Preparation method for black-silicon poly-silicon PERC cell structure with selective emitter

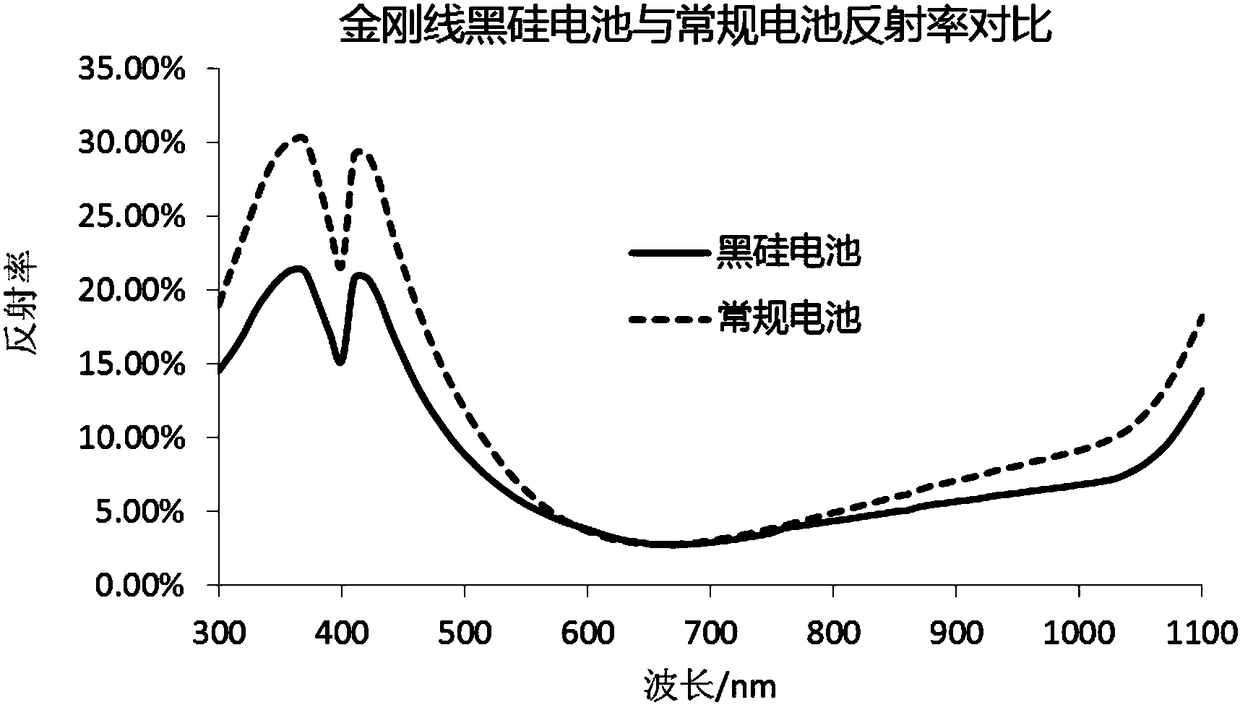

An emitter, selective technology, applied in chemical instruments and methods, circuits, crystal growth, etc., can solve the problem of inability to ensure accurate alignment of grid lines and selective emitters, difficulty in forming high-quality fine grid lines, and surface reflectivity. High problems, to achieve the effect of low energy consumption cost, reduced preparation cost, and improved collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: A method for preparing a selective emitter black silicon polycrystalline PERC cell structure, comprising the following steps:

