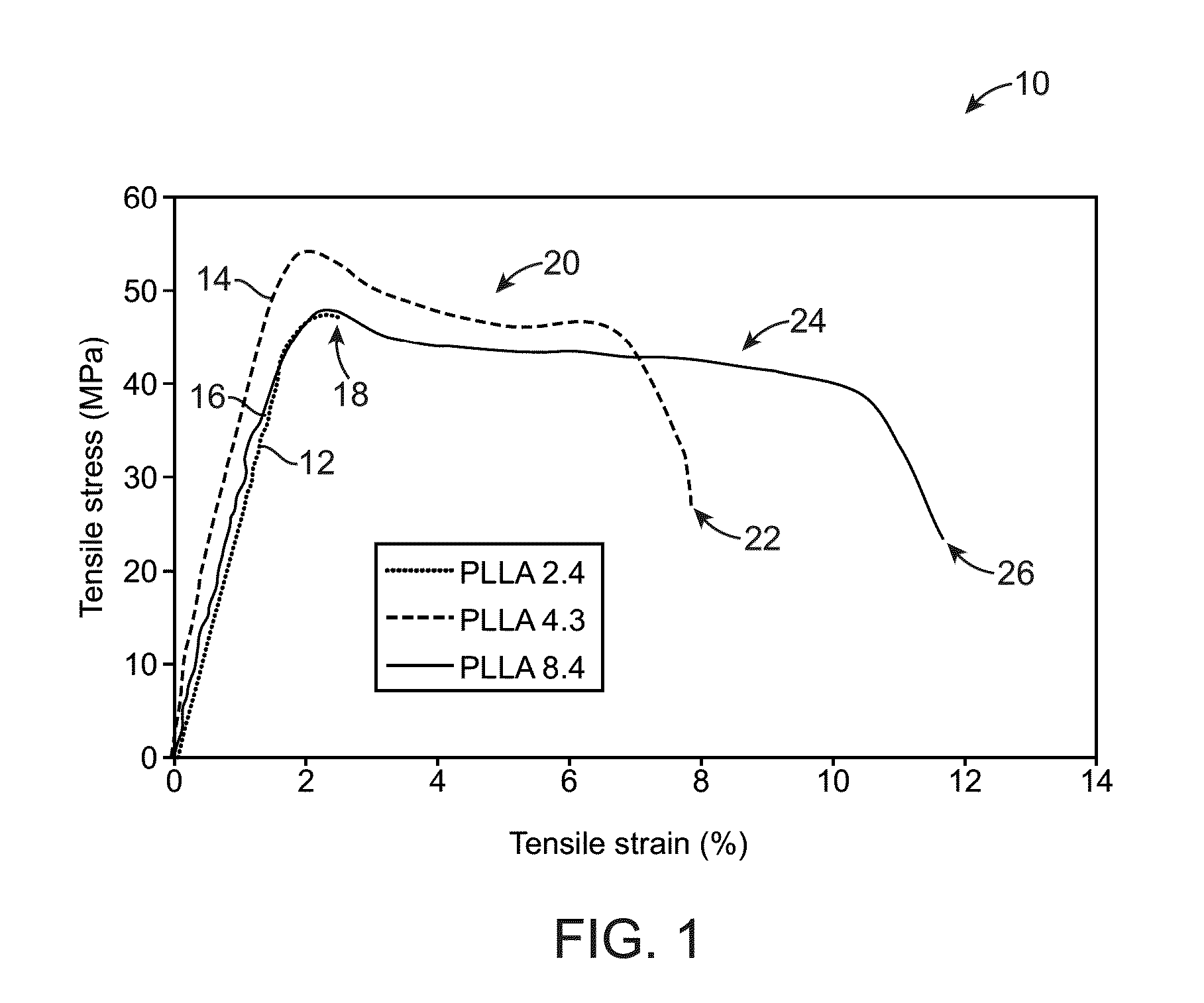

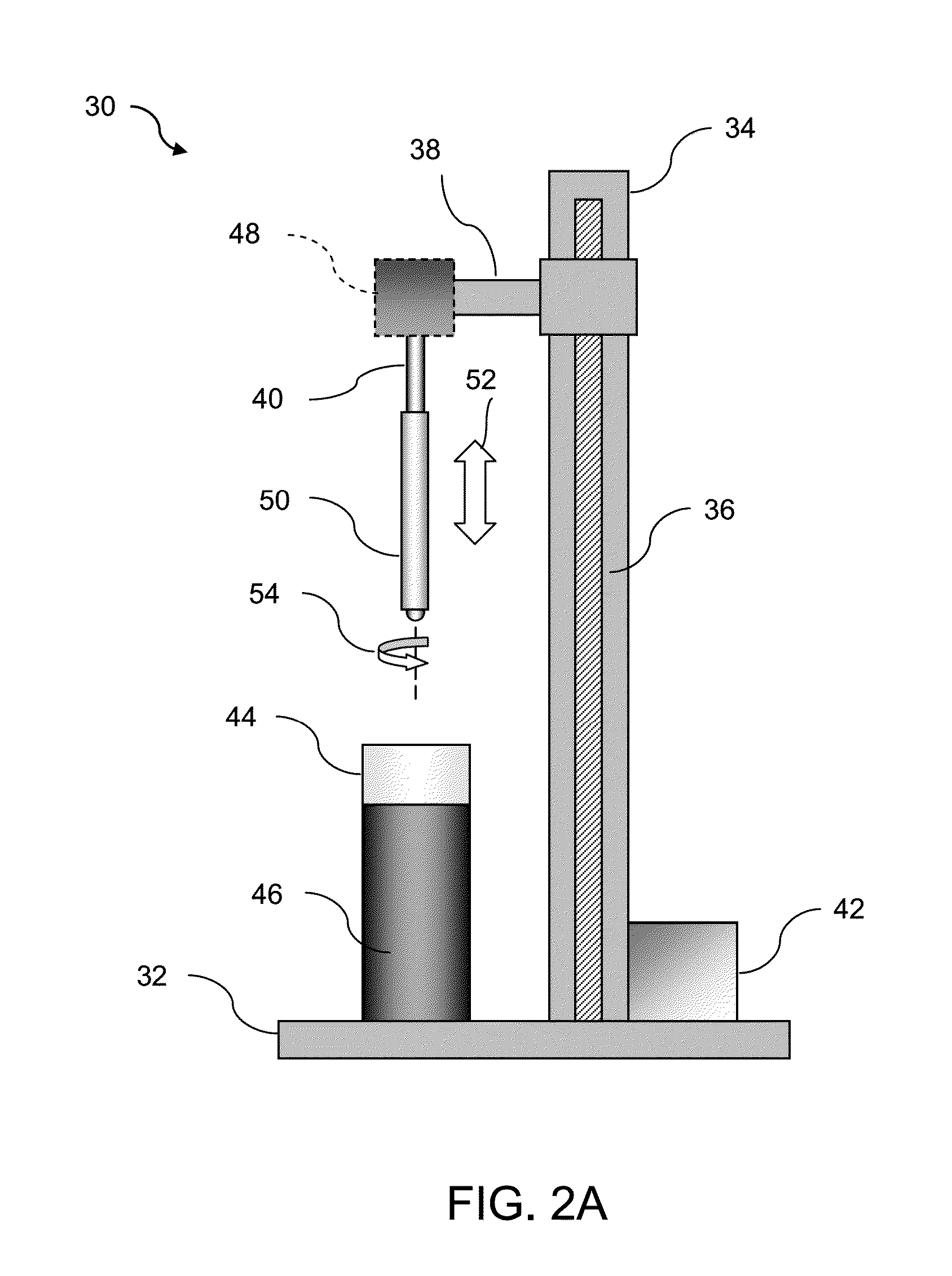

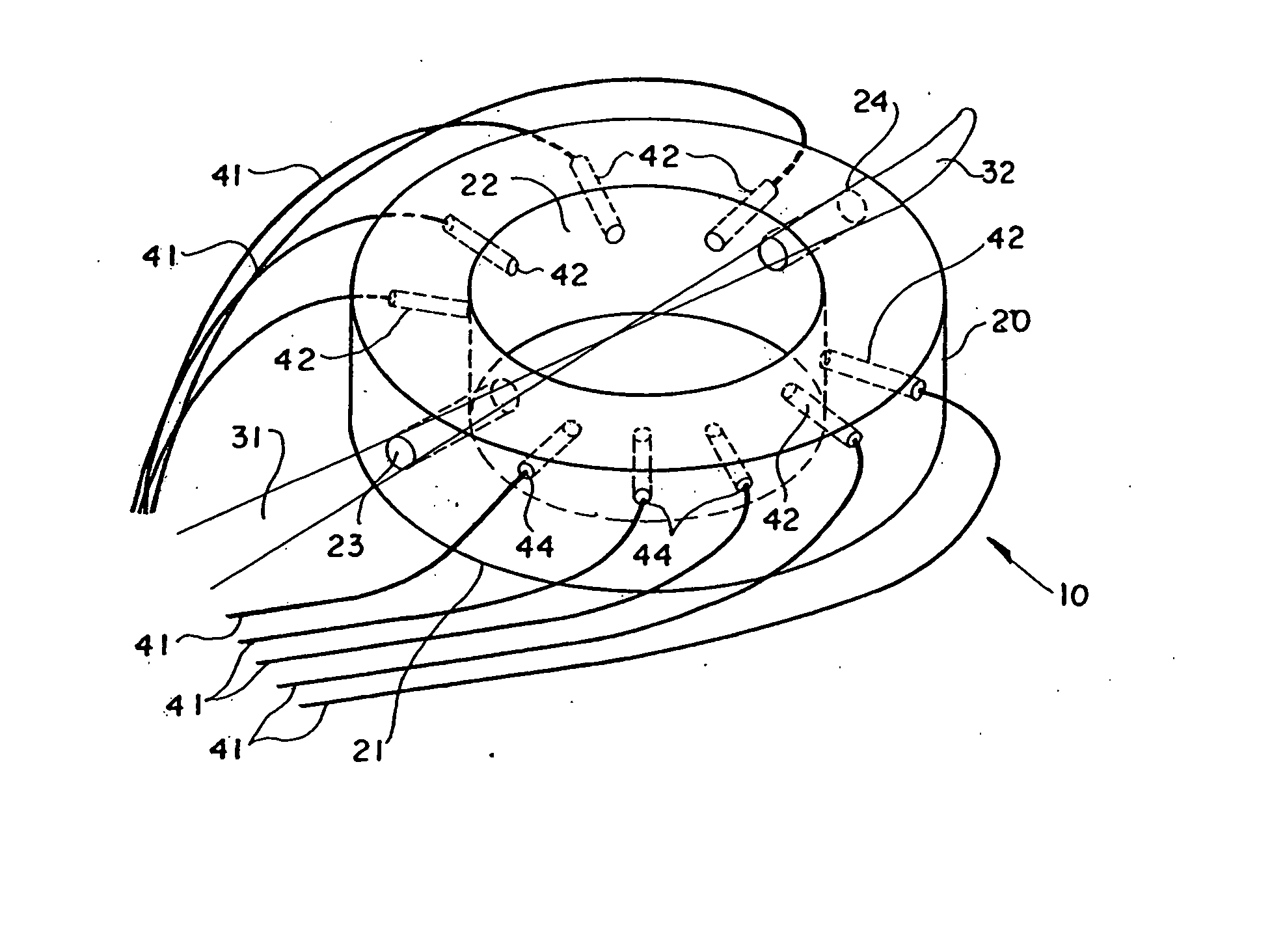

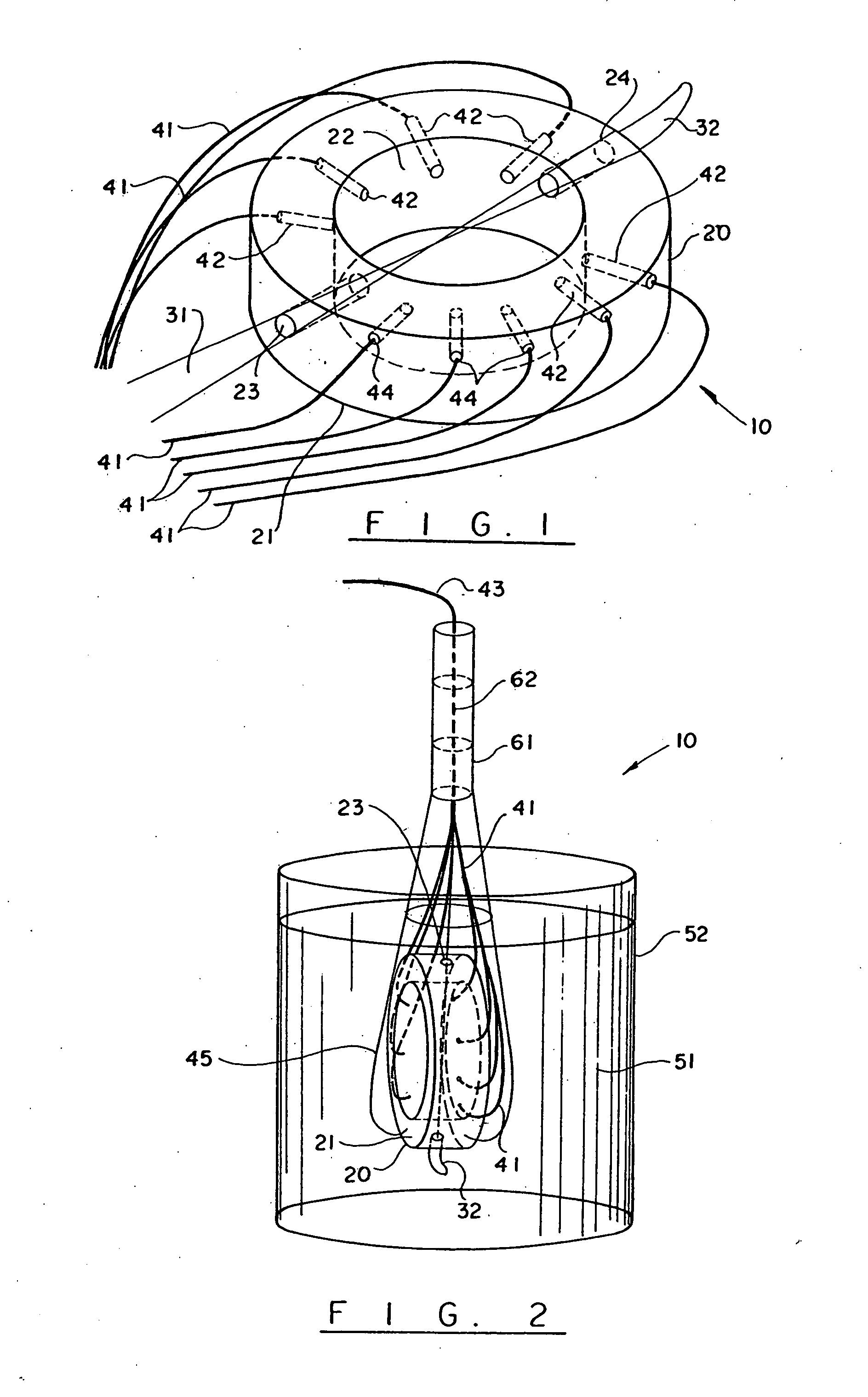

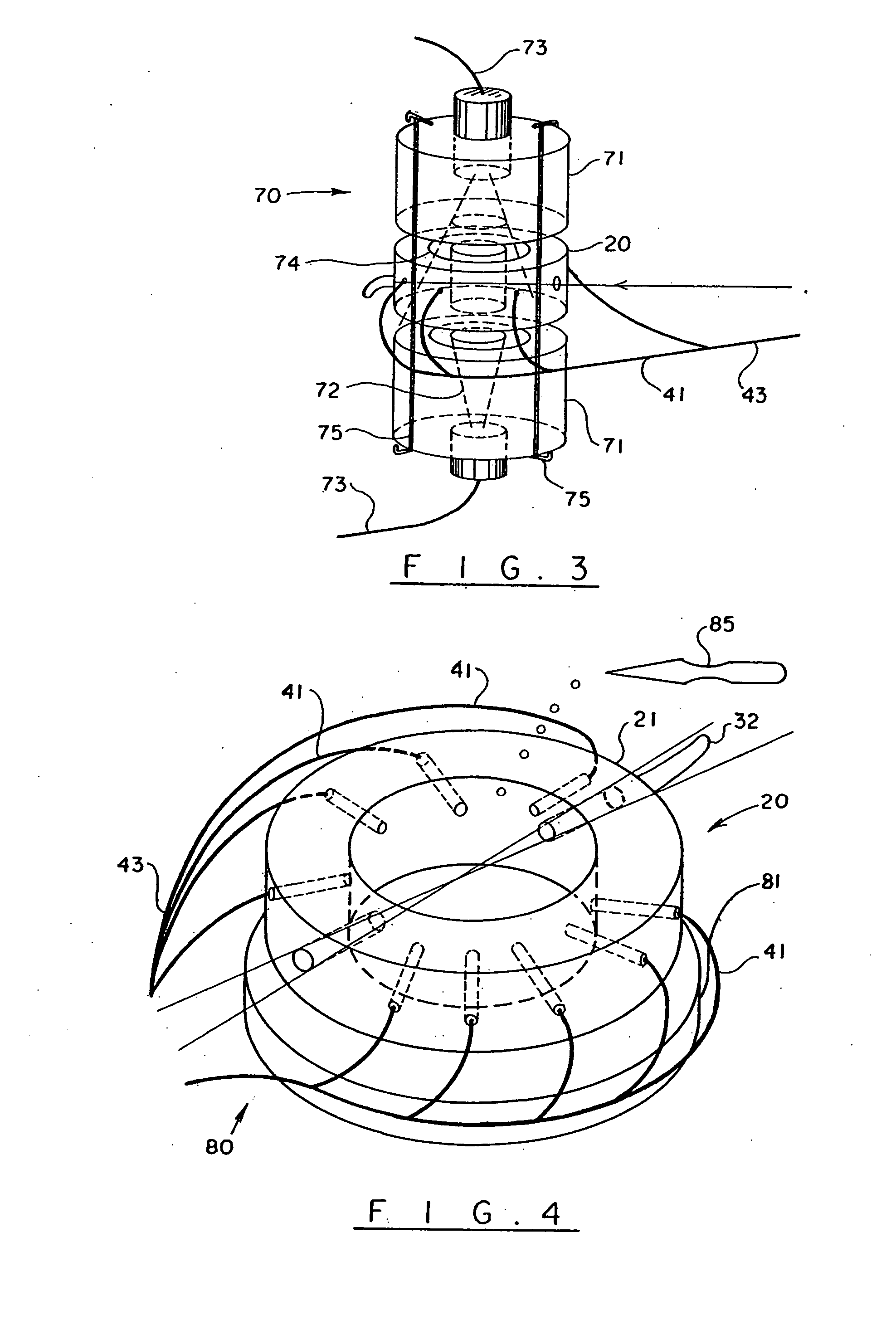

Stent fabrication via tubular casting processes

ActiveUS20100004734A1Improve mechanical propertiesReduced flexibilityOrganic active ingredientsStentsDip-coatingPolymer solution

