Patents

Literature

484results about How to "Good printing adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High peeling environment-friendly type aqueous transfer coating and use thereof

InactiveCN101407654AReduce manufacturing costGood printing adaptabilityCoatings with pigmentsPolyurea/polyurethane coatingsVolatile organic compoundChemistry

The invention relates to a high peeling-off environment-friendly waterborne transfer coating and an application thereof, wherein, the waterborne transfer coating takes the following components with the contents (parts by weight) as raw materials: 10 to 60 parts of waterborne resin; 0 to 10 parts of auxiliary agent; 0 to 10 parts of rheological control agent; 0 to 30 parts of cosolvent; 0 to 10 parts of pigment; 30 to 80 parts of deionized water; and 0 to 5 parts of pH value regulator. Compared with the prior art, the waterborne transfer coating has the following advantages of: (1) environmental protection and cost advantages: the waterborne transfer coating takes water as a main dispersion medium and has no organic solvent basically, very low content of volatile organic compounds (VOCs) and low production cost; (2) good printing adaptability: compared with a the solvent system, a waterborne system is different on the resin and the polarity from the solvent, thereby having good solvent resistance and being more applicable to the printing modes (such as gravure printing and screen printing) with higher requirements on the solvent resistance; and (3) the waterborne transfer coating can be directly used for replacing the existing solvent high peeling-off transfer coating by the pilot scale production confirmation.

Owner:SHANGHAI WEIKAI CHEM

Environment-friendly holography aluminising transfer paint, preparation and uses thereof

InactiveCN101402817ASimple processIncrease productivityCoatings with pigmentsCoatingsSolventChemistry

The invention relates to an environment protective type holographical aluminized transferring coating as well as a preparation method and an application thereof. The coating is prepared by adopting the following components and contents (weight percent): 0 to 16 percent of cellulose rein, 0 to 6 percent of chloroacetic resin, 4 to 20 percent of acrylics, 0 to 3 percent of accessory ingredient and 70 to 87 percent of solvent. Compared with the prior art, the invention has the advantages of: (1) peeling performance is excellent and holographical aluminized layer transferring is very sufficient; (2) single channel coating only has simple working procedure, high production efficiency and less energy consumption, but also has less coating amount and relative lower cost of the needed coating; (3) the coating layer has good flexibility, is hard to be chapped and the color of the coating is hard to be faded; moreover, the adhesion between the coating and the aluminum layer is quite good; the printing suitability of oil ink is high; (4) a PET basic film peeled off can be recoated and used for a plurality of times, thus reducing the product cost; and (5) the holographical aluminized transferring coating belongs to product of universal grade and has broad application range.

Owner:SHANGHAI WEIKAI CHEM

Environment-friendly type moldable aqueous transfer coating, preparation and use thereof

ActiveCN101407656AReduce contentReduce manufacturing costCoatings with pigmentsPolyurea/polyurethane coatingsSolvent basedPolyresin

The invention relates to an environment-friendly moldable waterborne transfer coating, a preparation method and an application thereof, wherein, the waterborne transfer coating takes the following components with the contents (parts by weight) as raw materials: 40 to 70 parts of waterborne resin; 10 to 20 parts of cosolvent; 18 to 40 parts of deionized water; 0.1 to 2 parts of pH value regulator; 0.1 to 0.5 part of wetting agent; 0.1 to 0.2 part of leveling agent; and 0.05 to 0.2 part of defoamer. Compared with the prior art, the environment-friendly moldable waterborne transfer coating has the following advantages of environmental protection and cost advantages, good printing adaptability, relatively wide range of suitable molding temperature during the molding, good molding effect and easy production control; furthermore, the environment-friendly moldable waterborne transfer coating can be directly used for replacing the existing solvent laser transfer coating by the pilot scale production confirmation.

Owner:SHANGHAI WEIKAI CHEM

Aqueous binding agent and preparation method thereof

ActiveCN101880512AGood storage stabilityEasy to storeMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesHot stampingEmulsion

The invention provides an aqueous binding agent which has washing resistance and is used for electrochemical aluminium hot stamping, and a preparation method thereof, belonging to a binding agent composition. The aqueous binding agent comprises 40-80 parts by weight of acrylic resin emulsion (with the solid content of 40-55%), 20-40 parts by weight of acrylic resin powder and 5-20 parts by weight of ethylene-vinyl acetate copolymer (EVA) emulsion (with the solid content of 40-60%). The binding agent does not contain organic volatile component, is harmless for the human body, is an environment-friendly electrochemical aluminium hot stamping binding agent, and is especially suitable for fabric which is needed to be printed and frequently washed.