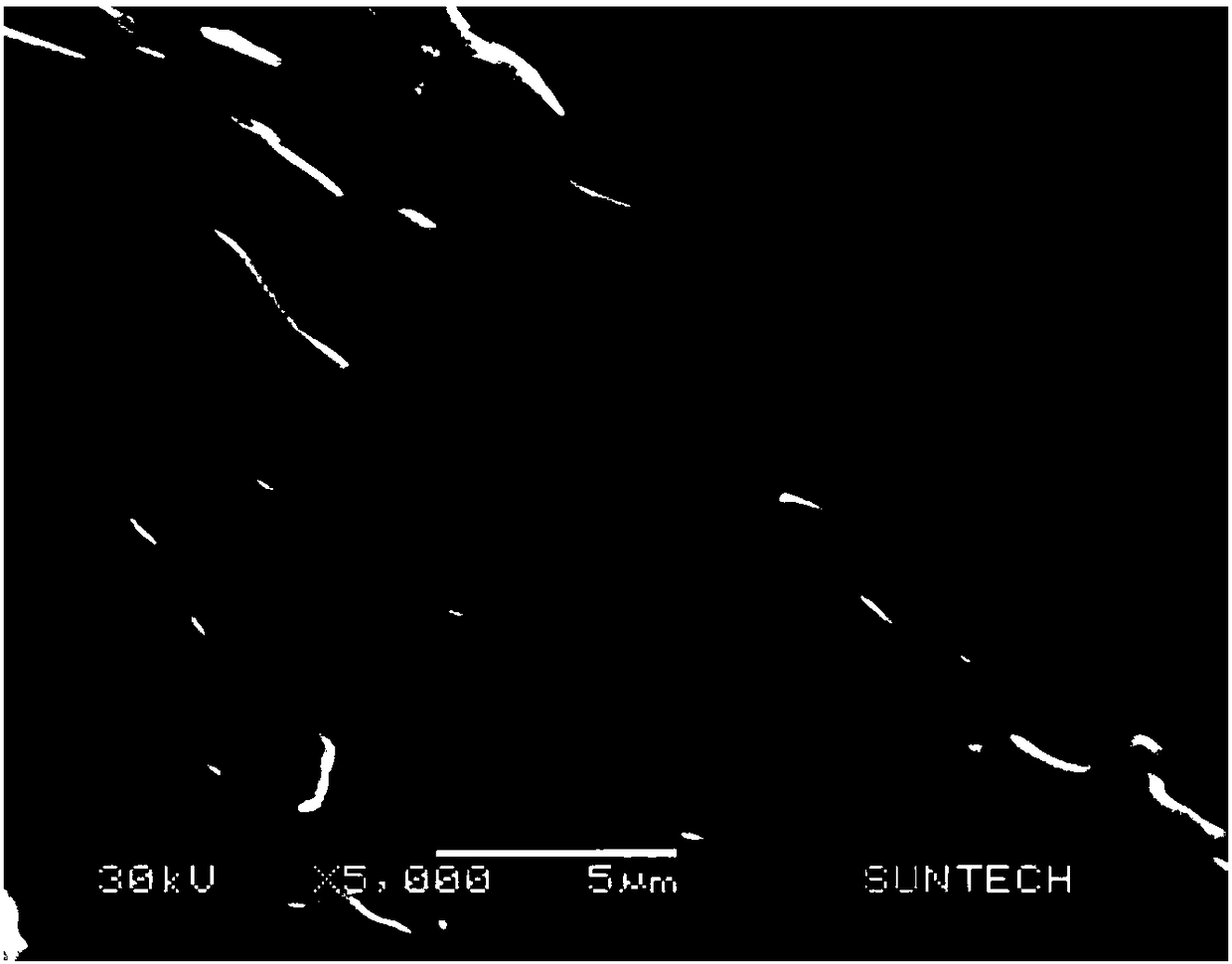

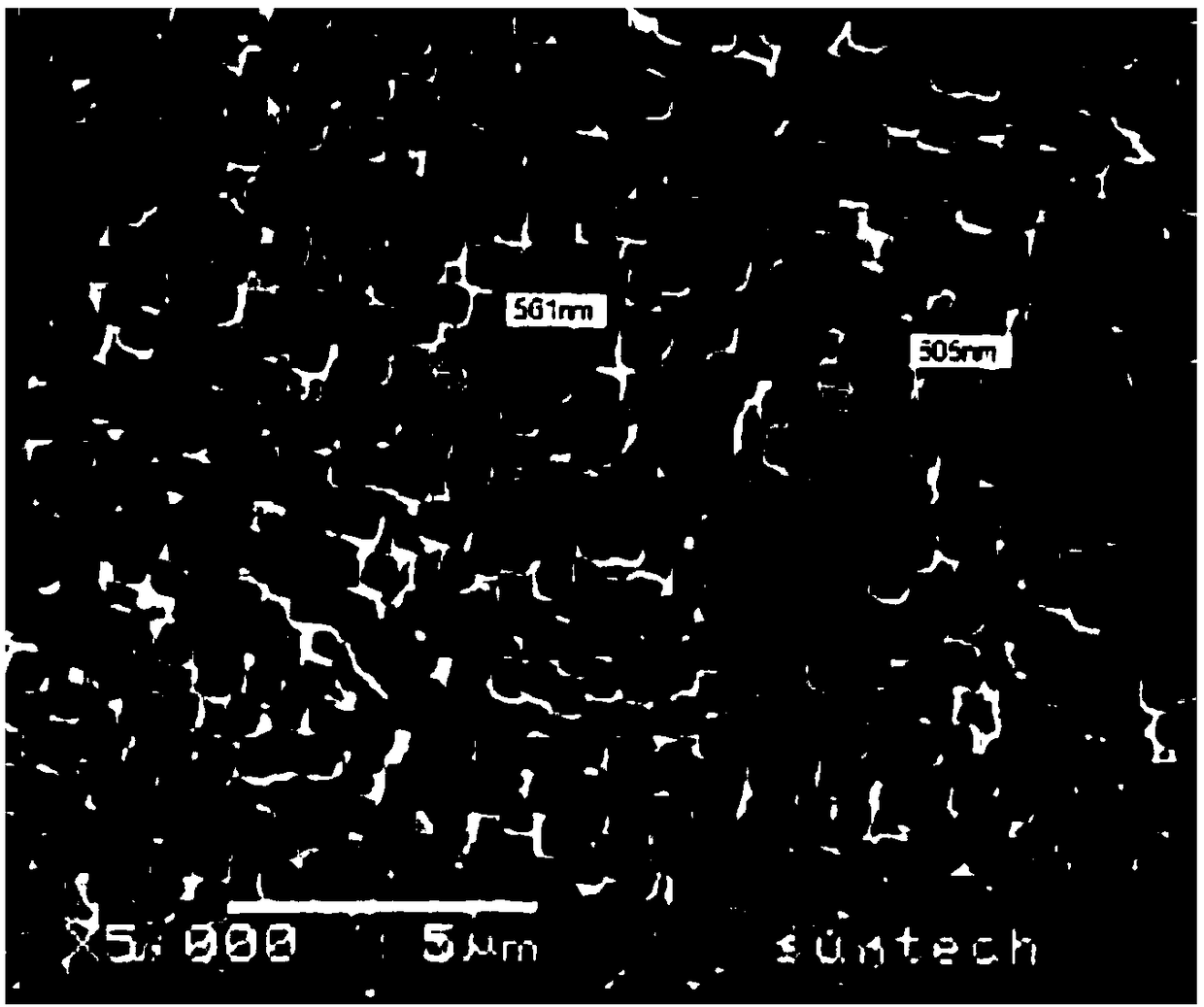

[0044] (1) Single-sided texturing: after loading → alkali polishing → pickling → immersion silver → digging → desilvering → reaming → alkali washing → pickling → splitting → pickling → water washing → drying, on the silicon wafer 1. Nano-textured surface is formed on the front side, and the back of the silicon wafer is a polished surface without a textured surface. The prepared nano-textured surface has an aperture of 600nm and a reflectivity of 18%;

[0045] (2) Diffusion: Using the method of phosphorus diffusion in a tube furnace, at a temperature of 880°C in the diffusion furnace, phosphorus oxychloride is used to diffuse phosphorus on the front side of the silicon wafer to form an N-type layer. After diffusion, the surface square resistance is 120Ω / □ ;

[0046] (3) Etching: use the water film protection etching method to remo...

Embodiment 2

[0056] Embodiment 2: A method for preparing a selective emitter black silicon polycrystalline PERC cell structure, comprising the following steps:

[0057] (1) Single-sided velvet making: including the following steps: loading → alkali polishing → pickling → immersion silver → digging → desilvering → reaming → alkali washing → pickling → splitting → pickling → water washing → drying, Nano suede is prepared on the front side of the silicon wafer, and the back is polished. The nano suede surface has an aperture of about 550nm and a reflectivity of 17%;