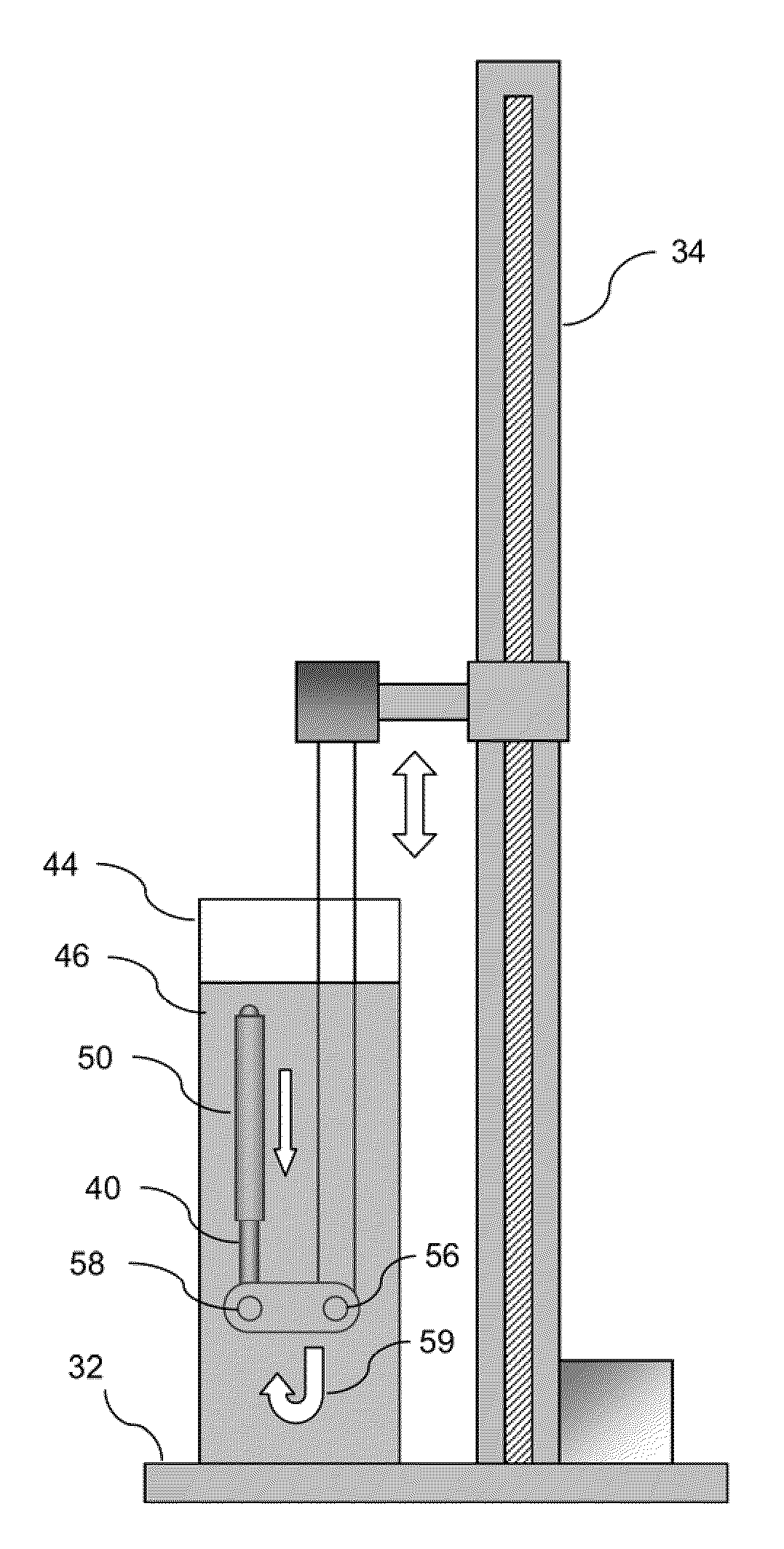

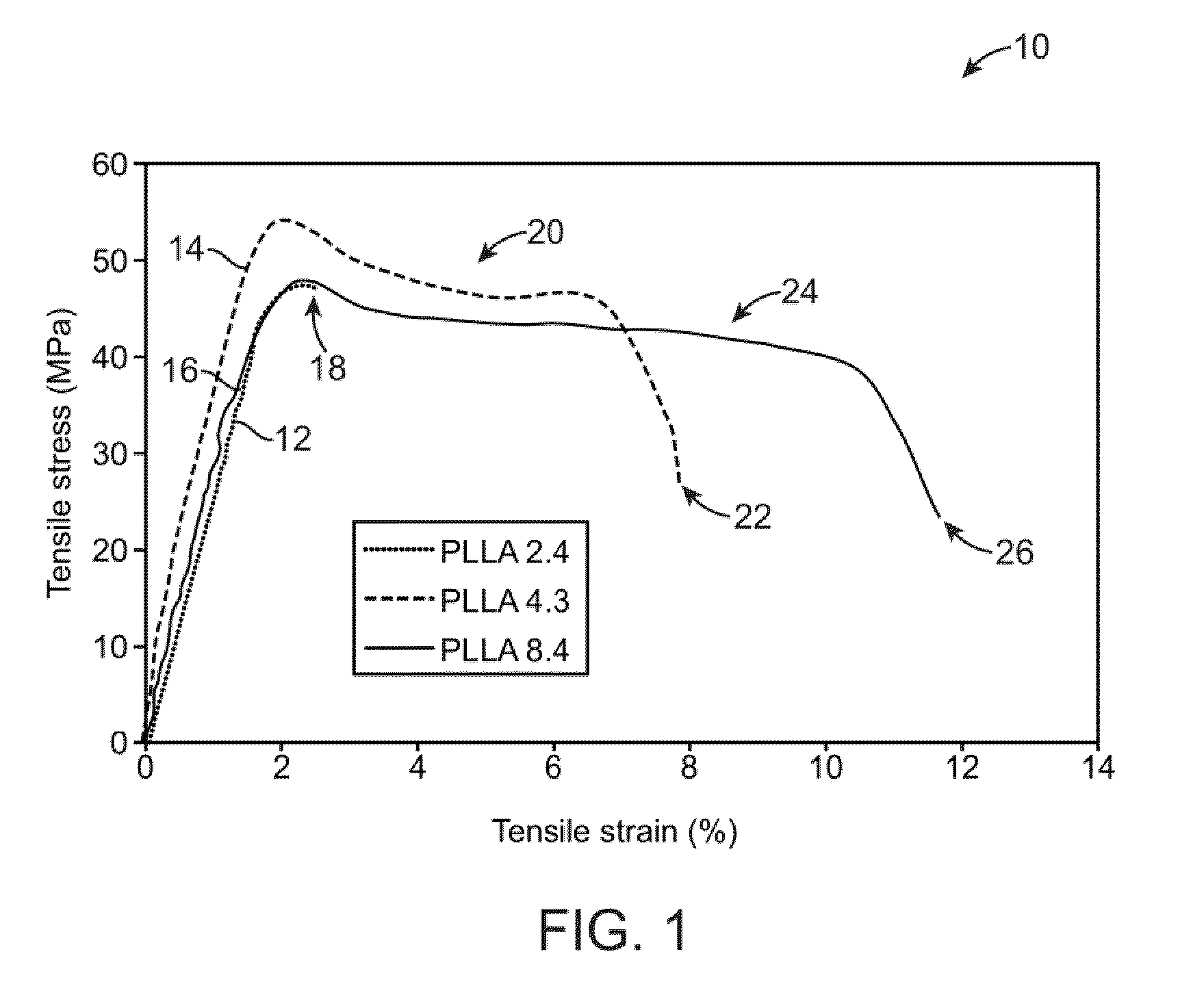

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

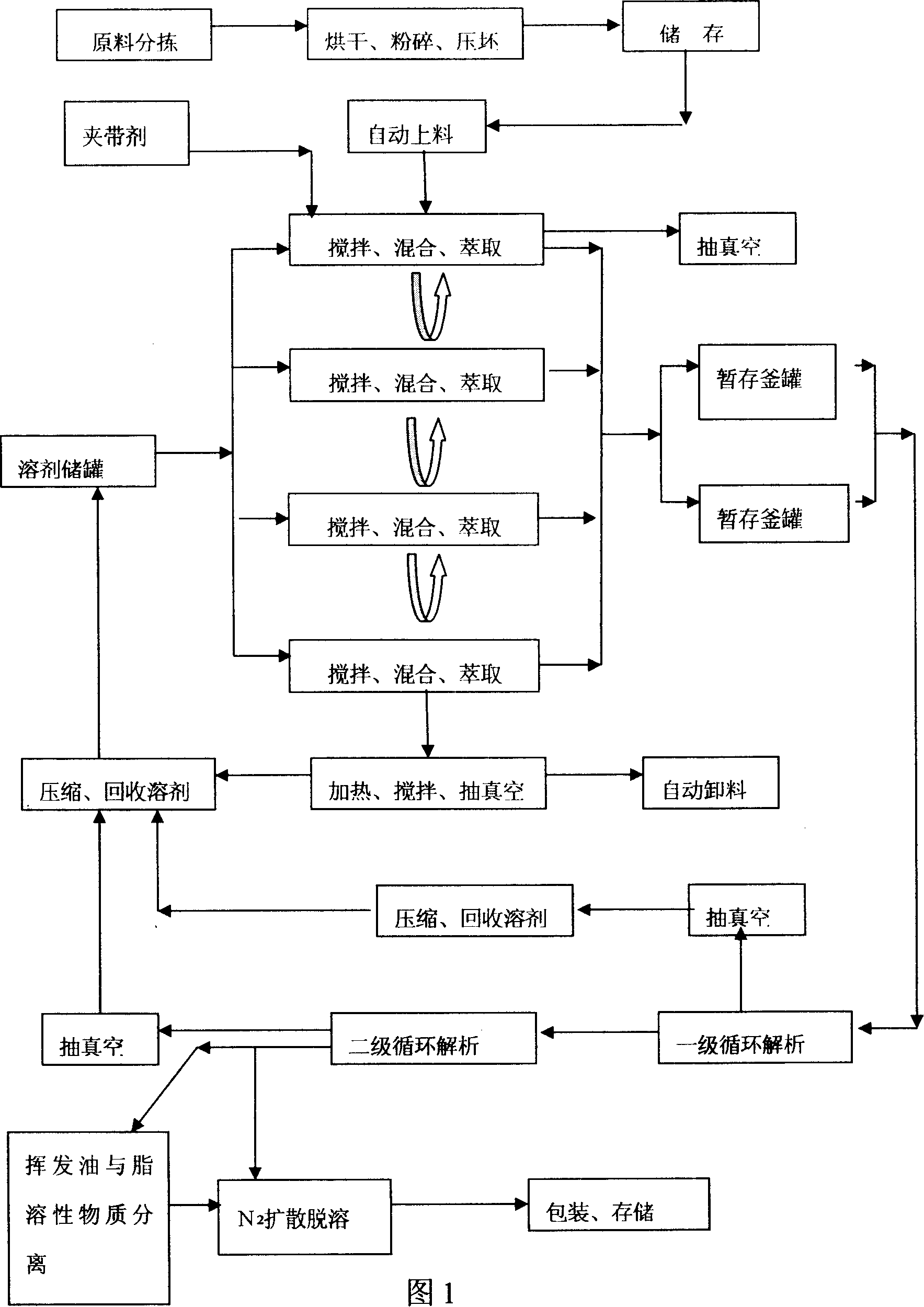

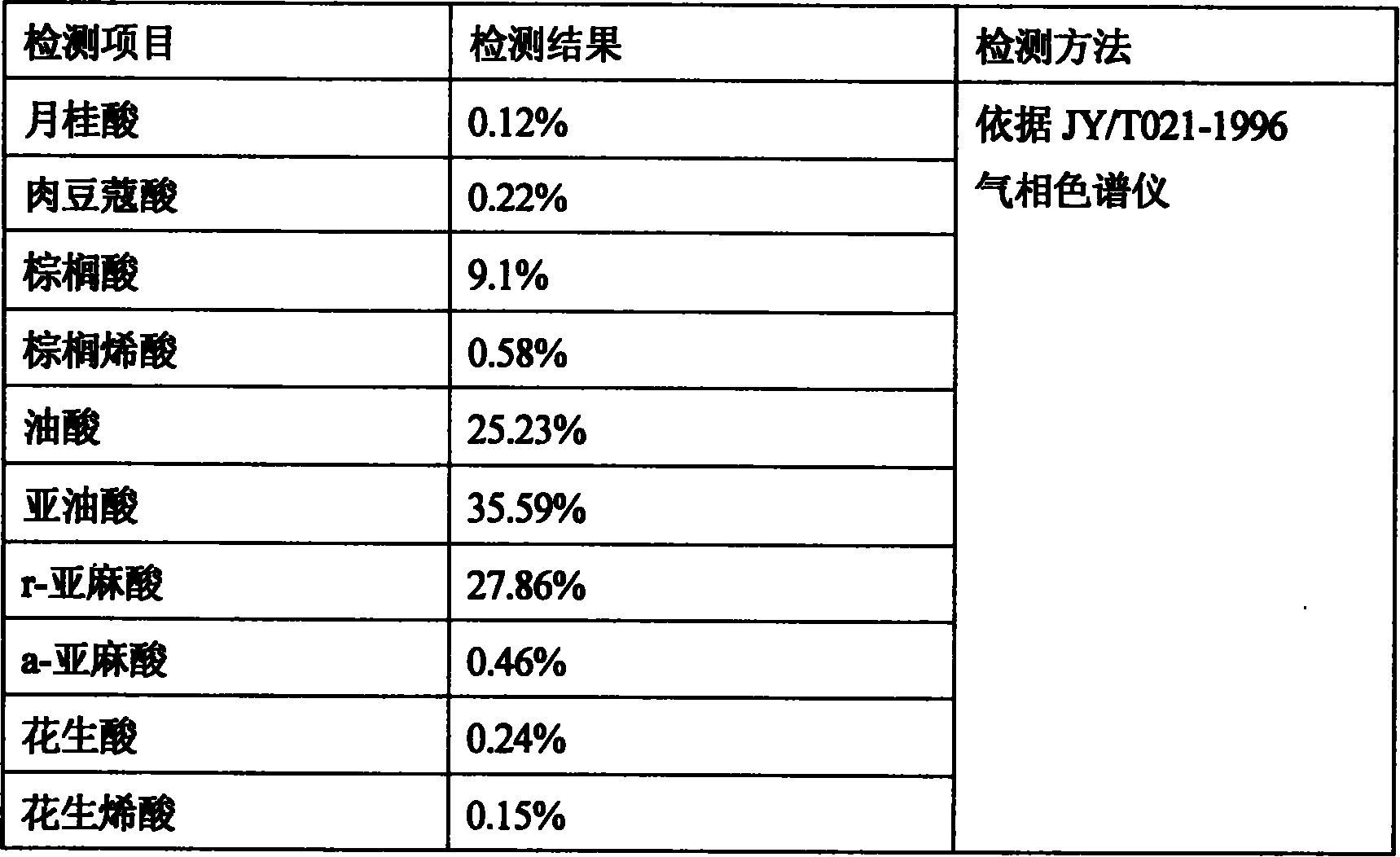

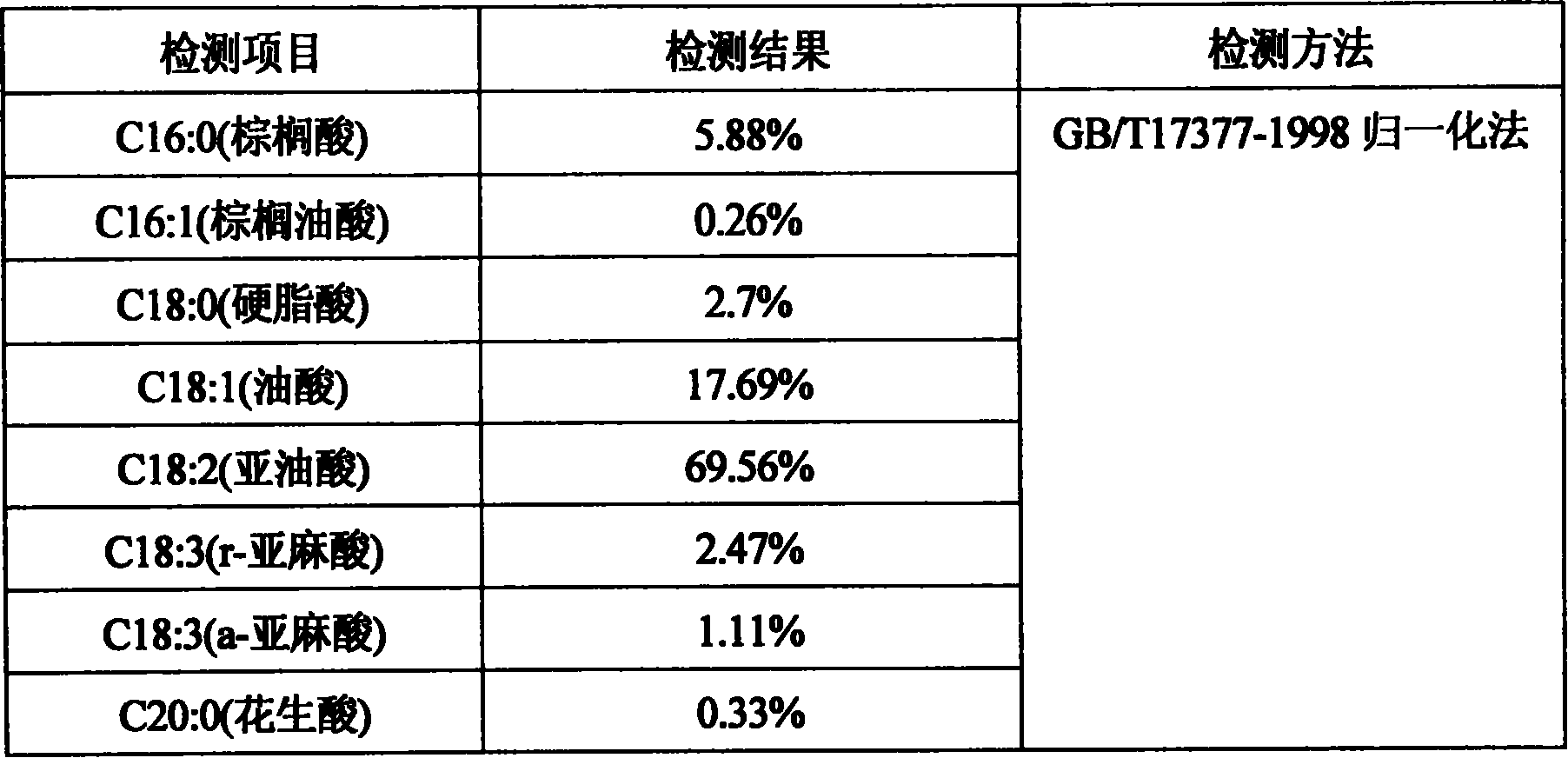

Sub-critical fluid extraction solvent and abstraction method

InactiveCN101161324AHigh extraction rateIncrease profitSolid solvent extractionSulfur hexafluorideAdditive ingredient

The present invention relates to a dissolvent with effective ingredient extracted from the plant-and-animal raw material and the extraction method thereof. One subcritical fluid extraction solvent includes an extraction solvent of a compound or composition extracted from the raw material containing compound or composition as component element, and the solvent is mainly characterized in that the liquid sulfur hexafluoride works as the extraction solvent. The invention also includes a method for extracting the subcritical fluid extraction solvent. The advantage of the invention is that the extraction and separation of the target component in the natural product are optionally executed to further increase the extraction rate of the intermediate product and the usage factor of the raw material while the unique dissolving character of the sulfur hexafluoride and the mixed solvent thereof to the liposoluble active ingredient is used. The physical features of strong dissolving capacity and low boiling point of the sulfur hexafluoride and the mixed solvent thereof are used to reduce the consumption quantity of the energy source, dissolvent of the system and the cost, and increase the market competition ability of the intermediate product.

Owner:韩延欣 +2

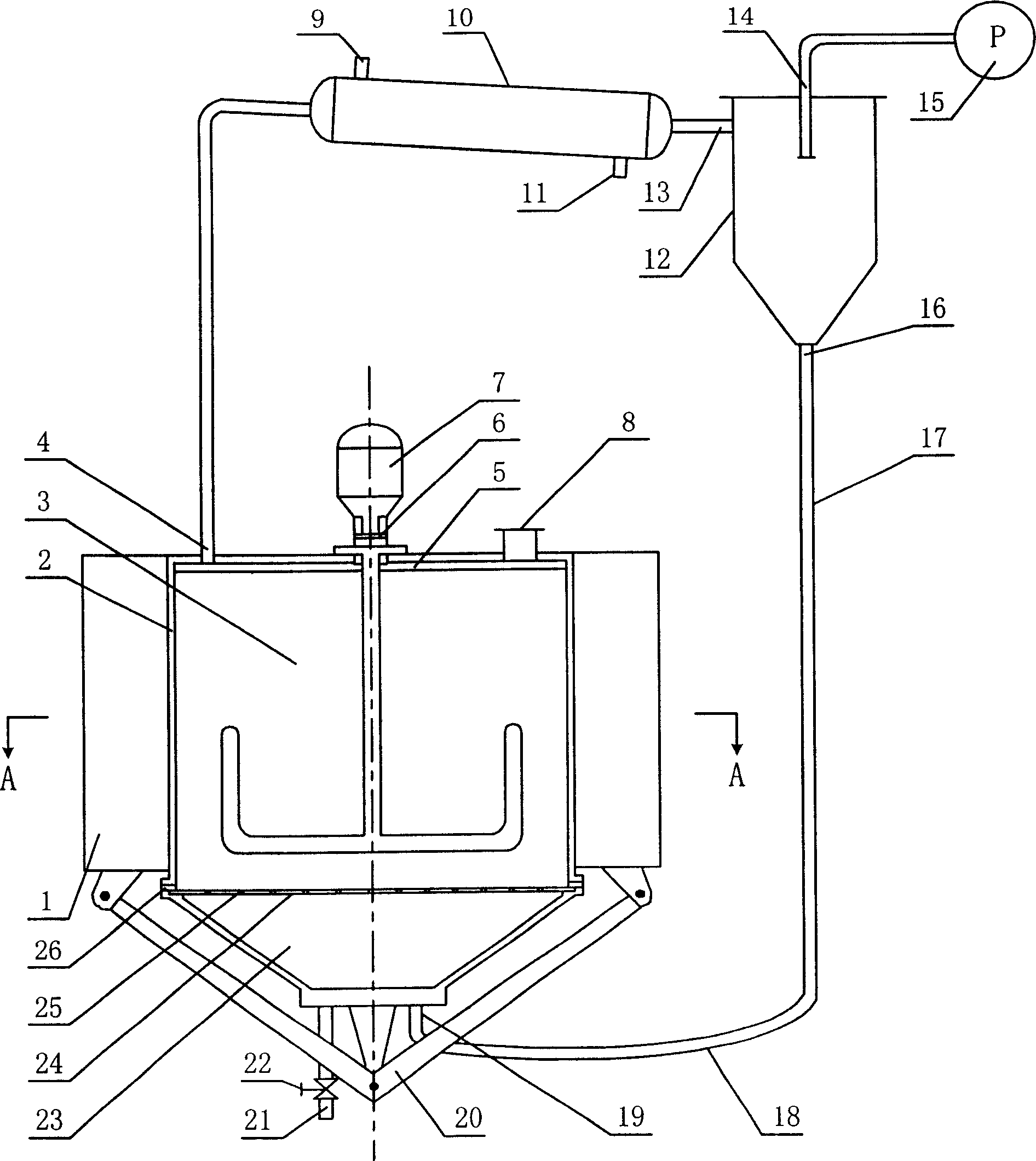

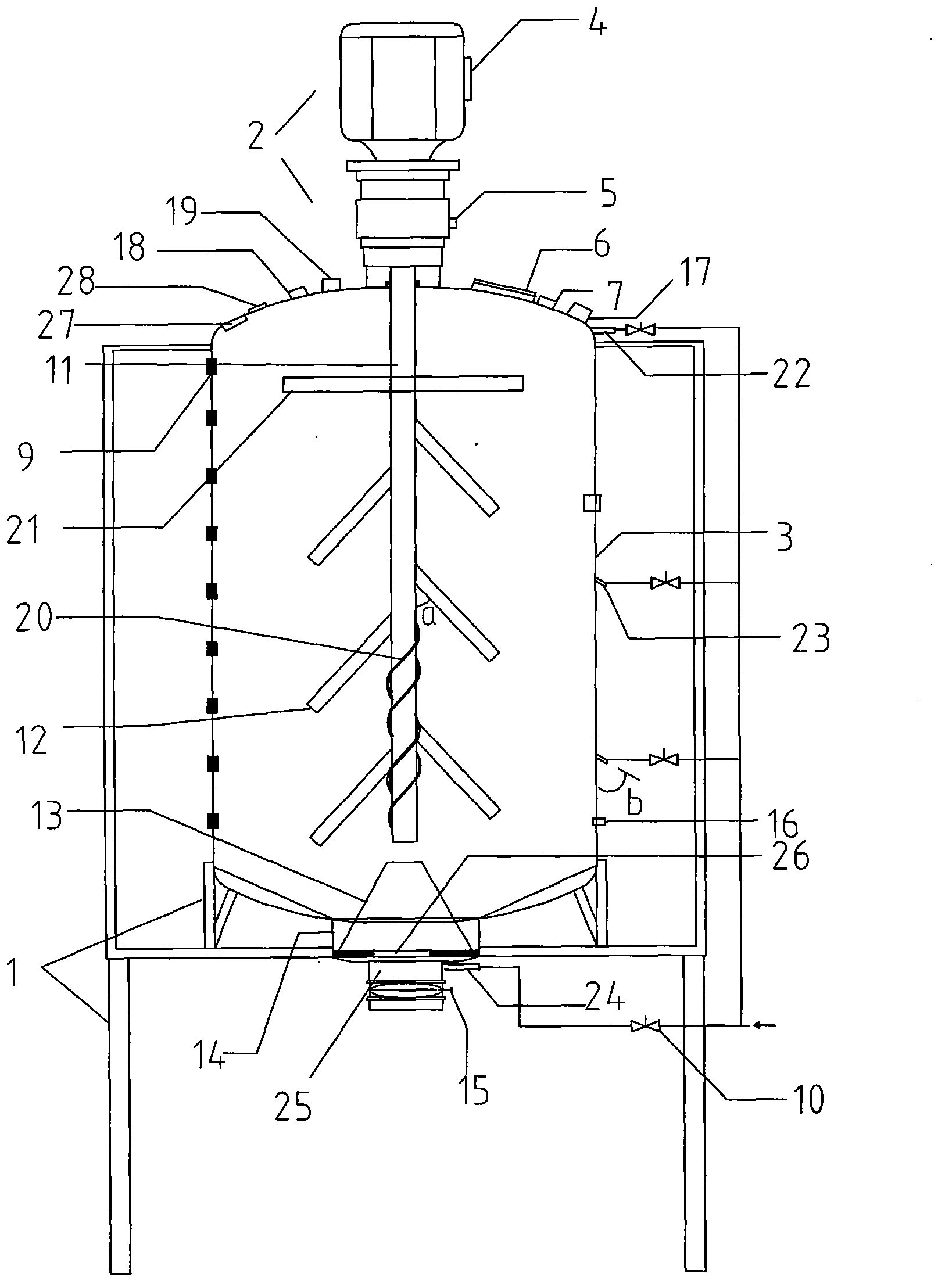

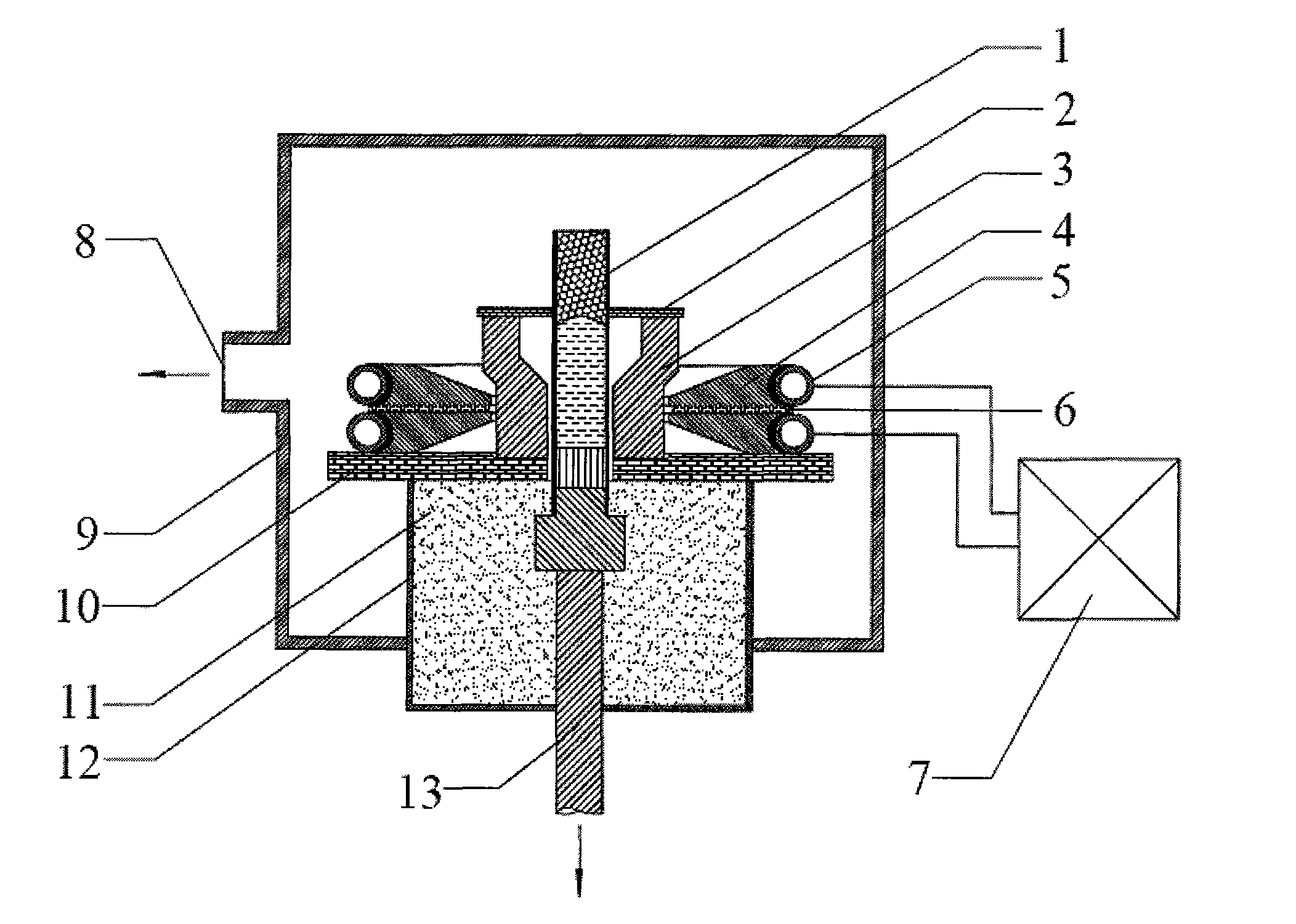

Decompressed microwave extraction device and method for extracting plant effective ingredient

InactiveCN1843552AAccelerated extraction and dissolutionReduce concentrationEnergy based chemical/physical/physico-chemical processesSolid solvent extractionMicrowaveVapor–liquid separator

The invention discloses a decompression micro-wave extraction device and method on the plant effective component, which is formed by a micro-wave oven, an extraction pot, a condenser, a liquid-gas separator, and a decompression device. Wherein, the micro-wave oven is arranged outside the extraction pot, while the micro-wave generators are uniformly arranged inside the micro-wave oven; the extraction pot is mounted with electric mixer, while its top is mounted with magnetic eraser; the upper part of extraction pot is a extraction chamber, the lower part is mounted with a solvent warehouse, and they are separated by a baffle plate with uniform solvent penetrate holes. Via decompression and micro-wave, the gas solvent is condensed into liquid solvent via the condenser and fed back into the solvent warehouse via the cycle tubes; the plant via micro-wave radiation is discharged via the discharge device at the lower part of extraction pot; since said invention uses decompression and solvent cycle devices, the process that extracting plant effective components is accelerated; said components will not thermal deteriorated via high temperature; and the extraction rate and quality are improved to apply the industrial production.

