Patents

Literature

85results about How to "Cost has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quenching oil for bearings and preparation method thereof

ActiveCN102140570ASolve for uniformitySolve the problem of not being brightQuenching agentsAntioxidantHardness

The invention relates to the technical field of quenching media in a heat treatment link in bearing production, in particular to quenching oil for bearings and a preparation method thereof. Each 100 weight parts of quenching oil comprises the following components in part by weight: 79 to 98.45 parts of base oil, 1 to 8 parts of cooling accelerant, 0.05 to 5 parts of brightening agent and 0.5 to 8parts of antioxidant. The high-end class II base oil is taken as a raw material, and is added with the cooling accelerant, the high temperature antioxidant and the brightening agent in different proportions to form the quenching oil for the bearings; after the bearings are quenched by the quenching oil, the bearings are uniformly silvery, the structure and hardness of the bearings meet or exceed the requirements of national standard, and the deformation of the bearings subjected to heat treatment is reduced by 30 percent than a standard value; meanwhile, the service life of an oil product is 5 years, and the cost of the oil product used in a factory is reduced. Meanwhile, the quenching oil has the advantages of energy conservation and environmental friendliness, and can improve the quality of industrial products.

Owner:CHANGZHOU LONGPONT LUBRICANTS

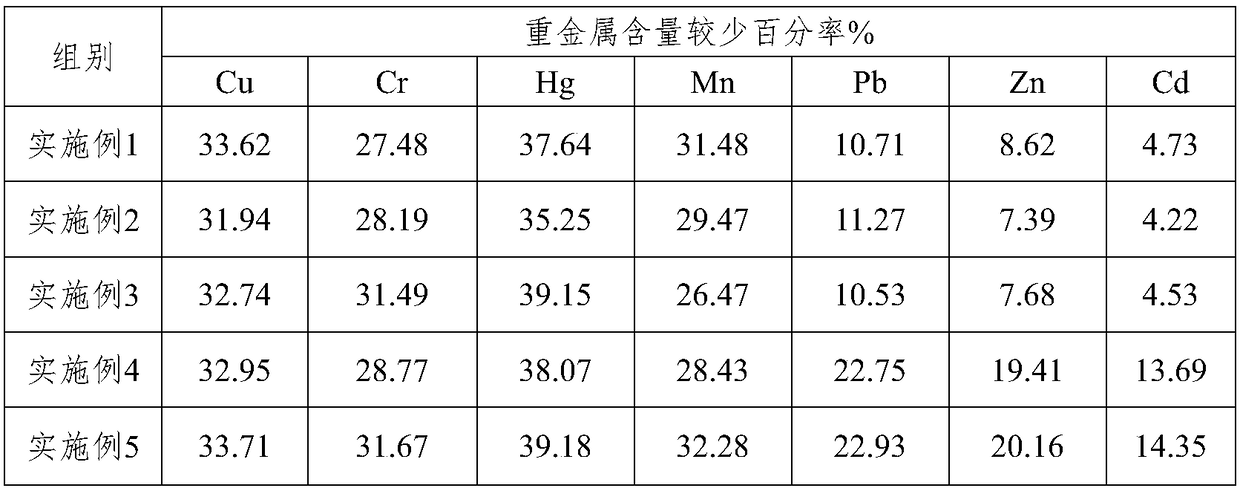

Disease and insect pest resisting high-efficiency fertilizer produced from traditional Chinese medicine residues and production method

The invention relates to disease and insect pest resisting high-efficiency fertilizer produced from traditional Chinese medicine residues and a production method. The technical formula of the fertilizer comprises: 70% of mixed medicine residues, 20% of animal bone protein, 5% of organic humic acid, 5% of polyaspartic acid (PASP), and 1 part of additive which accounts for 0.5% of the raw materials, wherein the additive comprises 40% of composite microorganism agent NSC-7, 30% of yeast, 20% of EM (effective microorganism) strain, 5% of DA-6 (diethyl aminoethyl hexanoate) and 5% of bacillus subtilis. The high-efficiency high-quality fertilizer is prepared by mixing the medicine residues, pulverizing, fermenting, adding microelements, and powdering or granulating. According to the invention, the cost for medicine residue re-treatment is avoided, the fertilizer production cost is lowered, the fertilizer has the function of resisting bacteria, diseases and insect pests, the amount of the nutrients in the fertilizer is greatly improved, the fertilizer has obvious yield increase effect, environmental pollution is reduced at the same time, and certain promotion action on yield increase of foodstuff in China is exerted.

Owner:韦文礼

Low sulfur eleaning fuel capable of substituting petroleum oil

InactiveCN1618933ACost hasReduce the pressure of transformationBiofuelsLiquid carbonaceous fuelsPollutantPetroleum

Owner:闵恩泽 +2

Display glass protection screen with antifogging coat and LCD using same

InactiveCN101236261AWith anti-fogging functionHigh light transmittanceLayered productsVacuum evaporation coatingLiquid-crystal displayDisplay device

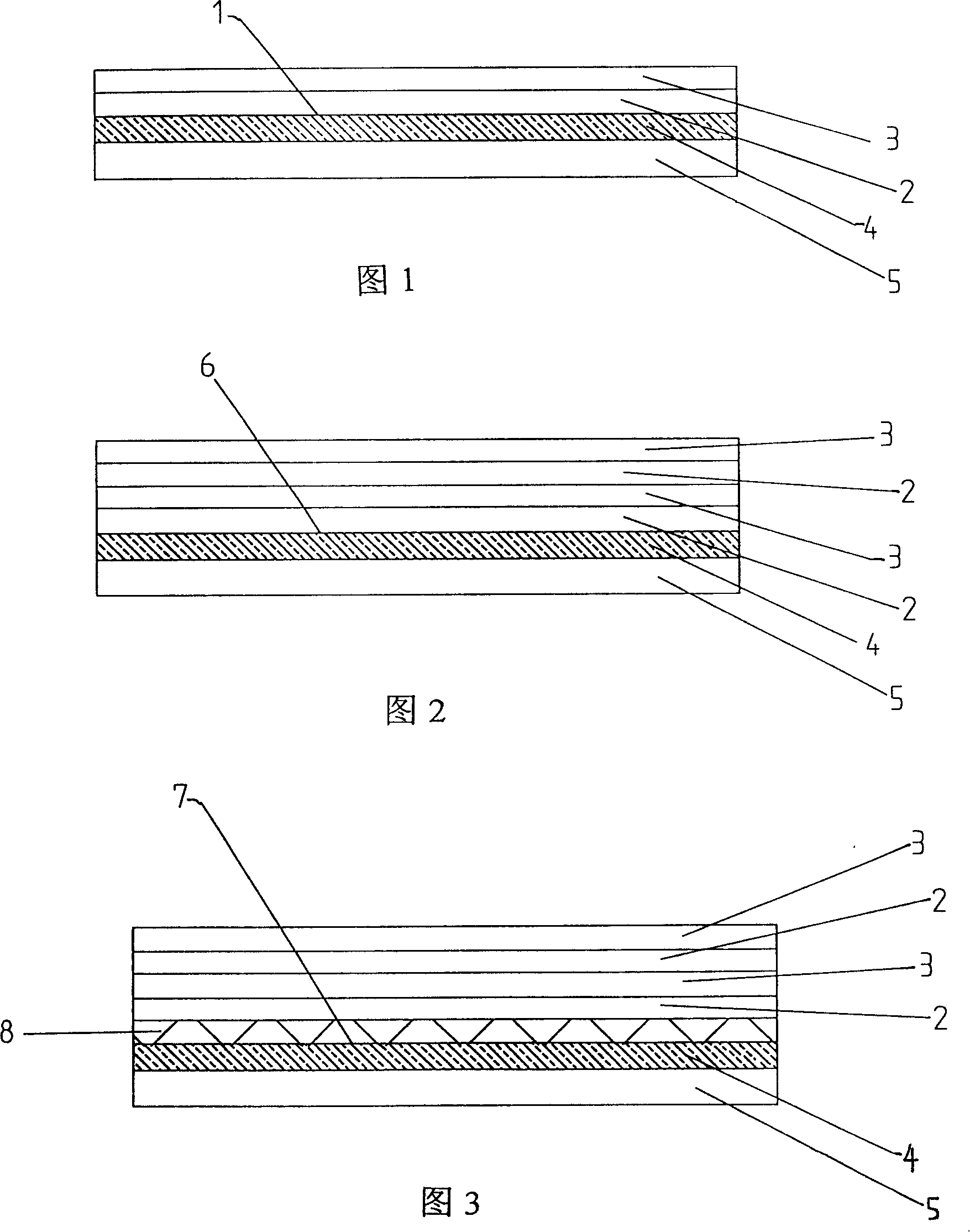

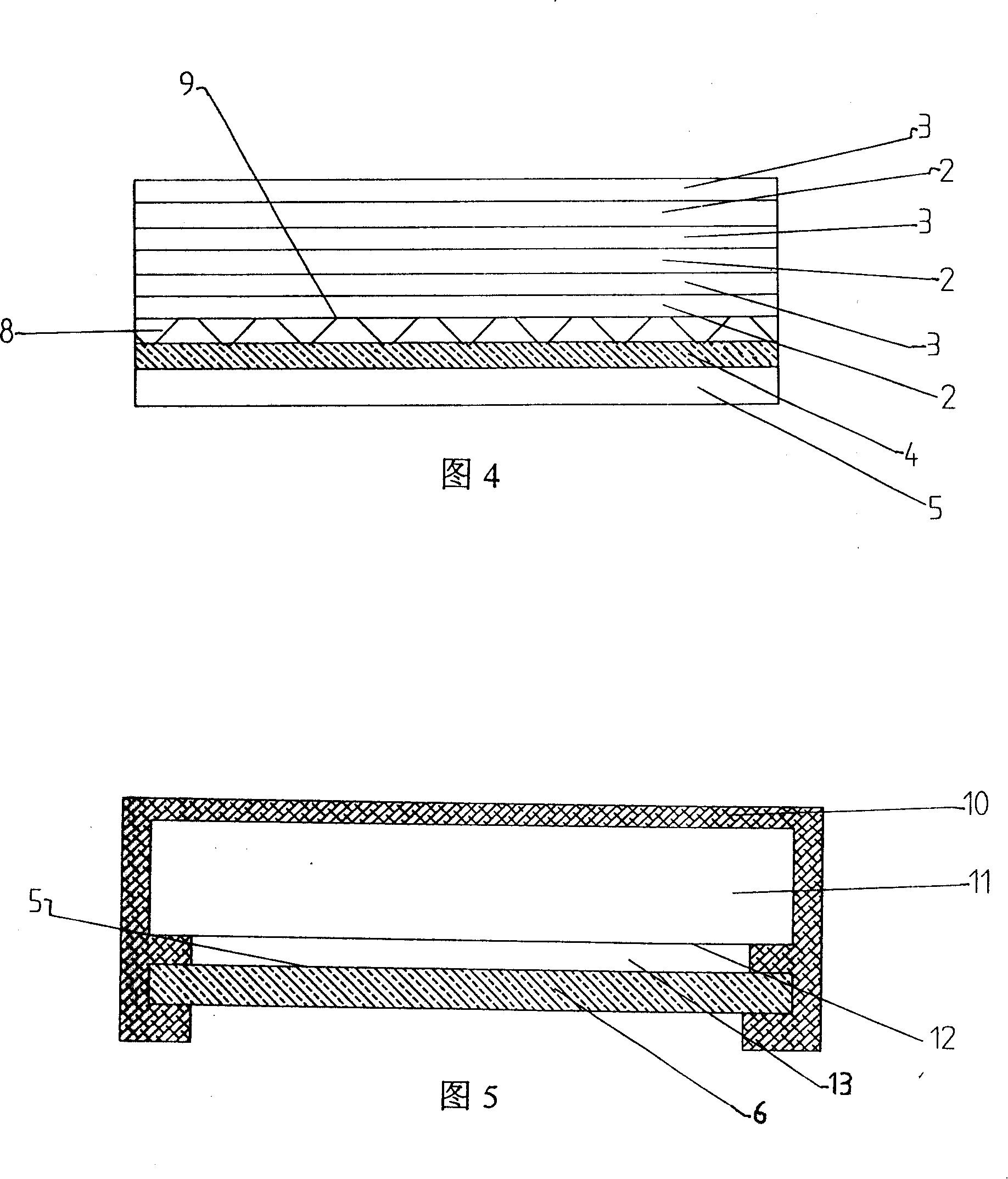

The invention provides a display glass protection screen provided with an antifogging coating, comprising a steel glass substrate, wherein, a double-layer antireflection filming layer of TiO2 / SiO2 or Nb2O5 / SiO2 is plated by adoption of the vacuum magnetron sputtering method on one surface of the substrate, or a multilayered antireflection filming layer of TiO2 / SiO2 or Nb2O5 / SiO2 is overlapped and plated; a double-layer filming layer of TiO2 / SiO2, a double-layer filming layer of Nb2O5 / SiO2, a multilayered overlapped filming layer of TiO2 / SiO2 or a multilayered overlapped filming layer of Nb2O5 / SiO2 are formed in turn from the substrate to the outside; a thermocuring / photo-curing acroid resin layer with at least one function among scratch resistance, antistatic function, antifogging function and antireflection is coated on the other surface of the substrate. The protection screen of the invention can reduce reflectivity, improve transmittance and optical image effects, greatly reduce cost and fully improve the impact failure resistance of the display screen and become a safe protection screen. The invention also provides a liquid crystal display using the glass protection screen.

Owner:甘国工

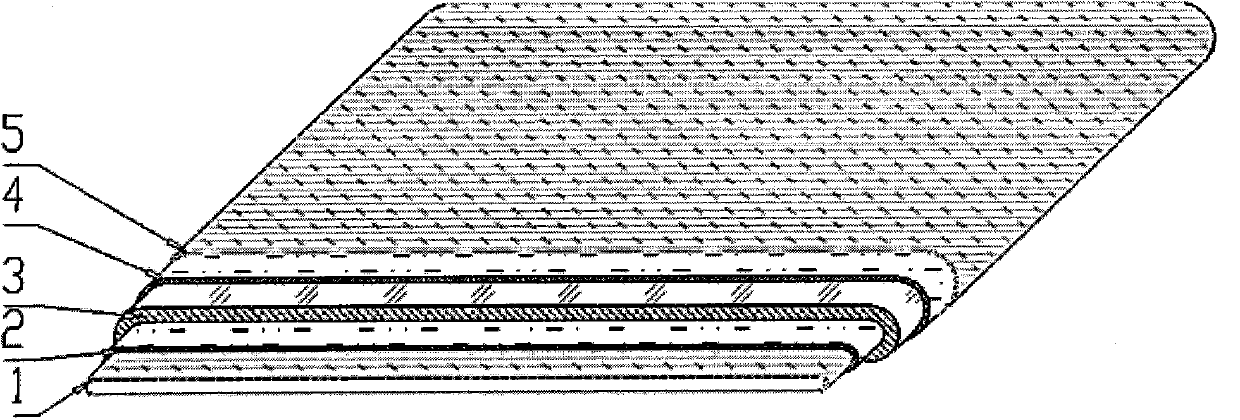

Integral moisture-retention cigarette case adopting annular opposed die cutting wrapping composite and manufacturing method of integral moisture-retention cigarette case

ActiveCN106672373AEasy accessSolve the shortcomings of high cost and waste of resourcesContainers for flexible articlesPackaging cigaretteMoisture retentionEngineering

The invention discloses an integral moisture-retention cigarette case adopting an annular opposed die cutting wrapping composite. The case structurally comprises a content, a paper inner frame and a wrapping composite material from inside to outside sequentially. A manufacturing method of the integral moisture-retention cigarette case comprises the following steps that A1, the paper inner frame wraps cigarettes and is made into a packaging inner container for standby application; and A2, the wrapping composite is folded and molded to wrap the packaging inner container, and then fixed in an adhesion mode or a local heat-sealing mode, so that the integral cigarette case is manufactured. The moisture-retention cigarette case adopting the annular opposed die cutting wrapping composite has the beneficial effects that the structure is concise; in the repeated opening and closing process, influence of the external temperature and humidity can be effectively prevented, destructive packaging protection is provided, the annular opposed die cutting wrapping composite replaces multiple materials of existing cigarette cases, and the opening process is smooth and convenient; the wrapping composite is good in printing adaptivity and excellent in processing resistance; and the moisture-retention cigarette case has the functions of damp prevention, moisture retention, fragrance retention, bacteria resistance and bacteriostasis, counterfeiting and copying are difficult, national tax erosion is effectively reduced, and the national economic benefits are protected effectively.