[0058] (2) Diffusion: Using the method of phosphorus diffusion in a tube furnace, at a temperature of 880°C in the diffusion furnace, phosphorus oxychloride is used to diffuse phosphorus on the front side of the silicon wafer to form an N-type layer. After diffusion, the surface square resistance is 130Ω / □ ;

[0059] (3) Etching: use the water film protection etching method to remove the phosphosilicate glass on the front side ...

Embodiment 3

[0070] Embodiment 3: A method for preparing a selective emitter black silicon polycrystalline PERC cell structure, comprising the following steps:

[0071] (1) Single-sided velvet making: including the following steps: loading → alkali polishing → pickling → immersion silver → digging → desilvering → reaming → alkali washing → pickling → splitting → pickling → water washing → drying, The front side of the silicon wafer is prepared with a nano-textured surface, and the back is a polished surface. The prepared nano-textured surface has an aperture of 400nm and a reflectivity of 15%;

[0072] (2) Diffusion: Using the method of phosphorus diffusion in a tube furnace, at a temperature of 890°C in the diffusion furnace, phosphorus oxychloride is used to diffuse phosphorus on the front side of the silicon wafer to form an N-type layer. After diffusion, the surface square resistance is 140Ω / □ ;

[0073] (3) Etching: remove the phosphosilicate glass on the front side of the silicon wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com