Owner:QILU UNIV OF TECH

Stent fabrication via tubular casting processes

ActiveUS20090319028A1Improve mechanical propertiesReduced flexibilityOrganic active ingredientsHeart valvesPolymer solutionDip-coating

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

Stent fabrication via tubular casting processes

ActiveUS8206635B2Improve radial strengthImprove overall strength levelsOrganic active ingredientsPeptide/protein ingredientsPolymer solutionDip-coating

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

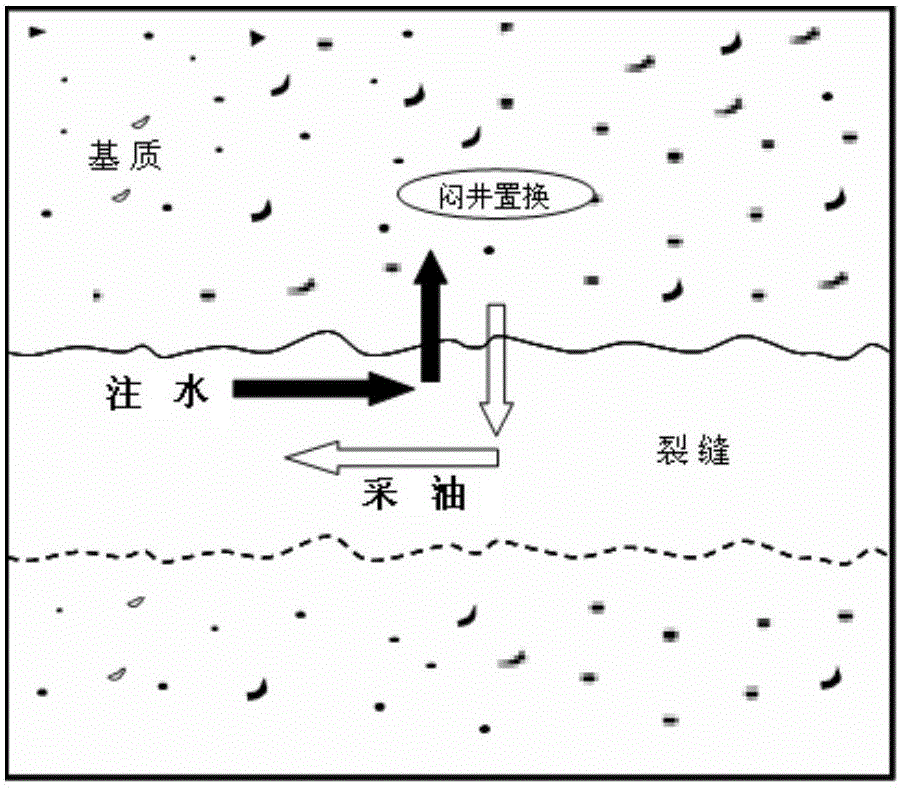

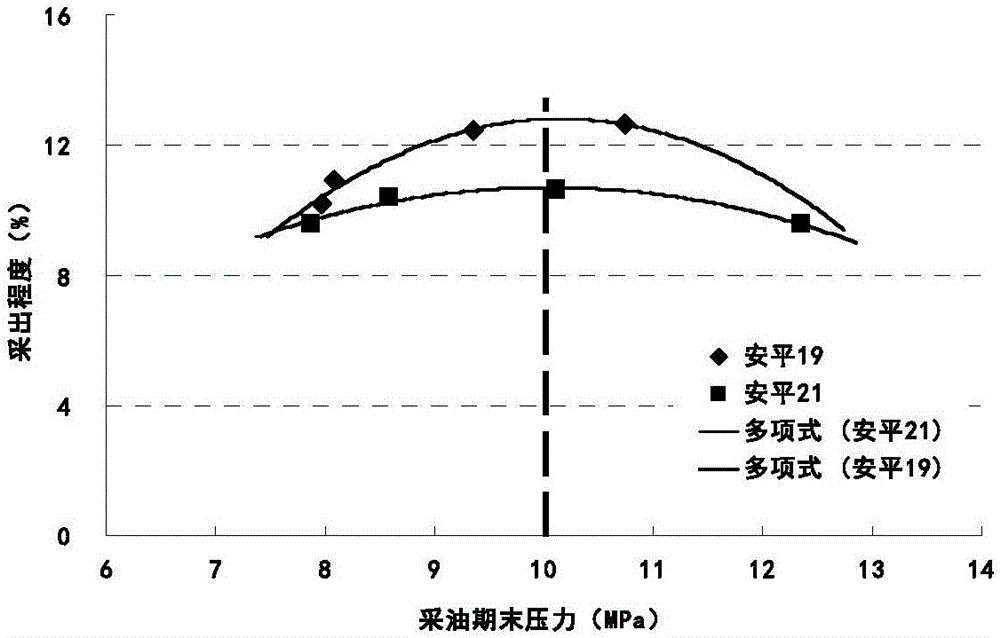

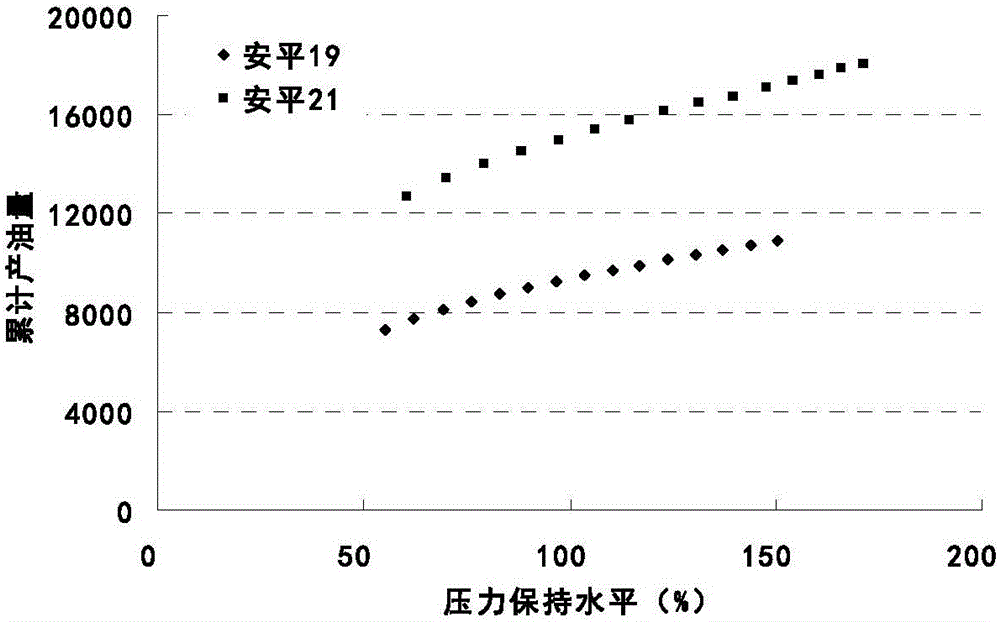

Method for improving recovery efficiency through huff and puffoil recoveryof tight oil fractured horizontal well

ActiveCN105888630AThe effect of increasing production is obviousLow investment costSurveyFluid removalTight oilControl area

The invention provides a method for improving recovery efficiency through huff and puffoil recovery of a tight oil fractured horizontal well. When reservoir pressure is reduced to a certain optimized pressure, the horizontal well is subjected to sand washing out and well flushing, water is injected into the reservoir at the specified daily water-injection rate, water injection is stopped when pressure at the end of injection life is maintained to be 100%, and then the accumulated water-injection rate is equal to accumulated fluid withdrawal rate in the previous production stage of the well; after water injection is ended, the horizontal well is closed and enters a closing-in stage to depend on imbibition replacement and other effects, so that crude reservoir oil enters a high-permeability channel; and during oil extraction, when formation pressure in the control area of the horizontal well is reduced to rated pressure, the well is closed, and second round of huff and puff oil recovery is performed. According to the method for improving recovery efficiency through the huff and puffoil recovery of the tight oil fractured horizontal well disclosed by the invention, crude oil in dense reservoir rock matrix pores developed in natural fracture is further extracted, the single well yield of an oil well is improved by comprehensively utilizing formation energy rising, injected water and crude reservoir oil imbibition replacement and other principles, and a new approach is developed for increasing the crude oil recovery rate of the dense oil reservoir.

Owner:PETROCHINA CO LTD

Multiple-magnetron type large-capacity microwave-assisted extraction machine and microwave-assisted extraction method thereof

InactiveCN103505902AHeating evenlyHigh extraction rateEnergy based chemical/physical/physico-chemical processesSolid solvent extractionEngineeringElectromagnetic field

The invention discloses a multiple-magnetron type large-capacity microwave-assisted extraction machine and a microwave-assisted extraction method thereof, belonging to the field of biological raw material extraction equipment and an extraction method. The multiple-magnetron type large-capacity microwave-assisted extraction machine comprises a rack, a transmission device, a microwave tank, a microwave device, an air-entrapping device, a rotor device, a discharging device and a control device, wherein a plurality of magnetron installing holes uniformly and equidistantly distributed are formed in the wall of the microwave tank; the microwave device comprises a plurality of high-frequency magnetrons which are uniformly and equidistantly arranged on the wall of the microwave tank, and the high-frequency magnetrons are connected with an external power source; the air-entrapping device comprises a plurality of compressed air inlets formed in the wall of the microwave tank, a compressed air input pipeline and a plurality of electromagnetic valves; the rotor device comprises a rotating shaft and a plurality of stirring wings which are fixed on the rotating shaft and form certain crossing angles with the rotating shaft. The multiple-magnetron type large-capacity microwave-assisted extraction machine has the advantages that feed liquid in the microwave tank continuously runs and interchanges, an extractive is uniformly subjected to the action of an electromagnetic field to be heated, the extraction rate is increased, and the extraction time is shortened.

Owner:永州中农银杏开发有限责任公司

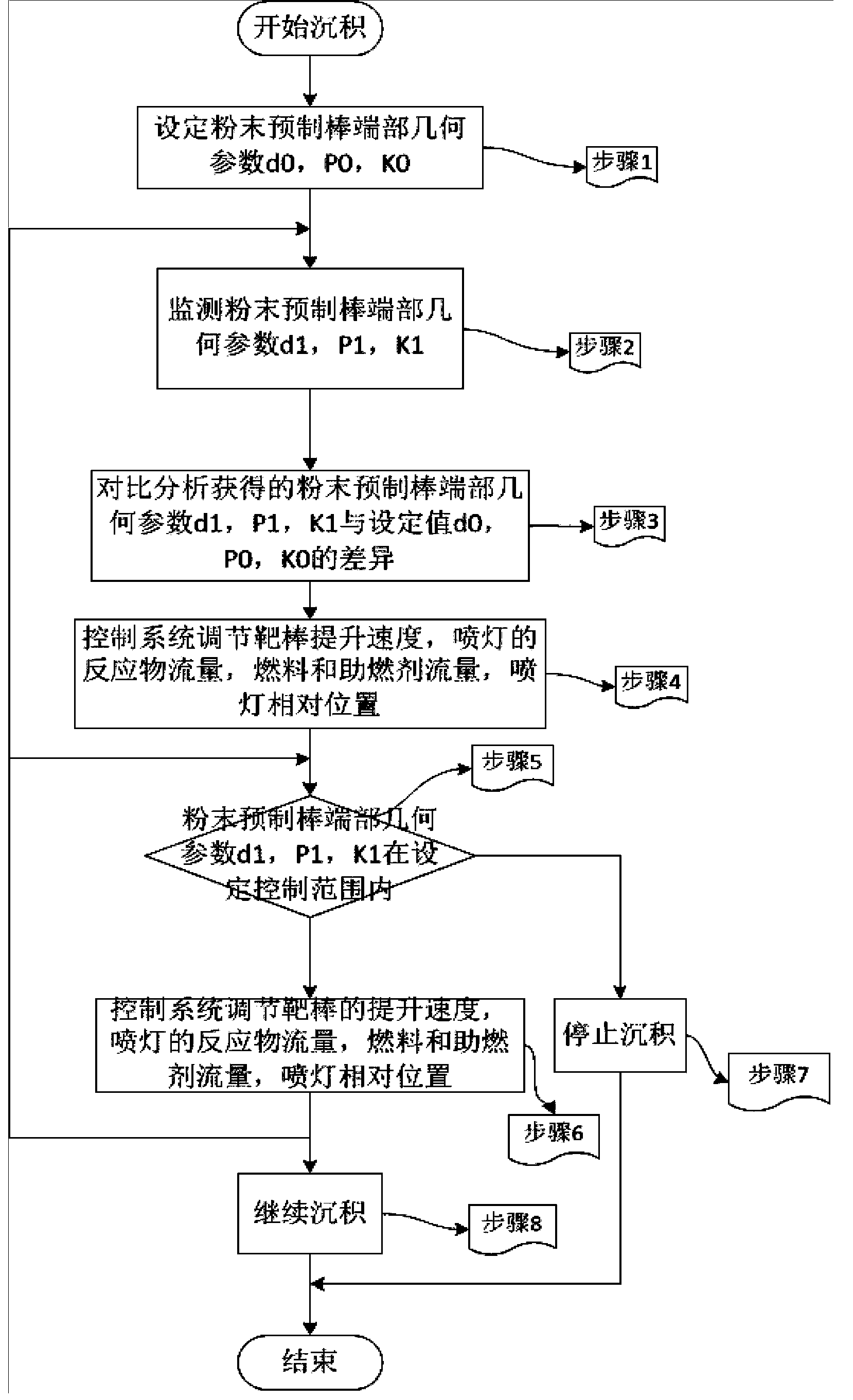

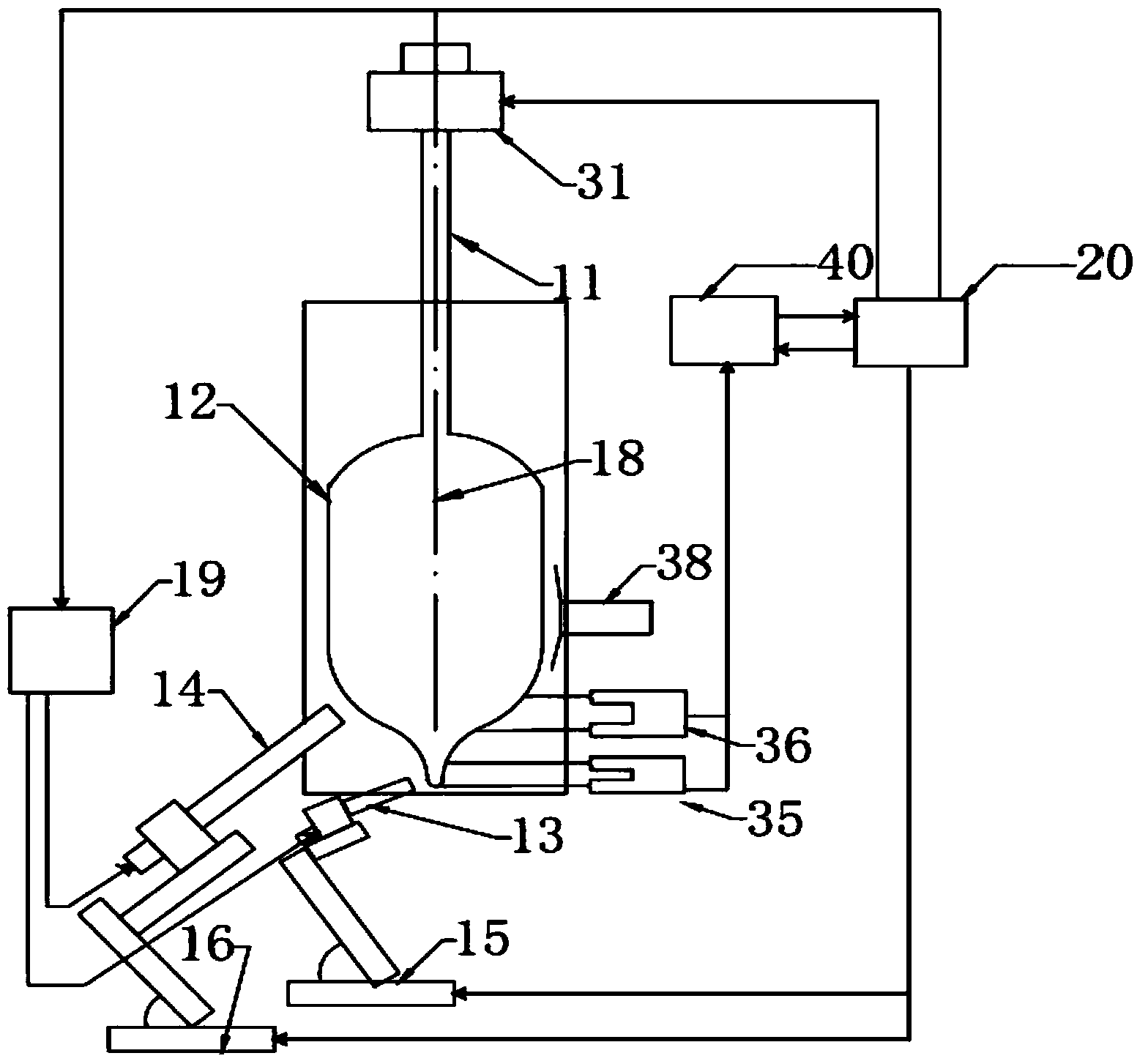

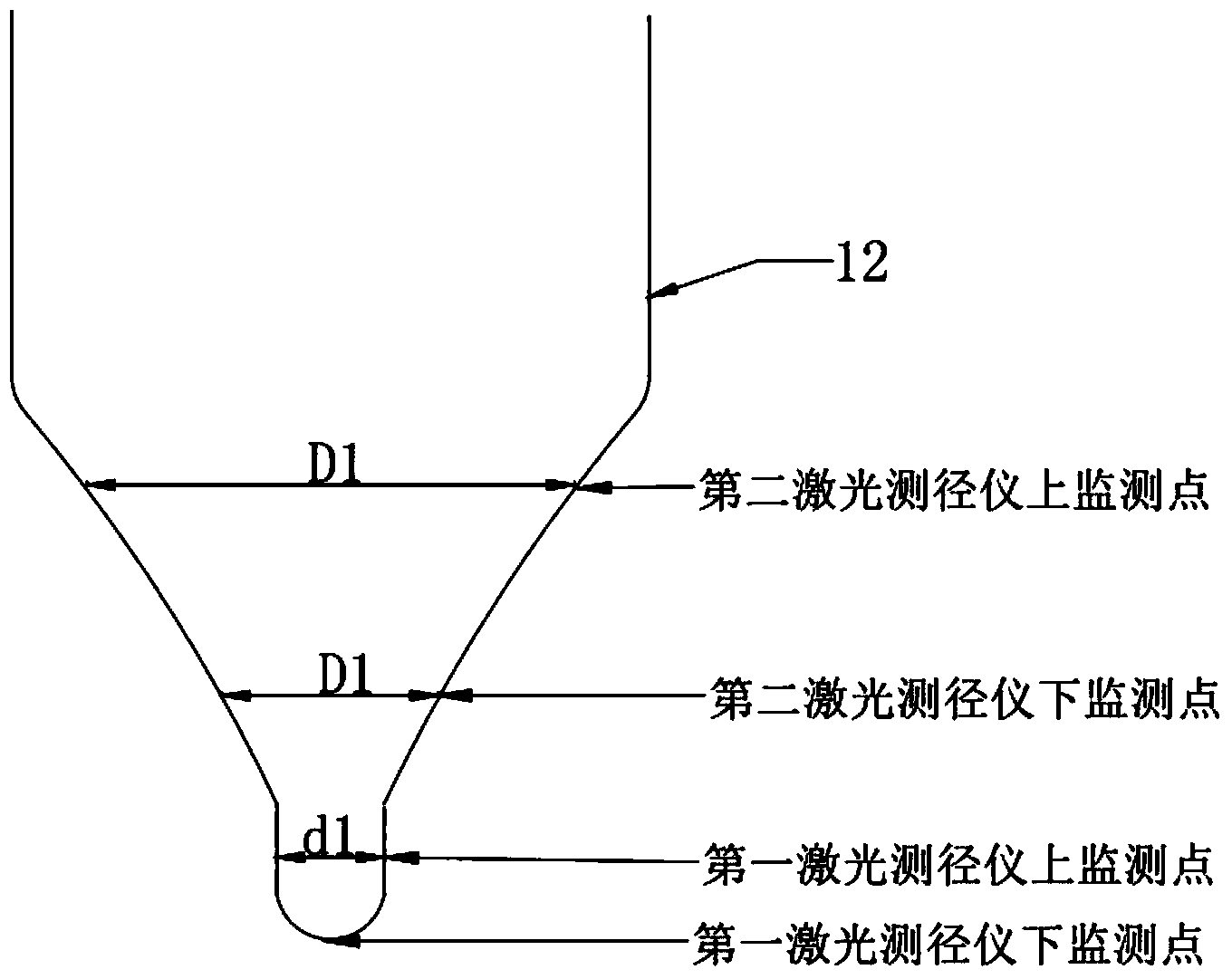

Optical fiber preform manufacturing method

InactiveCN104355532AReduce manufacturing costHigh precisionGlass deposition burnersMeasuring instrumentControl system

The invention discloses an optical fiber preform manufacturing method which comprises the following steps: an upper laser of a first laser instrument measures the diameter d of a sandwich layer, a lower laser measures the top end shape P of a powder preform, and a system determines the withdrawal rate of the powder preform according to the top end shape P; an upper laser and a lower laser of a second laser instrument measure diameters of an upper point and a lower point of a coating layer respectively to further calculate the slope K of the deposition coating layer. An analytical system compares the differences between the actual parameters d1, P1 and K1 and the set parameters d0, P0 and K0 of the deposition powder preform. During the deposition process of the powder preform, a measuring system (a laser diameter measuring instrument), a control system and the analytical system are in closed cycle, the system is in real-time measurement, analysis and adjustment processes, and the deposition process can be controlled through the K value at the initial period when the top end shape of the coating layer deviates from the control mid-value so as to obtain the coating layer with uniform external diameter and improve the quality of the powder preform.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Stent fabrication via tubular casting processes

ActiveUS20120232643A1Improve radial strengthImprove overall strength levelsStentsHeart valvesDelayed timePolymer solution

