Patents

Literature

164results about How to "Overcoming quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric welding rod for hand welding X80 grade steel oil, gas transmission pipe

ActiveCN101362257AHas tensile strengthHas a shock valueWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

The invention relates to an electric welding rod used for manual welding. The electric welding rod comprises core welding-wires containing the following chemical compositions (wt%): 0.020-0.100 of C, 0.350-0.550 of Mn, 0.015-0.030 of Si, 0.005-0.015 of P, 0.002-0.005 of S, 0.01-0.20 of Cr, 0.01-0.30 of Ni, 0.01-0.20 of Cu, 98.675-99.47 of Fe, and the residue of impurity; the electrode coating comprises the following compositions: 28-38 of marble powder, 16-28 of fluorite powder, 2-8 of feldspar powder, 2-7 of white titanium pigment, 4-8 of electrolytic manganese, 3-7 of ferrosilicon powder, 6-9 of ferrotitanium powder, 0.5-2 of ferromolybdenum powder, 3-8 of nickel powder, 10-25 of iron power and 5-8 of other elements. The chemical compositions, the performance and the structure of the welding seam of a grade X80 steel pipe welded by using the electric welding rod are closer to the pipe body, and without heat treatment, the welding seam can meet the requirements on technical indicators such as high strength, high toughness, low hardness and the like of the grade X80 steel pipe used for oil and natural gas transferring; the electric welding rod overcomes the defaults in the prior art that the welding seam is required to be heat-treated after welding, the quality is poor, and engineering accidents are easy to happen when in use and the like.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

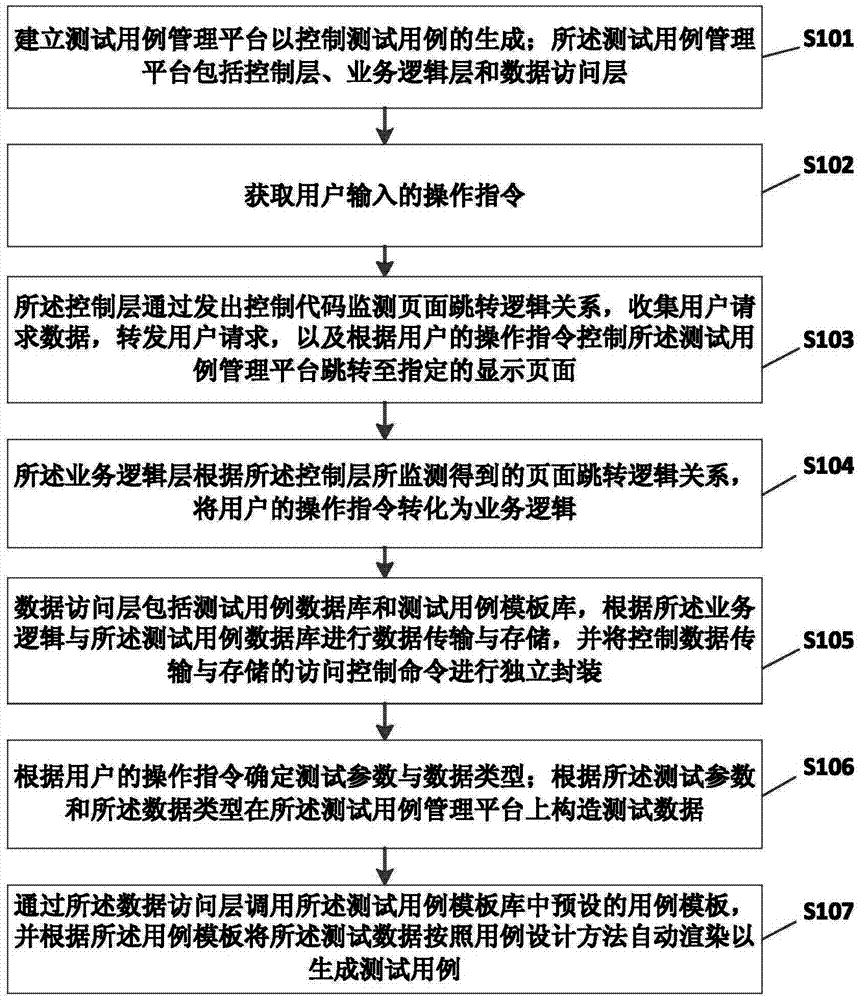

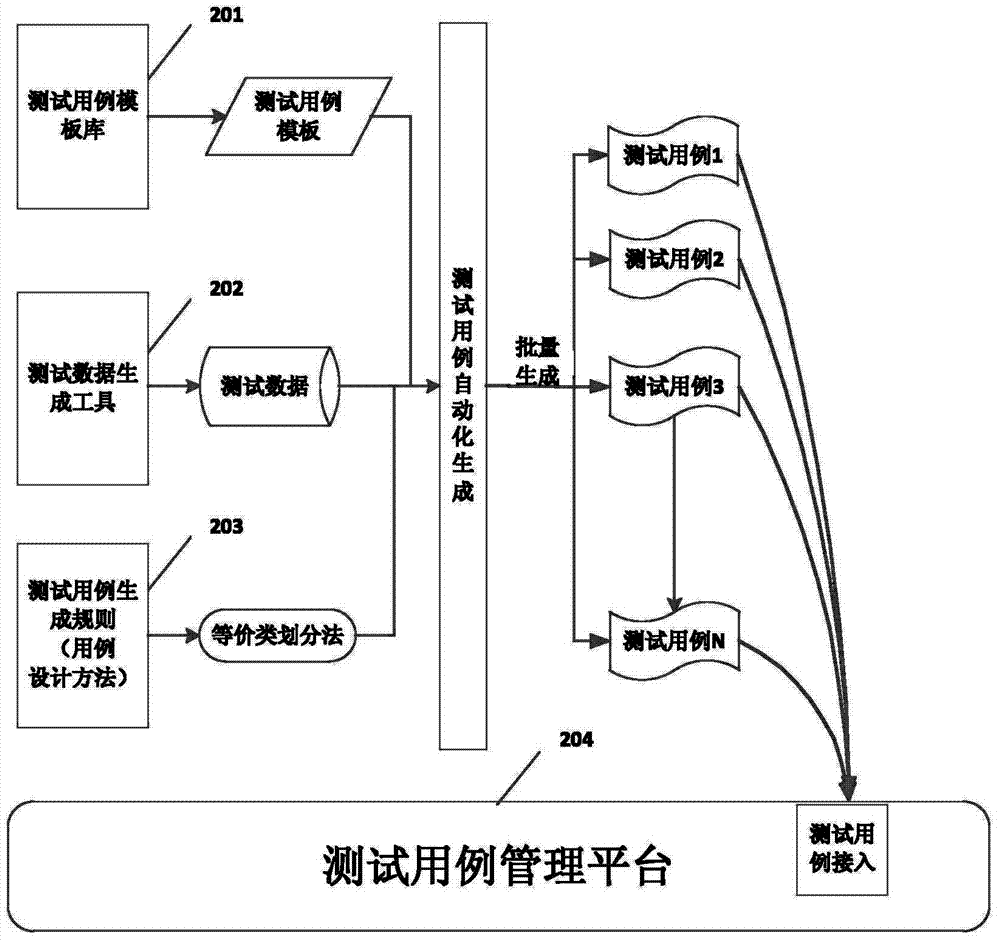

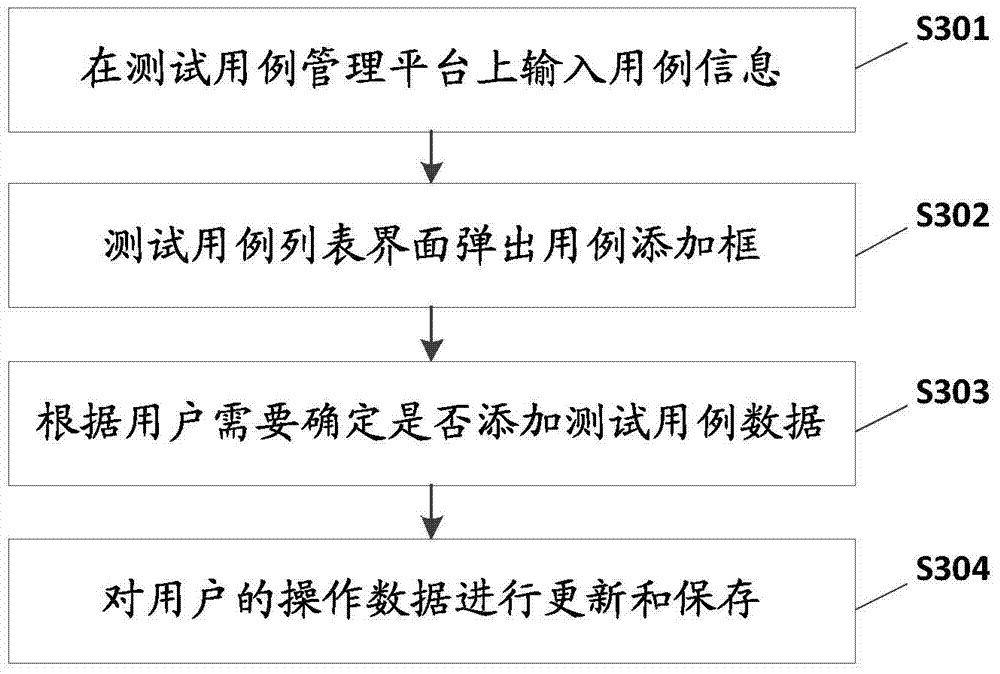

Method for automatically generating testing cases

InactiveCN104123227AOvercome efficiencyOvercoming qualitySoftware testing/debuggingBusiness logicTest case

The invention discloses a method for automatically generating testing cases. The method includes the steps of building a testing case management platform to control generation of the testing cases, wherein the testing case management platform comprises a control layer, a service logical layer and a data accessing layer; obtaining an operation instruction input by a user; determining testing parameters and data types according to the operation instruction of the user; building testing data on the testing case management platform according to the testing parameters and the data types; calling case templates preset in a testing case template base through the data accessing layer, and automatically rendering the testing data with a case design method according to the case templates to generate the testing cases. The method for automatically generating the testing cases has the advantages that the automation degree is high, and the testing cases are comprehensive, normative, accurate and reasonable; the generating efficiency and the quality of the testing cases are greatly improved.

Owner:GUANGDONG POWER GRID CO LTD INFORMATION CENT

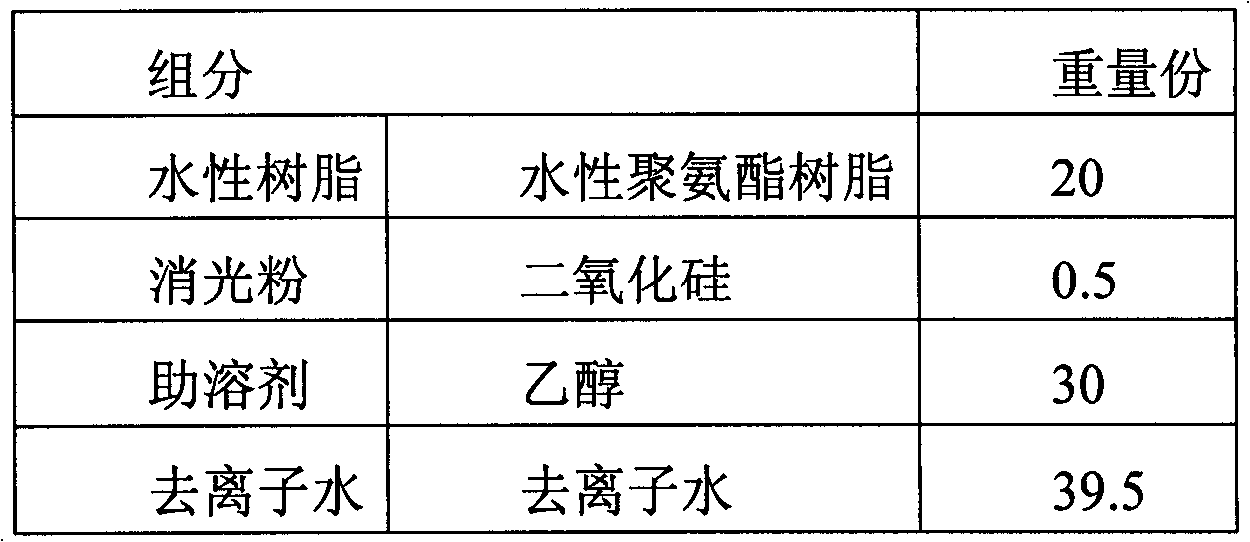

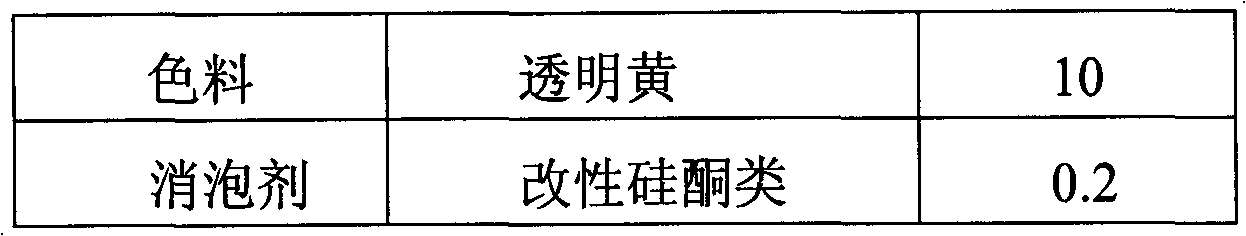

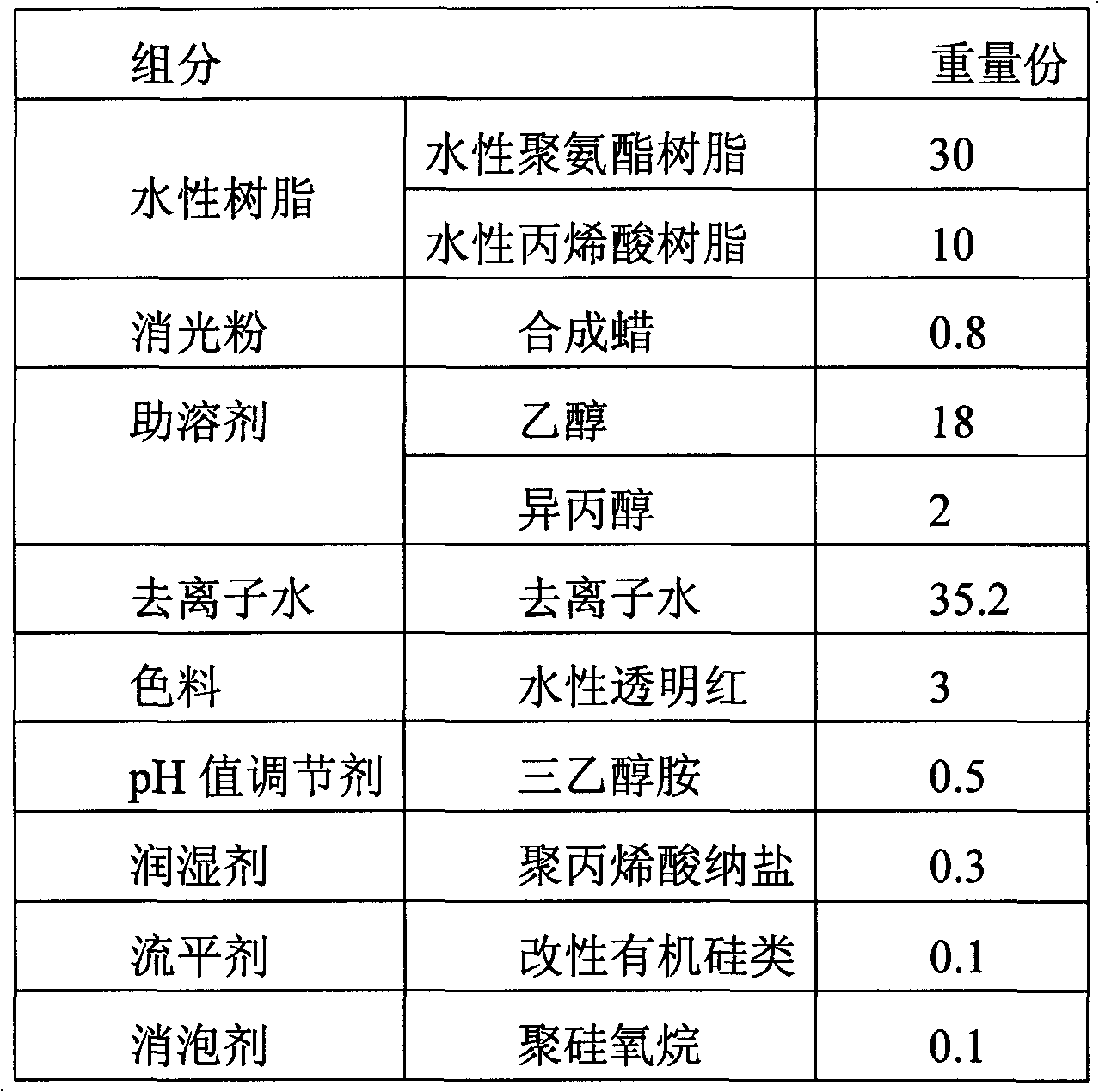

Aqueous single-coating matt transferring aluminum-plating paint and preparation method thereof

InactiveCN102367348AReduce contentEnvironmental costPolyurea/polyurethane coatingsSolventDefoaming Agents

The invention relates to an aqueous single-coating matt transferring aluminum-plating paint and a preparation method thereof. The paint comprises the following components in parts by weight: 20-70 parts of aqueous resin, 10-70 parts of deionized water, 0.5-2 parts of delustering powder, 5-30 parts of cosolvent, 0-10 parts of pigment, 0-2 parts of pH value regulating agent, 0-0.5 part of wetting agent, 0-0.2 part of flatting agent and 0.05-0.2 part of defoaming agent. Compared with the prior art, the aqueous single-coating matt transferring aluminum-plating paint has the advantages of excellent delustering property, simple production process and the like, and is environmentally-friendly.

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

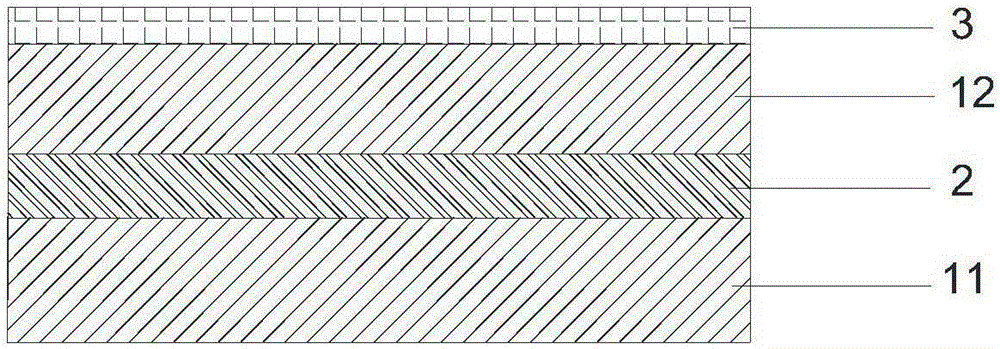

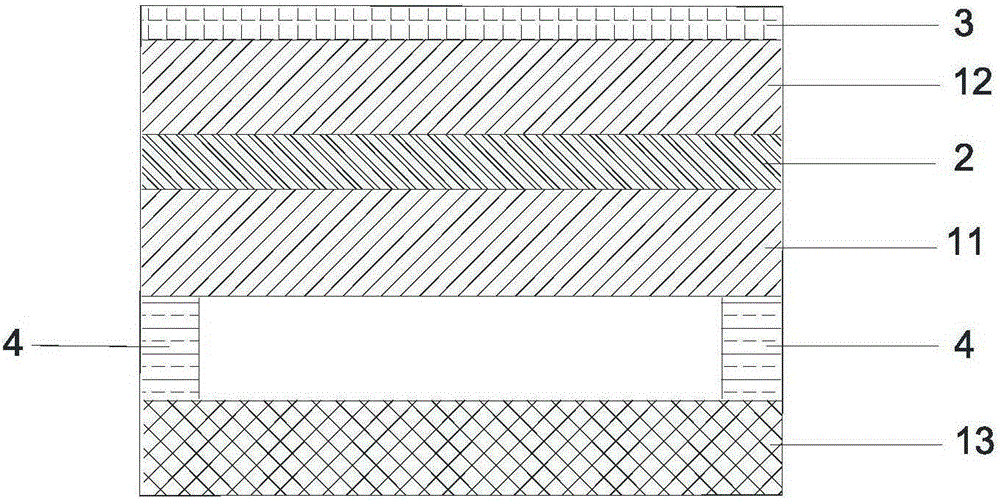

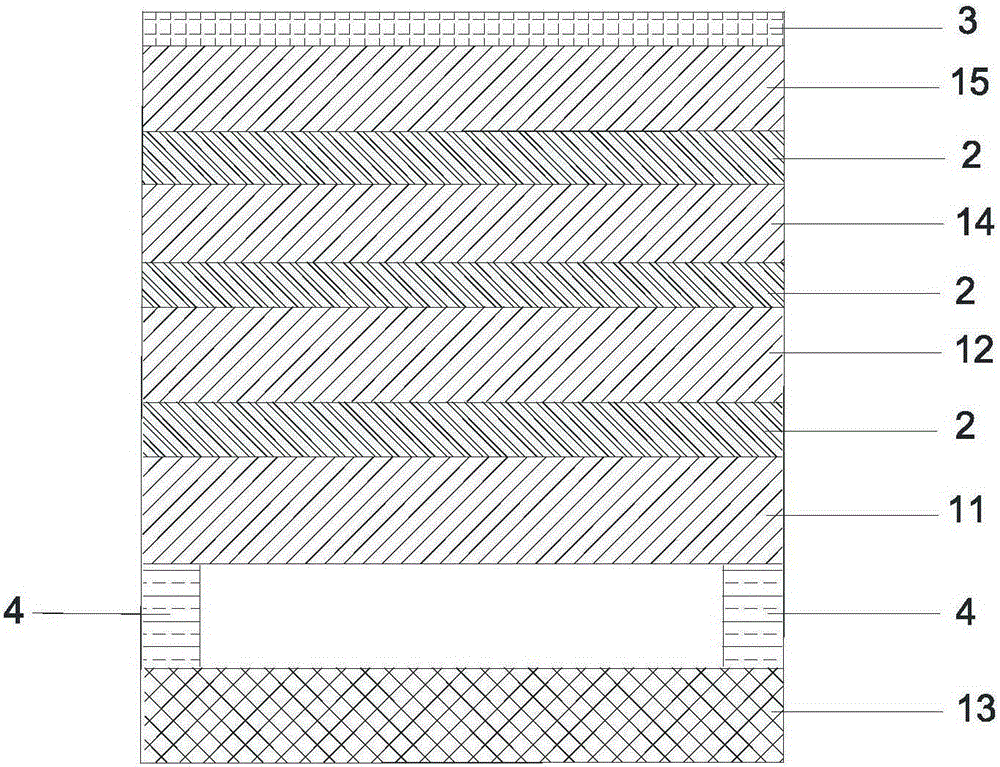

Fire-proof glue of fire-proof glass, preparation method thereof and composite fire-proof glass

ActiveCN105295741AOvercome microbubblesOvercoming qualityNon-macromolecular adhesive additivesAcid polymer adhesivesCross-linkMicro bubble

The invention discloses a fire-proof glue of a fireproof glass, a preparation method thereof and the composite fire-proof glass. The fire-proof glue comprises the following components in parts by weight: 50-150 parts of hydrophilic nano core-shell structure organic-inorganic hybrid particles, 50-150 parts of deionized water, 0.5-5 parts of glycerin, 0.5-3 parts of a char-forming agent, 0.5-3 parts of a char-forming auxiliary agent, 0.5-3 parts of a heat-resistant stabilizer, 0.05-0.5 parts of an ions fixing agent, 0.3-0.6 parts of a storage stabilizing agent, 0.1-0.2 parts of an antifoaming agent, 0.3-0.6 parts of a levelling agent, 0.2-1 part of a cross-linking agent and 15-45 parts of a potassium hydroxide aqueous solution with mass percentage concentration being 50%. The composite fire-proof glass has the advantages of no micro-bubbles, high transmittance and long fire-proof time.

