Integral moisture-retention cigarette case adopting annular opposed die cutting wrapping composite and manufacturing method of integral moisture-retention cigarette case

A wrapping material and integrated technology, which is applied in the direction of packaging cigarettes, applications, packaging, etc., can solve the problems of unreasonable packaging structure, high cost, lack of function, etc., achieve good material surface roughness and water absorption performance, and perfect molding Processing adaptability, solve the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

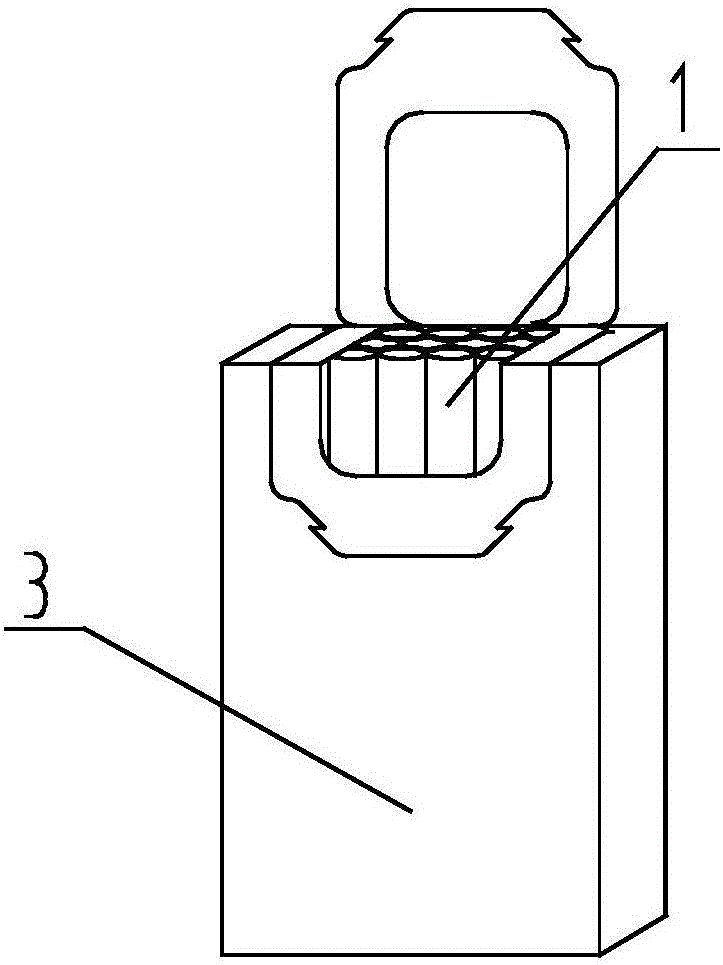

[0093] Step 1, place the cigarette 1 vertically, let the paper inner frame 2 wrap the cigarette 1, and make it into a packaging liner for future use. Such as Figure 5 , 6 shown.

[0094] Step 2, making the upper dense layer 4 for later use. The raw materials of polypropylene and polyethylene pellets are mixed evenly according to the mass ratio of 4:1 and poured into the plastic melting extruder, and melted at a temperature of 390°C in a liquid state, extruded into a thin curtain and drenched on the paper 8 Between the PET reinforcement layer 10, the paper is double-sided coated paper with a basis weight of 50g / m 2 , with a thickness of 0.09 mm, the two are glued together to obtain an upper dense layer 4 and rolled up for later use. The thickness of the upper dense layer 4 is controlled between 0.11mm and 0.12mm. Such as Figure 31 shown.

[0095] Step 3, making the lower dense layer 7 for use. The raw materials of polypropylene and polyethylene pellets are mixed evenl...