Owner:CHINA TOBACCO YUNNAN IND

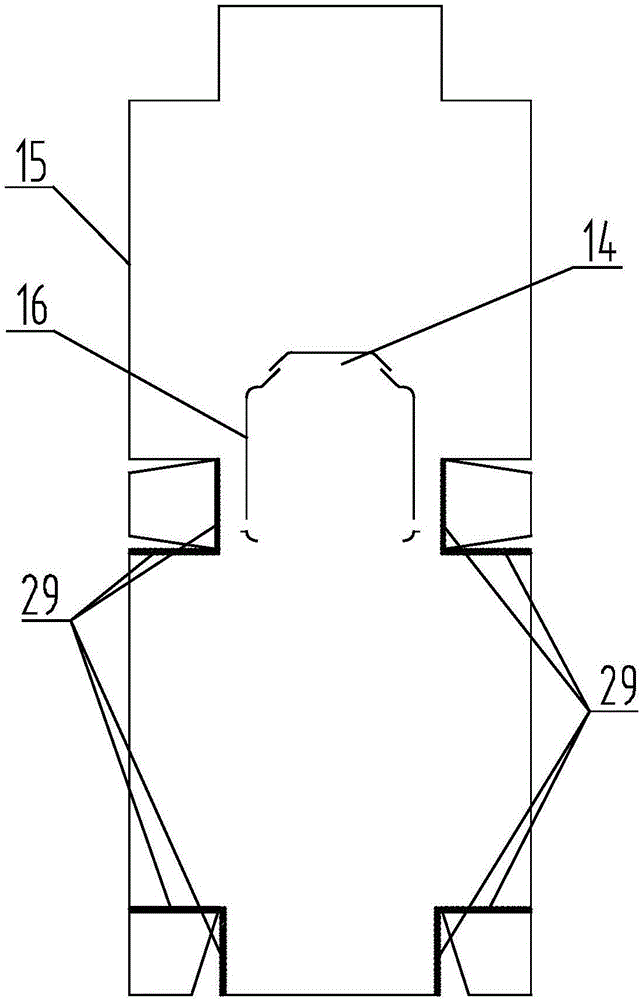

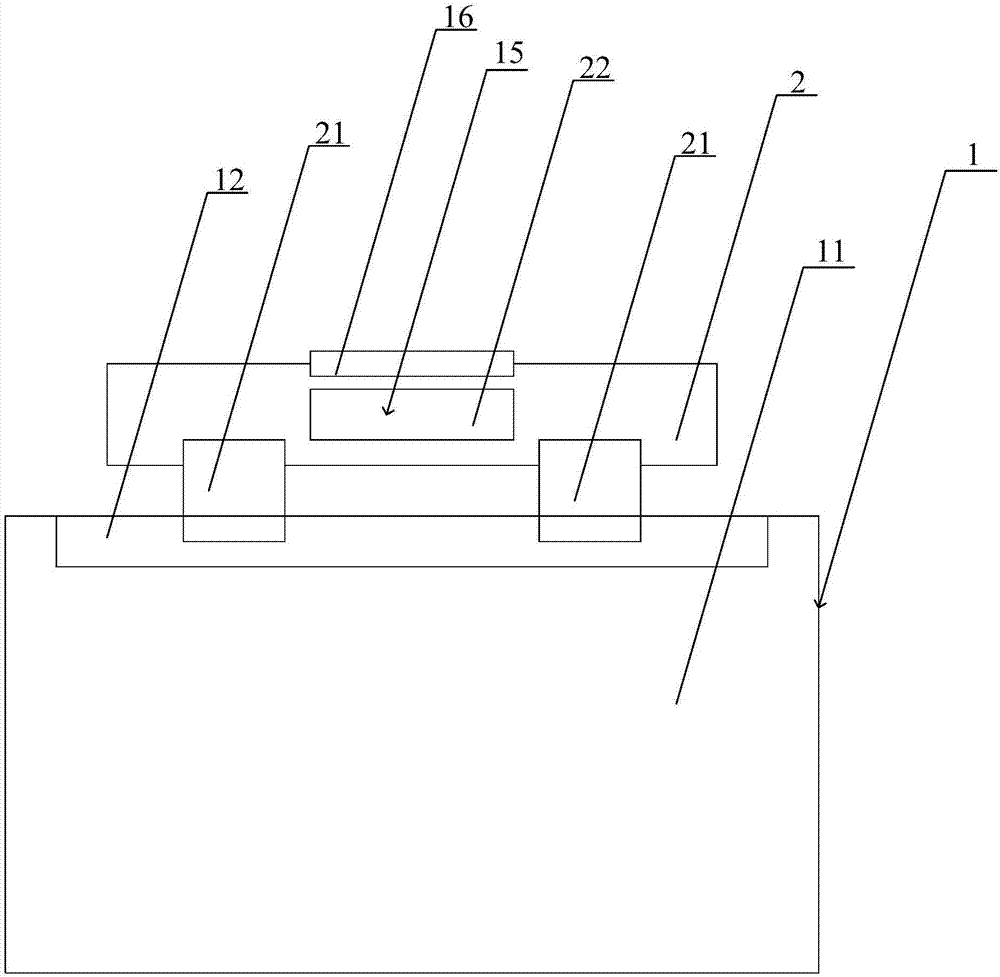

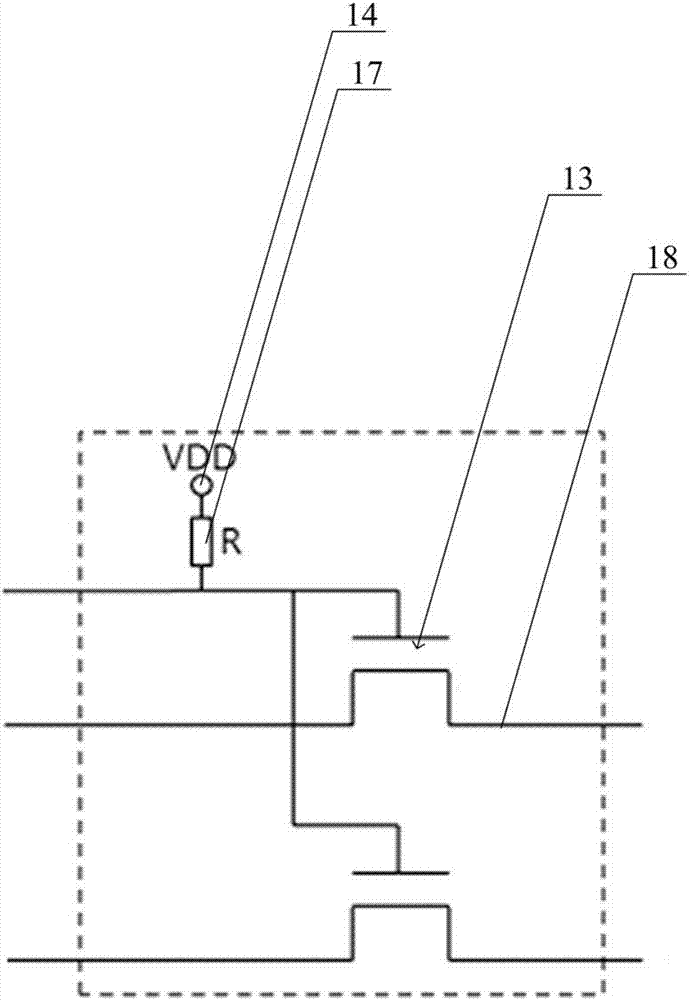

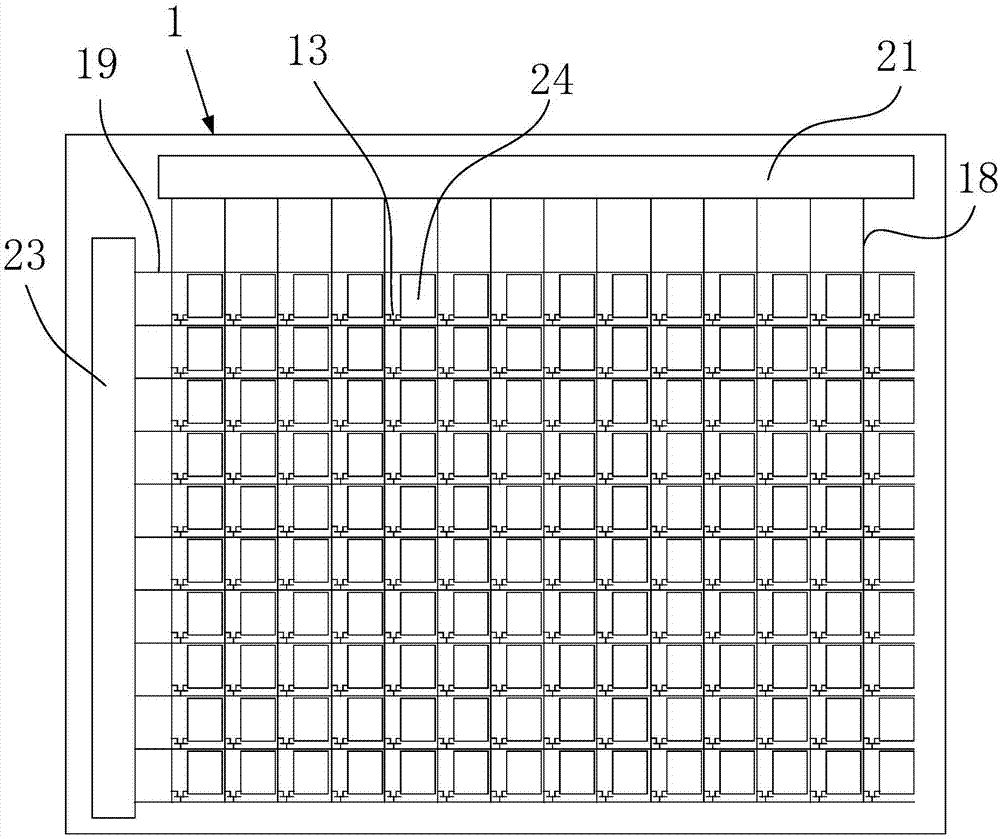

Display panel and display device

InactiveCN107479278AImplement selective refreshReduce power consumptionStatic indicating devicesNon-linear opticsComputer moduleDisplay device

The invention discloses a display panel. The display panel comprises a substrate, a data driving circuit, an active switch and a control module, wherein multiple data cables are formed in a display area of the substrate, the data driving circuit is used for driving the data cables, the active switch connects the data driving circuit and the data cables, and the control module is coupled to a control end of the active switch. When previous frame information is same with current frame information, the control module controls the active switch to be switched off, the data driving circuit is connected with the data cables through the active switch, signal transmission between the data driving circuit and the data cables can be effectively controlled, the output of the data driving circuit and actual input of the display panel are separated by using the active switch, selective refreshing effect of the display area of the substrate is achieved, and the power consumption of the display panel is further lowered.

Owner:HKC CORP LTD +1

Hot-compress dip-coating insulation method of copper bar

InactiveCN101582310AImprove insulationReduce labor intensityInsulating conductors/cablesElectricityFluidized bed

The invention relates to an insulation method of copper bars, in particular to a hot-compress dip-coating insulation method of copper bar, solving the defect and insufficiency of the existing insulation method of copper bars. The hot-compress dip-coating insulation method comprises the following steps: 1. a copper bar is cleaned, and the electric interface of the copper bar is protected and bound up; 2. the copper bar is preheated at the temperature of 170 to 190 DEG C, and kept for 20 minutes at the temperature of 170 to 190 DEG C; 3. the preheated copper bar is put in an epoxy encapsulating material fluidized bed, the surface of the copper bar is treated with hot pack by epoxy encapsulating material, and then dusting powder on the surface of the copper bar is quickly twittered; 4. the electric interface of the copper bar, which is treated with hot pack, is protected and eliminated, and the end of the electric interface is trimmed; and 5. at the temperature of 140 to 150 DEG C, the copper bar is solidified for 30 minutes, and then the solidified copper bar is dried. The invention improves the insulativity, the chemical resistance, the weather fastness and the like of the copper bar, lightens labor intensity, saves cost, improves the service life of the copper bar, and solves the inextricable problems of the existing insulation lapping and heat shrinking of tubing.

Owner:YONGJI XINSHISU ELECTRIC EQUIP

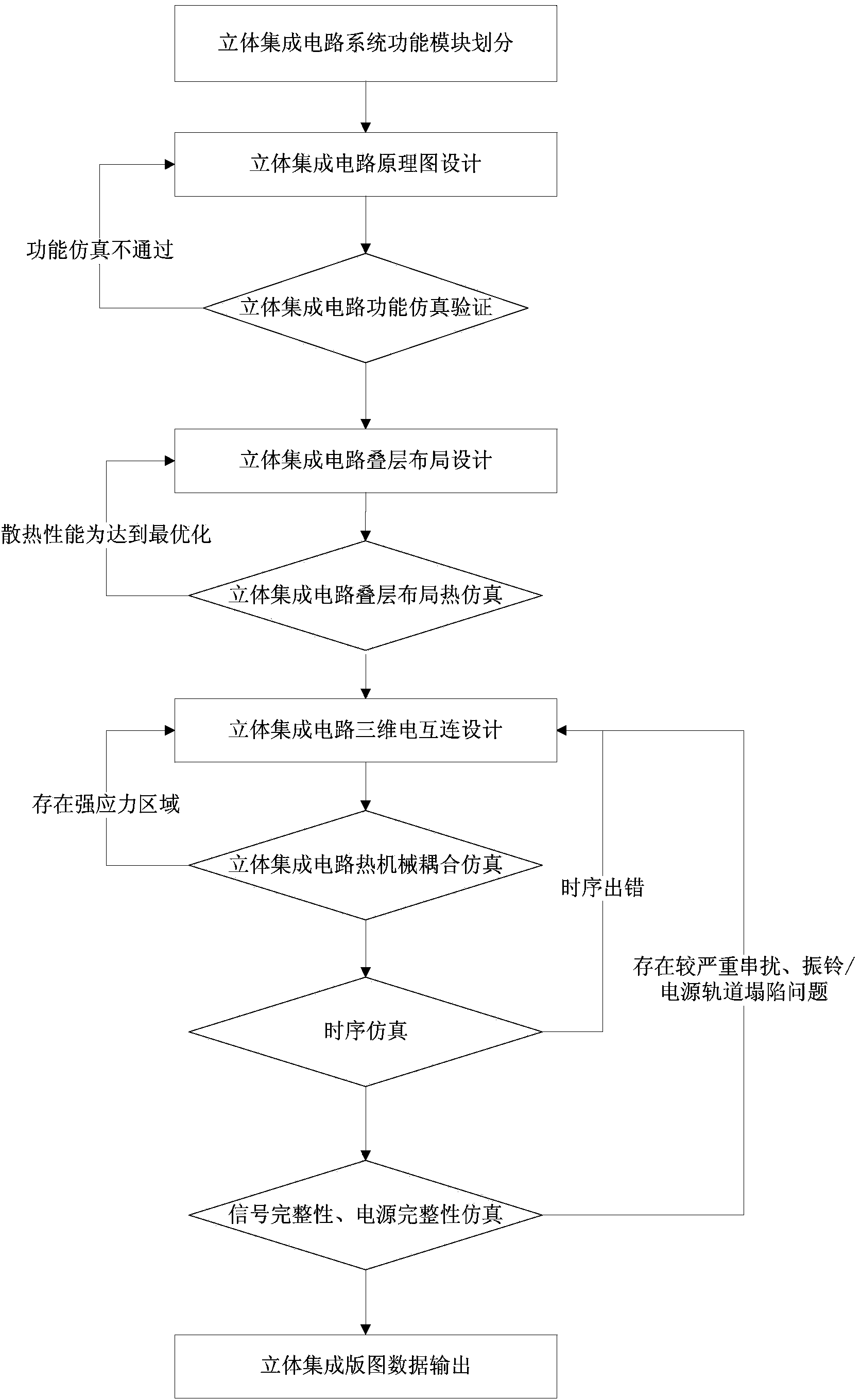

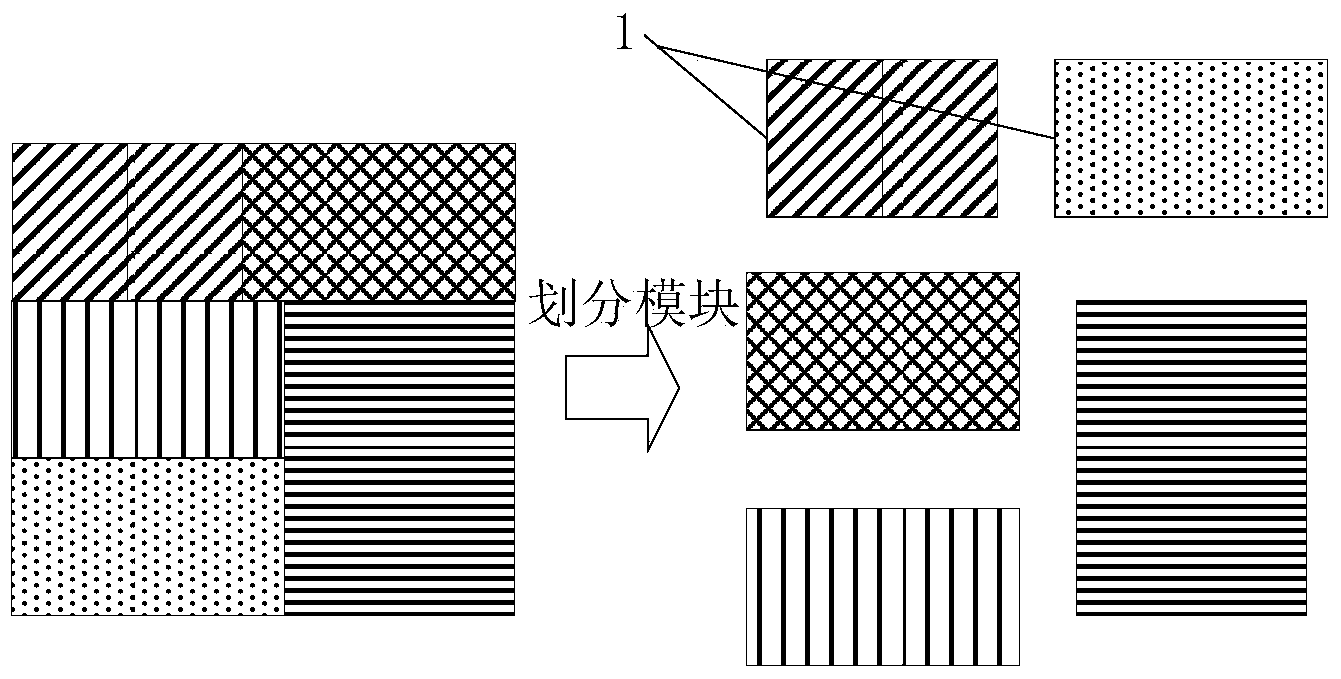

Three-dimensional integrated circuit multi-physical-domain collaborative design method based on through-silicon via

ActiveCN103942393AGuaranteed Reliability Design RequirementsOvercome lack of heatSpecial data processing applicationsElectricityCircuit reliability

The invention discloses a three-dimensional integrated circuit multi-physical-domain collaborative design method based on the through-silicon via. Influences, caused by coupling among the thermology physical domain, the mechanics physical domain and the electricity physical domain, on reliability of a three-dimensional integrated circuit are taken into consideration, the thermology design step and the mechanics design step are added, and the thermology, mechanics and electricity multi-physical-domain collaborative design method is built. According to the multi-physical-domain collaborative design method, mutual iteration is carried out among the thermology design step, the mechanics design step and the electricity design step till the thermology design step, the mechanics design step and the electricity design step all meet the design requirements, and the design requirement of the three-dimensional integrated circuit for high reliability is ensured. The defect that an existing three-dimensional integrated circuit design process is lacking in the thermology design step and the mechanics design step is overcome.

Owner:珠海天成先进半导体科技有限公司

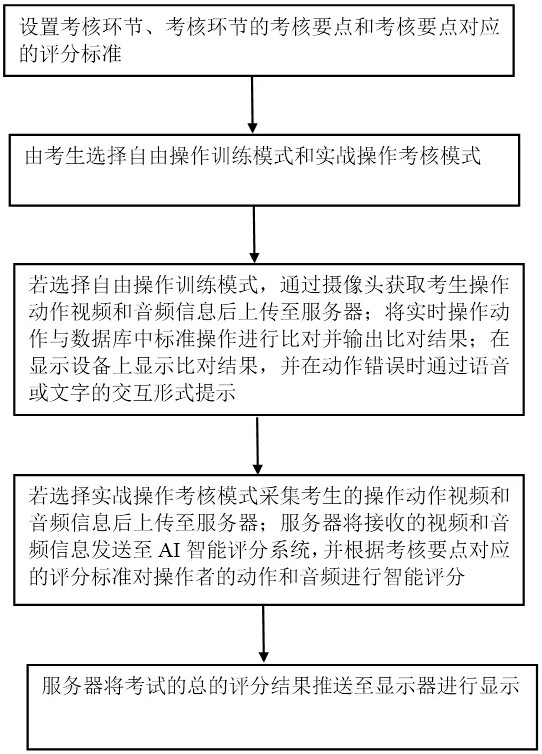

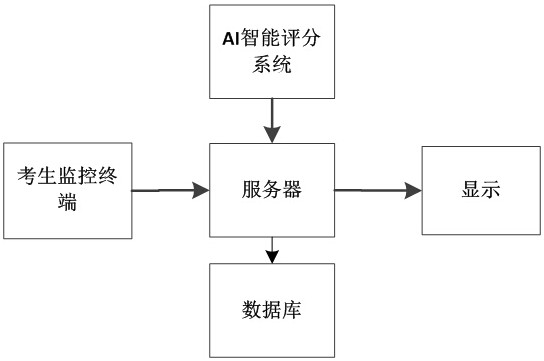

Scoring method and system for CPR examination training and examination of doctors

InactiveCN112233516AReduce labor costsSave time and costCharacter and pattern recognitionEducational modelsDisplay deviceEmergency medicine

The invention discloses a scoring method for CPR examination training and examination of a doctor. The method comprises the steps: selecting a free operation training mode and an actual combat operation examination mode by an examinee; obtaining examinee operation action video and audio information through a camera, and uploading the examinee operation action video and audio information to a server; comparing the real-time operation action with a standard operation in a database and outputting a comparison result; displaying the comparison result on a display device, and prompting in a voice or character interaction mode when the action is wrong; sending the received video and audio information to an AI intelligent scoring system by the server and carrying out intelligent scoring; and pushing the total scoring result of the examination to a display for display by the server. According to the invention, the problems of many students needing to be trained and insufficient practice opportunities at present are solved, the quality is improved, the cost is reduced, the unmanned examination needs to be evaluated by teachers, the AI score is added, a score standard is formulated, and theinvigilation evaluation efficiency is greatly improved.