Owner:CHINA BUILDING MATERIALS ACAD

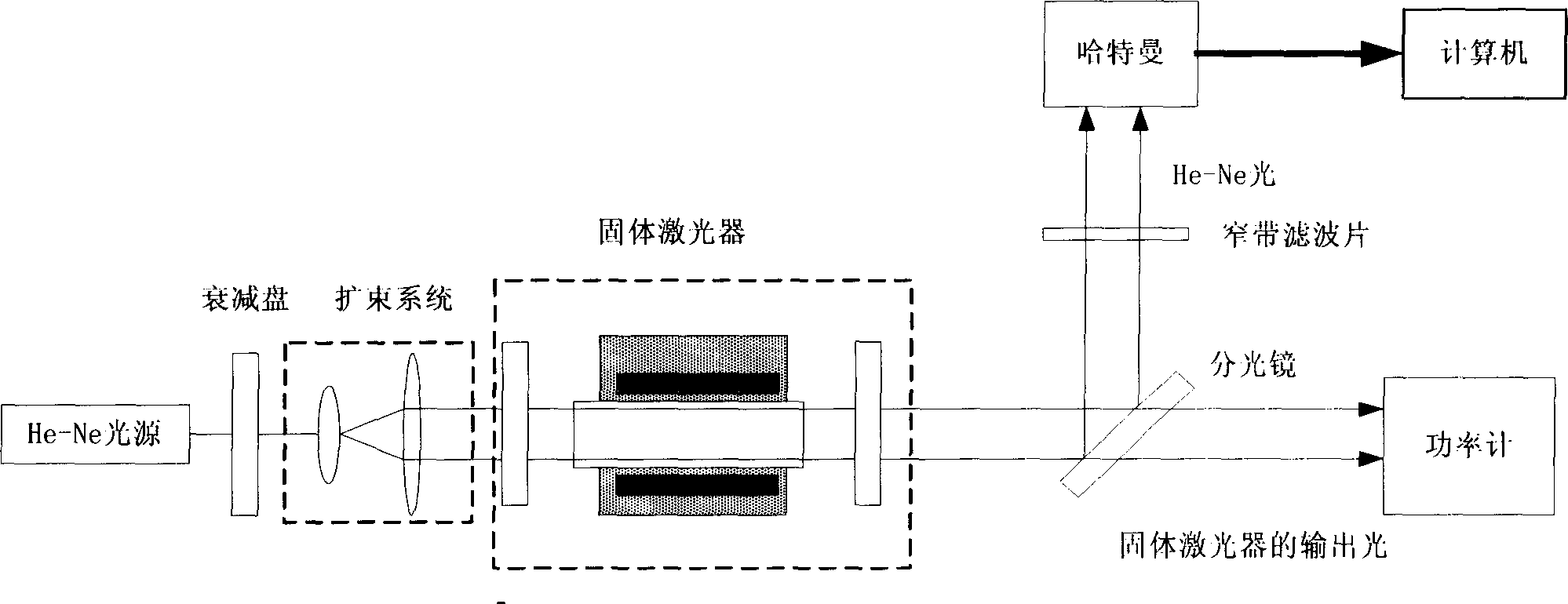

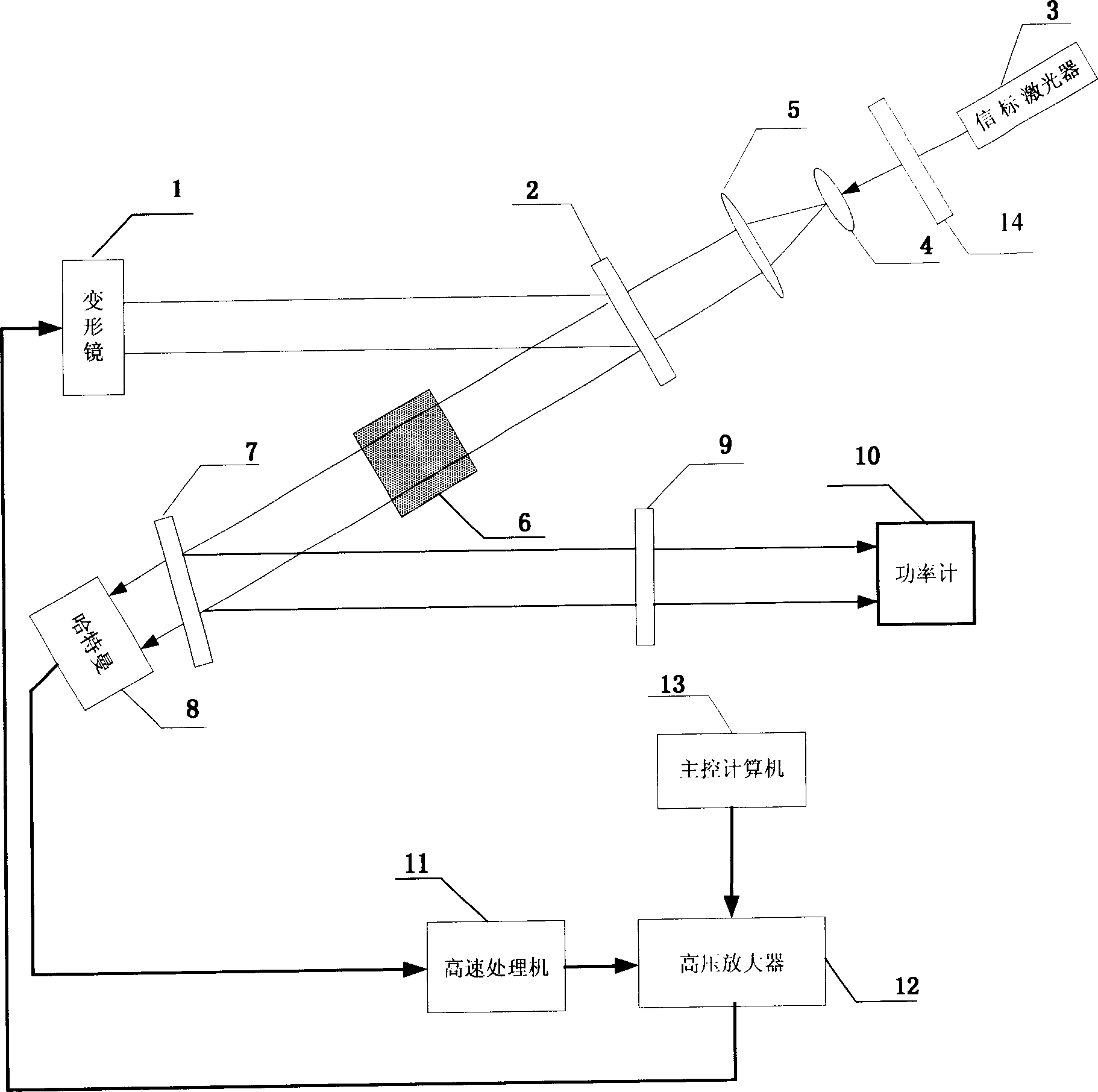

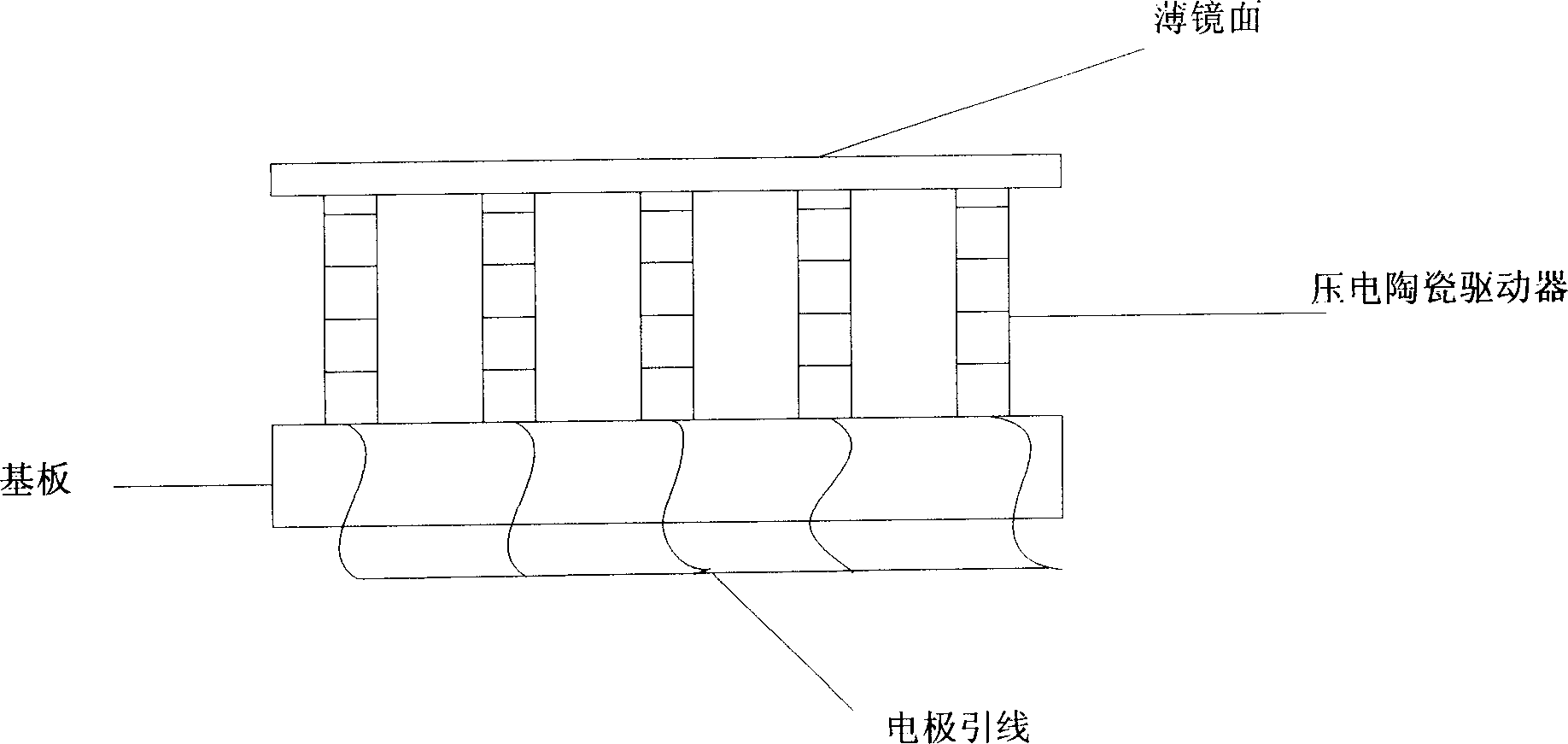

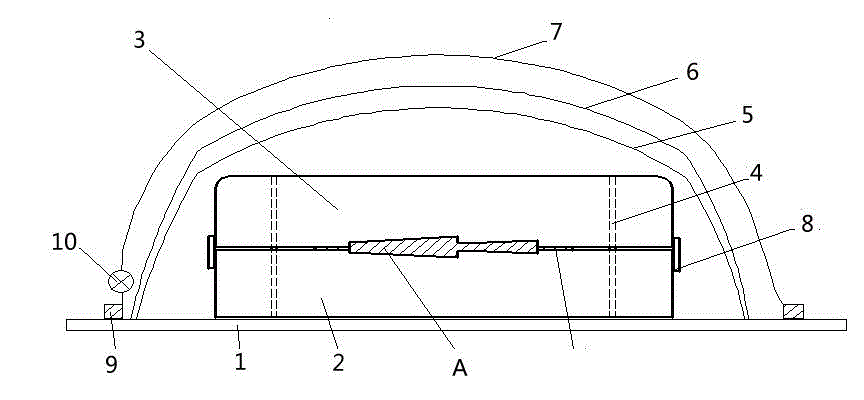

Apparatus for improving light beam quality of solid laser by using in-chamber adaptive optical technology

InactiveCN1804711AHigh beam qualityChange output modeLaser detailsNon-linear opticsBeam splitterWavefront sensor

The invention relates to a device for using intracavity self-adaptive optical technique to improve the solid laser beam quality which is formed by a He-Ne laser, a variable density fading disk, a beam-amplifying system, a distorting lens, a solid laser yield medium, a matching beam-amplifying concave mirror, a beam splitter, an output coupling mirror, a Hageman wave front sensor, a power meter, a high pressure amplifier, a high speed processor and a host computer, wherein the He-Ne laser sent light beacon is leaded into the solid laser yield medium by the concave mirror and is divided into two paths of signal by the beam splitter, one path uses the output coupling mirror to output the laser beam of the solid laser beam; the other path uses the Hageman wave front sensor to real-time probe the intracavity image differential information and uses the high speed processor to process it and obtains the corresponding voltage control signal; it adds the voltage to the deformation driver so that it can compensate the intracavity image difference of the solid laser.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

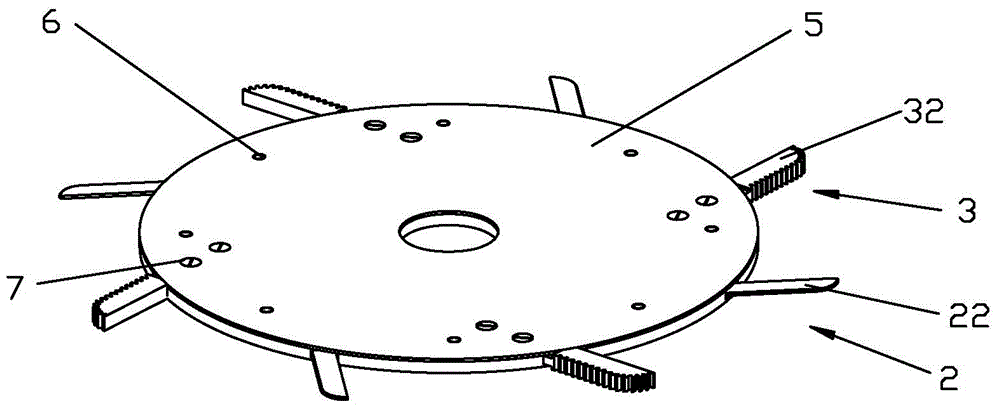

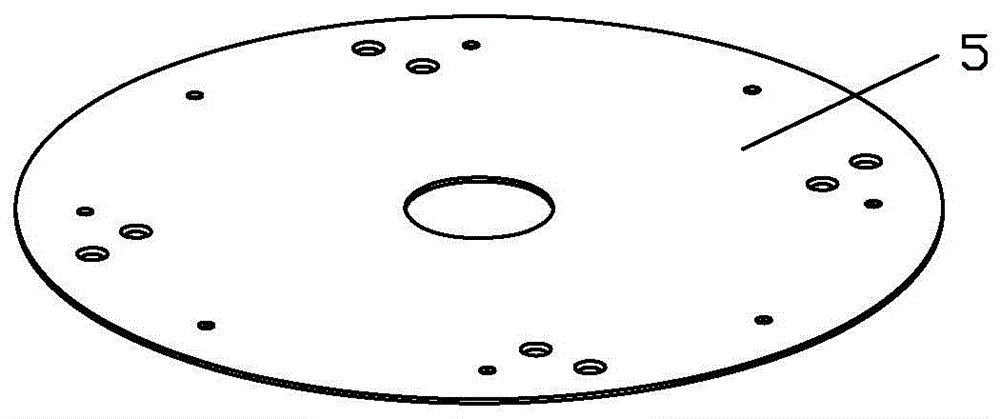

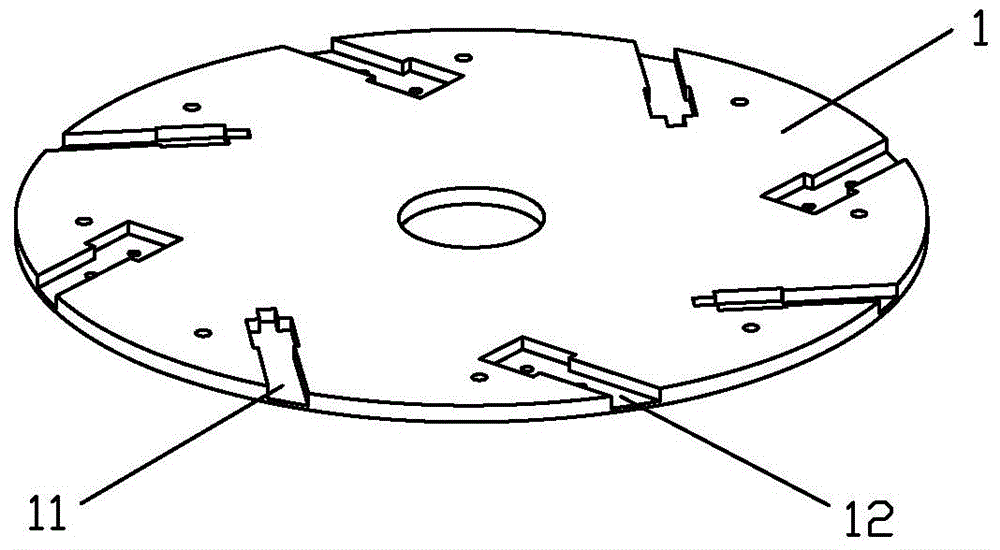

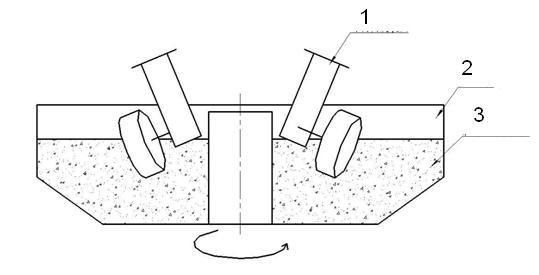

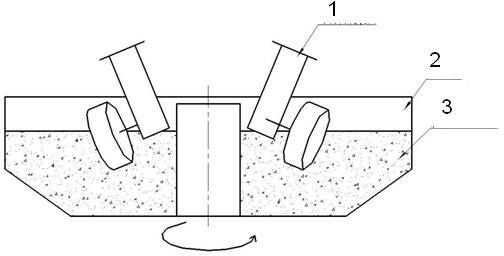

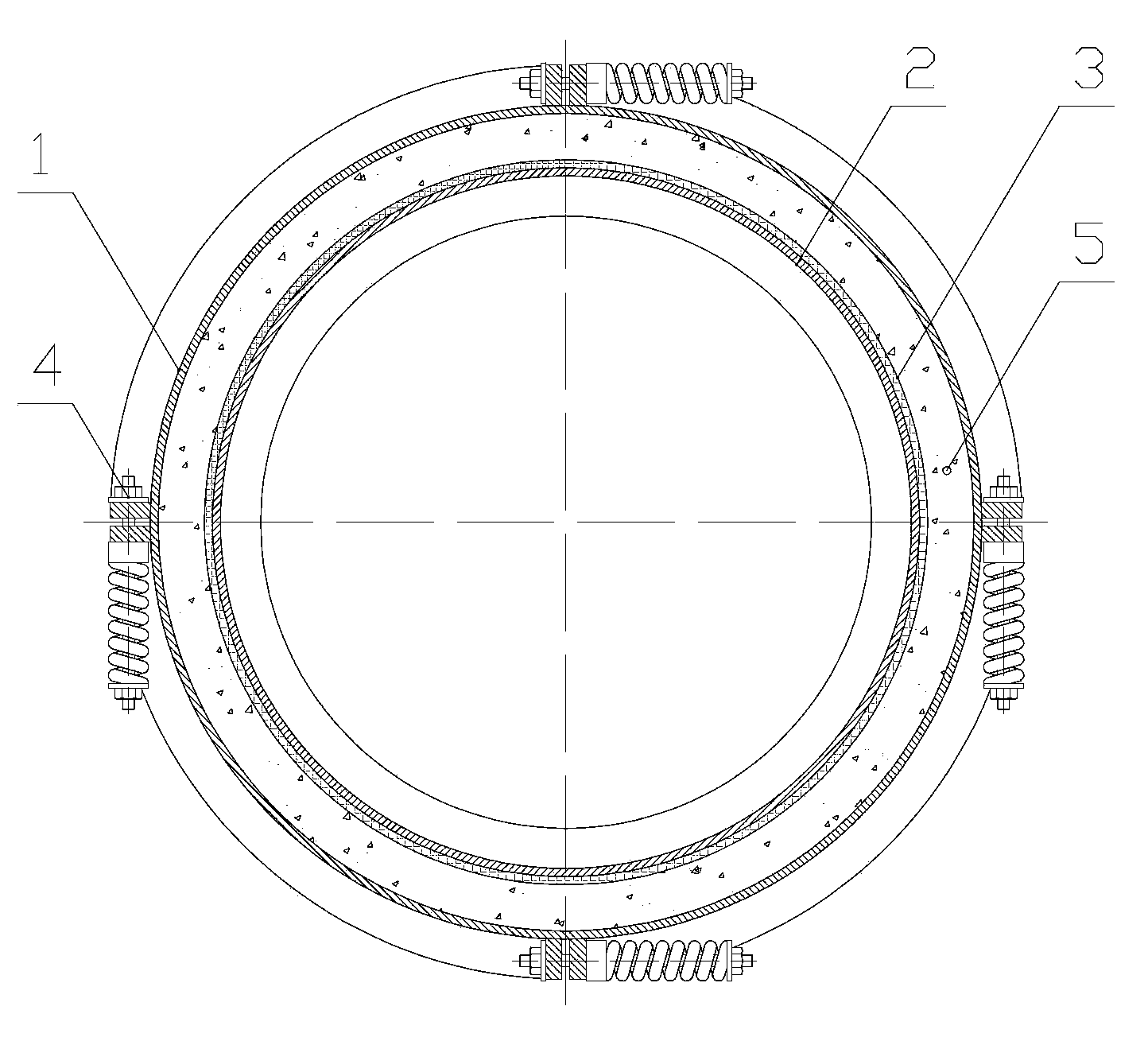

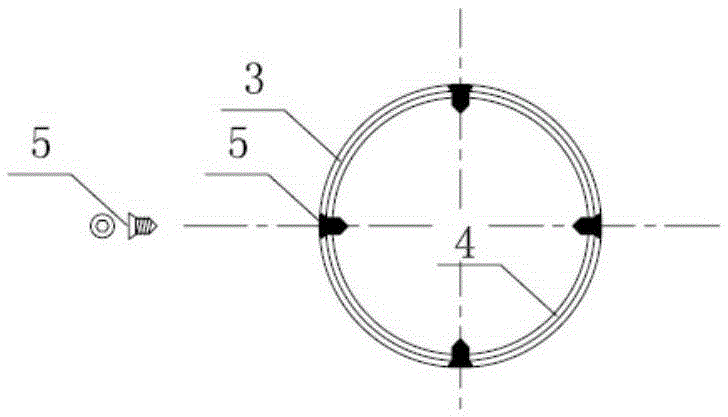

Flesh and bone cutter

The invention discloses a flesh and bone cutter which comprises a baseplate (1), flesh cutters (2), bone cutters (3) and an outer cover (5), wherein the flesh cutters (2) and the bone cutters (3) are arranged at intervals in the circumference direction along the baseplate (1) alternatively; shank parts (21) of the flesh cutters (2) are connected to the baseplate through elastic pieces (4); an included angle being 90-135 degrees is formed between the length direction of the flesh cutters (2) and the bone cutters (3) and the tangent line on which the flesh cutters (2) and the bone cutters (3) are crossed with the periphery of the baseplate (1); when the flesh cutters (2) come into contact with bones, automatic withdrawing can be realized to avoid the condition that the cutter is worn, which is caused by the fact that the bones are forcibly cut; the outer cover (5) and the baseplate (1) can be connected onto a main shaft of a motor; the flesh and bone cutter is driven by the motor to rotate to cut flesh and bones. Different cutters are automatically switched to cut bones and flesh, the synchronous mechanized cutting of bones and flesh is realized, and not only is the smoothness of flesh and bone cuts improved, but also the labor cost during the slaughtering process can be reduced.