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

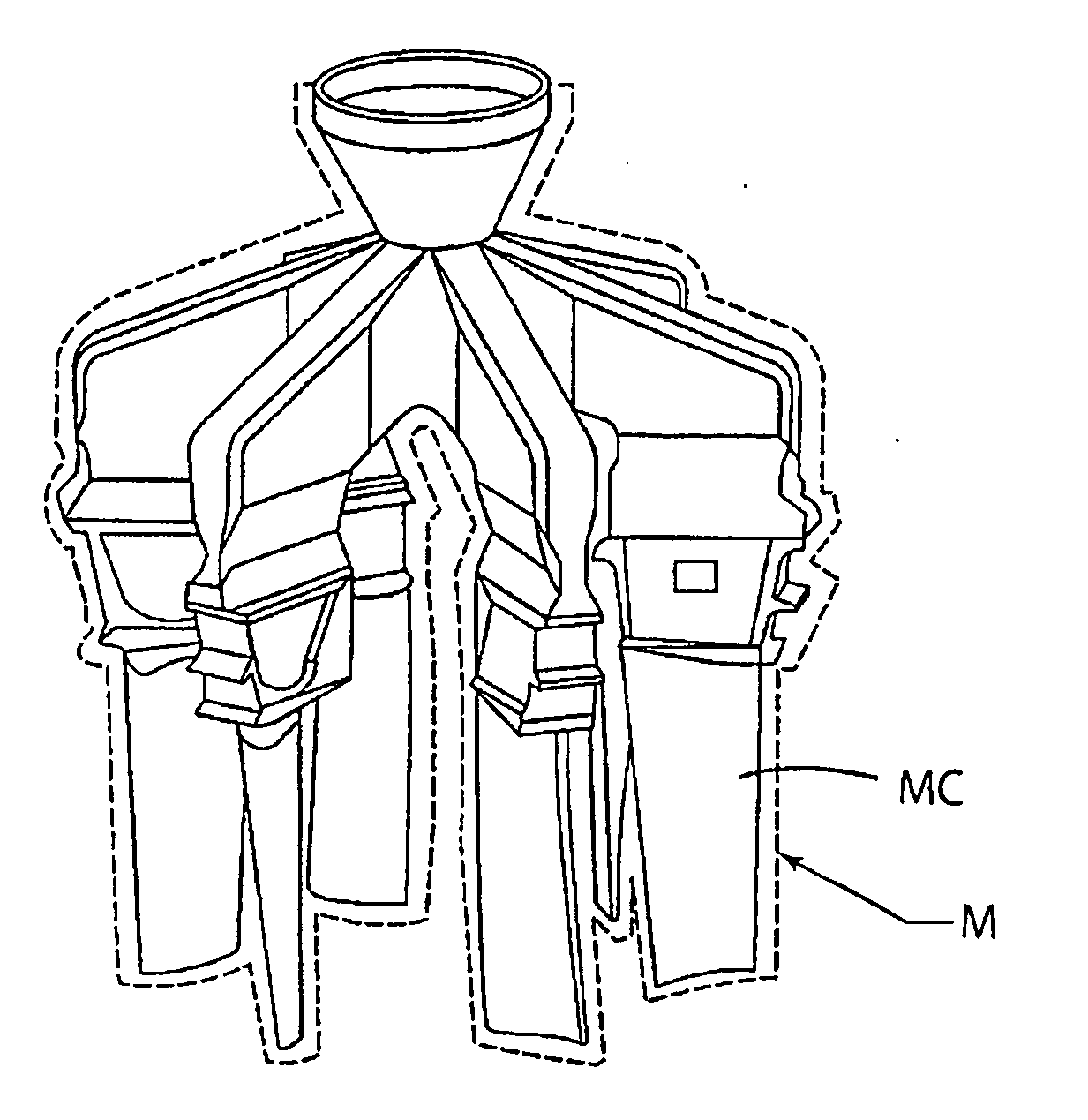

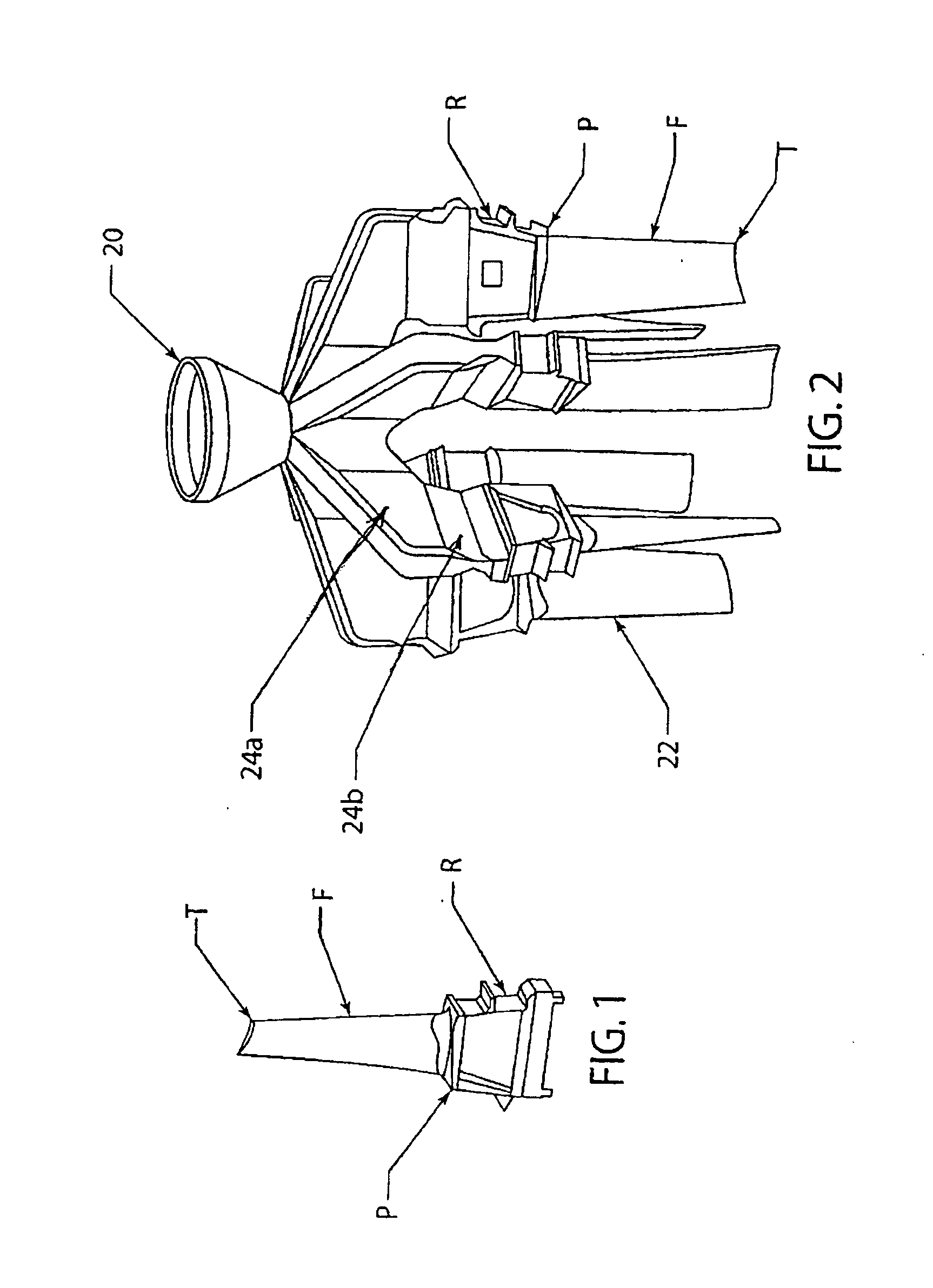

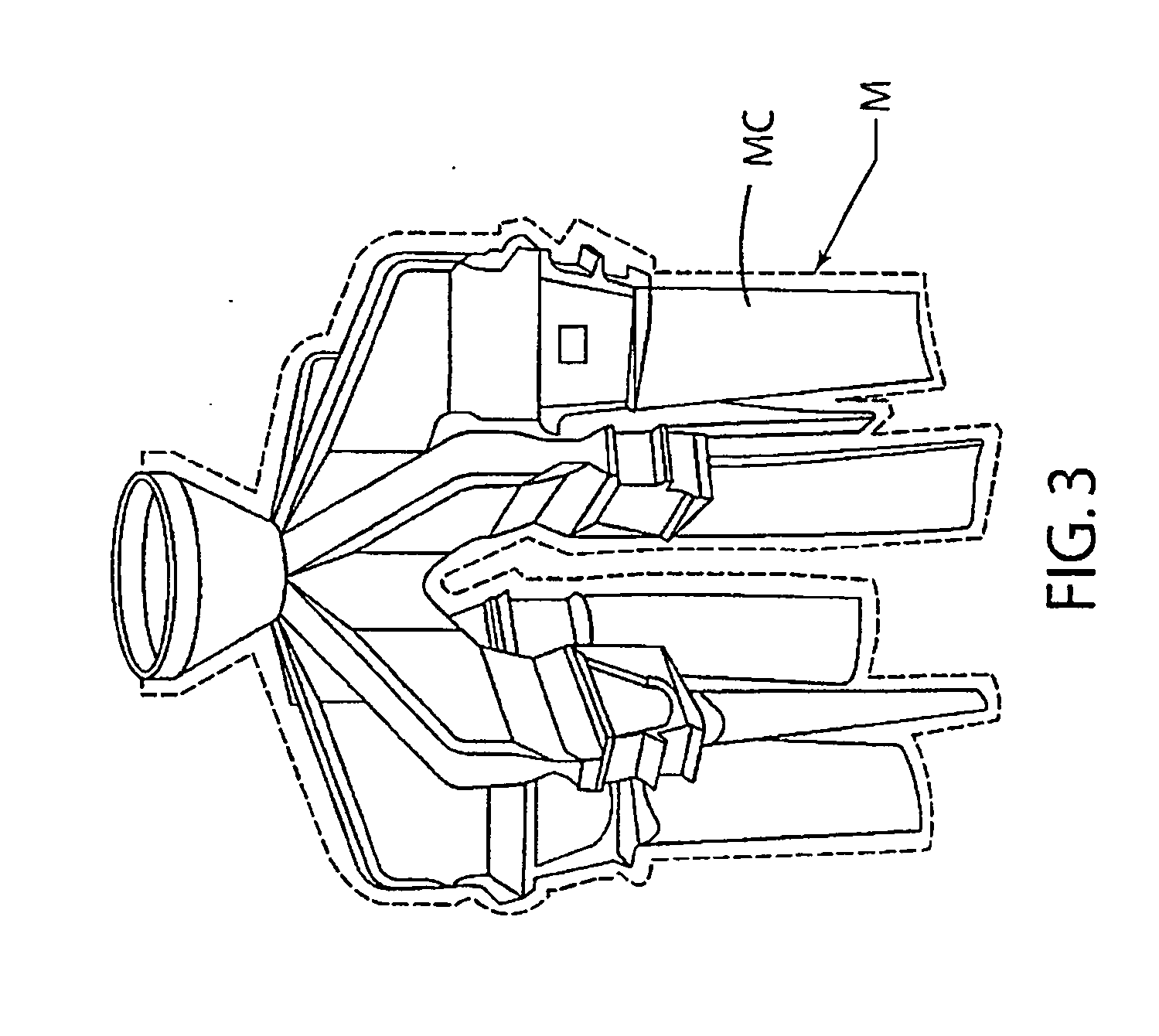

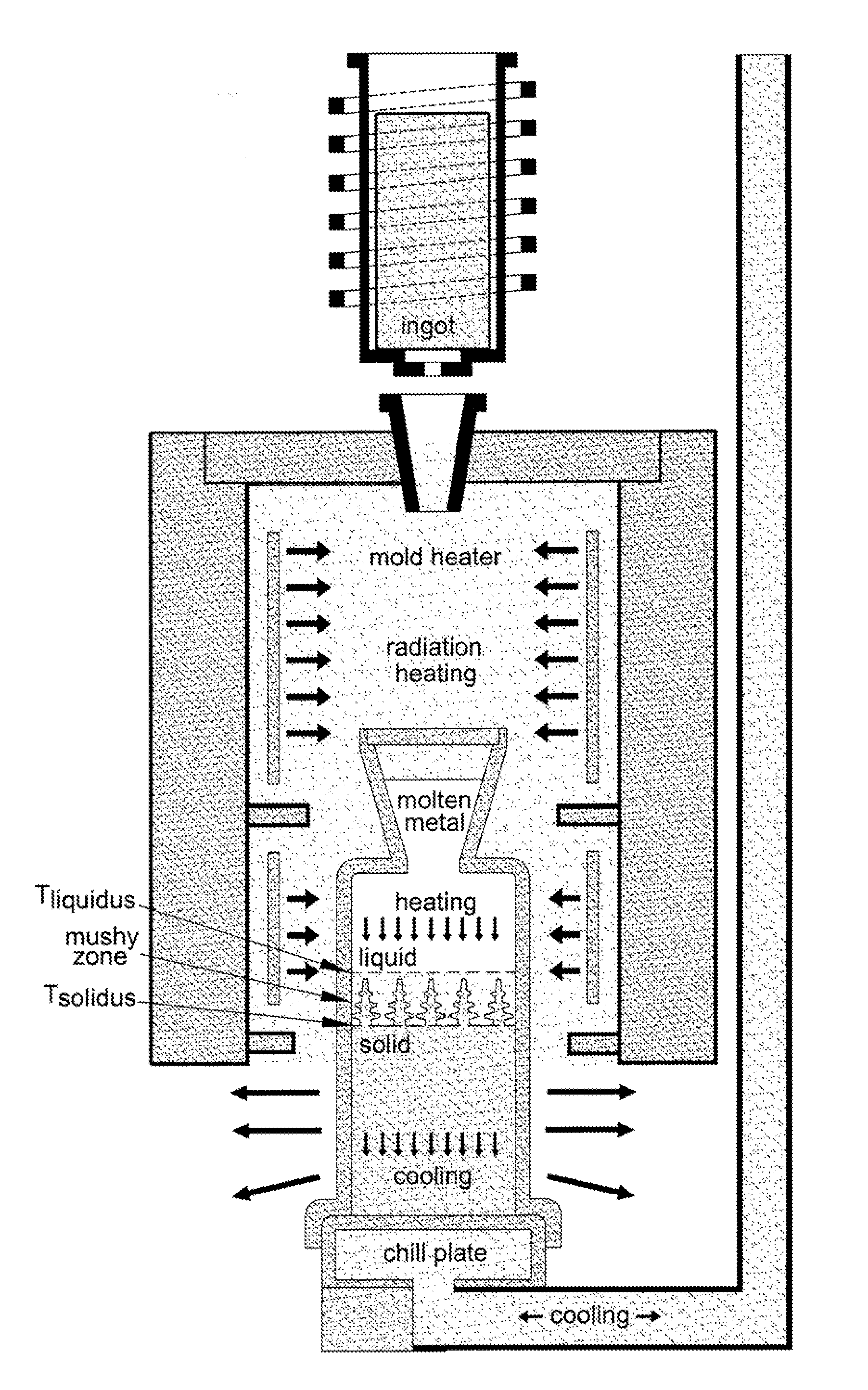

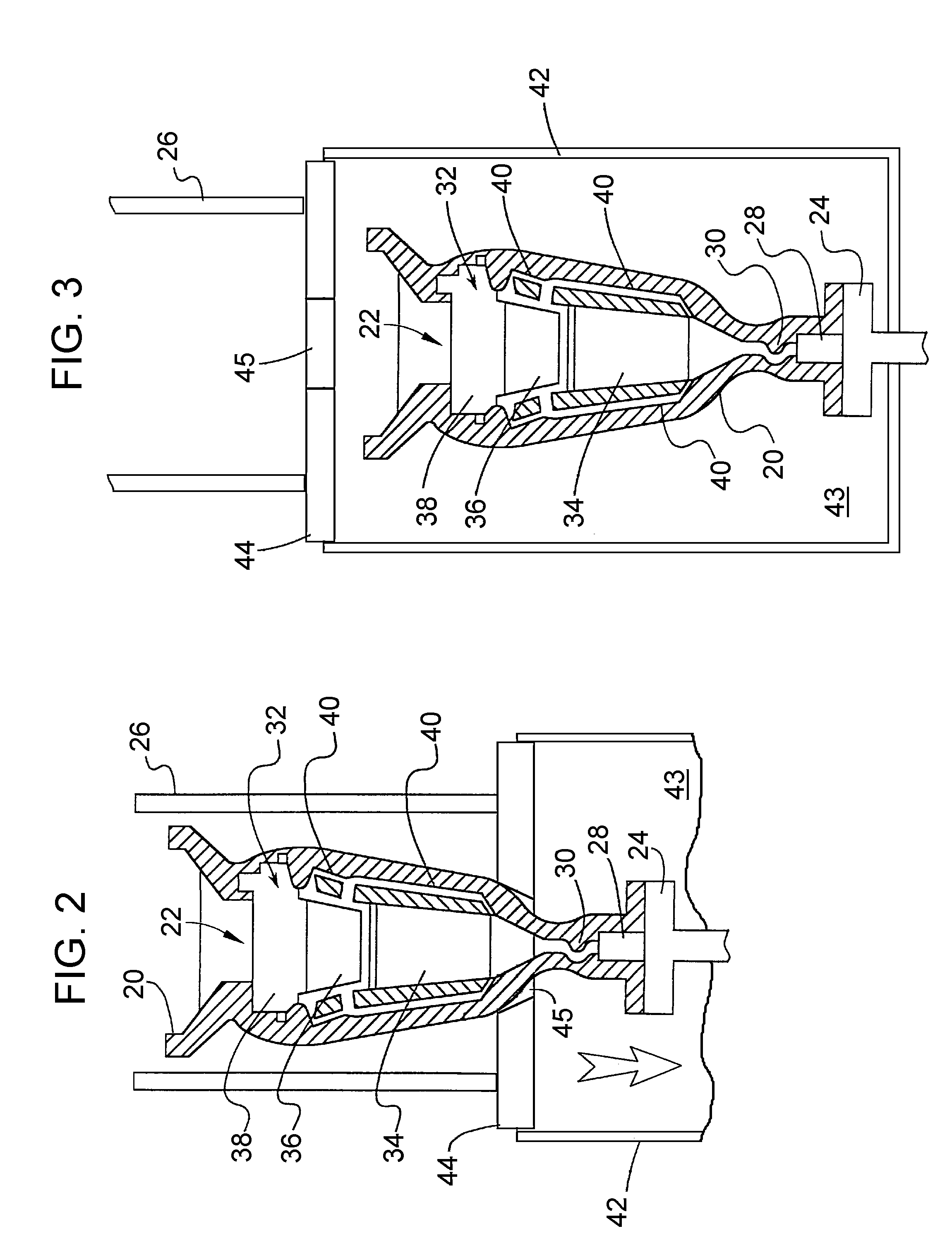

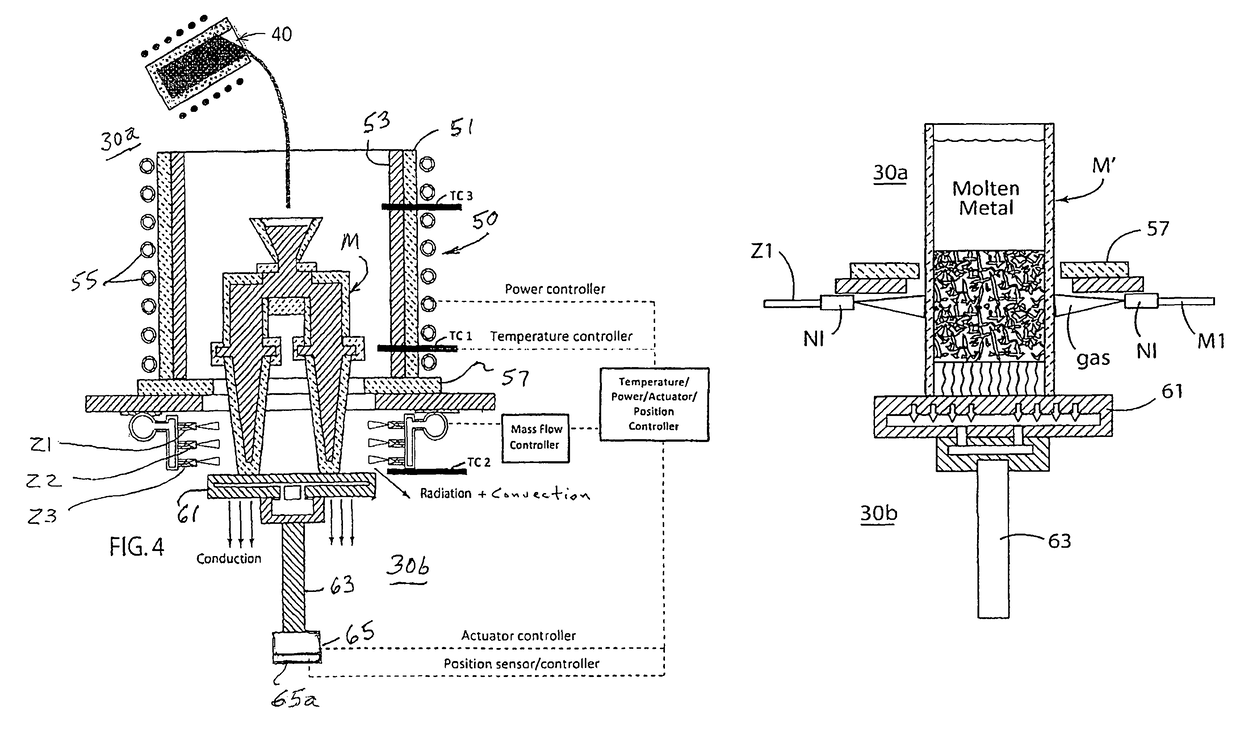

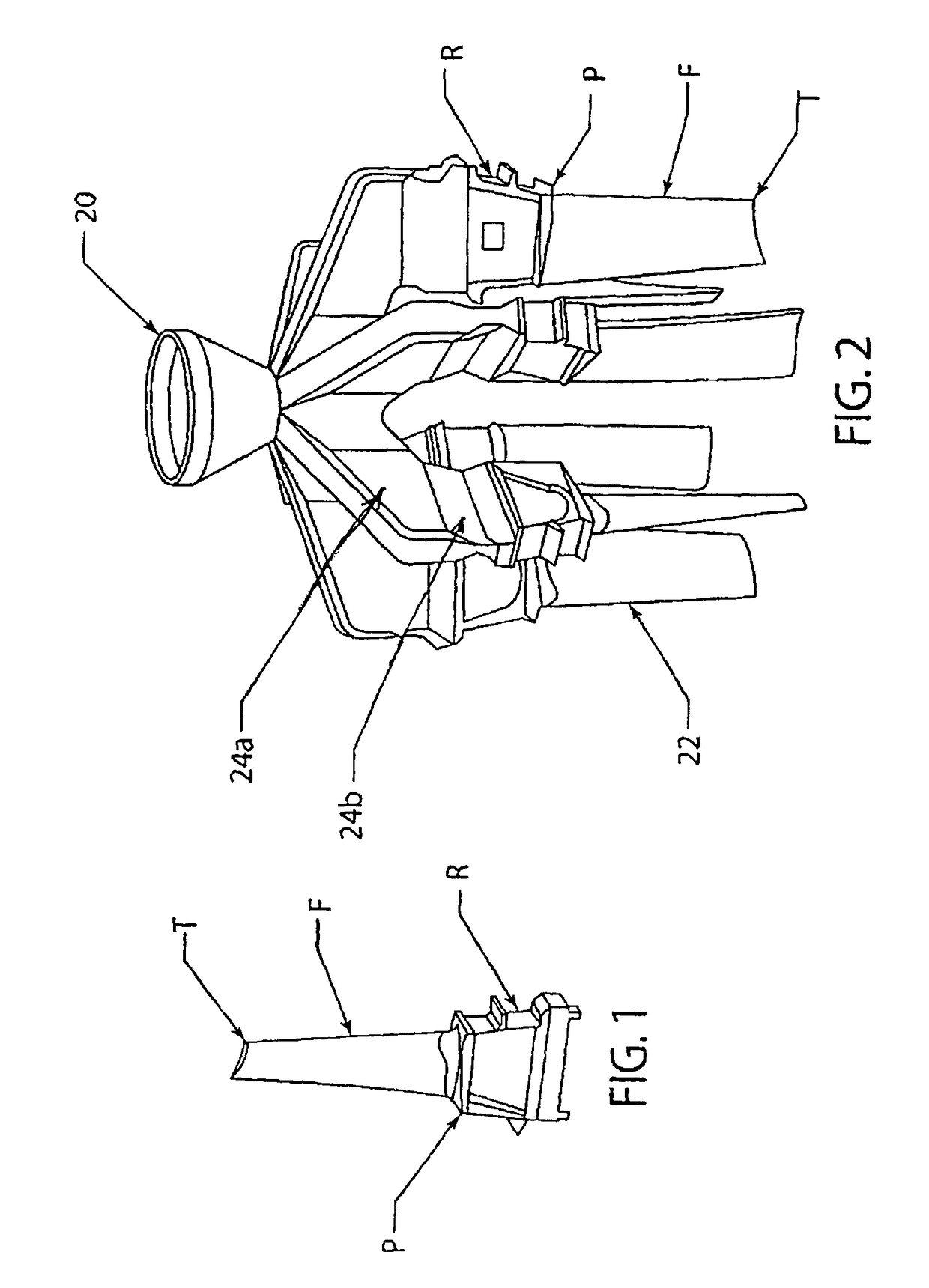

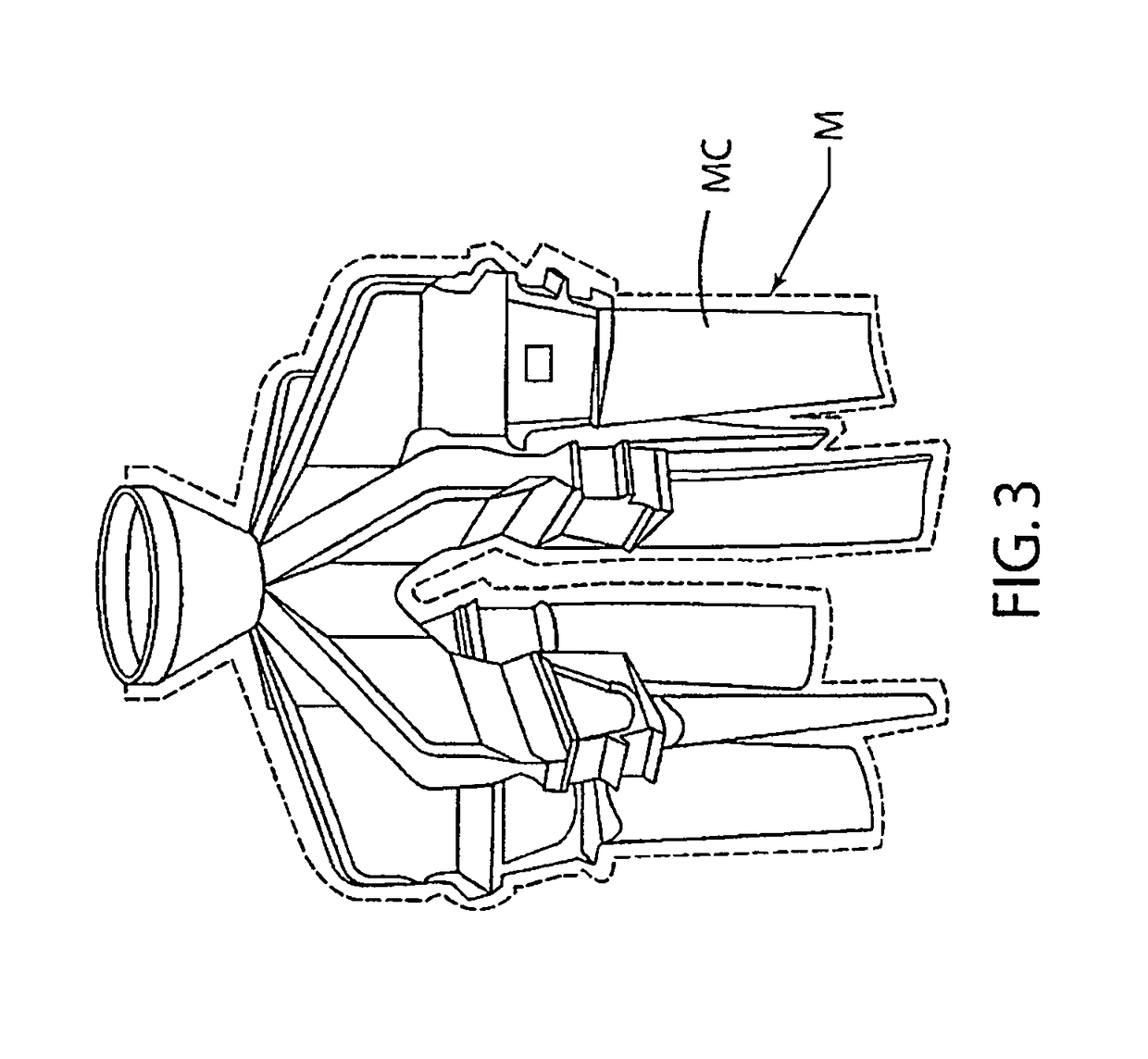

Casting method, apparatus, and product

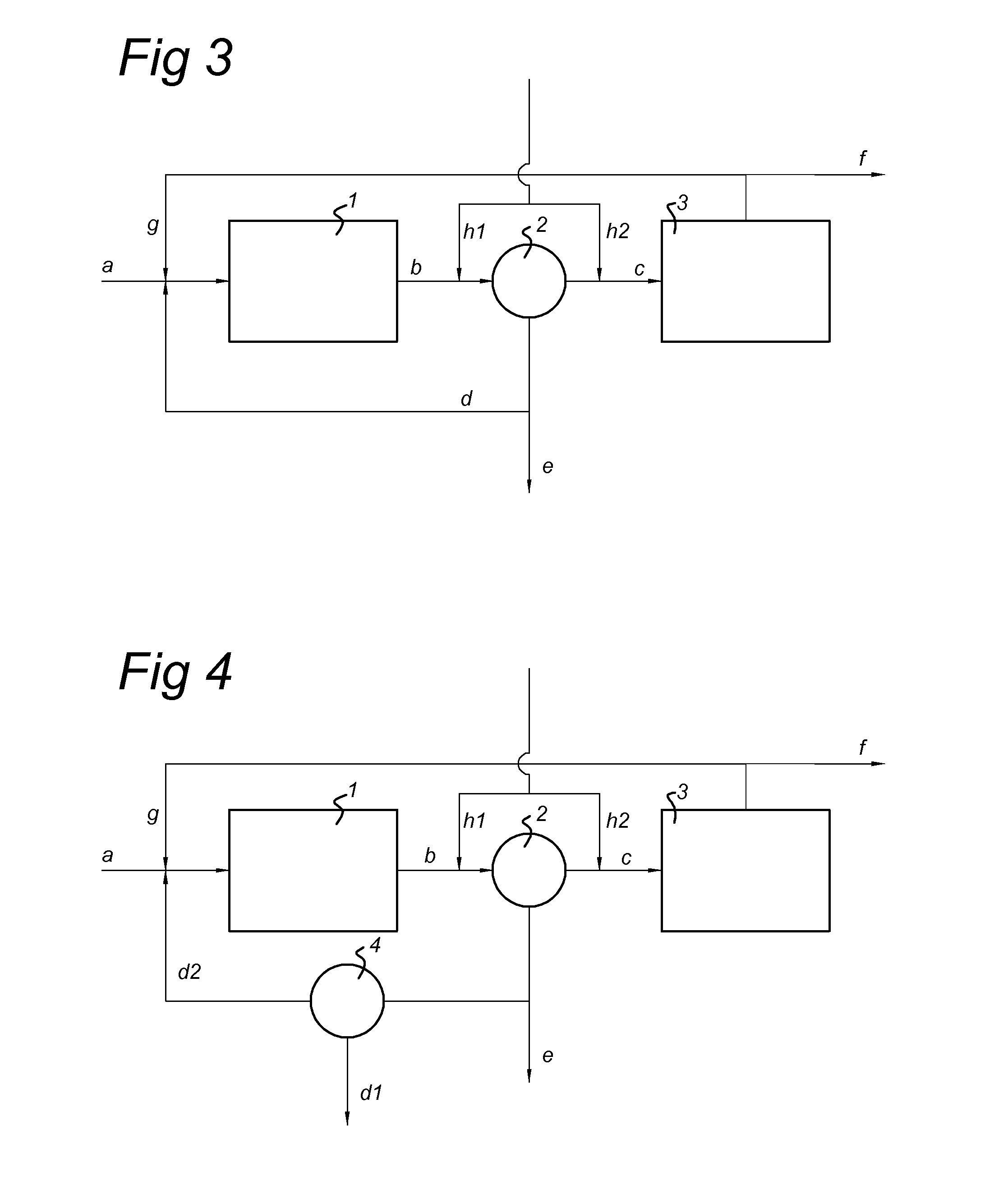

ActiveUS20140127032A1Facilitate heat extractionLow thermal expansionPropellersPump componentsActive coolingHeating furnace

A casting method and apparatus are provided for casting a near-net shape article, such as for example a gas turbine engine blade or vane having a variable cross-section along its length. A molten metallic melt is provided in a heated mold having an article-shaped mold cavity with a shape corresponding to that of the article to be cast. The melt-containing mold and mold heating furnace are relatively moved to withdraw the melt-containing mold from the furnace through an active cooling zone where cooling gas is directed against the exterior of the mold to actively extract heat. At least one of the mold withdrawal rate, the cooling gas mass flow rate, and mold temperature are adjusted at the active cooling zone as the melt-containing mold is withdrawn through the active cooling zone to produce an equiaxed grain microstructure along at least a part of the length of the article.