Owner:萱闱(北京)生物科技有限公司

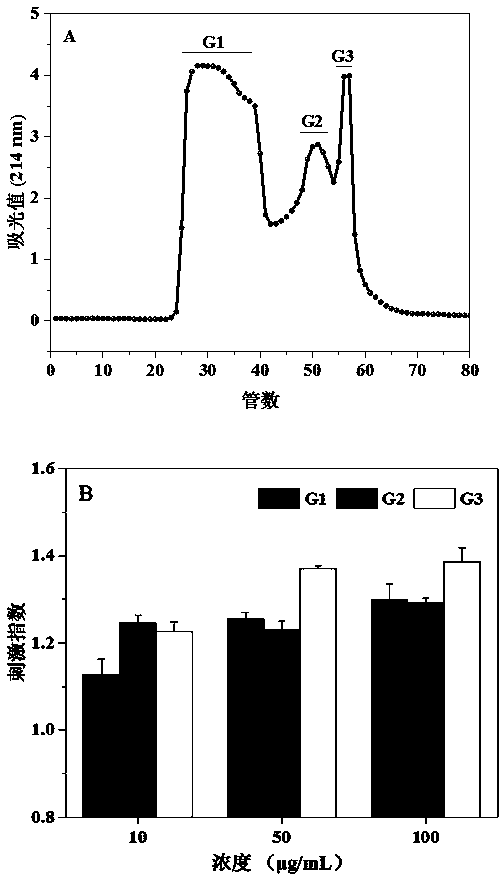

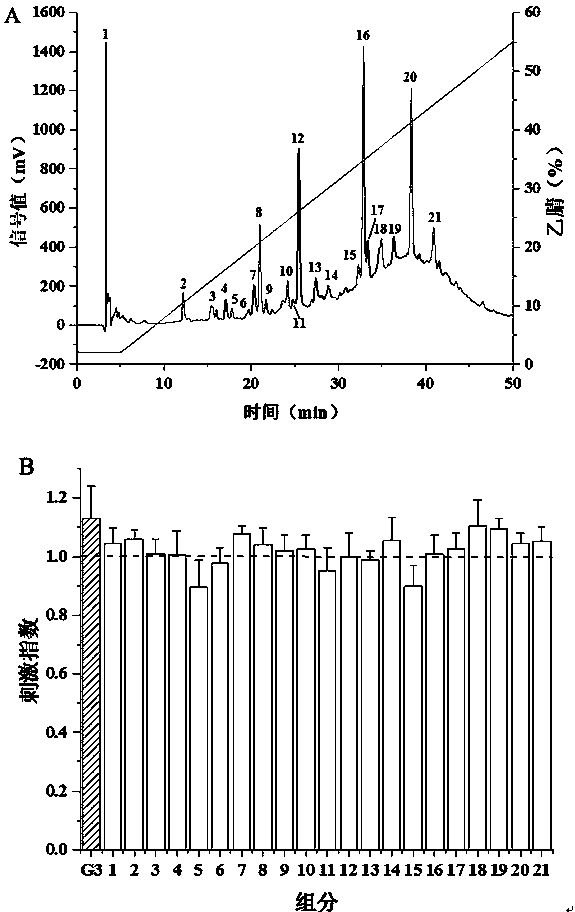

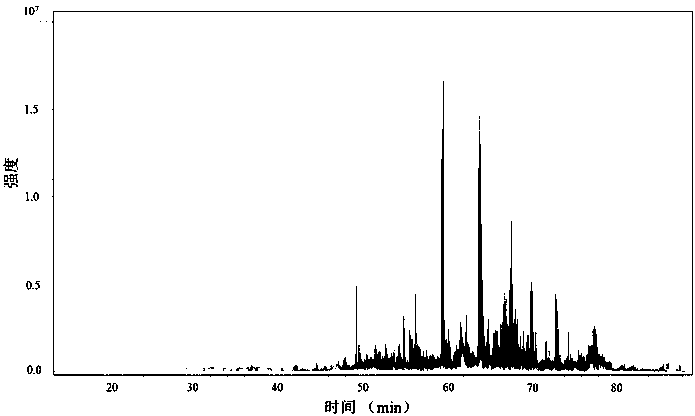

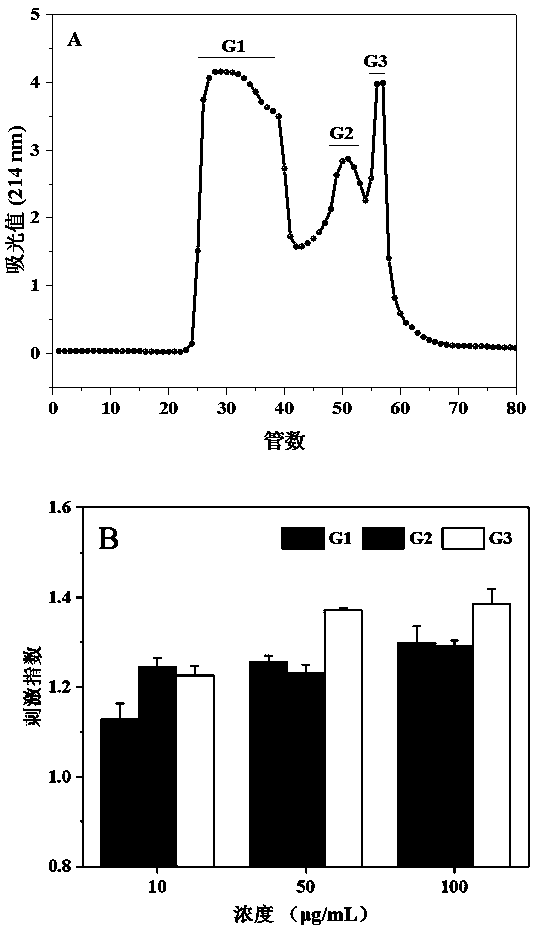

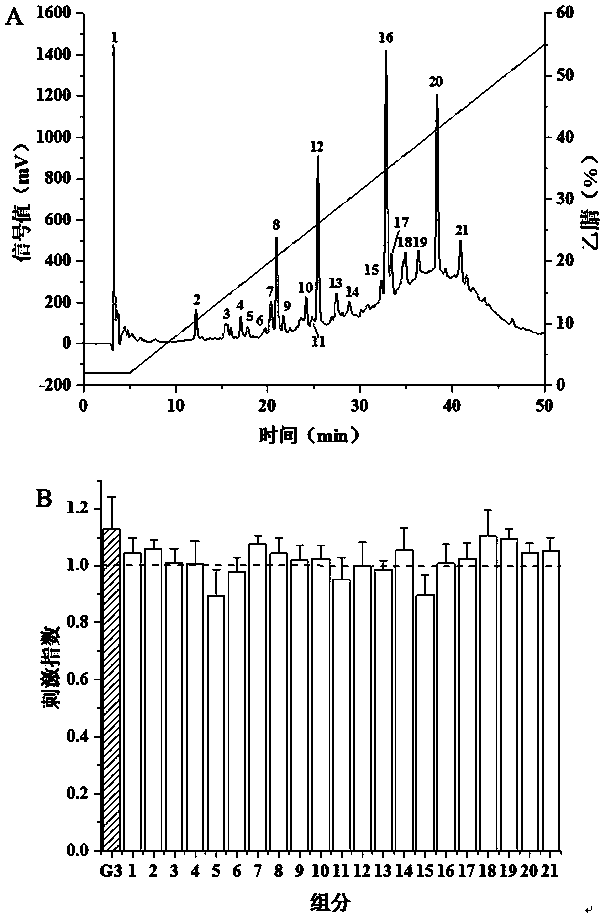

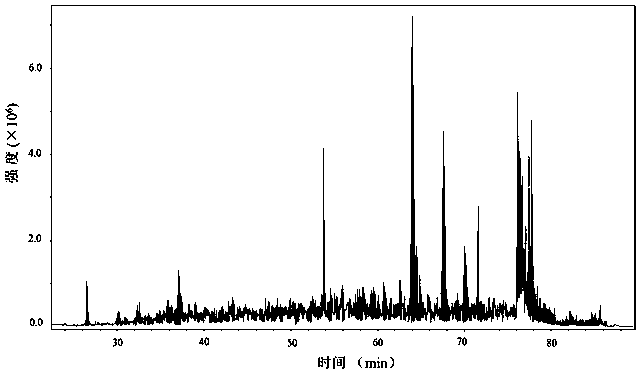

Preparation and method of immunoregulatory peptide

ActiveCN110655556AEnzyme technology is simple and efficientAvoid cost wastePeptide preparation methodsFermentationProtein proteinSpecific immunity

The invention provides a method for separating and purifying immunoregulatory peptide by using radix pseudostellariae. The method for separating and purifying the immunoregulatory peptide by using theradix pseudostellariae comprises the steps that the radix pseudostellariae is used as a raw material, through protein extraction and dual-step enzymolysis of pepsase and trypsin, separation and purification and freeze drying are carried out to obtain specific immunity polypeptide, the molecular weight of the specific immunity polypeptide is 522 Da, and an amino acid total sequence of the specificimmunity polypeptide is Arg-Gly-Pro-Pro-Pro. According to the method for separating and purifying the immunoregulatory peptide by using the radix pseudostellariae, the defects of immunoregulatory drugs are overcome, the anxiety of the public to artificial immunity regulators is eliminated, and a theoretical basis is laid for developing immune polypeptide based on a food source and searching the wide application of the immune polypeptide in food and medicine.

Owner:FUZHOU UNIVERSITY

Load type catalyst for treating organic wastewater and preparation method thereof

InactiveCN102039192ALow costCost hasCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyDiethylenetriamine

The invention discloses a load type catalyst for treating organic wastewater through oxidation and a preparation method thereof. The load type catalyst is characterized by comprising the active component of Fe<2+> with the load capacity being 1-3%; and an epoxy resin-based porous polymer is used as a carrier and has the mean particle size being 2-5mm. The preparation method comprises the steps of: mixing polyethylene glycol, epoxy resin and diethylenetriamine by mass ratio to obtain a thick liquid; placing the thick liquid into an empty tubular column and sealing the tubular column; reacting in a thermostatic box to obtain white solids; cooling and then washing the white solid blocks with deionized water to remove the polyethylene glycol to obtain blocky materials of the epoxy resin-based porous polymer; cutting the blocky materials into catalyst carriers with the particle size being 2-5mm; drying and adding the catalyst carrier into a 0.1mol / L ferrous sulfate solution with the pH bing 1-5; carrying out thermostatic oscillation; and filtering, washing and drying solids to obtain the product. The load type catalyst has high catalytic activity, is easy to separate and can be used in a CWPO (Catalyst Wet Peroxide Oxidation) process to treat toxic and harmful organic wastewater difficult for biodegradation; in addition, a preparation process is simple and is low in cost, which is beneficial to the popularization and use of the catalyst.

Owner:NINGBO UNIV

Organic-inorganic composite water plugging reinforcement material and preparation method thereof

InactiveCN104804172ALow costQuick water plugging and leak repairDrilling compositionOrganometallic catalysisChemistry

The invention discloses an organic-inorganic composite water plugging reinforcement material and a preparation method thereof. The material consists of a component A and a component B, wherein the component A comprises the following ingredients by weight percent: 97-99% of water glass, 0.5-1.5% of a chain extension cross-linking agent, 0.2-0.6% of an organo-metallic catalyst, and 0.3-0.9% of an amine catalyst; the component B comprises the following ingredients by weight percent: 65-75% of crude MDI, 0-8% of PPG (polypropylene glycol)-2000, 2-10% of polyether triol 330N, 14-23% of a diluent and 1-2% of a foam stabilizer; the mass ratio of the component A to the component B is 1:(0.7-1.2). The preparation method comprises the following steps: mixing the ingredients of the component B according to the weight percent, leaving the mixture to stand for 12 hours, adding the component A, and uniformly stirring, so as to obtain the water plugging reinforcement material which is high in strength, good in environment friendliness and durability, non-flammable, and low in cost. According to the invention, the limitation problem that a polyurethane water plugging material can be used for reinforcement or plugging of a small amount of leakage water only.

Owner:SHANDONG YOUGU NEW MATERIAL TECH CO LTD

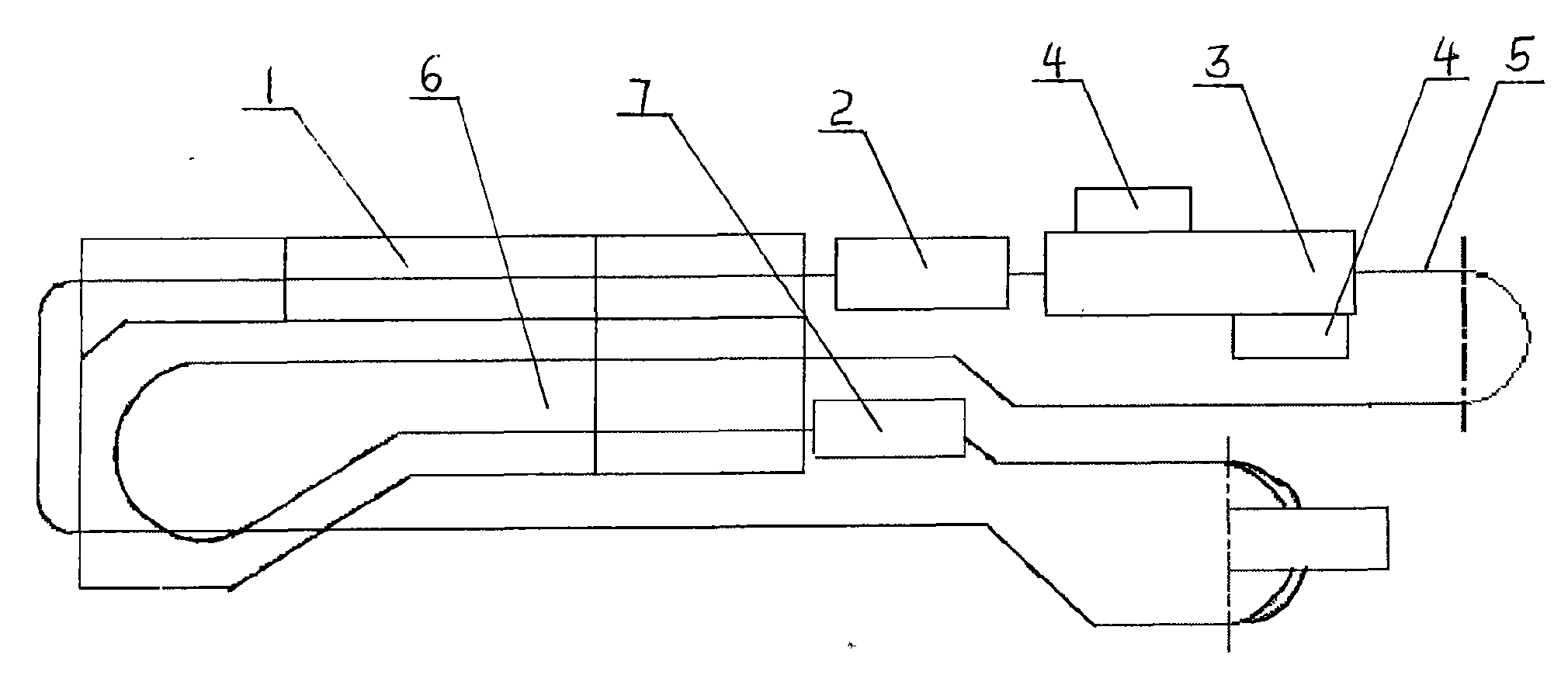

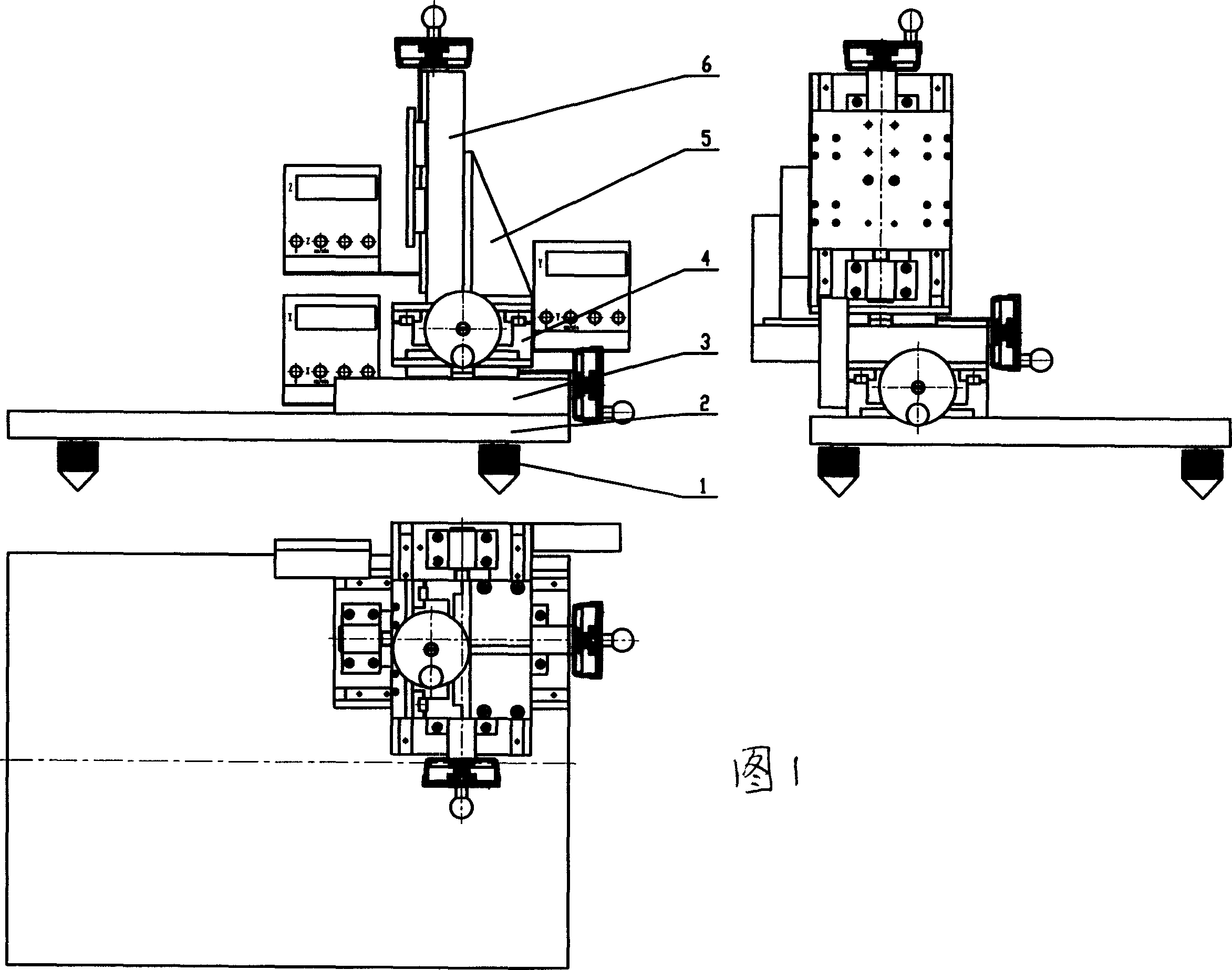

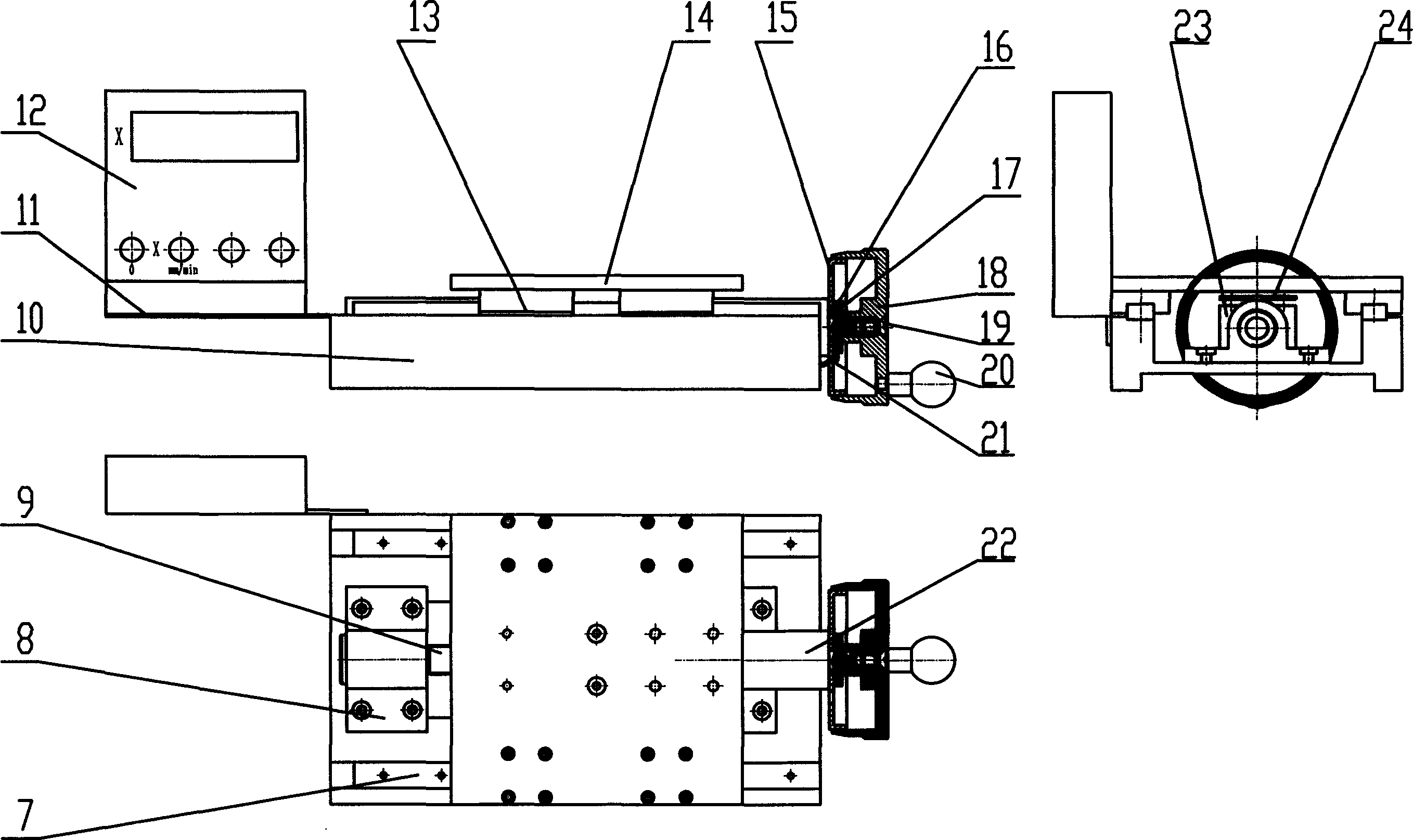

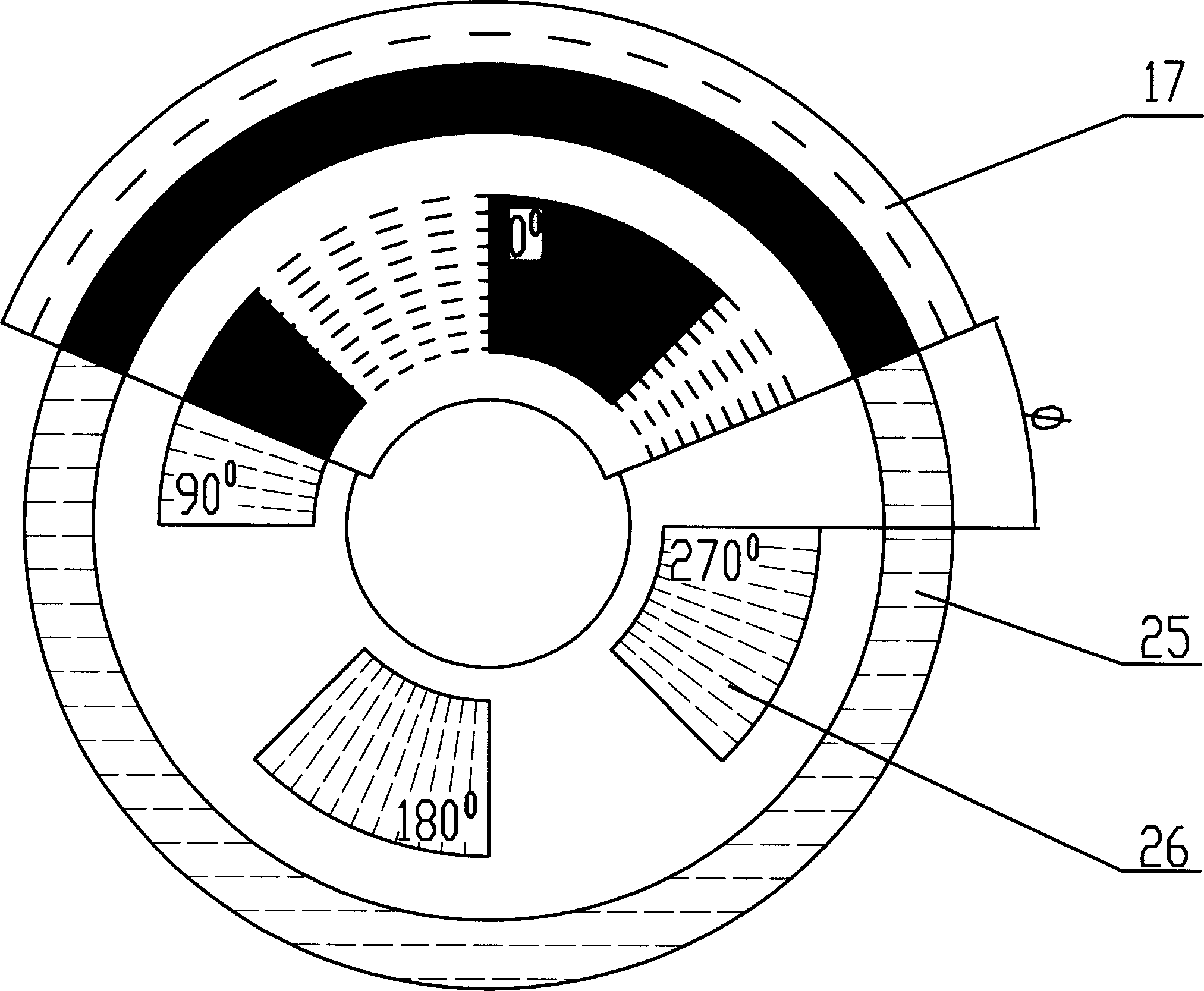

Tricoordinate precision moving platform

InactiveCN1556369AEasy to moveLow costEngine testingMechanical measuring arrangementsCapacitanceEngineering