Owner:HUAQIAO UNIVERSITY

Method for treating process liquid generated in production process of polyphenylene sulfide

InactiveCN101429288AImprove cycle performanceShort heating timeAlkali metal halide purificationBuffer tankBoiling point

The invention discloses a method for treating a process liquid generated in the process of producing polyphenylene sulfide, which has high separation efficiency, small energy consumption and low cost, and can be continuously performed. The method comprises the following steps: firstly, a dewatering liquid directly enters into a rectification tower for decompression rectification, and a solvent is collected; secondly, a washing solution enters into a triple-effect evaporator for decompression evaporation, and condensed liquids obtained by various effect evaporators are collected into a buffer tank, wherein a liquid subjected to two-effect evaporation and condensation is led off for centrifugal separation, and a separated liquid enters into a third effect evaporator; a liquid subjected to three-effect evaporation and condensation is also led off for centrifugal separation, and a separated liquid returns back to the third effect evaporator; and filtrate directly enters into the third effect evaporator for evaporation; and thirdly, the condensed liquid accumulated in the buffer tank is sent into the rectification tower for decompression rectification, a component with low boiling point - water is collected on the top of the tower, and a component with high boiling point - a solvent is collected at the bottom of the tower; and the process for treating the process liquid is completed.

Owner:JIANGSU XINZHONG INVESTMENT

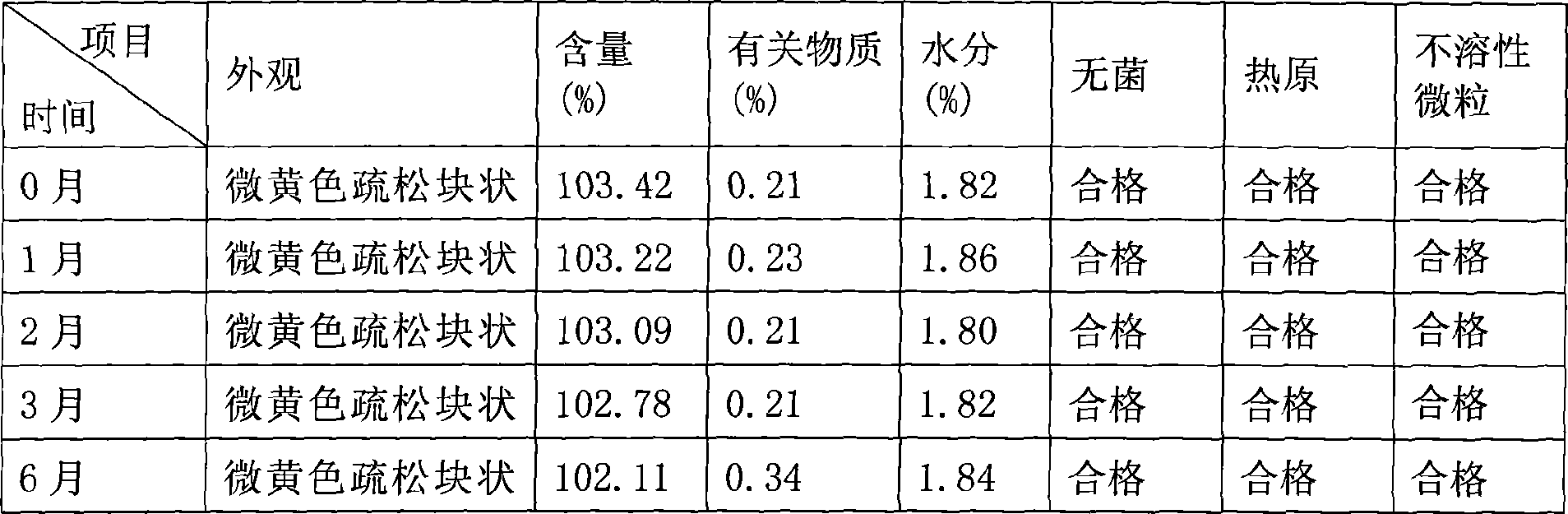

Aluminum wheel finishing process

InactiveCN102430974AOvercoming qualityOvercome efficiencyEdge grinding machinesPolishing machinesAlloy wheelAluminium alloy

The invention discloses an aluminum alloy wheel finishing process, which comprises the steps of: aslant pouring and immersing aluminum alloy blank subjected to thermal processing in a rotating container filled with a grinding material and a grinding agent, forming a medium flow in the front of the wheel through the rotation of the wheel and the relative movement of the container, and carrying out regular and efficient grinding and polishing processing on the front of the wheel and window parts by the medium flow, and finally realizing a mirror polishing effect with extremely excellent surface consistency. By adopting the process, the problems of poor appearance quality in tradition mechanical polishing and low efficiency of a vibration finishing process are overcome, the labor intensity of workers is greatly reduced, the labor environment of the workers is improved, the efficiency is 5-6 times that of the tradition polishing process and vibration finishing, and great cost advantage is achieved.

Owner:CITIC DICASTAL +1

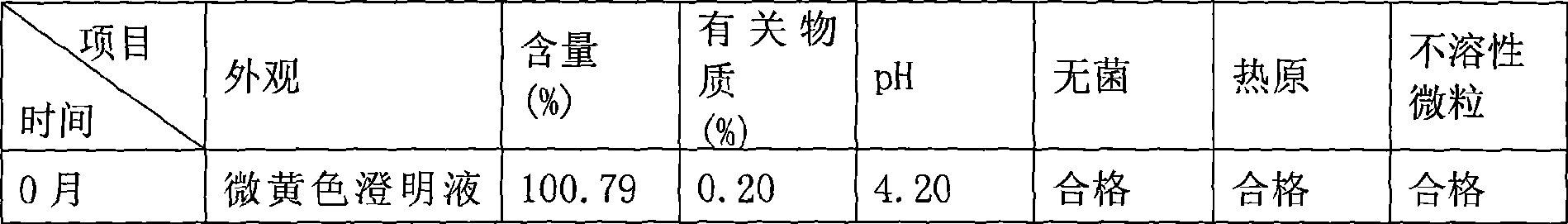

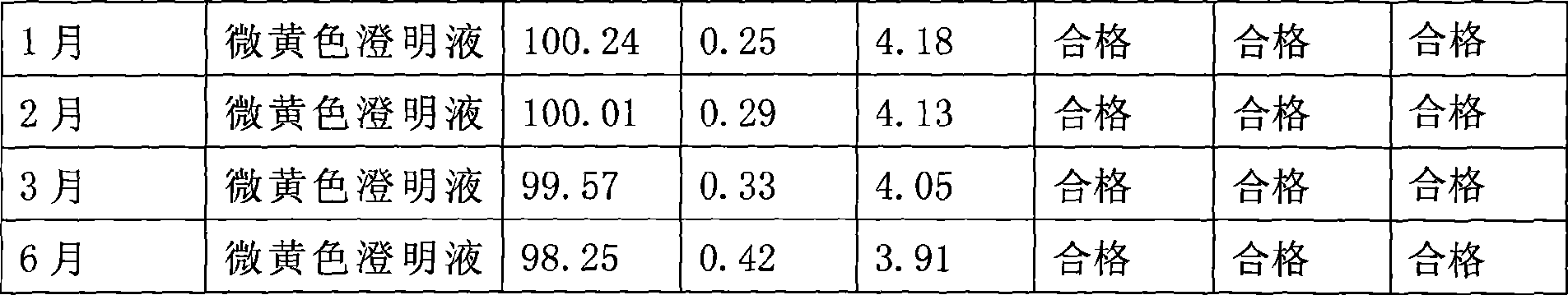

Coenzyme Q10 pharmaceutical composition

InactiveCN101480381AOvercoming easily turbid precipitationOvercoming qualityOrganic active ingredientsPowder deliveryPolyoxyethylene castor oilMonoglyceride

The invention discloses a coenzyme Q10 pharmaceutical composition which mainly comprises components: (1) coenzyme Q10 is active ingredient; (2) one or multiple of polyethylene 15-oxhydryl glycol stearate (Solutol HS 15), polysorbate, PEG, poloxamer, and polyoxyethylene castor oil derived products are solubilizer; (3) one or multiple of midchain monoglyceride and derived products thereof, medium saturated or unsaturated fatty acid are oil component; and (4) injection water is solvent. One or multiple of excipient, chemical inhibitor, and osmotic pressure regulator are added for preparing injection and freeze drying agent. Compared with the traditional coenzyme Q10 pharmaceutical composition, the injection administration coenzyme Q10 pharmaceutical composition has better storage and transportation stability and higher clinical application safety and patient compliance. The injection has simple preparation process, convenient quality control, lower production cost and convenient industrial production.

Owner:郑微

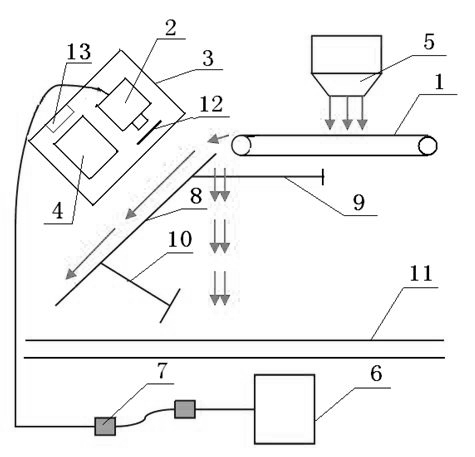

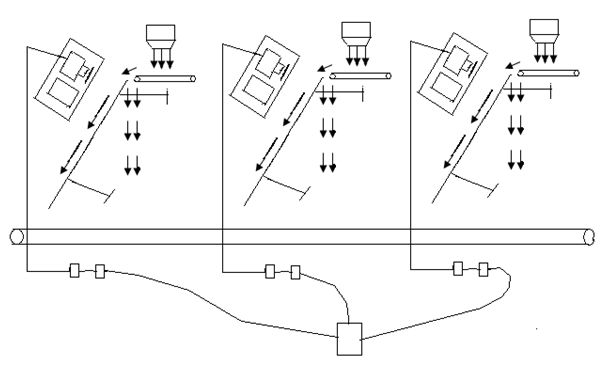

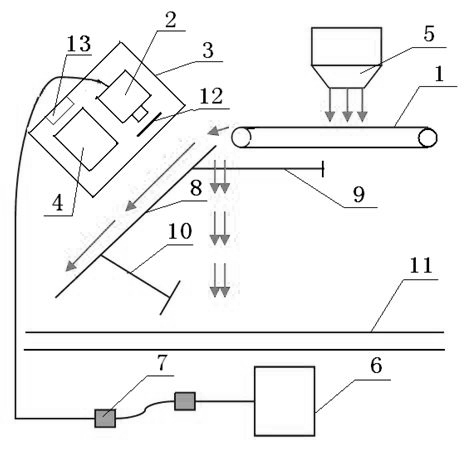

Digital imaging acquisition system for aggregate grading detection and acquisition method thereof

InactiveCN101929943AQuick collectionHigh detection costVolume/mass flow measurementParticle size analysisDigital imagingPoor Quality Image

The invention discloses a digital imaging acquisition system for aggregate grading detection. The system consists of an aggregate sampling device, an image acquiring device, an optical processing optimizer and communication and storage equipment, wherein the aggregate sampling device comprises a material dividing plate, a distance adjusting rod and an angle adjusting rod; the image acquiring device comprises an infrared laser, a linear array camera and an image acquiring card; the optical processing optimizer comprises a filter device and a diffuse coating layer; and the communication and storage equipment comprises a data line and a computer. A digital imaging acquisition method for aggregate grading detection comprises the following steps of: setting the aggregate sampling device; setting the image acquiring device; setting the communication and storage equipment; acquiring an image of a sampled aggregate; and transmitting and storing the image. An aggregate stream is sampled and acquired by arranging the material dividing plate, so the problem that the image of a falling stream of the aggregate must be completely acquired is solved and the defects of poor quality of the acquired image, difficult separation of particles and a large amount of processing data are overcome.

Owner:CHANGAN UNIV

Split die vacuum bag-autoclave forming method of irregular composite material

To solve the problems in the prior art that the surface quality and the shape of a non-adhered die plane need to be completed and accomplished through processes of mechanical machining, polishing, painting and the like in the vacuum bag-autoclave forming process, the invention provides a split die vacuum bag-autoclave forming method of irregular composite materials. A lower die and an upper die are manufactured according to the appearance size and the shape of a composite material part to be formed; a raw rubber sheet layer is paved on the split plane of the upper die and the lower die; and the thickness of the raw rubber layer meets the requirement that the sum of the rubber thickness of the vulcanized raw rubber and the height of the forming chamber of the die is equal to the thickness of the composite material part to be formed. The method has the beneficial technical effects that advantages that the vacuum bag-autoclave forming process is high in density and uniform in distribution and the die forming process is accurate in appearance size and shape are both considered.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Method for preparing single-crystal copper bonding wire

InactiveCN101524721AHigh strengthHigh elongationPolycrystalline material growthSolid-state devicesMegasonic cleaningSingle crystal

The invention relates to a method for preparing a single-crystal copper bonding wire, which uses copper as a raw material. The method comprises the following steps: melting high purity copper of which the purity is higher than 99.995 percent by using a high-vacuum furnace, raising the temperature to between 1,100 and 1,180 DEG C, refining the copper for 60 to 120 minutes, and adopting high purity argon for protection in the whole melting process; broaching single-crystal copper rods of phi 4 to phi 8 mm in a directional solidification mode, and then coldworking the single-crystal copper rods to between phi 0.95 and phi 1.102 mm with the broaching working rate of 15 to 25 percent for each gate; broaching the single-crystal copper rods to between 0.020 and 0.05 mm with 47 to 70 gates and the working rate of 7.59 to 17.82 percent for each gate; and carrying out sonicleaning on the surface of the single-crystal copper bonding wire when the wiredrawing temperature is between 35 and 45 DEG C, carrying out heat treatment on the cleaned single-crystal copper bonding wire, and using H2+Ar2 for protection with the temperature of between 410 and 425 DEG C, the time of between 0.7 and 2.0s and the annealing rewinding tension of between 0.6 and 2.8g.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