Embodiment 2

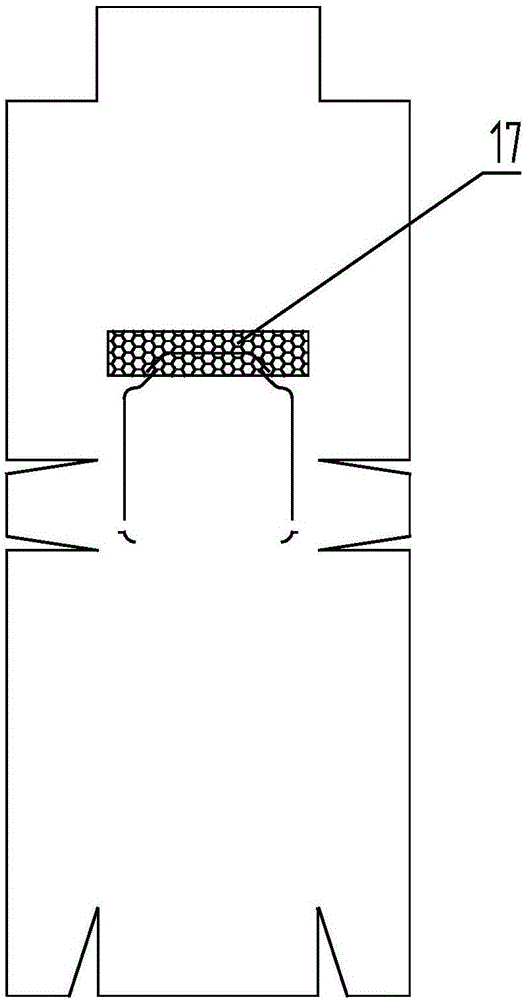

[0105] Step 1, place the cigarette 1 vertically, let the paper inner frame 2 wrap the cigarette 1, and make it into a packaging liner for future use. Such as Figure 12 , 13 , 14 shown.

[0106] Step 2, making the upper dense layer 4 for later use. The upper dense layer 4 is made of BOPP film with a thickness of 0.025mm, and is made after vacuum aluminum plating and transparent yellow printing, and is rolled up for later use. The thickness of the upper dense layer 4 is controlled between 0.028mm and 0.0.03mm. Such as Figure 31 shown.

[0107] Step 3, making the lower dense layer 7 for use. The lower dense layer 7 is made of BOPP film with a thickness of 0.025mm, and is produced after vacuum aluminum plating and transparent red printing, and is rolled up for later use. The thickness of the lower dense layer 7 is controlled between 0.028mm and 0.0.03mm. Such as Figure 32 shown.

[0108] Step 4, coating the adhesive layer 6 on the lower dense layer 7 . The non-printe...

Embodiment 3

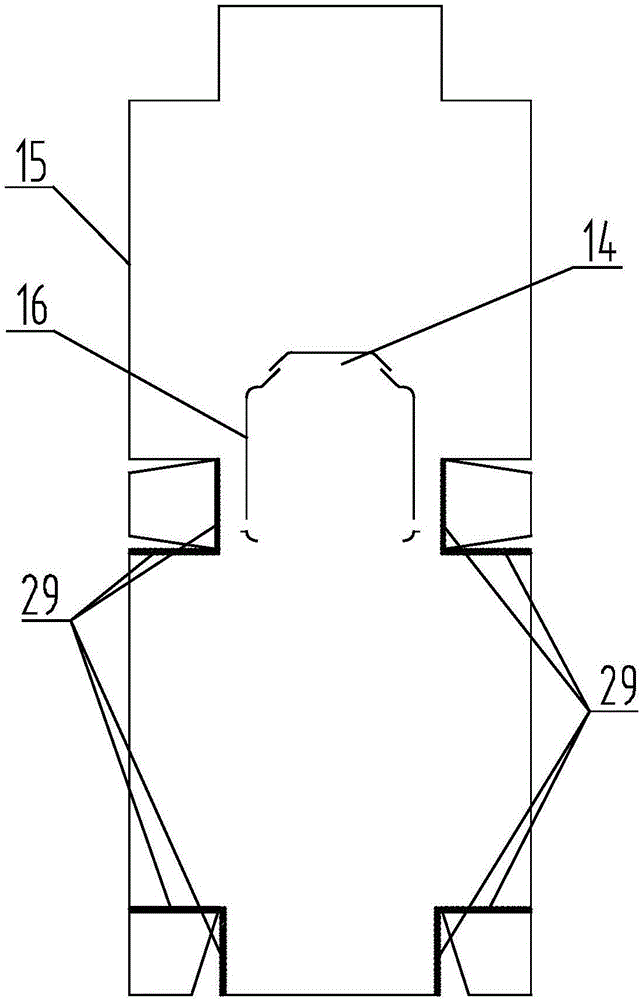

[0117] The cigarette case that is made according to the method of embodiment 2 is used as the moisturizing inner box, and the opening 14 of the outer opening sheet 16 is glued, put into the fully open packaging 27, and the moisturizing inner box is opened from the inside of the fully open packaging 27. Permanently bonded with it to produce a fully open moisture-retaining cigarette case. Such as Figure 19 , 20 , 21 shown. When the shake cover of full-open packing box 27 is opened, the outer open piece 16 and the inner open piece 18 can be opened together with the shake cover; when the shake cover of the fully open package box is closed, the outer open piece 16 and the inner open The flap 18 can be closed together with the flap. Such as Figure 22 , 23 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com