Owner:浙江德尚化工科技有限公司

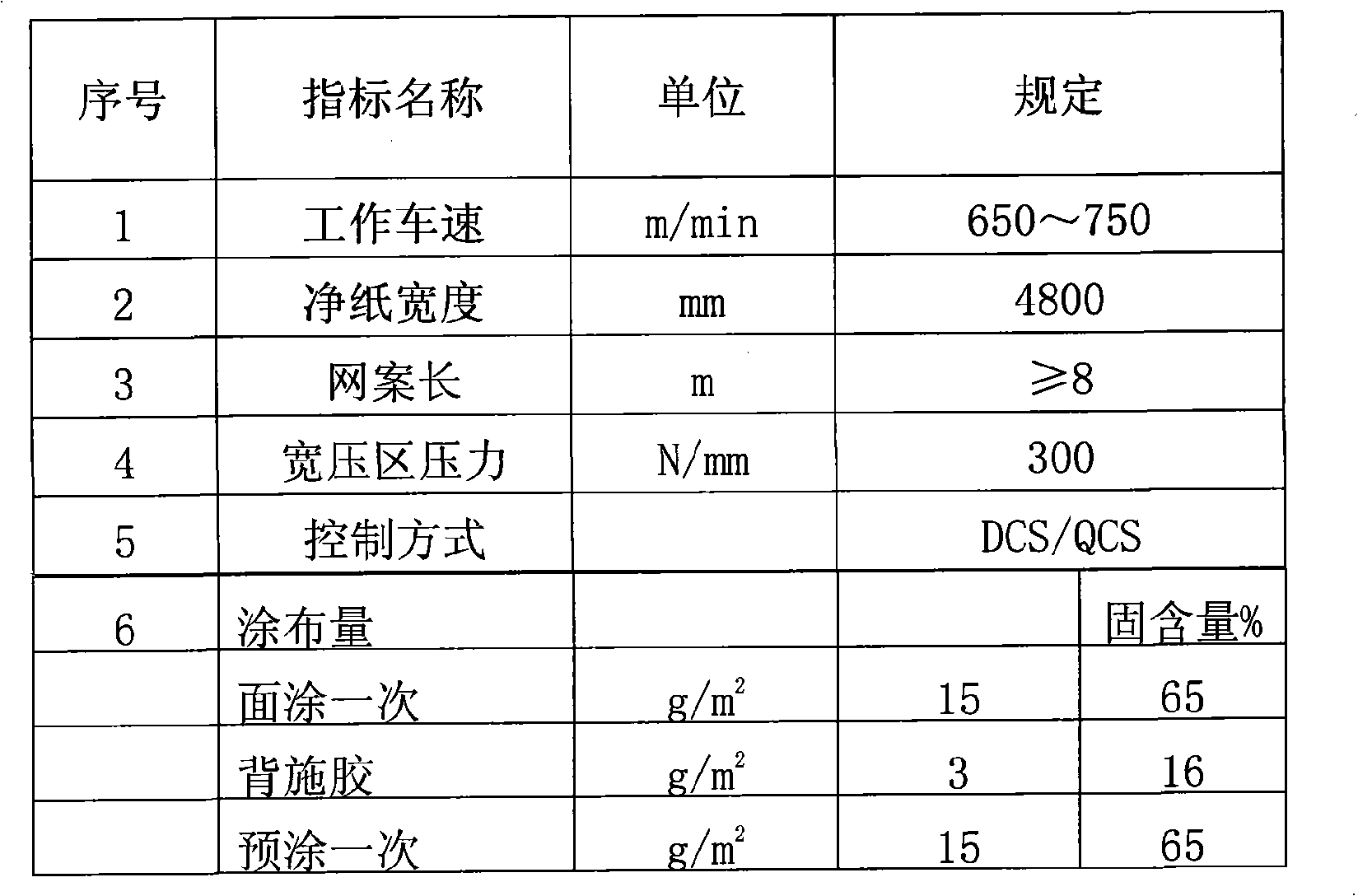

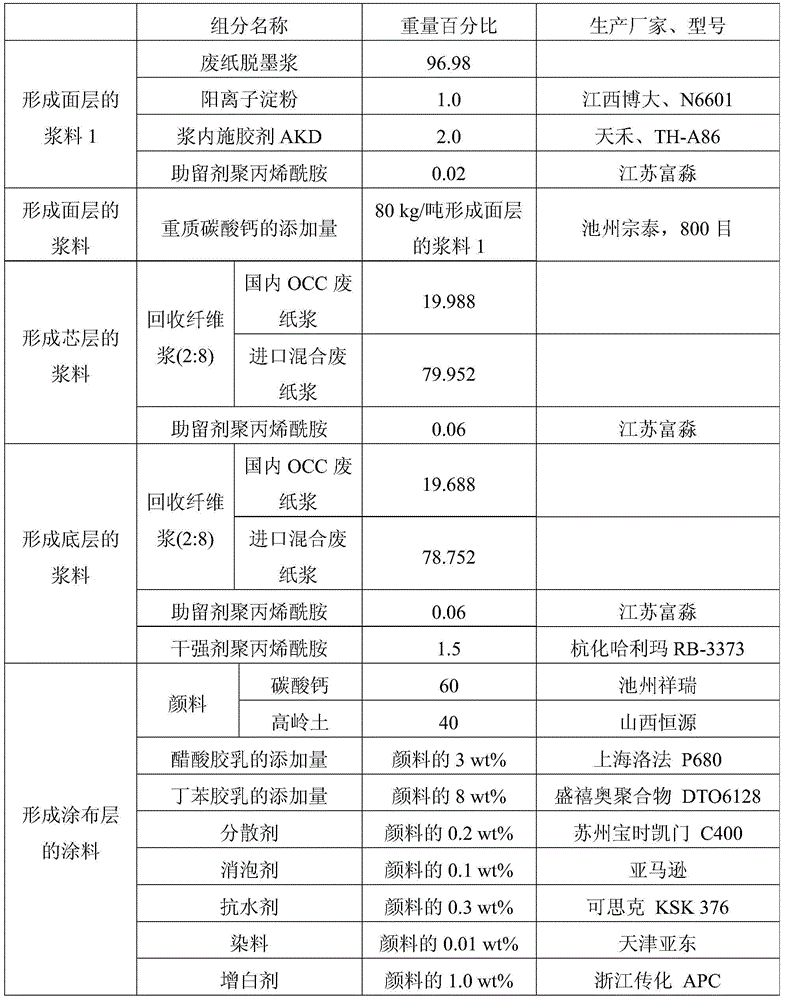

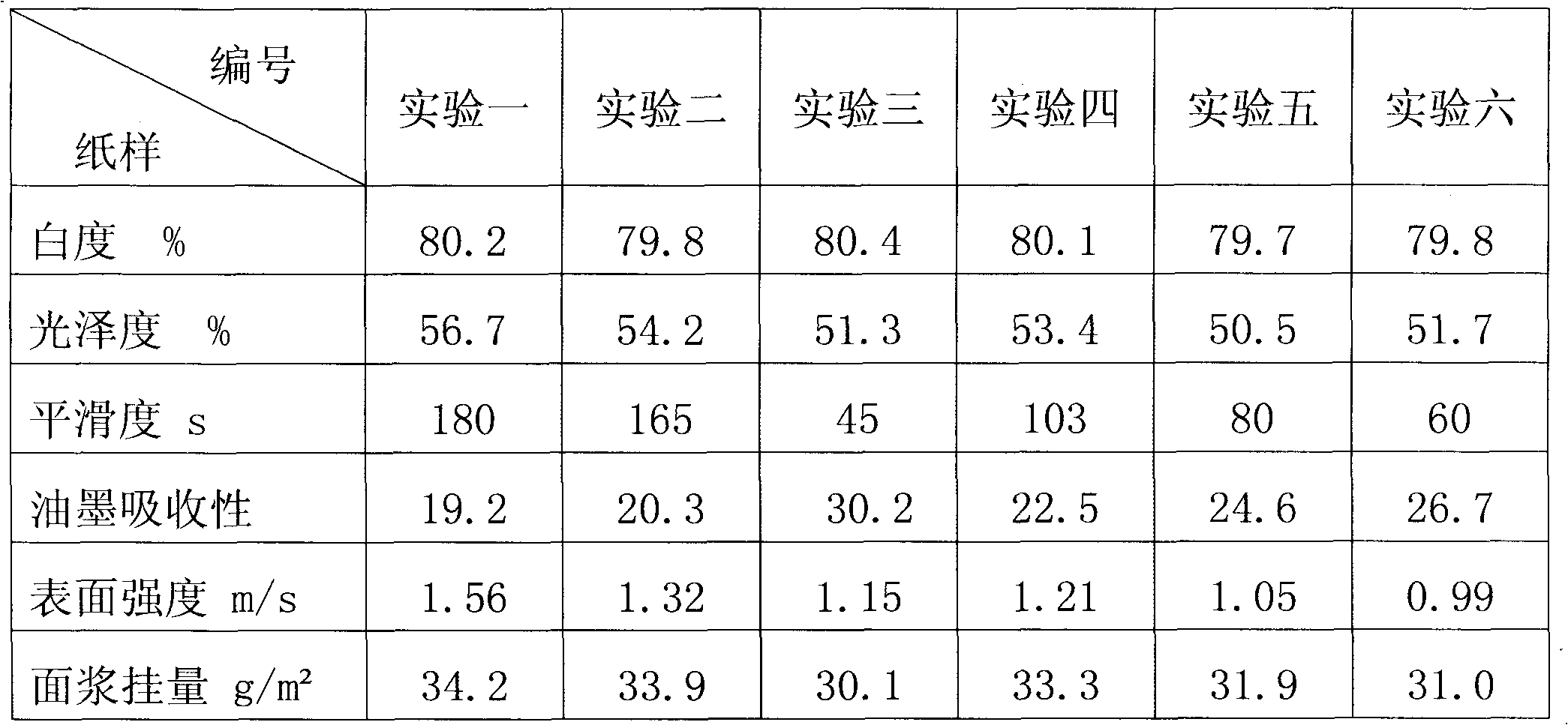

Method for producing coated kraft card board by home-made paper machine

The invention relates to technical field of coated kraft liner producing method. The producing method comprises feeding surface pulp, lining pulp, core pulp and bottom pulp pumped from machine chest of pulping workshop into respective machine chest; slushing and pressure screening the lining pulp, the core pulp and the bottom pulp by offline back water bank, then slushing and pressure screening the surface pulp by the offline back water bank after removing impurities in the surface pulp in a low concentration sand remover, finally all the pulp entering into a flow box to flow onto wire; after the pulp flowing onto wire, feeding the pulp into a coating system after forming by a four-long net forming machine, second shoe pressing, drying, glue blending, redrying, and press polishing by a two-roller hot pressing machine; feeding the coated paper into a state-regulating cylinder and a soft calendar to finish, then reeling by a horizontal paper reeling machine. The coated kraft liner producing method disclosed by the invention can greatly reduce use cost of the coated kraft liner to make the domestic market not dependent on import any longer.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

Water flexible painting plate ink and preparing method thereof

The invention relates to a waterborne soft printing ink comprising the components: film-forming resin emulsion of 8.7-47.2wt percent, waterborne acrylic color paste of 40-50wt percent, antifoam agent of 0.1-0.3wt percent, waterborne wax paste of 0.2-2.0wt percent, isopropyl alcohol of 2-8wt percent, ethylene glycol of 10-30wt percent, ethanolamine of 0.5-1wt percent and water of the rest percent. The invention further provides a method to prepare the waterborne soft printing ink. The waterborne soft printing ink of the invention is nontoxic and environmental friendly, has good safety, stable performance and good adaptability to coated art paper printing, and can be continuously used in printing without mackle, has clear printing effect and low production cost.

Owner:GUANGDONG YINGKE GRP CO LTD

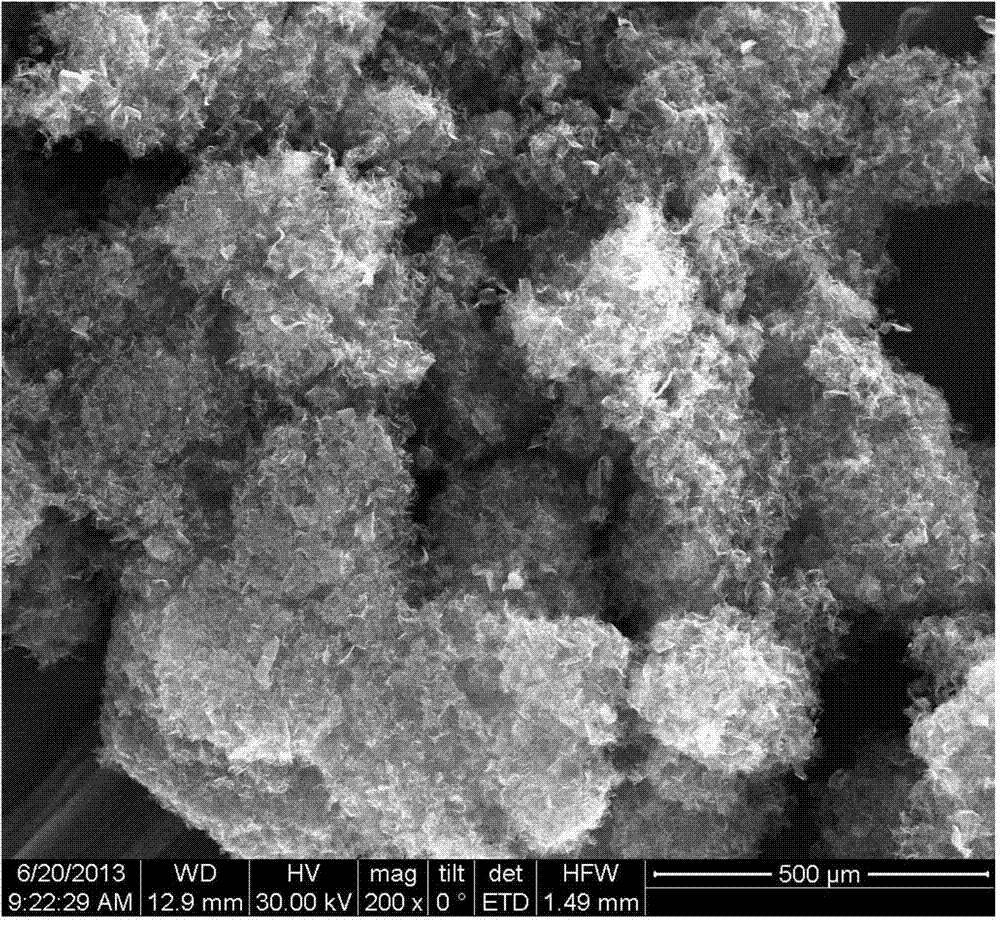

Graphene cluster based carbon system electric heating slurry as well as preparation method and application thereof

ActiveCN104517664ALow resistivityImprove conductivityNon-conductive material with dispersed conductive materialHeating element materialsManufacturing cost reductionSlurry

The invention discloses graphene cluster based carbon system electric heating slurry as well as a preparation method and application thereof. The slurry comprises the following components in parts by weight: 10-70 parts of a conductive heat-conduction agent, 10-70 parts of a far-infrared reinforcing agent, 10-60 parts of a solvent, 0.1-10 parts of an additive and 5-60 parts of a resin connecting agent, wherein the conductive heat-conduction agent comprises graphene clusters. By adoption of the mode that the graphene clusters are separately combined with other carbon materials so as to be used as the conductive heat-conduction agent and the far-infrared reinforcing agent of the electric heating slurry, the electrical resistivity of the slurry after being printed into films is greatly reduced, the heat conduction property, the electric heating conversion efficiency and the far-infrared radiation intensity are improved, the manufacturing cost is lowered, the velocity of the slurry is also reduced, the flowability and the transferring printing adaptability of the slurry are improved, and the electric heating slurry has great significance for energy conservation, consumption reduction, health physiotherapy and the like.