Owner:HOWMET CORPORATION

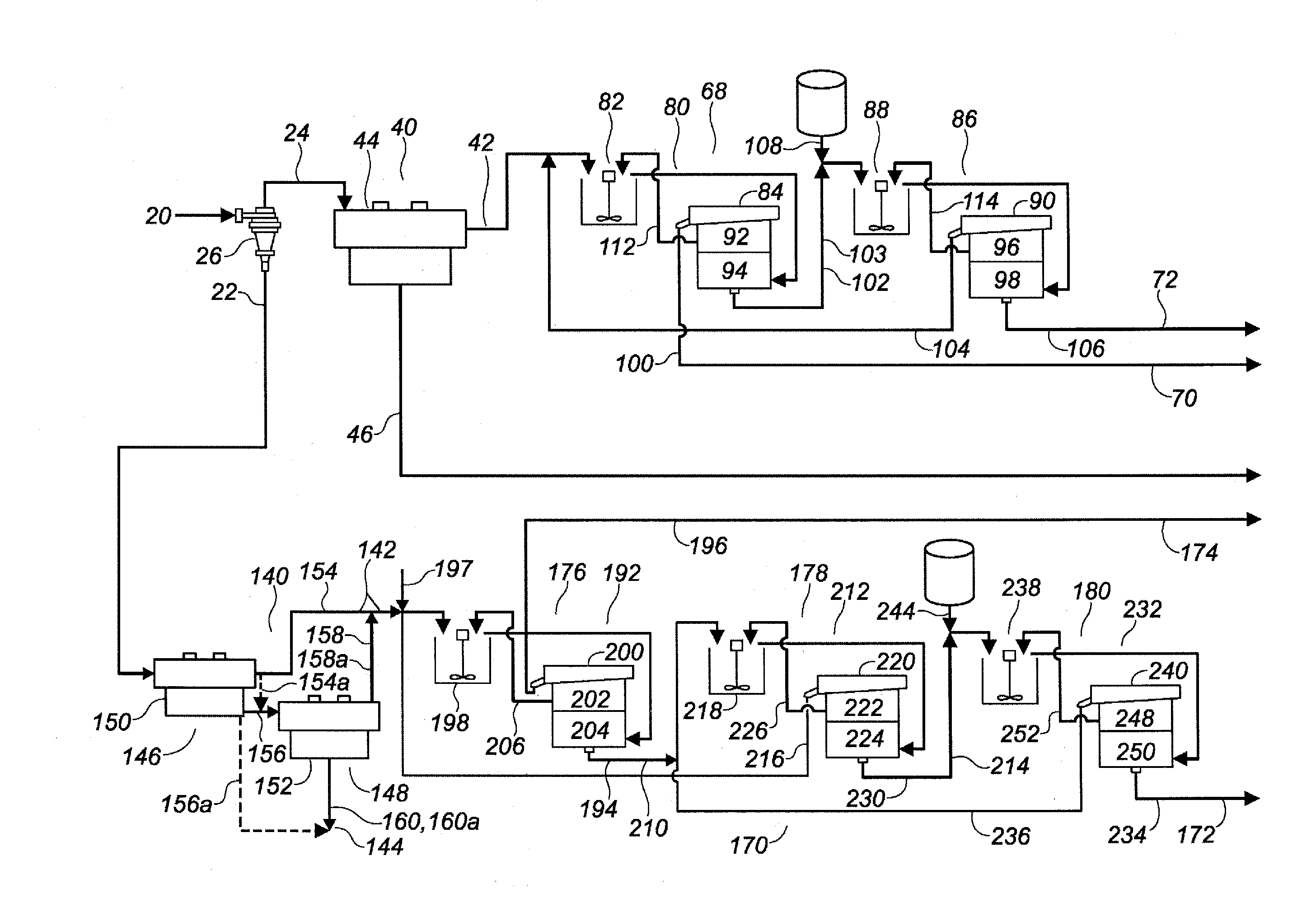

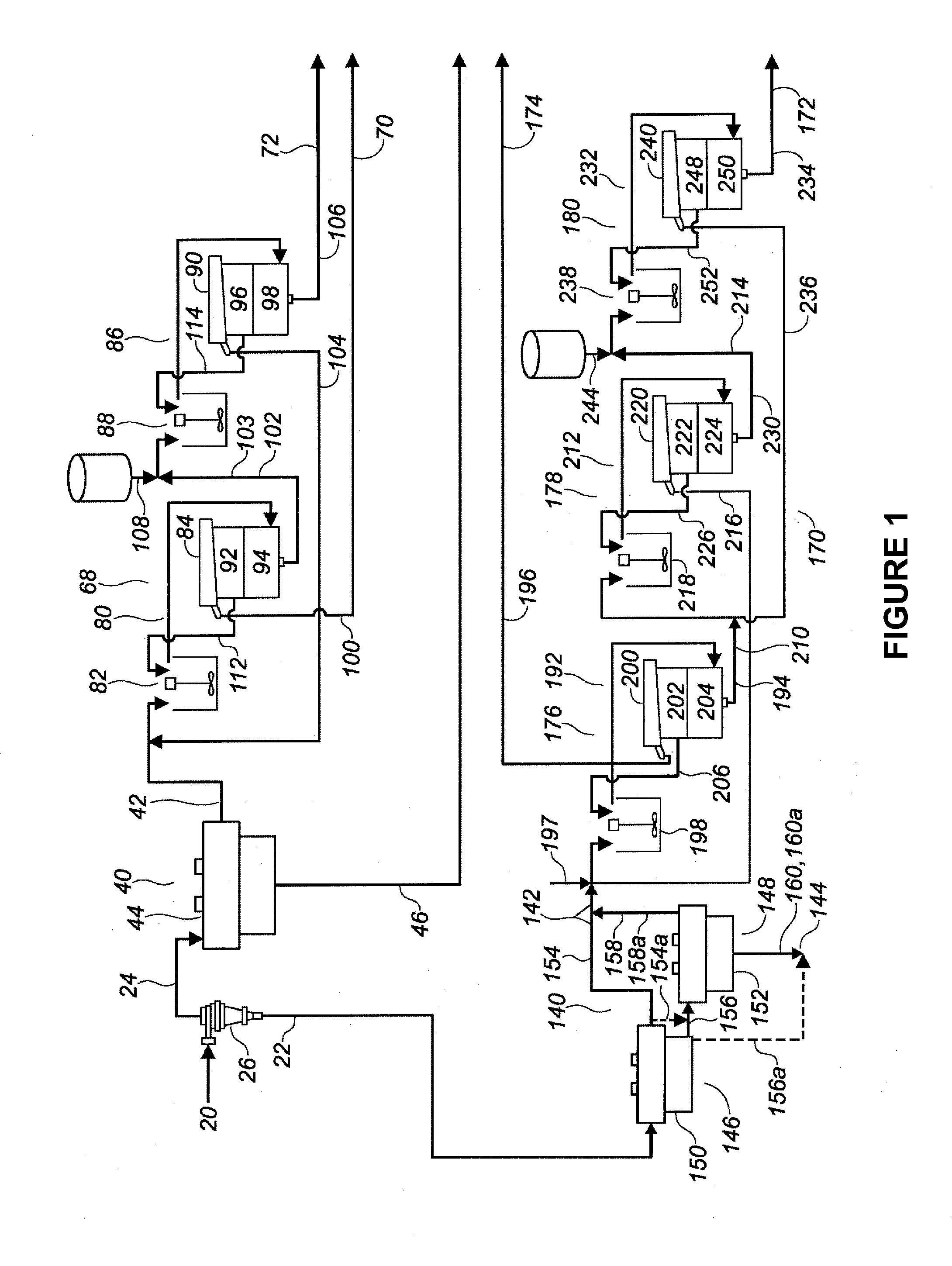

Automatic sampling and dilution apparatus for use in a polymer analysis system

Owner:THE ADMINISTRATORS OF THE TULANE EDUCATIONAL FUND

Stent fabrication via tubular casting processes

ActiveUS8206636B2Improve ductilityHigh strengthOrganic active ingredientsPeptide/protein ingredientsPolymer solutionDip-coating

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

Method for separating and purifying effective ingredients in natural product

InactiveCN101797447AHigh purityHigh selectivityIon-exchange process apparatusSemi-permeable membranesAdditive ingredientSolvent

The invention relates to a method for separating and purifying effective ingredients in a natural product. The method comprises the following steps: 1) extracting effective ingredients of the natural product; 2) removing impurities through membrane separation; and 3) purifying through adsorption. The beneficial effects of the invention are as follows: 1) the separation and purification technological processes are considered from an overall perspective, thus making up the defects of membrane separation in the aspect; 2) compared with the traditional 'water extraction and alcohol precipitation' method, the method of the invention uses water as solvent or adds a certain proportion of ethanol according to the characteristics of effective ingredients of the natural product; 3) compared with the ultra-low temperature freezing technology, the method does not adopt the ultra-low temperature state and is more convenient; and 4) compared with the supercritical or subcritical solvent extraction, continuous operation can be realized at room temperature without phase transition course, the technology is simple and is not harsh to devices, the extraction rate is higher, and the final product has high purity.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

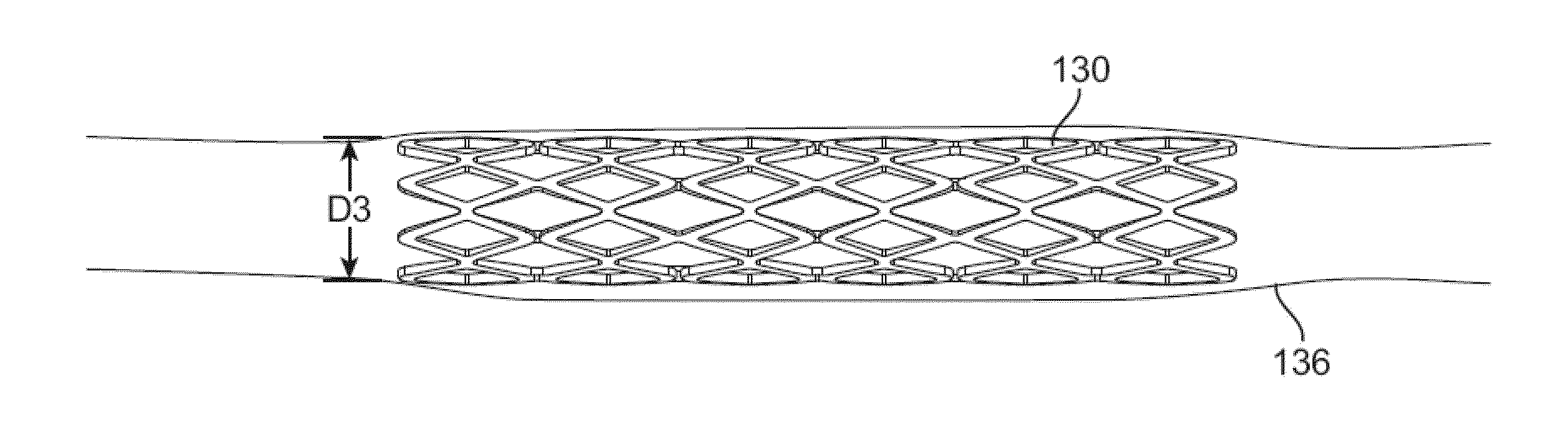

Bioabsorbable stents

InactiveUS20150342764A1Improve mechanical propertiesReduced flexibilityStentsSurgeryDelayed timeEngineering

Tubular casting processes, such as dip-coating, may be used to form substrates from polymeric solutions which may be used to fabricate implantable devices such as stents. The polymeric substrates may have multiple layers which retain the inherent properties of their starting materials and which are sufficiently ductile to prevent brittle fracture. Parameters such as the number of times the mandrel is immersed, the duration of time of each immersion within the solution, as well as the delay time between each immersion or the drying or curing time between dips and withdrawal rates of the mandrel from the solution may each be controlled to result in the desired mechanical characteristics. Additional post-processing may also be utilized to further increase strength of the substrate or to alter its shape.

Owner:RAZMODICS LLC

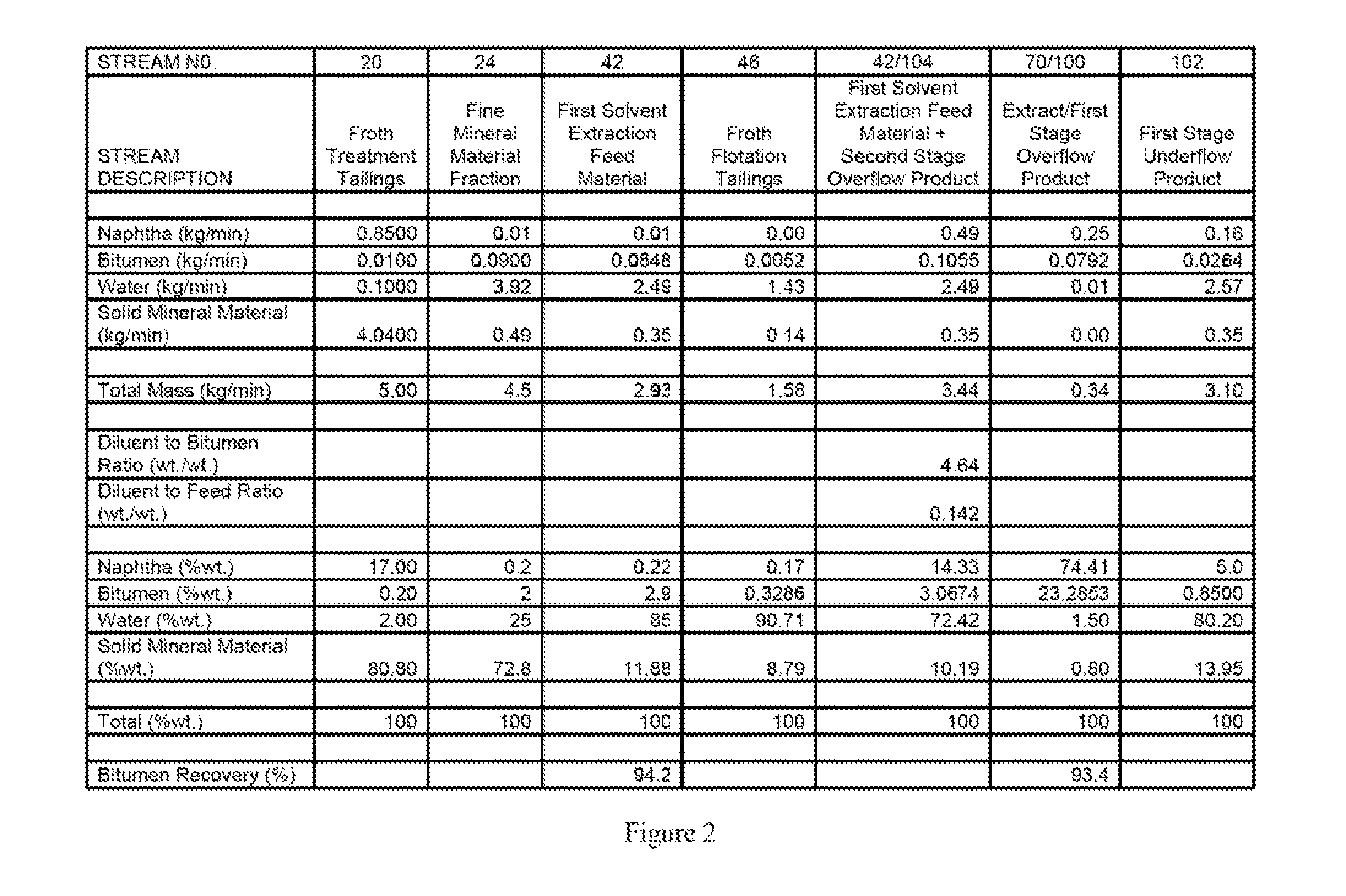

Methods for separating a feed material derived from a process for recovering bitumen from oil sands

ActiveUS20120000831A1Negative effectEasy to separateLiquid hydrocarbon mixture productionFlotationRaffinateSolvent extraction

Separation methods for producing an extract and a raffinate from a solvent extraction feed material, wherein the feed material is derived from a process for recovering bitumen from oil sands. The methods may include producing an intra-stage recycle component from an overflow zone of a solvent extraction stage and recycling the intra-stage recycle component to the solvent extraction stage, and / or the methods may include providing an underflow component withdrawal rate for a solvent extraction stage other than a final solvent extraction stage which is greater than an underflow component withdrawal rate for the final solvent extraction stage.

