Patents

Literature

906 results about "Aluminum paste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

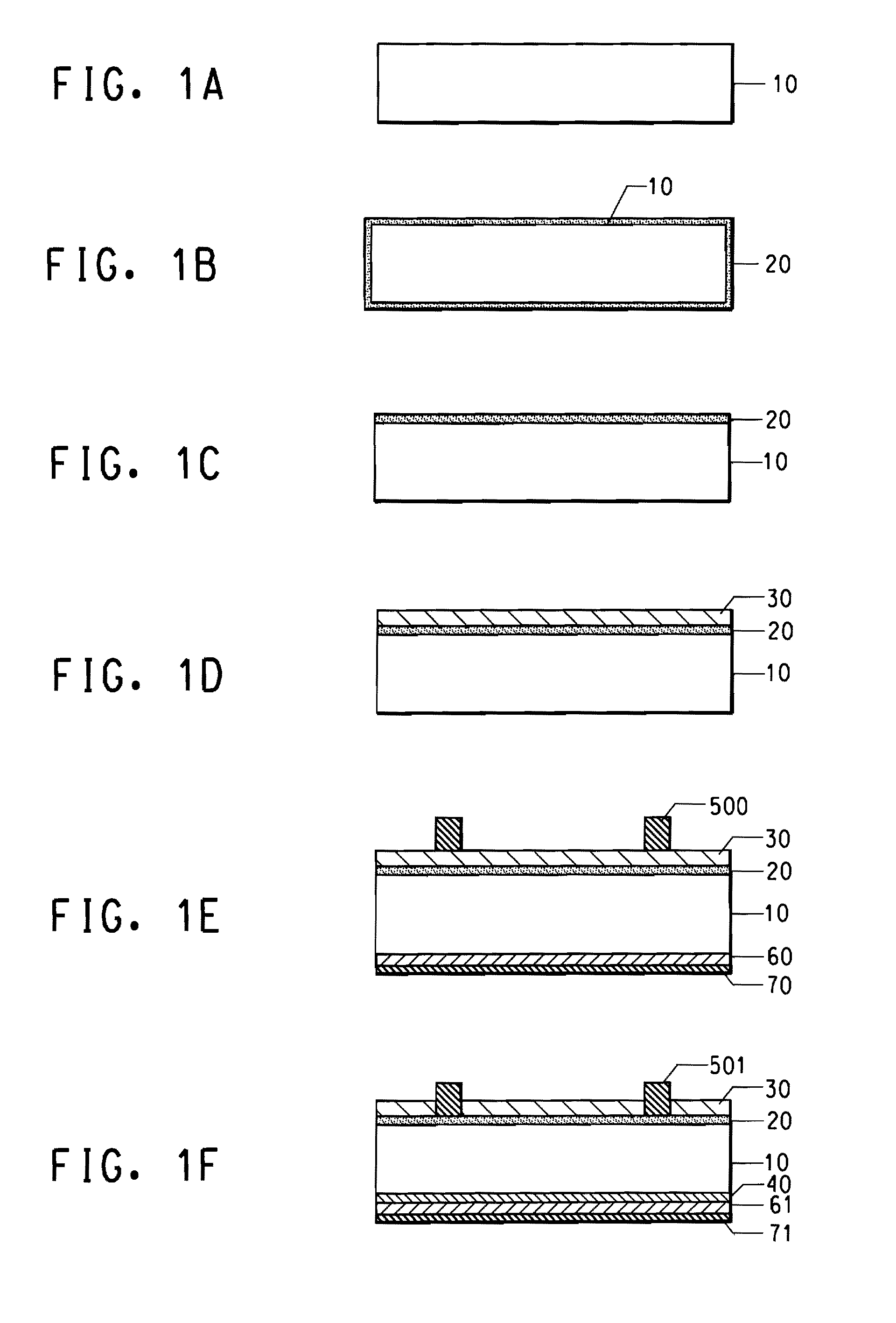

Process of forming an aluminum p-doped surface region of an n-doped semiconductor substrate

ActiveUS20130112251A1Final product manufactureSemiconductor/solid-state device manufacturingParticulatesMetallurgy

A process for the formation of at least one aluminum p-doped surface region of an n-type semiconductor substrate comprising the steps:(1) providing an n-type semiconductor substrate,(2) applying and drying an aluminum paste on at least one surface area of the n-type semiconductor substrate,(3) firing the dried aluminum paste, and(4) removing the fired aluminum paste with water,wherein the aluminum paste employed in step (2) includes particulate aluminum, an organic vehicle and 3 to 20 wt. % of glass frit, based on total aluminum paste composition.

Owner:SOLAR PASTE LLC

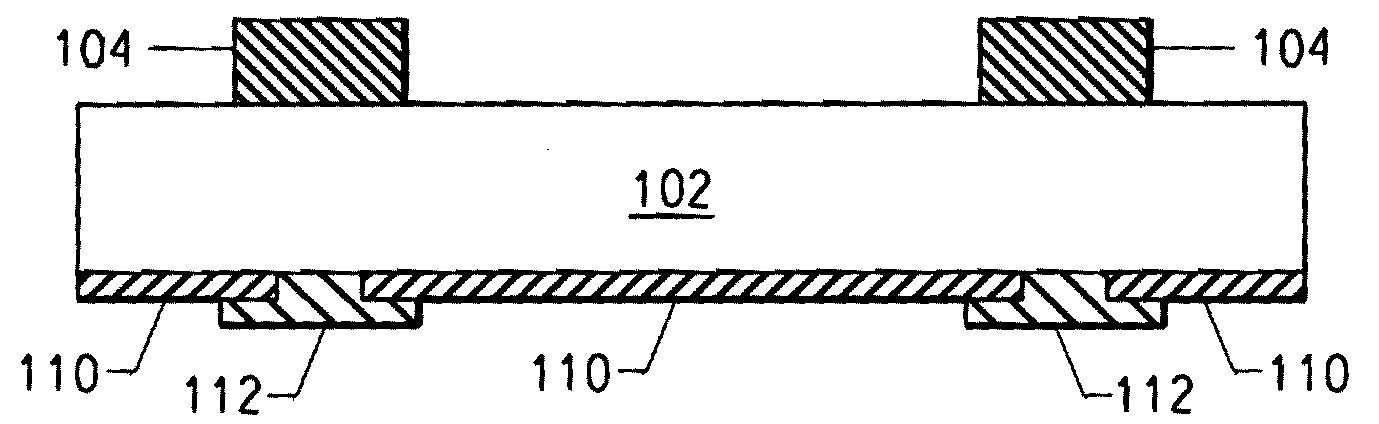

Thick Film Pastes For Fire Through Applications In Solar Cells

InactiveUS20090056798A1Improve battery efficiencyFinal product manufactureConductive materialEngineeringMetal

Formulations and methods of making solar cell contacts and cells therewith are disclosed. The invention provides a photovoltaic cell comprising a front contact, a back contact, and a rear contact. The back contact comprises, prior to firing, a passivating layer onto which is applied a paste, comprising aluminum, a glass component, wherein the aluminum paste comprises, aluminum, another optional metal, a glass component, and a vehicle. The back contact comprises, prior to firing, a passivating layer onto which is applied an aluminum paste, wherein the aluminum paste comprises aluminum, a glass component, and a vehicle.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

Aluminum pastes and use thereof in the production of silicon solar cells

InactiveUS20090255583A1Semiconductor/solid-state device manufacturingNon-conductive material with dispersed conductive materialParticulatesSilicon solar cell

Aluminum pastes comprising particulate aluminum, a tin-organic component and an organic vehicle and their use in forming p-type aluminum back electrodes of silicon solar cells.

Owner:EI DU PONT DE NEMOURS & CO

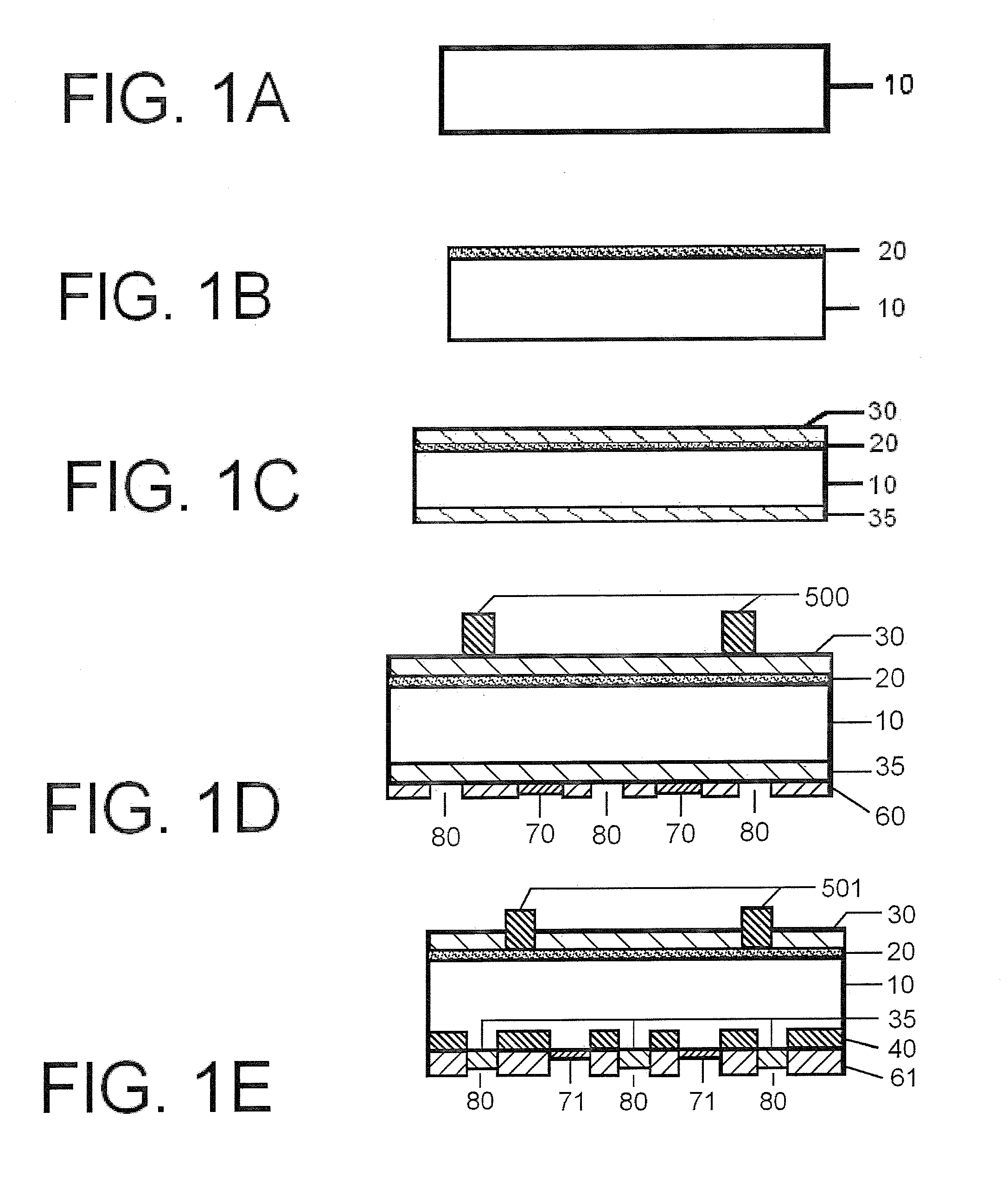

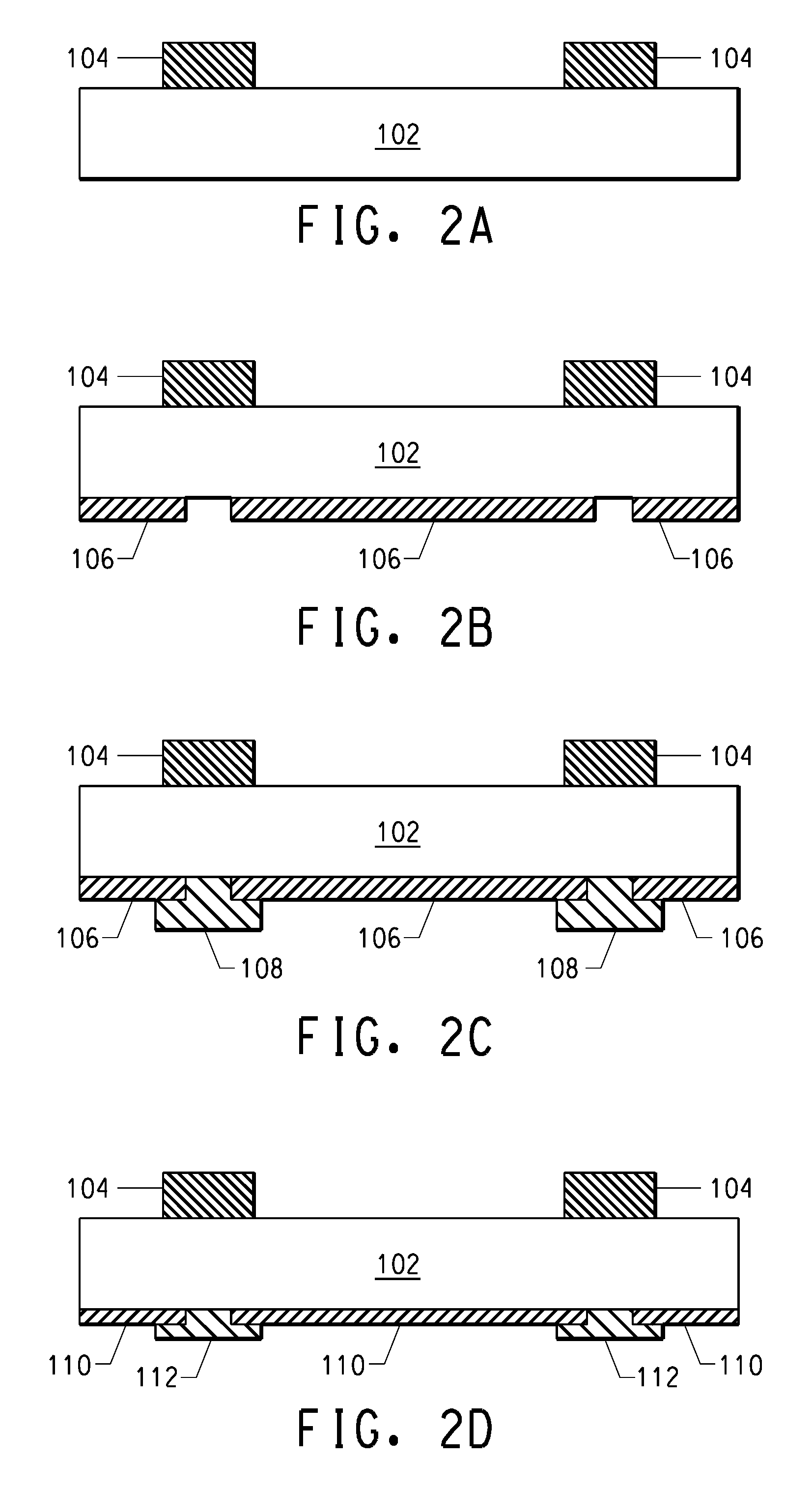

Solar cell having high quality back contact with screen-printed local back surface field