Owner:苏州格瑞丰纳米科技有限公司

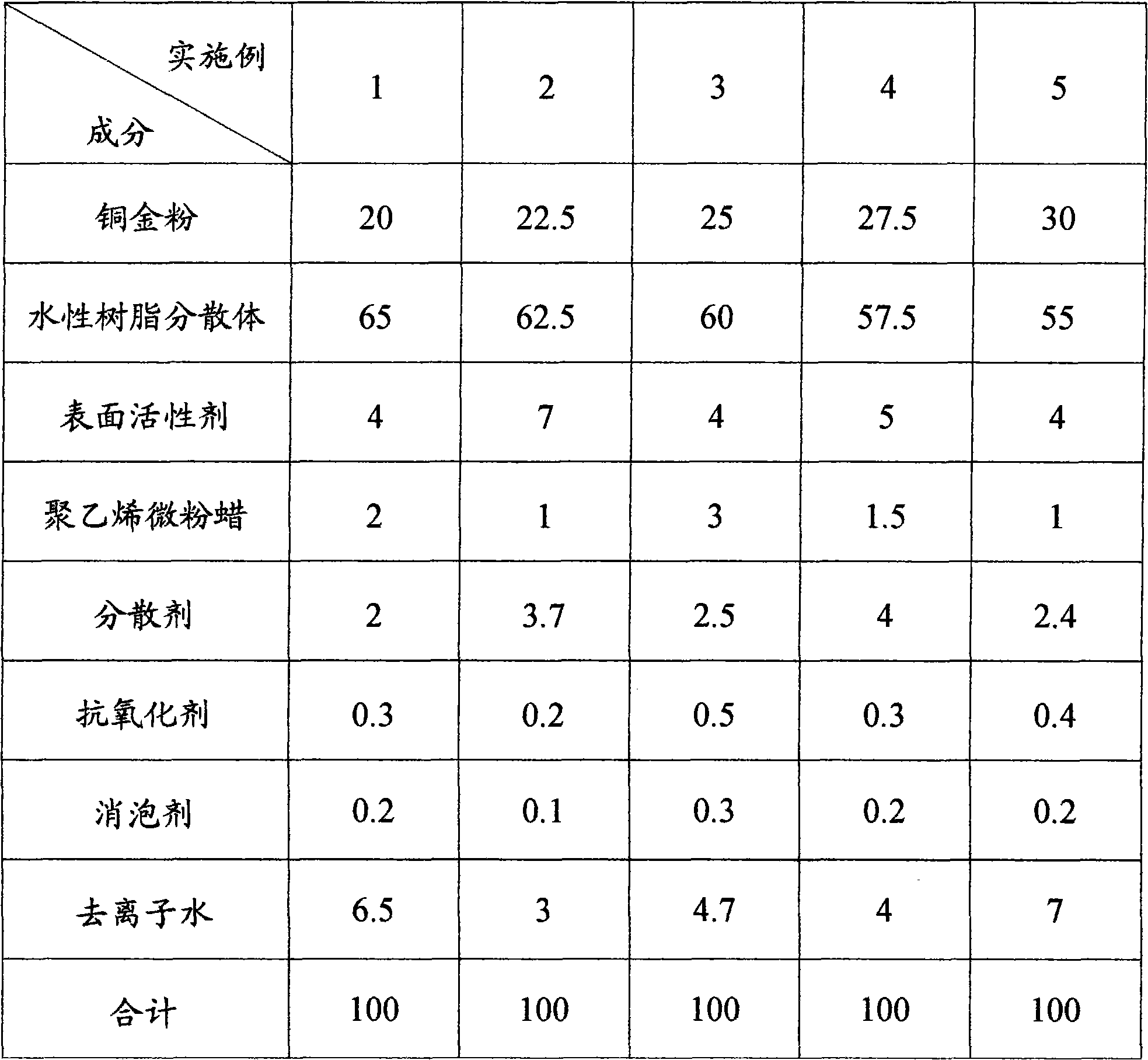

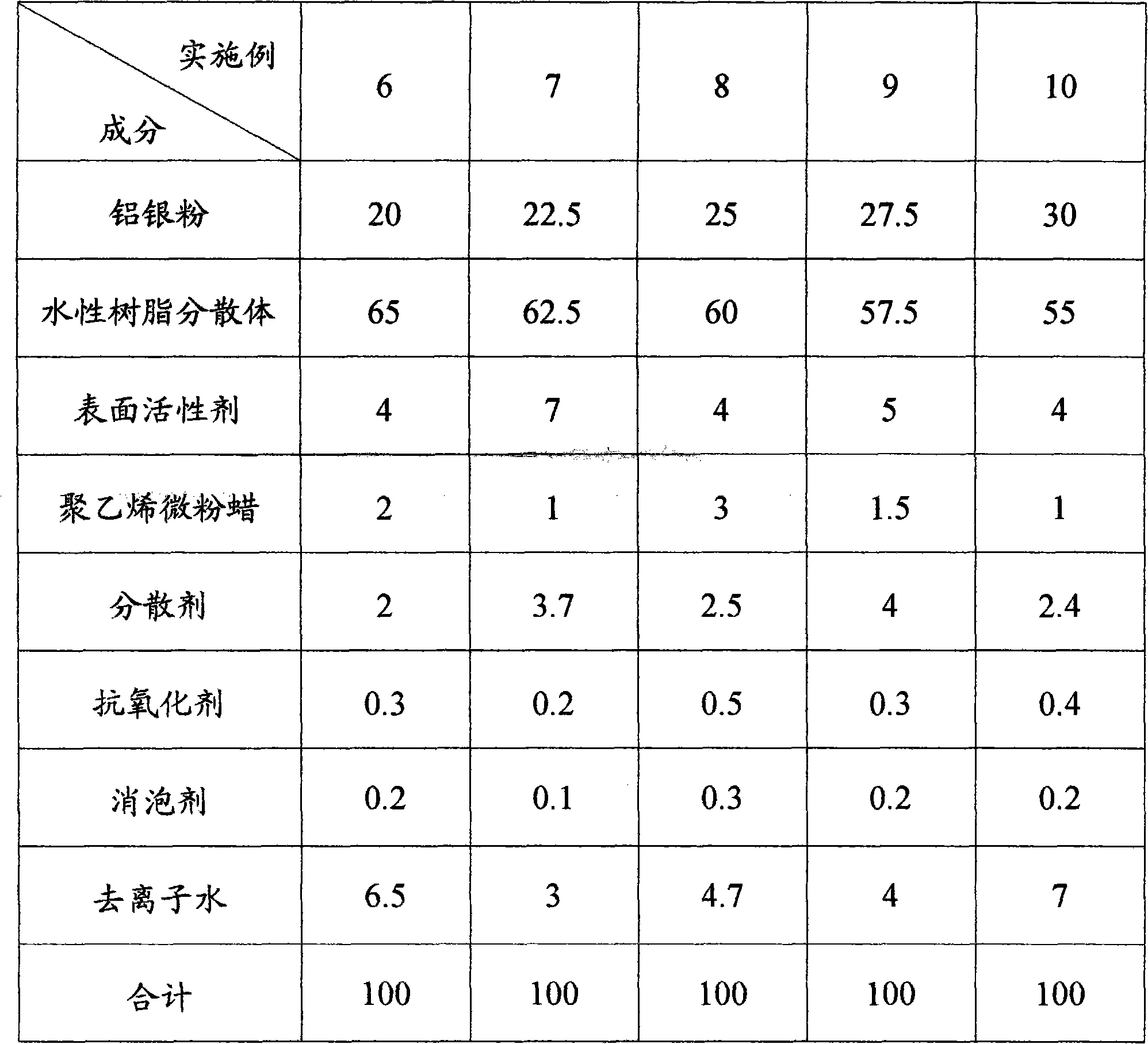

Aqueous metal ink and preparation method thereof

The invention relates to the field of ink and discloses an aqueous metal ink. The aqueous metal ink comprises a metallic pigment, an aqueous resin dispersion, a surfactant, polyethylene micronized powder, a dispersant, an antioxidant, a defoamer and deionized water, wherein the aqueous resin dispersion is one or the combination of aqueous acrylic resin solution, which is nonacid and does not contain sulfides and oxides, aqueous polyurethane resin and aqueous silicone acrylate resin. The invention also discloses the preparation method of the aqueous metal ink. The aqueous metal ink provided bythe invention is very stable and aging resistant and has high adhesive force, the cost of the aqueous metal ink is lowered by 30 to 40 percent, and the preparation process is simple.

Owner:广东天龙油墨有限公司

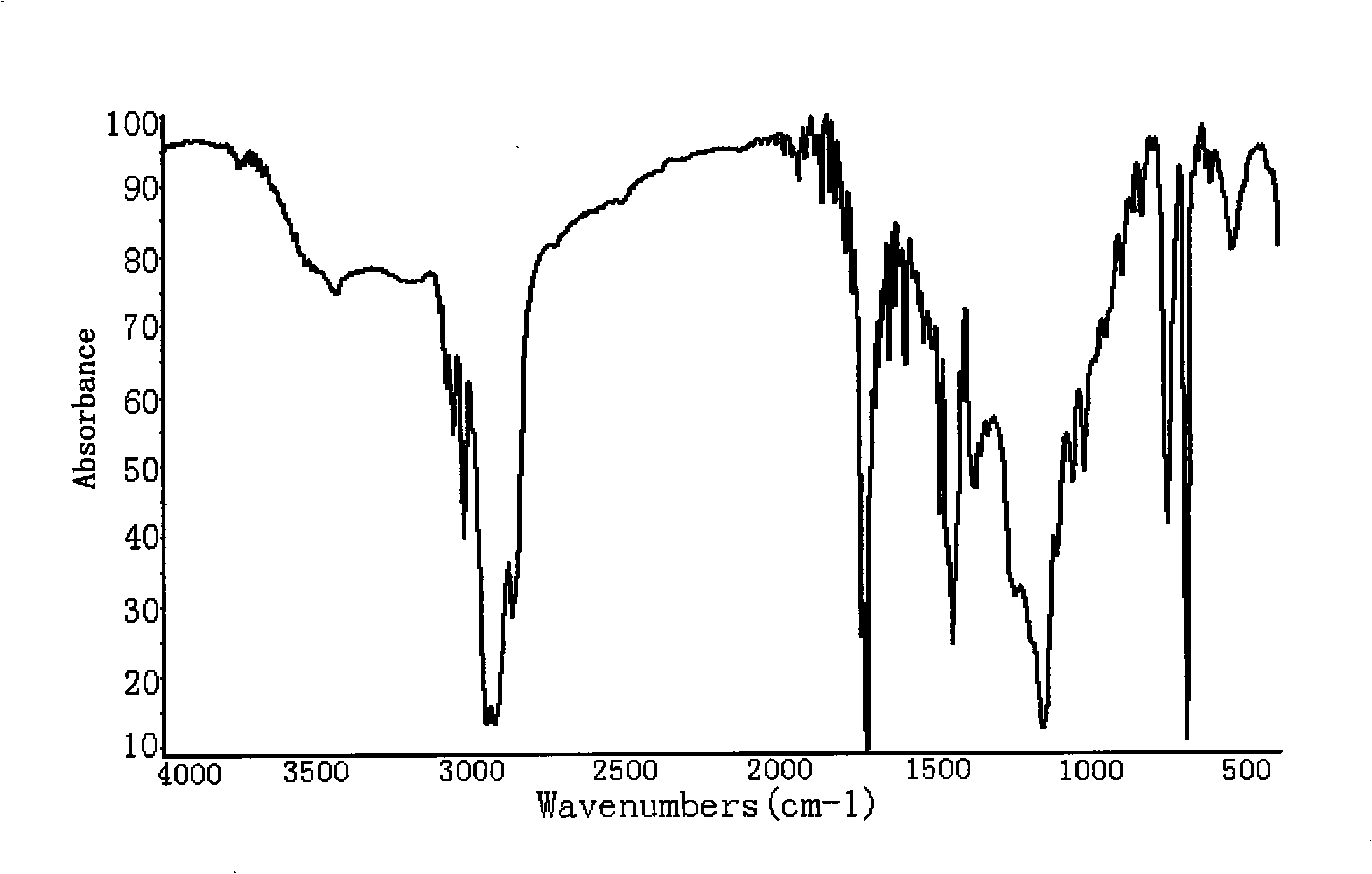

Cation surface sizing agent and preparation method thereof

InactiveCN101649583AReduce manufacturing costPrevent penetrationWater-repelling agents additionPaper/cardboardAmylaseSizing

The invention provides a cation surface sizing agent and preparation method thereof. Raw materials are as follows by weight percent: 8-17% of styrene, 5-15% of butyl acrylate, 0.5-5% of acrylamide, 0.5-5% of N-hydroxymethyl acrylamide, 1-5% of methyl acryloyl ethyl trimethylammonium chloride, 2-8% of starch, 0.001-0.003% of amylase, 0.2-0.7% of organic acid, 0.2-0.8% of emulsifier, 1-5% of 27% hydrogen peroxide, 0.01-0.05% of iron dichloride, the balance water. The cation surface sizing agent is prepared by starch pasting, monomer pre-emulsion and emulsion polymerization. The invention is usedfor surface sizing of paper and achieves the aim of improving physical performances of paper such as water-resistance, ring crush compression resistance, surface strength and the like.

Owner:东莞市清正合成高新材料有限公司 +1

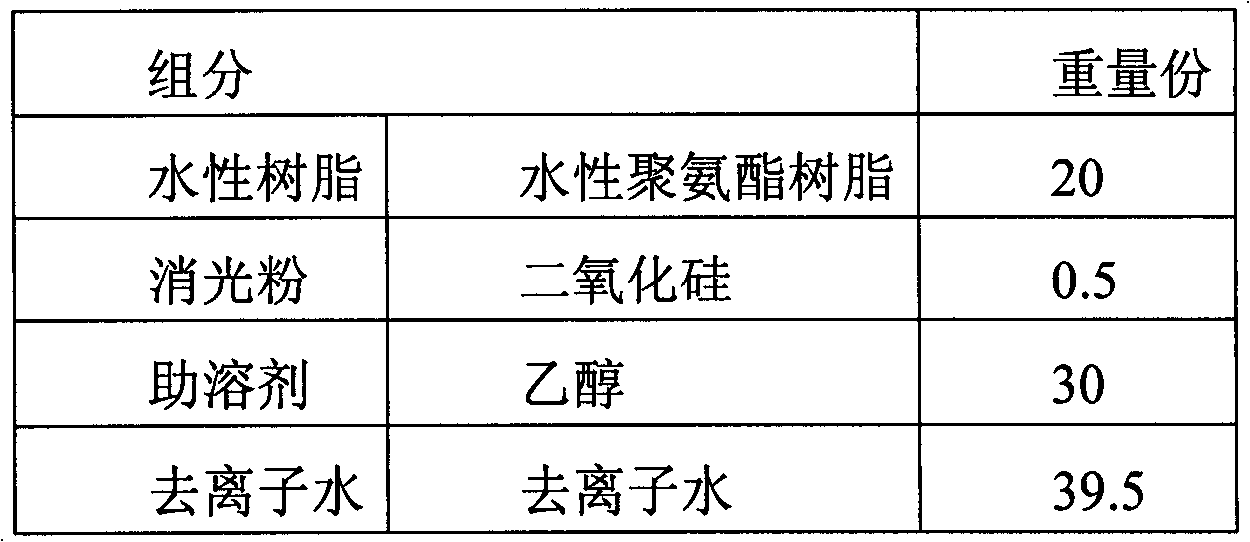

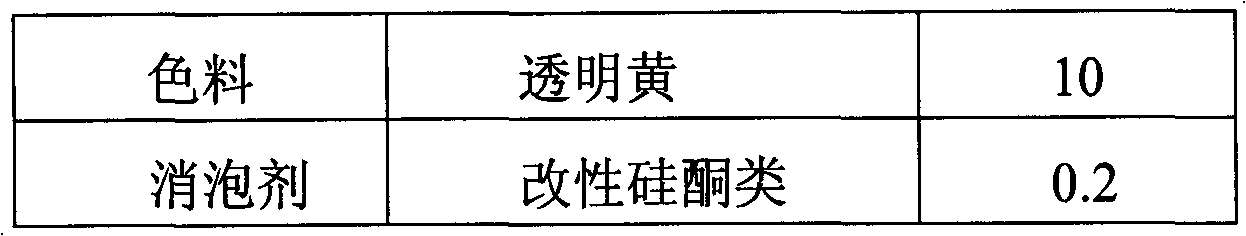

Aqueous single-coating matt transferring aluminum-plating paint and preparation method thereof