Disclosed moving platform includes moving parts capable of moving along X, Y, Z three directions. Bottom board of X direction moving part is fixed on base; Y moving part is fixed on carriage of X moving part. Bottom board of Z moving part through joining angle iron is fixed on carriage of Y moving part. Each X, Y, Z moving part is composed of gearing, guiding, driving mechanisms and device for displaying moving displacement. Gearing mechanism includes slide screw rod, supports for screw rod, bottom board. Guiding mechanism includes rolling guide and slide block. Driving mechanism includes capacitance grid sensor composed of static electrode, rotating electrode, hand wheel and handle. The invention realizes fine motion in X, Y, Z directions to meet requirement in experiment of measuring liquid.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

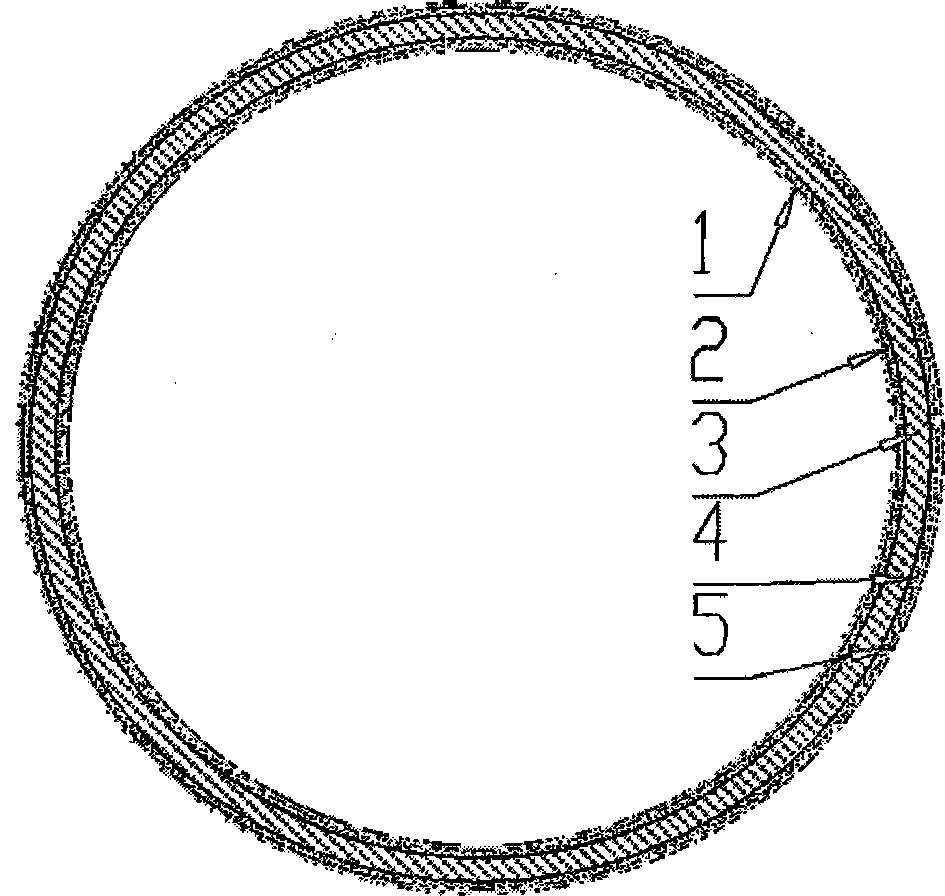

Steel bar lap joint structure containing FRP constraint ring

A steel bar lap joint structure containing an FRP constraint ring belongs to the technical field of the concrete member. The joint structure includes an upper layer prefabricated component, a lower layer prefabricated component, an FRP constraint ring, a pre-embedded steel bar and a protruding connection steel bar. The FRP constraint ring is arranged in the lower end of the upper layer prefabricated component; the lower part of the FRP constraint ring is provided with a grouting hole, and the upper part of the FRP constraint ring is provided with a discharging hole; the top end of the FRP constraint ring is provided with a sealing elastic rubber sealing ring with a round hole; the pre-embedded steel bar of the upper layer prefabricated component passes through the round hole on the sealing ring and extends into the FRP constraint ring; the protruding connection steel bar in the lower prefabricated component extends into the FRP constraint ring to form lap joint with the pre-embedded steel bar in the upper layer prefabricated component; and an expansion grouting material is grouted along the grouting hole of the FRP constraint ring to fill the FRP constraint ring, so as to form an assembled monolithic joint structure. The steel bar lap joint structure provided by the invention has the advantages of reliable and stable joint performance, low cost, low precision requirement for on-site installation and easily guaranteed construction quality.

Owner:SHENYANG JIANZHU UNIVERSITY

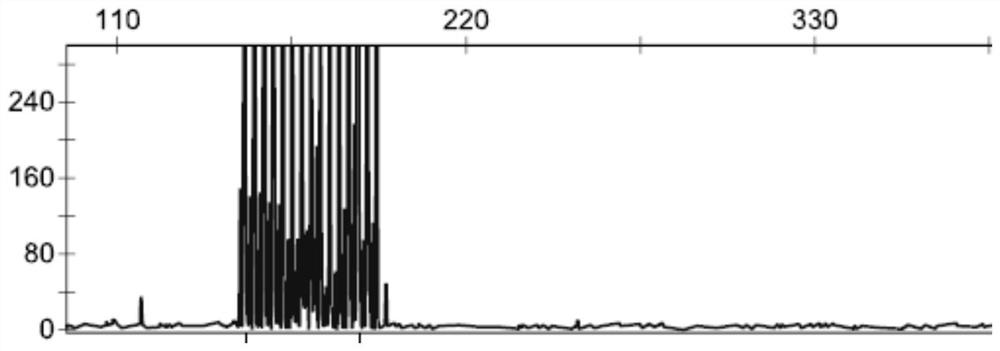

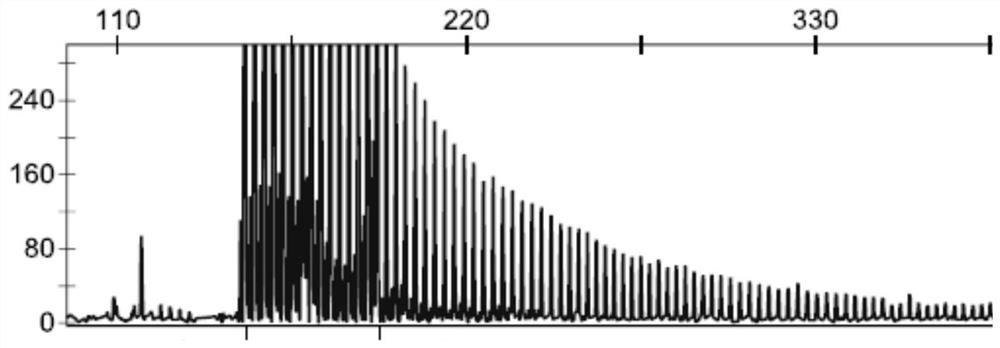

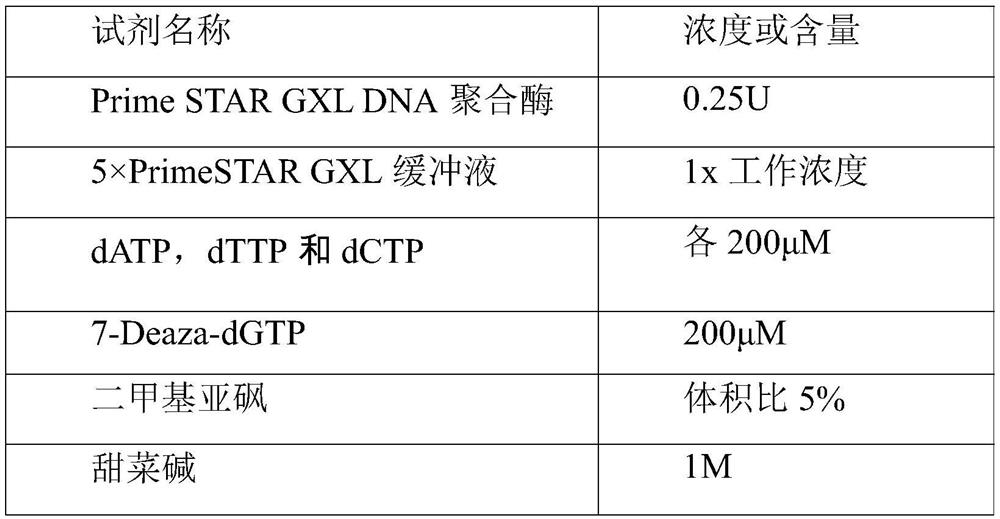

Method for amplifying GGC repetitive sequence of NOTCH2NLC gene

PendingCN112553299AGood application effectAmplification satisfiedMicrobiological testing/measurementRepetitive SequencesDisease

The invention belongs to the technical field of biology, and particularly relates to a method for amplifying a GGC repetitive sequence of an NOTCH2NLC gene. The PCR reaction procedure for amplifying the GGC repetitive sequence of the NOTCH2NLC gene comprises the following steps: reacting at 98 DEG C for 10 minutes; then carrying out 9 cycles: reacting at 98 DEG C for 30 seconds, reacting at 66 DEGC for 15 seconds, lowering the temperature by 1 DEG C in each cycle, and reacting at 72 DEG C for 4 minutes; carrying out 30 cycles: reacting at 98 DEG C for 30 seconds, reacting at 58 DEG C for 15 seconds, and reacting at 72 DEG C for 4 minutes; and finally, conducting the extension step at 72 DEG C for 10 minutes. According to the PCR reaction procedure, the PCR time is greatly shortened, the total time is shortened from 10 hours to 4.5 hours, the repeatability is high, the use is convenient, the cost is slightly low, the applicability of the RP-PCR technology in clinical gene diagnosis ofNIID (neuronal intranuclear inclusion disease) is greatly improved, and the demand for the amplification of large-scale samples can be met.

Owner:PEKING UNIV FIRST HOSPITAL

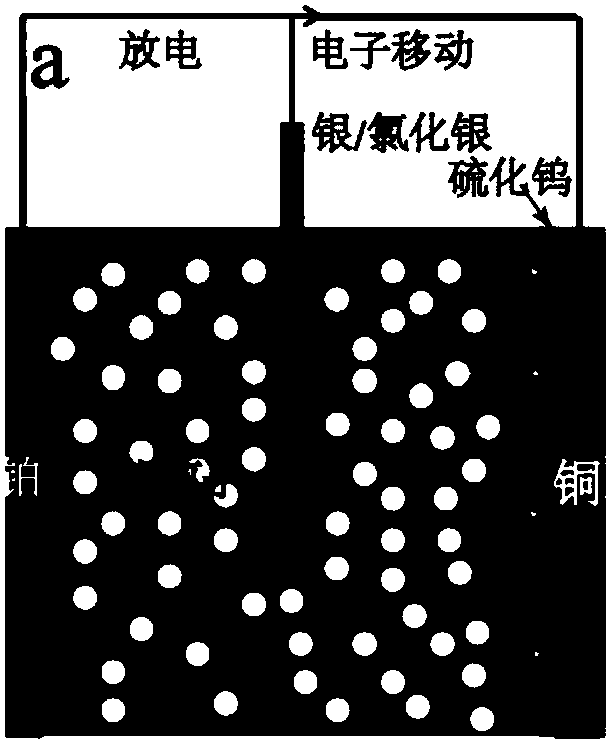

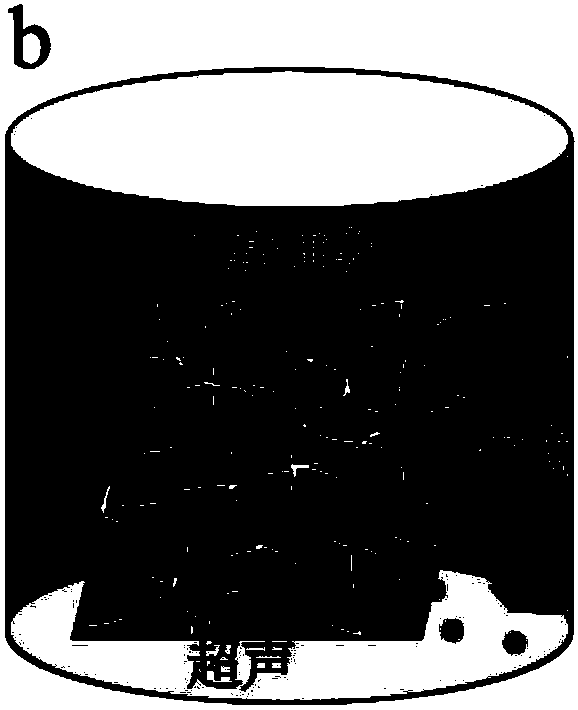

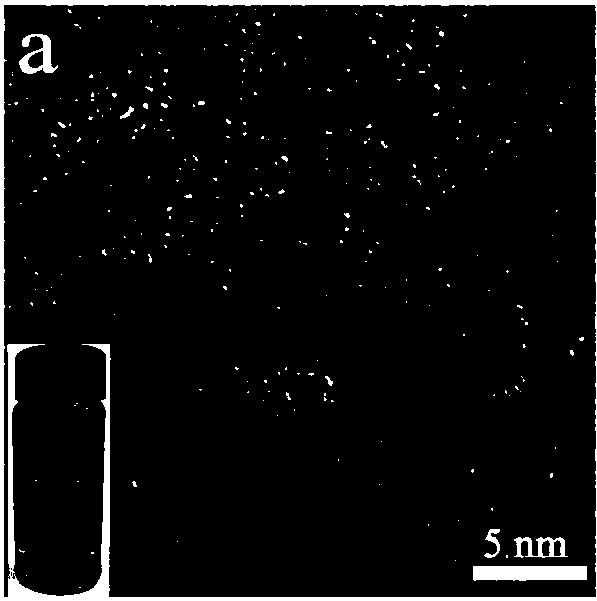

Method for preparing inorganic non-metallic material quantum dots by electrochemical ion impact and application thereof

ActiveCN108468071ASimple preparation processEasy to operateMaterial nanotechnologyAnalysis by material excitationExplosive AgentsMetallic materials

The invention discloses a method for preparing inorganic non-metallic material quantum dots by electrochemical ion impact and an application thereof. The method comprises the following steps of: underthe action of an electric field, a metal cation impacts an active substance to destroy the internal structure of the active substance and redistribute the electric charge in the active substance, sothat the quantum dots of the inorganic non-metal material are prepared. According to the invention, the preparation process of the inorganic non-metallic material quantum dots is simple, easy to operate, mild in condition, low in cost and controllable in preparation time within 10min, has universality and is suitable for large-scale production, and the morphology of the prepared inorganic non-metallic material quantum dots is controllable, can be uniformly and stably dispersed in a dispersing agent, has excellent performance, and has wide application prospect in the fields of explosive detection, piezoelectric device, biological imaging, electrochemical hydrogen evolution, photocatalytic hydrogen production and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

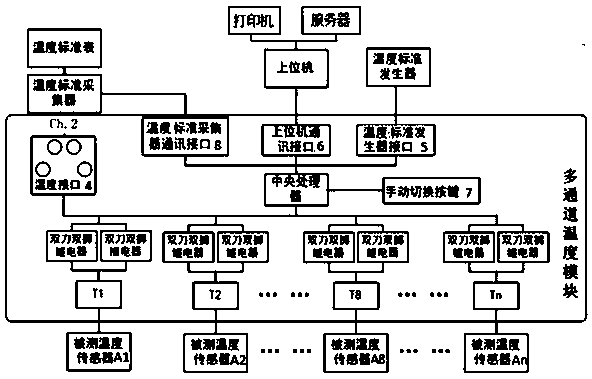

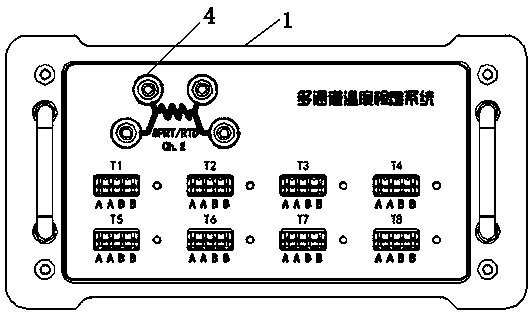

Device and method for multi-channel temperature calibration

PendingCN109269680AMeet the needs of different conditions of useRealize verification workThermometer testing/calibrationTechnical standardData acquisition

The invention relates to a device and a method for multi-channel temperature calibration. The method comprises the steps that: a calibration personnel controls an upper computer, and when a set temperature value is reached, a temperature indicating value of a calibrated sensor A1 and indicating value data of a temperature standard meter at the same time are uploaded to the upper computer; after aset time S1 arrives, a central processor of a multi-channel temperature module controls a plurality of pairs of double-pole double-throw relays to switch off, a channel interface T2 end is conducted by switching on double-pole double-throw relays A1, and a temperature indicating value of a calibrated sensor A2 and indicating value data of the temperature standard meter at the same time are uploaded to the upper computer, so as to complete calibration of the calibrated sensors in sequence; the obtained data is compared according to rules, a calibration certificate is generated according to thesensor determined to be qualified, and the calibration certificate is printed, output and uploaded to a server; and for the sensor determined to be unqualified, the calibration personnel switches theunqualified calibrated sensor to a current data acquisition state through manually switching buttons for reexamination and debugging. The invention can simultaneously realize the verification work ofthe 8-way tested temperature sensor and improve the verification efficiency. The device and the method can realize the calibration of 8 channels of tested temperature sensors, and improve the calibration efficiency.