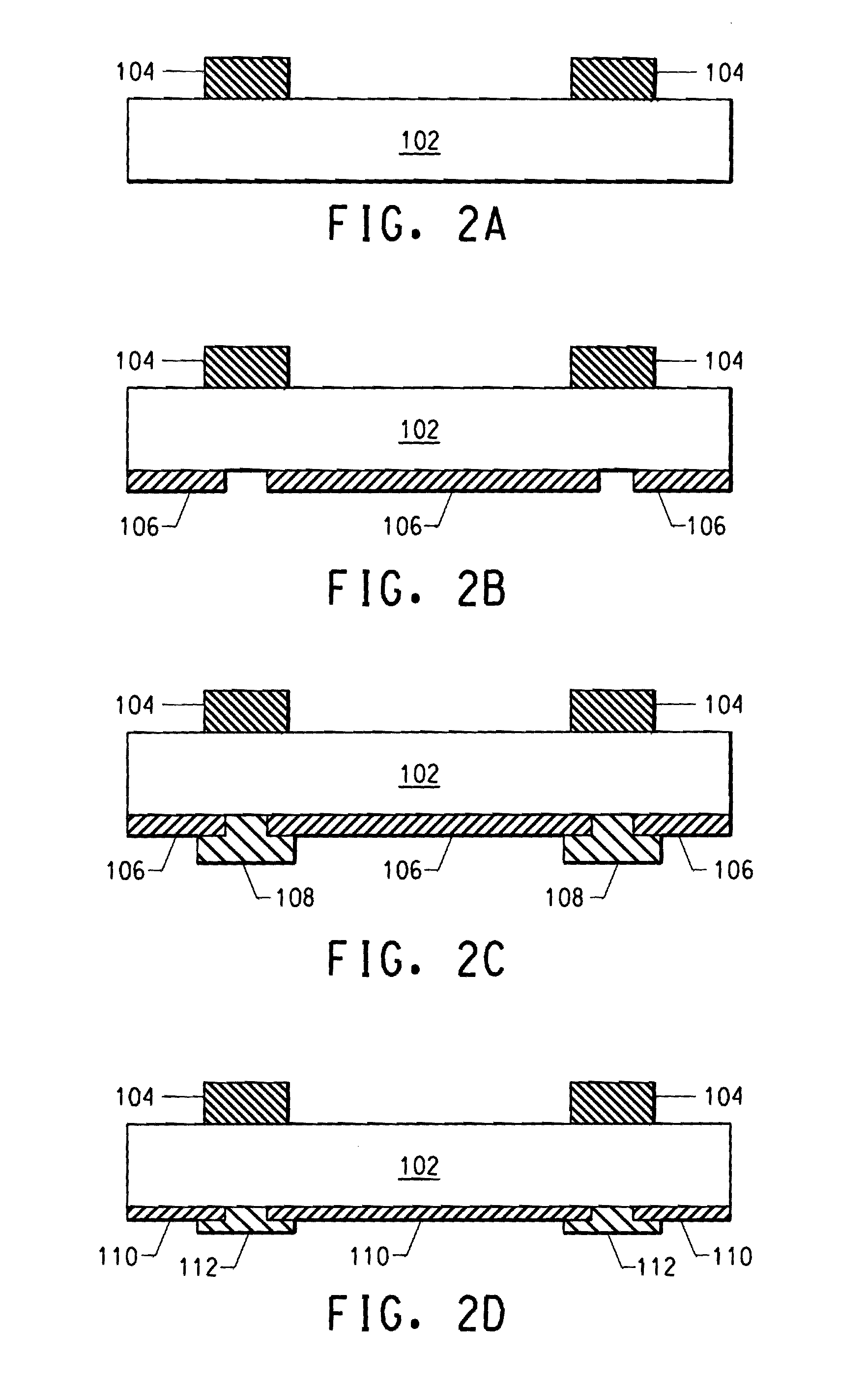

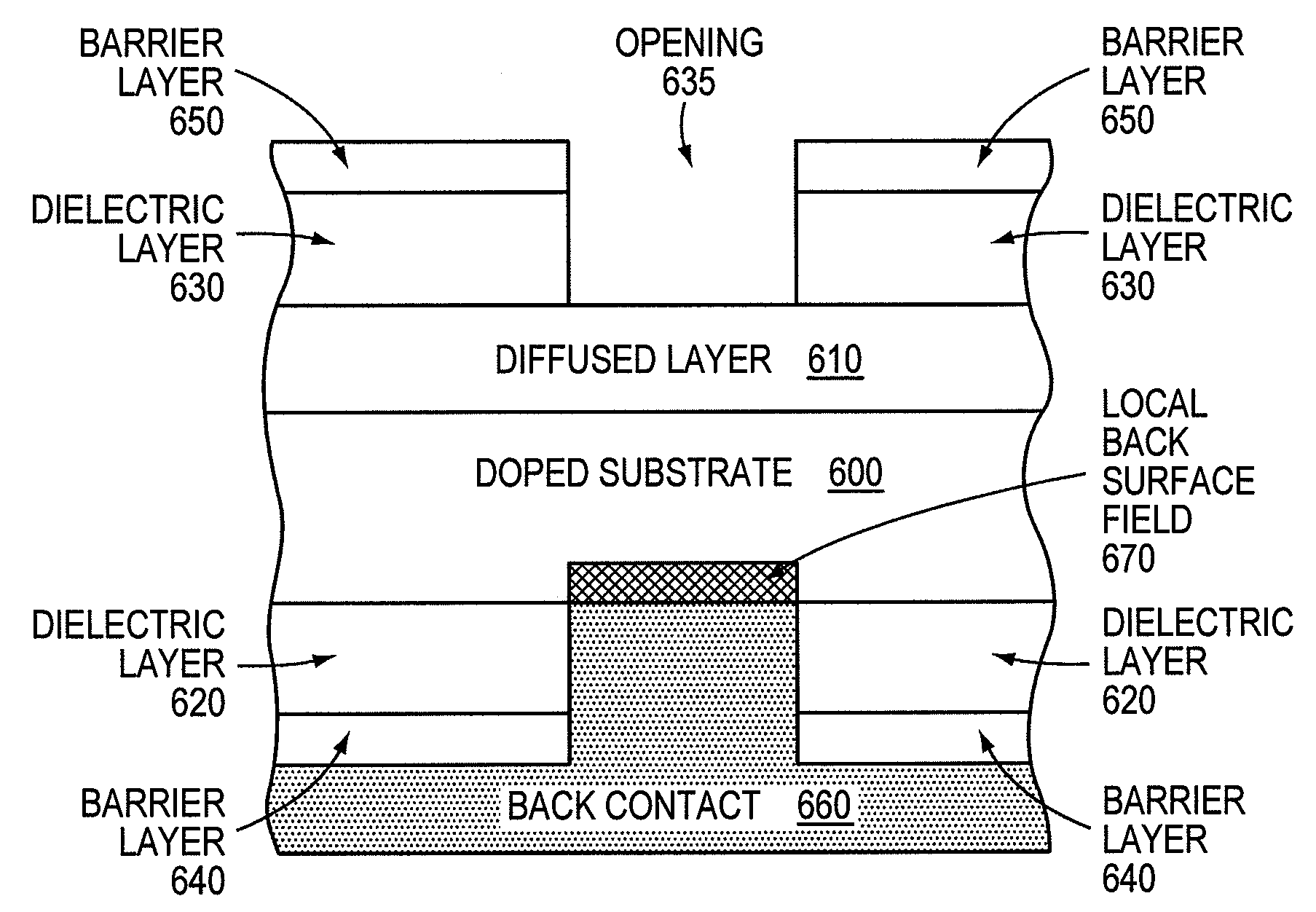

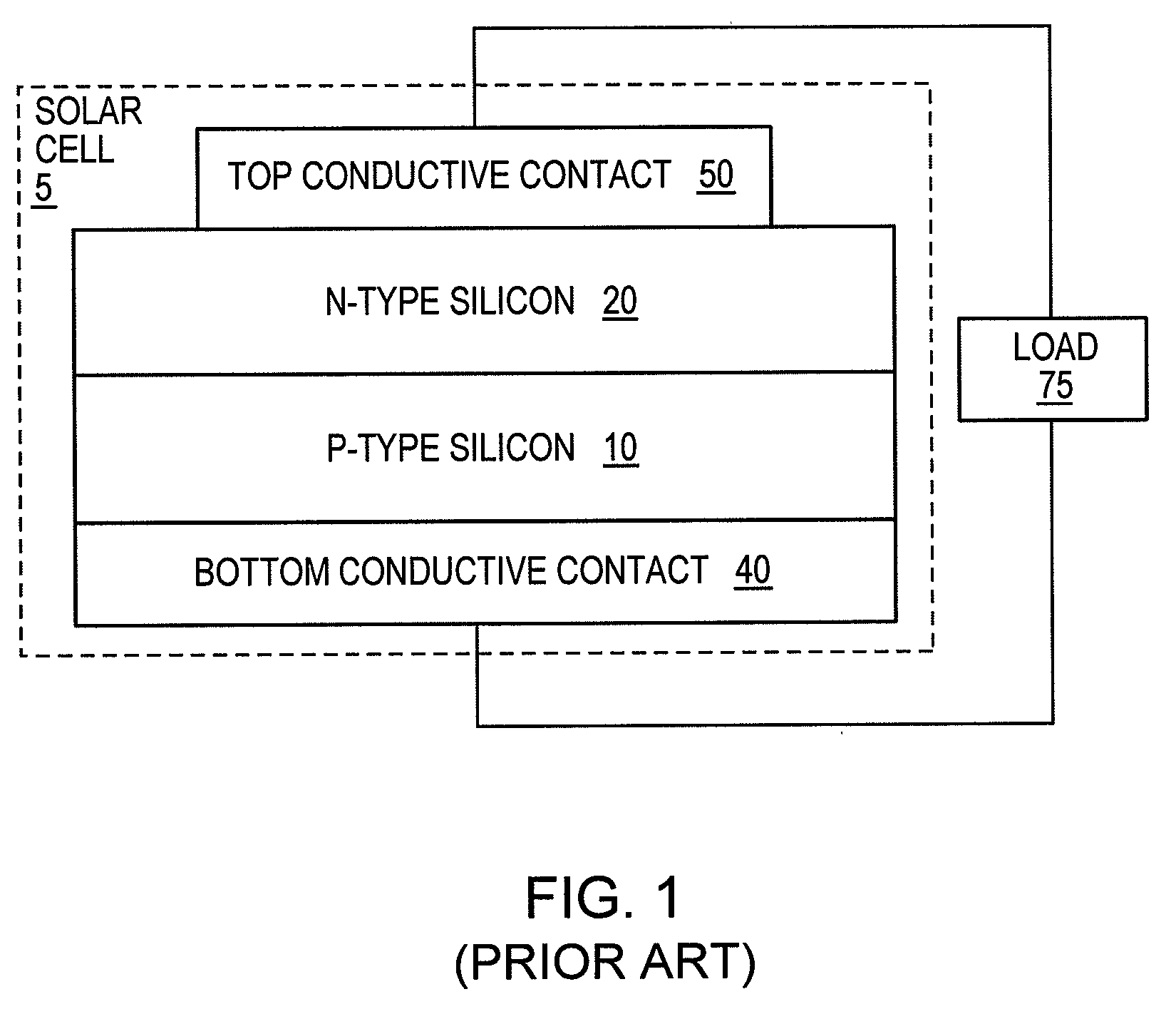

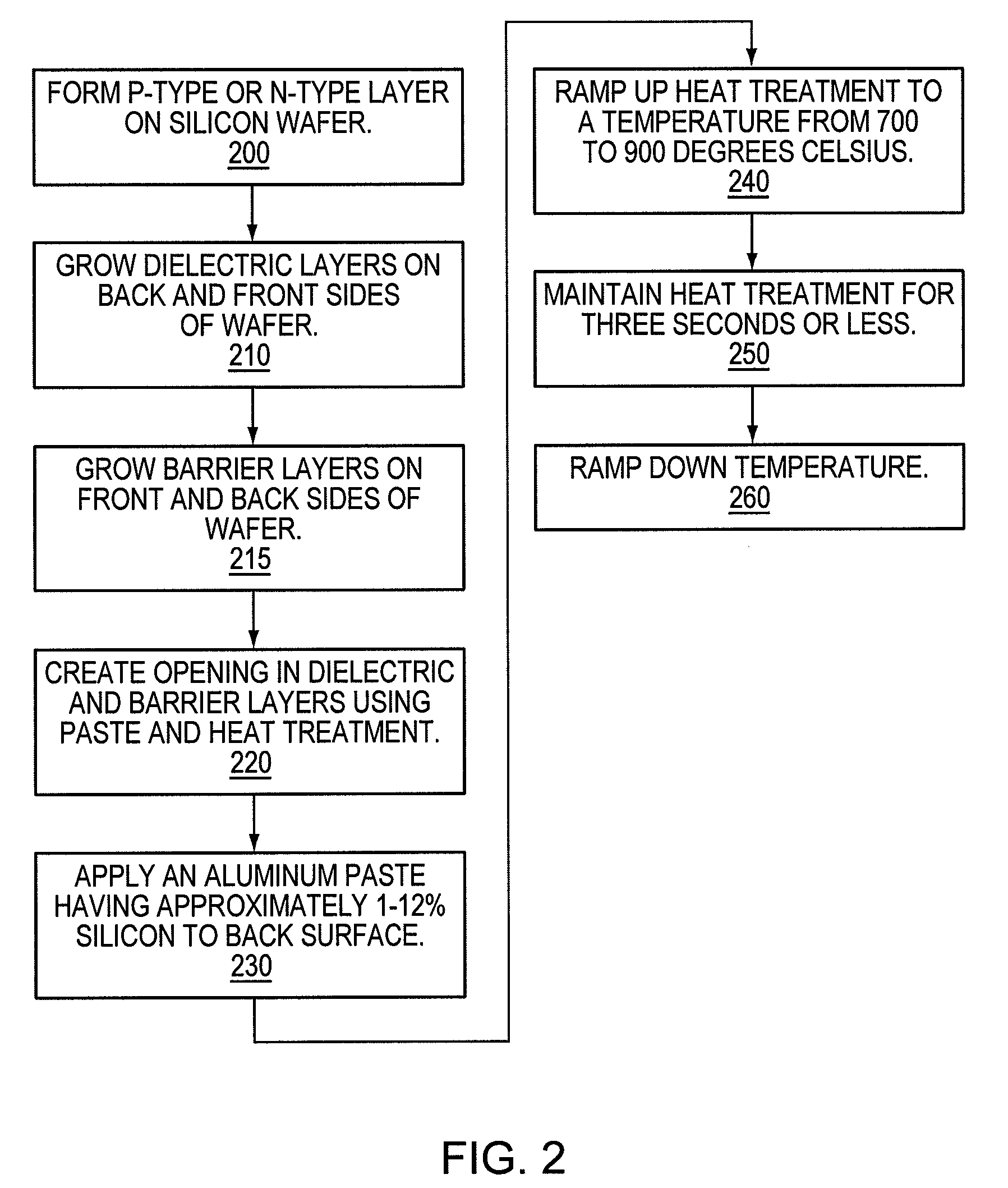

InactiveUS20090025786A1Final product manufacturePhotovoltaic energy generationScreen printingCelsius Degree