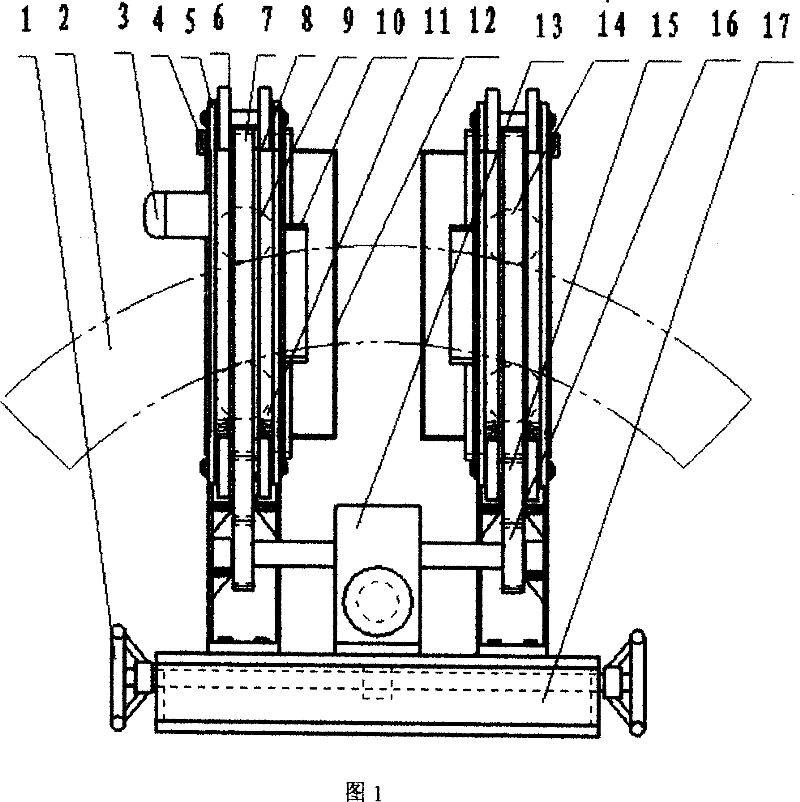

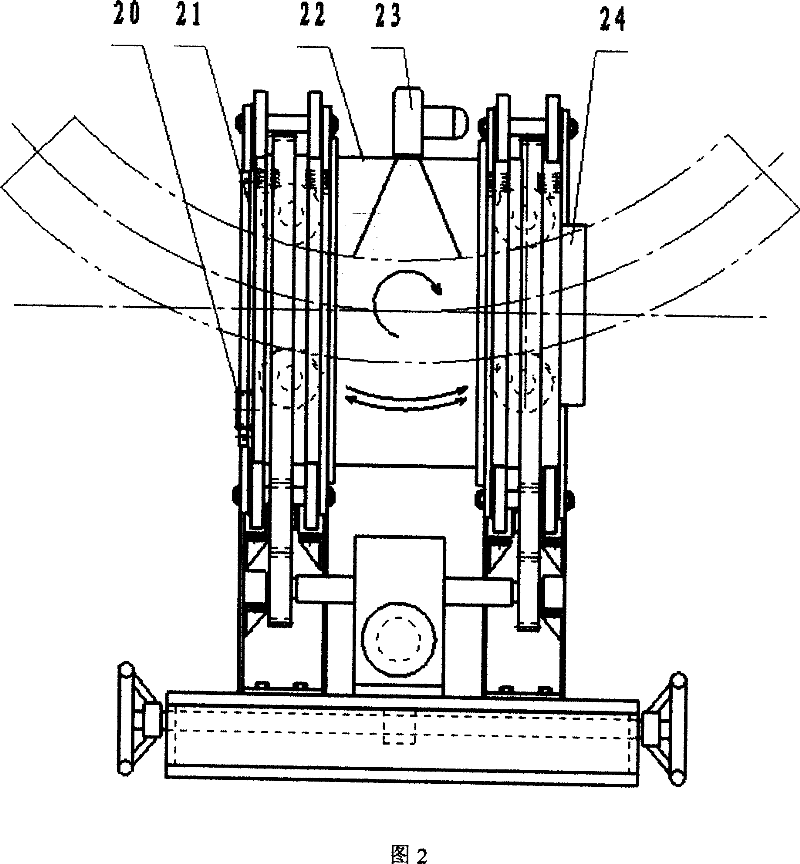

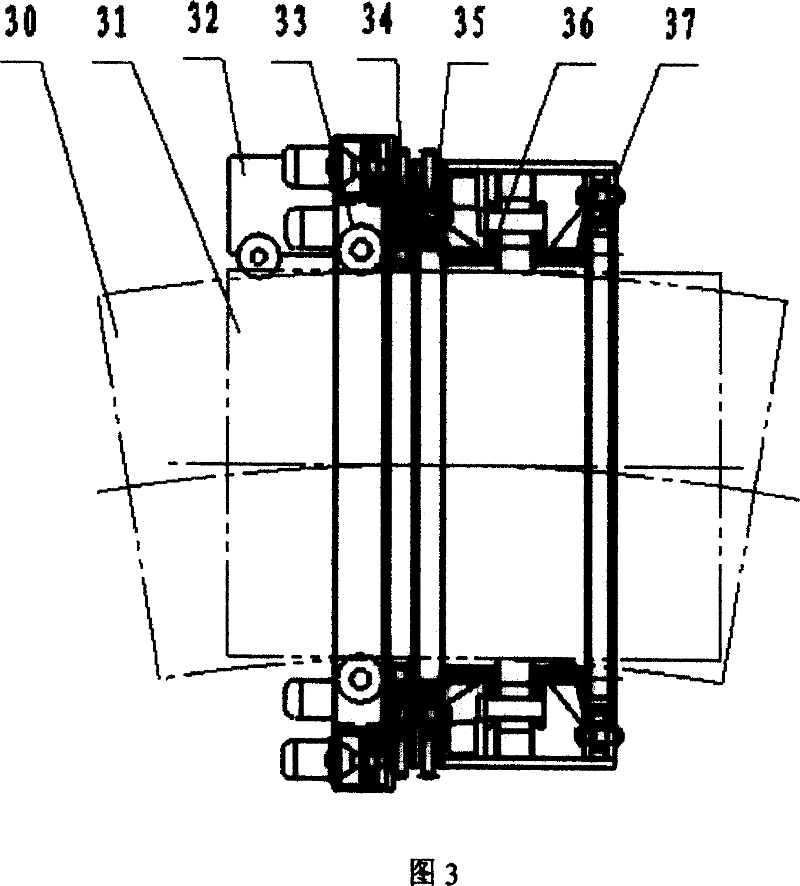

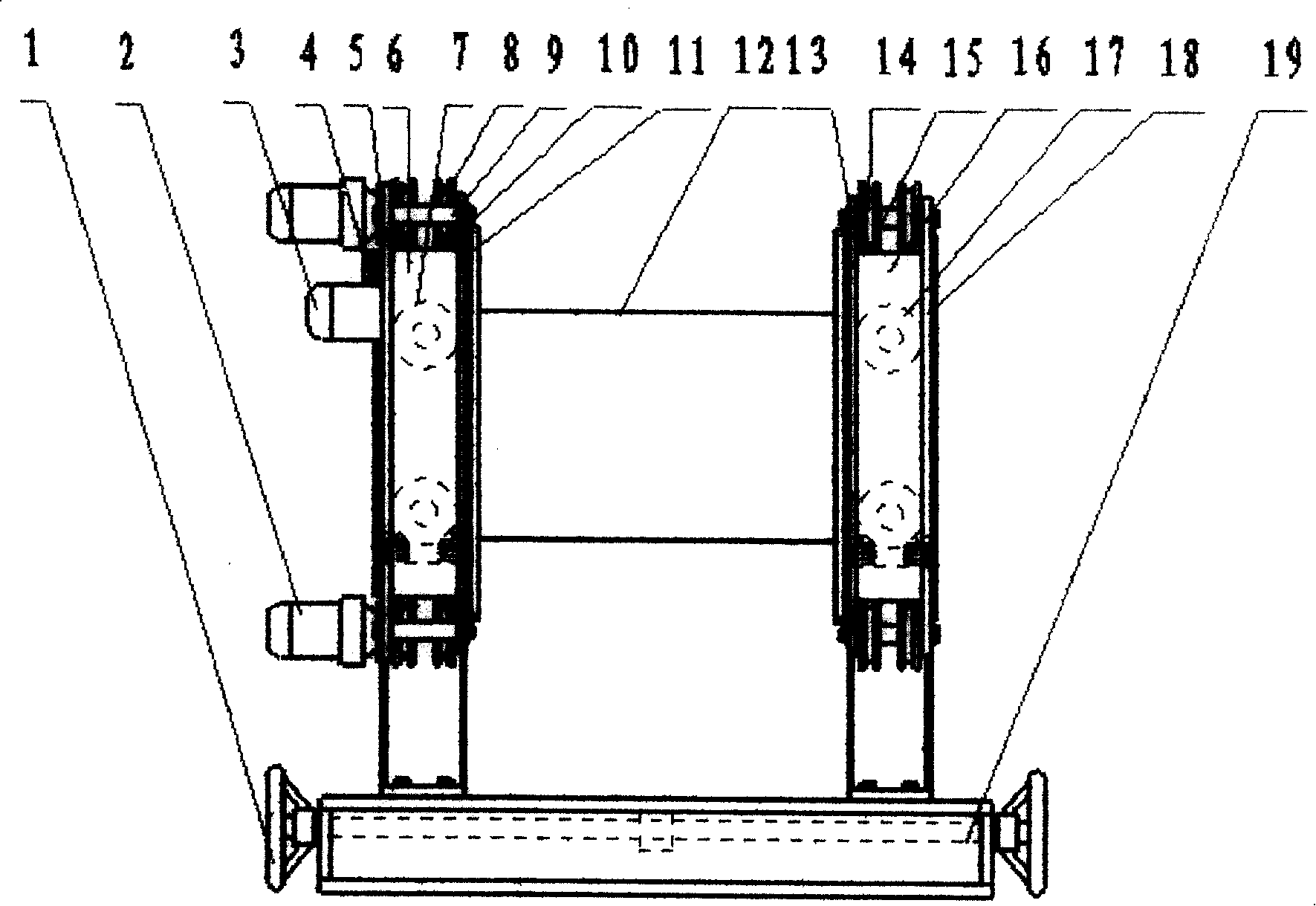

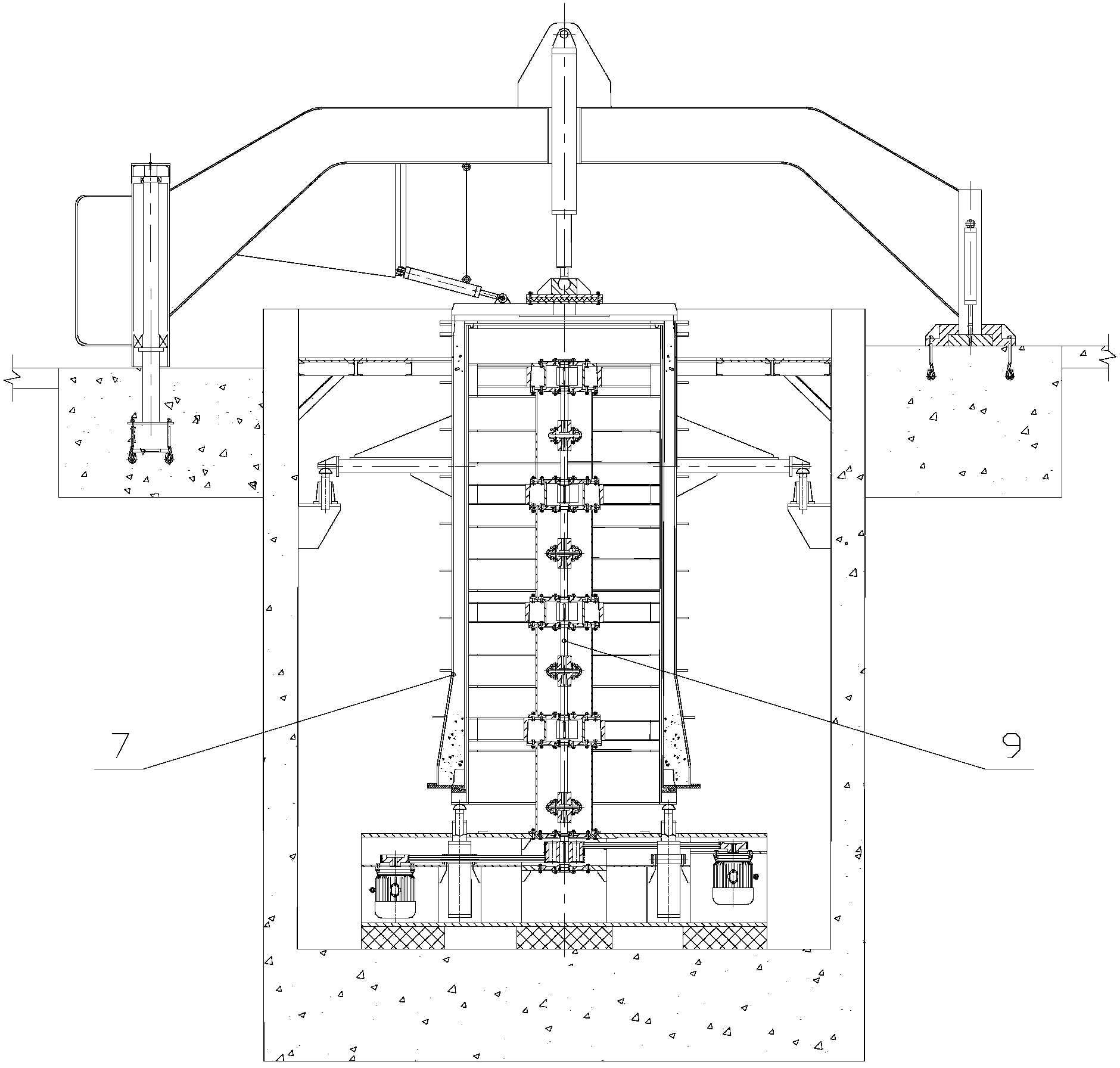

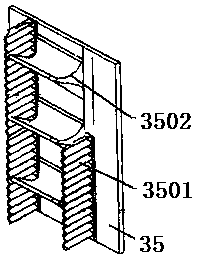

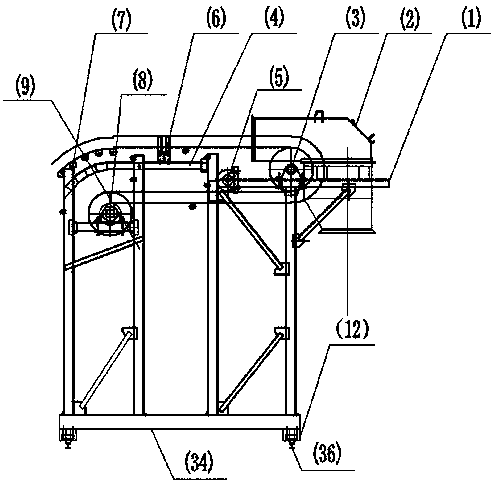

Polyethylene coated steel pipe, online production and equipment thereof

InactiveCN101038048AOvercoming qualityOvercome mechanical propertiesRigid pipesTransformerLow voltage

The invention relates to a polyethylene coated steel pipe and on-line method and apparatus for preparing same. Steel pipe is employed as base material for polyethylene coated steel pipe, and the outer surface of the steel pipe is coated with jointless annular polyethylene gummed tape. Production facilities of the pipe includes steel pipe shot-blast rust cleaning machine comprised of a rotating cylinder bracket, a rotating cylinder, a feeding wheel, a support wheel, a feeding worm wheel speed reducer, a feeding direct current dynamo, a high-frequency induction heating coil, a driving worm wheel speed reducer, a driving AC motor and a electrical control cabinet, and a steel pipe outer anticorrosion coating machine comprised of a induction heating transformer, a walking frame, a swing frame, a rotating frame, a winding device, a supporting frame, a low-voltage electrical casing and a controller. In pipeline installation locale, the steel pipes are welded into pipelines after derusted by the steel pipe shot-blast rust cleaning machine, the steel pipe outer anticorrosion coating machine is nested on the pipeline and carries out helical motion, after high-frequency induction heating on the steel pipe, the spray head injects the epoxy powder on outer surface of the steel pipe, after high-frequency induction heating of the belt-winding cylinder, adhesive tape and polyethylene gummed tape pulled out from the winding device become hot tapes, by helical motion of the steel pipe outer anticorrosion coating machine along pipeline centre-line, the adhesive tape and polyethylene gummed tape are coated on the outer surface of the steel pipes.

Owner:陈炯

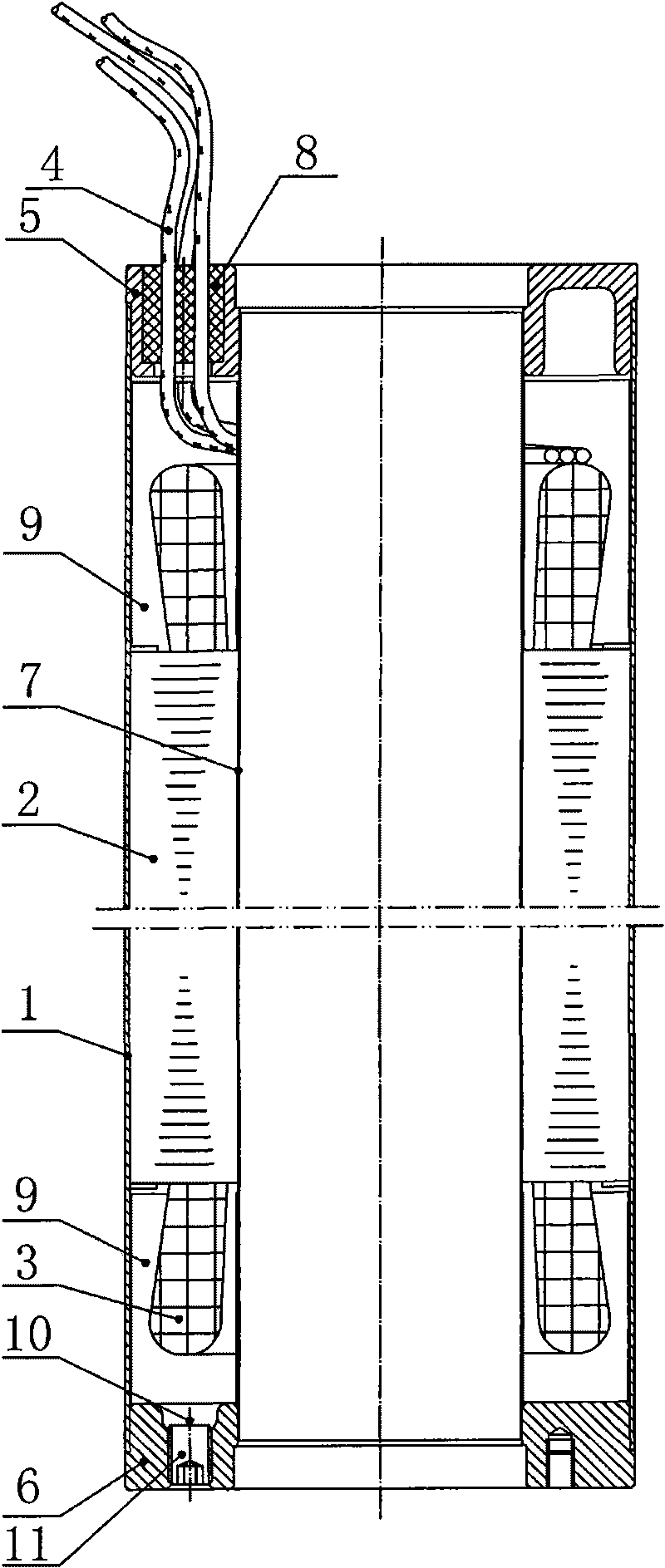

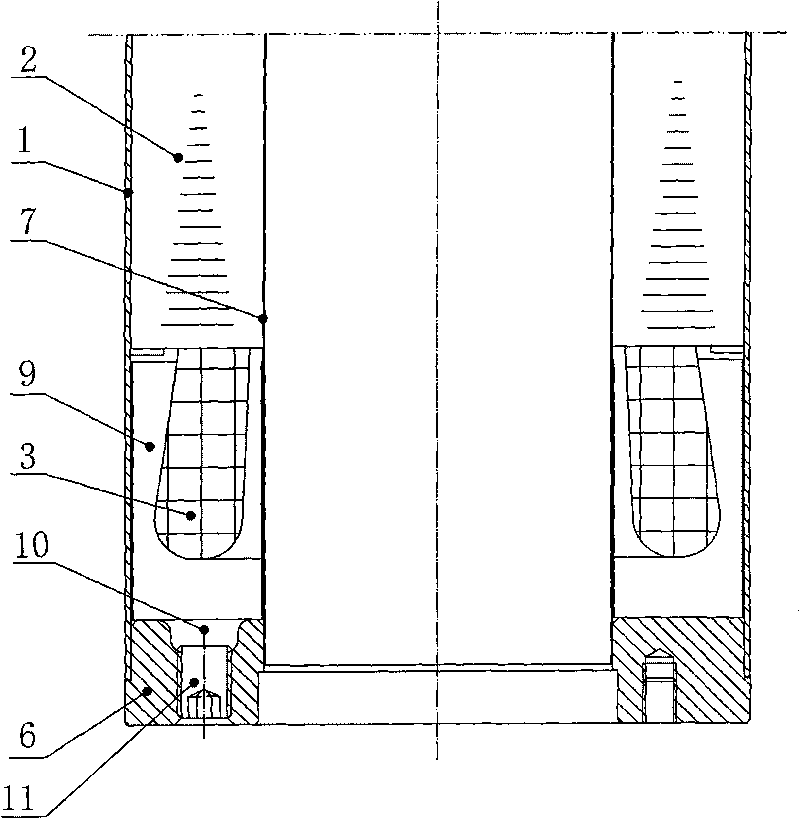

Stator structure of submersible motor and manufacturing method thereof

ActiveCN101764451AAchieve sealingImprove sealingWindings insulation shape/form/constructionMagnetic circuit stationary partsEngineeringConductor Coil

The invention discloses a manufacturing method of a stator structure of a submersible motor, wherein the stator structure comprises a stator case, an iron core, a stator winding and a winding lead wire; the upper end and the lower end of the stator case are respectively welded with an upper flange end ring and a lower flange end ring in a sealing way and also fixed with a stainless steel shielding sleeve and a lead wire sealing device that is used for sealing and wrapping the edge of the winding lead wire; insulating fluid sealant is filled in the clearances among the stator case, the stainless steel shielding sleeve, the upper flange end ring, the lower flange end ring, the iron core and the stator winding. The method for manufacturing the stator structure of the submersible motor includes the following sequential steps of manufacturing the stator case and the stainless steel shielding sleeve by rolling according to the argon arc welding means; manufacturing the stator winding and the iron core; lathing the upper flange end ring, the lower flange end ring and a small V-shaped convex ring; assembling, sealed-welding and reshaping; preparing the insulating fluid sealant; filling the insulating fluid sealant; and sealing. The stator structure has the benefits of complete sealing of the stator winding of the motor, high watertight and insulating performances, simple structure and safe and reliable operation.

Owner:GUANGDONG RUIRONG PUMP IND

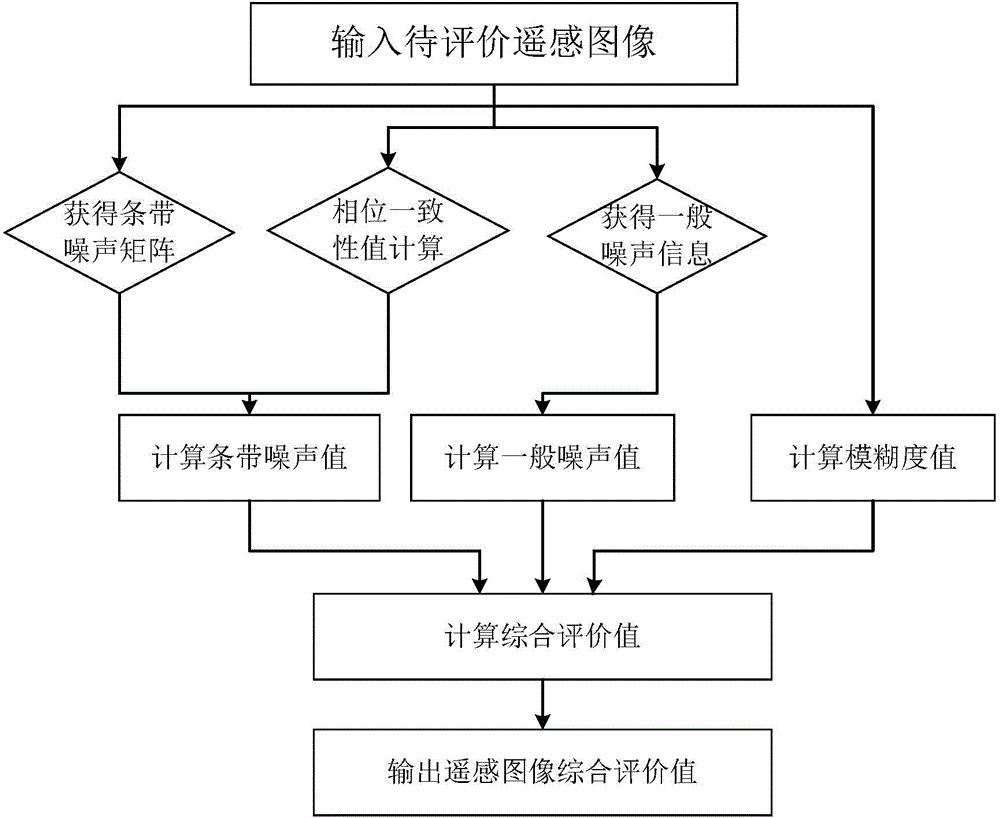

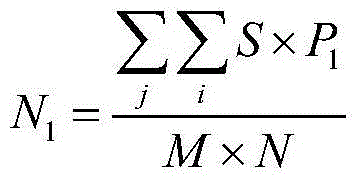

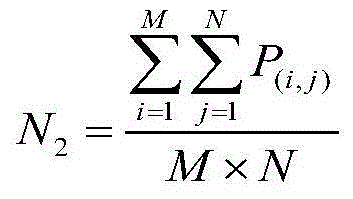

Remote sensing image quality evaluation method based on phase congruency

ActiveCN104680541AOvercoming the problem of not taking band noise into accountThe result is accurateImage analysisComputer scienceNo reference

The invention discloses a remote sensing image quality evaluation method based on phase congruency, and aims to overcome the defect in the prior art that the remote sensing image quality is only represented through a single parameter. The remote sensing image quality evaluation method comprises the following steps: (1) inputting a remote sensing image to be evaluated; (2) acquiring a phase congruency value of the remote sensing image in a strip noise direction; (3) performing binarization processing on the phase congruency value; (4) acquiring a strip noise intensity matrix; (5) calculating a strip noise value; (6) acquiring ordinary noise information; (7) calculating an ordinary noise value of the remote sensing image; (8) calculating an ambiguity value of the remote sensing image; (9) acquiring a comprehensive evaluation value of the remote sensing image by using a choquet ambiguity integral; (10) outputting the comprehensive evaluation value of the remote sensing image. The remote sensing image quality evaluation method has the advantages that no reference is needed, the quality of the remote sensing image can be comprehensively evaluated, and the evaluation result can relatively well accord with subjective evaluation.