Owner:ZHONGHUAN TIG TIANJIN METEOROLOGICAL INSTR +1

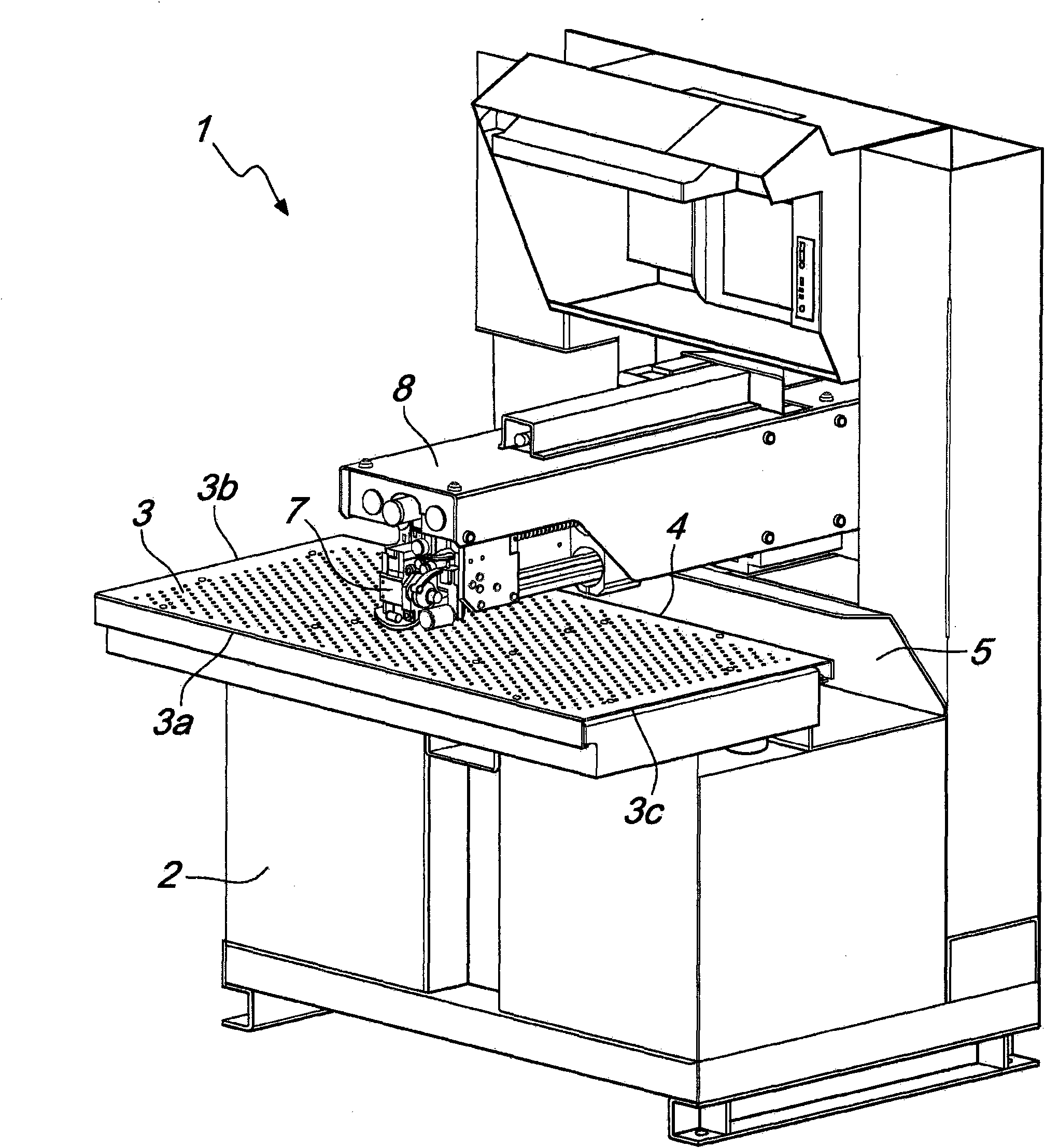

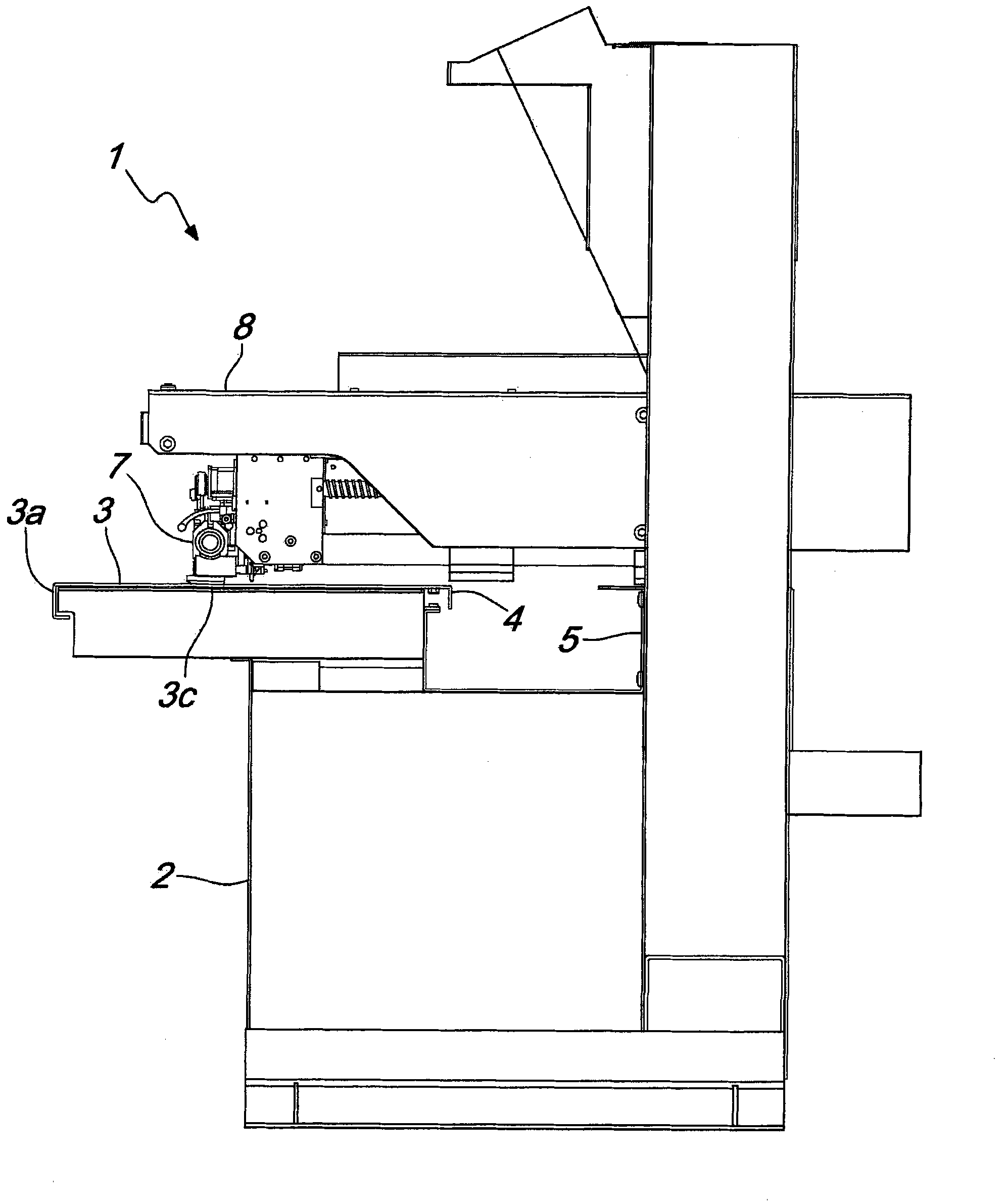

Machine for cutting hides and the like and sheet-like materials in general, with simplified-access worktable

ActiveCN101952092AEasy to provideHighly reliableLeather clicking/perforating/clickingMetal working apparatusCantileverMechanical engineering

Owner:COMELZ SPA

Preparation, separation and purification method for immunological peptide

ActiveCN110590907AEnzyme technology is simple and efficientAvoid cost wastePeptide preparation methodsFermentationProtein proteinSpecific immunity

The invention provides a method for carrying out separation and purification on pseudostellariae radix to obtain an immunoregulation peptide. The method takes the pseudostellariae radix as a raw material, purification and separation are carried out through protein extraction and the double-step enzymolysis of pepsin and trypsin to obtain a specific immune polypeptide, the molecular weight of the specific immune polypeptide is 949 Da, and the amino acid complete sequence of the specific immune polypeptide is Tyr-Gly-Pro-Ser-Ser-Tyr-Gly-Tyr-Gly. The method overcomes the defects of an existing immunoregulation medicine, in addition, the worry of the public for an artificial immunomodulator is eliminated, and a certain theoretical foundation is laid for developing the immune polypeptide basedon a food source and exploring the wide application of the immune polypeptide in food and medicine fields.

Owner:FUZHOU UNIVERSITY

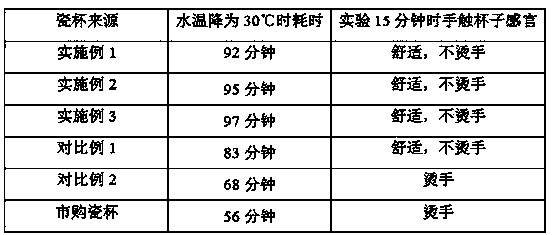

Magnesium jade porcelain and production method thereof

InactiveCN104291799AReduce manufacturing costImprove thermal stabilitySolid waste disposalThermal insulationTalc

The invention relates to a magnesium jade porcelain and a production method thereof. The blank of the magnesium jade porcelain comprises the following raw materials in parts by weight: 45-50 parts of calcninated talc, 30-35 parts of clay, 10-20 parts of feldspar, and 5-10 parts of serpentine waste (based on dry materials); the serpentine wastes is filter residue obtained after extracting serpentine mineral powder through inorganic acid. Due to use of serpentine waste, the production cost of the magnesium jade porcelain is lowered, the combination of the formula can ensure a high yield of the fired magnesium jade porcelain finished products and the cost is further lowered; the serpentine is of multiple colors and easy to dye, thus the prepared magnesium jade porcelain is colorful; serpentine has thermal insulation and heat preservation characteristics, so that the thermal insulation property of the magnesium jade porcelain is improved and the heat preservation effect is good. According to the method, the synergistic effect of all components in the formula can be fully played, the fired porcelain is high in yield, has many colors, good thermal insulation property, and is especially applicable to porcelain for cantering.

Owner:CHONGQING DUMAI PORCELAIN

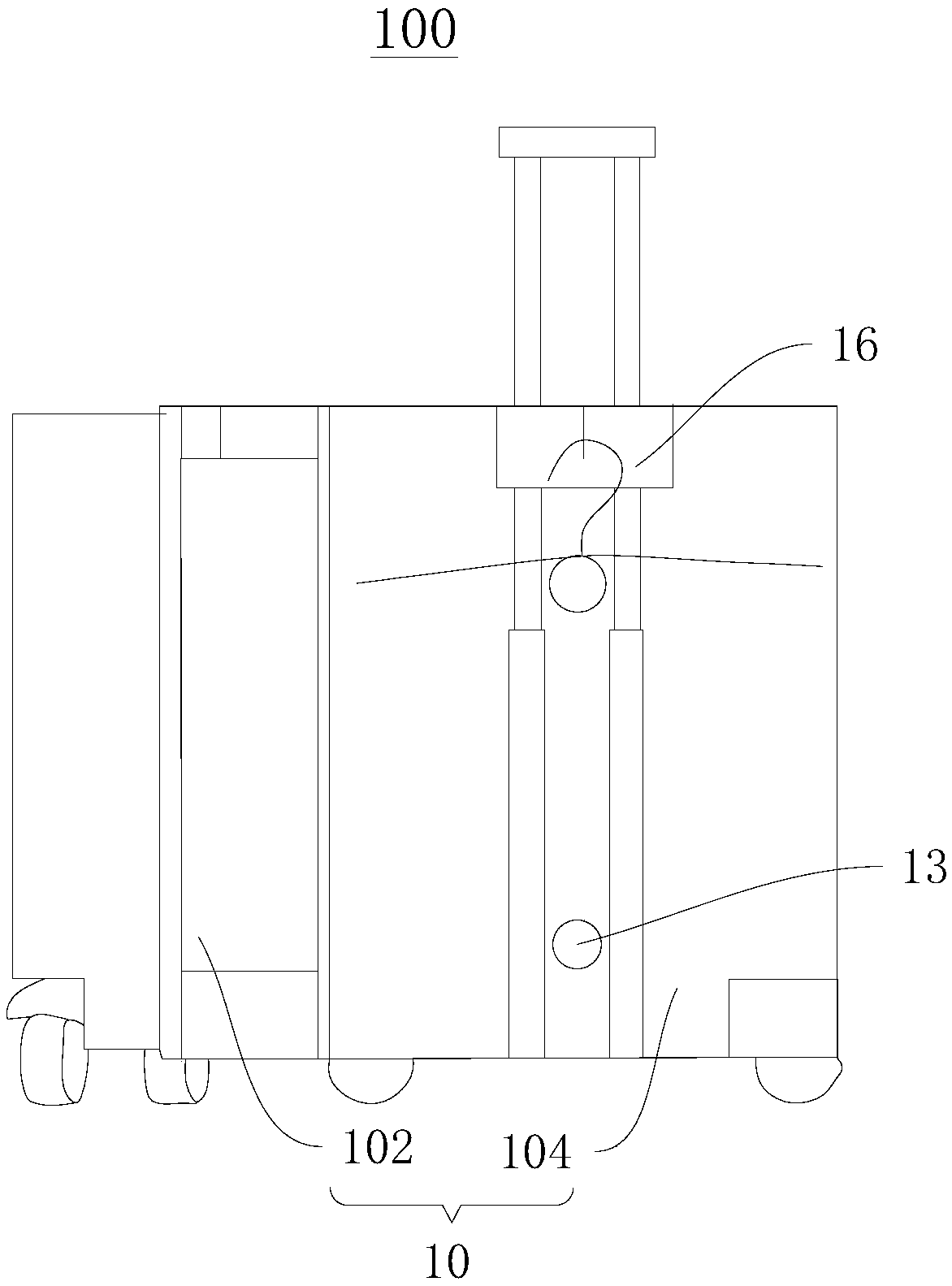

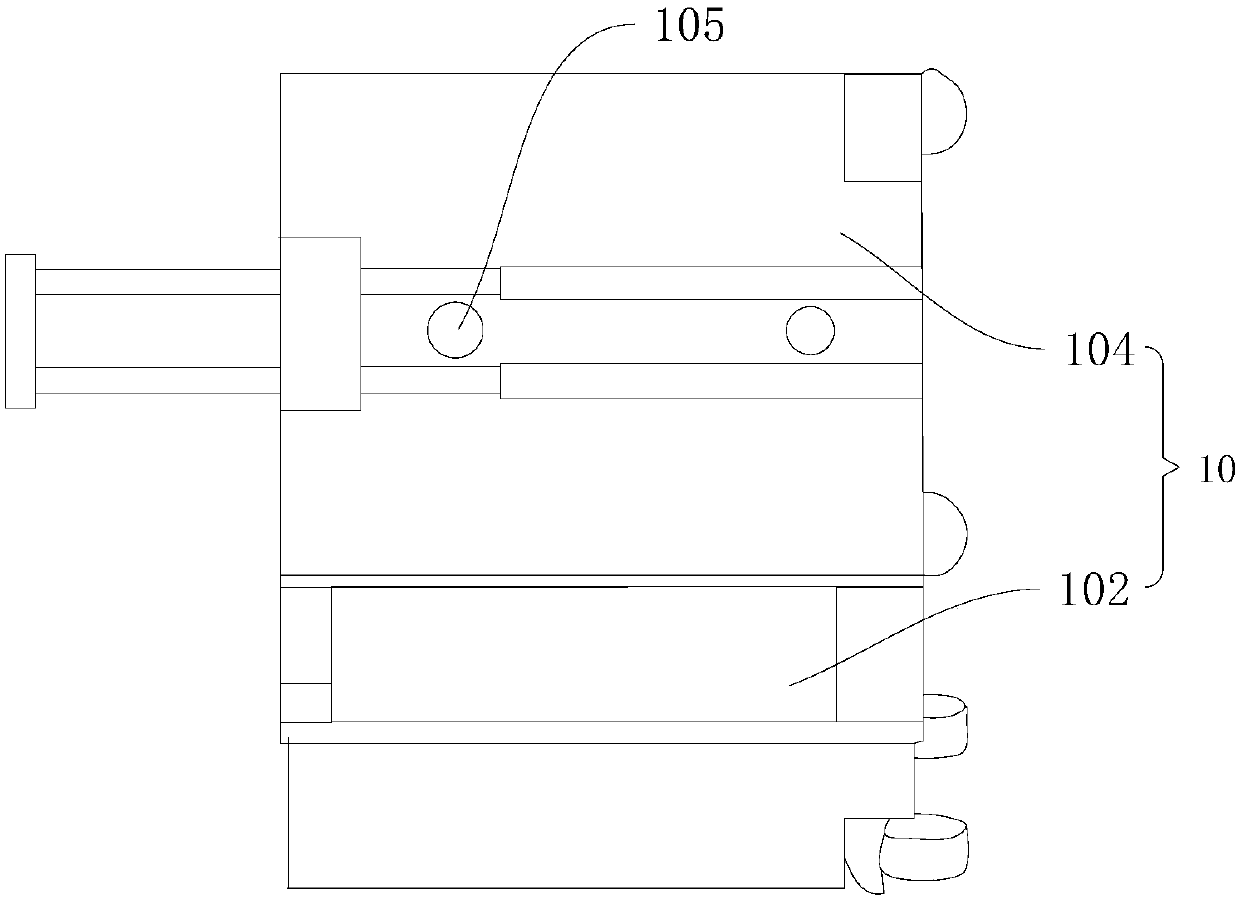

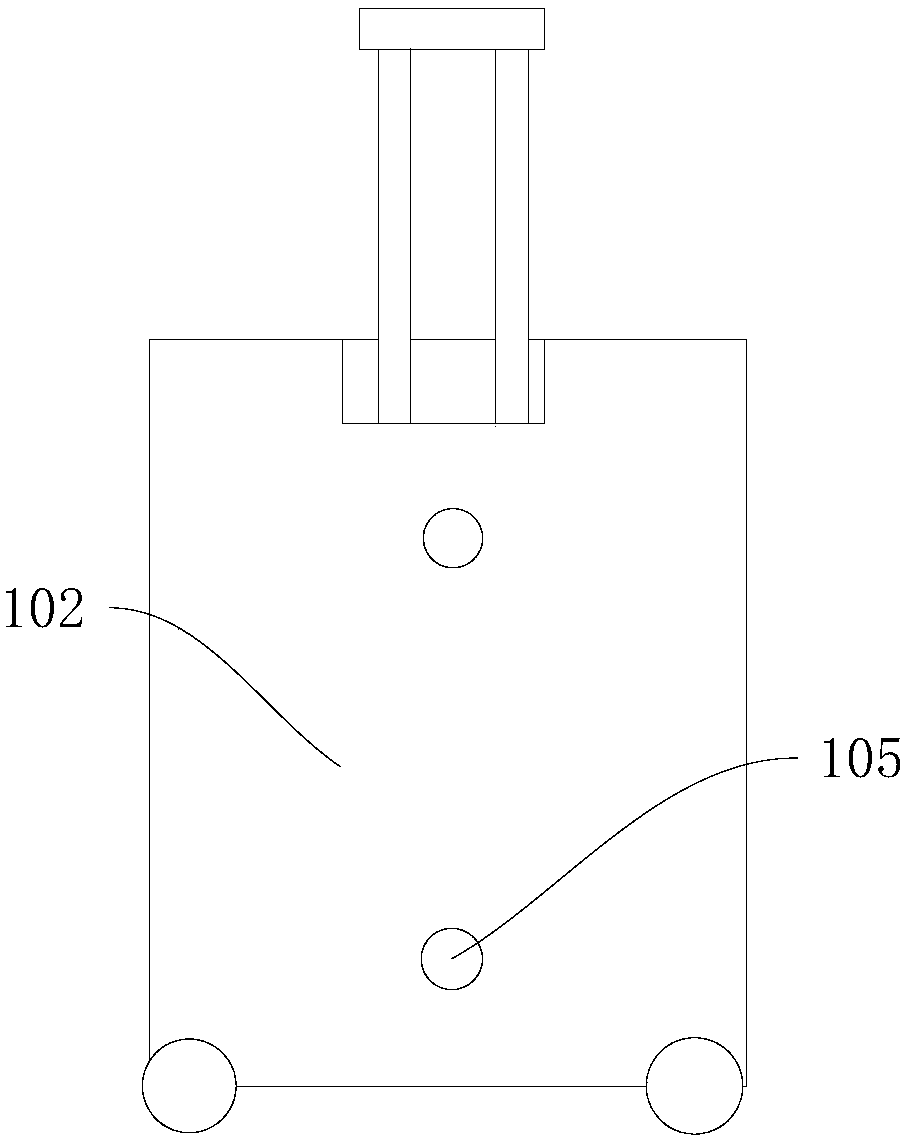

Luggage drying case and luggage containing device with drying function

The invention discloses a luggage drying case and a luggage containing device with a drying function and relates to the technical field of articles for daily life. The luggage drying case comprises aluggage case body, at least two ventilation assemblies and a clothes airing assembly, wherein at least two ventilation holes are formed in the luggage case body; the ventilation assemblies and the ventilation holes have the same quantity and form one-to-one correspondence; the clothes airing assembly is arranged in a containing cavity of the luggage case body and is used for suspending clothes tobe dried. Each ventilation assembly comprises a cover body and a lock catch part; each lock catch part is fixedly arranged in an inner wall of each ventilation hole; each cover body can be buckled tothe corresponding ventilation hole and is locked and fixed with the corresponding lock catch part; each cover body has a first state of being unlocked with the corresponding lock catch part to open the corresponding ventilation hole and a second state of being locked with the corresponding cover body and lock catch part to close the corresponding ventilation hole. The luggage drying case disclosedby the invention is reasonable in design and simple in structure; the luggage case has a function of rapidly drying clothes under the condition that the weight and the cost are hardly increased; onecase has two functions so that the luggage drying case has better practicability and provides extremely great convenience for the travelling of people.