Owner:TITANIUM CORP

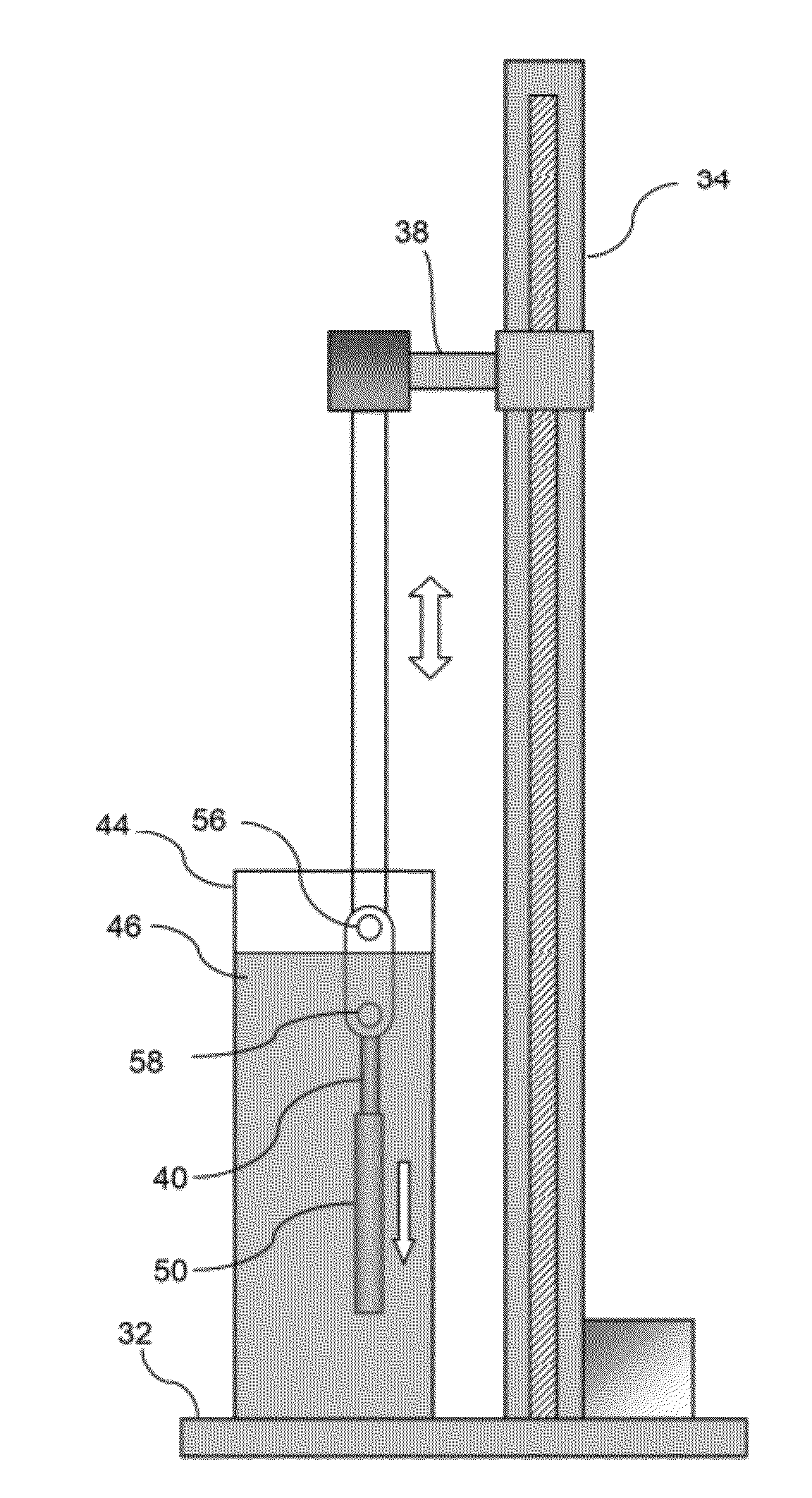

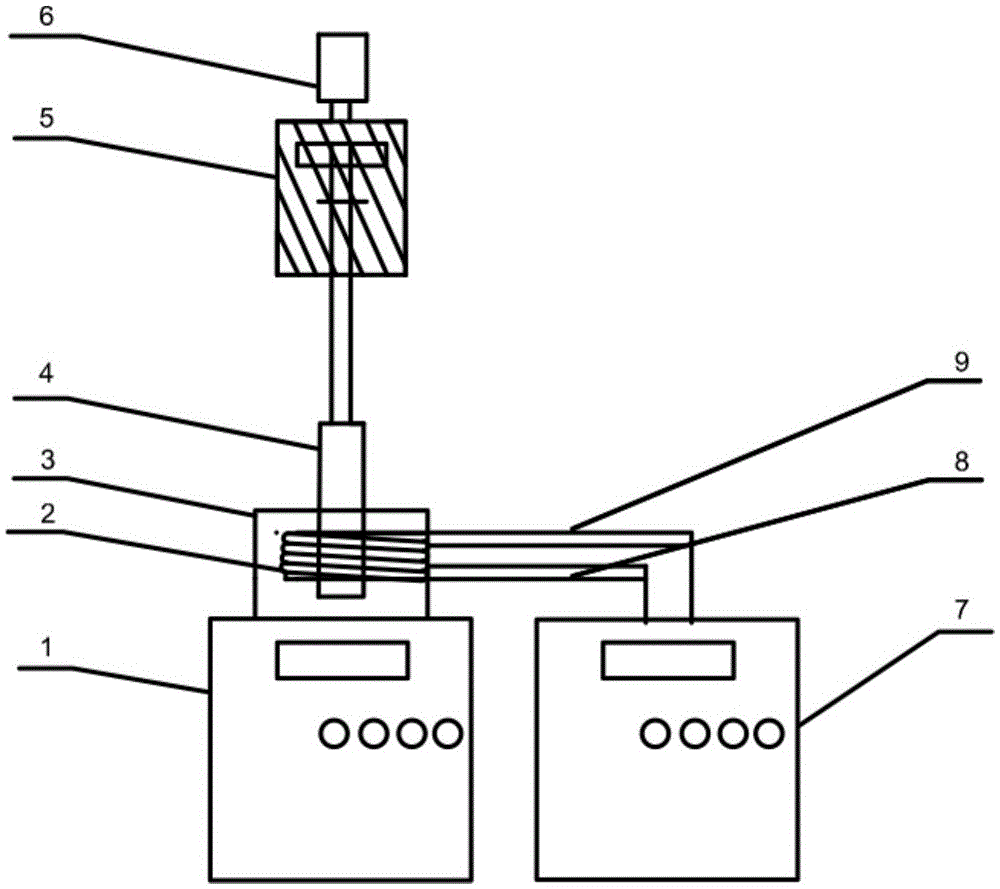

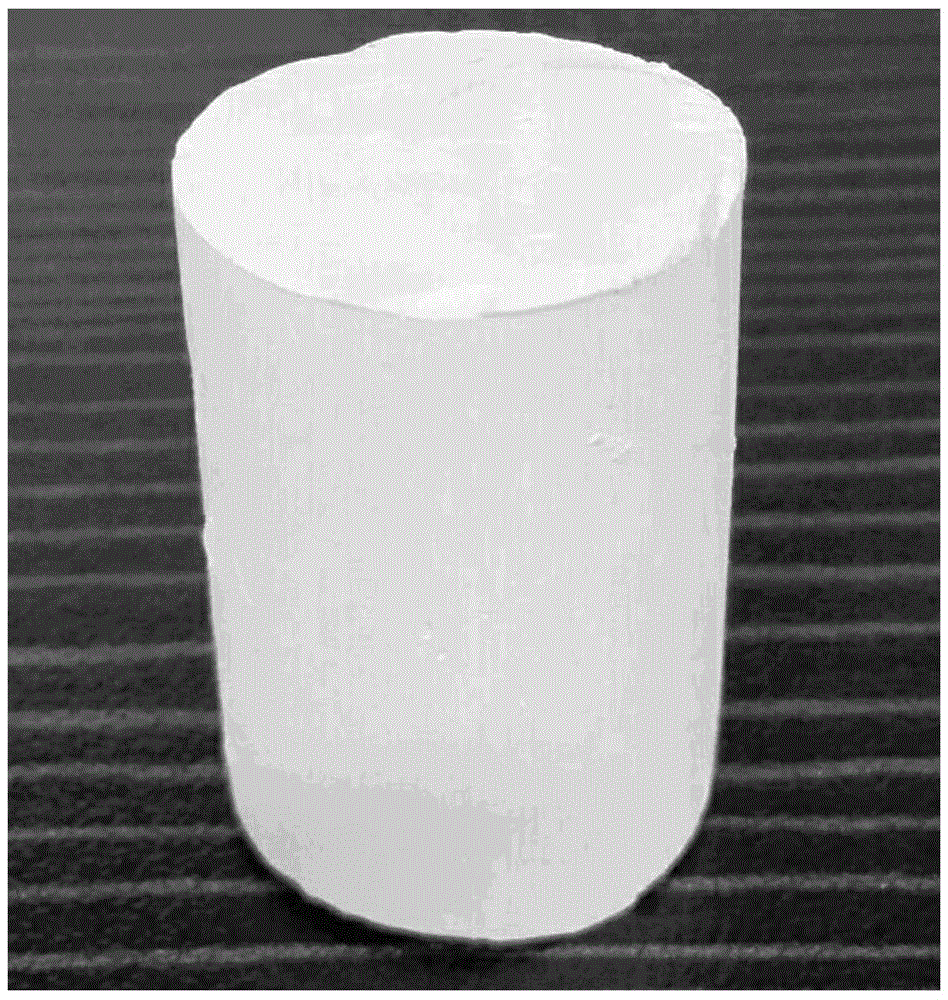

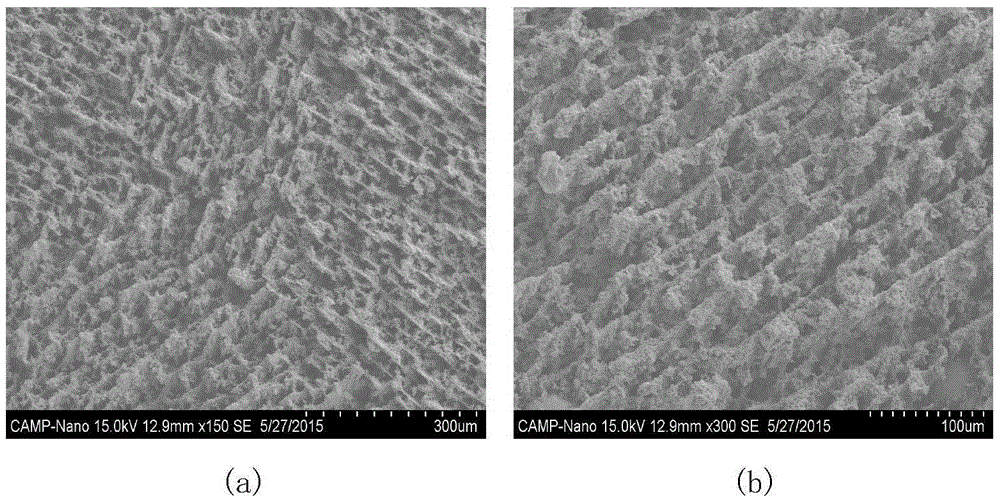

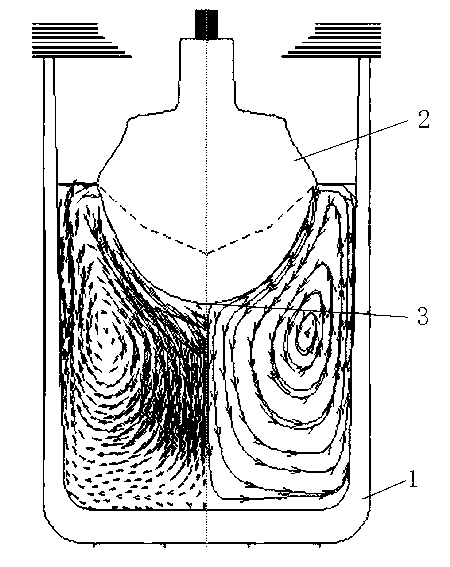

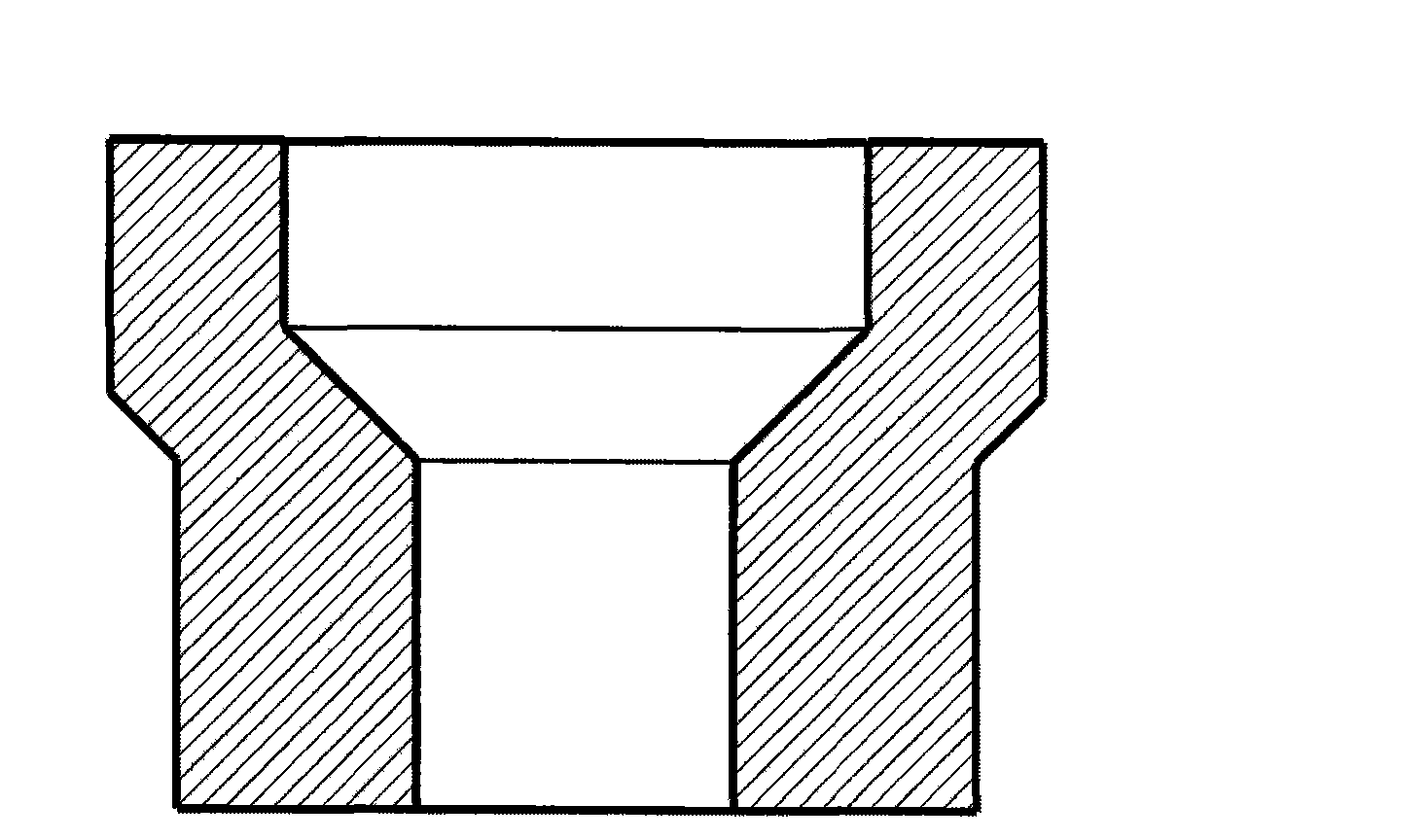

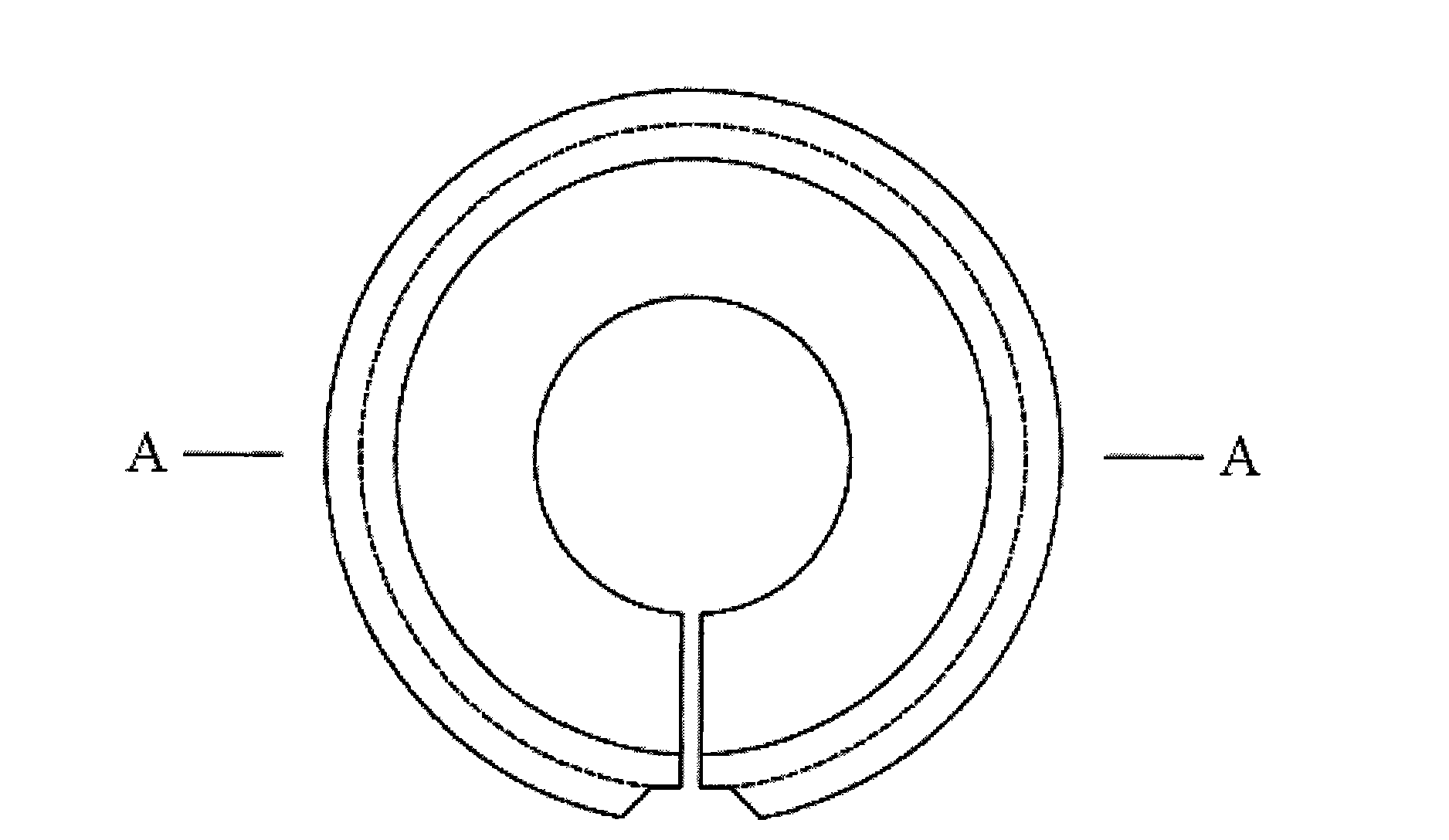

Directional solidification apparatus for preparation of porous ceramics based on ice template method and preparation method thereof

InactiveCN105541369AUniform sizePrecise Control of MorphologyCeramicwareSlurryDirectional solidification

The invention discloses a directional solidification apparatus for preparation of porous ceramics based on an ice template method and a preparation method thereof. The directional solidification apparatus comprises a servo mechanism, a motor, a low temperature circulator, a constant temperature bath and a die. A refrigeration mode with refrigeration at one end and heating at the other end is used for generating a uniform temperature field, the motor and the servo mechanism are controlled for providing a solidification rate which is higher than 500 [mu]m / s, so that a better microscopic structure of the product is provided with better mechanical properties. Two independent technological parameters including temperature gradient and withdrawal rate are regulated separately, so that solidification process of a ceramic slurry is controlled, the regulation and control scope of the withdrawal rate is wide, and the regulated scope is 1-3000 [mu]m / s. A more uniform temperature field is generated by using the high-speed directional solidification method, the cooling rate is higher, the dimension of ice crystal with orientated growth is more uniform, and the porous ceramics with an oriented structure is obtained; form, structure and porosity of the prepared oriented porous ceramic pores are accurately controlled.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

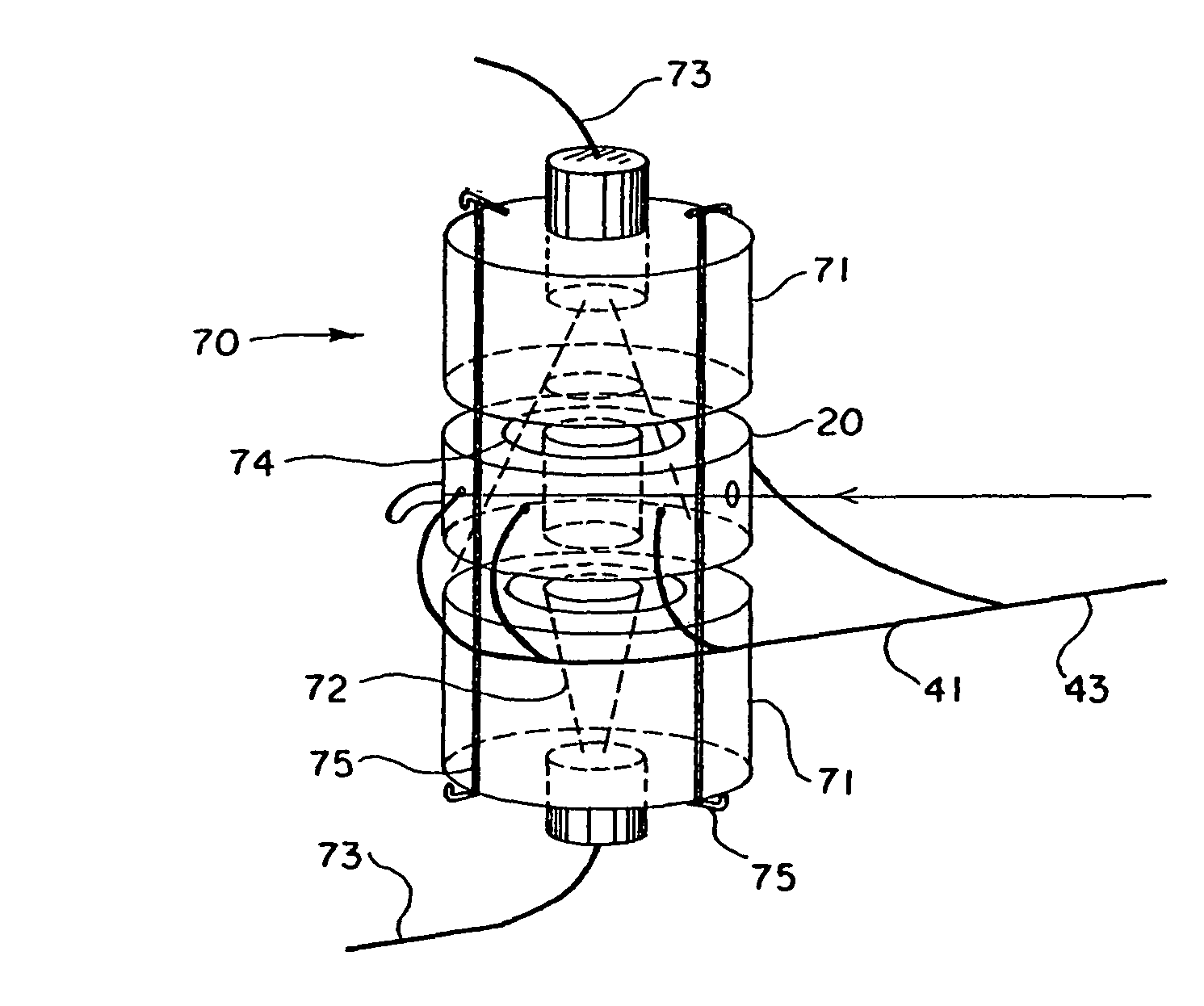

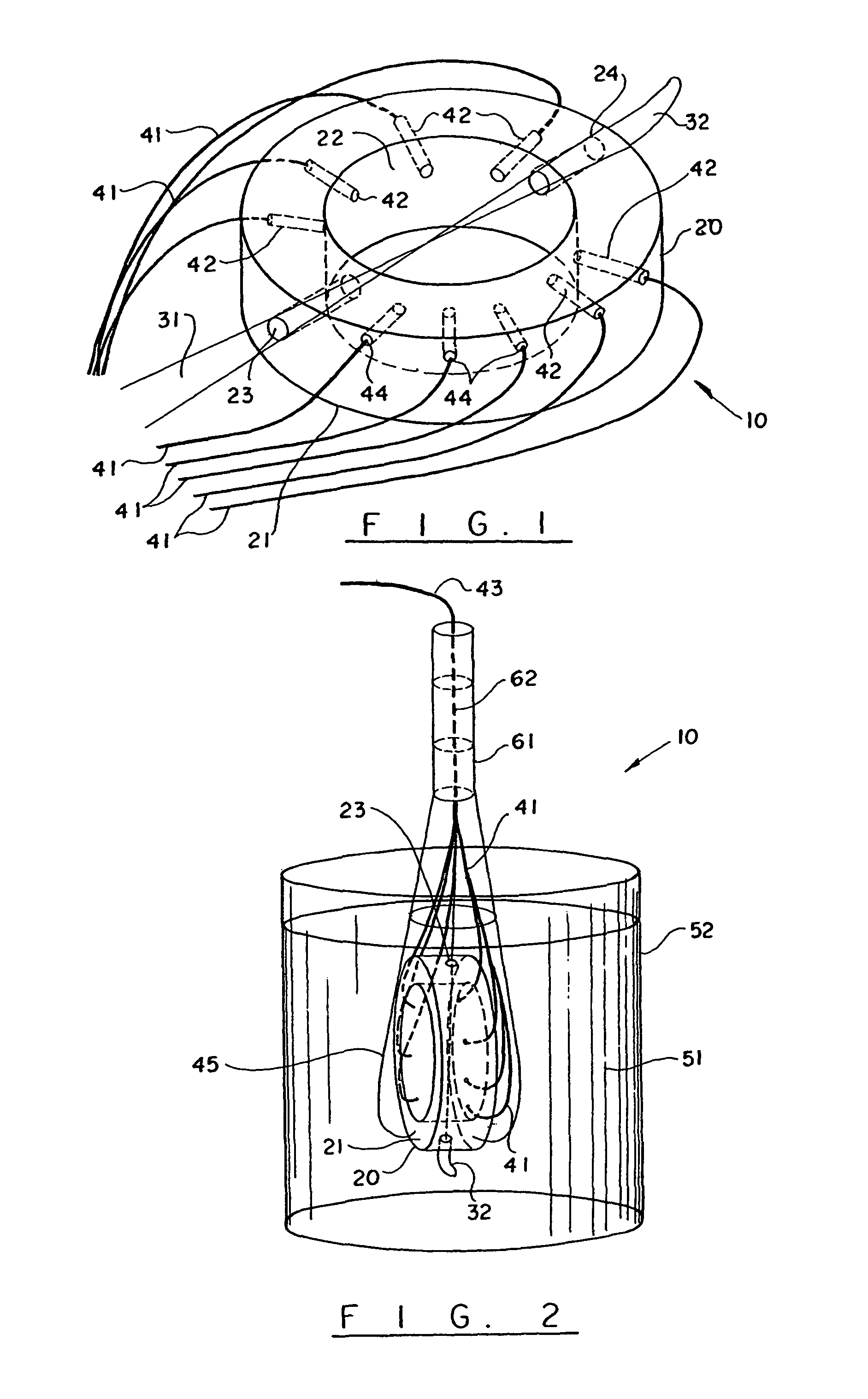

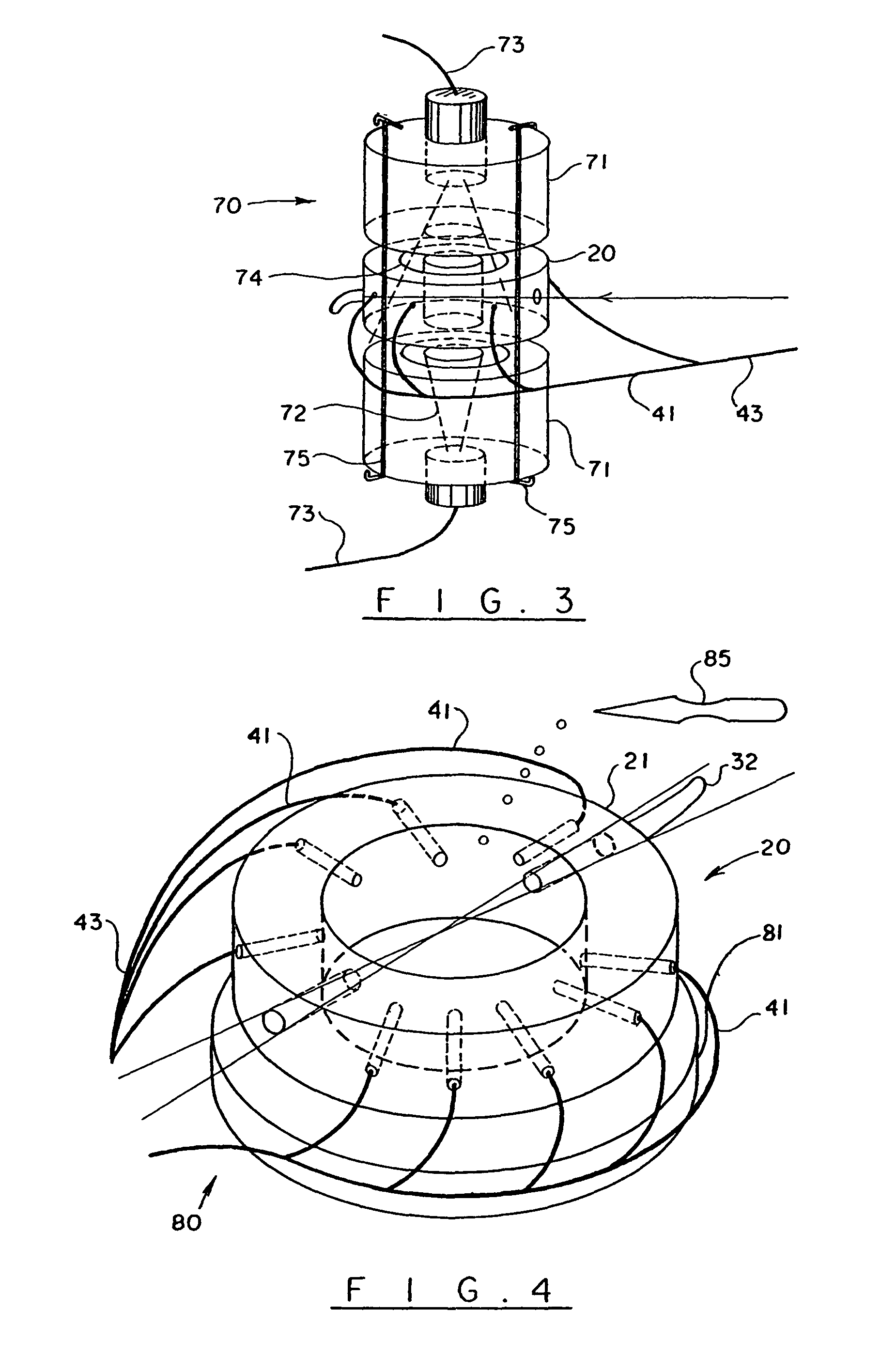

Automatic sampling and dilution apparatus for use in a polymer analysis system

ActiveUS20080008623A1Low viscosityWide versatilitySamplingChemical analysis using titrationEngineeringSolvent

The present invention provides an automatic sampling and dilution apparatus for use in a polymer analysis system. The apparatus comprises (a) a primary mixing chamber; (b) a primary pump capable of continuously withdrawing a variable viscosity liquid from a reactor at a selectable, fixed withdrawal rate over a varying viscosity range of about 50 to about 5,000,000 centipoise (cP) for continuously conveying the variable viscosity polymer-containing liquid into the primary mixing chamber; (c) a first dilution pump for continuously delivering a first dilution solvent into the primary mixing chamber at a selectable, fixed flow rate to mix with the variable viscosity liquid in the mixing chamber and thereby form a diluted polymer-containing liquid therein; and (d) a secondary pump for continuously conveying the diluted polymer-containing liquid into a flow-through detector. A polymer analysis system utilizing the automatic sampling and dilution apparatus is also provided.