Owner:XIDIAN UNIV

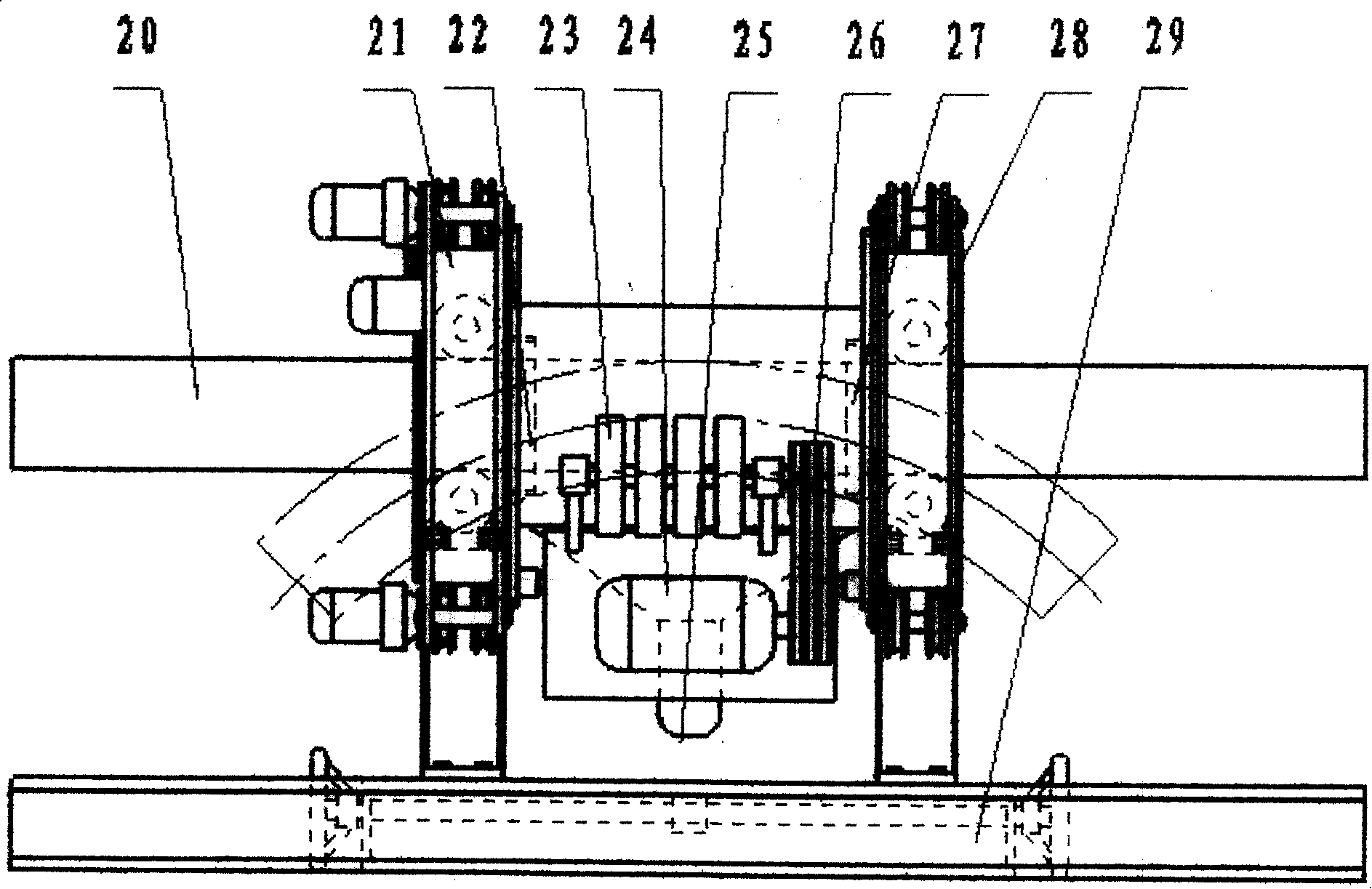

Polyethylene coating steel pipe and its producing method and production line

InactiveCN101191577AOvercoming qualityOvercome mechanical propertiesLiquid surface applicatorsCorrosion preventionEpoxyAdhesive

The invention relates to a steel pipe painted with polythene and manufacturing method and mobile production line. A drum type rust remover, a drum type threading machine, a drum type spray coater, a drum type winding machine, a drum type cooling fan, a drum type dust removing threading machine, and a drum type spray winding machine are connected in turn to form the mobile production line. At a pipe laying site, a steel pipe in turn enters the drum type rust remover, the drum type threading machine, the drum type spray coater, the drum type winding machine and the drum type cooling fan, and makes helical movement under the support of a feeding wheel and a supporting roller in a rotating drum body. The steel pipe is heated through a high-frequency induction heating method, and rust spots are removed from the external surface of the steel pipe through a mechanical method and the steel pipe is threaded also through a mechanical method, the epoxy powder spray coater is used to spray epoxy powder to the external surface of the steel pipe, the epoxy powder and a composite polythene cold adhesive tape are heated indirectly through the high-frequency induction heating method and the cold adhesive tape is turned into a composite polythene hot adhesive tape, and through a mechanical winding method, the composite polythene adhesive tape is applied onto the epoxy powder layer to produce the steel pipe painted with polythene.

Owner:陈炯

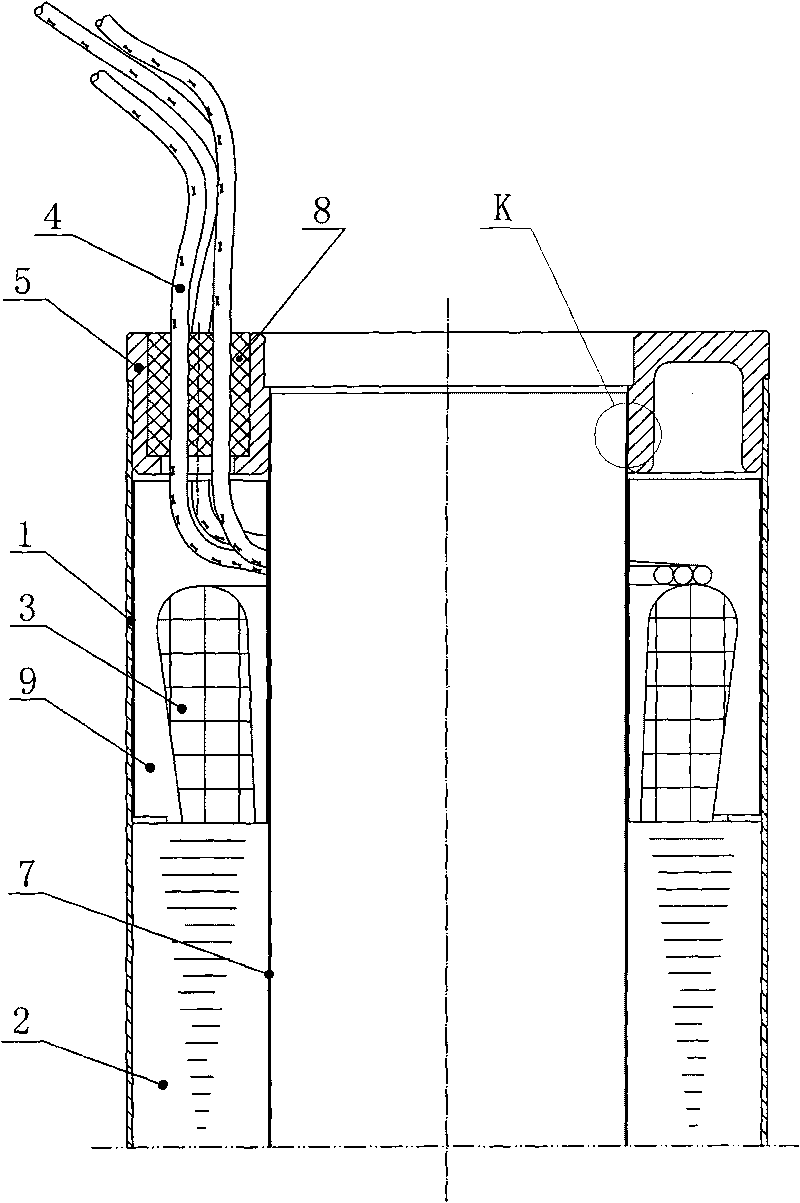

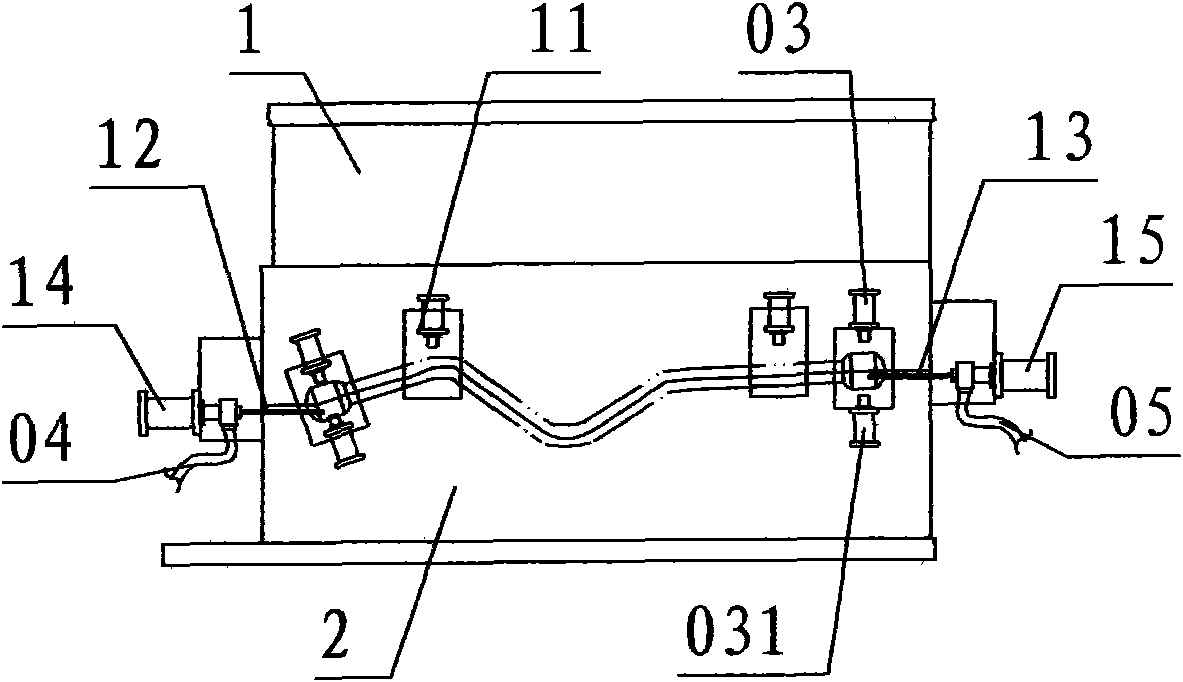

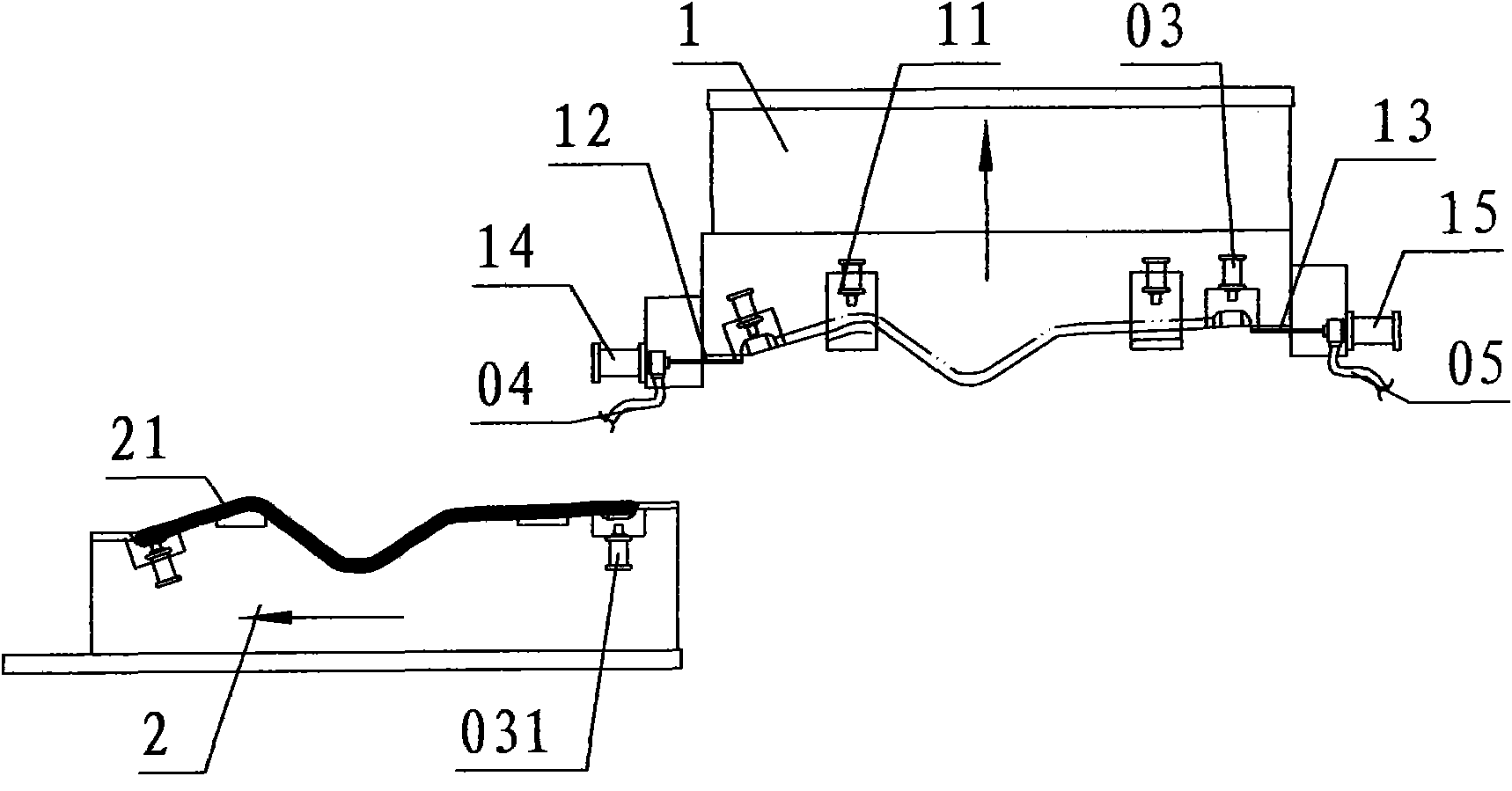

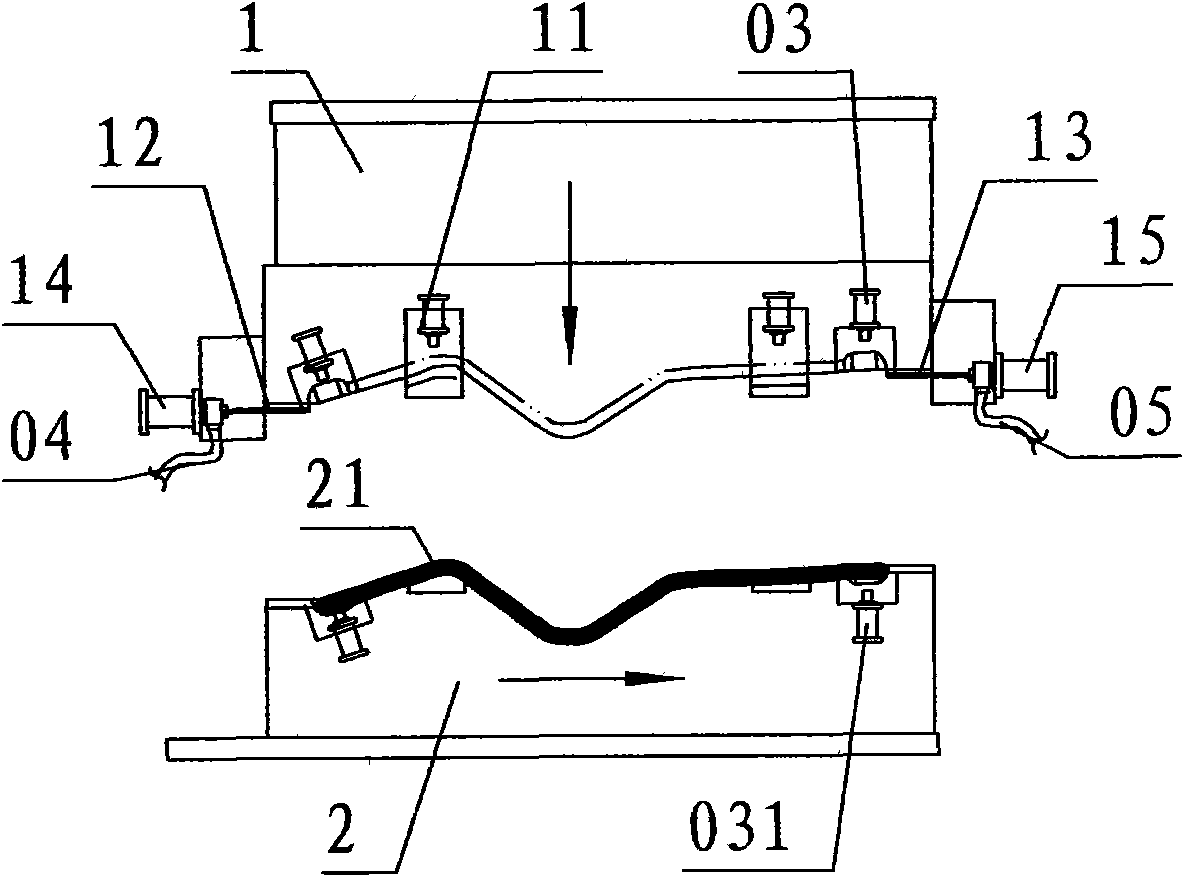

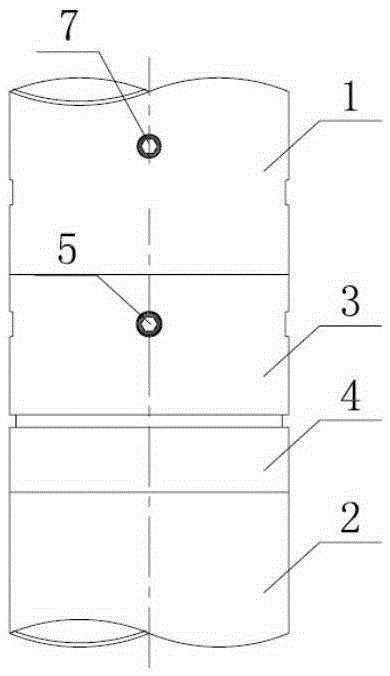

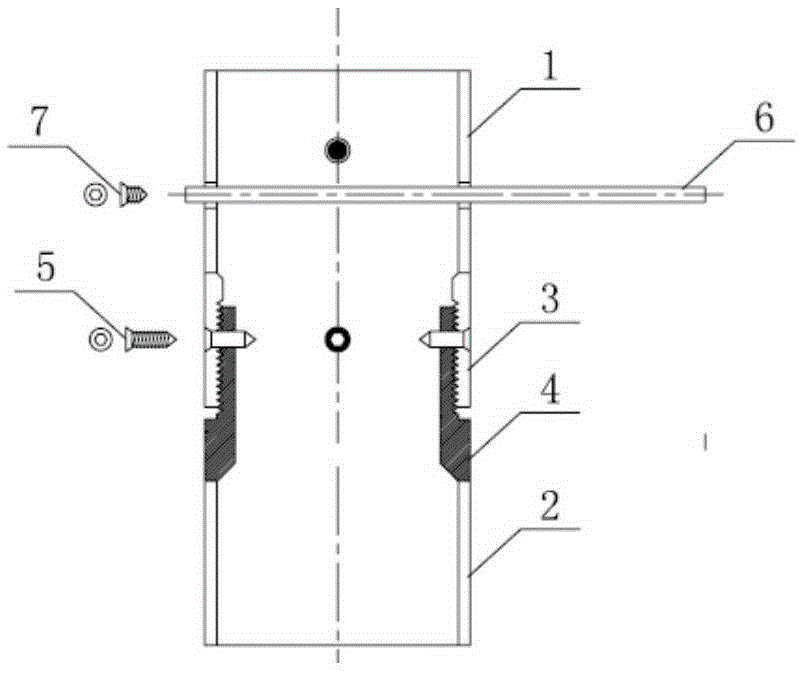

Horizontal type blow molding die for automobile oil tube and blow molding method thereof

ActiveCN102107523AOvercoming qualityOvercome the hidden dangers of leakage accidentsTubular articlesBlow moldingEngineering

The invention discloses a horizontal type blow molding die for an automobile oil tube and a blow molding method thereof. The horizontal type blow molding die comprises an upper die (1) and a lower die (2). In the technical scheme, the blow molding method comprises the following steps of: manufacturing the blow molding die to form two coincidental dies which are arranged horizontally and correspond up and down; when the blow molding die operates, lifting the upper die, moving the lower die out horizontally to load tubular blanks; restoring the lower die restores, pressing the upper die to close the die, blowing air to the tubular blanks for bubbling, and maintaining pressure and cooling, so that the blanks are formed to form a hollow oil tube product; and opening the die, clamping the product to lift upwards by the upper die, moving the lower die out horizontally, and allowing the upper die to release the product, so that the product drops to demold. In the horizontal type blow moldingdie for the automobile oil tube, due to the adoption of the horizontal die, the tubular blanks are put into a curved cavity of the lower die conveniently according to the shape of the oil tube product, and are formed without generating flashes; and thus, the defects of treating the flashes by a vertical die are overcome, and the blow molding of the automobile oil tube fulfills the aims of improving quality, saving raw materials, reducing cost, saving energy and reducing energy consumption.

Owner:NINGBO FANGZHENG TOOL

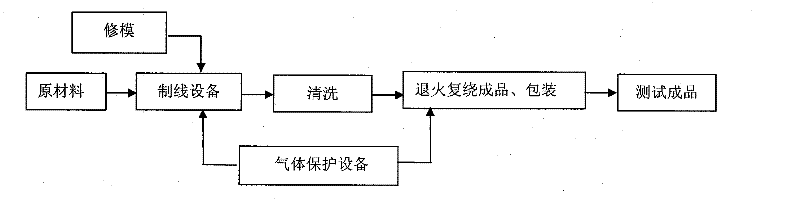

Single crystal copper bonding lead and preparation method thereof

InactiveCN102637657AHigh strengthHigh elongationSemiconductor/solid-state device detailsSolid-state devicesCopper wireDying processes

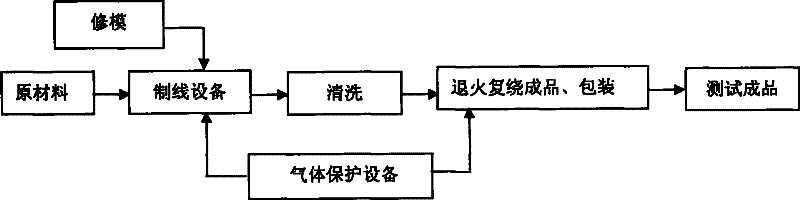

The invention discloses a single crystal copper bonding lead and a preparation method thereof, relating to the field of production of microelectronic materials. The production technology integrates a metal material preparation process, a heat treatment process and a diamond die process, ensures the production consistency and reliability and realizes the large-scale production. The adopted production process comprises the steps of providing die repair and gas protection equipment, smelting, wiredrawing, cleaning, and compounding, packaging and testing a finished product. The single crystal copper bonding lead has the beneficial effects that as a signal crystal copper material has a compact solidification structure, lateral crystal boundaries are eliminated, the casting defects of shrinkage cavities, pores and the like are avoided, the plastic working performance, the mechanical performance, the electric performance and the like of the signal crystal copper material are obviously higher than those of the conventional oxygen-free copper, the defects of more end breakage, low quality and low productivity in the wiredrawing process of the conventional copper wire are overcome, and an electronic packaging bonding wire with the wire diameter reaching 0.015m, high strength, high elongation and stable performance can be prepared.