A thin silicon solar cell having a back dielectric passivation and rear contact with local back surface field is described. Specifically, the solar cell may be fabricated from a crystalline silicon wafer having a thickness from 50 to 500 micrometers. A barrier layer and a dielectric layer are applied at least to the back surface of the silicon wafer to protect the silicon wafer from deformation when the rear contact is formed. At least one opening is made to the dielectric layer. An aluminum contact that provides a back surface field is formed in the opening and on the dielectric layer. The aluminum contact may be applied by screen printing an aluminum paste having from one to 12 atomic percent silicon and then applying a heat treatment at 750 degrees Celsius.

Owner:GEORGIA TECH RES CORP

Aluminum pastes and use thereof in the production of silicon solar cells

InactiveUS20090229665A1Semiconductor/solid-state device manufacturingOrganic dyesParticulatesSilicon solar cell

Disclosed are aluminum pastes comprising particulate aluminum, a zinc-organic component and an organic vehicle and their use in forming p-type aluminum back electrodes of silicon solar cells.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of MWT (Metal Wrap Through) solar cell

ActiveCN102208486AImprove efficiencyBusbarPhotovoltaic energy generationSemiconductor devicesPhotovoltaic industryChemical solution

The invention discloses a preparation method of an MWT (Metal Wrap Through) solar cell, comprising the following steps of: (1) carrying out phosphorous diffusion by using a p-type crystal silicon substrate; (2) etching one surface of the crystal silicon substrate by using a chemical solution to remove a phosphorous diffused layer so as to form a polished surface; (3) depositing a passivated antireflective film on the other surface of the crystal silicon substrate to form a light receiving surface; (4) forming a conductive through hole on the crystal silicon substrate by using laser lights; (5) filling a conductive silver paste into the conductive through hole by using a wire mesh on the polished surface so as to form an emitter contact electrode; (6) printing an aluminum paste on the polished surface by using a wire mesh so as to form a base contact electrode; (7) printing a silver contact grid line on the light receiving surface and connecting the silver contact grid line with the conductive through hole; and (8) forming the ohmic contact between a metal and the silicon substrate through sintering so as to finish the solar cell making process. The preparation method of the MWT (Metal Wrap Through) solar cell, disclosed by the invention, has the advantages of simple process flow and easiness in operation, is completely compatible with a solar cell production line widely applied in the current photovoltaic industry and is suitable for mass production.

Owner:JA SOLAR TECH YANGZHOU

High-photoelectric-conversion-efficiency crystalline silicon solar battery aluminum paste and preparation method thereof

InactiveCN102324267AReduce dosageImproved aluminum back fieldNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon alloyBack surface field

The invention relates to a high-photoelectric-conversion-efficiency crystalline silicon solar battery aluminum paste, which consists of the following raw materials by mass percent: 60-70 percent of aluminum powder, 20-35 percent of organic bond, 1-10 percent of aluminum-silicon alloy powder, 0.2-2 percent of glass powder and 0.1 to 1.5 percent of adjuvant, wherein the sum of the mass percent of the raw materials is 100 percent, the content of aluminum contained in the aluminum-silicon alloy powder is 8-15 percent and the average grain size of the aluminum-silicon alloy powder is small than 2mum. The invention additionally provides a preparation method for the crystalline silicon solar battery aluminum paste. After the paste is screen-printed, dried and sintered, an aluminum back surface field is formed on a silicon wafer. The adhesive force of the aluminum back surface field is high, the warping degree of cells is low, the photoelectric conversion efficiency is high, the cost is low and the aluminum paste is nontoxic.

Owner:JIANGSU HOYI TECH

Conductive paste for crystalline silicon solar cell and preparation method of conductive paste

ActiveCN104078090AHigh tear strengthImprove adhesion strengthNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteConductive paste

The invention provides conductive paste for a crystalline silicon solar cell. The conductive paste comprises the following components in parts by weight: 100 parts of conductive metal powder, 1.0-10 parts of inorganic binder, 10-65 parts of organic carrier and 0.05-5.0 parts of conductive carbon. The conductive paste is excellent in conductivity; the photoelectric conversion efficiency of the cell is not influenced; and widely applied conductive paste for the crystalline silicon solar cell such as front-side silver paste, front-side seed layer silver paste, back-side silver paste and back electric field aluminum paste can be prepared.

Owner:BYD CO LTD

Haydite autoclaved aerated concrete and production method

InactiveCN101497517AImprove featuresLight weightSolid waste managementCeramic shaping apparatusSlagExpanded clay aggregate

The invention discloses a ceramsite autoclaved aerated concrete and a production method. The concrete consists of ceramsite, coal ash, sand, quartz tailing powder or silicon slag, lime, cement, gypsum, aluminum powder or aluminum paste powder, and admixture. The production method comprises the steps of measuring raw materials, blending and stirring, pouring and feeding a die, generating gas by static electricity, mold stripping, autoclaving, mechanical cutting and the like. The concrete has precise dimension and good performance.

Lead-free aluminum paste for solar battery

InactiveCN101789456AMeet environmental protection requirementsStrong adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAluminium powderSolar battery

The invention provides a lead-free aluminum paste for a solar battery, which is mainly used for producing a conductive electrode for a solar battery. The lead-free aluminum paste mainly comprises the following components by weight percent: 70 to 80 percent of aluminum powder, 19 to 30 percent of organic bond, 0.1 to 5 percent of inorganic glass powder and 0.1 to 2 percent of a first additive. The organic bond comprises the following components by weight percent: 40 to 60 percent of terpineol, 1 to 5 percent of ethylcellulose, 1 to 5 percent of lecithin and 20 to 50 percent of a second additive. The lead-free aluminum paste for the solar battery mainly solves the technical problems that the existing aluminum paste for the solar battery has poor electrical conductivity and low photoelectric conversion efficiency. The lead-free aluminum paste has the advantages of good electric conductivity, high photoelectric conversion efficiency and the like.

Owner:西安宏星电子浆料科技股份有限公司

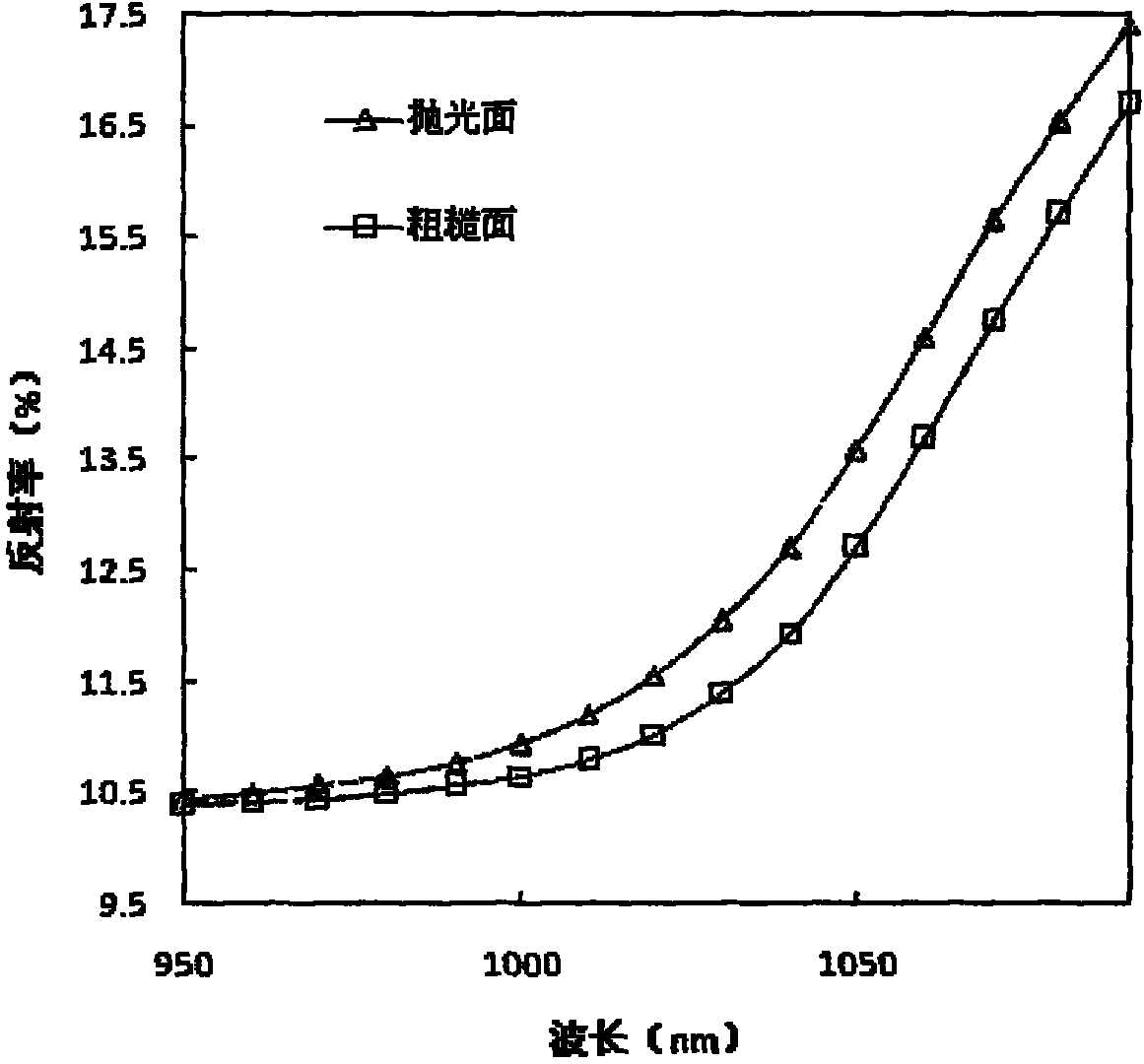

Industrialized production process of crystalline silicon solar battery

ActiveCN101840961AReduce the probability of electric leakageReduce process stepsFinal product manufactureSemiconductor devicesSpectral responseBack surface field

The invention discloses an industrialized production process of a crystalline silicon solar battery, which comprises the following steps of: selecting a silicon chip; performing front surface matte making, phosphorous diffusion, the removal of phosphorosilicate glass formed on the surface during the phosphorous diffusion, and the deposition of silicon nitride on the front surface through PECVD inturn, and then putting an anti-reflecting film protected silicon ship provided with the front surface silicon nitride into heated alkali liquor to perform back polishing so as to remove a diffusion layer on the back surface; and washing and drying the silicon chip, and printing and sintering the silicon chip by adopting a bending-resistant aluminum paste silk screen. The process adopts a chemicalmethod to replace a plasma etching process, realizes non-contact of a matte surface of the silicon chip in the whole production flow, avoids matte surface damages caused by silicon chip friction, so the probability of electric leakage after facade silver paste sintering is reduced; the flat and clean back surface is favorable for the reaction of aluminum and silicon during the sintering to form amore uniform aluminum back surface field; and a polished surface has a stronger reflex action compared with an irregular matte surface, and can increase the absorption of incident light, improve the spectral response of the long-wavelength of a battery chip, and significantly improve a short-circuit current and an open-circuit voltage.

