Aqueous single-coating matt transferring aluminum-plating paint and preparation method thereof

A coating and matte technology, applied in the field of water-based single-coat matte transfer aluminized coating and its preparation, can solve problems such as damage to the health of production personnel, environmental pollution, and increase in production costs, and achieve excellent printing adaptability, coating Simple process, overcoming the effect of dark stripes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

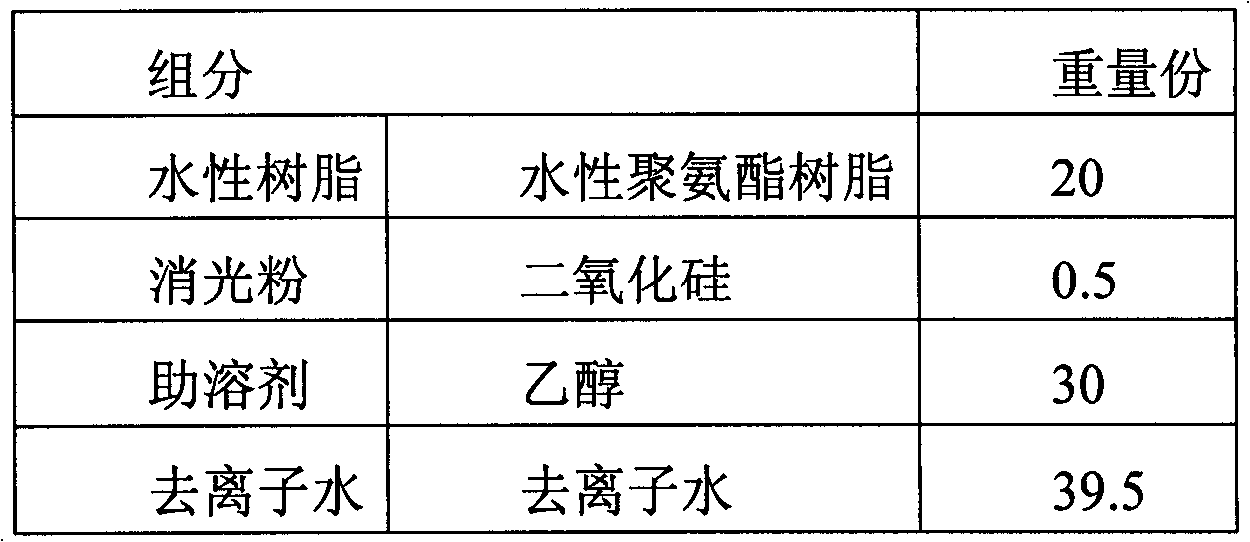

[0067] A kind of water-based single coating matte transfer aluminized coating, the coating is prepared by following components and content (weight part):

[0068]

[0069]

[0070] The weight-average molecular weight Mw of the waterborne polyurethane resin is 40,000, and the softening point is 250°C;

[0071] (2) Add the water-based resin and coloring material into the reaction kettle, and stir evenly at a low speed of 300-500rpm;

[0072] (3) After mixing the co-solvent and deionized water evenly, add 90% into the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0073] (4) Add a defoamer to the reaction kettle, stir at a high speed of 1000-1200rpm for 20-30 minutes, and obtain a matte base material;

[0074] (5) Add matting powder into another reaction kettle, then add the remaining 10% co-solvent and deionized water mixture to soak for 10 minutes, and then control the rotation speed to 100-1200rpm to disperse for 10 minutes; ...

Embodiment 2

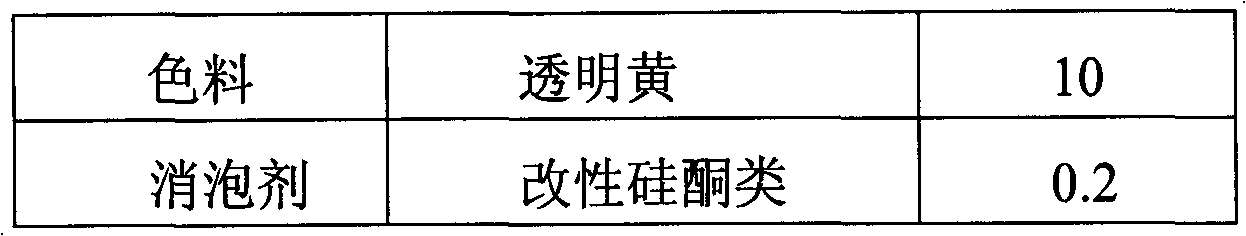

[0078] A kind of high stripping environment-friendly water-based transfer paint, this water-based transfer paint is made of following components and content (weight part):

[0079]

[0080] The softening point of the waterborne polyurethane resin is 180°C, the glass transition temperature Tg of the waterborne acrylic resin is 30°C, and the weight average molecular weight (Mw) is 140,000;

[0081] (2) Add the water-based resin and colorant into the reaction kettle, and stir at a low speed of 300-500rpm;

[0082] (3) After mixing the co-solvent and deionized water evenly, add 90% into the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0083] (4) Add a pH regulator to the reaction kettle so that the pH of the system is between 8.0 and 9.0;

[0084] (5) Add wetting agent and leveling agent to the reaction kettle in sequence, and stir at a medium speed of 700-800rpm for 10-20min;

[0085] (6) Add a defoamer to the reaction kettle, an...

