Digital imaging acquisition system for aggregate grading detection and acquisition method thereof

An acquisition system and acquisition method technology, applied in the direction of measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., to achieve the effects of overcoming poor image quality, eliminating repair costs and specimen transportation costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

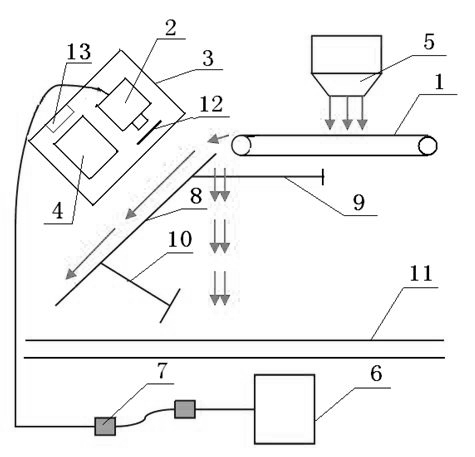

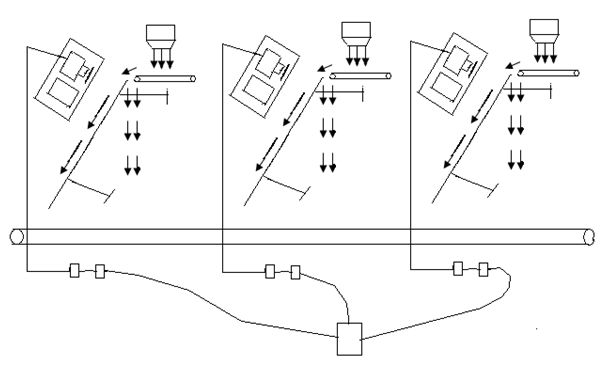

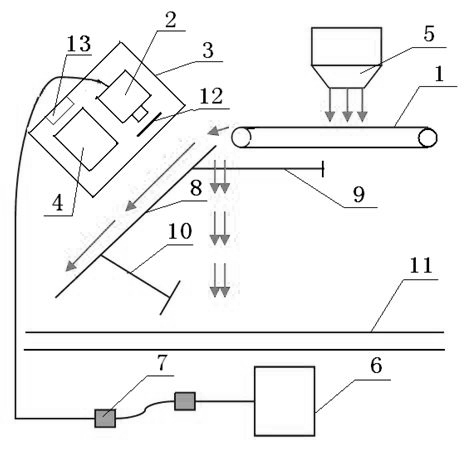

[0037] Such as figure 1 As shown, the digital imaging acquisition system for aggregate gradation detection of the present invention consists of the following modules:

[0038]The collection sampling device includes a material distribution plate 8, a distance adjustment rod 9 and an angle adjustment rod 10. The material distribution plate 8 is installed obliquely at the end of the primary conveyor belt 1 and is not in contact with the end of the primary conveyor belt 1; The material distribution plate 8 slides down to the conveyor belt 11 of the mixing floor, and the other part falls to the conveyor belt 11 of the mixing floor through the gap between the material distribution plate 8 and the primary conveyor belt 1; the distance adjusting rod 9 is installed on the upper end of the material distribution plate 8 and The first conveyor belt 1 is parallel, and the distance adjusting rod 9 is telescopic to drive the material distribution plate 8 to move left and right to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com