Owner:赵朝文

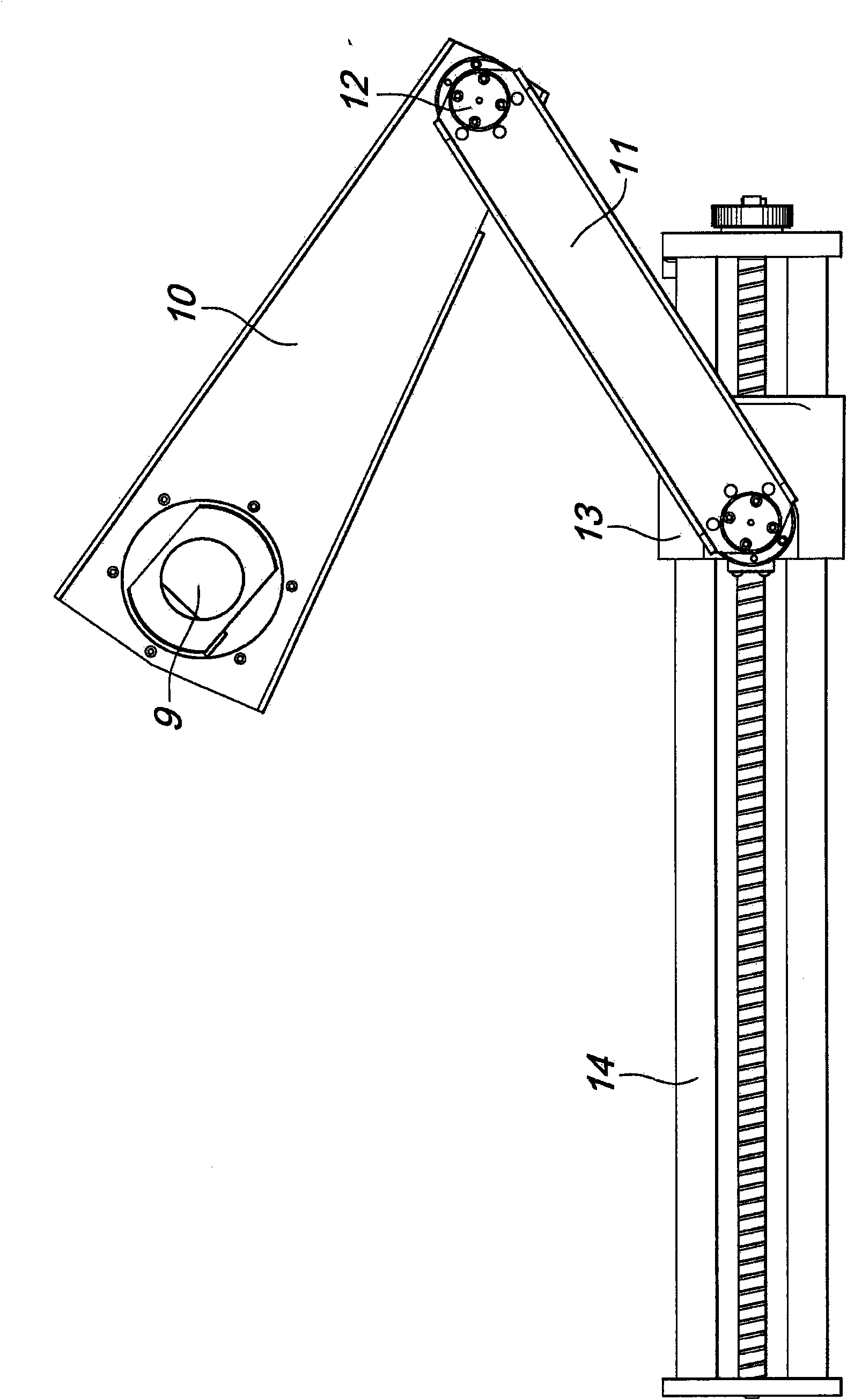

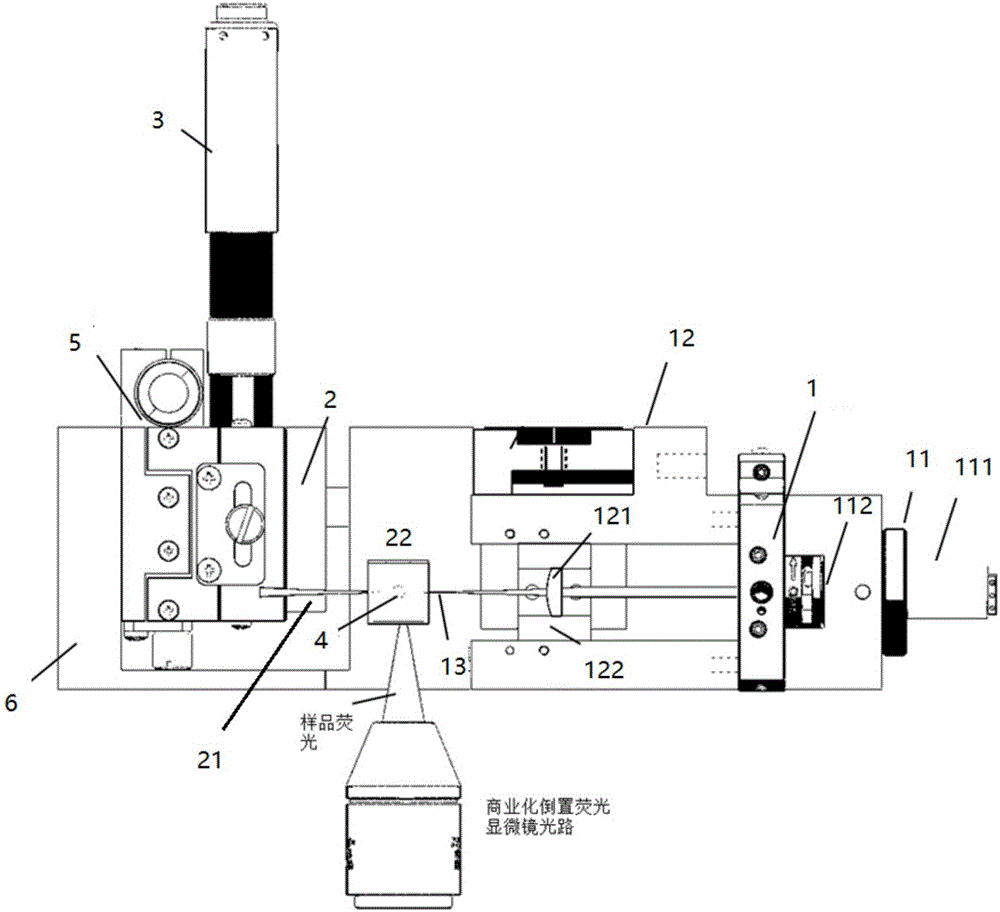

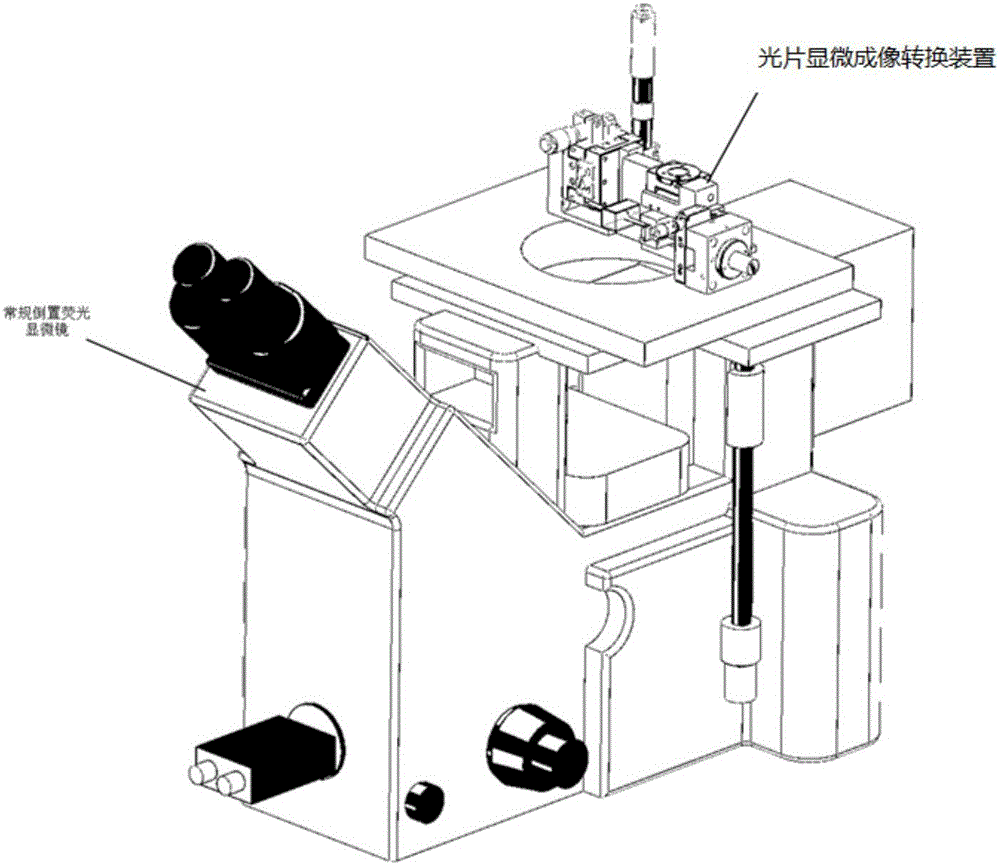

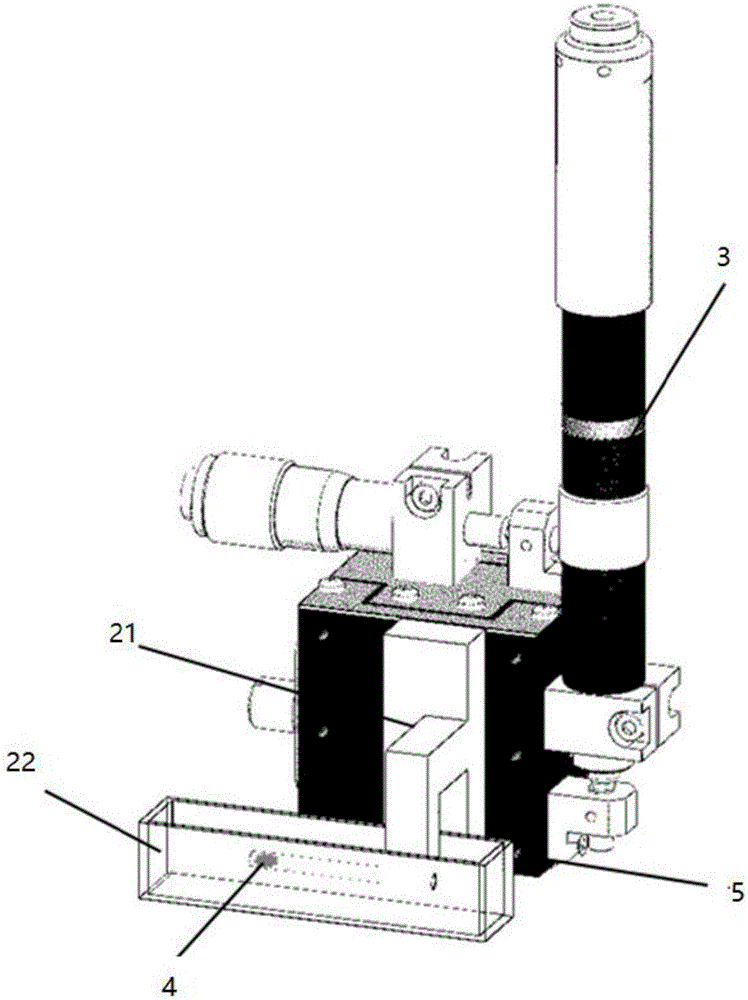

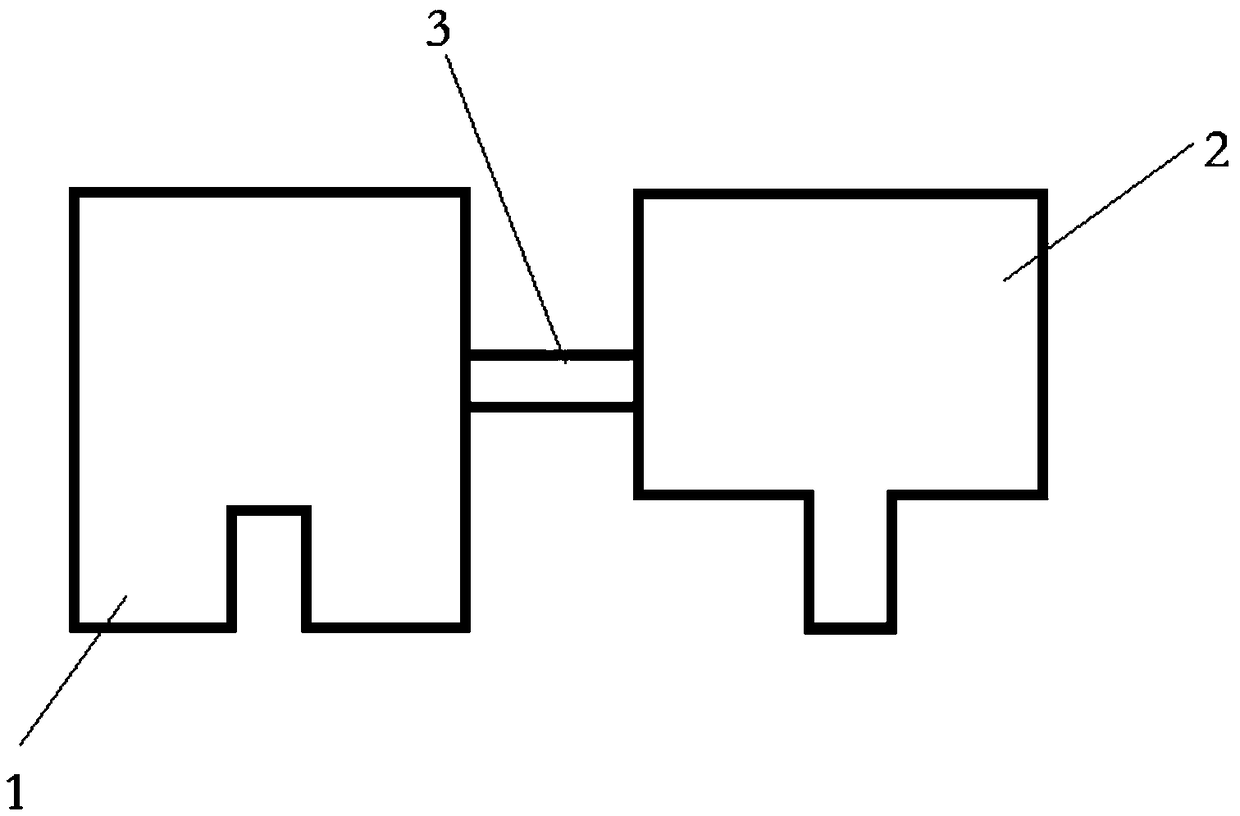

Light sheet microscopic imaging conversion apparatus

The invention discloses a light sheet microscopic imaging conversion apparatus. The light sheet microscopic imaging conversion apparatus comprises a light sheet laser light source, a sample clamping device and a motion device; the light sheet laser light source generates light sheet laser which is horizontally irradiated onto a sample which is fixedly arranged on the sample clamping device; and the motion device is connected with the sample clamping device and used for driving the sample clamping device to move in a direction forming an angle less than 15 degrees with the vertical direction. The light sheet microscopic imaging conversion apparatus is a small-sized conversion apparatus with low cost; the light sheet microscopic imaging conversion apparatus is installed on an ordinary inverted fluorescence microscope, so that the light sheet microscopic imaging conversion apparatus has a light sheet microscopic imaging capacity; and a great breakthrough on the three-dimensional imaging can be realized by virtue of small modification, so that the three-dimensional imaging cost of a biological sample can be greatly reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Artificial fish reef materials and method for preparing fish reef thereof

ActiveCN109258540ALight in massIncrease flexibilityClimate change adaptationPisciculture and aquariaSodium BentoniteShrimp

The invention belongs to the technical field of artificial fish reefs, and particularly relates to artificial fish reef materials and a method for preparing a fish reef thereof. Raw materials of polyethylene, cellulose-thiosemicarbazide, bentonite, illite powder, coupling agent KH-550 and tert-butylsilane vinyl triperoxide are adopted to be prepared into an artificial fish reef. The fish reef hasthe advantages of low mass, low cost, high strength, corrosion resisting, environmental friendliness and long service life, heavy metal ions and other harmful substances can be effectively absorbed, and the growing environment of fish, shellfish and shrimp can be ensured.

Owner:GUIZHOU UNIV OF ENG SCI

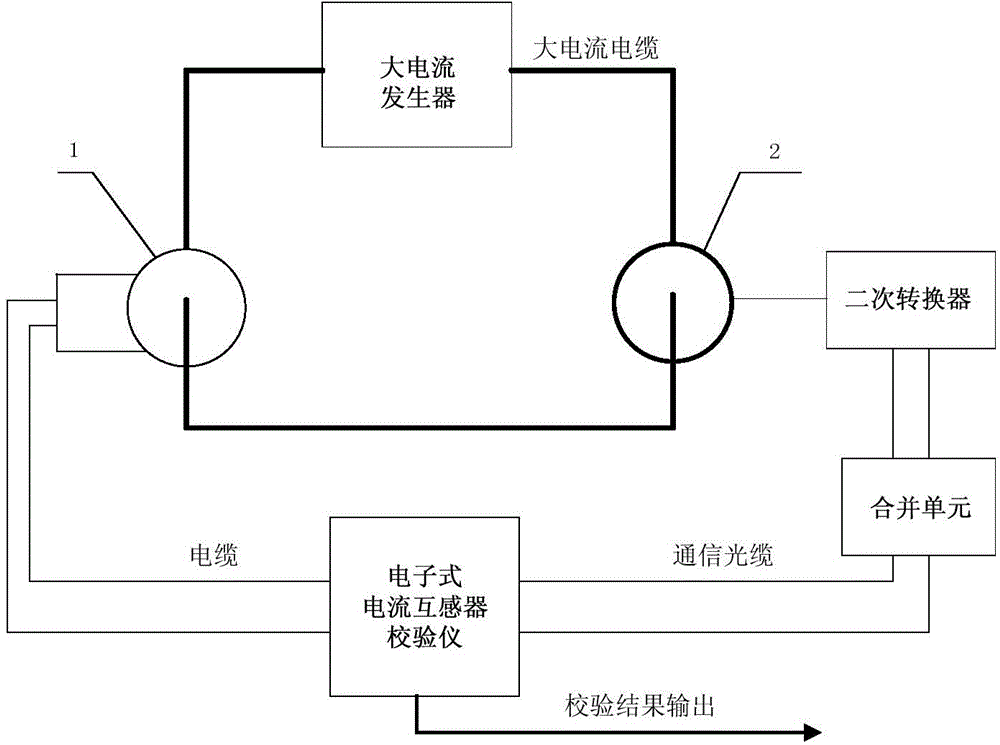

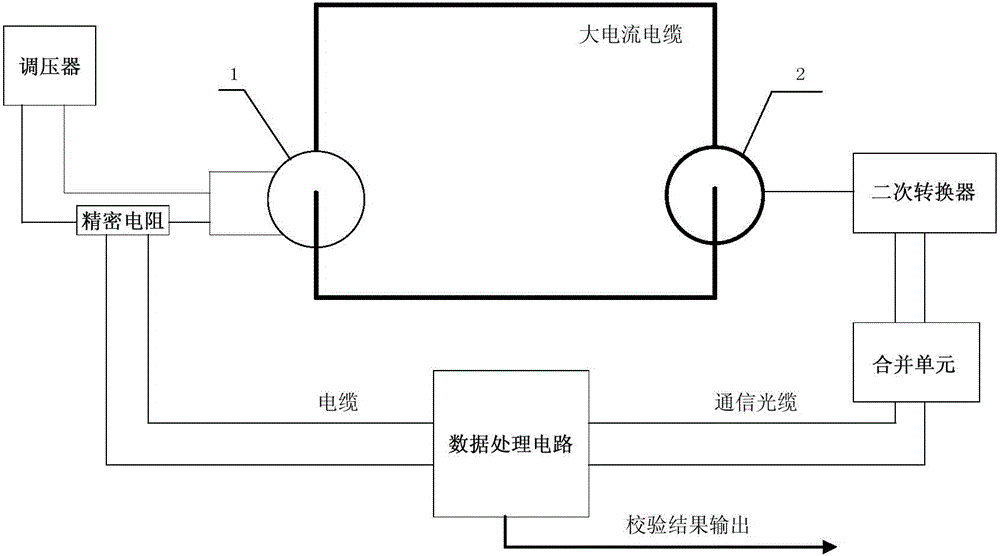

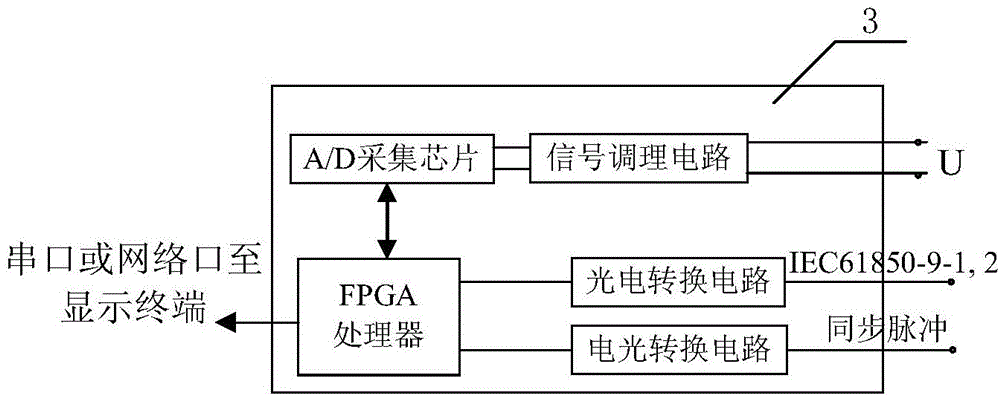

Device and method for checking portable electronic current transformer

ActiveCN104880686AReduce calibration costsImprove verification efficiencyElectrical measurementsElectrical resistance and conductanceSecondary side

The invention relates to a device and method for checking a portable electronic current transformer. The device includes a standard current transformer, a heavy current cable, a secondary converter, a merging unit, a voltage regulator, a precision resistor, and a data processing circuit. Voltage output by the voltage regulator is connected to a secondary side input terminal of the standard current transformer via series connection of the precision resistor; voltage at the two ends of the precision resistor are led into the data processing circuit via the cable; the primary side output terminal of the standard current transformer is connected to the heavy current cable; the heavy current cable is further in series connection with a to-be-measured electronic current transformer and is connected with the primary side input terminal of the to-be-measured electronic current transformer; the secondary side output terminal of the to-be-measured electronic current transformer is connected to the secondary converter and the merging unit in sequence; the merging unit outputs a to-be-measured current signal to the data processing circuit; and the data processing circuit outputs a checking result. The device has advantages, such as high checking precision, small size, light weight, portability, and low cost.