Owner:THE ADMINISTRATORS OF THE TULANE EDUCATIONAL FUND

Method for separating parenchyma cells from fibers in bamboo wood

The invention belongs to the field of separation of bamboo wood, and particularly relates to a method for separating parenchyma cells from fibers in bamboo wood. Currently, in industrial utilization of the bamboo wood, bamboo fibers are mainly used, and parenchyma cells are processed as waste, not only are resources wasted, but also the environment pollution problem is caused. According to the provided physical method for quickly separating the bamboo fibers and the parenchyma cells in an environment-friendly mode, the method specifically includes the following steps of 1, smashing; 2, screening; and 3, separation. By means of the separating method, the parenchyma cell extraction rate can reach 85% or so, and the purity can reach 95%. The dispersing media adopted in the method are wide in source, low in cost and easy to obtain.

Owner:INT CENT FOR BAMBOO & RATTAN

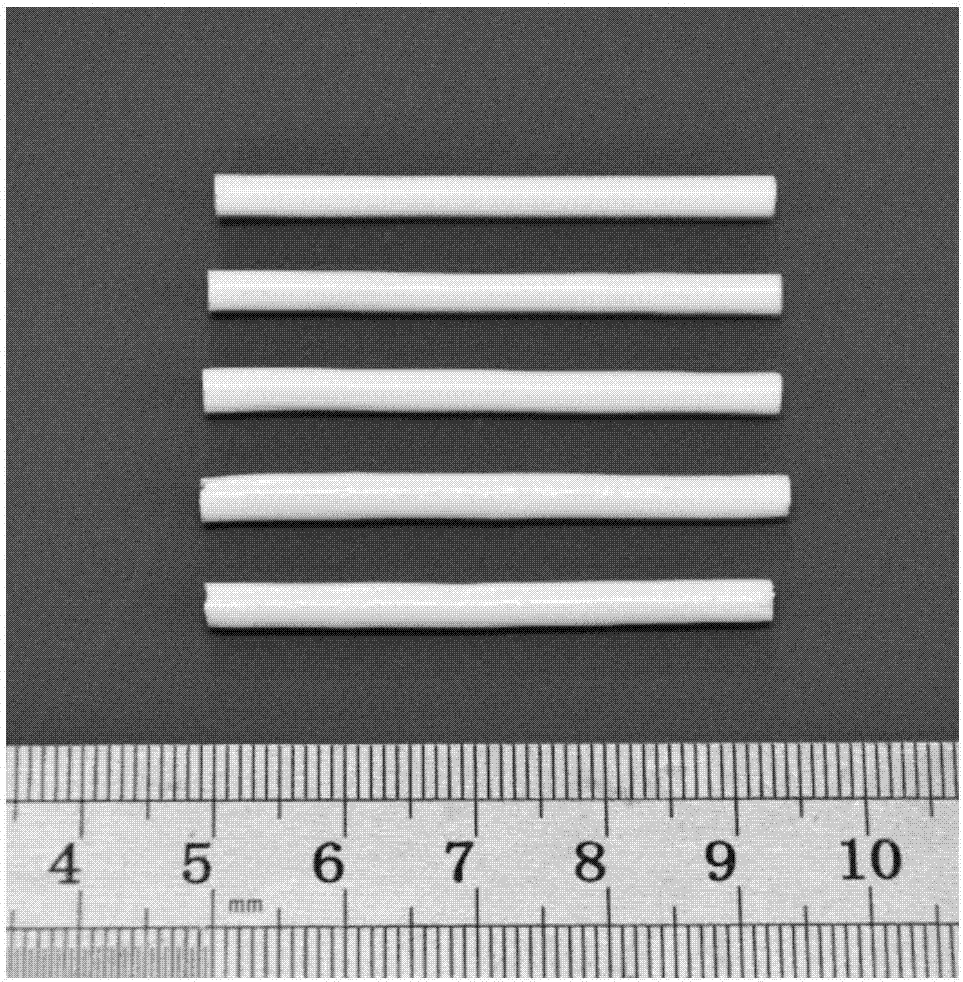

Rotary shoulder technique for growing sapphire crystal by kyropoulos method

InactiveCN103014842AQuality improvementIncrease profitPolycrystalline material growthUsing seed in meltEngineeringCrystal growth

The invention discloses a rotary shoulder technique for growing sapphire crystal by a kyropoulos method. In the sapphire growth process employing the kyropoulos method, the power is reduced to enter the shoulder stage after seeding of the crystal is finished; the crystal is kept in a rotary state at this stage, and meanwhile, the withdrawal rate of the crystal is kept; the diameter of the crystal is gradually enlarged along with an upward pulling process; rotation of the crystal is stopped when the growth weight achieves 8-10% of inventory; and the crystal enters an equant growth stage in a vertical pulling state. By adopting the rotary shoulder technique disclosed by the invention, vortex rotating along with the crystal is formed by flux on a solid-liquid interface along with rotation of the crystal; and an air bubble gathered on the solid-liquid interface is gradually discharged along with flow of the flux. Therefore, the content of the air bubble can be effectively reduced; the quality and the utilization rate of the crystal are improved; crystal sticking on crucible caused by over-quick crystal growth in one direction and uneven temperature field also can be effectively avoided; molding of the appearance of the crystal is facilitated; subsequent crystal manufacturing procedures are facilitated; the stick cutting rate can be improved; and the product usage is also improved.

Owner:江苏国晶光电科技有限公司

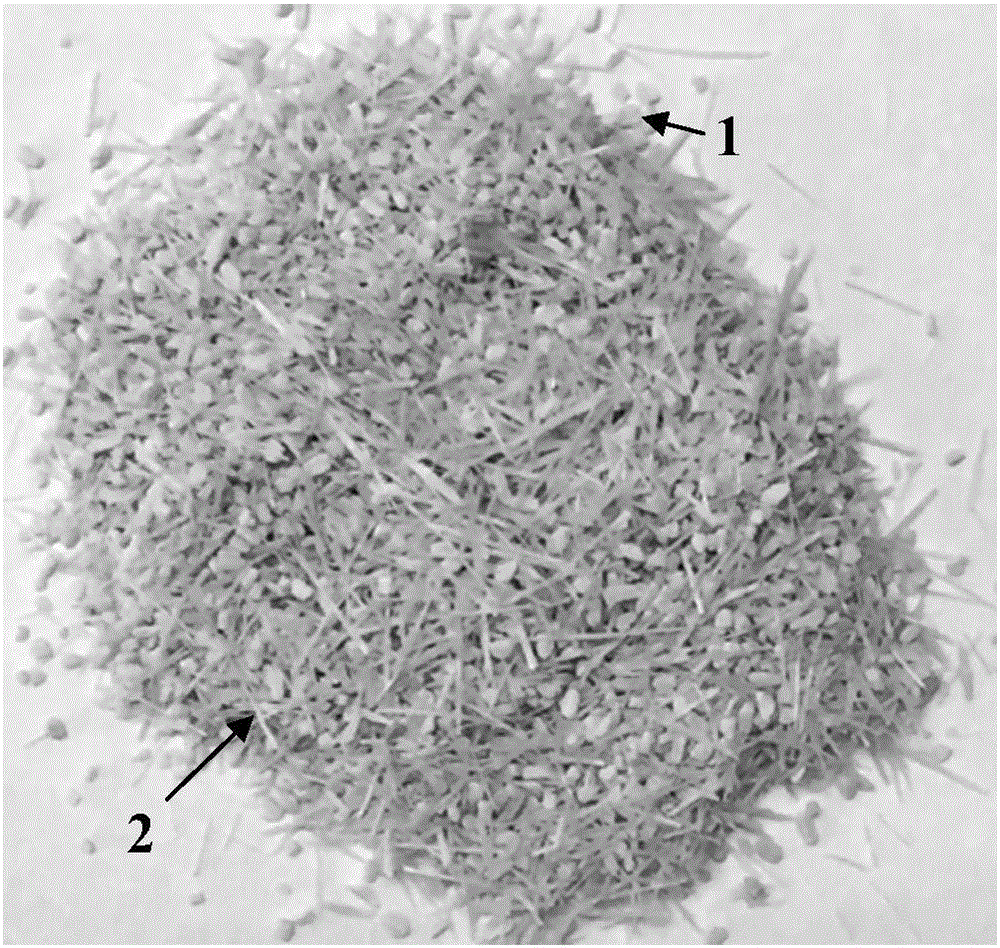

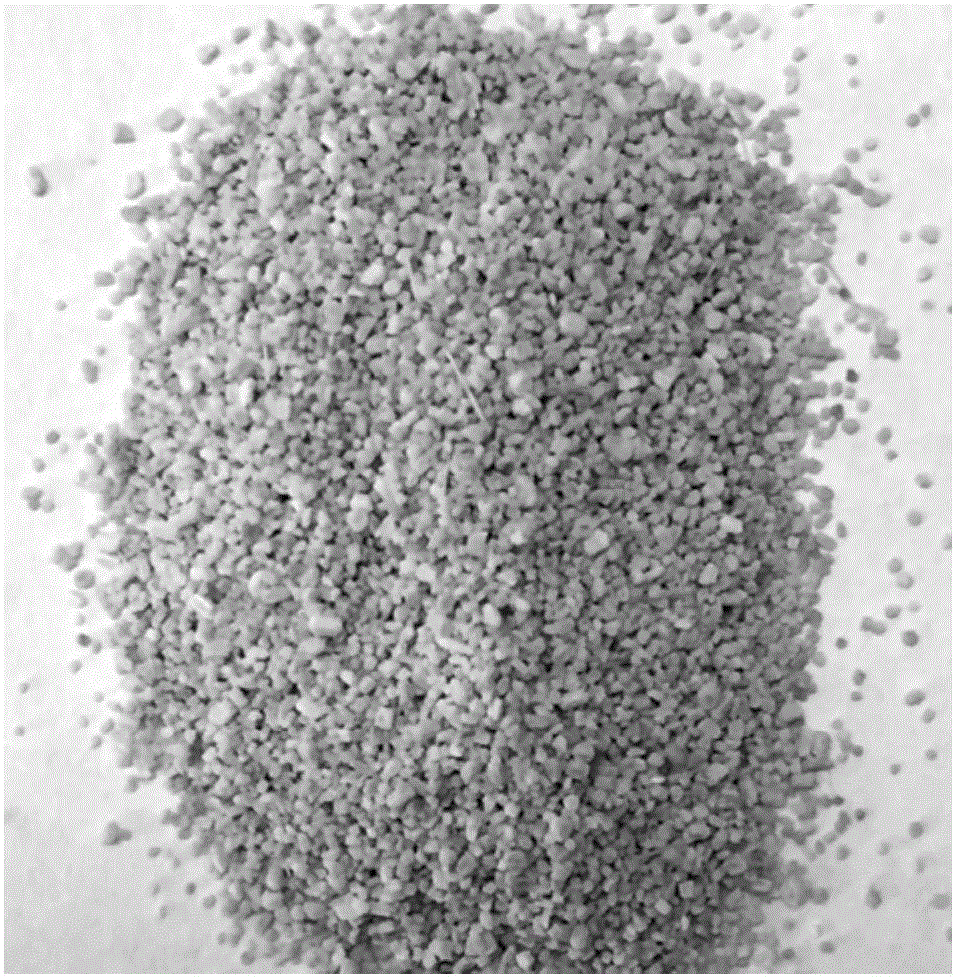

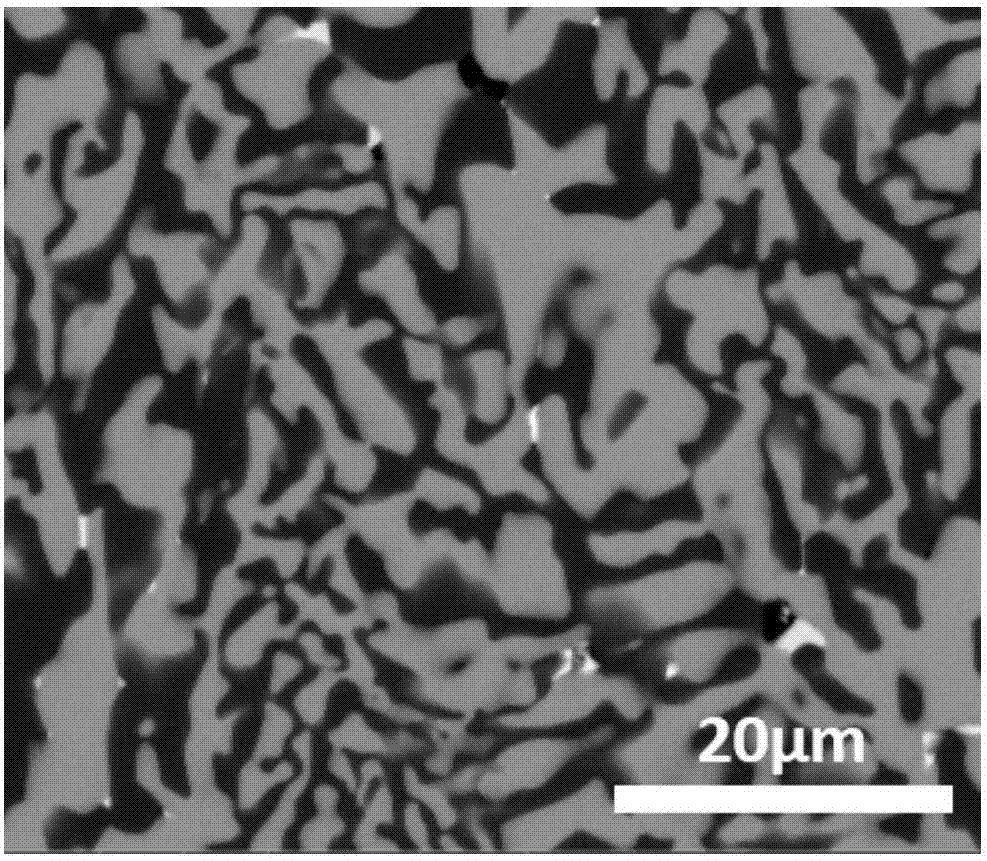

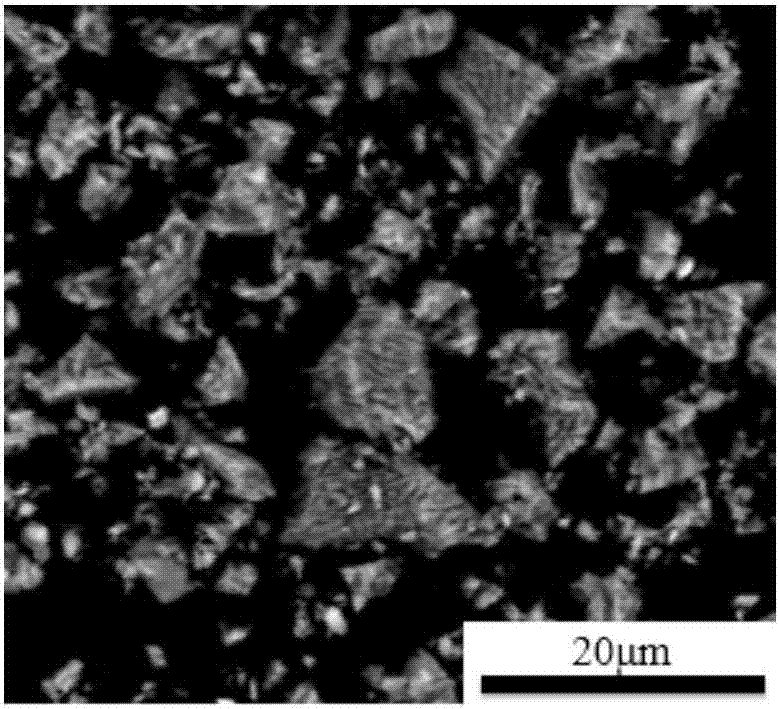

Preparation method of oxidecocrystal structureceramic powder

The invention discloses a preparation method of oxideeutecticstructureceramic powder. The method comprises the following steps: preparing an eutecticmaterial with fine and uniform tissue through a laser floating zone melting technology, then preserving a microcosmiceutectic structure with strong interface bonding into eutectic powder through crushing and screening, and further preparing eutectic powder with certain particle size distribution, thereby effectively reserving an eutecticstructure in an initial eutectic sample into a sinteredeutectic crystalthrough reasonable collocation of lamellar spaces and eutectic powder particle size of the initial eutectic sample. Theoxideeutecticstructureceramic powder is in a typicaleutectic morphology; eutecticmaterials with different lamellar spaces are obtained by changing the withdrawal rate during a laser floating zone melting process; eutectic powder with differentparticle size distribution is obtained through the combination of the withdrawal rate and ball milling time.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

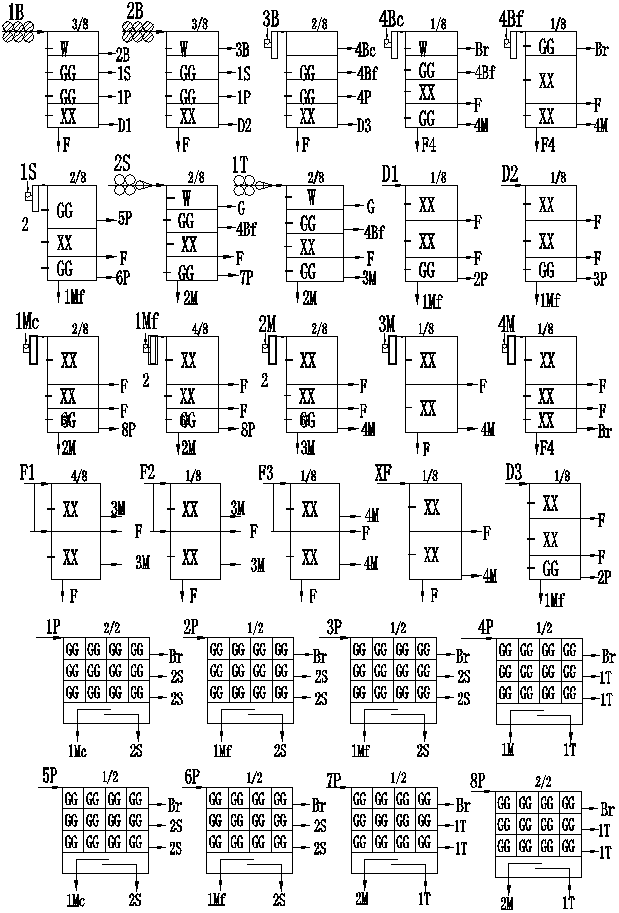

High-efficiency low-temperature wheat squeezing-cutting smashing milling process and milling device

The invention discloses a high-efficiency low-temperature wheat squeezing-cutting smashing milling process which comprises a shelling process, a sizing process, a reduction process, a tail grinding process and a purifying process. In the shelling process, four times of shelling are carried out, in the sizing process, two times of sizing are carried out, and in the reduction process, four times of reduction are carried out; a high-speed squeezing-cutting smashing machine is adopted for the third shelling, a minimum gap between a rotor pin and a stator pin of the high-speed squeezing-cutting smashing machine is 0.3 to 1mm, and a linear speed of the rotor pin on the outermost circle is 30m / s to 70m / s; the high-speed squeezing-cutting smashing machine adopted in the third shelling machines coarse bran flake produced in the second shelling. The invention further discloses a milling device using the high-efficiency low-temperature wheat squeezing-cutting smashing milling process. According to the invention, the milling process is redesigned; the third shelling, the fourth shelling and the first sizing adopt the high-speed squeezing-cutting smashing machine; a reduction system adopts a water-cooling high-speed squeezing-cutting smashing machine; germ extraction is carried out in the second sizing, so that a germ extraction rate of a production line is improved by at least twice, flour accuracy and a total flour extraction rate are improved, investment of the production line is greatly reduced, and original fragrance of the wheat is kept.

Owner:王洪福

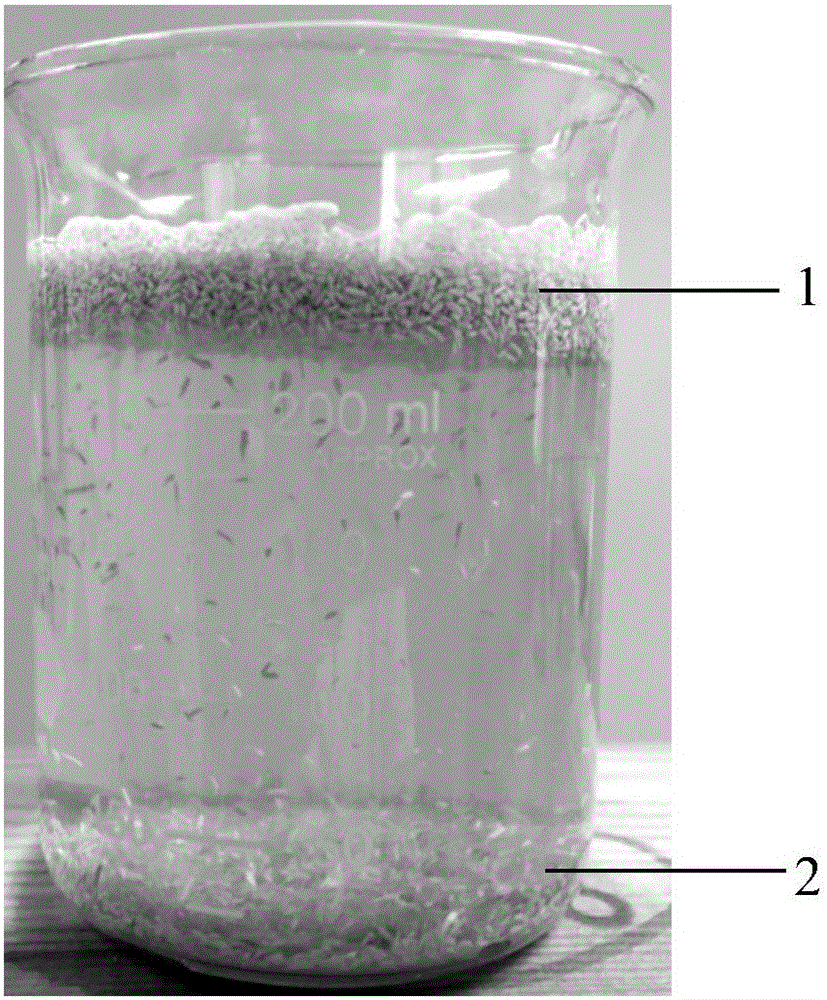

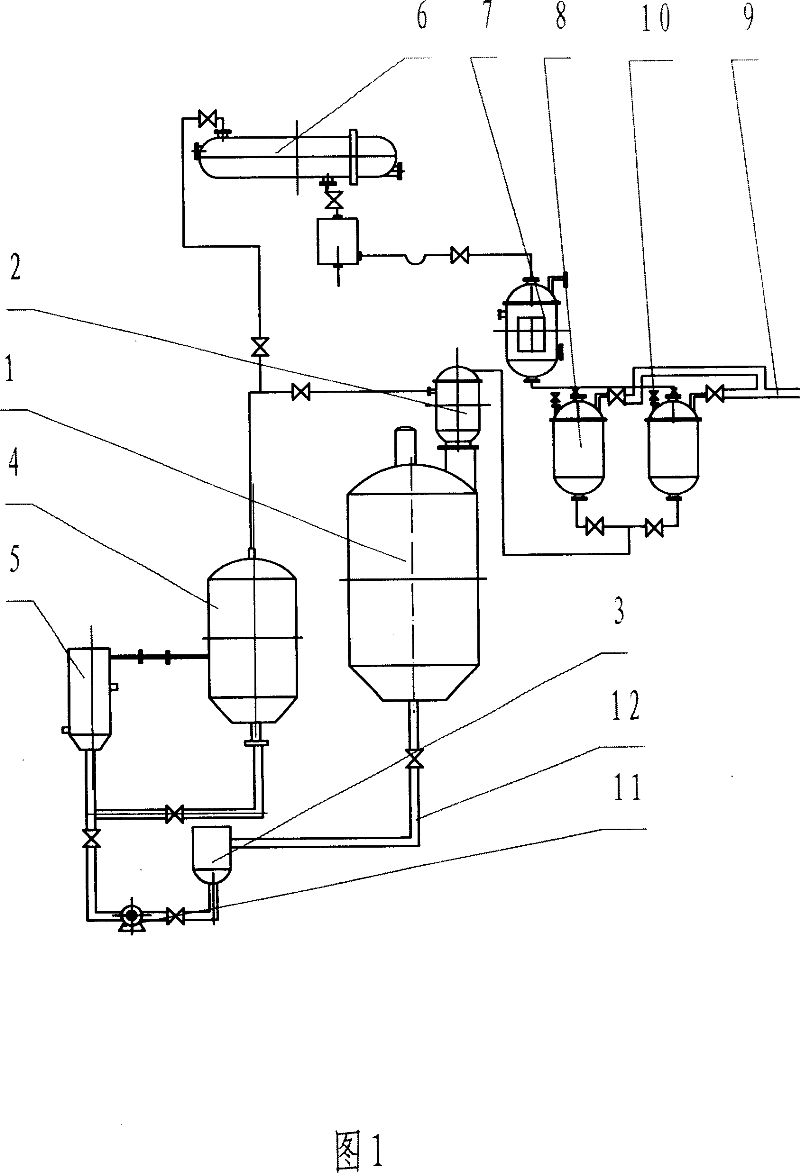

Continuous extracting method of microwave

InactiveCN101041116AQuick extractionEfficient extractionEnergy based chemical/physical/physico-chemical processesSolid solvent extractionChemical industryVacuum pumping

The invention mainly relates to a microwave continuous extraction process, belonging to pharmacy, food and chemical industry so on, which extracts material in microwave and evaporates and concentrates it in single-effect external cycle. It comprises a microwave extraction equipment (1), a collector for air foam (2) for collecting the foam generated in heating process to material, a filter (3) at the bottom of microwave extraction equipment (1), a concentration heater (5) connected with the filter (3) through a transporting pipe (12), a concentration and evaporation room (4) for heated extraction liquid by pressure and concentration differences, a cooling system (6), an oil-water separator (7) for cooling the gaseous available component and collecting aromatic stem oil material, a liquid storage tank (8), a vacuum pumping system (9) and a blow-off valve (10) set on the liquid storage tank (8). The whole extraction and concentration process is continuous and at the same time so that producing time, energy source and manpower are saved greatly. It is provided with high extraction rate, low using cost and it is the most advanced extraction and concentration process. It can extract continuously and also extract in cold-hot reflux.