Owner:宋东升

Unmanned aerial vehicle variable-quantity accurate pesticide applying system and method

PendingCN109720578AOvercome the disadvantages of being easily limited by the natural environmentOvercome carryingAircraft componentsInsect catchers and killersLaser rangingControl system

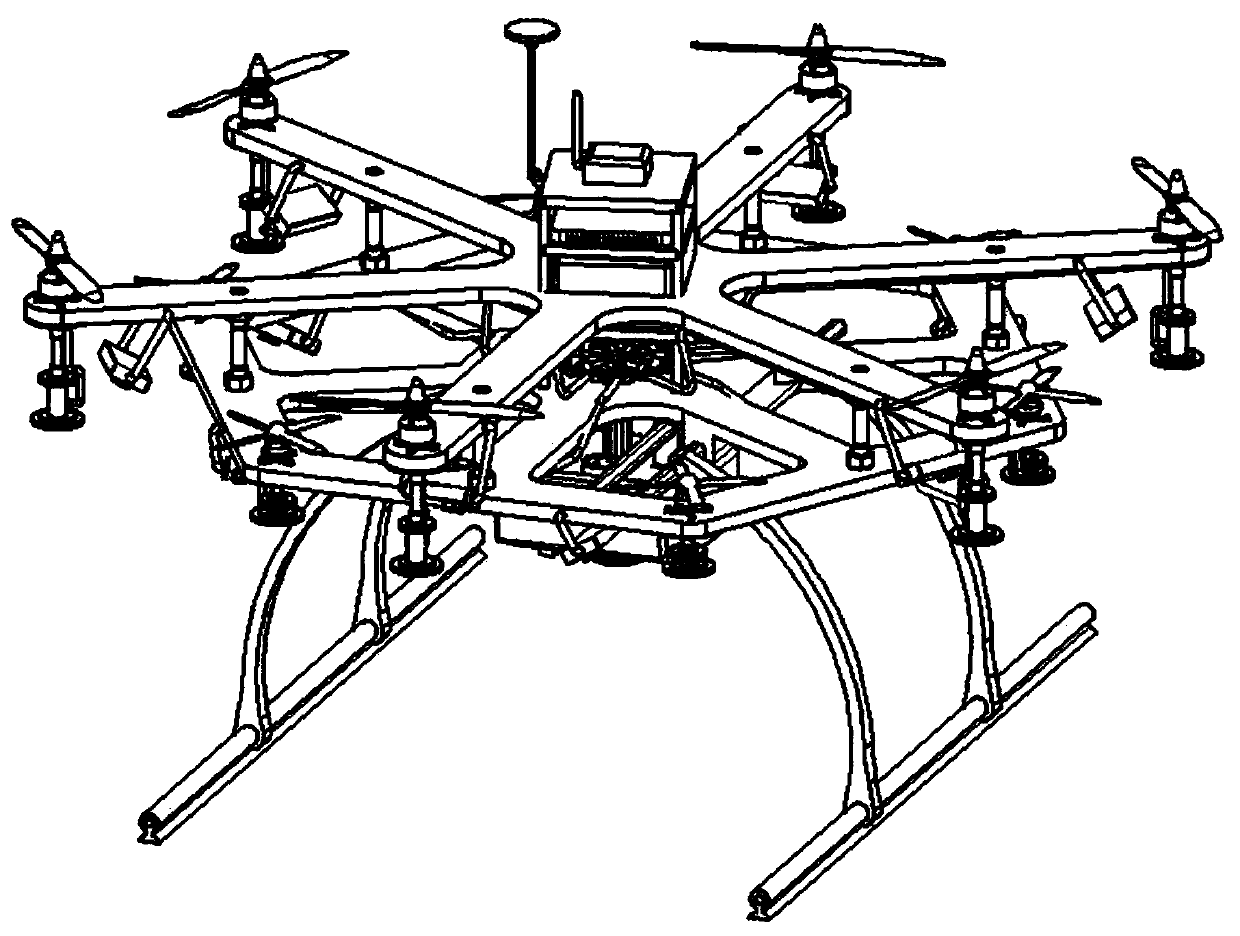

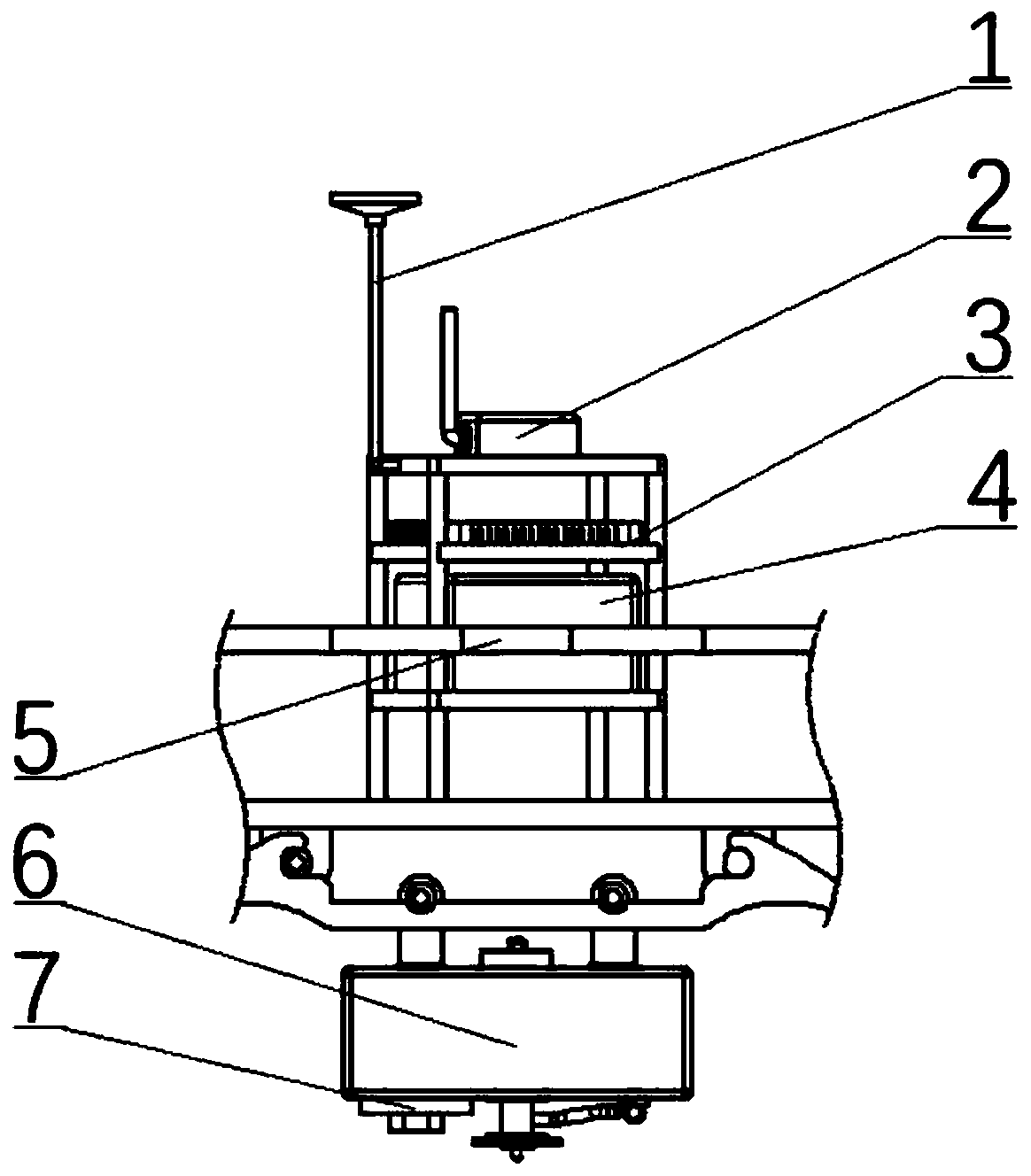

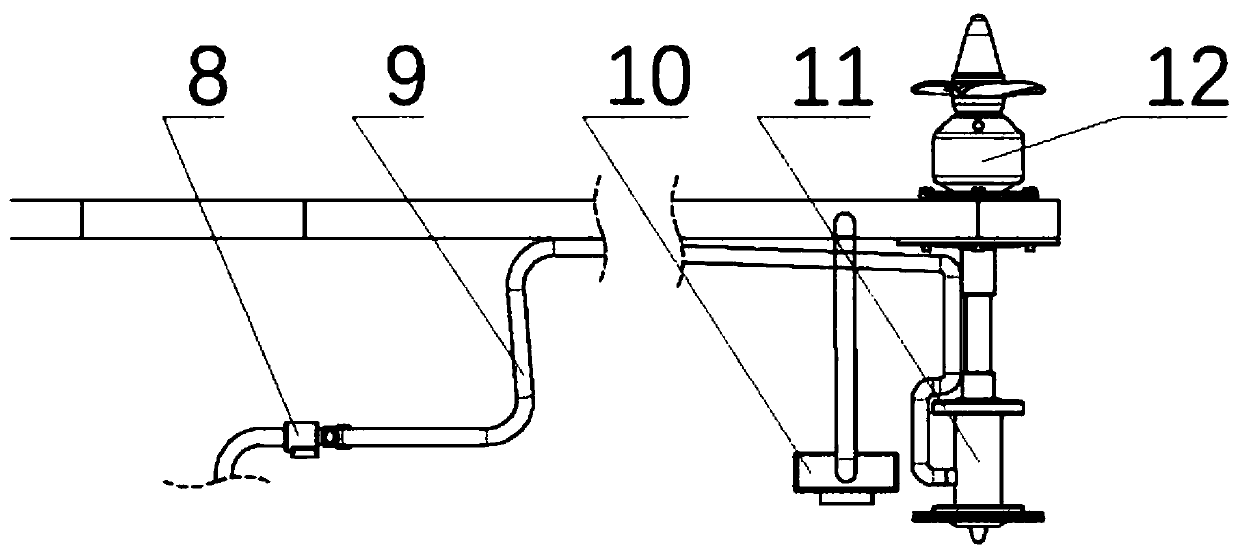

The invention discloses an unmanned aerial vehicle variable-quantity accurate pesticide applying system and method. The system comprises an unmanned aerial vehicle, a tree crown detection system, a pesticide liquid conveying system and a control system. The tree crown detection system is composed of an image acquisition device and a two-dimensional laser ranging scanning device. The pesticide liquid conveying system is composed of a pesticide box, water pumps, connecting pipes and nozzles. The control system is composed of a flight control module and a pesticide application control module. Thevariable-quantity accurate pesticide applying system is finished through the tree crown detection system, the pesticide liquid conveying system and the control system. By the adoption of the variable-quantity accurate pesticide applying method, the unmanned aerial vehicle can be controlled to hover over the center of a tree crown, the relative height of the unmanned aerial vehicle is adjusted, the flow of each water pump is controlled through the pesticide application control module, pesticide is sprayed at multiple points at the same time, so that the accuracy and comprehensiveness of pesticide application are guaranteed, and the state of an illness of a tree is effectively controlled.

Owner:NANJING FORESTRY UNIV

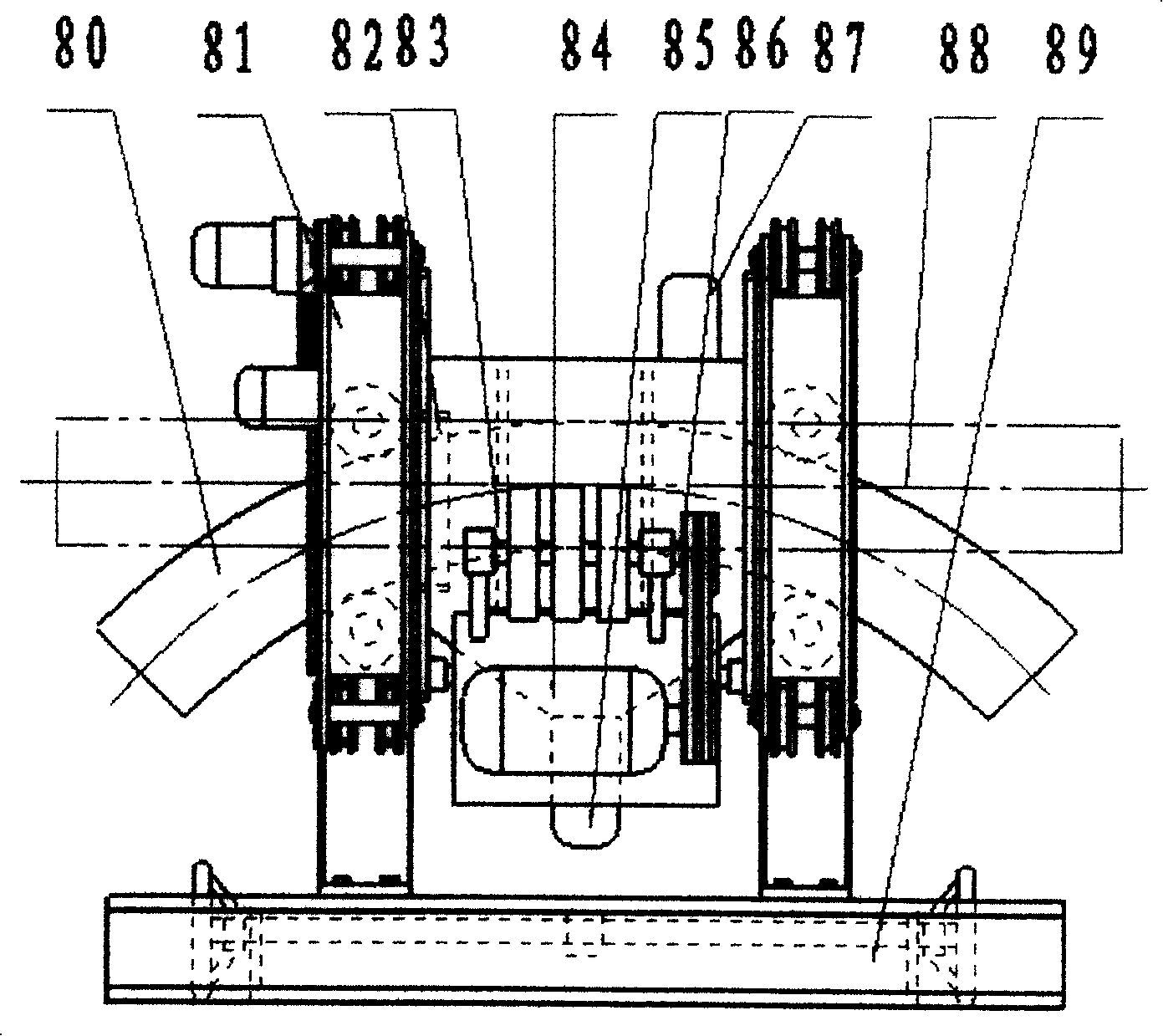

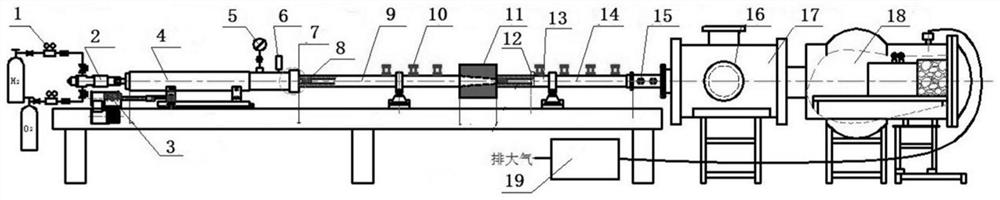

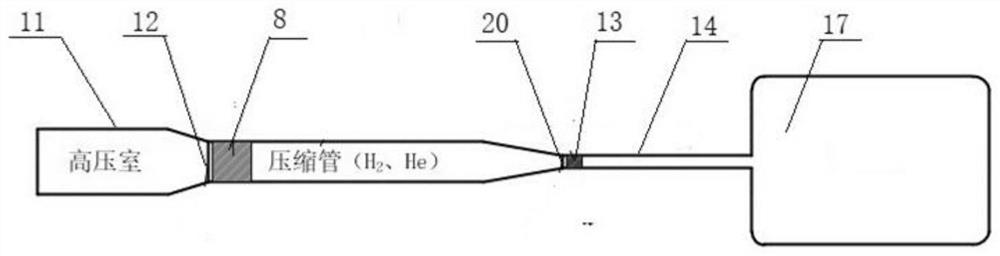

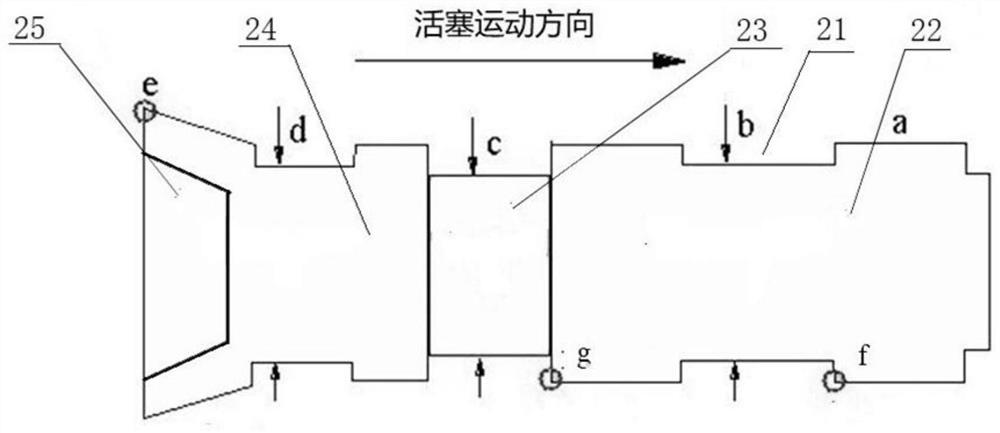

Gas detonation driven ultra-high-speed launching system

ActiveCN112902771AOvercoming qualityOvercoming the low speed of soundAmmunition testingAerodynamic testingUltra high speedDetonation

The invention belongs to the technical field of ultra-high-speed launching test experimental equipment, and discloses a gas detonation driven ultra-high-speed launching system in order to overcome the defects that gunpowder is large in molecular mass, the sound velocity is low, products are toxic, and transportation and storage are limited. A launching main body is sequentially connected with a detonation pipe, a compression pipe, a film clamping machine and a launching pipe; the launching main body is installed on a guide rail, and the guide rail is fixedly installed on a supporting frame; and the front end of the launching main body is connected with an oxyhydrogen inflation system through an ignition pipe, the rear end of the launching main body is connected with a test bin through a sealing device, the test bin is connected with a buffer box, and the buffer box is connected with a vacuum system. According to the gas detonation driven ultra-high-speed launching system, a detonation driven two-stage light gas gun technology adopting oxyhydrogen detonation as driving energy instead of the gunpowder is a low-cost and environment-friendly gas gun driving technology without needing initiating explosive devices, and higher efficiency and good launching repeatability are achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

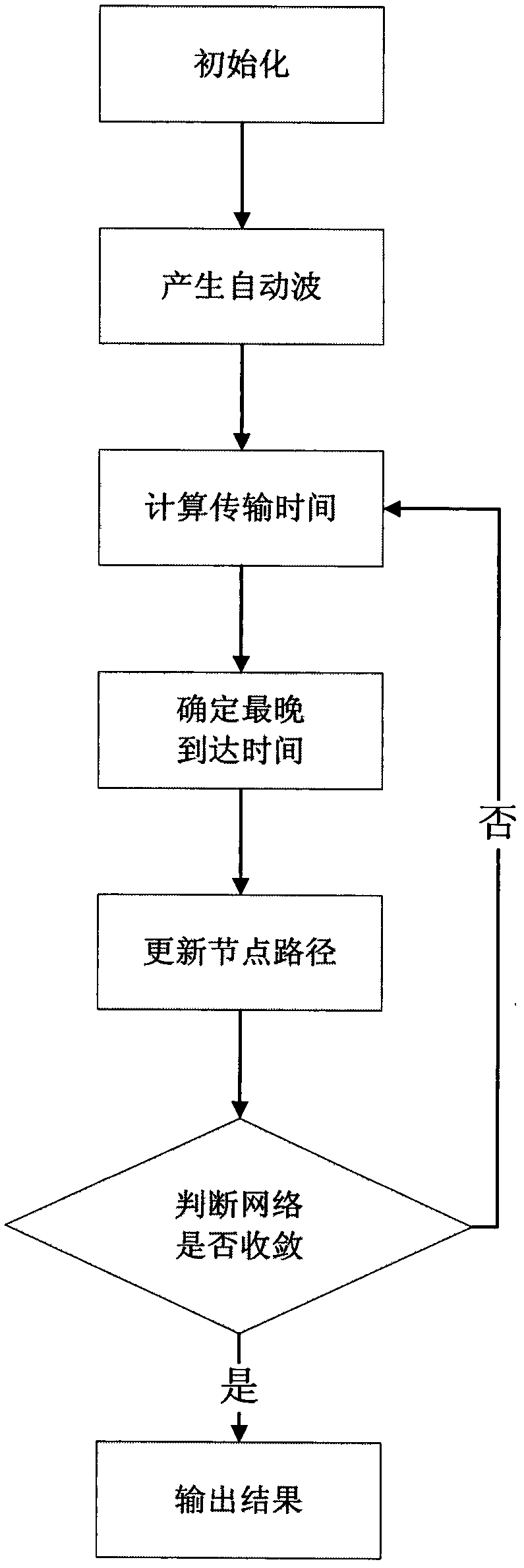

Method for figuring out shortest path of large scale graphs based on fewest resource neural networks

InactiveCN102360452AOvercoming the disadvantages of serial solvingReduce time complexityBiological neural network modelsNetwork ConvergenceArrival time

The invention discloses a method for figuring out shortest path of large scale graphs based on fewest resource neural networks. The invention is used for finding a shortest path tree of large scale data through fewest resources, and the found resolution is an optimal resolution, so that the optimal resolution can be applied on network route, transport dispatch and urban traffic planning. The method provided by the invention comprises the steps of: initializing a large scale graph network; generating an automatic wave at a network source node; calculating transmission time of the node; determining the latest arrival time of the node; figuring out the competition win node, and adding the competition win node in the shortest path of the node; adding an iteration time, repeatedly calculating the transmission times and latest arrival times of the corresponding nodes, and updating the shortest path until the network convergence; and outputting the found shortest path and the corresponding transmission time.