Owner:GUIZHOU POWER GRID CO LTD

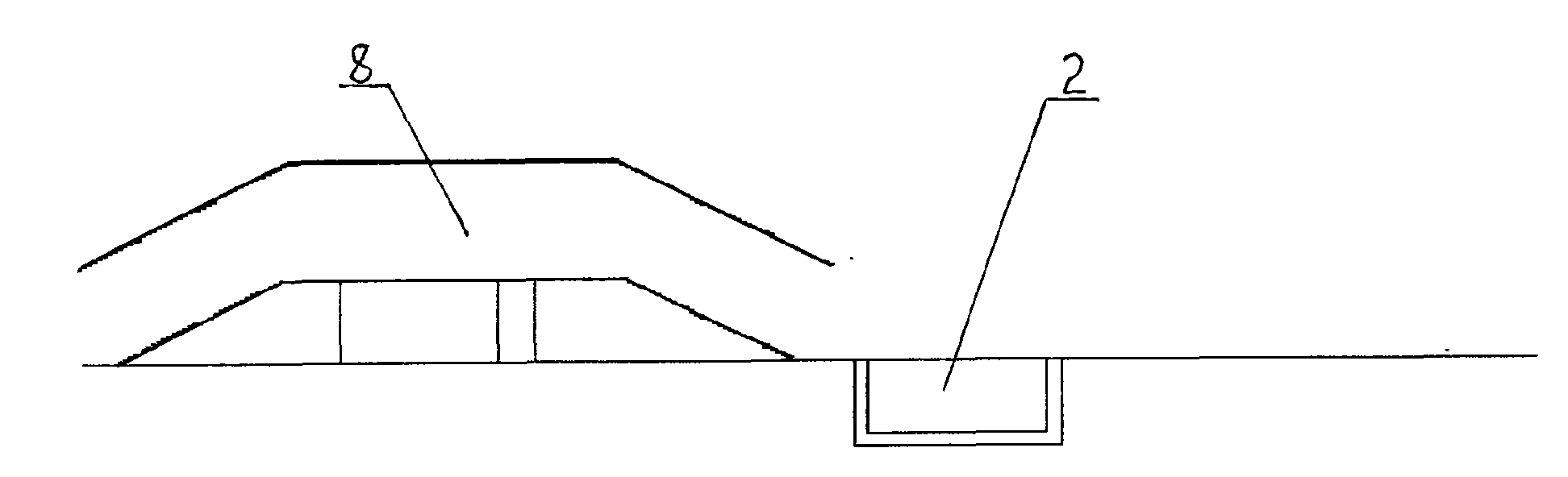

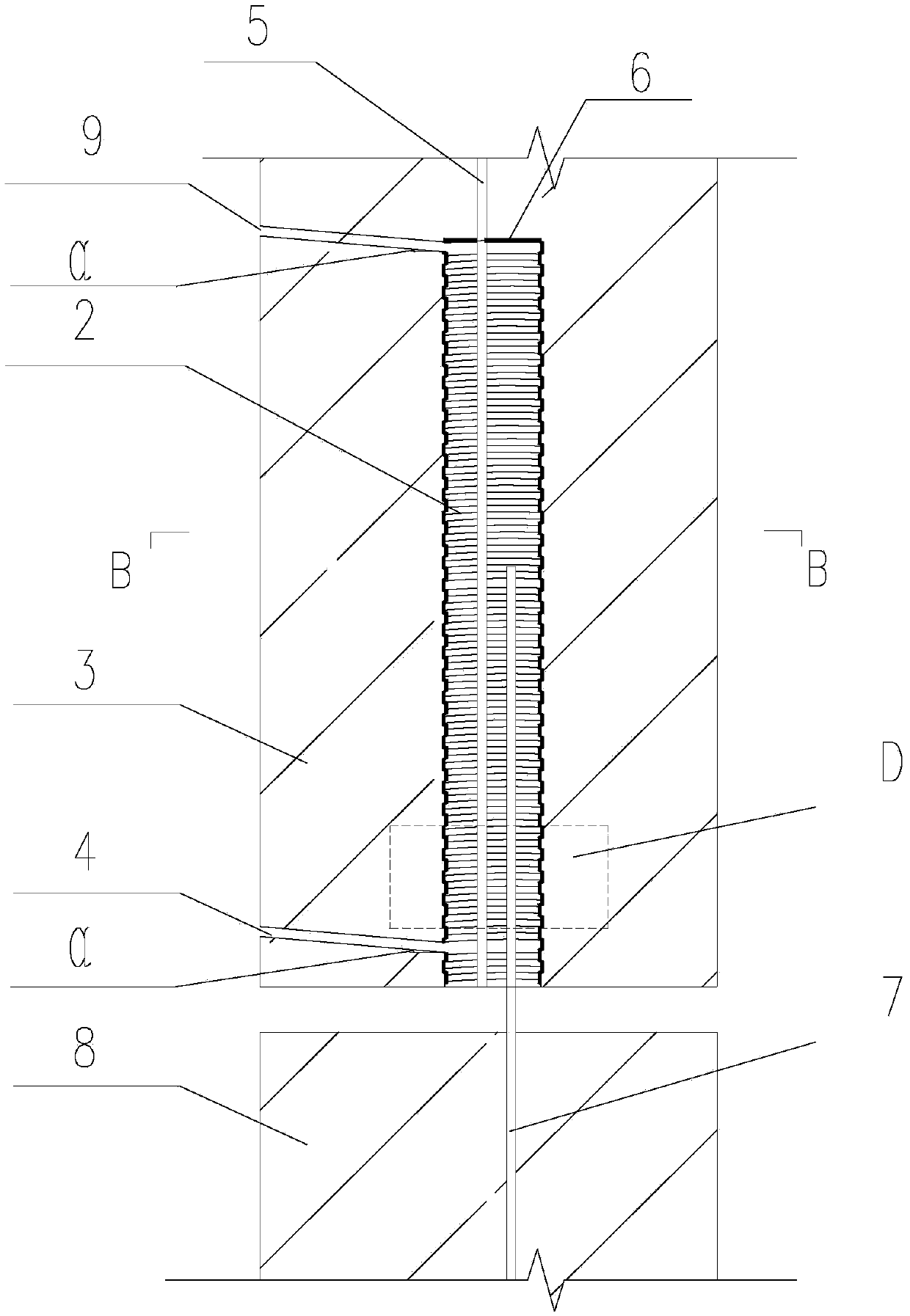

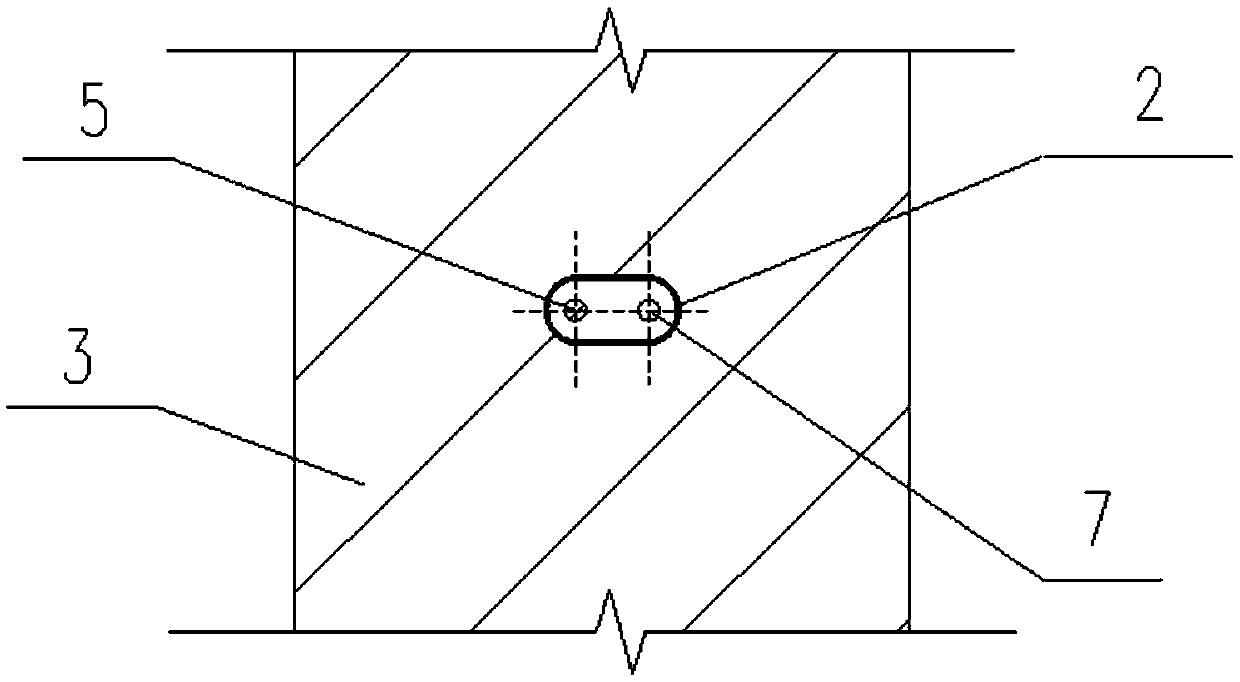

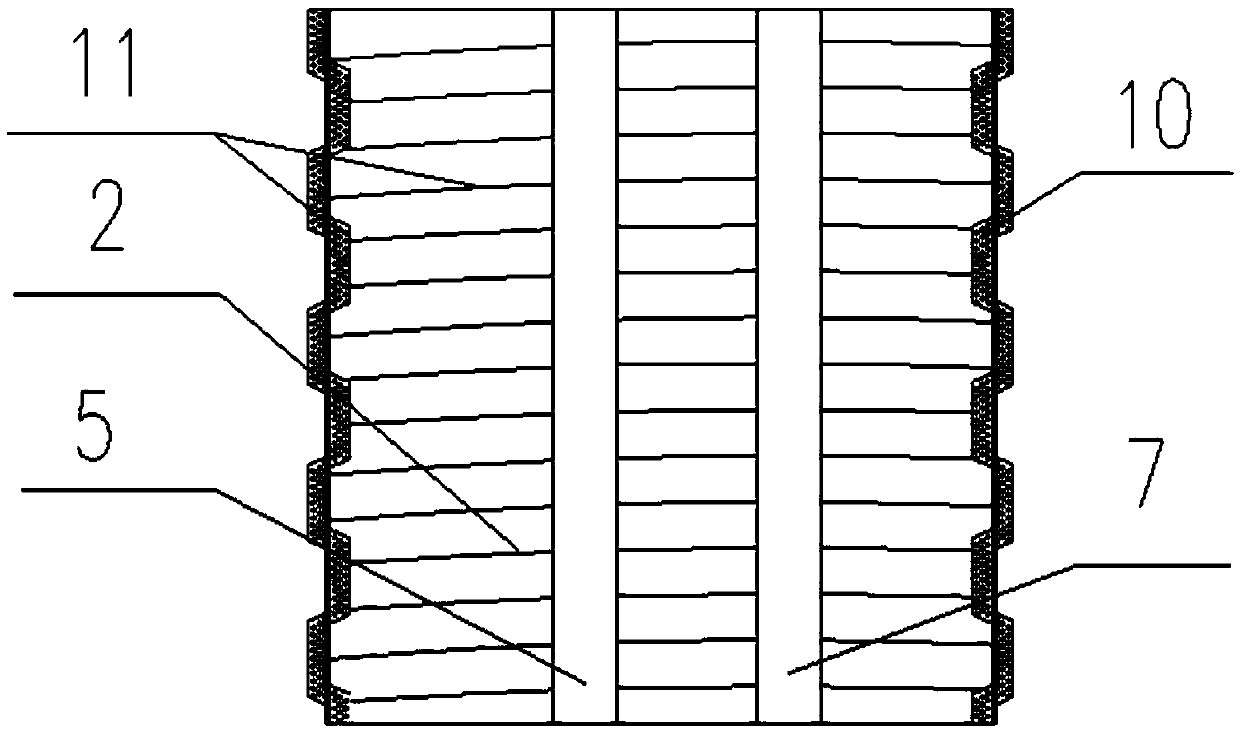

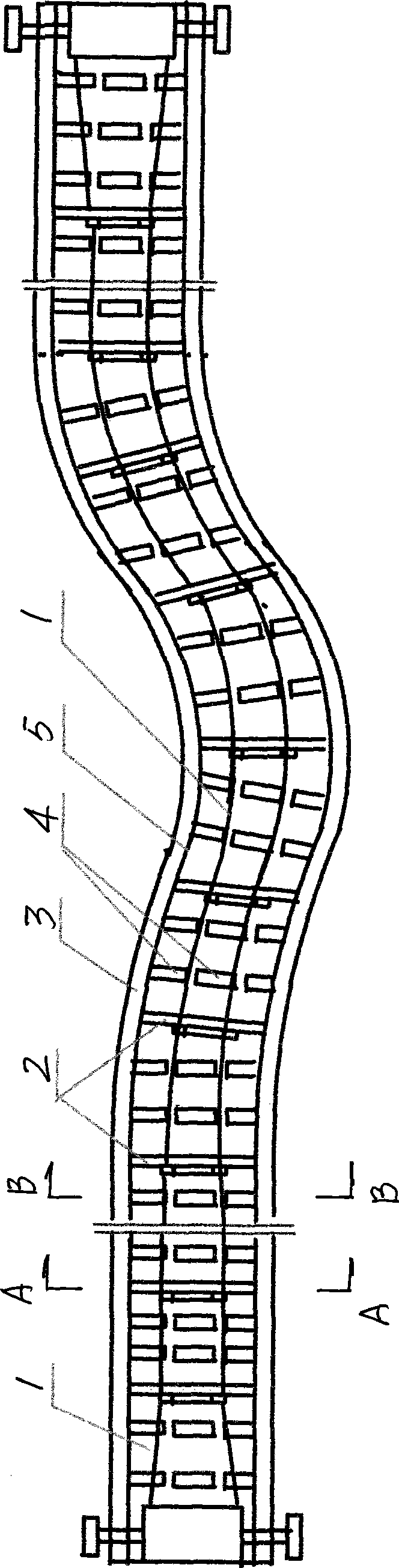

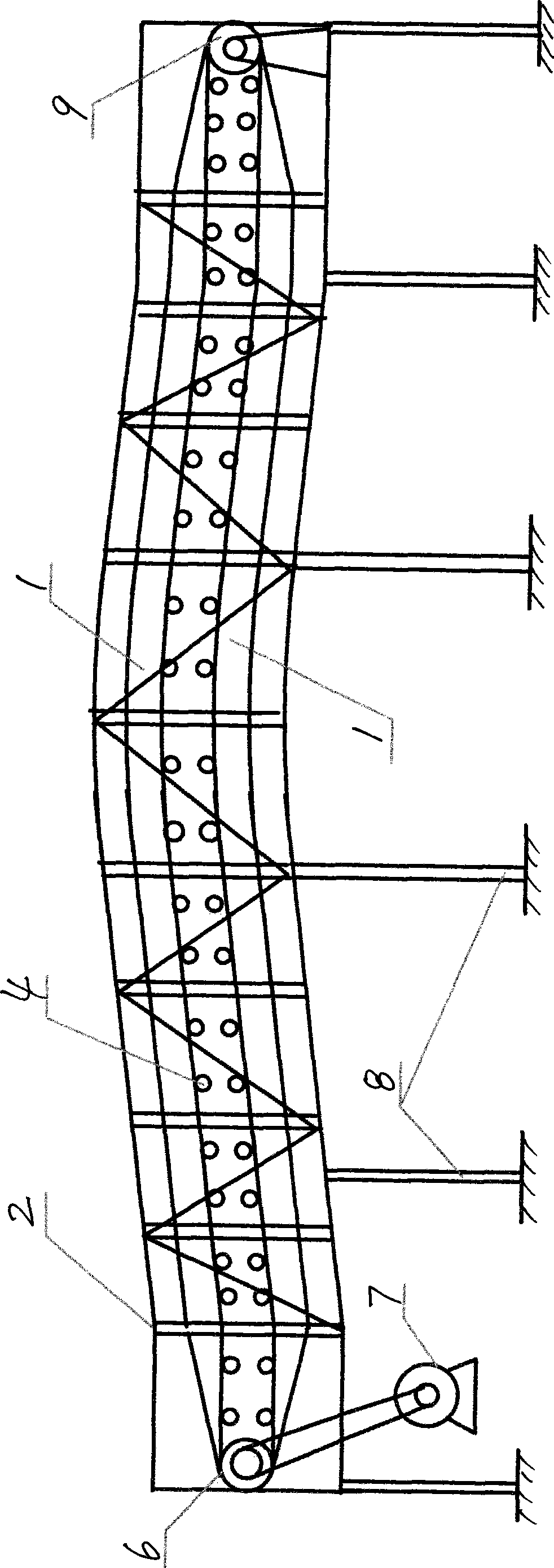

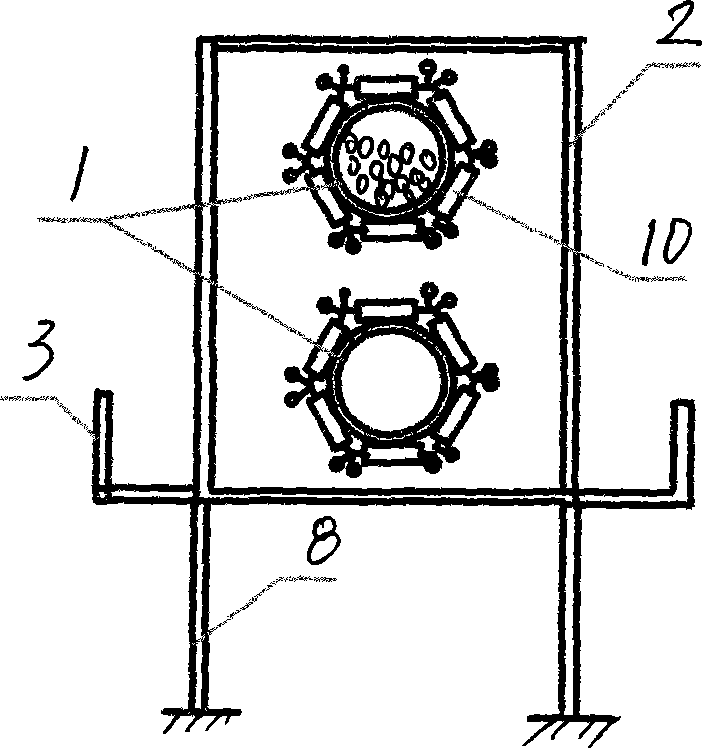

Tubular tape sealing machine applying carrier roller

InactiveCN101544303ASolve corrosiveSolve easy oxidation and rustConveyorsSupporting framesAdhesive beltEngineering

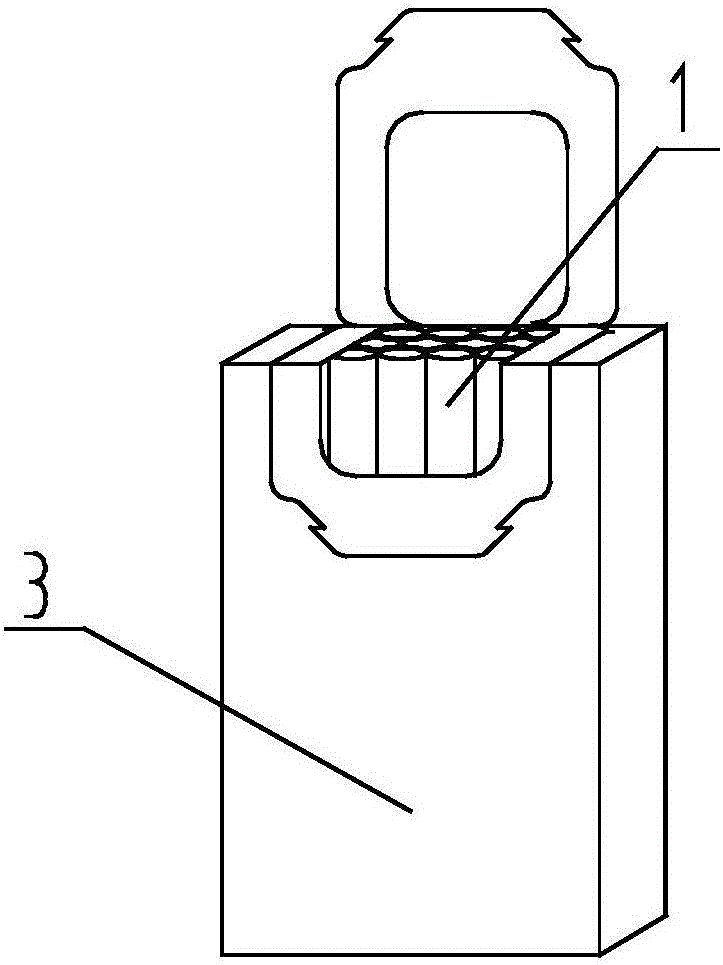

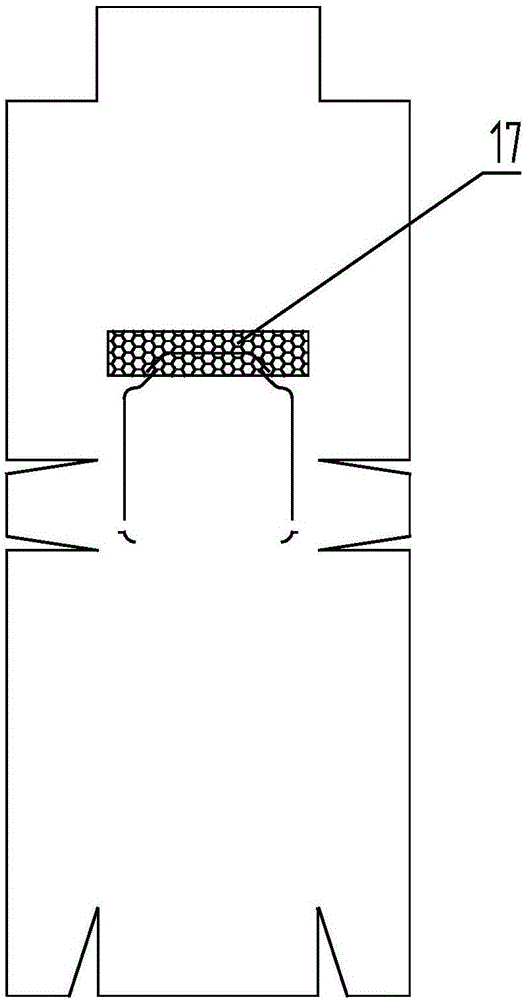

The invention discloses a tubular tape sealing machine applying a carrier roller (comprising a high-toughening aluminum ceramic carrier roller, a middle aluminum ceramic carrier roller and a high aluminum ceramic carrier roller); the tubular tape sealing machine applying the carrier roller is a conveying belt system consisting of a receiving section, a discharging section, a linear section, a horizontal bent section, a vertical bent section and a three-dimensional variable section; the conveying belt system comprises struts (8), frames (5), enclosed frames (2), adhesive taps (1), driving rollers (6), supporting carrier rollers (4) and molding carrier rollers (10); the enclosed frames and corridors are alternately arranged on the frames of the horizontal bent section, the vertical bent section and the three-dimensional variable section; the upper part and the lower part of the enclosed frame are provided with the molding carrier rollers (10) in orthohexagonal arrangement respectively; at least one row of the supporting carrier rollers in trapezoidal arrangement are arranged between the enclosed frames (2); the supporting carrier roller and the molding carrier roller comprise a cylinder body (14) of the ceramic carrier roller; the ceramic carrier roller has the advantages of high strength, good rigidity and wearing resistance, high temperature resistance, acid and alkali corrosion resistance and anti-oxidation; and the tubular tape sealing machine improves the conveying efficiency of the tubular tape sealing machine, reduces the maintenance expense and labor intensity, is rainproof and theftproof, saves materials and is convenient to manufacture and mount.

