Horizontal type blow molding die for automobile oil tube and blow molding method thereof

A technology of blow molding and tubing, which is applied to household appliances, tubular objects, and other household appliances. It can solve the problems of increased product cost, waste of raw materials, and increased energy consumption, and achieve the goals of saving raw materials, reducing costs, and improving quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

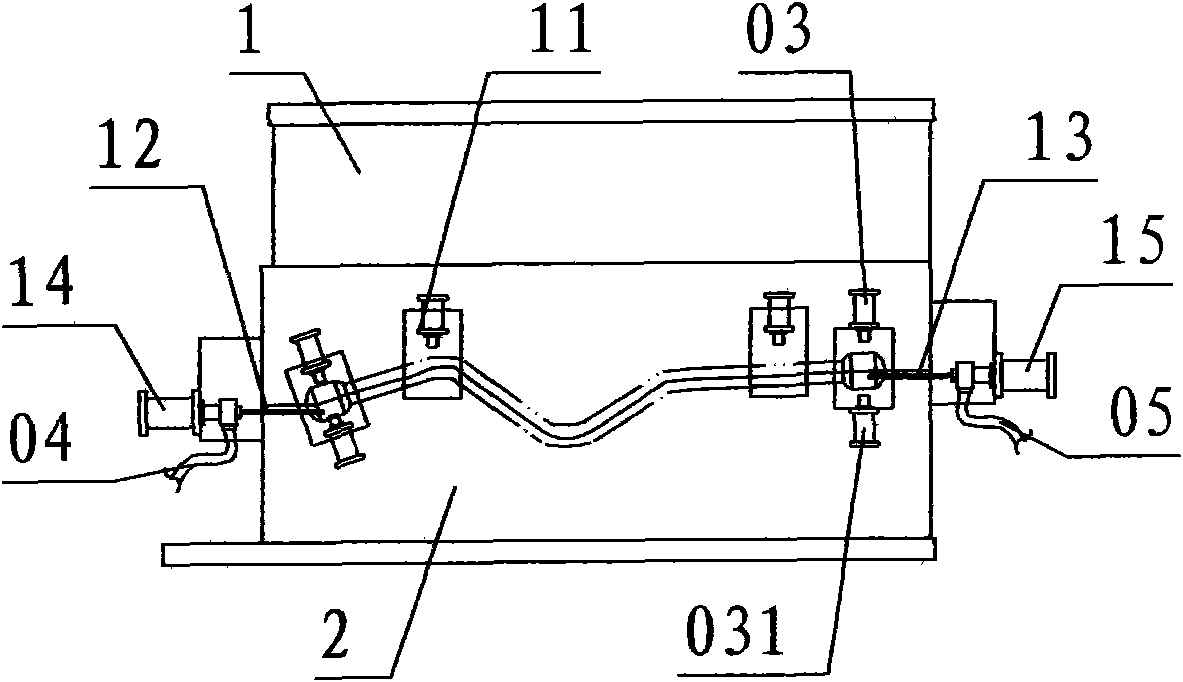

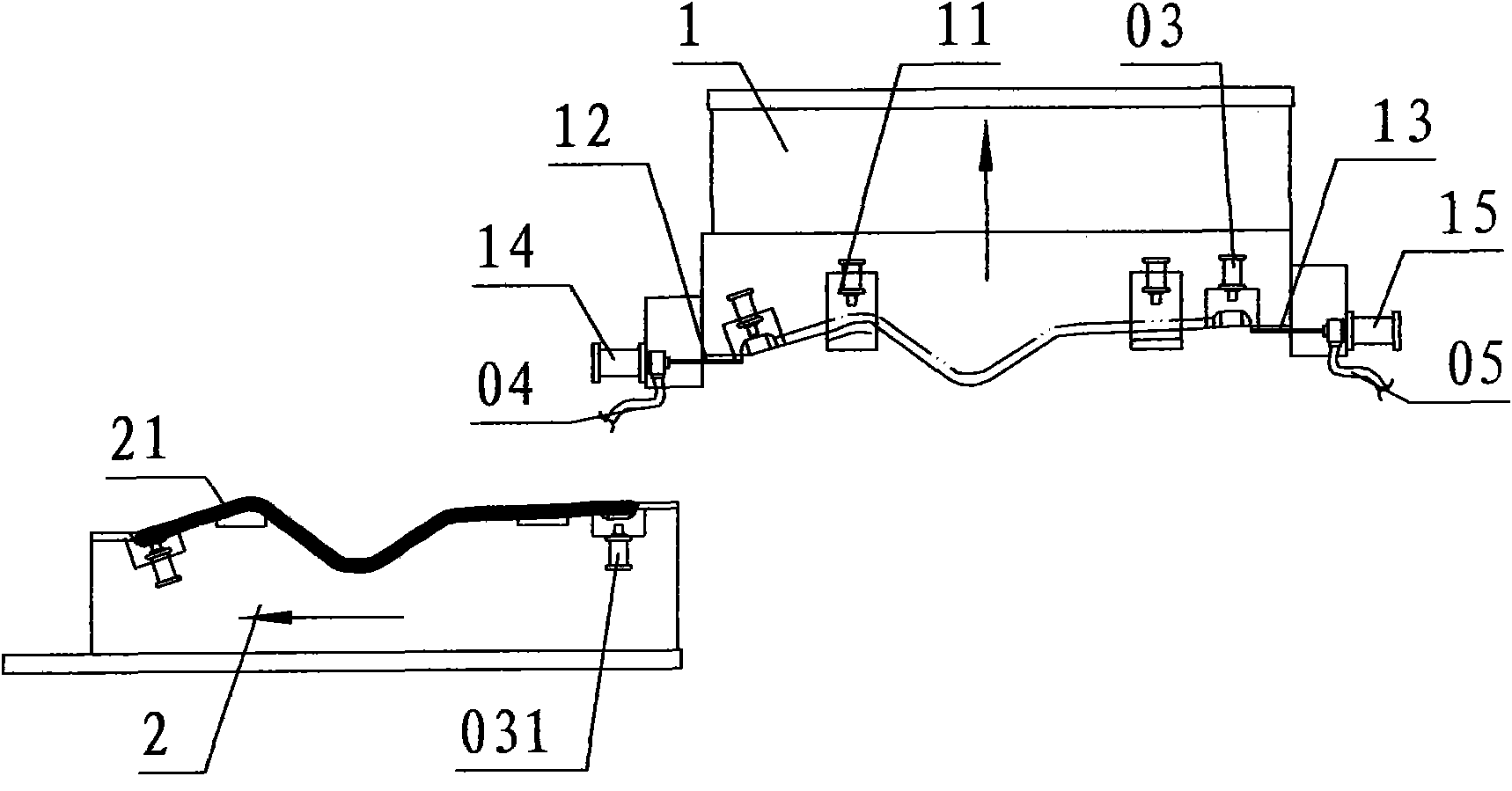

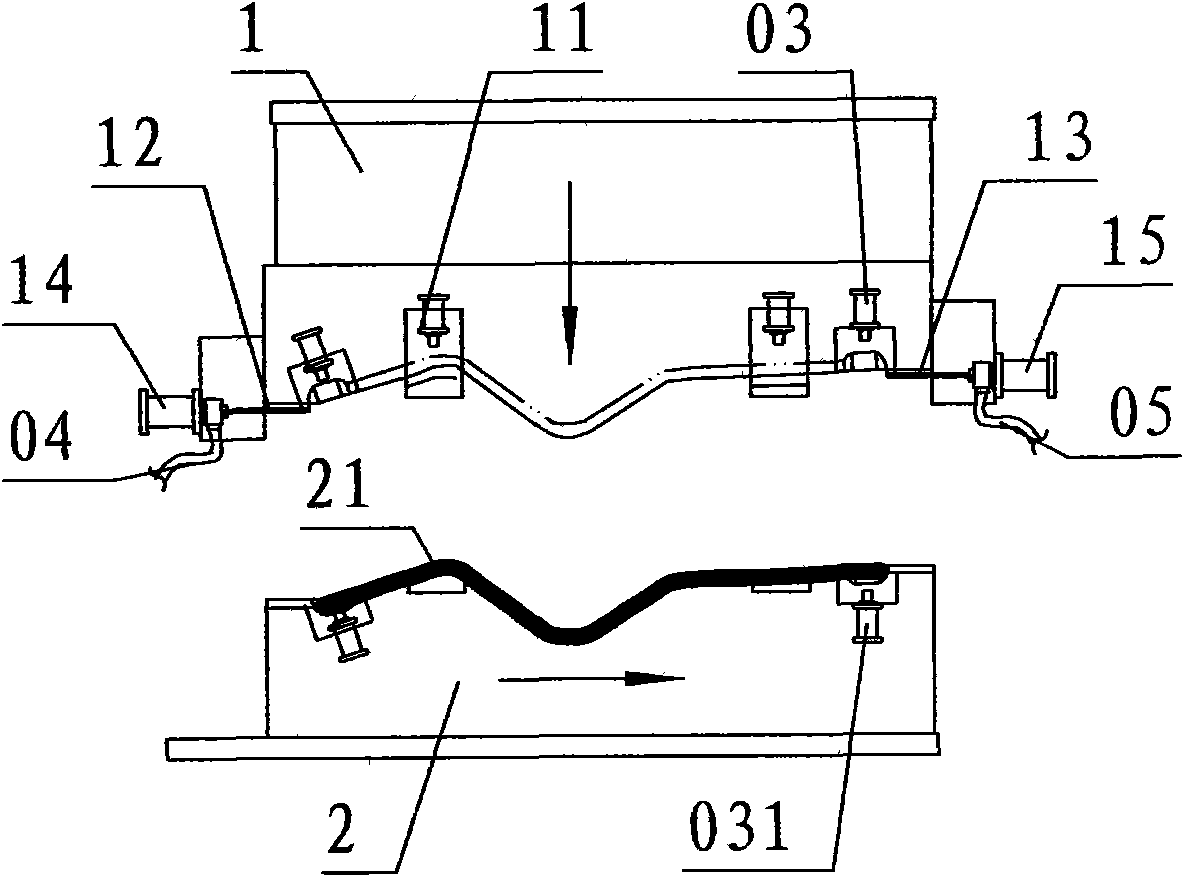

[0029] refer to Figure 1 to Figure 9 , a horizontal blow molding mold for automobile tubing and a blow molding method thereof of the present invention, comprising an upper mold 1, a lower mold 2 and a blow molding method, wherein: the upper mold 1 is fixed on a horizontal The upper half of the horizontal blow molding mold that moves up and down on the vertical lifting workbench above the type blow molding machine; Valve cavity; the two sides of the upper half valve cavity of the upper mold 1 are symmetrically provided with a number of demoulding clips 11 composed of movable sliders driven by respective cylinders. The outer walls of the two sides of the tubing product 4 have the same shape; they are located at the two ends of the upper half of the die cavity of the upper mold 1, and one end is provided with a blowing needle 12 and the other end is provided with an exhaust needle 13, and the blowing needle cylinder 14 and the Driven by the needle row cylinder 15; located at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com