Method for improving recovery efficiency through huff and puffoil recoveryof tight oil fractured horizontal well

A technology for horizontal wells and tight oil, applied in the field of oil production from wells, can solve problems such as low recovery rate, and achieve the effects of low investment cost, obvious production stimulation effect and good economic benefit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

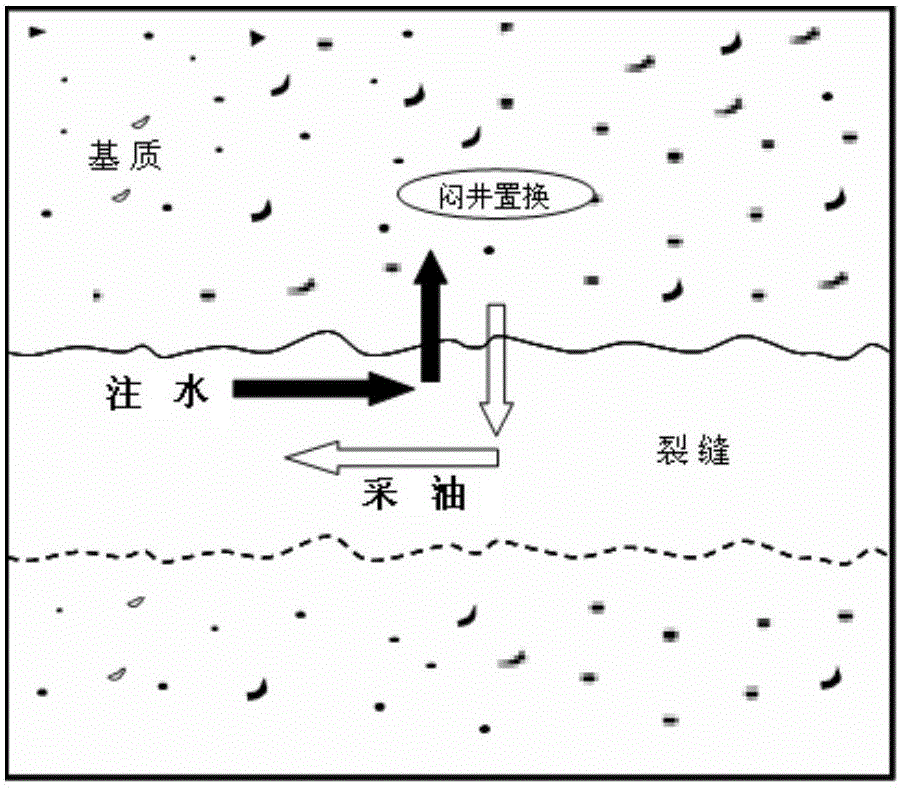

[0039] In order to overcome the problem of low recovery rate of the natural energy depletion development mode in the existing tight oil reservoir fracturing horizontal well development, the present invention provides such figure 1 Shown is a method for improving oil recovery by huff and puff recovery of tight oil fracturing horizontal wells. The invention improves the effect of imbibition flooding in fractured tight oil reservoirs, improves the interpenetration capacity between fractures and matrix in low permeability reservoirs, and increases the The degree of crude oil recovery, the use of horizontal wells after volume fracturing to develop tight oil reservoirs, fully increases the oil-water contact area in artificial fractures and natural fractures in the reservoir, and further improves the overall imbibition of the reservoir The effect of increasing production.

[0040] A method for improving oil recovery by huff and puff recovery of tight oil fracturing horizontal wells, ...

Embodiment 2

[0064] Based on the above embodiments, in this embodiment, the oil reservoir is a single-layer oil reservoir with a thickness of 2-100m; the average permeability of the reservoir matrix is generally less than 0.3mD, the average porosity is 9%, and the average fracture density 0.29 bars / m; the reservoir type is an unsaturated, low-pressure reservoir with no bottom water / gas cap.

[0065] The oil well in the oil reservoir is a horizontal well with a horizontal section of 850m and a well row spacing of 600m; when the oil well is completed, the oil well that undergoes staged volume fracturing after casing cementing is used, and the average fracturing Construction displacement>6m 3 / min, the average interval between fracturing stages is 80-100m.