Owner:萍乡市新安工业有限责任公司

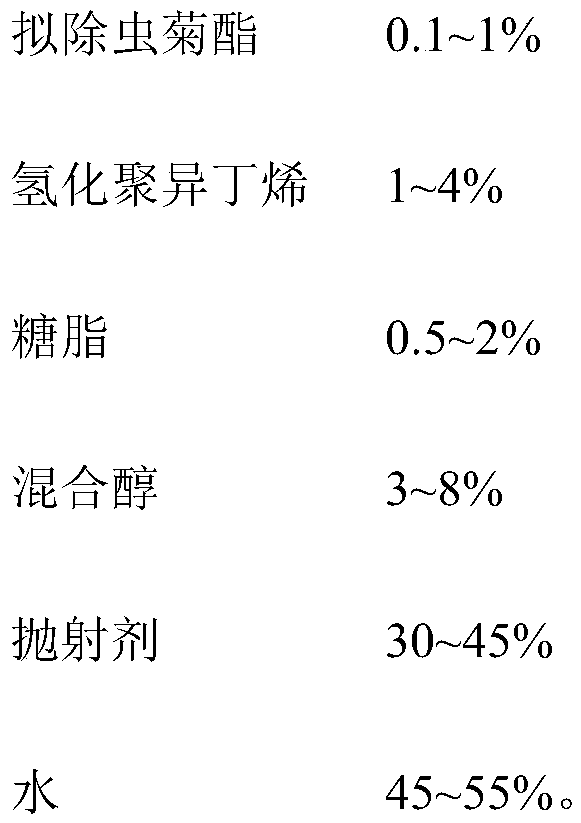

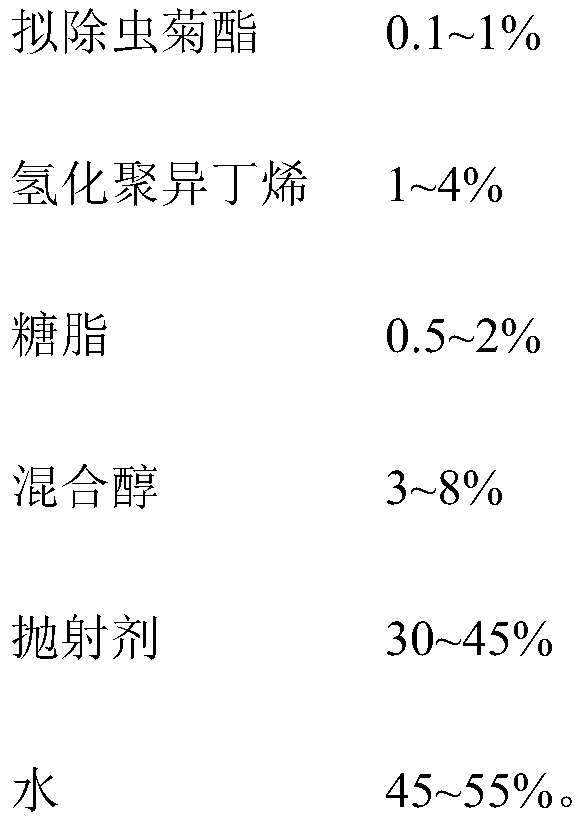

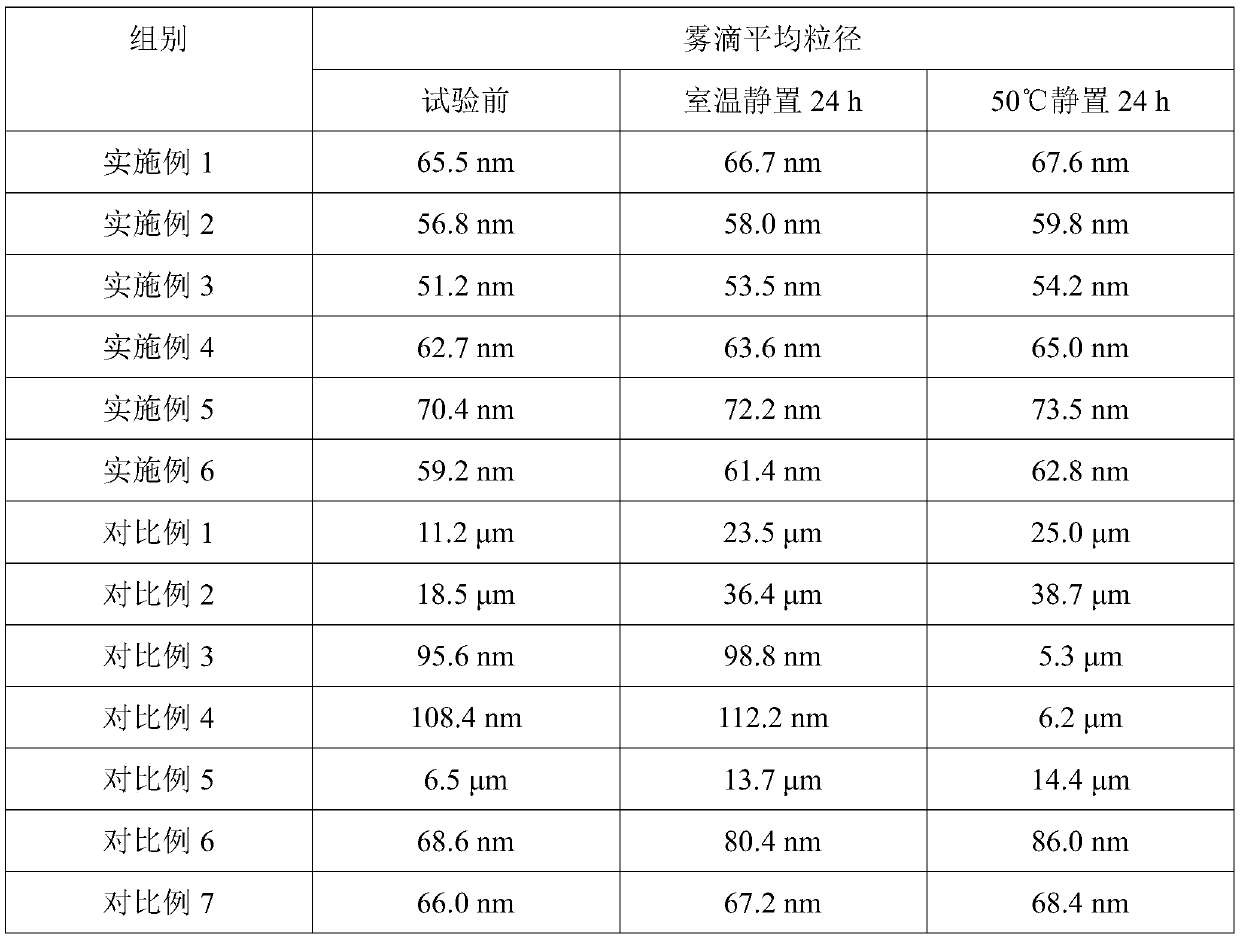

Insecticidal aerosol and preparation method thereof

ActiveCN110384091AImprove permeabilityImprove thermal stabilityBiocideAnimal repellantsWater basedAlcohol

The invention discloses an insecticidal aerosol and a preparation method thereof. The insecticidal aerosol comprises the following components in percentage by mass: 0.1-1% of pyrethroid, 1-4% of hydrogenated polyisobutene, 0.5-2% of glycolipid, 3-8% of mixed alcohol, 0.1-0.5% of a synergist, 0.05-0.3% of an essence, 30-45% of a propellant and 45-55% of water. The insecticidal aerosol disclosed bythe invention is a thermodynamically stable water-based microemulsion system, has a particle size in a range of 10-100 nm, has transparent appearance, is not layered after being stood for a long time,has good stability, and can be directly sprayed without shaking. In addition, the insecticidal aerosol has an insecticidal effect close to an oil-based product, and has fast killing effects on mosquitoes, flies and cockroaches.

Owner:LOOBI GUANGZHOU HEALTH IND CO LTD

Rapid molding method of pre-stressed tubular member

The invention discloses a rapid molding method of a pre-stressed tubular member. Reeling is carried out before molding in order to save the space and the amount, the onsite molding method is simple, and solves the problems of high transportation cost and difficult transportation of tubular members especially large tubular members in the market, and a reinforcing material (such as a continuous glass fiber) has certain pre-stress, is positioned in a pre-tensioning state, has extremely good mechanical, physical and chemical performances. The molding method has the advantages of rapid and simple molding, onsite molding as needed, material waste avoiding, great cost reduction and wide market prospect.

Owner:北京恒吉星科技有限责任公司

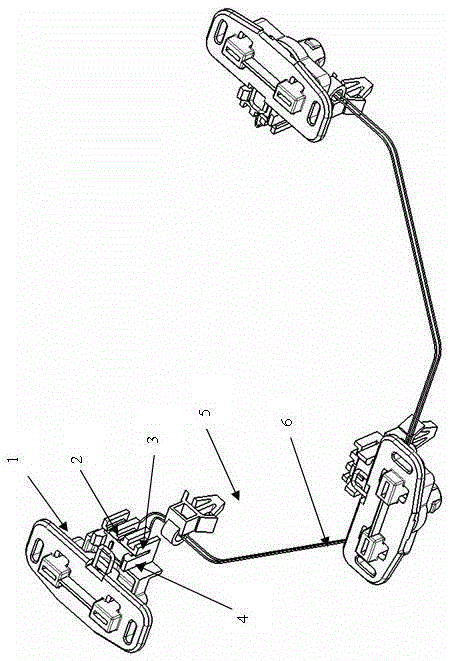

A car horn ringing mechanism

ActiveCN103568942BSimple designChange the switch principleAcoustic signal devicesSteering wheelEngineering

A novel automobile horn sounding mechanism comprises a steering wheel decoration cover. At least three structure units which are distributed in the circumferential direction are fixedly arranged below the steering wheel decoration cover. Each structure unit is composed of a supporting plate fixedly connected with the steering wheel decoration cover, a fixed support installed below the supporting plate, a supporting spring located between the fixed support and the supporting plate and a micro-switch arranged on the fixed support. The tail ends of the supporting springs arranged on the supporting plates are triggering points, the motion stroke of the supporting plates is larger than the distance between the tail end triggering points of the supporting springs and the triggering ends of the micro-switches, and the micro-switches are connected through wires. According to the novel automobile horn sounding mechanism, the switching principle of an existing automobile steering wheel horn sounding mechanism is changed, the micro-switches which are mature in technology and long in service life are applied to the automobile horn sounding mechanism, the design of a steering wheel is simplified, the cost is lowered, the service life is prolonged, the reliability is improved, and compared with an existing horn sounding structure, the novel automobile horn sounding mechanism has cost and performance advantages.

Owner:JINZHOU JINHENG AUTOMOTIVE SAFETY SYST

Nano-grade modified sintered brick and production method thereof

InactiveCN105000863ALow densityLow thermal conductivitySolid waste disposalFurniture waste recoveryBrickSlag

The invention discloses a nano-grade modified sintered brick and a production method thereof. The brick is prepared from the raw materials of, by weight, 2-4 parts of nano-grade alumina, 10-15 parts of sculpture clay, 8-12 parts of sea mud, 5-10 parts of polyvinyl acetate, 4-6 parts of tung oil, 3-6 parts of waste syrup, 1-2 parts of sodium lauroyl sarcosinate, 3-5 parts of fir balsam, 4-8 parts of asbestos fiber, 6-8 parts of an additive, a proper amount of water, and the like. According to the invention, waste brick slag is adopted as a main raw material, such that clay resource is saved, production cost is reduced, a waste brick slag treatment problem is solved, and environment pollution caused by the waste brick slag is avoided. The sintered brick provided by the invention has the advantages of high strength, high bearing capacity, low density, low heat conductivity coefficient, wide application range, and good market prospect. The sintered brick meets the requirements of users. The added polyurethane elastomer has excellent wear resistance and oil resistance, and is a polar polymer which can be organically combined with polypropylene, such that polypropylene mechanical performances can be improved. The added fluororubber has the characteristics of high-temperature resistance, oil resistance and the like. With the other fillers other physical performances and processing performances can be enhanced.

Owner:CHANGZHOU WUJIN GOLDEN SUNSHINE ELECTRONICS

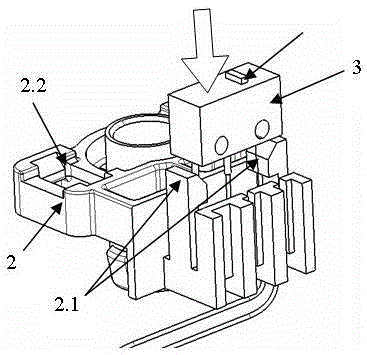

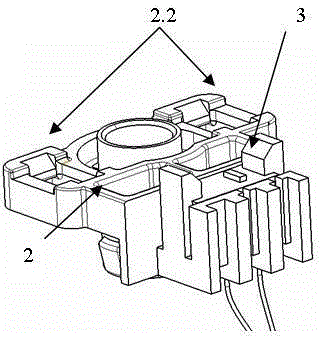

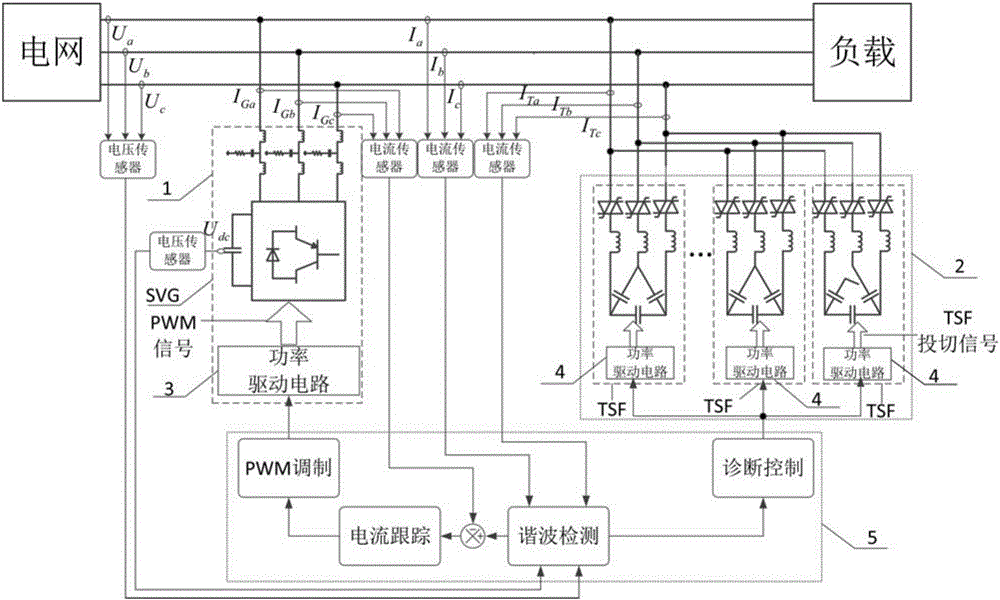

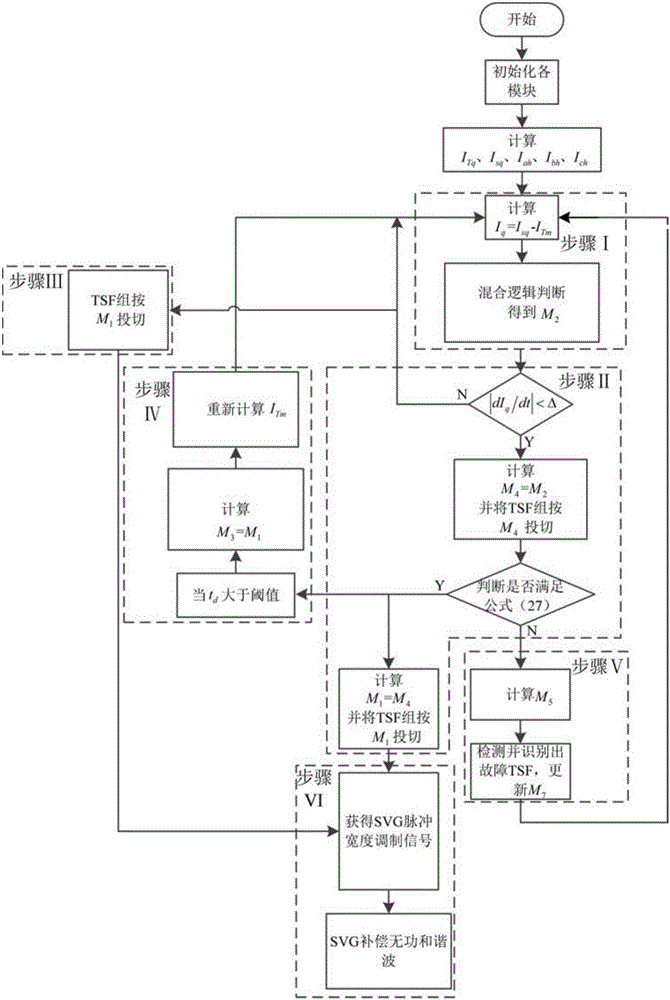

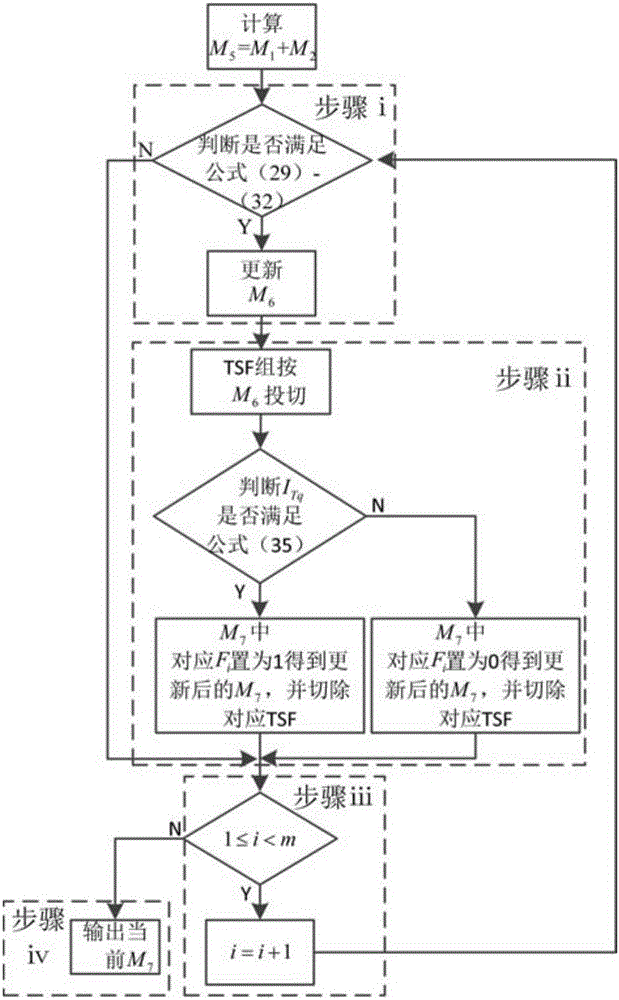

Control method with fault diagnosis and automatic restoration function for hybrid compensation system

ActiveCN105071391AImprove robustnessReduce post-maintenance costsReactive power adjustment/elimination/compensationReactive power compensationHarmonicEconomic benefits

The invention discloses a control method with fault diagnosis and automatic restoration functions for a hybrid compensation system. According to the control method for the hybrid compensation system, power grid three-phase currents between an SVG and a TSF group as well as output three-phase currents of the TSF group are regarded as detection objects, voltage and current values acquired by sensors are processed through a controller, the TSFs are controlled to compensate most of reactive power of a load in a graded manner and filter out specific subharmonic waves by using a diagnostic control module, when one of the TSFs fails, the faulty TSF is diagnosed and cut off automatically, and the normal TSFs are reconfigured on demand and put into service, so that the hybrid compensation system has the automatic restoration function; in addition, control parameters of the SVG are obtained according to an instantaneous power theory, so as to achieve continuous compensation of residual reactive power and harmonic waves of the load. The control method ensures stable and reliable operation of the hybrid compensation system in normal and fault states of the TSFs, greatly increases system operating efficiency, and reduces system later-stage maintenance cost. The control method for the hybrid compensation system saves energy, reduces emission, is green and environmentally friendly, has good social and economic benefits, and is particularly suitable to be used in the petroleum drilling field with high damage rate of the TSF due to harsh environment.

Owner:江苏辰午节能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com