Owner:JA YANGZHOU SOLAR PHOTOVOLTAIC ENG

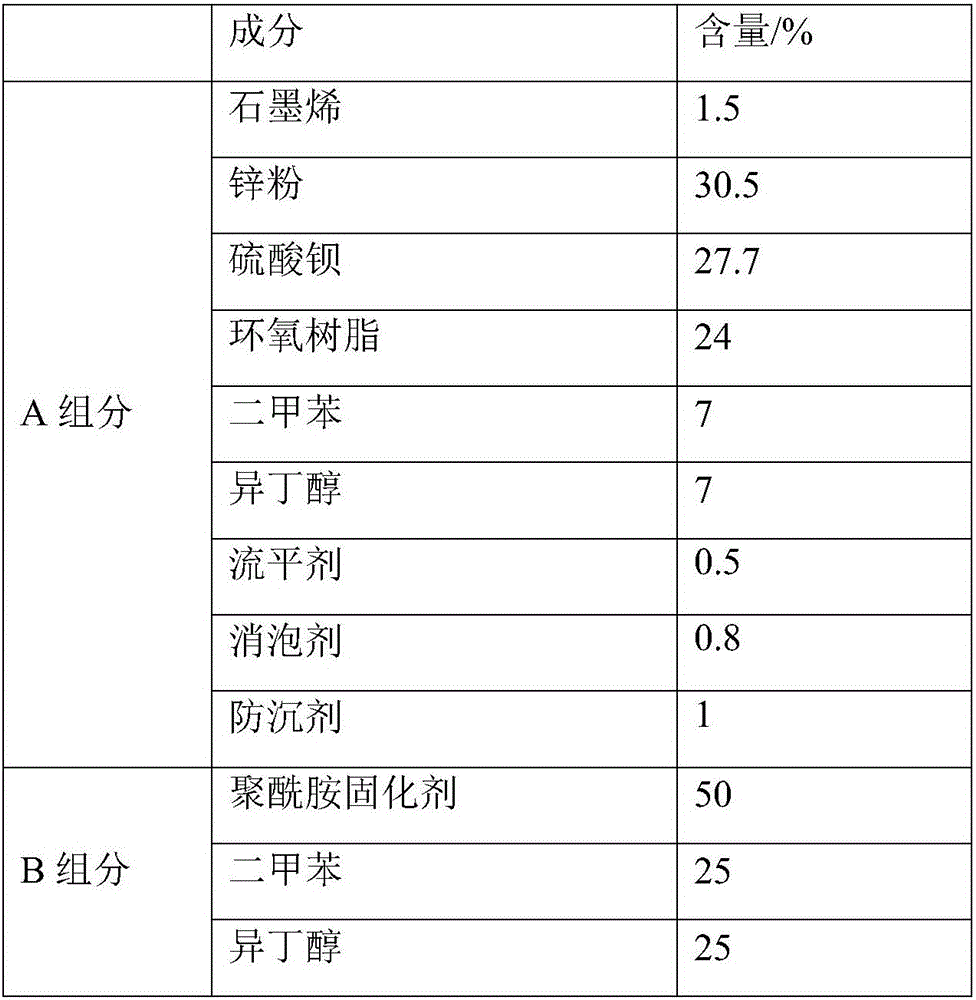

Graphene anticorrosive coating and preparation method thereof

ActiveCN106189719AEasy reunionSolving Dispersion ProblemsAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention provides a graphene anticorrosive coating and a preparation method thereof. The graphene anticorrosive coating is prepared from a component A and a component B, wherein in percentage by weight, the component A comprises 20%-30% of epoxy resin, 1%-3% of graphene, 0.5%-2% of a dispersing agent, 15%-25% of talcum powder, 10%-20% of zinc powder and 1%-5% of aluminum paste, and the component B comprises 30%-50% of cashew nut shell oil phenolic amide and 10%-30% of polyamide. The graphene anticorrosive coating provided by the invention is safe and environment-friendly, is moderate in cost, simple and convenient in process, stable in storage, excellent in adhesive force on base materials such as steel, iron and the like, excellent in mechanical performance such as flexibility, wear resistance performance and the like, and prominent in protective effects in chemical media such as an acid, an alkali, a salt and the like, shows excellent protective performance such as high and low temperature resistance, high salinity resistance and the like in a condition of a simulation marine environment experiment, and can be applied as primer for an anticorrosive coating in ocean engineering with various steel and iron materials.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

Sliver-powder conducting glue and its production

InactiveCN1939999AImprove electrical performanceEpoxy resin adhesivesElectrically-conducting adhesivesRoom temperatureHydrazide

Aluminum paste conductive glue and its production are disclosed. The glue consists of epoxy resin 10-20 proportion, acid anhydride curing agent 5-25 proportion, active diluting agent 1-10 proportion, curing improver 0.01-0.1 proportion, flake aluminum paste 5-85 proportion, grain aluminum paste 5-85 proportion. The process is carried out by curing at 120 degree for 30mins, and storing at room temperature for 3 months. The acid anhydride curing agent substitutes 1,3-diazole, dicyanodiamide, organic hydrazide or their modifiers as latent curing agent. It has excellent performances.

Owner:上海特视精密仪器有限公司

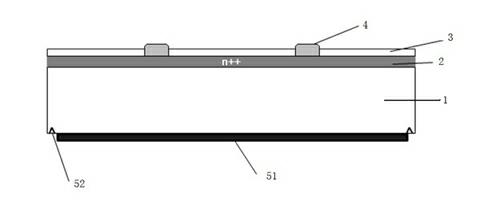

Polymer solar cell and preparation method thereof

InactiveCN102447064AImprove photoelectric conversion efficiencyImprove the utilization rate of sunlightSolid-state devicesSemiconductor/solid-state device manufacturingCarbon nanotubeCharge carrier mobility

The invention relates to a polymer solar cell, which includes a transparent electrode, a donor material, an active layer material, a receptor material and a metal electrode, wherein a transparent base body which is covered by ITO (Indium Tin Oxide), FTO (Flouride-doped Tin Oxide), ATO (Arsenic Trioxide), graphene, carbon nanotubes or a conjugated polymer thin film is used by the transparent electrode; a nano composite material of conjugated polymer, a metal nanomaterial and a semiconductor quantum point nano material is adopted as the donor material; the active layer material is a nano composite material of conjugated polymer, graphene, carbon nanotubes or fullerene and derivatives thereof in the presence of a modifier; graphene, carbon nanotubes or fullerene and the derivatives thereof are adopted as the receptor material; and the metal electrode is made of silver paste, aluminum paste, silver aluminum paste or metal paste. The donor material, the active layer material, the receptor material and the metal paste are printed on the transparent electrode by using an ink printing machine in sequence, and are subjected to drying treatment at 50-100 DEG C in sequence to obtain the polymer solar cell. The cell has high utilization rate to sunshine, high carrier mobility, high compatibility of donor and receptor, high photoelectric conversion efficiency, simple and convenient preparation process and capability of realizing large-scale industrial application.

Owner:东莞市万能电池实业有限公司

Preparation method of aluminum paste for water paint

InactiveCN101633798AGood dispersionAccelerated corrosionPigmenting treatmentPaints with free metalsAlcoholDistilled water

The invention discloses a preparation method of aluminum paste for water paint, comprising the steps: firstly, realizing hydroxylation on the surface of the raw material of aluminum powder; adding siloxane for producing silanol by a hydrolytic reaction; combining the siloxane with a hydroxyl group on the surface of the aluminum powder; coating a layer of protective film on the surface of the aluminum powder; and grinding and preparing aluminum paste for water paint by using distilled water as a solvent through a ball mill. The aluminum paste for water paint has good dispersibility in alcohol solvents and water solvents, excellent corrosion resistant performance, weather resistant performance and good metal effect and can be used as an environmental protection metal pigment for environmental protection water paint, automobile finish and water printing ink.