Owner:XIDIAN UNIV

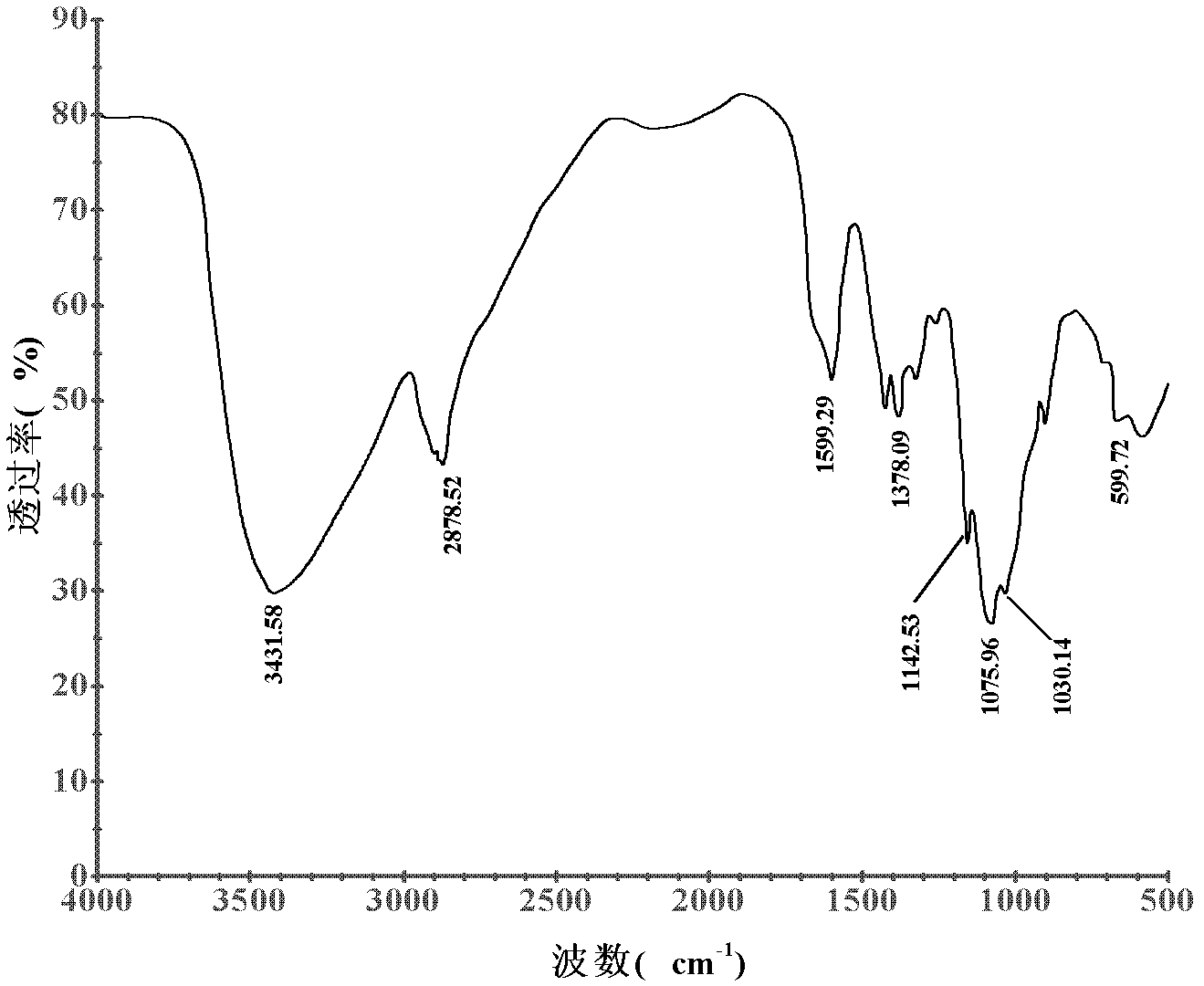

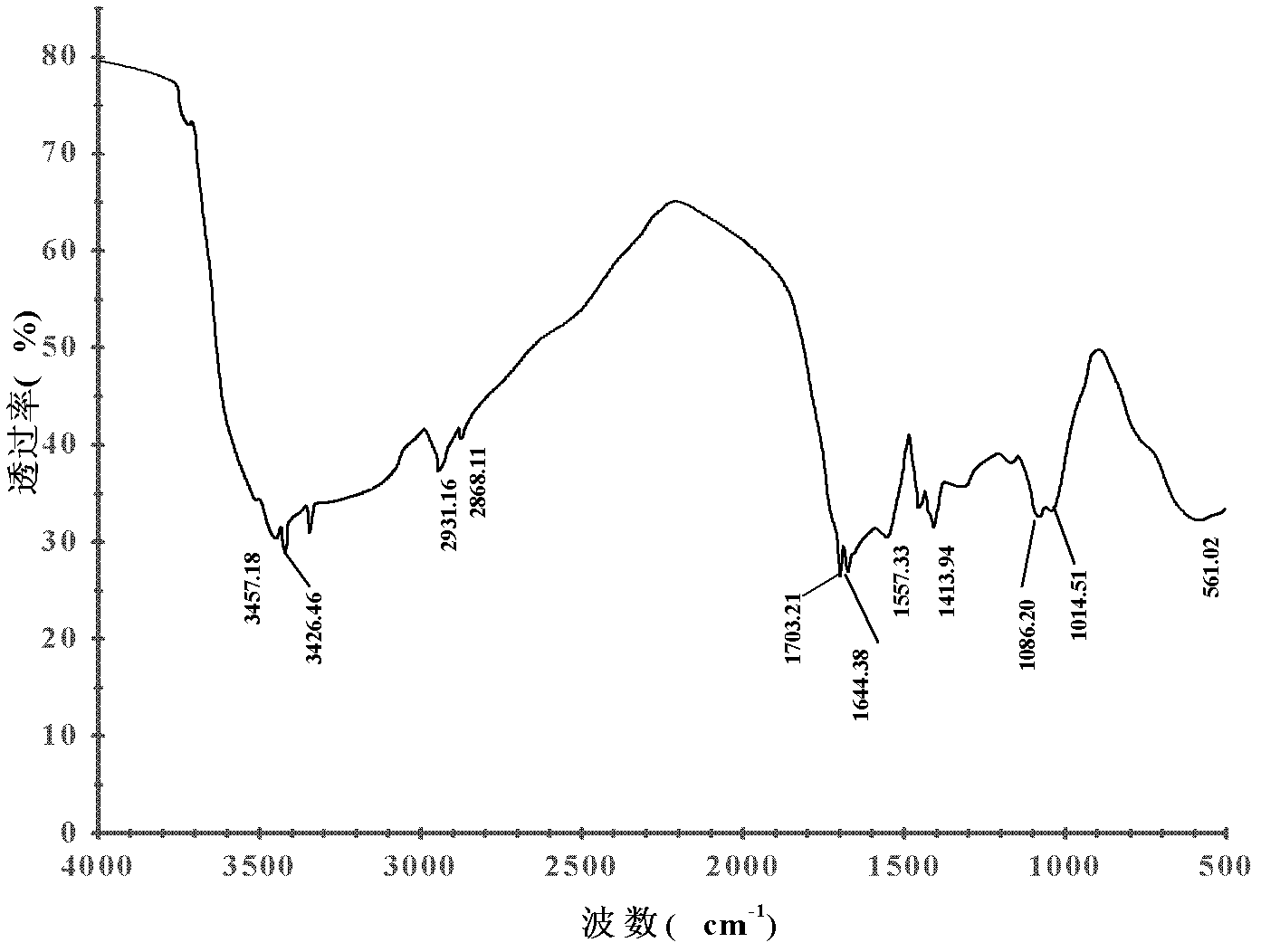

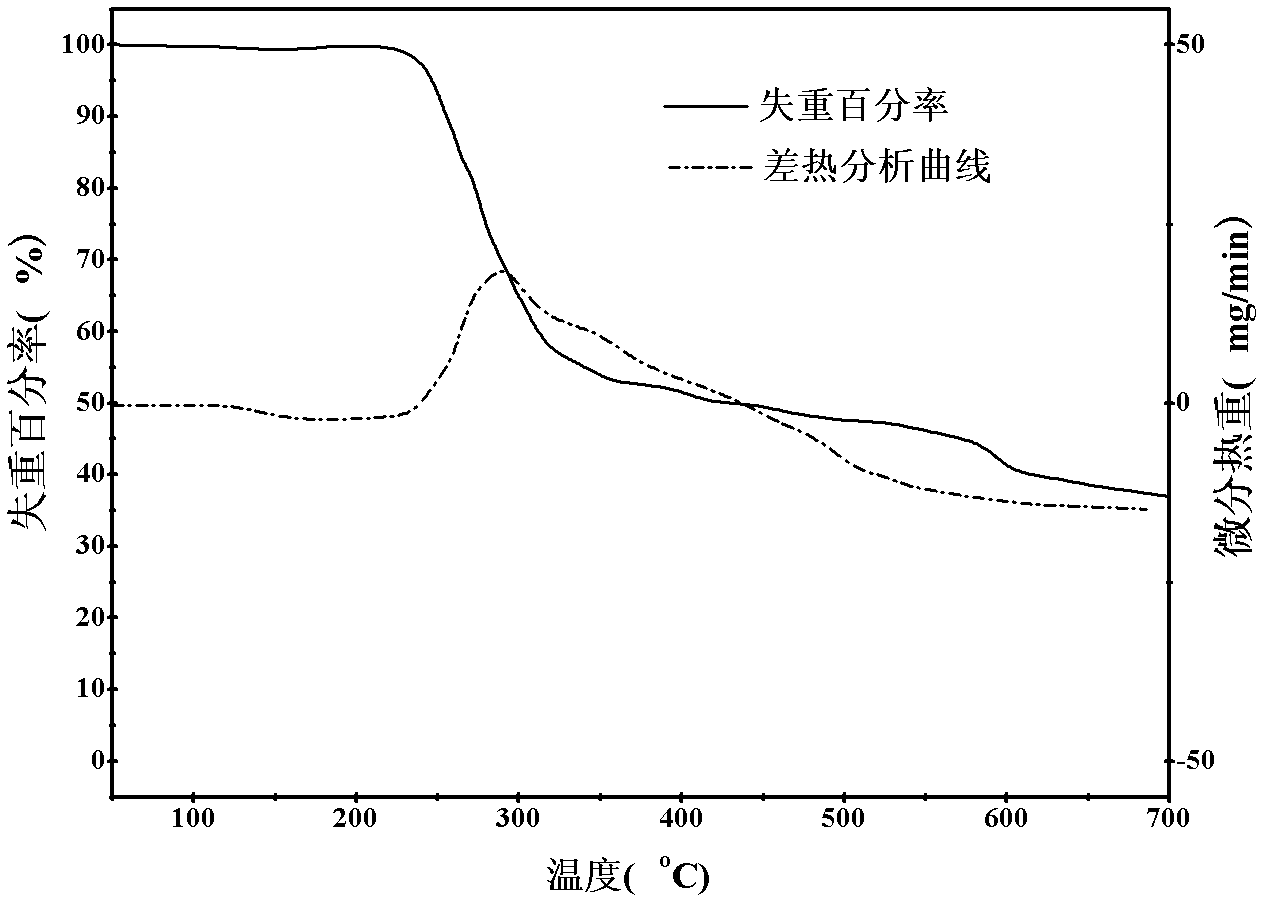

Chitosan derivative and preparation method thereof

InactiveCN102617798AOvercoming qualityOvercoming Poor Bridging AbilityWater/sewage treatment by flocculation/precipitationAcetic acidWastewater

The invention discloses a chitosan derivative which is prepared by taking dipotassium sulphate-sodium bisulfite as initiating agent to carry out graft copolymerization to chitosan, acrylamide and acrylic acid, and the materialization indexes of the chitosan derivative are as follows: pale yellow powdered solid is dissolved into acetic acid, and the molecular weight is 50 to 70 KD; and the removal ratios of the chitosan derivative to complexing state Cu2+, Pb2+ and Zn2+ with the concentration of 10mg / L reach 91.9 percent, 98.2 percent and 99.0 percent respectively. The chitosan derivative provided by the invention overcomes the defects of small chitosan molecular mass, poor bridge erecting bridge erecting and high using cost, has better removing capability than chitosan to the three complexing state ions, and can be used as flocculating agent for removing CU2+, Pb2+ and Zn2+ in waste water.

Owner:OCEAN UNIV OF CHINA

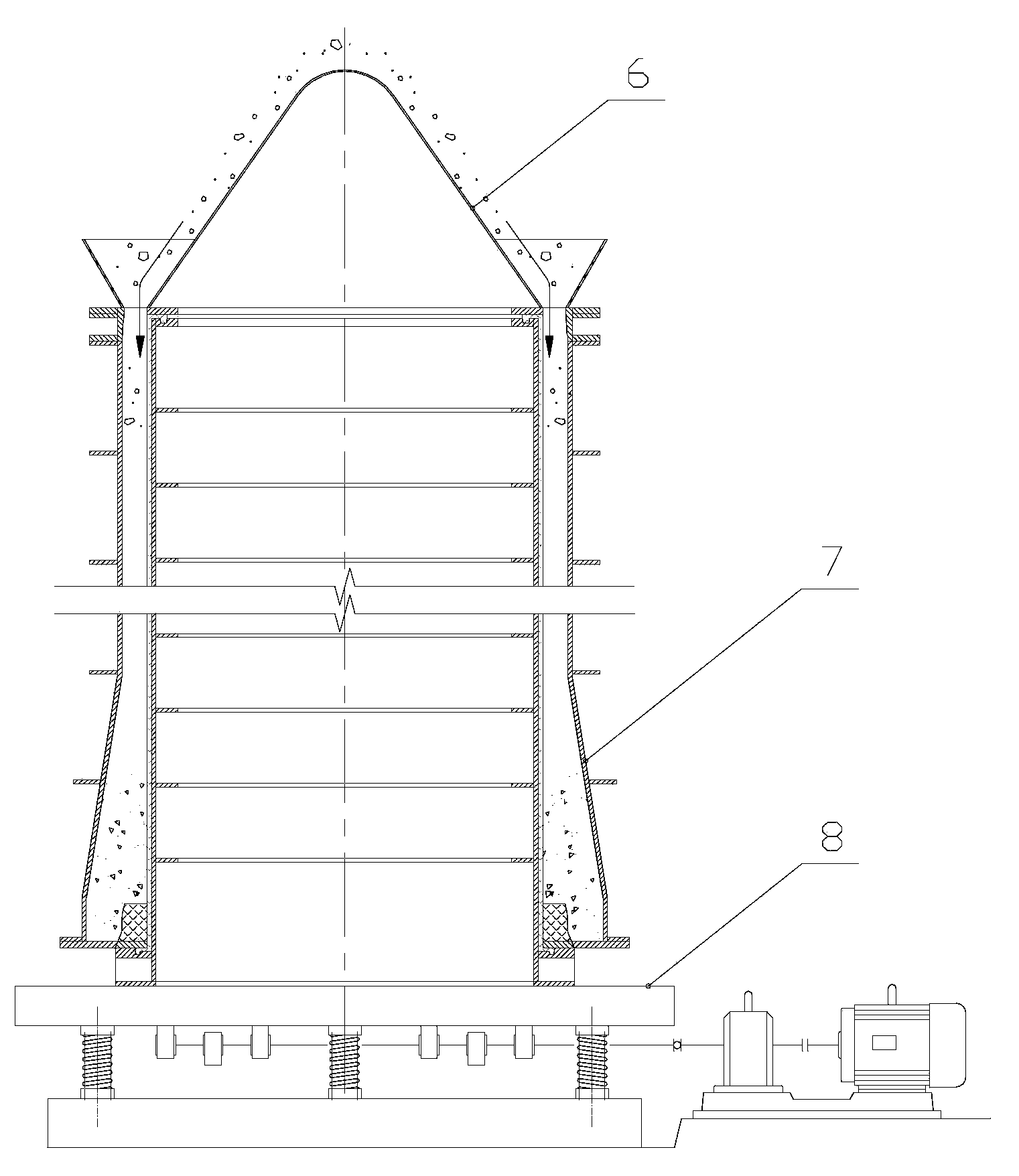

Process for forming vibration and extrusion process prestressed concrete pipe through core mold vibration method

InactiveCN103895098AUniform qualityOvercome a series of defects caused by vibration-forming plastic concrete mixturesCeramic shaping apparatusPre stressUltimate tensile strength

The invention provides a process for forming a vibration and extrusion process prestressed concrete pipe through a core mold vibrator. An inner mode and an outer mold which are completely installed are hoisted to be arranged on the core mold vibrator in a sleeved mode together so that a model and the core mold vibrator can be tightly attached to each other through locking devices. A feed hopper is arranged above the model, the core mold vibrator is started and conducts feeding while vibrating till the model is filled with concrete mixtures, and then other procedures are completed. According to the process, the vibration and extrusion process prestressed concrete pipe is formed by the core mold vibrator which is high in vibration intensity and good in vibration effect, quality of the prestressed concrete pipe can be improved, production cost can be reduced, the environment can be protected, and the waste residue discharge can be reduced.

Owner:TIANJIN ZEBAO CEMENT PROD

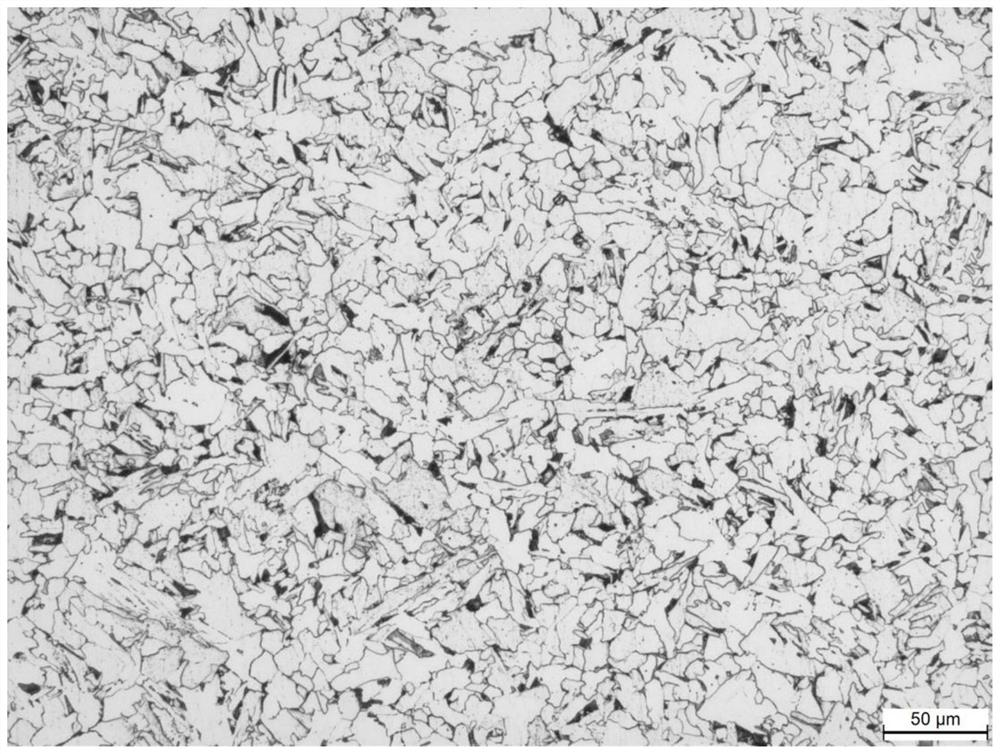

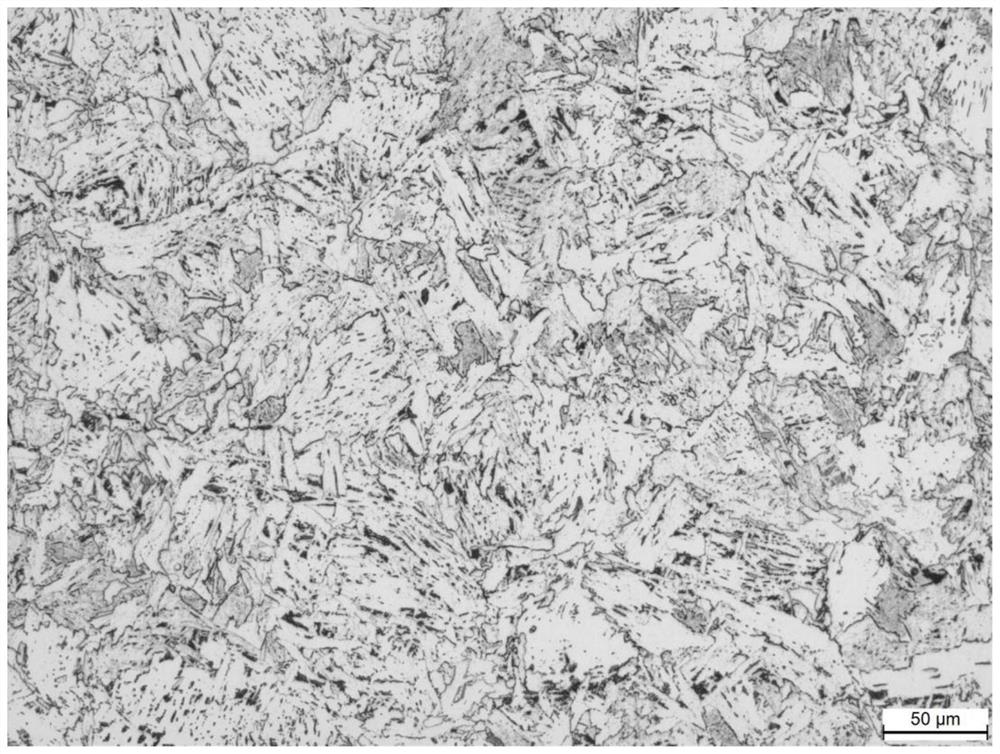

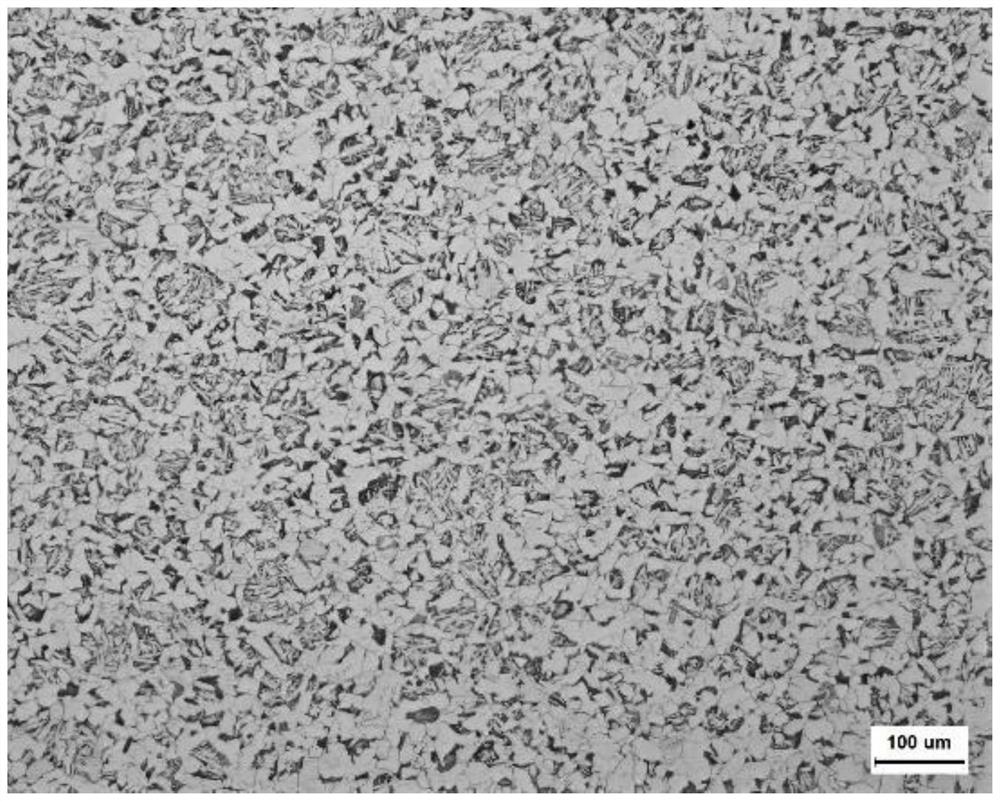

Hot-rolled seamless steel tube and deformation and phase transformation integrated type structure regulation and control method thereof

ActiveCN113025904AImprove performanceInhibition of abnormal phase transition tissueTemperature control deviceFurnace typesChemical compositionToughness

The invention discloses a hot-rolled seamless steel tube and a deformation and phase transformation integrated type structure regulation and control method thereof, and belongs to the field of hot-rolled seamless steel tube production. The hot-rolled seamless steel tube comprises the following elements: 0.04% to 0.4% of C, 0.1% to 0.8 % of Si, 0.3% to 2.5% of Mn, 0.001% to 0.03% of P, 0.001% to 0.03% of S, 0.001% to 0.05% of Al, 0.003% to 0.03% of Ti, 0.001% to 0.01% of Mg+Ca +Zr +B, 0.001% to 0.008% of O, 0.003% to 0.012% of N and the balance Fe and inevitable impurity elements. According to the regulation and control method, chemical components and inclusion distribution of the steel tube are optimally designed, smelting, rolling and cooling processes are reasonably controlled, special inclusion particles are utilized to play a role in structure refinement, so that coarse unfavorable structures such as grain boundary ferrite, a widmannstatten structure and side bar ferrite are eliminated, a fine grain structure is obtained, and the strength and toughness of the tube are improved.

