Selective emitter electrode black silicon double-face PERC crystalline silica solar energy battery manufacturing method

A technology of solar cells and manufacturing methods, which is applied in the directions of crystal growth, photovoltaic power generation, chemical instruments and methods, etc., can solve the problems of limiting the development of silicon wafer thinning, silicon wafer warping, high cost, etc., to solve the problem of surface chromatic aberration, High aspect ratio, low shading loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

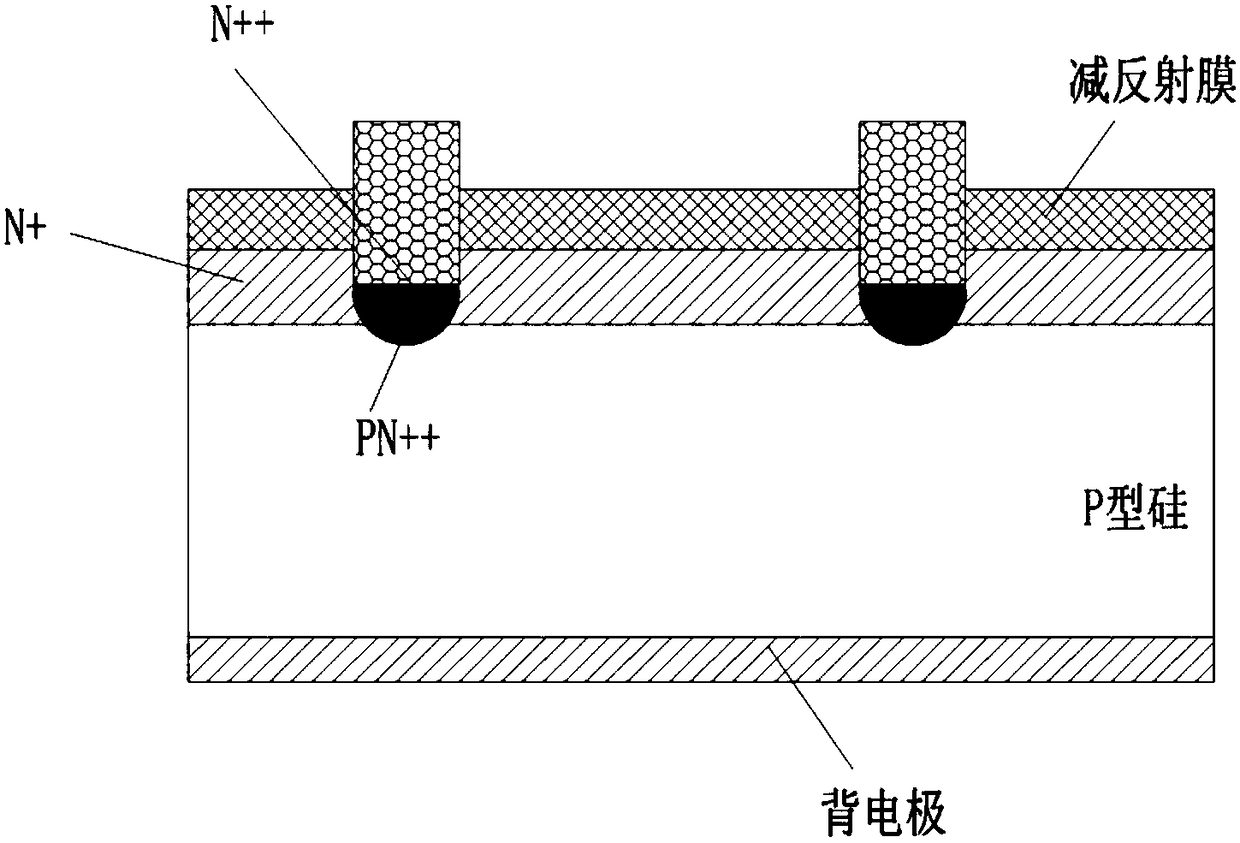

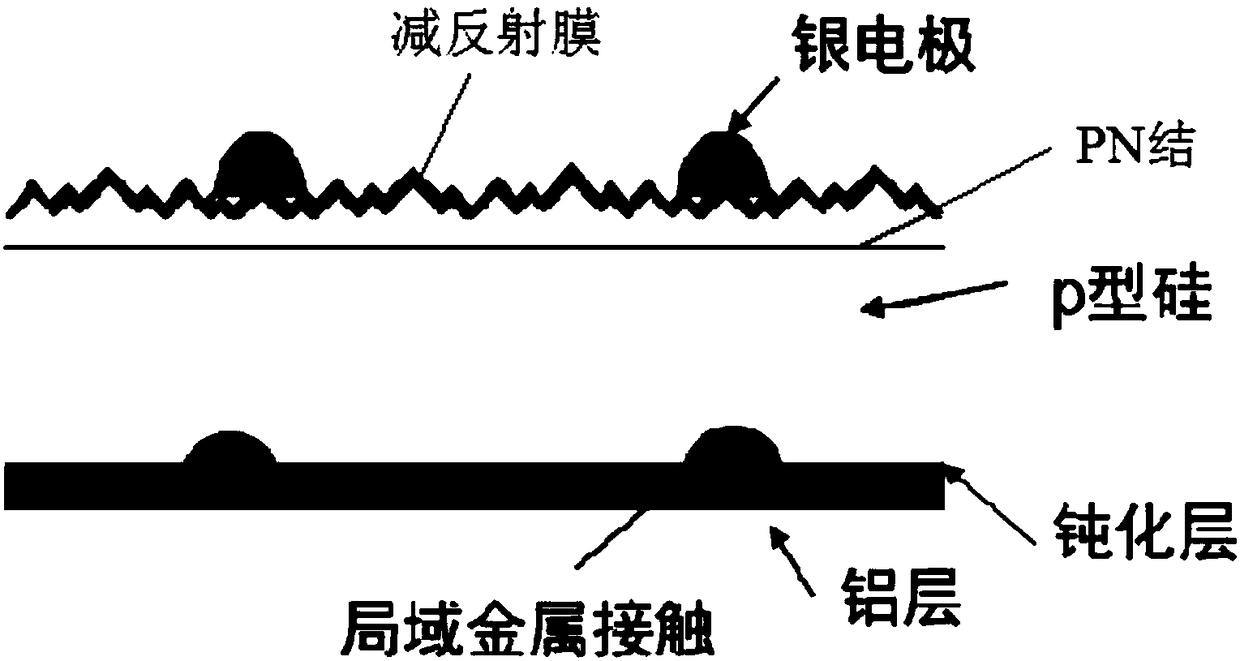

[0036] Embodiment 1: A method for manufacturing a selective emitter black silicon double-sided PERC crystalline silicon solar cell, comprising the following steps:

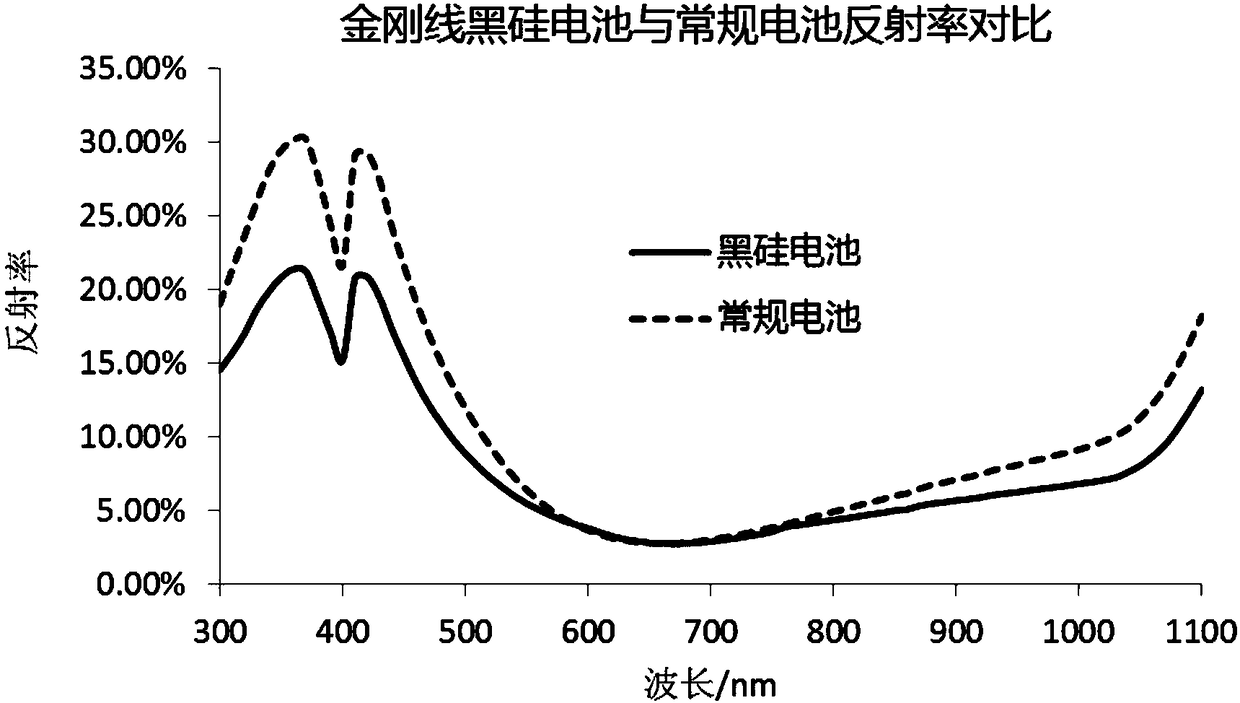

[0037](1) Texturing: Choose 156.75mm*156.75mm P-type diamond wire-cut polycrystalline silicon wafer as the base material, with a resistivity of 3Ω•cm, after alkali polishing, pickling, immersion silver, digging, desilvering, hole expansion, alkali Washing, pickling, water washing, and drying to prepare the textured surface, the thinning amount of the textured surface is 0.38g, the pore diameter of the nano-textured surface is 550nm, and the surface reflectance of the silicon wafer is 20.3% after textured;

[0038] (2) Diffusion: Using the method of phosphorus diffusion in a tube furnace, in the diffusion furnace at a temperature of 830°C, phosphorus oxychloride is used to diffuse phosphorus on the front side of the silicon wafer to form an n-type layer. The total time of the diffusion process is 80 minutes. Diffus...

Embodiment 2

[0047] Embodiment 2: A method for manufacturing a selective emitter black silicon double-sided PERC crystalline silicon solar cell, comprising the following steps:

[0048] (1) Texturing: Choose 156.75mm*156.75mm P-type diamond wire-cut polysilicon wafer as the base material, with a resistivity of 2Ω•cm, after alkali polishing, pickling, immersion silver, digging, desilvering, hole expansion, alkali Washing, pickling, water washing, and drying to prepare the textured surface, the thinning amount of the textured surface is 0.45g, the pore diameter of the nano-textured surface is 700nm, and the surface reflectance of the silicon wafer after textured is 21.0%;

[0049] (2) Diffusion: Using the method of phosphorus diffusion in a tube furnace, in the diffusion furnace at a temperature of 820°C, phosphorus oxychloride is used to diffuse phosphorus on the front side of the silicon wafer to form an n-type layer, and the diffusion resistance is controlled at 140Ω / □ left and right;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com