Owner:KUNMING UNIV OF SCI & TECH

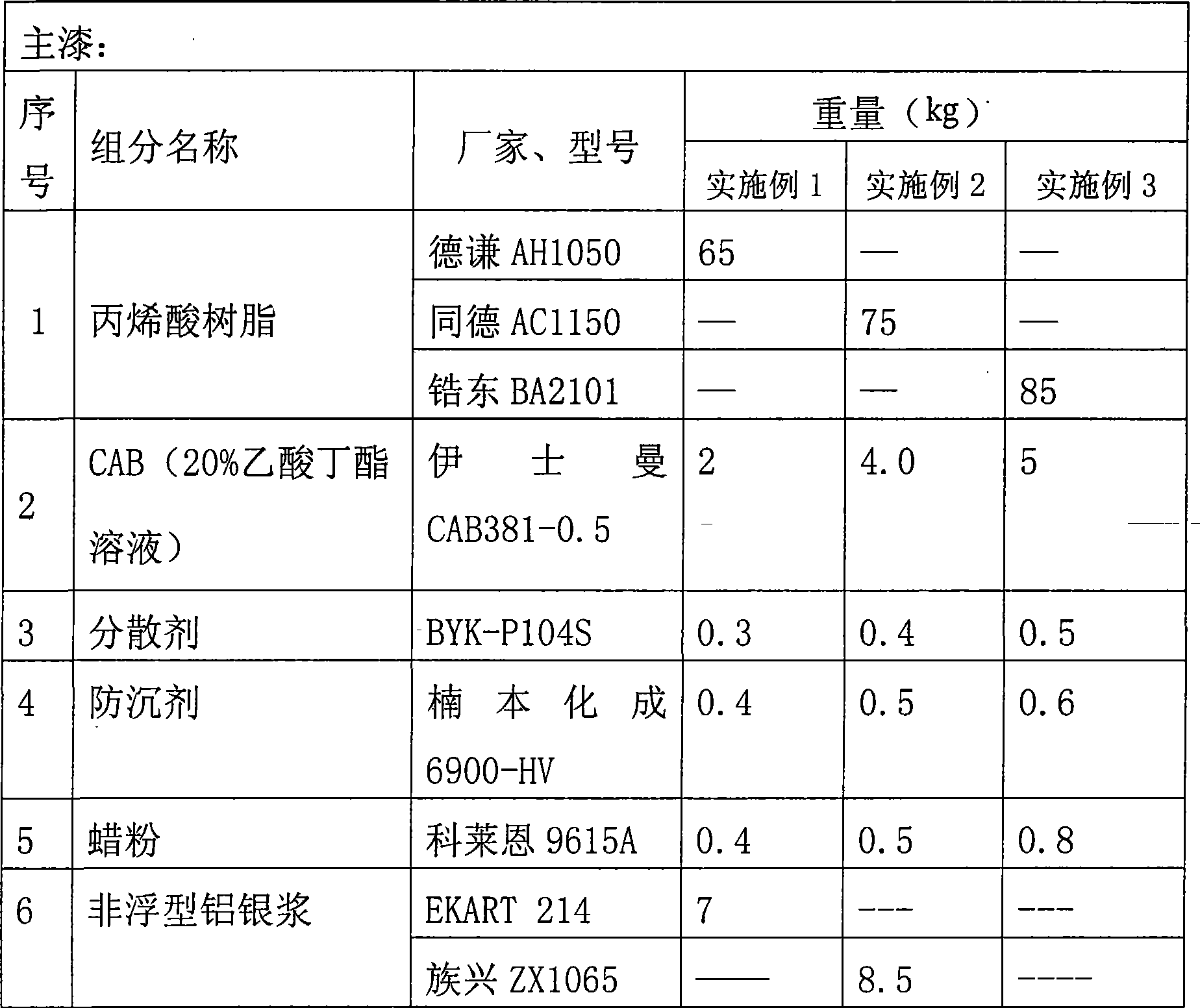

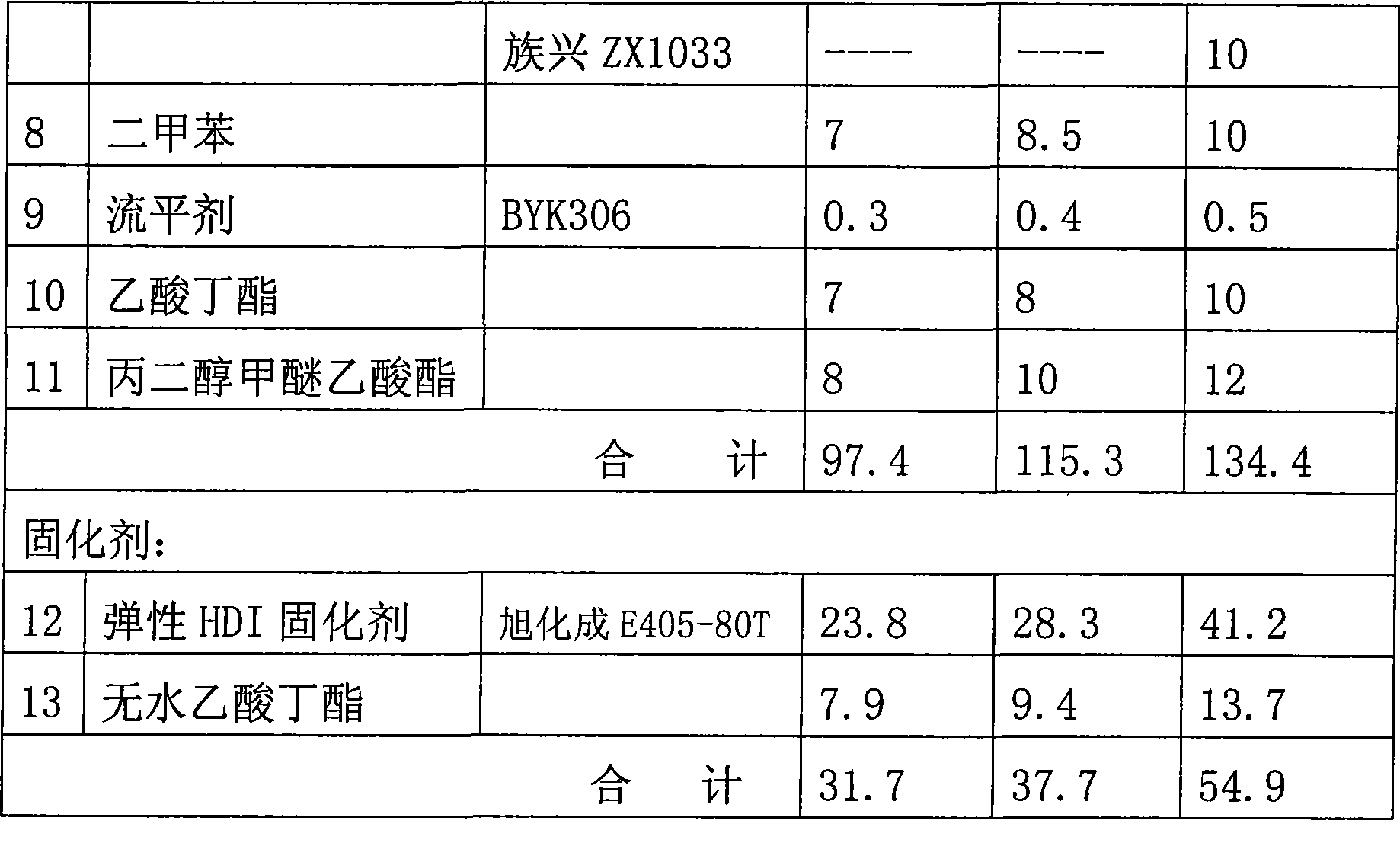

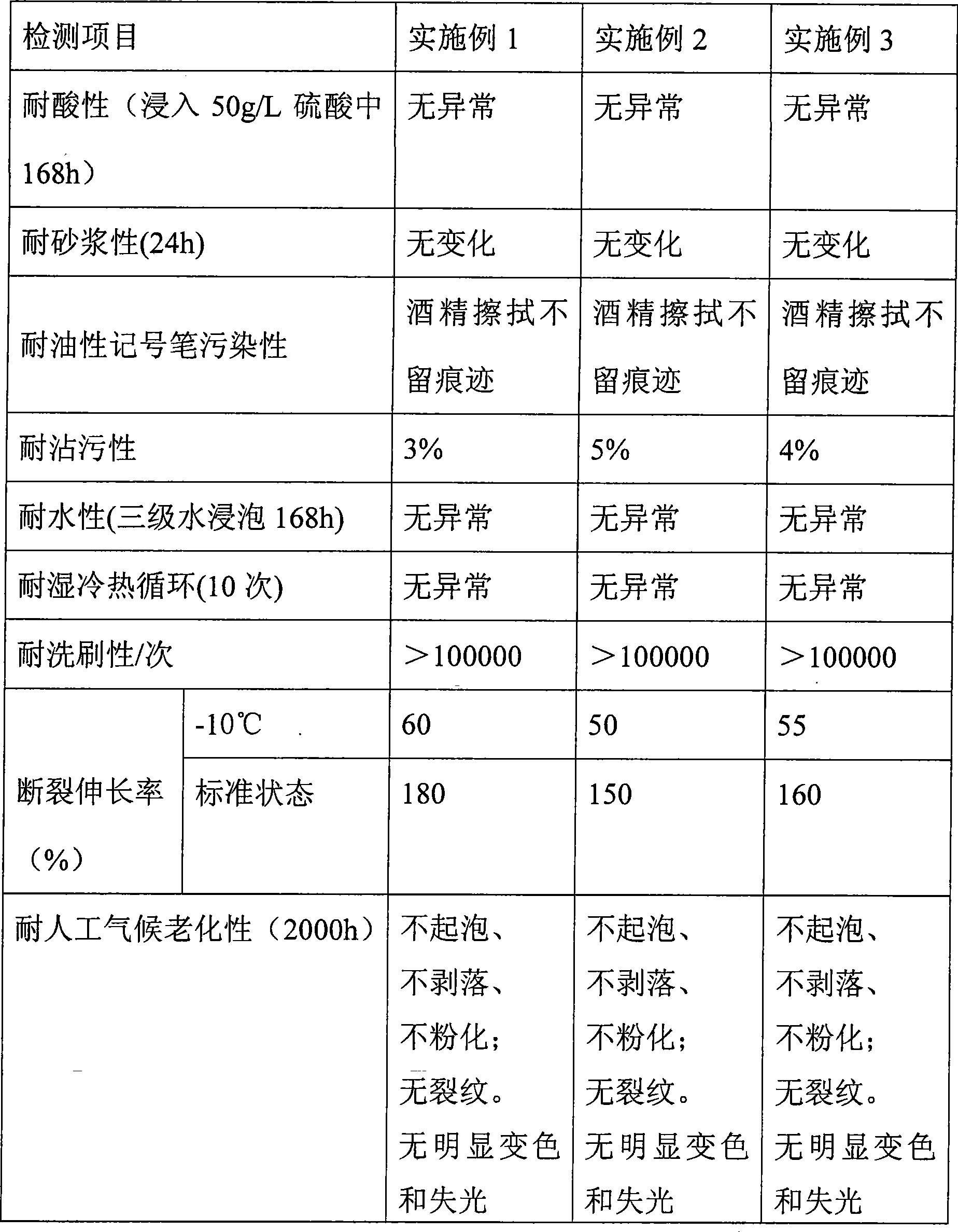

Elastic polyurethane silver paint and preparation method and use method thereof

ActiveCN101386771AGood room temperatureIncrease elasticityLiquid surface applicatorsPolyurea/polyurethane coatingsWaxWeather resistance

The invention discloses elastic polyurethane silver paint. Main paint of the elastic polyurethane silver paint is prepared from compositions according to the following weight proportion: 65 to 85 percent of a hydroxy acrylic acid resin, 2 to 5 percent of 20 percent CAB381-0.5, 0.3 to 0.5 percent of a dispersant, 0.4 to 0.6 percent of an anti-settling agent, 0.3 to 0.5 percent of a flatting agent, 0.4 to 0.8 percent of wax powder, 7 to 10 percent of non-leafing aluminum paste, 7 to 10 percent of dimethylbenzene, and 15 to 22 percent of mixed solvent; a curing agent of the elastic polyurethane silver paint is formed by mixing compositions according to the following weight percent: 75 percent of elastic HDI curing agent, and 25 percent of absolute butyl acetate; and the weight proportion of the main paint to the curing agent is calculated based on a hydroxyl value of acrylic acid resin and the NCO content of the curing agent, and OH / NCO is equal to 1 to (1.05-1.15). The elastic polyurethane silver paint has excellent weather resistance, stain resistance, scrubbing resistance and decoration property, is a coating variety with excellent performance which is second only to fluorocarbon paint, also has good elasticity at normal temperature and low temperature, can resist fine cracks, can prevent cracks on the surface of a coating caused by the fine cracks of a putty layer, and can also be used as finish for a complete anti-cracking aluminum-imitation plate coating system that flexible putty is matched with an elastic primer and an elastic middle coating.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

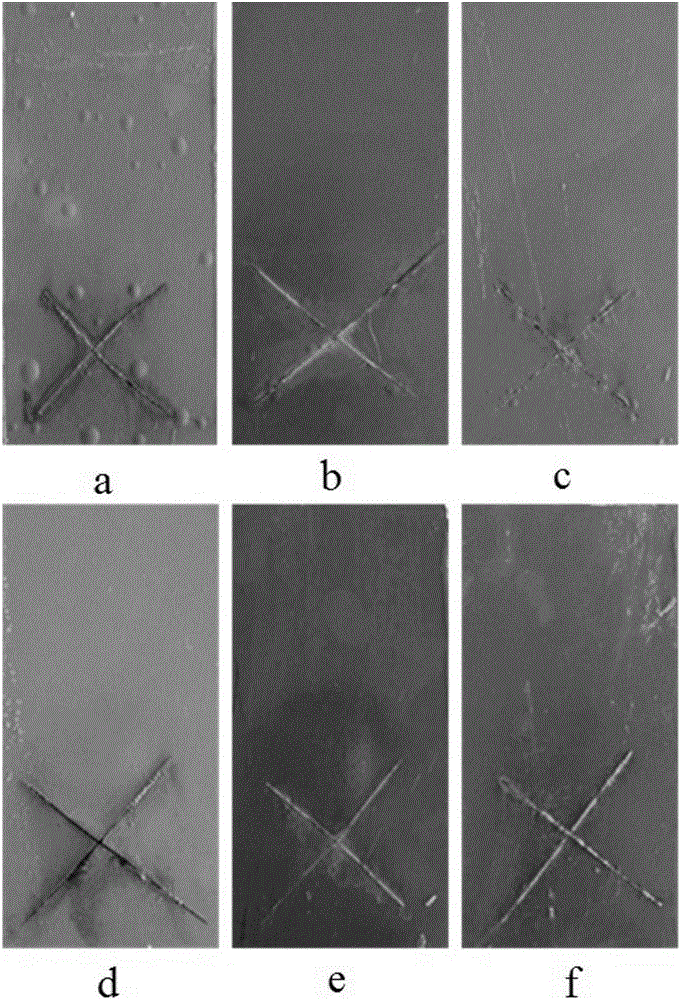

Method for manufacturing selective emitter solar cell from local laser melting phosphorosilicate glass

ActiveCN102110743ANo damageSimple processFinal product manufactureOther printing apparatusSilver pasteScreen printing

The invention discloses a method for manufacturing a selective emitter solar cell from local laser melting phosphorosilicate glass, which comprises the following steps of: texturing the surface of a chip; performing phosphorous diffusion by utilizing thermal diffusion, and generating the phosphorosilicate glass on the surface; diffusing the phosphorous element in the phosphorosilicate glass on a laser scanning part into the chip through local chip-melting; isolating the boundary; removing a damaged layer formed in the laser chip-melting process; removing the residual phosphorosilicate glass; forming a coating on the front surface; plating silver paste on the front surface of the chip in a screen printing mode, and obtaining a front electrode in a laser scanned area; plating the silver paste on a rear surface of the chip to form a back electrode, and plating aluminum paste on the rear surface of the chip in the screen printing mode to form a back electric field; and sintering the chip to make the metal electrode element and silicon in the chip eutectic. Only one diffusion process is present in the whole process, and the process is simple, has no damage to the silicon chip and has good gettering effect.