Owner:TIANSHUI HUAYUAN PHARMA EQUIP TECH

Process for producing methane from biomass

InactiveUS20120094350A1Increase ratingsAvoid adjustmentBioreactor/fermenter combinationsBiological substance pretreatmentsVolatile fatty acidsMethanogenesis

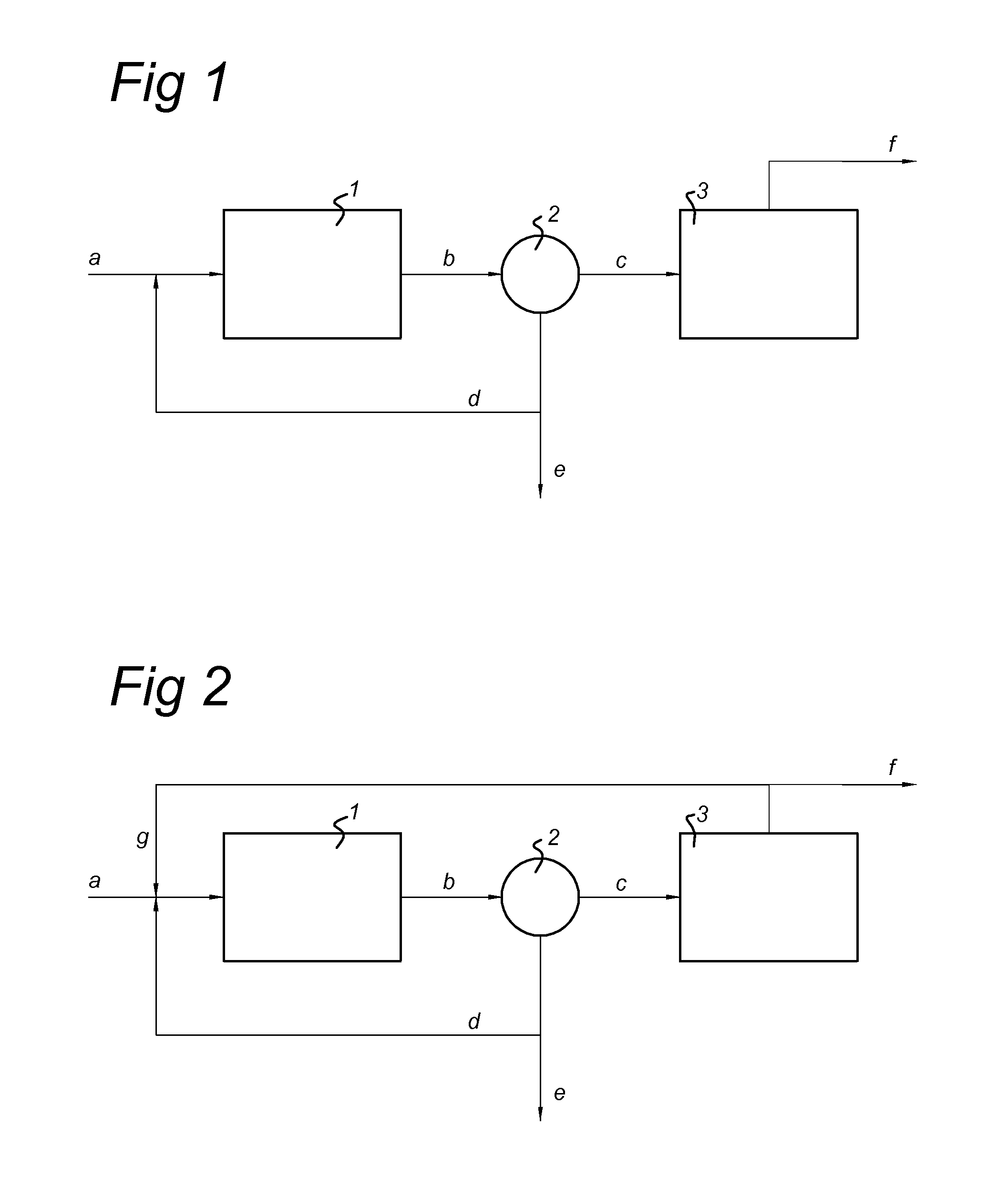

The invention pertains to a process for producing methane by a two-stage anaerobic digestion of organic feed, comprising i) subjecting an organic feed suspension (a) to acidogenesis and methanogenesis in a first reactor (1); ii) withdrawing an effluent (b) from said first reactor and subjecting it to solid / liquid separation (2), thus obtaining effluents high (d) and low (c) in solids, wherein the volatile fatty acid (VFA) concentration in said first reactor is controlled by the withdrawal rate; iii) subjecting the effluent low in solids (c) to acidogenesis and methanogenesis in a second reactor (3), thus producing methane gas in said first and second reactor.

Owner:KONINK COOPERATIE COSUN U A

Unidirectionally-solidification process and castings formed thereby

InactiveUS20130022803A1Minimizes gradientExceed in length and cross-section and weightPropellersPump componentsCrystal structureDirectional solidification

A process capable of producing large metallic castings having lengths of one hundred centimeters or more and a unidirectional crystal structure substantially free of freckle defects. The process includes preheating a mold within a heating zone of a directional casting apparatus, pouring a molten metal alloy into a cavity of the mold, and then withdrawing the mold from the heating zone, through a heat shield, and into a cooling zone of the directional casting apparatus to directionally solidify the molten metal alloy within the cavity. The heating and cooling zones establish an axial thermal gradient that defines a solidification front in the molten metal alloy within the cavity. The mold is withdrawn at a withdrawal rate that, in combination with the axial thermal gradient, causes the solidification front to be substantially flat and perpendicular to the withdrawal direction.

Owner:GENERAL ELECTRIC CO

High temperature gradient low melt flow electromagnetic induction heating device

InactiveCN101636015AFully meltedShielded forced stirringFurnaces without endless coreInduction heatingLeading edge

The invention relates to a high temperature gradient low melt flow electromagnetic induction heating device, wherein, a high-frequency inductor (4) has two turns with the upper and lower surfaces being inclined planes to form an inner cone; an insulation board (6) is arranged between the two turns of high-frequency inductors and an open circuit groove is arranged along the direction of the radius. The thickness of the inner circle in the high-frequency inductor is one fourth of that of the outer circle; the inner diameter and the outer diameter of one end of a funnel-type graphite heating body (3) are both greater than the inner diameter and the outer diameter of the other end, and a 45-degree inclined plane is used for the transition between a big end and a small end; the inner diameter of the small end of the heating body (3) is greater than the outer diameter of a ceramic crucible (1); the knife edge part of the high-frequency inductor (4) performs compulsory induction heating on the small end of the graphite heating body (3), and high temperature gradient can be obtained at the leading edge of the melt solid / liquid interface; the big end of the graphite heating body (3) performs preheating on a test bar in the ceramic crucible (1), so as to ensure that the test bar can melt and superheat fully under the high withdrawal rate and the high temperature gradient low melt flow can be realized in the directional solidification process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

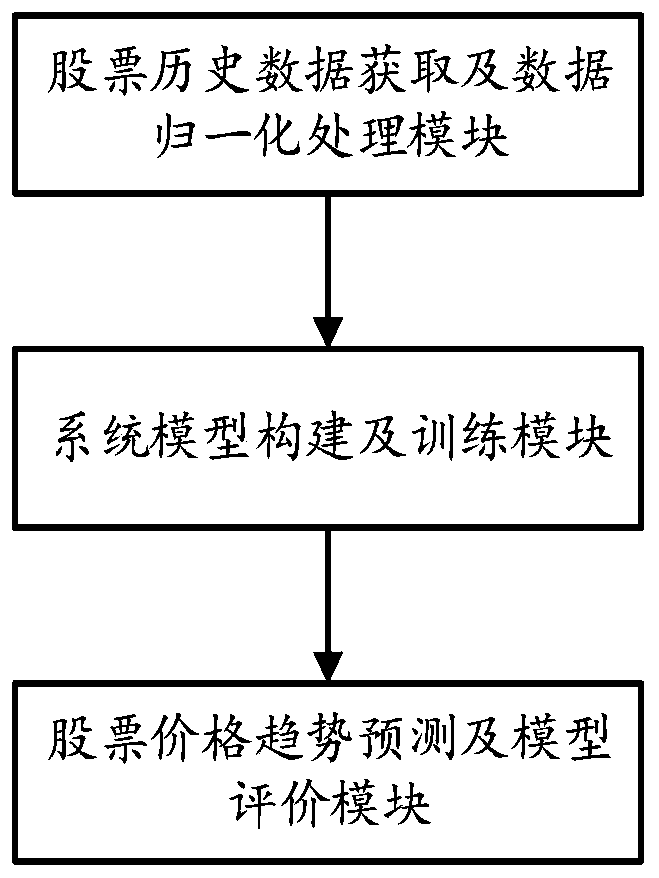

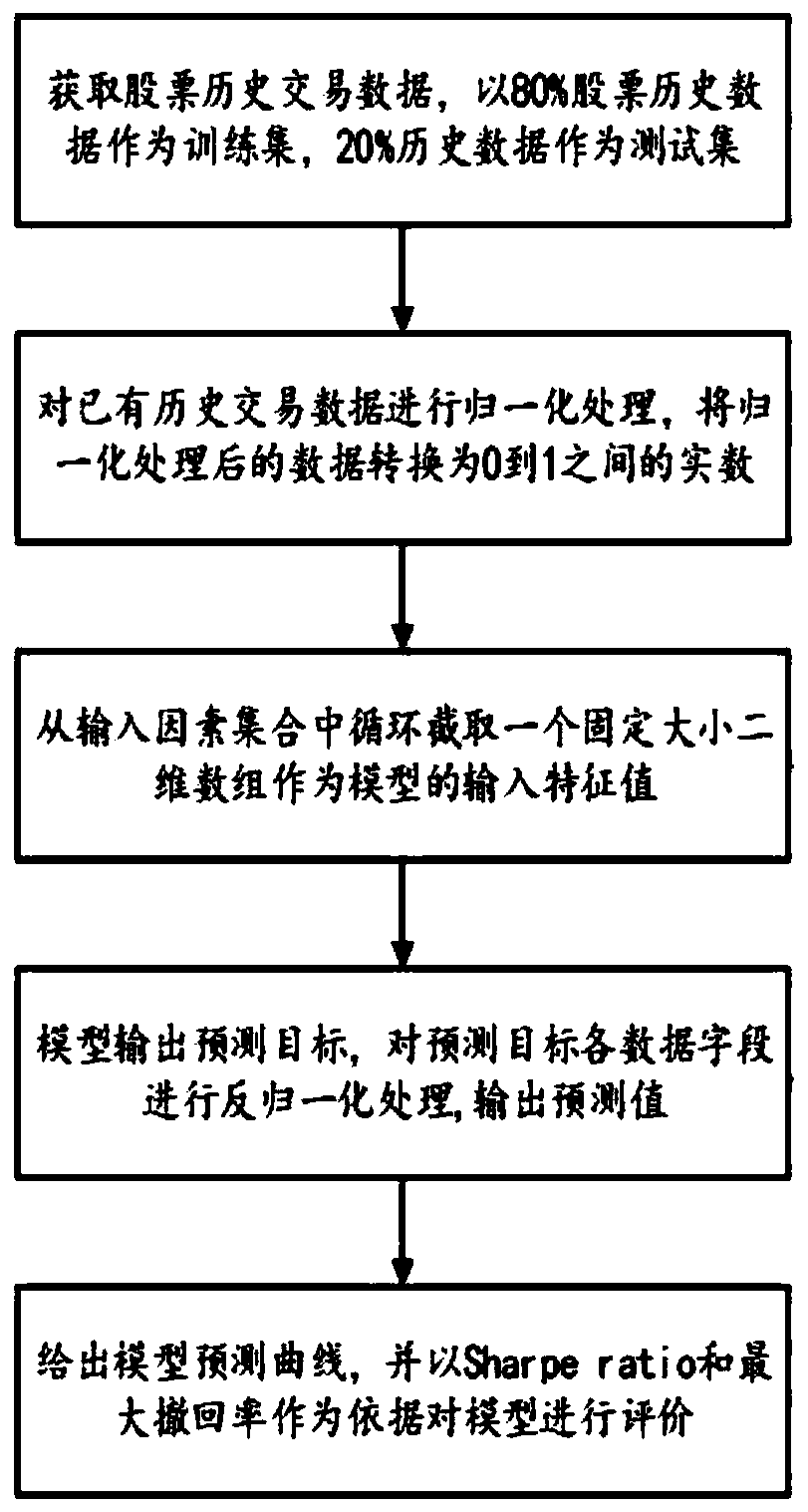

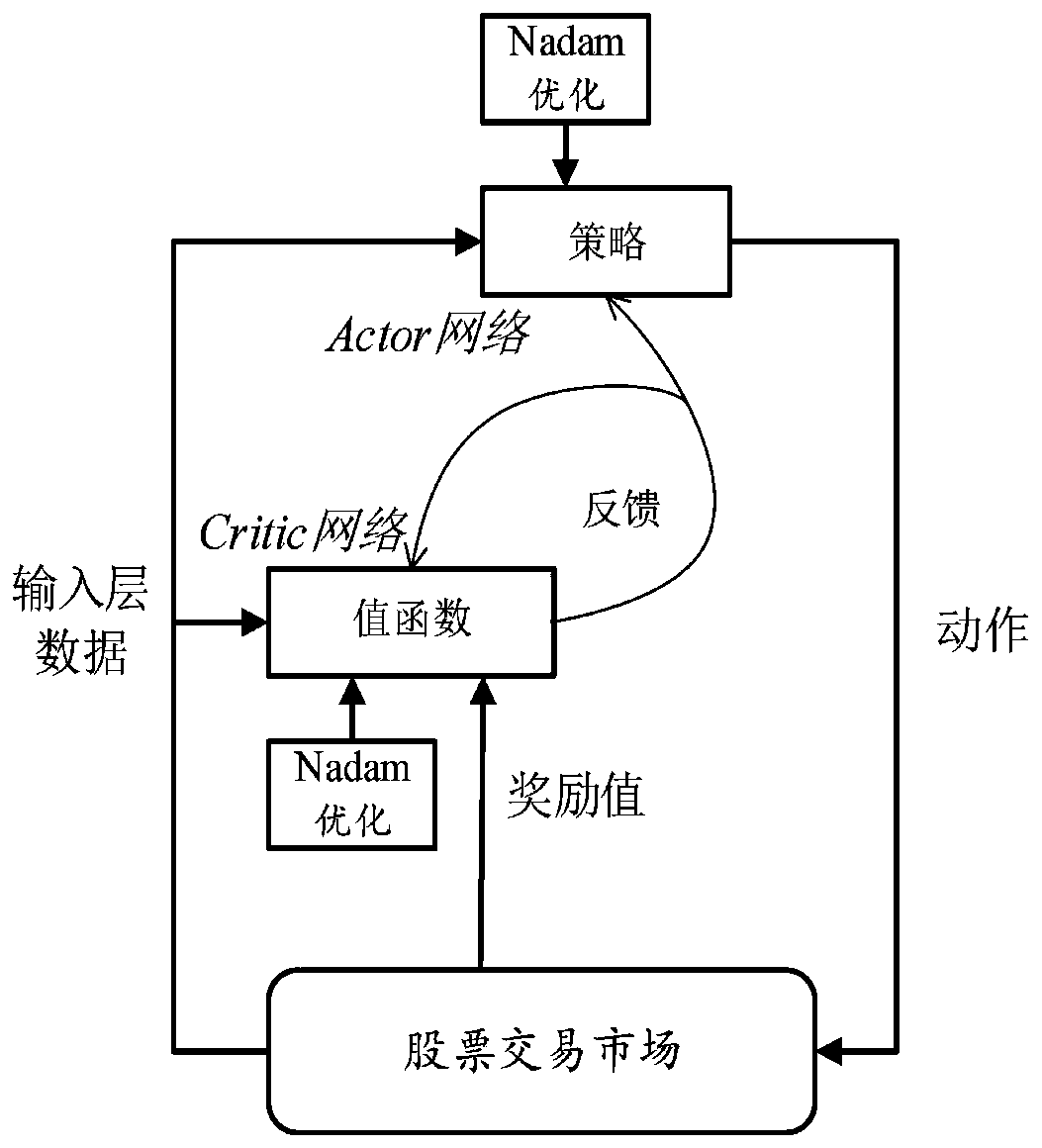

Stock prediction method and system based on reinforcement learning

InactiveCN110059896AReduce riskReduce the impact of noiseFinanceForecastingHidden layerReinforcement learning

The invention discloses a stock prediction method and system based on reinforcement learning, and the method comprises the following steps: a, obtaining the historical data of a target stock, carryingout the normalization processing of the historical data, enabling all kinds of numerical values in the historical data to be zoomed to the same scale, and forming a training set; b, constructing a stock prediction model based on the reinforcement learning theory, wherein the stock prediction model comprises an input layer, a hidden layer and an output layer; inputting the training set into a stock prediction model for training; c, performing stock prediction by using the trained stock prediction model, and evaluating the stock prediction model on the basis of the summer general ratio and themaximum withdrawal rate. The method can achieve the purpose of predicting the stock price trend direction, helps a stock market investor to reduce the risk degree of stock investment, and obtains expected benefits.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Casting method, apparatus, and product

ActiveUS10082032B2Low thermal expansionMore thermally conductiveBlade accessoriesMachines/enginesActive coolingHeating furnace

A casting method and apparatus are provided for casting a near-net shape article, such as for example a gas turbine engine blade or vane having a variable cross-section along its length. A molten metallic melt is provided in a heated mold having an article-shaped mold cavity with a shape corresponding to that of the article to be cast. The melt-containing mold and mold heating furnace are relatively moved to withdraw the melt-containing mold from the furnace through an active cooling zone where cooling gas is directed against the exterior of the mold to actively extract heat. At least one of the mold withdrawal rate, the cooling gas mass flow rate, and mold temperature are adjusted at the active cooling zone as the melt-containing mold is withdrawn through the active cooling zone to produce an equiaxed grain microstructure along at least a part of the length of the article.

Owner:HOWMET CORPORATION

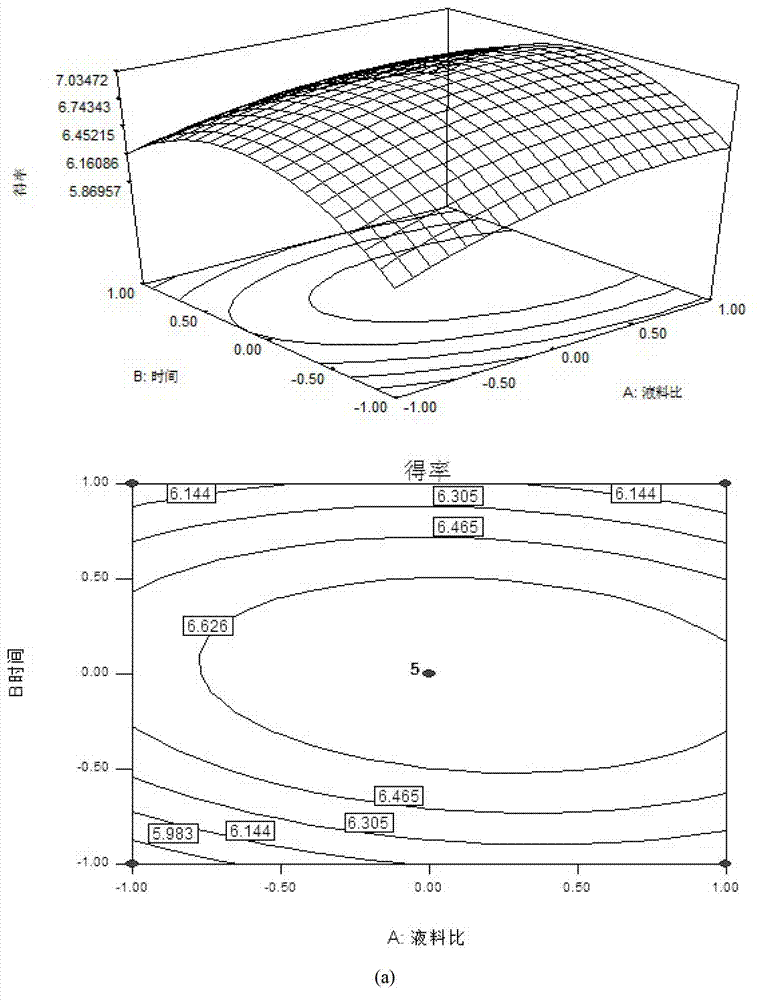

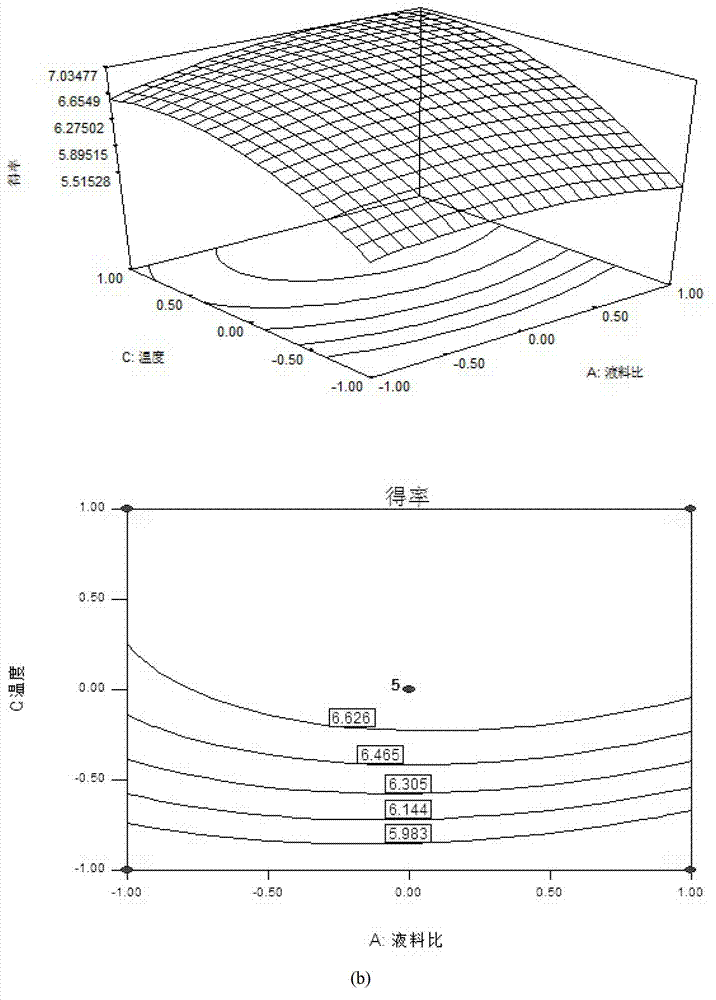

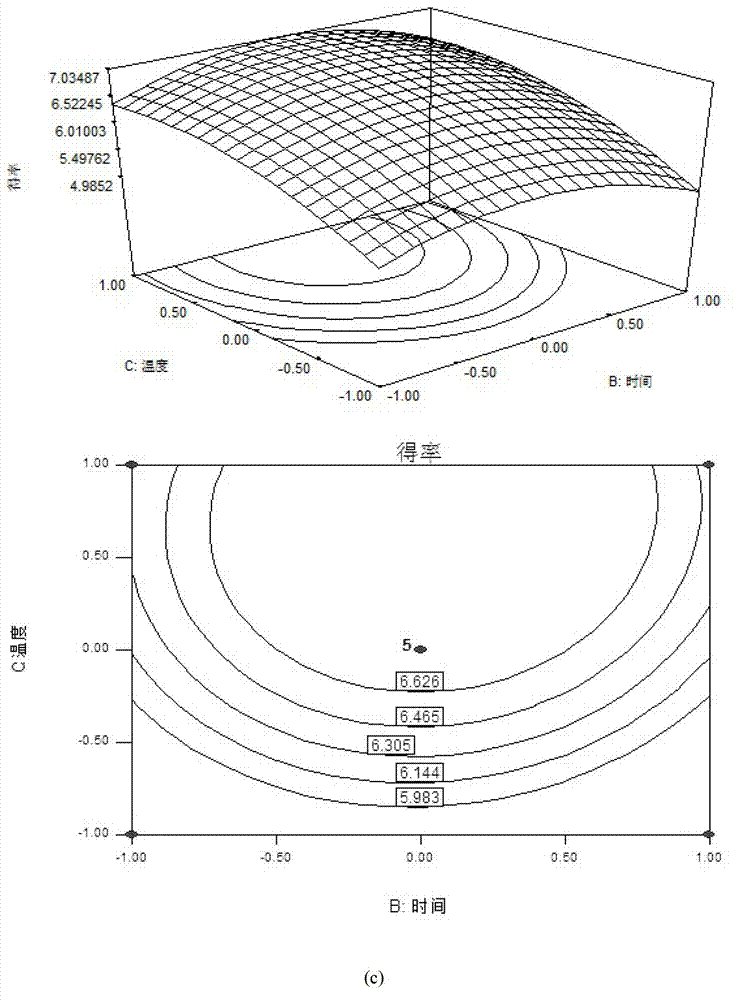

Method for extracting borneol camphor tree leaf crude extract and applied response surface methodology

InactiveCN103083939AHigh extraction rateHigh puritySolid solvent extractionDesign–ExpertLiquid ratio

The invention discloses a method for extracting a borneol camphor tree leaf crude extract. The method comprises the following steps of: mixing borneol camphor tree leaves and petroleum ether according to a material to liquid ratio of the petroleum ether to the borneol camphor tree leaves of 34-36 ml / g, and extracting at the temperature of 48-49 DEG C for 2 to 2.1 hours; and evaporating the obtained extract as the petroleum ether serving as a solvent, thus obtaining the borneol camphor tree leaf crude extract. The invention also provides a method for optimizing the borneol camphor tree leaf crude extract extraction method by response surface methodology. The following three variables are provided, namely the liquid to material ratio of the borneol camphor tree leaves to the petroleum ether, the extraction temperature and the extraction time; and optimization is executed according to Box-Behnken design by using design expert software. By the extraction method, the extraction rate of ice sheets can be increased, and consumption of solvents and resources is reduced, and production and emission of pollutants during production are reduced.

Owner:浙江桐庐百草园中药材开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com