InactiveCN102367348AReduce contentEnvironmental costPolyurea/polyurethane coatingsSolventDefoaming Agents

The invention relates to an aqueous single-coating matt transferring aluminum-plating paint and a preparation method thereof. The paint comprises the following components in parts by weight: 20-70 parts of aqueous resin, 10-70 parts of deionized water, 0.5-2 parts of delustering powder, 5-30 parts of cosolvent, 0-10 parts of pigment, 0-2 parts of pH value regulating agent, 0-0.5 part of wetting agent, 0-0.2 part of flatting agent and 0.05-0.2 part of defoaming agent. Compared with the prior art, the aqueous single-coating matt transferring aluminum-plating paint has the advantages of excellent delustering property, simple production process and the like, and is environmentally-friendly.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

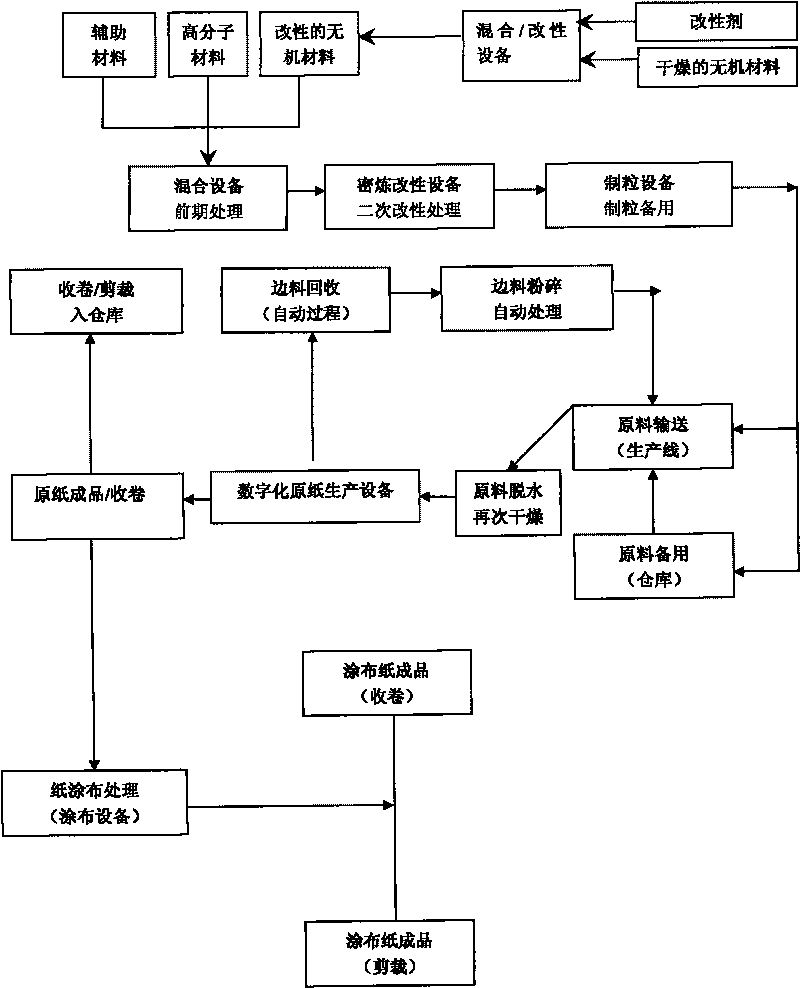

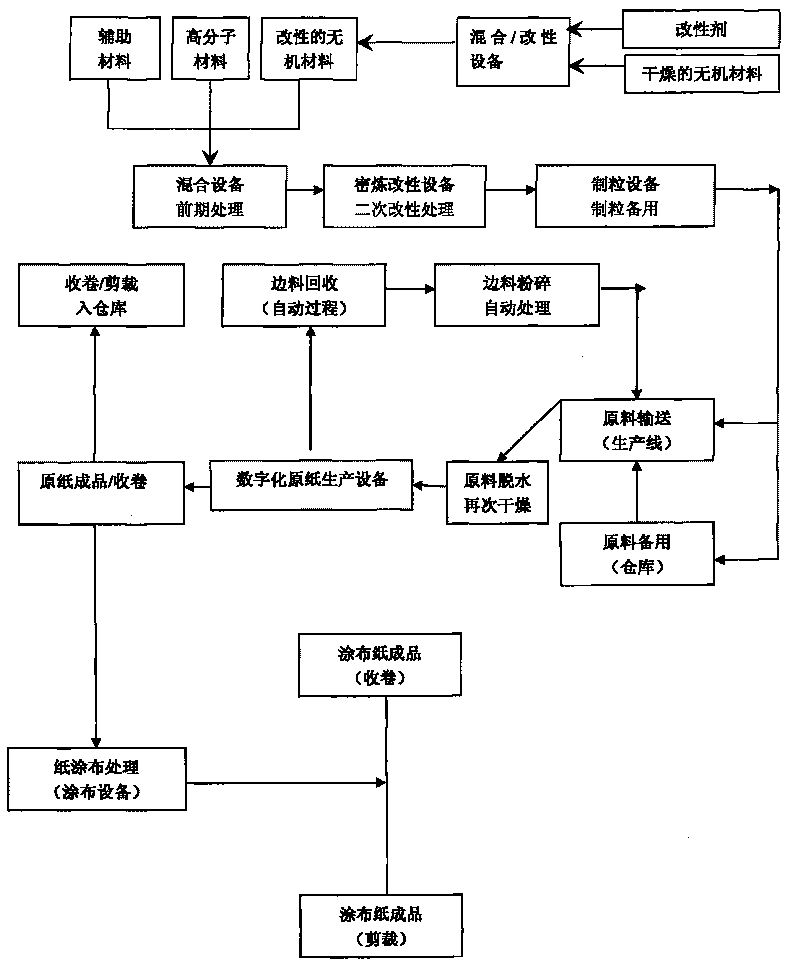

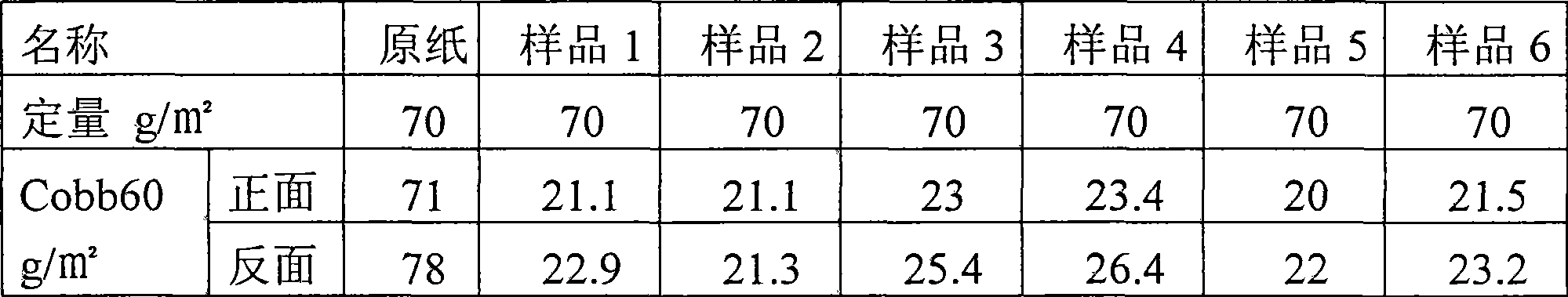

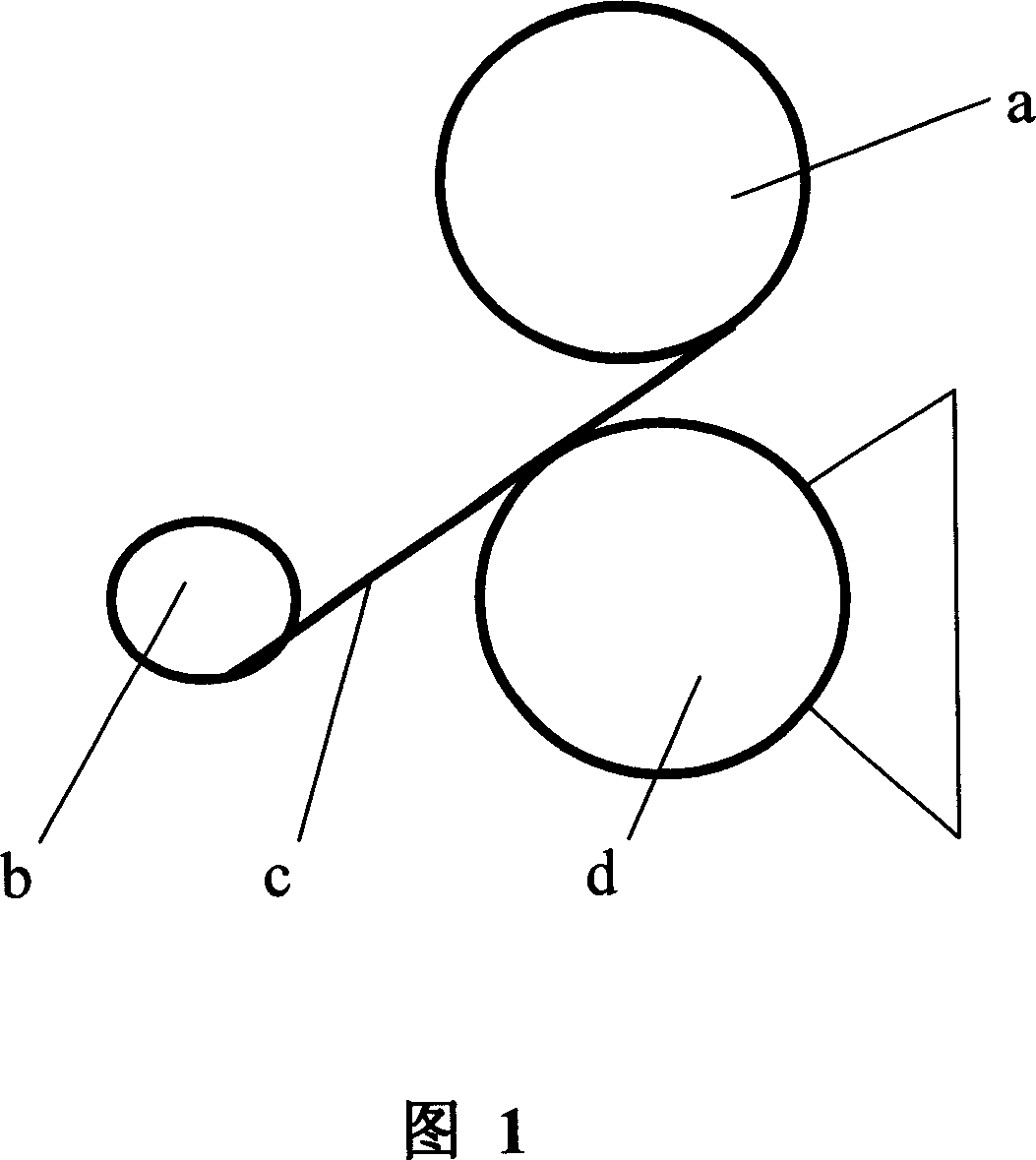

Stone water-free paper-making method and flow

InactiveCN101701433AFast productionIncrease productionSpecial paperPaper/cardboardPrinting inkInorganic materials

The invention relates to a stone water-free paper-making method and a flow thereof; the process method and the flow are that: after inorganic material is dried, a modifier is added in the inorganic material to carry out mixing modification in mixing / modifying equipment, and then the inorganic material which is activated and modified and organic material and accessory ingredients are mixed and are conveyed to the modifying equipment to carry out secondary modifying treatment (banburying), and then extrusion granulation is carried out to form granulated raw material, and the granulated raw material is conveyed to raw material drying equipment to carry out secondary drying by raw material conveying equipment, and the dried raw material is directly conveyed to a film casting and laminating machine and a drawing mill to be produced into body paper, and then the body paper is cut and rolled for spare, and the cut rim charge is recycled; corona treatment is carried out to the body paper, and then surface coating treatment is carried out in a coating machine, so as to obtain coated paper; by adopting the method to produce stone paper, the production speed is rapid, the output is high, the flatness and smooth finish of the finished paper are good, the product quality is high, and various printing modes and printing inks are suitable for the paper. The process in the invention is simple and rational, the product quality is stable and the effect is good.