Embodiment 3

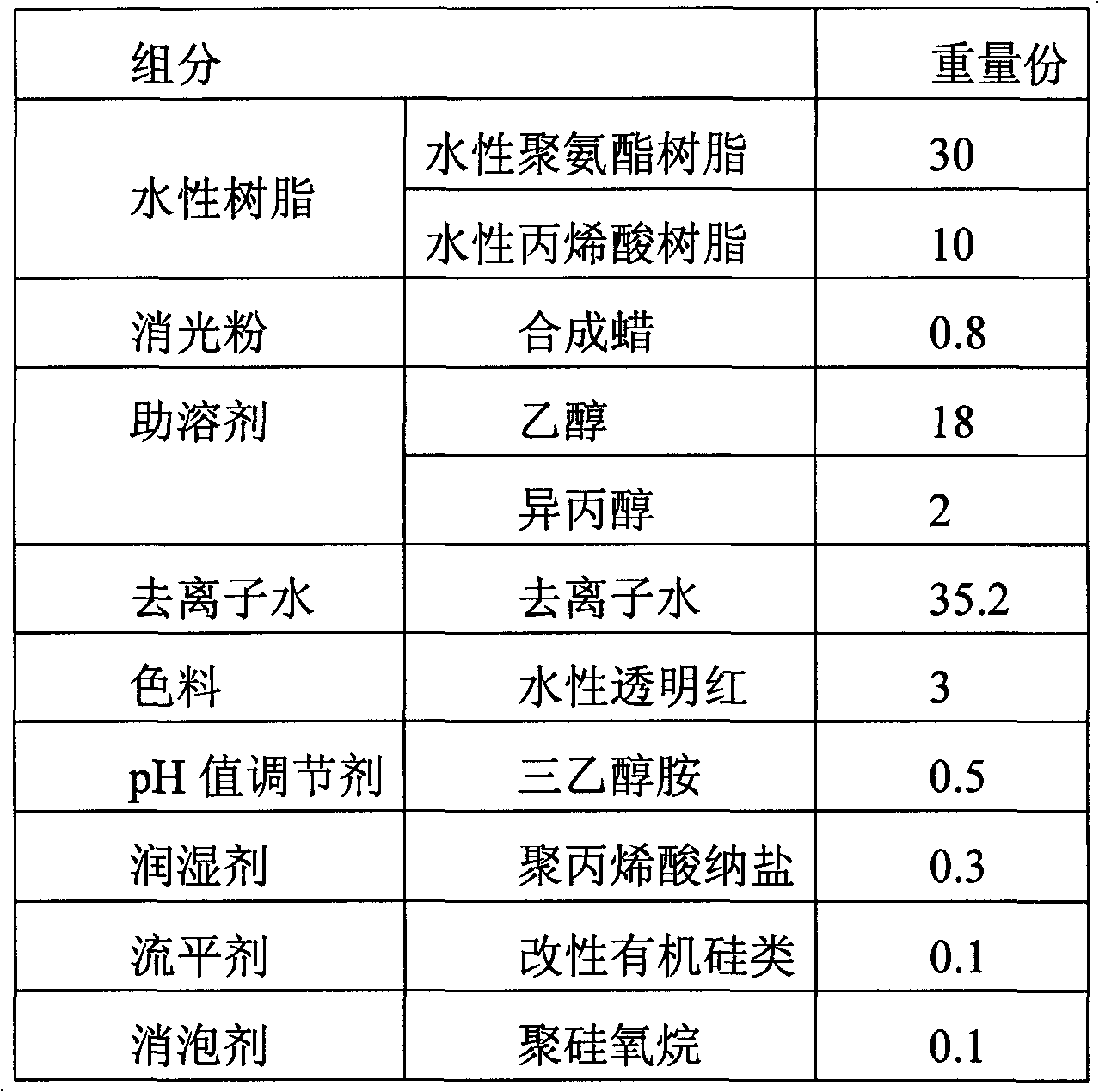

[0090] A kind of high stripping environment-friendly water-based transfer paint, this water-based transfer paint is made of following components and content (weight part):

[0091]

[0092] The softening point of waterborne polyurethane resin is 150°C;

[0093] (2) Add the water-based resin and colorant into the reaction kettle, and stir at a low speed of 300-500rpm;

[0094] (3) After mixing the co-solvent and deionized water evenly, add 90% into the reaction kettle while stirring, and stir at a low speed of 300-500 rpm for 5-10 minutes;

[0095] (4) Add a pH regulator to the reaction kettle so that the pH of the system is between 8.0 and 9.0;

[0096] (5) Add wetting agents to the reaction kettle in turn, and stir at a medium speed of 700-800rpm for 10-20min to obtain a matte base material;

[0097] (6) Add matting powder into another reaction kettle, then add the remaining 10% co-solvent and deionized water mixture to soak for 10 minutes, and then control the rotation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com