Owner:HANWHA SOLARONE QIDONG

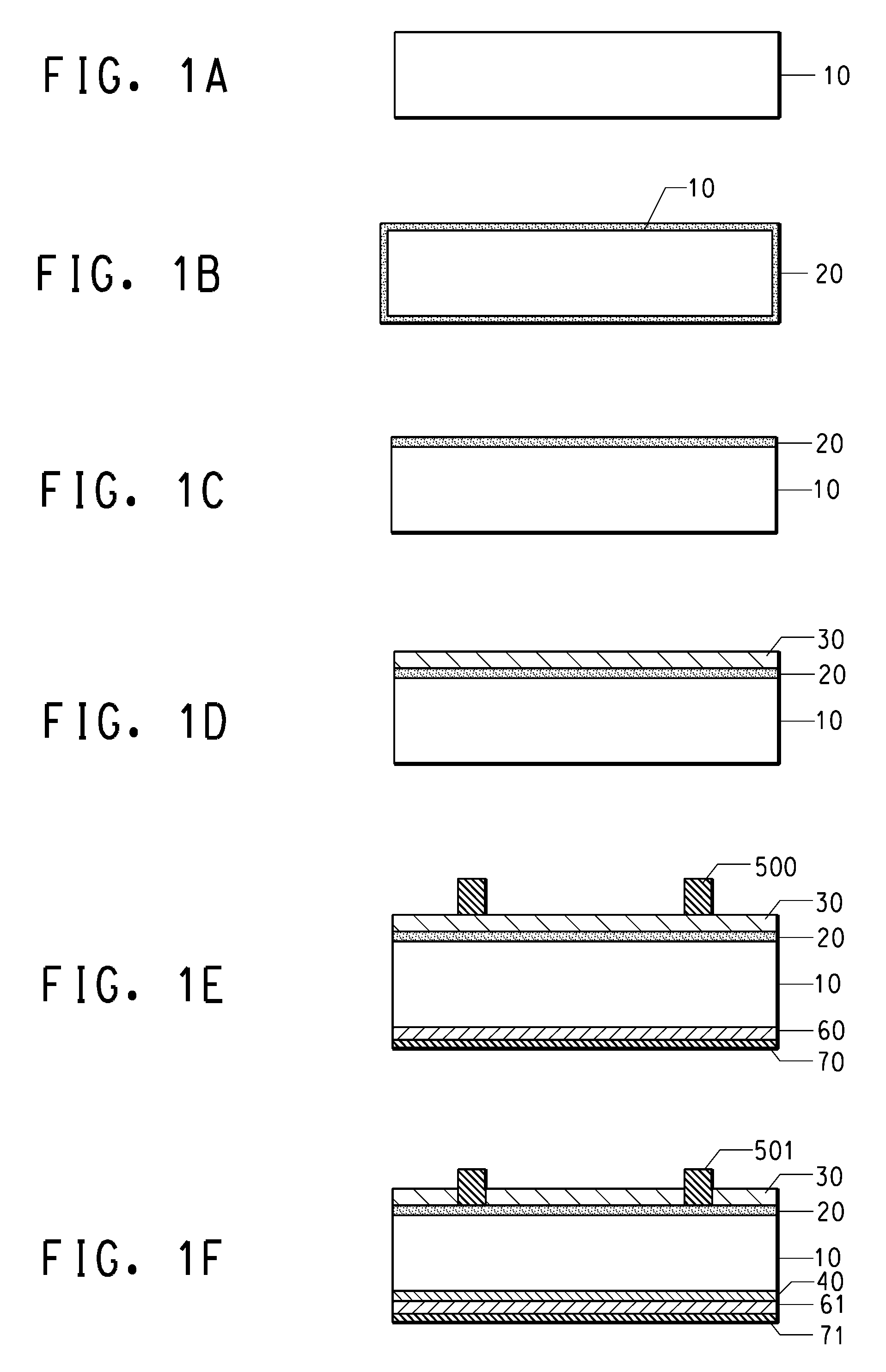

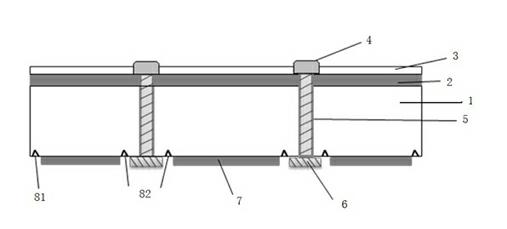

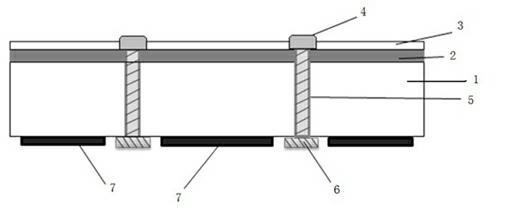

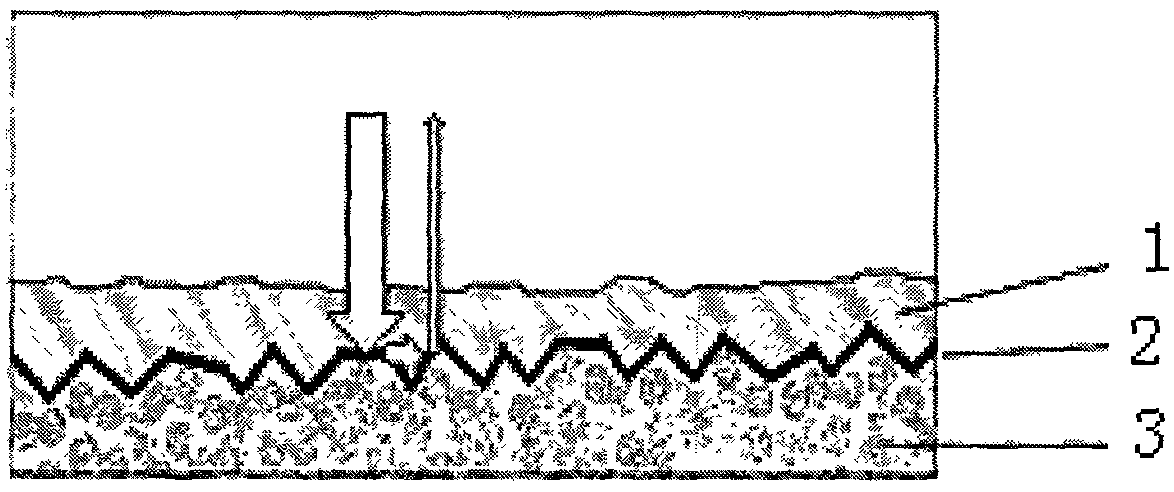

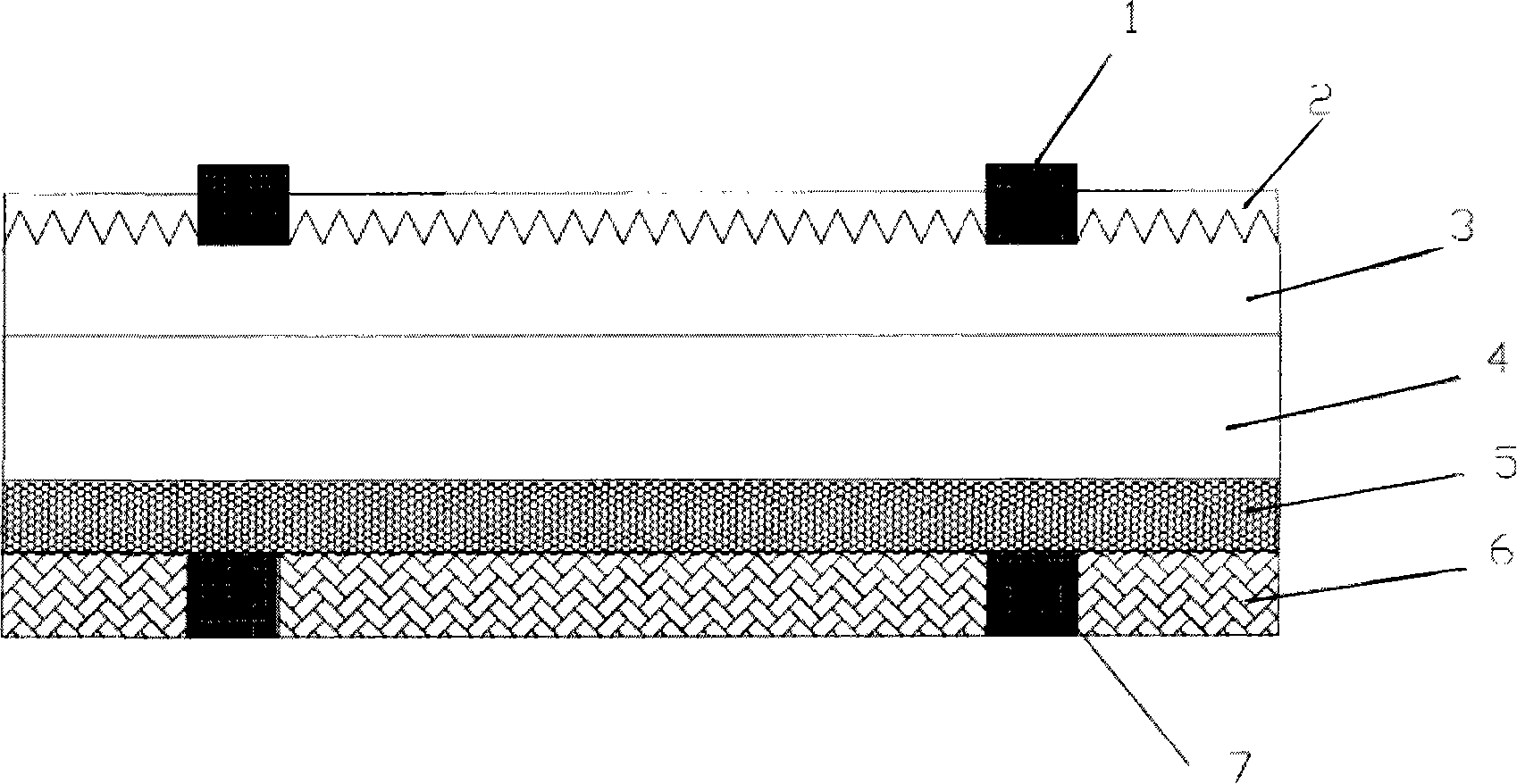

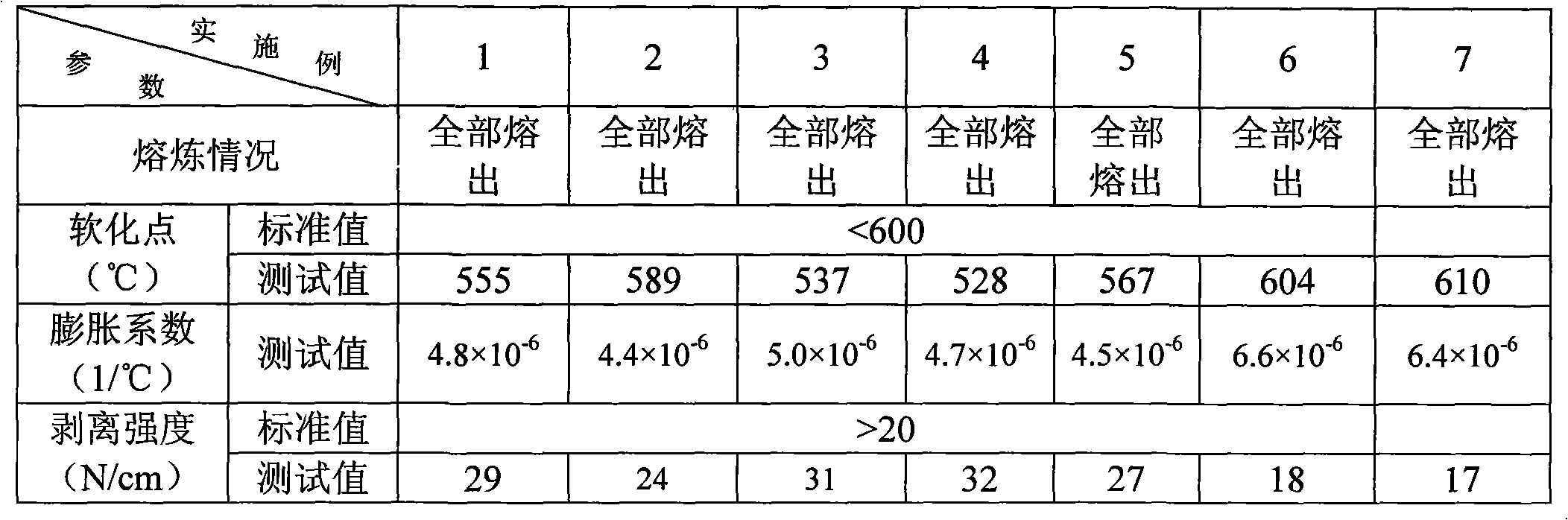

Novel aluminum emitter junction N type single crystal silicon solar battery

ActiveCN101150148ASolderabilitySolve problems that cannot be solved by firmness problemsFinal product manufacturePhotovoltaic energy generationScreen printingGrating

This invention provides a new type of type-N monocrystal silicon solar cells of Al back emission junction including: 1, Ag grating positive electrode, 2, SiNx reduction reflection layer of 80nm thick, 3, a positive N+phosphor diffusion layer of 0.3-0.5um thick, 4, type-N monocrystal silicon chip with the resistivity of 0.2-15ohmcm, 5, a P+ Al-Si alloy layer, 6,a back Al electrode, 7, a back AgAl master grating elctrode, in which, sintering of AlSi alloy and that of the back electrode are separated by two times of silk screen printing Al slurry and two times of sintering.

Owner:NINGBO ULICA SOLAR SCIENCE & TECHNOLOGY CO LTD

A reworking method on degraded products after the printing of crystal silicon solar battery

ActiveCN101217169AImprove pass rateImprove yieldFinal product manufactureSemiconductor devicesFailure rateSilver paste

The invention discloses a rework method of defective products of crystalline silicon solar cells after printing. The method includes the following three steps: an aluminum paste at the back surface of a cell is removed by using an HCl cleaning liquid; silver pastes at the positive and negative surfaces of the cell is removed by using isopropanol; the cell, the pastes of which is basically removed is treated with deep cleaning by using the deep cleaning liquid so as to thoroughly clean tiny impurities. The conversion efficiency of the cell can achieve the level of a normal cell by using the method for processing, and the appearance is not different from the normal cell, thus the invention achieves the purpose of rework cleaning. The failure rate of the silk screen printing of the cells is reduced to about 0.2 percent from original about 2 percent, thereby increasing the qualified rate and the yield of the silicon solar cells.

Owner:ZHEJIANG FORTUNE ENERGY

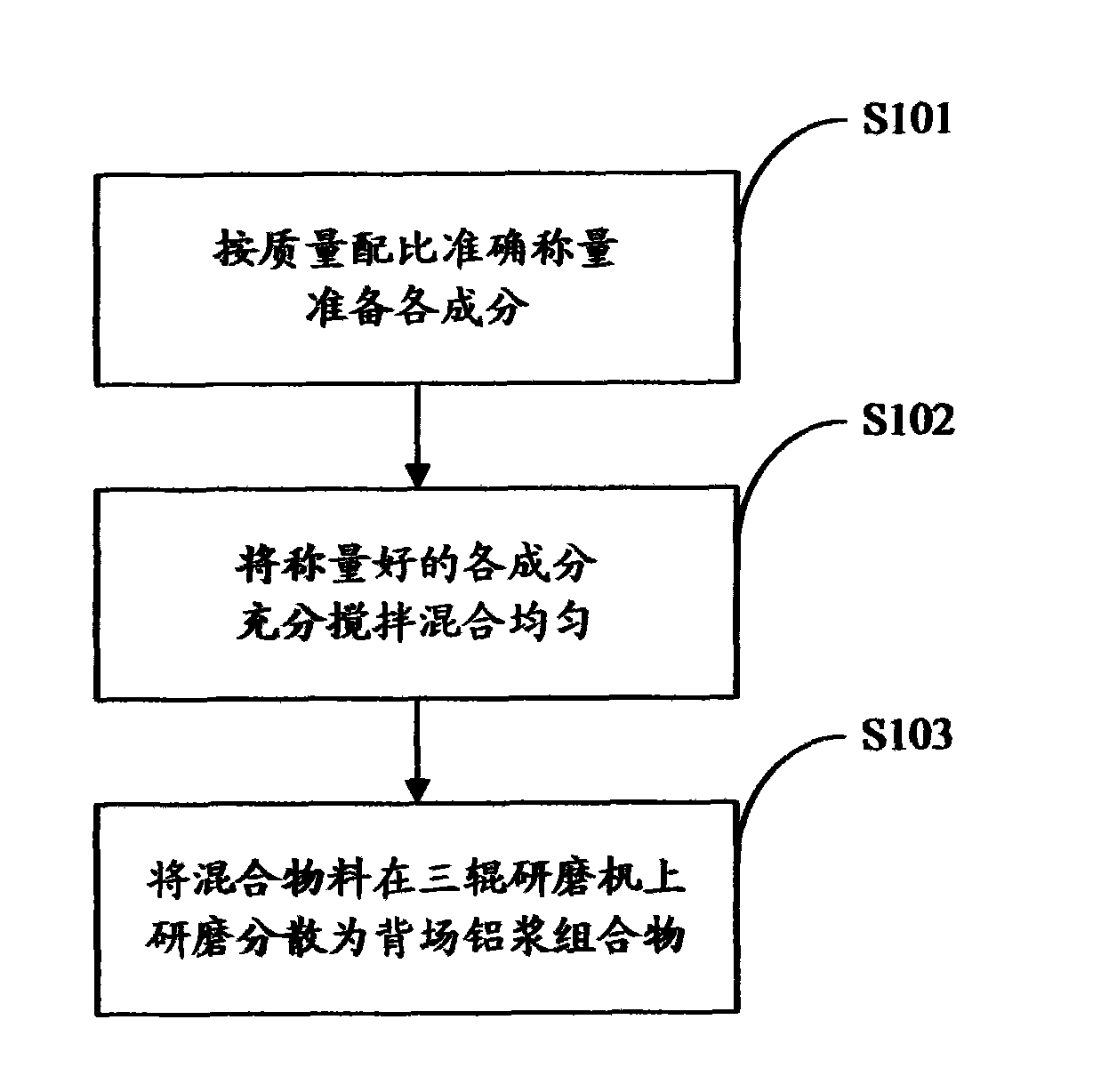

Back field aluminum paste composition of solar battery and preparation method thereof

InactiveCN101916610AReduce stressReduce warpageNon-conductive material with dispersed conductive materialCable/conductor manufactureMass ratioDiameter ratio

The invention relates to a back field aluminum paste composition of a solar battery, wherein the back field aluminum paste composition of the solar battery comprises the following components in percentage by weight: 70-76 percent of aluminum powder, 1-3 percent of glass binder phase and 20-30 percent of organic carrier, wherein the aluminum powder is formed by mixing fine aluminum powder with grain diameter of 3-5mum and coarse aluminum powder with grain diameter of 6-8mum in a predetermined mass ratio, and the grain diameter ratio of the fine aluminum powder to the coarse aluminum powder is greater than 0.414. In the back field aluminum paste composition of the solar battery and the preparation method thereof provided by the technical scheme of the invention, by reasonably designing the grain diameter ratio of the fine aluminum powder to the coarse aluminum powder, the stress generated in process of sintering is minimum, therefore, the purpose of reducing warping is realized.