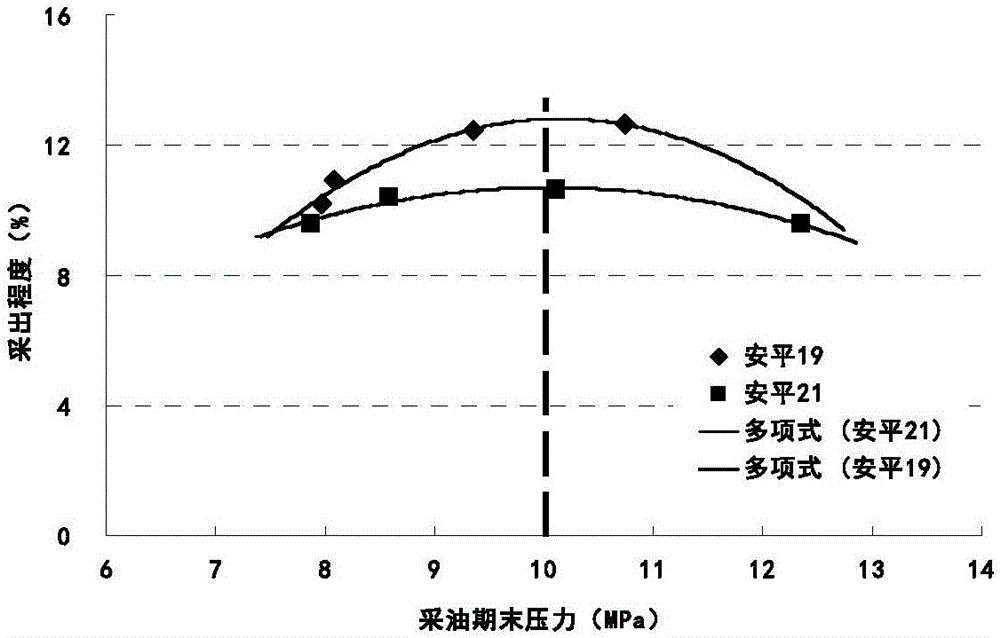

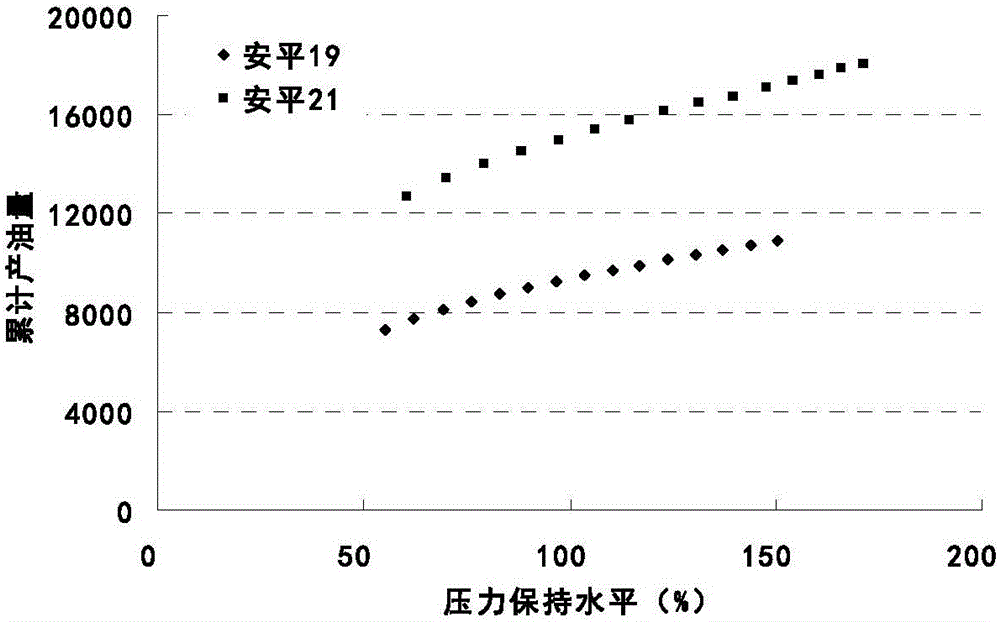

[0066] The pressure at the end of the oil recovery in step 3) is 10 MPa, and the pressure maintenance level is 59%.

[0067] The step 1) is based on numerical simulation research and mineral test analysis, in the water injection stage...

Embodiment 3

[0074]This example mainly focuses on tight oil reservoirs in the Xin'anbian area of the Ordos Basin. This area is one of the tight oil test areas of Changqing Oilfield. The tight oil reservoir is Chang 7 layer, the buried depth of the reservoir is 2190-2570m, and the physical properties of the reservoir are poor (the average porosity obtained by core analysis is 8.9%, and the average permeability is 0.12mD ), the original formation pressure is low (average original formation pressure 15.8MPa, average pressure coefficient 0.81), conventional fracturing vertical wells have low production, and cannot be effectively developed. The head of the district 7 2 The average oil layer thickness of the reservoir is 10m, the porosity of the core analysis is 7%-9%, the average is 8.9%, the permeability is 0.1-0.2mD, the average is 0.12mD, the natural fractures in the reservoir are developed, the average fracture density is 0.29 / m, and the viscosity of the crude oil in the formation is 1.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com