Owner:蔡茂友

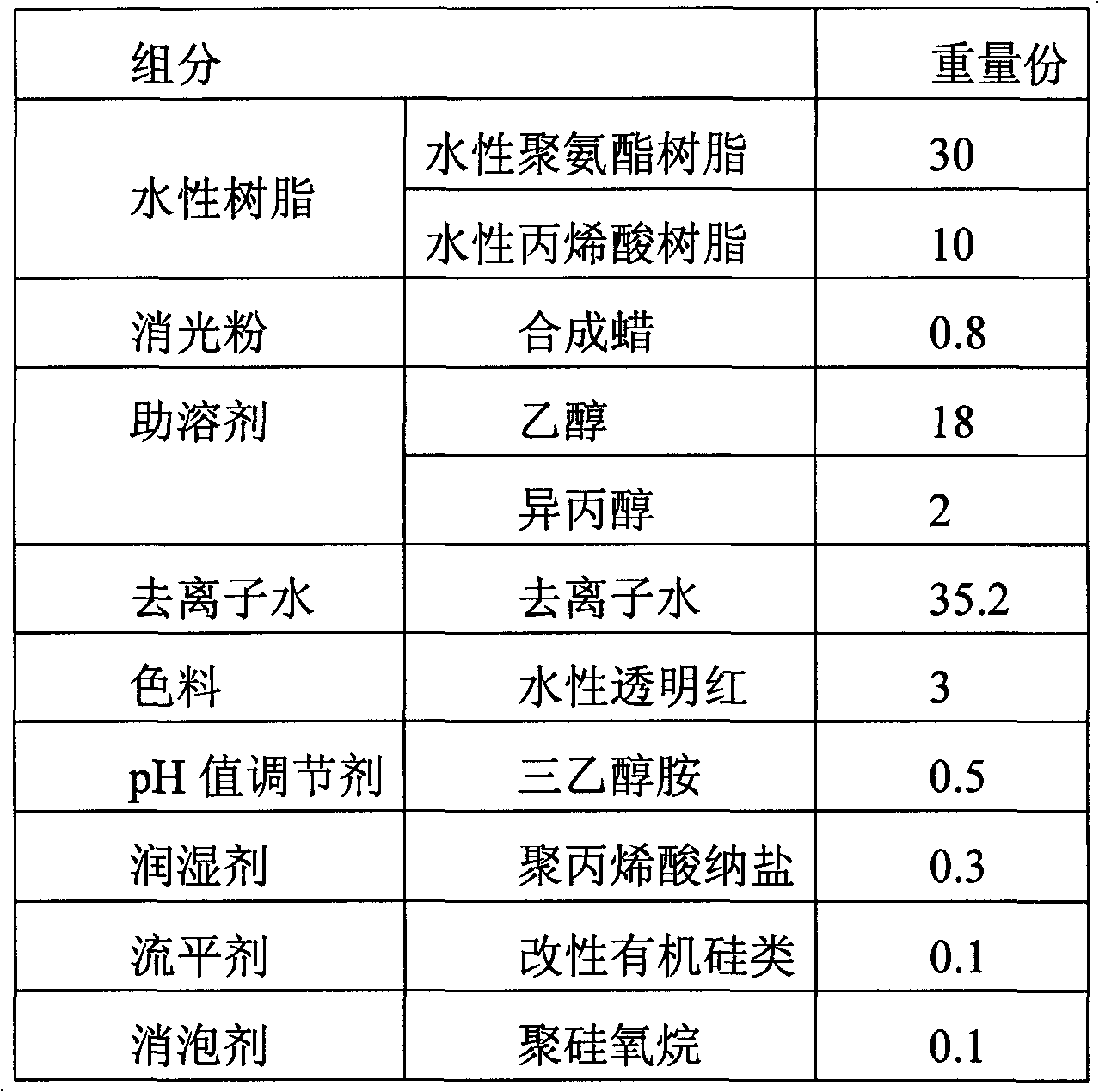

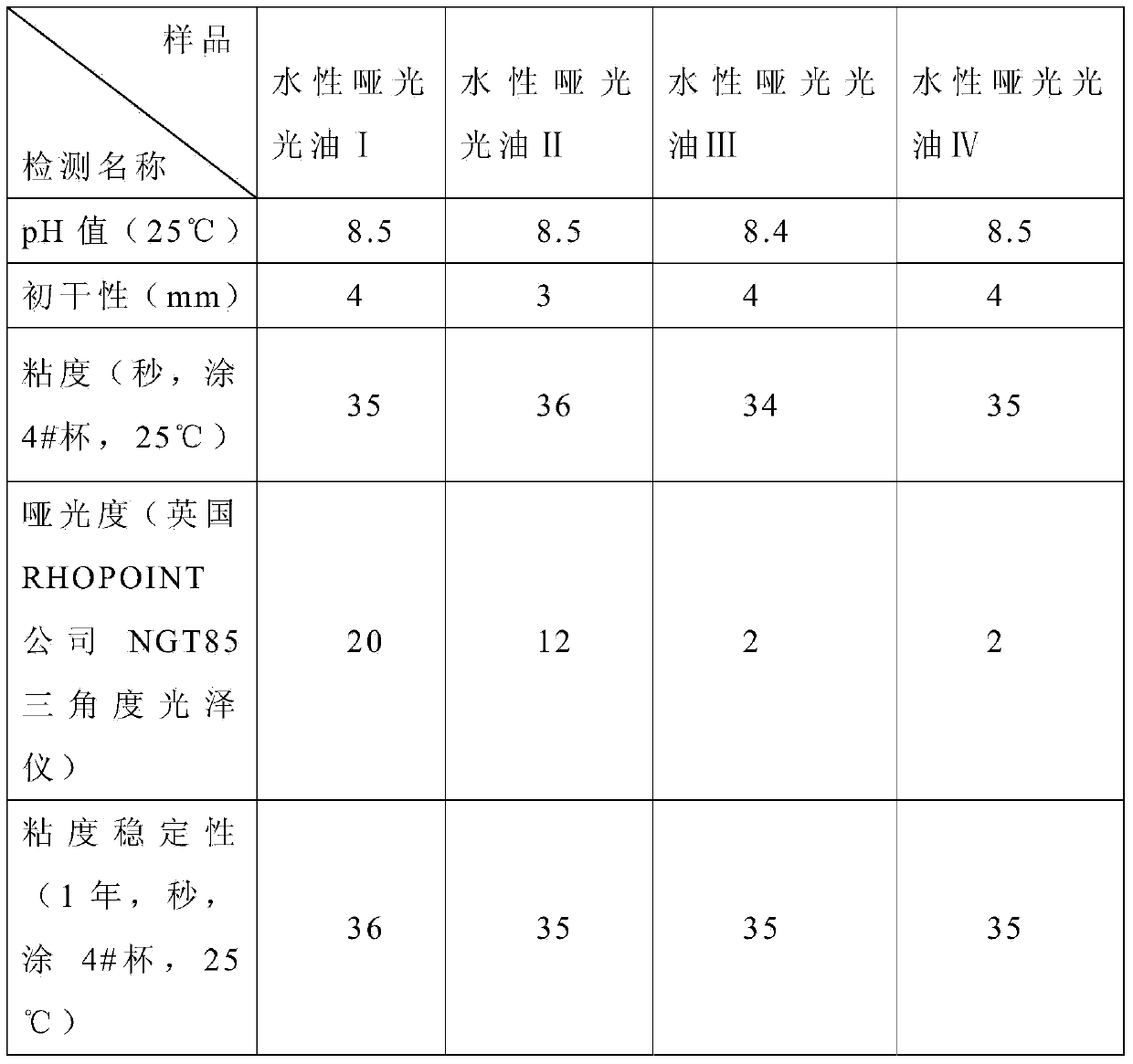

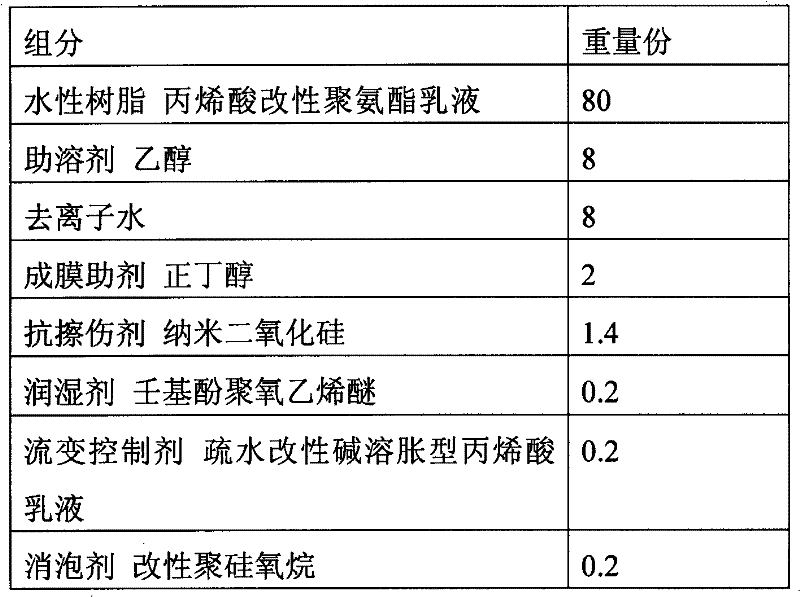

Environment-friendly watersoluble tintage paint, preparation and uses thereof

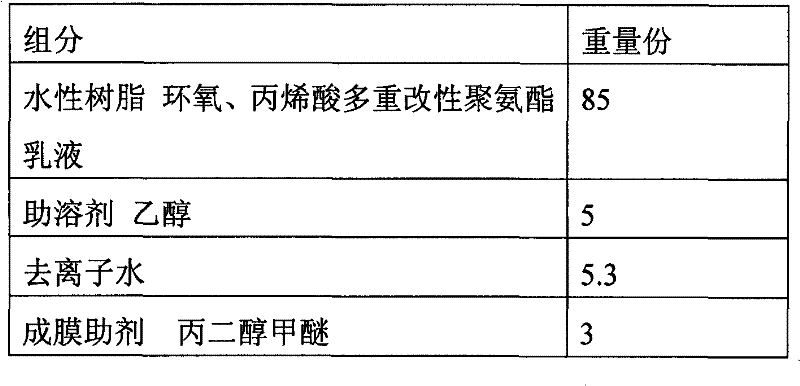

ActiveCN101402818AReduce manufacturing costGood printing adaptabilityCoatings with pigmentsPolyurea/polyurethane coatingsDefoamerIon

The invention relates to an environment protective type water coloring coating as well as a preparation method and an application thereof. The water coloring coating consists of the following components and contents (weight portions): 40 to 60 portions of water-base resin; 10 to 25 portions of latent solvent; 20 to 25 portions of de-ionized water; 0 to 3 portions of film forming additive; 0.1 to 2 portions of pH value regulator, 0.1 to 2 portions of scratch-resistant agent; 0.1 to 0.5 portion of wetting agent, 0 to 0.2 portion of rheological controlling agent and 0.05 to 0.2 portion of foam killer. Compared with the prior art, the invention has the advantages of environment protection performance, low production cost and good printing suitability, being incapable of destroying the bottom layer during coating process and avoiding lifting phenomenon generated by solvent coating; and the environment protective type water coloring coating can be directly used for replacing the existing solvent coloring coating through pilot scale production confirmation.

Owner:SHANGHAI WEIKAI CHEM +1

Printing ink

A print ink contains ester, alcohol solution of polyurethane resin, chloroacetate resin, pigment, propyl acetate, iso-proparol and ethyl acetate. Its advantages are high print effect, low poison and no damage to human body.

Owner:汕头市金平区五星油墨实业有限公司

Styrene-acrylic microemulsion surface sizing agent with high solid content and core shell structure and preparation method and application thereof

InactiveCN101544717AImprove water resistanceLarge particle sizeWater-repelling agents additionPaper/cardboardEmulsionOxidation-Reduction Agent

The invention discloses a styrene-acrylic microemulsion surface sizing agent with high solid content and core shell structure and a preparation method and an application thereof. The preparation method comprises the following steps: adopting a seed emulsion method to synthesize core emulsion, dropping core pre-emulsified monomer solution and redox initiator into core the emulsion, controlling the dropping time, filtering the product of reaction by using a 250 mesh or 300 mesh sieve, discharging, and obtaining the microemulsion with hard core and soft core shell structure, wherein the microemulsion has a grain diameter of 20-100nm and the solid content of 40-48 percent. The surface sizing agent has the base characteristics of styrene-acrylic emulsion, good stability, core shell structure, small grain diameter, high solid content, and better gluing effect and can endow paper with better water resisting property and improve the surface property of the paper.