Owner:CHANGZHOU YINGDE ENERGY TECH

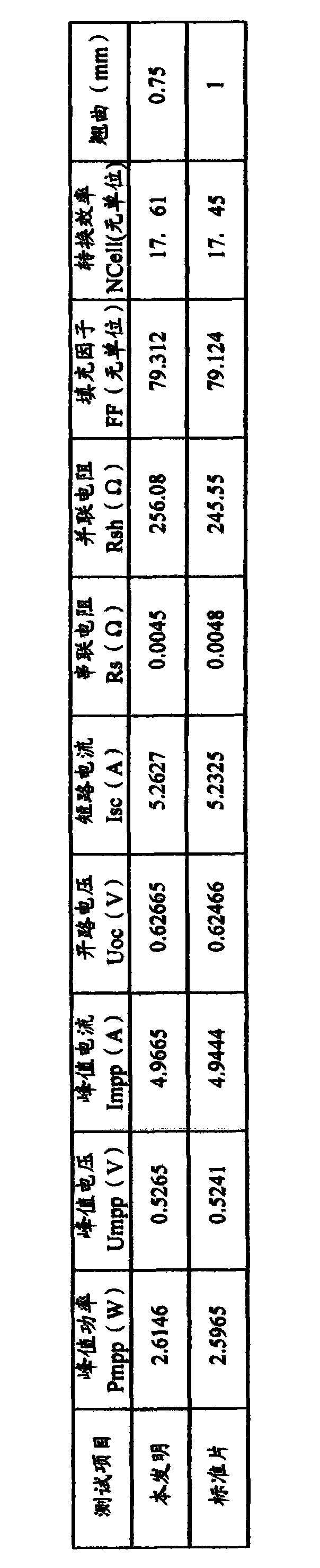

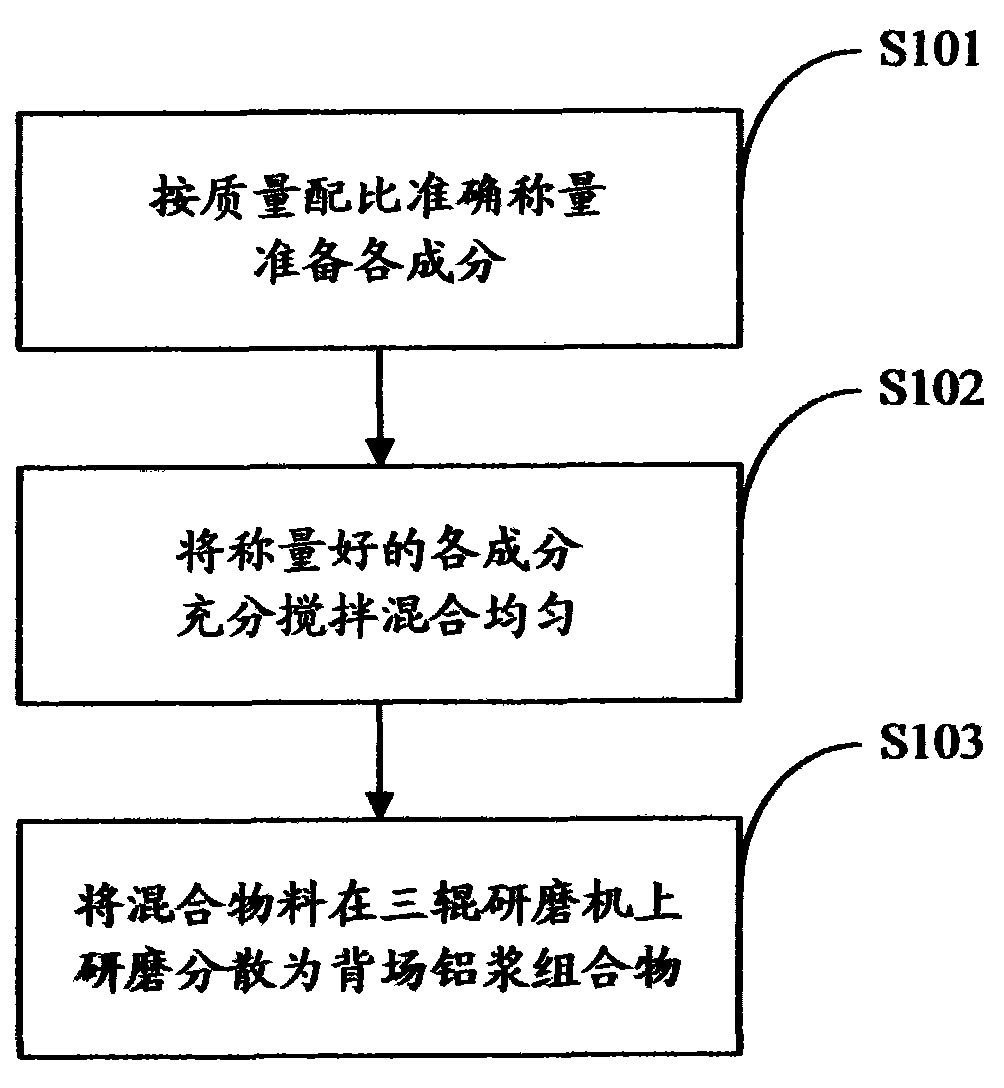

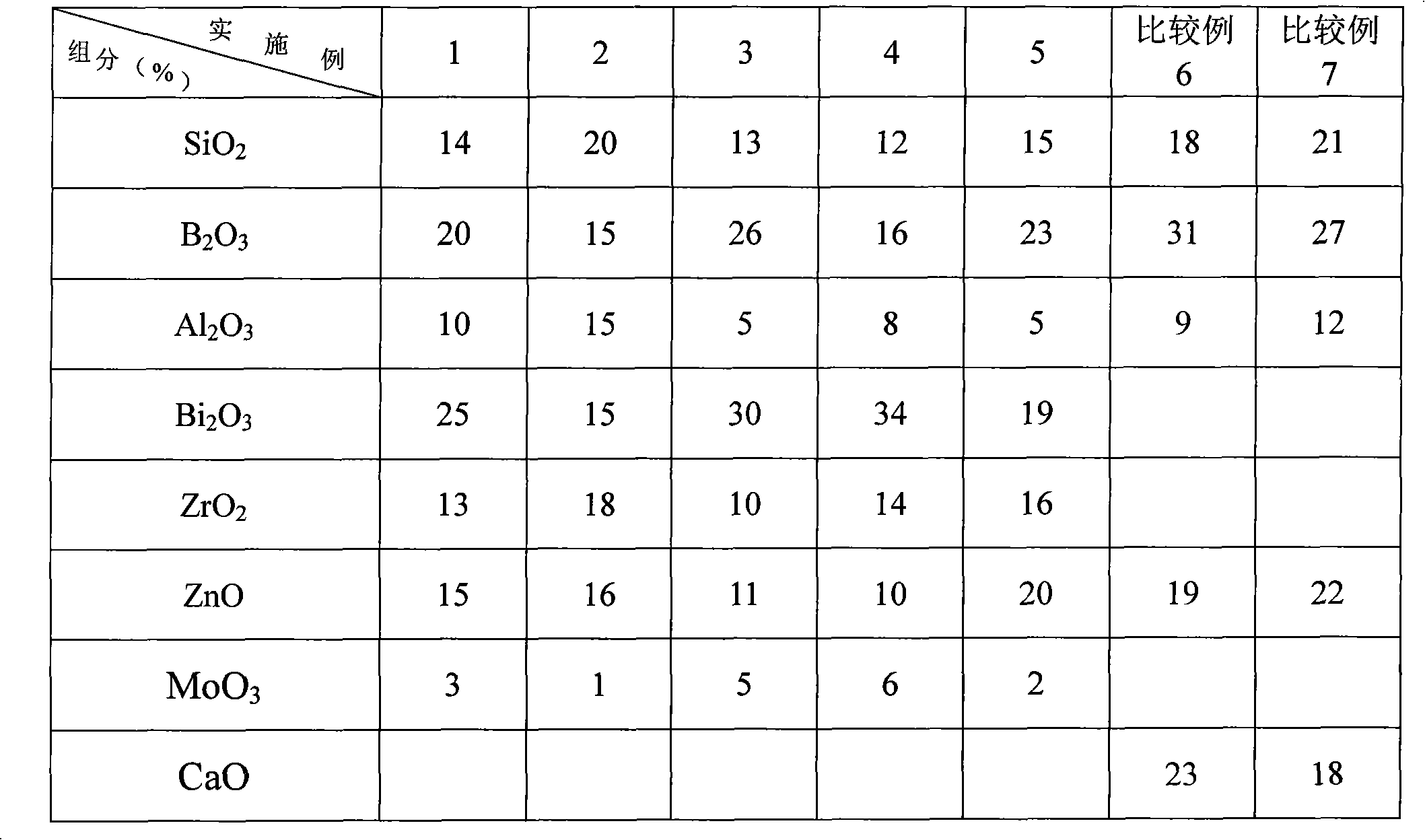

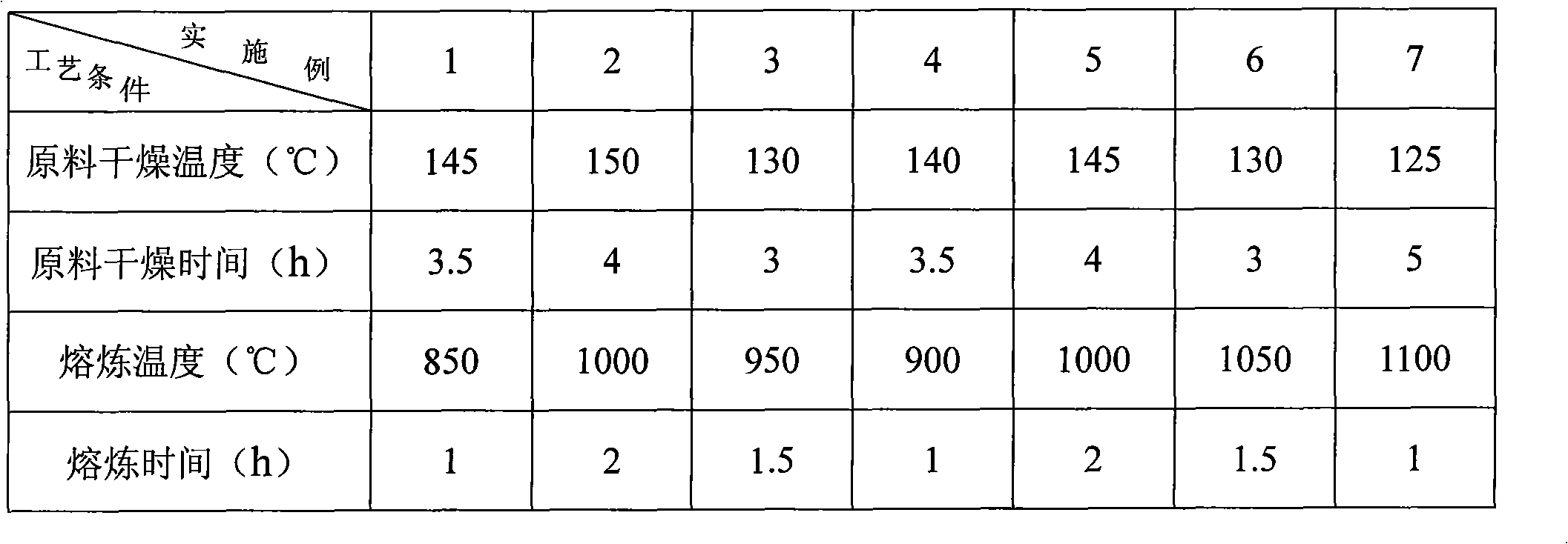

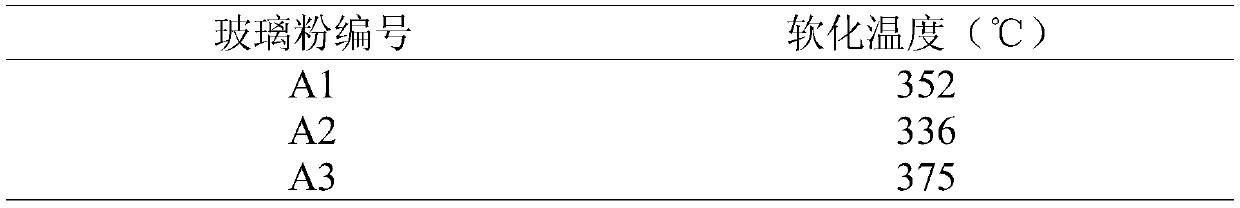

Inorganic adhesive for aluminum paste of silicon solar cells and preparation method thereof

ActiveCN101555388ASmall expansion coefficientLess bendingFinal product manufactureInorganic adhesivesAdhesiveSilicon solar cell

The invention provides inorganic adhesive for the aluminum paste of silicon solar cells and a preparation method thereof. The inorganic adhesive comprises the following components by the weight part: 10% to 20% of SiO2, 15% to 30% of B2O3, 5% to 15% of Al2O3, 15% to 35% of Bi2O3, 10% to 18% of ZrO2, 10% to 25% of ZnO and 1% to 8% of MoO with the total amount being 100%. The preparation method comprises the following steps: putting the components forming the inorganic solvent into a mixer to mix the components uniformly; loading the mixed components into a porcelain crucible and placing the porcelain crucible into a baking oven to be dried at the temperature of 120 to 150 DEG C for 3 to 5 hours; then, placing the porcelain crucible into a high-temperature furnace to melt at the temperature of 800 to 1,100 DEG C for melting for 1 to 2 hours; carrying out water-quenching and oven-drying; milling the components with a planetary ball mill until the particle size is lower than 10 mum; and oven-drying the components to obtain the final product of the inorganic adhesive. The glass powder has lower softening temperature and high adhesion when the aluminum paste prepared from the inorganic solvent is used for sintering, so that the aluminum powder layer can be firmly adhered to silicon chips; the expansion coefficient is lower after sintering; the bending degree of cell chips is lower; and the breakage rate is reduced.