Owner:NORTHEASTERN UNIV

Culture method of peony embryonic callus as well as culture medium

InactiveCN103355165AReduce the impactHarm reductionHorticulture methodsPlant tissue cultureGrowth plantMicrobiology

The invention discloses a culture method of peony embryonic callus as well as a culture medium. The peony embryonic callus is induced through adopting an MS culture medium which contains special components after modification (such as substances of 6-BA, KT cytokinin, TDZ plant growth regulators, PIC herbicide as well as casein hydrolysate); aiming at a peony embryo explant, the induction rate of the peony callus can achieve 100% by adopting the specific culture method provided by the invention, wherein the induction rate of embryonic callus can achieve 86% above.

Owner:SHANGHAI BOTANICAL GARDEN +2

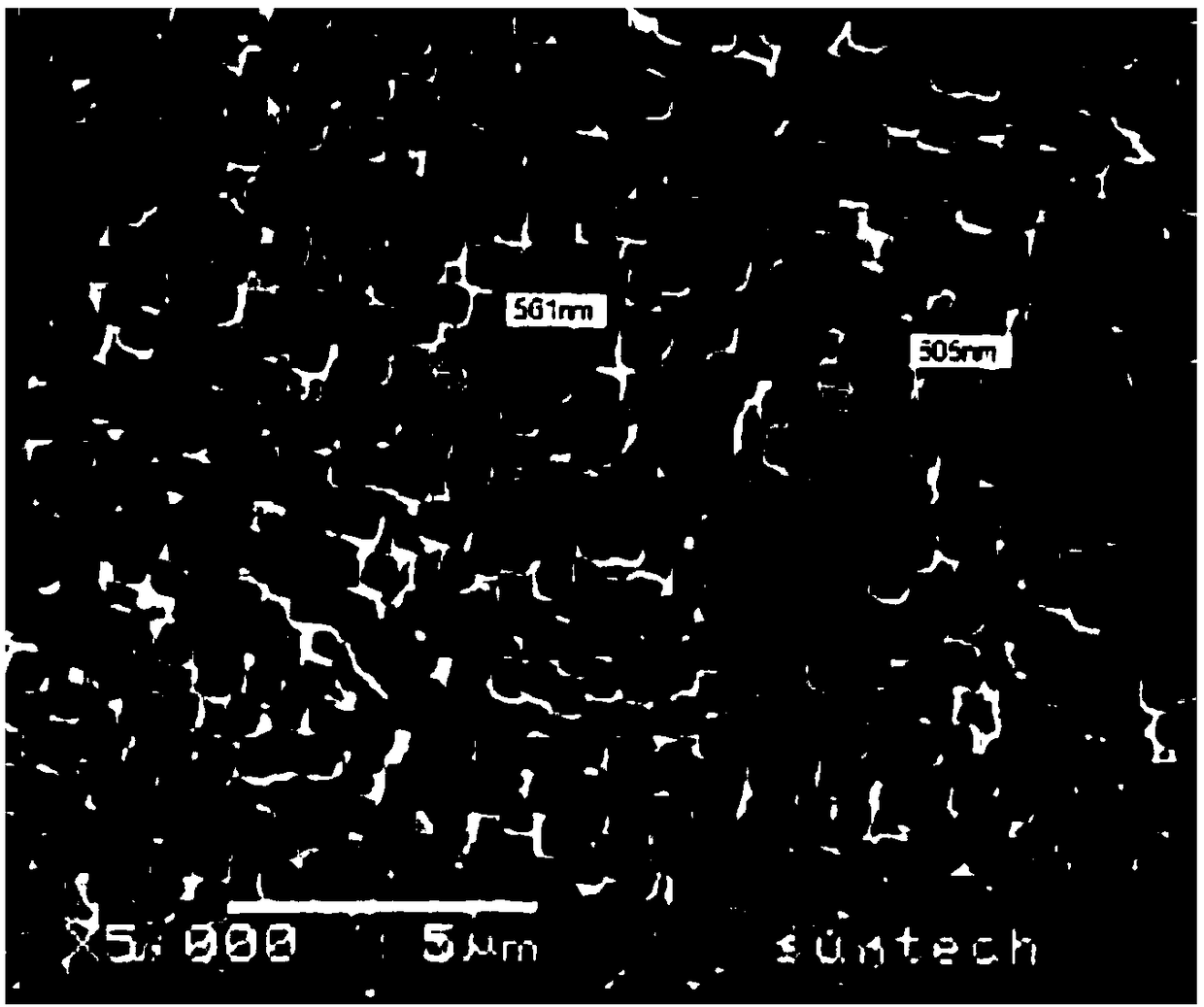

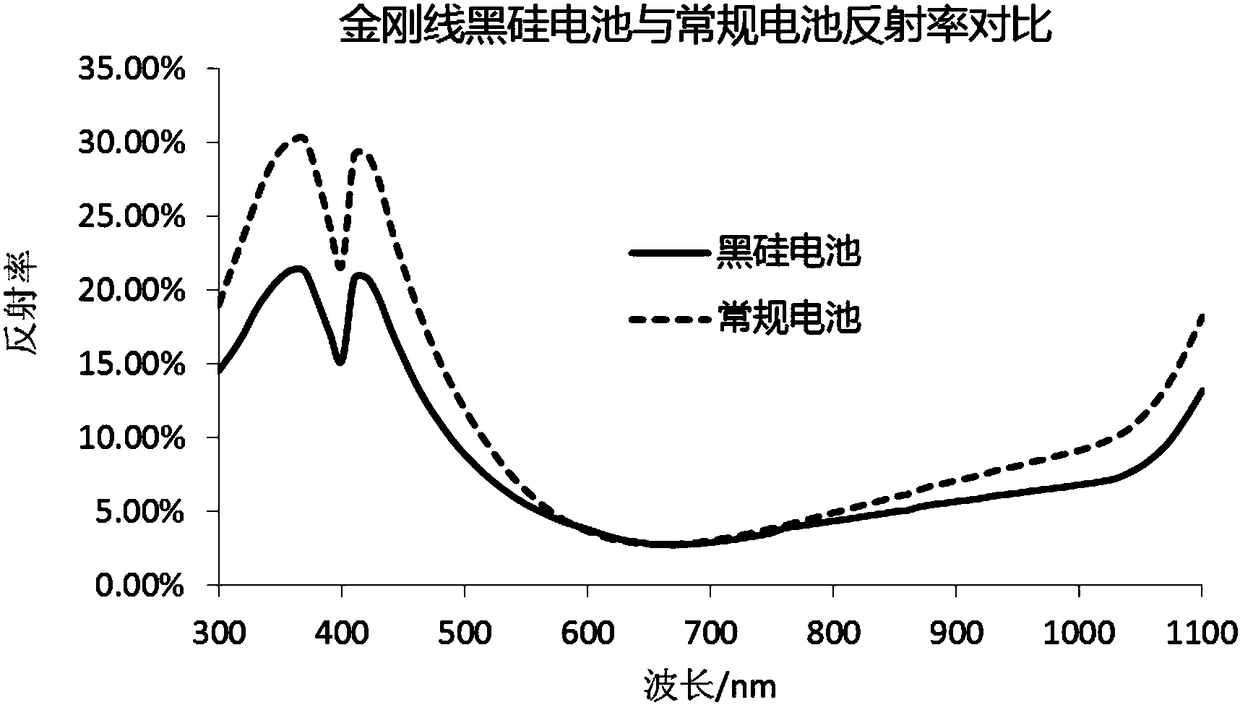

Preparation method for black-silicon poly-silicon PERC cell structure with selective emitter

InactiveCN108365022ASolve the problem of high surface reflectivityImprove conversion efficiencyAfter-treatment detailsFinal product manufactureScreen printingSilver electrode

The invention relates to a preparation method for a black-silicon poly-silicon PERC cell structure with a selective emitter. The preparation method is characterized by comprising the following steps of (1) forming a nanometer texturing surface on a front surface of a silicon wafer, wherein a back surface is a polishing surface; (2) performing front-surface diffusion of the silicon wafer to form anN-type layer, and removing front-surface phosphorosilicate glass and a back-surface pn junction; (3) depositing a silicon nitride anti-reflection film layer on the front surface of the silicon wafer,and depositing a passivation dielectric layer on the back surface; (4) dotting or routing the back surface of the silicon wafer, and printing a silver electrode and aluminum paste; (5) performing low-temperature sintering to form a local aluminum back field; (6) spraying a mixed solution of phosphoric acid and alcohol on the front surface of the silicon wafer, and forming a main grid line regionand a secondary grid line region after heavy doping by laser; and (7) immersing the front surface of the silicon wafer in an electroplating solution, electroplating the front surface of the silicon wafer under an illumination condition, and annealing after electroplating. By the preparation method, the defects that a high-quality fine grid line is difficult to form by silk-screen printing and thegrid line and a selective emitter cannot be enabled to be accurately aligned are overcome, and shielding and leakage current caused by an electrode are minimum.

Owner:WUXI SUNTECH POWER CO LTD

Special mortar for dry method construction of self-insulation aerated concrete and preparation method thereof

ActiveCN103739241AImprove thermal insulation performanceLight weightSolid waste managementPolyethylene vinyl acetateSlag

The invention relates to special mortar for dry method construction of self-insulation aerated concrete and a preparation method thereof, and belongs to a construction material technology field, wherein the mortar is characterized in that the mortar is composed of fly ash, phosphorus slag, cement clinker, phosphogypsum, carbide slag, graphite tailing sand, shale pottery sand, alkali lignin, polyethylene-vinyl acetate and hydroxypropyl methyl cellulose, and is prepared by the following steps of: (1) preparing an ecological composite gel material, which is prepared by mixing the following raw materials by weight: 35-45% of fly ash, 25-50% of phosphorus slag, 8-10% of cement clinker, 3-8% of phosphogypsum, and 2-6% of carbide slag; (2) preparing an additive by mixing and stirring the following raw materials by weight: 35-50% of alkali lignin, 15-30% of polyethylene- vinyl acetate, and 20-40% of hydroxypropyl methyl cellulose; and (3) preparing the plastering mortar by stirring according to a mass ratio of the ecological composite gel material, the graphite tailing sand, the shale pottery sand to the additive being 1:0.7:0.3:0.004.

Owner:湖北远固新型建材科技股份有限公司

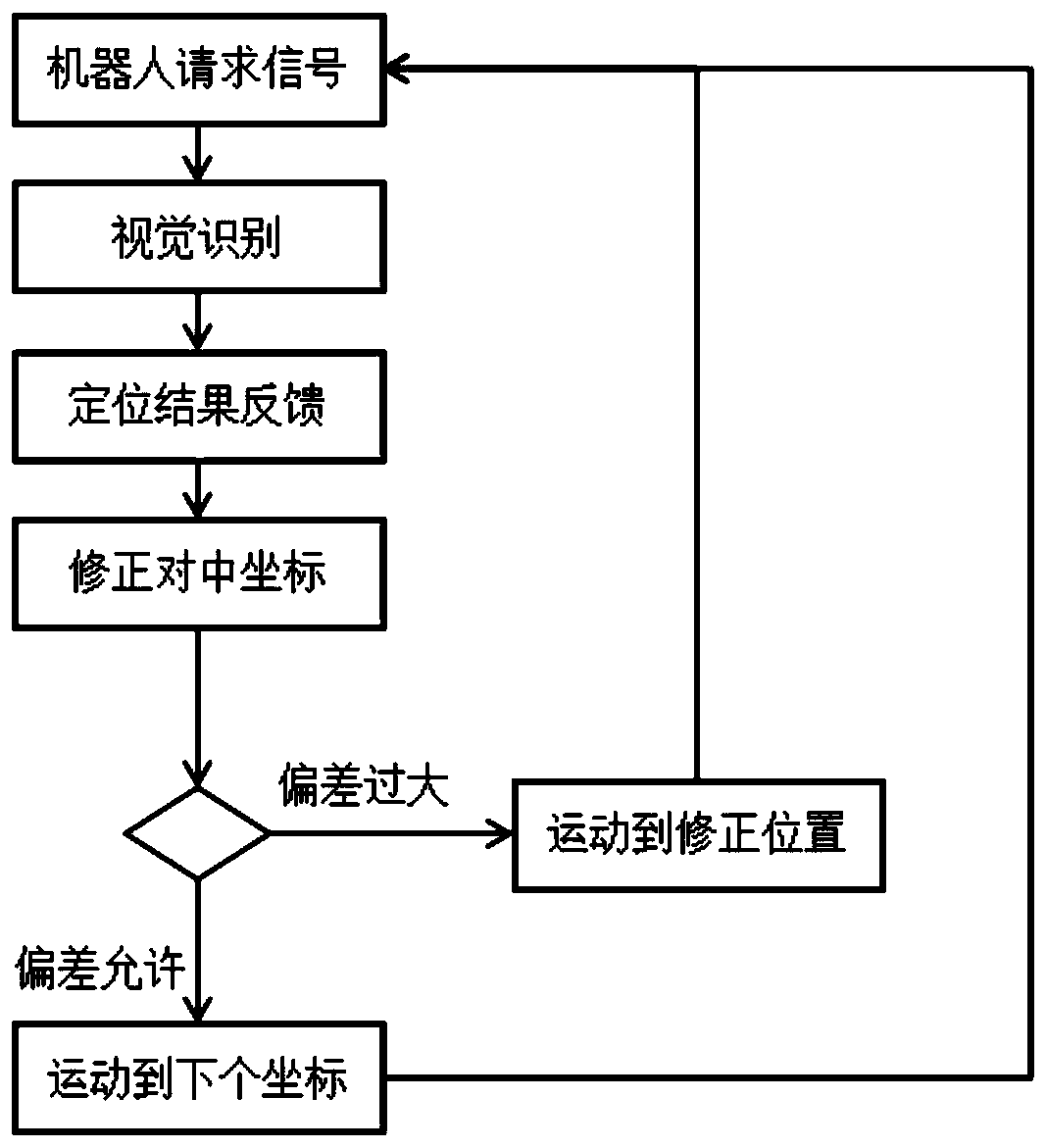

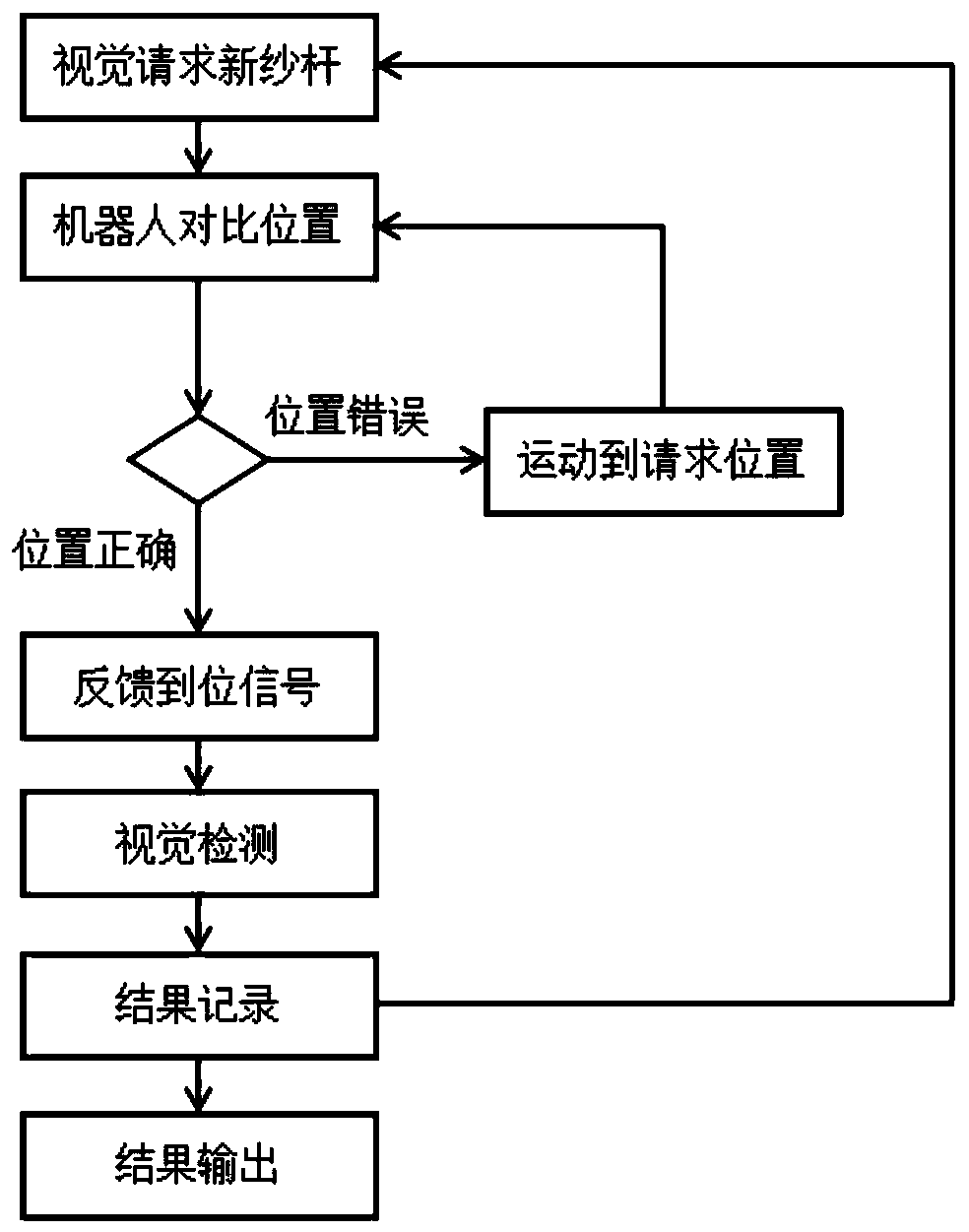

Cheese yarn rod positioning visual detection method

ActiveCN110501342AOvercome efficiencyOvercoming fatigueOptically investigating flaws/contaminationUsing optical meansYarnVisual positioning

The invention relates to a cheese yarn rod positioning visual detection method. The method comprises the steps of arranging a vision system and a robot vision detection system, wherein the vision system includes a vision camera and a light source for illumination; using the vision camera to carry out image acquisition on a yarn rod and transmitting to a robot, and using the robot to process an image; carrying out visual positioning calibration on each yarn rod, and calibrating and recording a centering reference coordinate of each yarn rod of the vision camera; sending a detection request to detect a new yarn rod, and writing a currently requested yarn rod number; determining whether the yarn rod numbers at a current position are the same in real time, sending a request continuing instruction when the positions are different, moving to the position above the yarn rod requested by the vision system when the positions are the same, and returning the current yarn rod number so as to showan in place state; and when the vision system reads that the current yarn rod number is equal to a request number, carrying out detection, recording a detection coordinate result, and completing yarnrod positioning vision detection. In the invention, on-line detection of a yarn rod head is realized, and detection efficiency and detection stability are increased.

Owner:BEIJING INFORMATION SCI & TECH UNIV

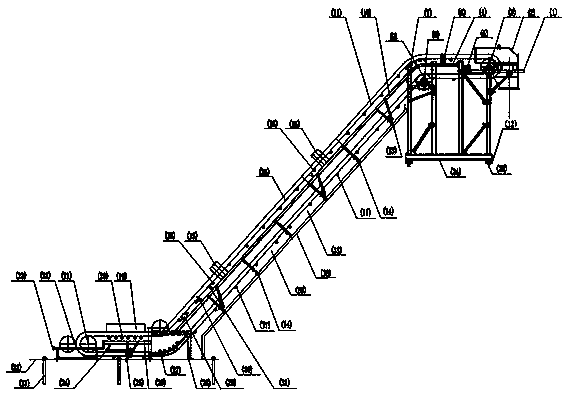

Integrated rail-traveling wave-shaped blocking edge and transverse partition plate belt conveyor

PendingCN109051538AOvercoming qualityOvercome disadvantagesConveyorsPackagingWave shapeAgricultural engineering

The invention discloses an integrated rail-traveling wave-shaped blocking edge and transverse partition plate belt conveyor. The integrated rail-traveling wave-shaped blocking edge and transverse partition plate belt conveyor is composed of a moving rail-traveling head rack, an overall integrated tail rack and a middle rack body. An integrated and modularized mode and an wave-shaped blocking edgeand transverse partition plate conveyor belt are adopted, therefore, disassembling and assembling are convenient, moving is quick, stability and fastness are achieved, large-inclination-angle conveying is achieved, the length and the angle of the rack body are convenient to adjust, and then the subway construction vertical soil digging condition is met. According to the integrated rail-traveling wave-shaped blocking edge and transverse partition plate belt conveyor, disassembling and assembling are convenient, quick moving can be achieved, efficient soil digging can be achieved in an open cutmethod of a subway station, and the integrated rail-traveling wave-shaped blocking edge and transverse partition plate belt conveyor has the great advantages in the aspects of surrounding traffic relief and building and foundation pit deformation control.

Owner:THE 4TH ENG OF CHINA RAILWAY 12TH BUREAU GROUP +1

Circular steel tube column in threaded connection and construction method

InactiveCN105275095AOvercoming qualityOvercoming disadvantages such as climate impactStrutsBuilding material handlingScrew threadWeather and climate

The invention relates to a circular steel tube column in threaded connection and a construction method. The circular steel tube column in threaded connection comprises a plurality of circular steel tube column units, the circular steel tube column units are in threaded connection at splicing segments, and the circular steel tube column units are linked to the splicing segments by use of welding. A circular steel tube column unit at an upper segment is provided with crowbar holes enabling crowbars to pass through; and when two circular steel tube column units adjacent to each other at an upper position and a lower position are hoisted in place, and the upper-segment circular steel tube column unit is screwed tight through applying forces to the crowbars inserted into the crowbar holes so as to finish threaded connection between the circular steel tube column units. The threaded connection pitch point provided by the invention overcomes the disadvantages of low efficiency of onsite welding pitch points, low quality, influences exerted by weather and climate and the like. The requirements for technical level of installation workers are reduced, and the circular steel tube columns can be spliced through simple operation.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com