Owner:SOUTH CHINA UNIV OF TECH

VMPET coated thin film, and production method

InactiveCN101092069AGood heat sealingImprove barrier propertiesFlexible coversWrappersPolyvinyl alcoholRaw material

The invention relates to a novel coated film and the producing method thereof. And it is a VMPET coated film, produced by coating PVDC, PVOH and AC as main raw materials on VMPET.

Owner:海南现代高科实业有限公司

Water printing ink using synthetic water solid acrylate resin as base material and its preparation method

A water ink based on the synthetic solid water acrylic resin is prepared through water-phase suspension copolymerizing reaction between acrylic acid monomer mixture and ammonium persulfate as trigger in water while stirring to obtain solid water acrylic resin, dissolving it in water, cosolvent, or amine, adding pigment, water and assistant, and grinding. Its advantages are high safety, adhesion and resistance to water and rubbing, not coloring, and low cost.

Owner:KUNMING YUEDUN INK SCI & TECH DEV

Polyethylene (PE) film and preparation method thereof

ActiveCN102179985AImprove mechanical propertiesGood solvent resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

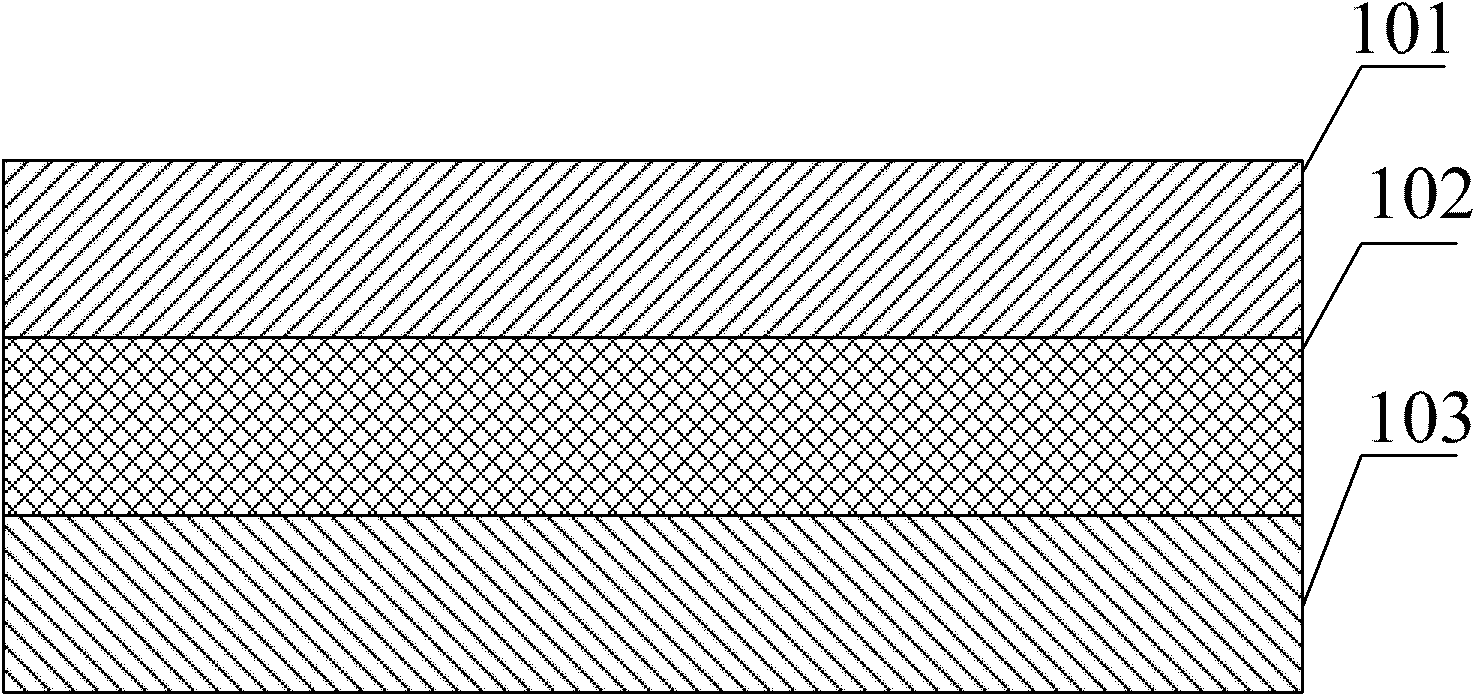

The invention provides a polyethylene (PE) film and a preparation method thereof. The PE film sequentially comprises a composite layer, an intermediate layer and a heat-seal layer, wherein the composite layer comprises 25 to 40 weight percent of low-density PE, 25 to 40 weight percent of linear low-density PE and 33 to 45 weight percent of modified metallocene linear low-density PE; the intermediate layer comprises 25 to 50 weight percent of the low-density PE and 50 to 75 weight percent of the linear low-density PE; and the heat-seal layer comprises 28 to 35 weight percent of the low-density PE and 65 to 72 weight percent of the linear low-density PE. The invention also provides a cleaning solution packaging composite film and a cleaning solution packaging bag, wherein the cleaning solution packaging composite film is prepared from the PE film. Correspondingly, the invention also provides a preparation method of the cleaning solution packaging composite film which is prepared from the PE film. A product is packaged by the PE film provided by the invention, so the packaging bag has certain solvent resistance and excellent heat-seal performance, the relatively high sealing property and tensile strength of a material subjected to heat sealing are guaranteed, and the leakage resistance and falling resistance of the composite film which is prepared by the material are further improved.

Owner:HUANGSHAN NOVEL

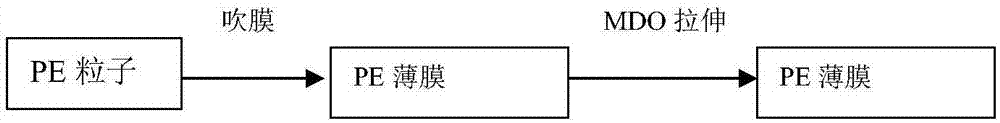

Uniaxially-tensioned high speed printing matt PE film and production technology thereof

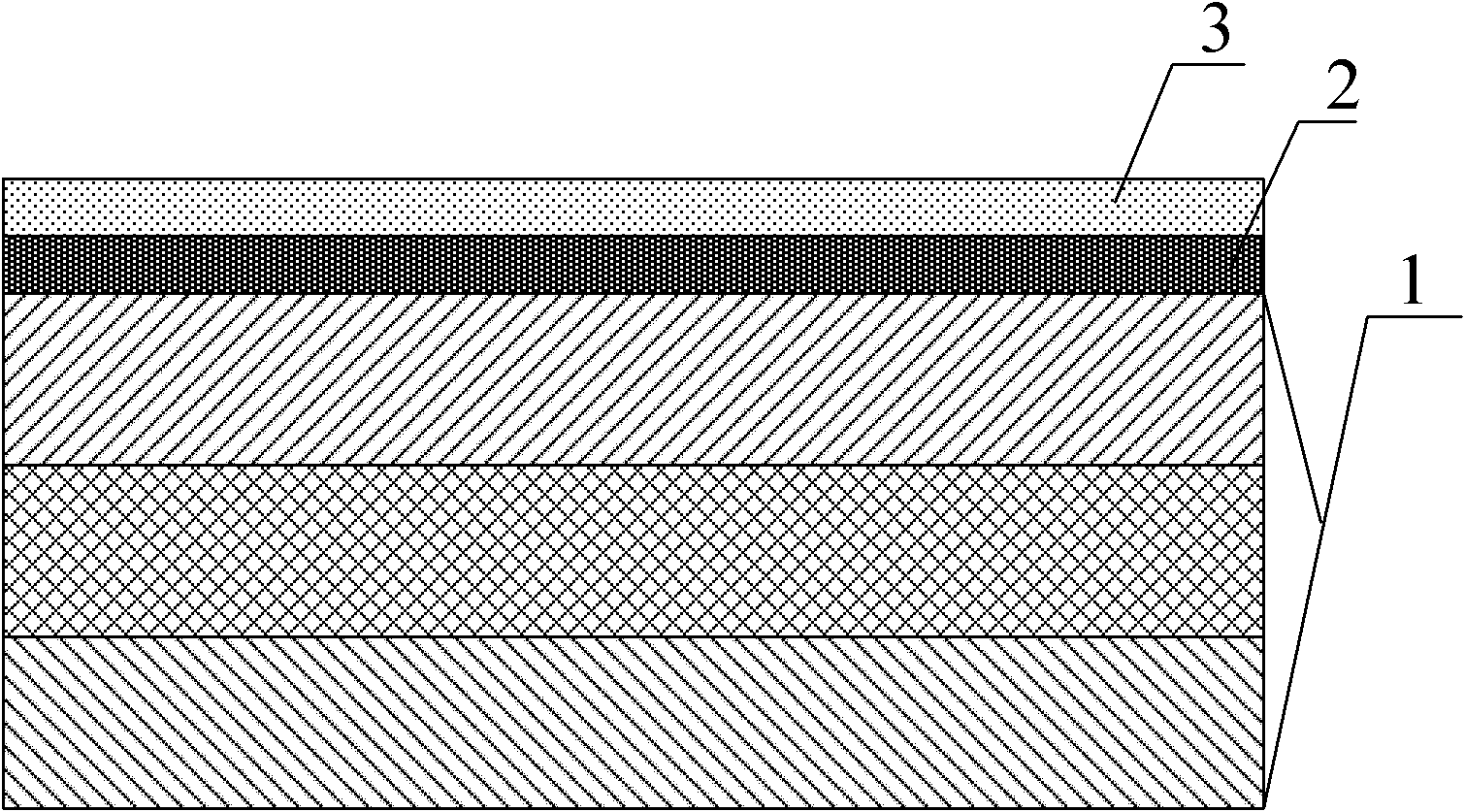

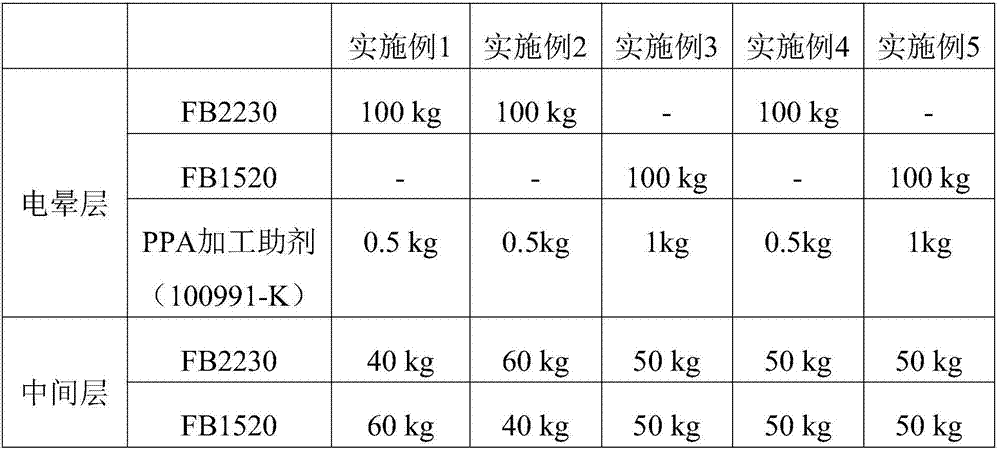

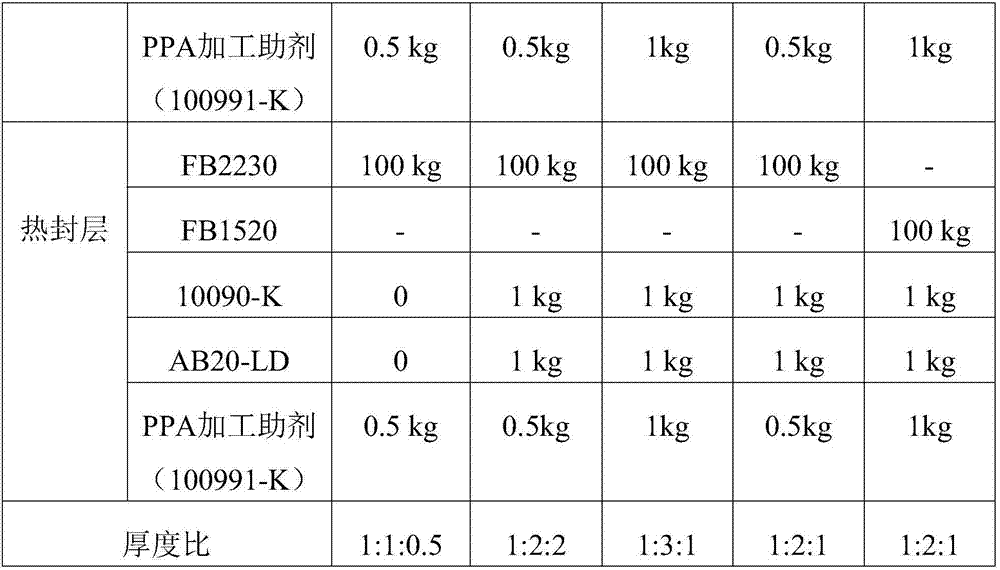

ActiveCN107351474AGood processing performanceGood resistance to stress crackingSynthetic resin layered productsDomestic containersEngineeringHigh stiffness

The invention discloses a uniaxially-tensioned high speed printing matt PE film and a production technology thereof. The matt PE film comprises a corona layer, a middle layer and a heat sealing layer, and the corona layer, the middle layer and the heat sealing layer respectively independently comprise blown film grade bimodal metallocene polyethylene. The uniaxially-tensioned high speed printing matt PE film has the advantages of guaranteeing of high haze, low crystallization point and high stiffness, and can meet the demands of high speed printing.

Owner:永新股份(黄山)包装有限公司

Alcohol-free environment-friendly fountain solution and preparation method thereof

ActiveCN105383203AExempt from addingReduce adverse effectsPrinting pre-treatmentWater basedAlcohol free

The invention relates to an alcohol-free environment-friendly fountain solution and a preparation method thereof. The fountain solution comprises, by weight, 70-85 parts of deionized water, 2-5 parts of pH modifiers, 10-25 parts of water-based colloid and 0.5-2 parts of nonionic surfactants. The preparation method includes the following steps that part of the deionized water is added into a stirred tank, the water-based colloid is added while the deionized water is stirred, stirring is continued until the water-based colloid is completely dissolved, and a colloid solution is obtained; the nonionic surfactants are added into the colloid solution, the nonionic surfactants and the colloid solution are fully stirred and mixed, and a mixed solution is obtained; and the pH modifiers are added into the remaining deionized water, the pH modifiers and the deionized water are stirred and mixed evenly and then added into the mixed solution, the mixture is fully stirred and dispersed, and the alcohol-free environment-friendly fountain solution is obtained. Compared with the prior art, the fountain solution is stable in property, safe, environmentally friendly, free of alcohol and good in printing adaptability; the added nonionic surfactants can effectively adjust the surface tension of the fountain solution, the preparation process is simple, the controllability is good, and the fountain solution is suitable for industrial production.

Owner:SHANGHAI JIEYISEN CO LTD

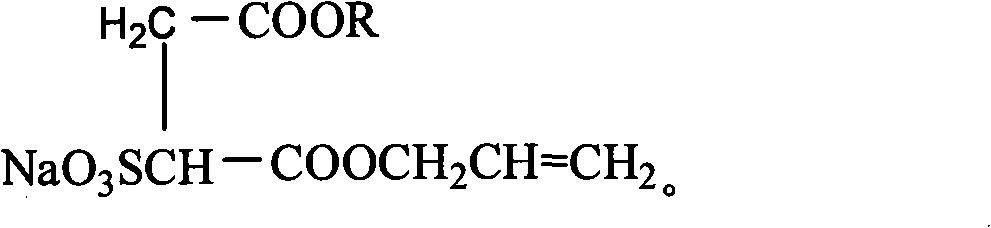

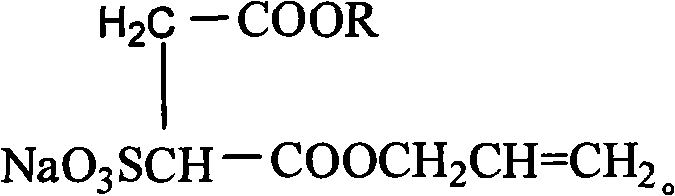

Self-crosslinking polyacrylate rubber latex, preparation method thereof and water-based paper printing ink

InactiveCN101870793APrevent sticking backFast dryingPaper coatingCoatingsWater basedHydrophilic monomer

The invention discloses self-crosslinking polyacrylate rubber latex, a preparation method thereof and water-based paper printing ink. The self-crosslinking polyacrylate rubber latex is prepared by the following steps: mixing an acrylic ester monomer, a hydrophilic monomer and ADH in a head tank A; mixing water, an emulsifier, the acrylic ester monomer and DAAM in a head tank B; adding water, the emulsifier and polymerizable self-emulsifying functional monomer, stirring the mixture, heating the mixture to 75 DEG C, and dripping a mixture in the head tank A and an initiator to prepare a protective colloid first; dripping the mixture in the head tank B and the initiator at 85 DEG C; and performing a constant-temperature reaction. The water-based paper printing ink is prepared by the following steps: dissolving a phenylethylene-acrylic acid polymer and a pH value regulator in water at 60 DEG C with stirring; adding a pigment and necessary assistant and mixing the mixture to prepare color paste; and uniformly mixing the color paste with the self-crosslinking polyacrylate rubber latex, a surface tension regulator and water. The water-based paper printing ink can be diluted by one or a mixture of two of water and ethanol, can be dried quickly and has high printing adaptability.

Owner:SUN YAT SEN UNIV +1

Radiation crosslinking modified ethylene-tetrafluoroethylene insulated wire cable

ActiveCN1866411ASimple processEasy to controlPlastic/resin/waxes insulatorsInsulated cablesCross-linkEngineering

The invention discloses an insulating wire cable of irradiation cross-linking modified ethane-perfluoroethylene polymer (X-ETFE) with metal screening layer and protecting layer, which is characterized by the following: the insulating thickness is 0.01-0.25 mm, which improves insulating wire heatproof grade; the product satisfies the aviation cable need under kinds of terrible climates.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

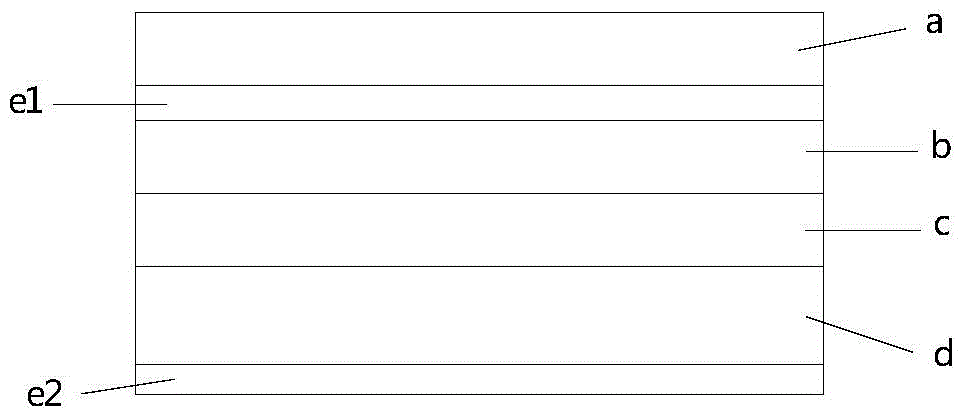

White manila board and preparation method thereof

ActiveCN104878659AQuantitative lowReduce manufacturing costSurface covering paperWater-repelling agents additionFiberPapermaking

The invention belongs to the technical field of papermaking, and particularly relates to a white manila board and a preparation method thereof. Three layers of forming nets and two passes of coating (curtain coating and knife coating) are adopted for the white manila board; moreover, a core layer and a bottom layer are manufactured by adopting recycled fiber pulp which is low-cost and is further more environment-friendly to replace wastepaper de-inked pulp; not only can a production process of the white manila board be greatly simplified and optimized, but also the consumption of chemicals and the power consumption can be greatly decreased, so that the qualified and low-basis-weight white manila board which more accords with market requirements can be produced with low cost.

Owner:JIAN GRP

Self-crosslinked polyacrylate latex and preparation method thereof, and water-based paper ink

InactiveCN102304262APrevent sticking backFast dryingPaper coatingCoatingsHydrophilic monomerPolymer science

The invention discloses self-crosslinked polyacrylate latex and a preparation method thereof, and water-based paper ink. The preparation method for the self-crosslinked polyacrylate latex comprises the following steps of: mixing acrylate monomers, hydrophilic monomers and alcohol dehydrogenase (ADH) in a head tank A; mixing water, an emulsifier, acrylate monomers and diacetone acrylamide (DAAM) in a head tank B; adding water, an emulsifier and polymerization self-emulsification functional monomers into a normal-pressure reaction tank, stirring, heating to 75DEG C, dripping a mixture in the head tank A and an initiator, and preparing protective colloid; dripping a mixture in the head tank B and an initiator at 85DEG C; and reacting at constant temperature. The water-based paper ink is prepared by the following steps of: stirring and dissolving styrene-acrylate copolymer, a pH regulator and water at 60DEG C; adding pigments and necessary aids, and mixing to obtain color paste; and uniformly mixing the color paste, the self-crosslinked polyacrylate latex, a surface tension regulator and water. The water-based paper ink can be diluted by one of water and ethanol or a mixture of water and ethanol, and has high drying speed and good printing adaptability.

Owner:SUN YAT SEN UNIV +1

Filming flow type polyacrylacid ester soap-free emulsion, synthetic process and use thereof in printing ink

The invention provides a soap-free acrylic acid latex, and a preparation method thereof and application in water-based ink. On one hand, a polymeric surfactant can be used to replace the prior surfactant during the reaction process; and after the latex is dried and forms a film, compounds with low molecular weight are reduced greatly and the water resistance of the film is effectively improved. On the other hand, protective glue is introduced into the reaction process to change the rheological property of the latex, and the rheological property of the latex is close to that of Newtonian liquid; simultaneously, the protective glue can also further improve the mechanical stability of the latex and make the latex more suitable for the water-based ink.

Owner:广东天龙油墨有限公司

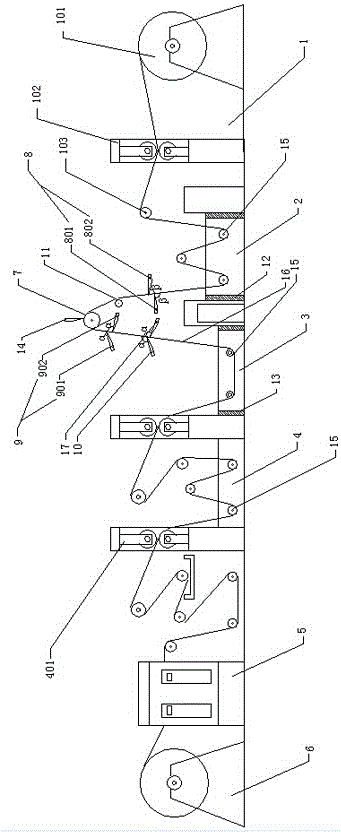

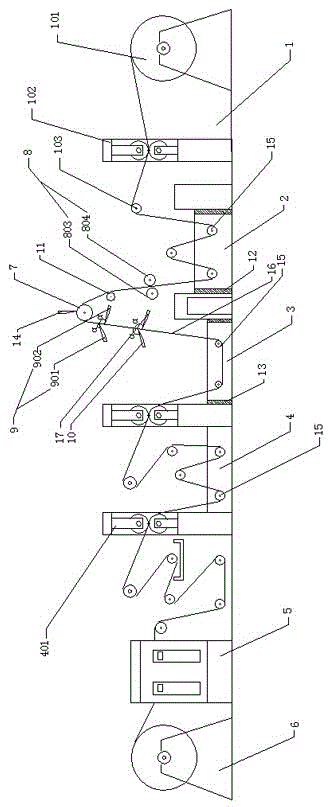

Sizing coating machine

ActiveCN104894784AQuality assuranceUniform treatmentSucessive textile treatmentsTextile treatment machine arrangementsPulp and paper industryCoating

The invention discloses a sizing coating machine, and belongs to the field of trademark fabric production equipment. The sizing coating machine comprises a fabric inlet device, a size tank, a consolidation tank, a cleaning tank, a drying device and a winding device which are sequentially arranged, a stabilizing roller is arranged between the size tank and the consolidation tank, the set position of the stabilizing roller is higher than tank opening positions of the size tank and the consolidation tank, a size scraping device for controlling uniformity and the thickness of fabric surface size is arranged between the stabilizing roller and the size tank, a whole surface scraper and at least one rear scraper are arranged between the stabilizing roller and the consolidation tank, and edges of the rear scrapers are positioned below an edge of the whole surface scraper. By the aid of the sizing coating machine, the trademark fabric surface size can be smoother and more uniform, and size fixing effects are better.

Owner:ZHEJIANG KING LABLE TECH CO LTD

Matte degree controllable core-shell emulsion as well as preparation method and application thereof

ActiveCN103467639ALong storage timeGood water resistance and weather resistanceCoatingsWeather resistanceChemistry

The invention relates to the technical field of water-base varnish and discloses matte degree controllable core-shell emulsion as well as a preparation method and application thereof to water-base matte varnish. The matte degree controllable core-shell emulsion comprises a vinyl monomer, an initiator, a molecular weight modifier, a reactive emulsifier, a pH modifier and deionized water. The matte emulsion with different matte degrees can be obtained by changing the amount of N-hydroxymethyl acrylamide in the shell vinyl monomer, has long storage time and good weather resistance and water resistance and dispenses with matting agents. The water-base matte varnish prepared from the matte degree controllable core-shell emulsion has the advantages of long storage time, good stability, good printing adaptability and the like.

Owner:广东天龙油墨有限公司

Heat-resistance type transfer aluminum plated paper and its producing process

InactiveCN101050605AImprove adhesionGood flexibilityNon-fibrous pulp additionPhysical paper treatmentAdhesiveHeat resistance

The present invention relates to a temperature-resistant type transfer aluminized paper and its production process. Said process successively includes the following steps: coating release layer on the film; coating anchoring layer on release layer; vacuum aluminizing on the anchoring layer; coating adhesive on the aluminized layer; then making them be combined with paper; stripping film from release layer so as to obtain the invented temperature-resistant type transfer aluminized paper.

Owner:SHAOGUAN DONGYANGGUANG PACKAGE PRINTING CO LTD

Production method of wet strong label paper

ActiveCN101368350AImprove wet strengthGood surface resistance to wet frictionCoatings with pigmentsWater-repelling agents additionWet strengthBottle

The invention discloses a production method for wet strength tagboards, including the processes of producing base paper, preparing dope, coating, and calendaring. The method is suitable for producing wet strength tagboards for labels on top grade beer bottles.

Owner:MINFENG SPECIAL PAPER

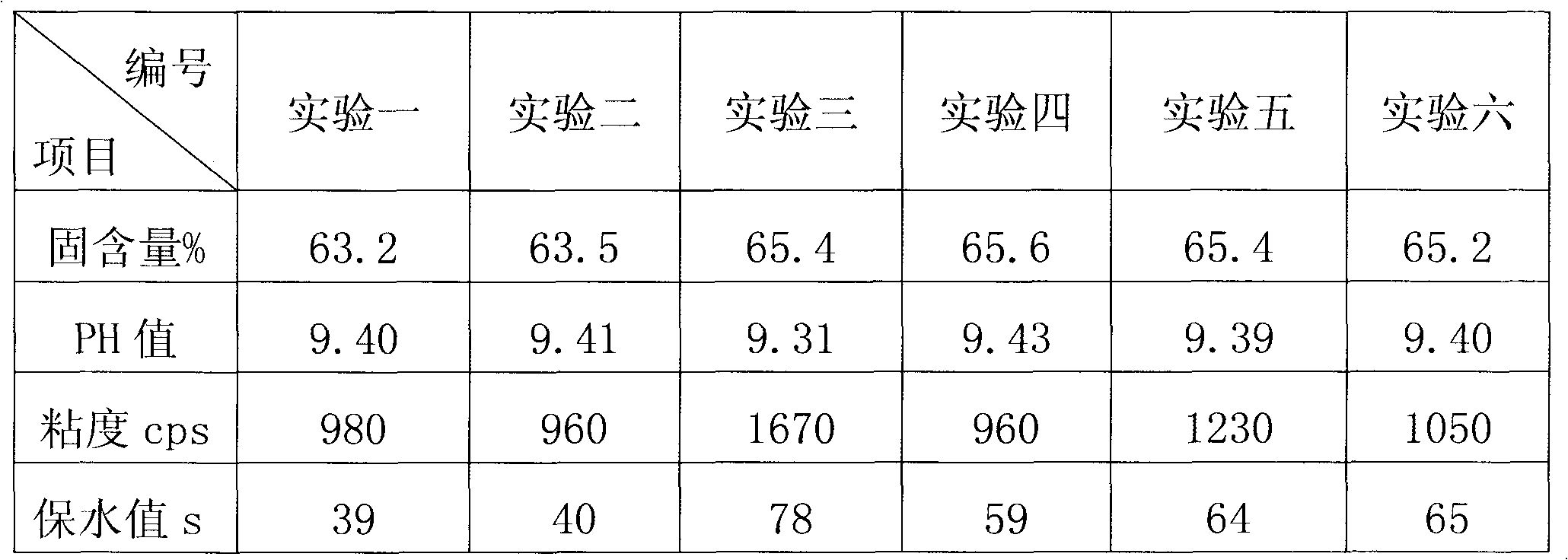

Environmentally-friendly quick drying aqueous glass imitation card transfer paint and preparation method as well as application thereof

InactiveCN102363934AFast dryingLow in volatile organic compounds (VOCs)Defoamers additionPaper coatingSolventCopper

The invention relates to an environmentally-friendly quick drying aqueous glass imitation card transfer paint and a preparation method as well as application thereof. The paint comprises the following component raw materials in parts by weight: 80-95 parts of aqueous resin, 0-8 parts of cosolvent, 0-8 parts of de-ionized water, 0-3 parts of filming auxiliary agent, 0-3 parts of anti-scratch agent, 0-0.5 part of moistening agent, 0-0.2 part of rheological control agent and 0-0.3 part of defoaming agent, and can be used for manufacturing glass imitation card paper or glass imitation copper plate paper. Compared with the prior art, the paint has the advantages of environmental friendliness, low smell, low VOC (Volatile Organic Compound), cost advantage, low production cot, high solid content, high drying speed, superior stripping property, high smoothness, high glossiness, simple application process, capability of recycling a transfer thin film for multiple times, no need of passing through a large-diameter mirror chromium plating drying cylinder like the conventional glass card and high printing adaptability.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

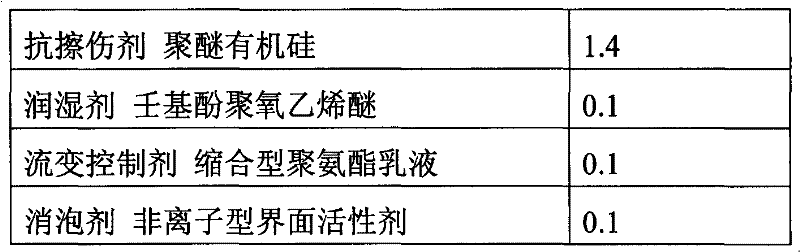

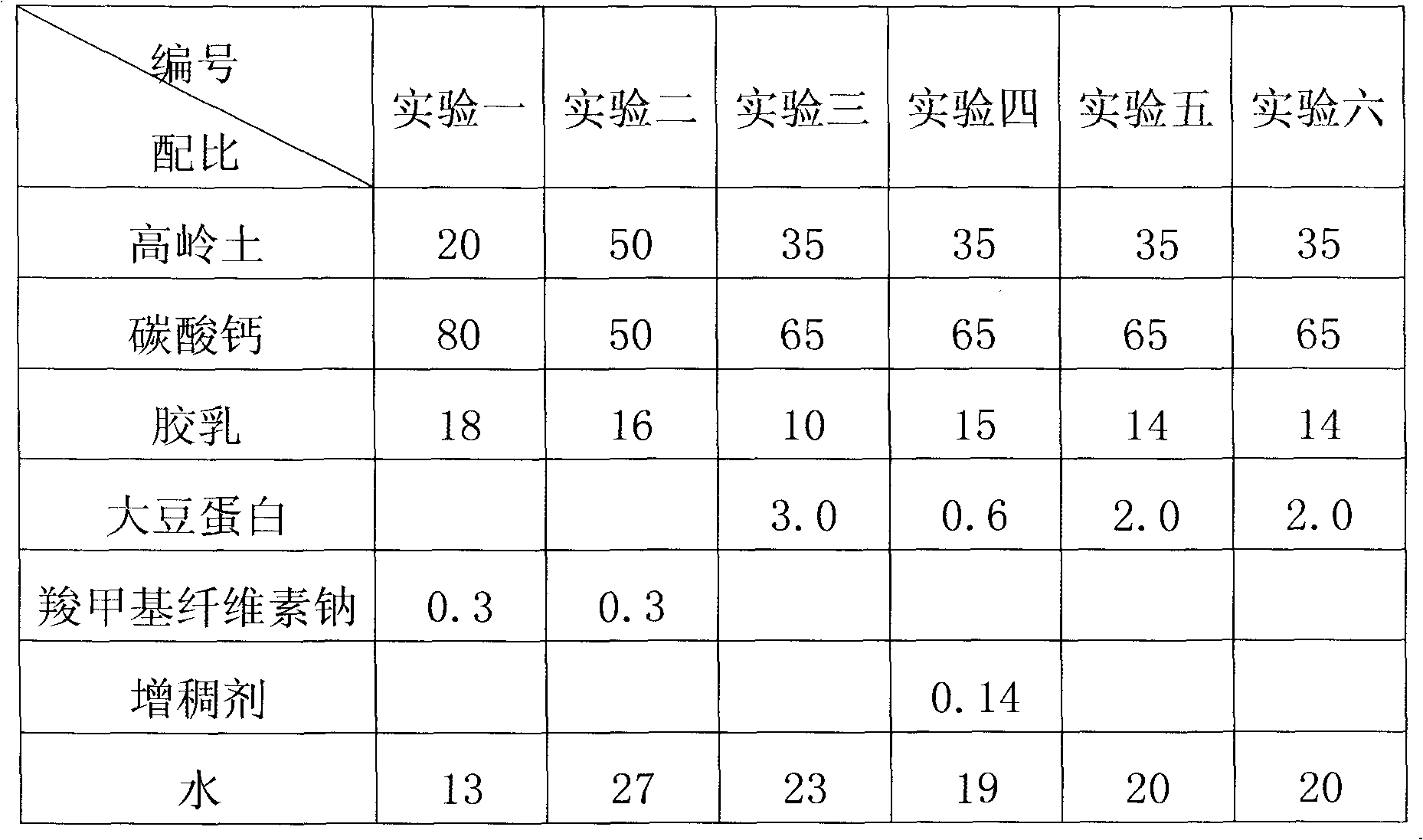

Top coating for coating layer of double-sided coating white board as well as preparation method and application thereof

The invention discloses a top coating for a coating layer of a double-sided coating white board as well as a preparation method and application thereof. As the top coating, the double-sided coating white board after being applied and coated by a coating machine not only is suitable for high-grade printing but also is suitable for vacuum forming. The top coating comprises the following components in parts by mass: 20 to 50 parts of kaolin, 50 to 80 parts of calcium carbonate, 10 to 18 parts of latex and 25 to 35 parts of water. The top coating also contains the components of a dispersant, a lubricant, a water repellent agent, a bactericide, a pH regulator and a functional assistant of 0.6 to 3.0 parts by mass of PC4200 soybean protein. By adding the functional assistant, the closure property of the coating layer can be opened, the covering property of the coating is enhanced, the use quantity of wood pulp is reduced, the smoothness of finished paper is lowered, and the infiltration of vacuum forming oil is benefited. The coating is applied and coated on a paperboard by the coating machine, can enable the paperboard to have favorable printing ink acceptance, improves the covering property of a paper face greatly and has lower smoothness and roughness and favorable printing adaptability.

Owner:YUANTONG PAPER SHANDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com