Owner:WUXI RUXING TECH DEV +1

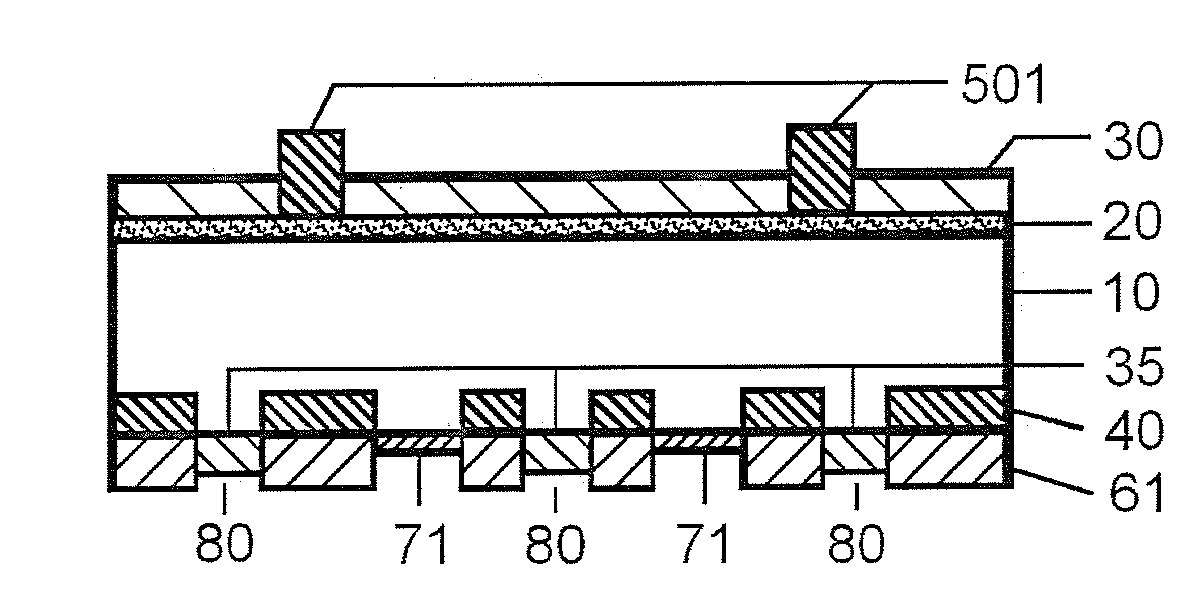

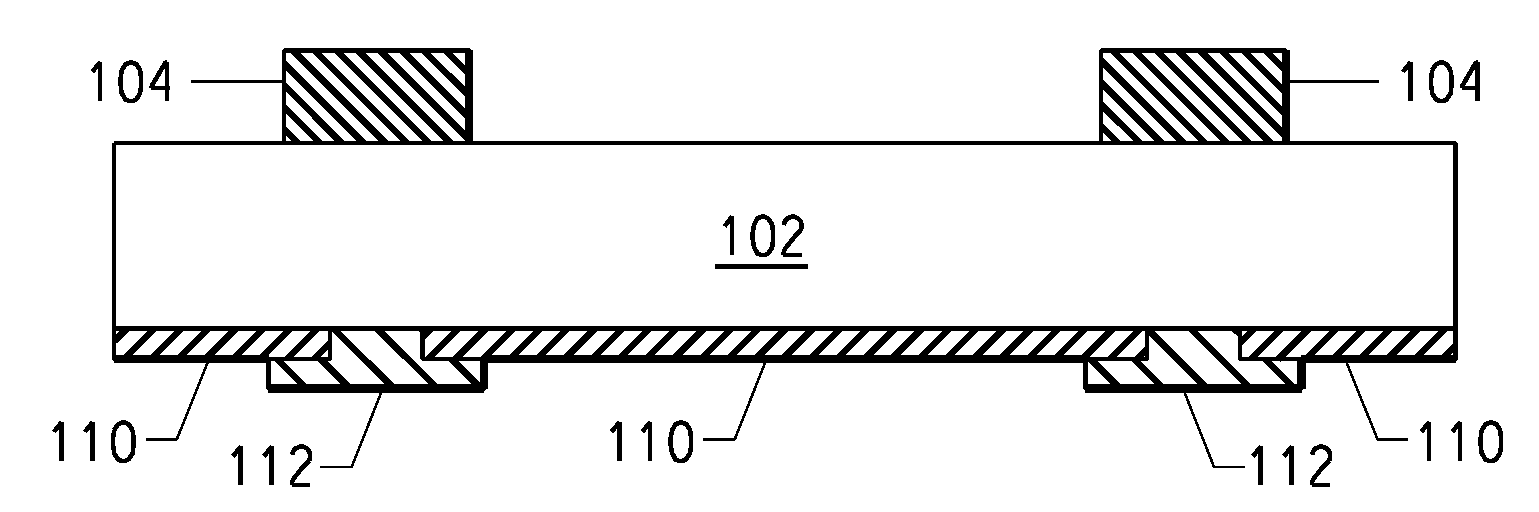

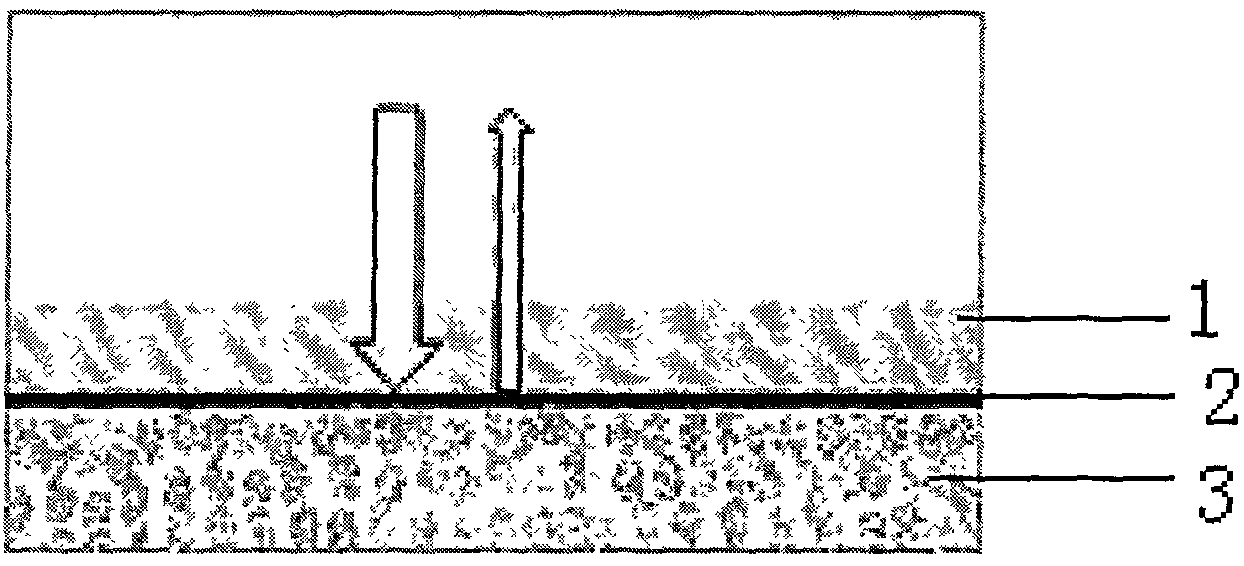

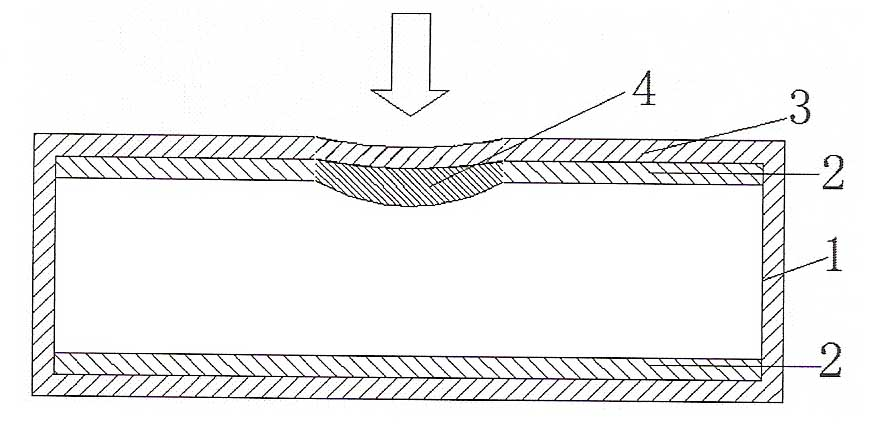

Method for manufacturing back passivation point contact solar cell of aluminum slurry burning-through local thin film

InactiveCN103996743AReduce manufacturing costSimple stepsFinal product manufacturePhotovoltaic energy generationThin membraneSolar battery

The invention provides a method for manufacturing a back passivation point contact solar cell of an aluminum slurry burning-through local thin film. The method comprises the steps of damage removing of a silicon wafer, woolen manufacturing, cleaning, phosphorus diffusion, back phosphorosilicate glass removing, back polishing, phosphorosilicate glass removing and cleaning, back aluminum oxide / silicon nitride laminated thin film growing, front silicon nitride antireflection thin film growing, reverse printing of burning-through aluminum paste, drying, reverse printing of a back electrode and an aluminum layer, front printing of a silver grid line, sintering and testing. burning-through type aluminum paste can be adopted by back point contact of the cell, meanwhile, thin film perforating is achieved, aluminum silicon contact is achieved, a local aluminum back field is formed at the contact position, and therefore two processing steps (laser perforating of the thin film, and aluminum paste sintering and silicon contact) are reduced into one step (adopting of aluminum paste of the burning-through thin film, and needing no thin film perforating in advance), investment of laser equipment is saved, idle printing equipment is fully utilized, and the method has the practical significance.

Owner:ALTUSVIA ENERGY TAICANG

Environment protective polyurethanes hammer paint

ActiveCN101353550AGood solvent resistanceGood acid and alkali resistancePolyurea/polyurethane coatingsOleoresinDimethyl siloxane

The invention discloses an environmental-protection polyurethane hammer paint which is applied to wood surface decoration and protection and consists of a component A, a component B and a component C; when in use, the component A, the component B and the component C can be evenly mixed by the weight ratio that component A: component B: component C is equal to 1: 0.4 to 0.6: 0.5 to 0.6; wherein, the component A consists of: short oil alkyd resin, 40 to 60 parts; long oleoresin, 2 to 5 parts; dispersing agent, 0.2 to 0.5 part; anti-sedimentation agent, 0.4 to 0.9 part; propylene glycol ether acetate 3 to 6 part; divalent ester 1 to 3 parts; pigment, 0 to 30 parts; defoamers, 0.2 to 0.5 part; leveling agent, 0.2 to 0.7 part; non-floating-type aluminum paste, 1 to 5 parts; n-butyl acetate 5 to 15 parts, polydimethylsiloxane, 0.1 to 0.5 part; the component B consists of the following materials by weight ratio: HDI trimer poly isocyanate: HDI-TDI trimer: n-butyl acetate is equal to 2 to 4: 3 to 5: 1 to 4; the component C consists of the following materials by weight ratio: n-butyl acetate: propylene glycol methyl ether acetate is equal to 7 to 9: 1 to 3. The invention has the advantagesof: 1. good paint film solvent resistance and acid and alkaline resistance, bright color, clear texture, and good hammer effective; 2. high paint film hardness and wide application range, not only being applicable to wood surface, but also being applicable to metal surface decoration and protection; and 3. triphenyl-free, low VOC, and high solid content, and meeting the requirements on environmental protection.

Owner:GUANGDONG SANVO CHEM IND TECH

Preparation method of water-borne coating additive for oily aluminum paste and water-borne coating prepared from water-borne coating auxiliary

InactiveCN103289012AExpensive to fixExcellent gas performanceCoatingsPigment treatment with macromolecular organic compoundsPhosphateSolvent

The invention relates to a water-borne coating additive, more specifically to the water-borne coating additive by the application of which oily aluminum paste may be directly used in a water-bone coating, and a preparation method of the water-born coating. The water-borne coating additive is an acrylate phosphate containing phosphate and hydroxyl. The content of phosphate is 5 to 25% by weight, and the content of hydroxyl is 1 to 5% by weight. Molecular weight is controlled at a range from 4000 to 20000, and molecular weight distribution Mw / Mn is 1.1 to 2.0. The oily aluminum paste is dispersed by a solvent, and then the water-borne coating additive is added. A dispersion liquid can be formed by wrapping treatment, and the dispersion liquid can be directly added into a water-borne resin to produce the water-borne coating. Operation processes of the method are simple, storage stability of the product is excellent. Gas generation of the aluminum paste (aluminum powder) in water can be prevented effectively. Resistances to high pressure conductivity, weather, heat and humidity, acid, alkali and pipeline circulation are excellent, and adhesive force to base materials is strong. No aluminum powder will drop in a long term.

Owner:SHANGHAI NUOQIA CHEM IND

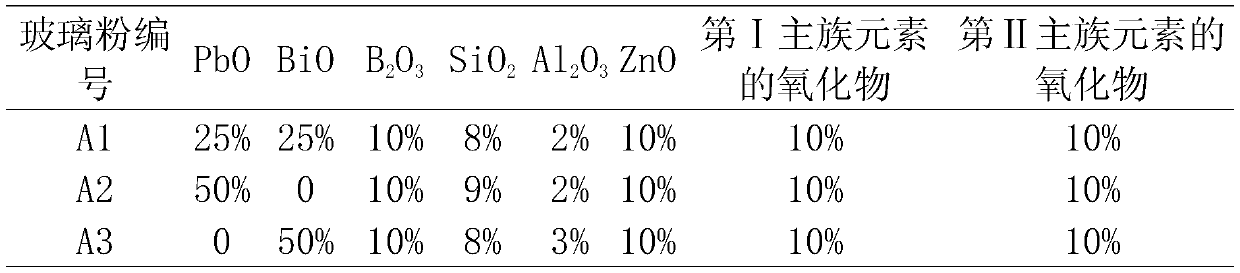

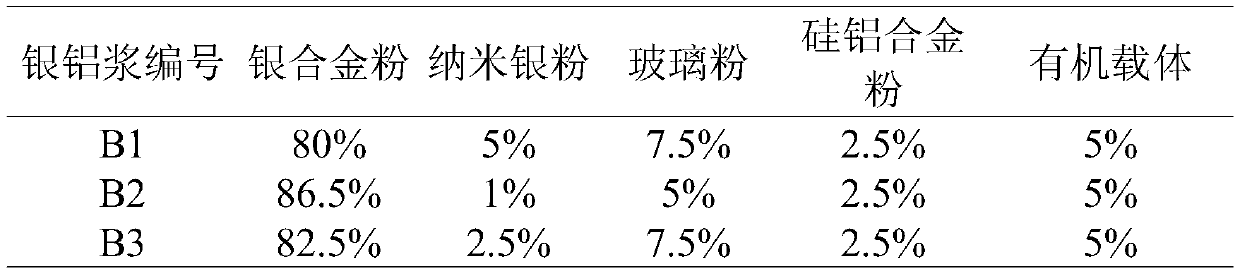

Glass powder and silver aluminum paste comprising glass powder and used on positive side of N-type double-sided solar cell

PendingCN110040968ALow softening temperatureIncrease the degree of vitrificationTransportation and packagingMetal-working apparatusMass ratioSilicon solar cell

The invention discloses glass powder and silver aluminum paste which comprises the glass powder and used on the positive side of an N-type double-sided solar cell. The silver aluminum paste comprisesconductive silver powder, silicon aluminum alloy powder, the glass powder and an organic carrier, wherein the glass powder is prepared from the following components in percentage by weight: 0-50% of PbO, 0-50% of BiO, 5-15% B2O3, 8-9% of SiO2, 2-3% of Al2O3 and 5-15% of ZnO; the mass ratio of silicon to aluminum in the glass powder is (4-5) to 1; the content of the conductive silver powder is 80wt% to 90wt%; the conductive silver powder comprises nano silver powder and silver alloy powder in a mass ratio of 1 to (18-90). The glass powder not only guarantees the corrosiveness of SiNx, but alsodoes not cause relatively strong metallized composition. The silver aluminum paste prepared by using the glass powder solves the problem of the contradiction between contact resistance and open circuit voltage when the silver aluminum paste is printed on the positive side of an N-type crystalline silicon solar cell.

Owner:NANTONG T SUN NEW ENERGY CO LTD

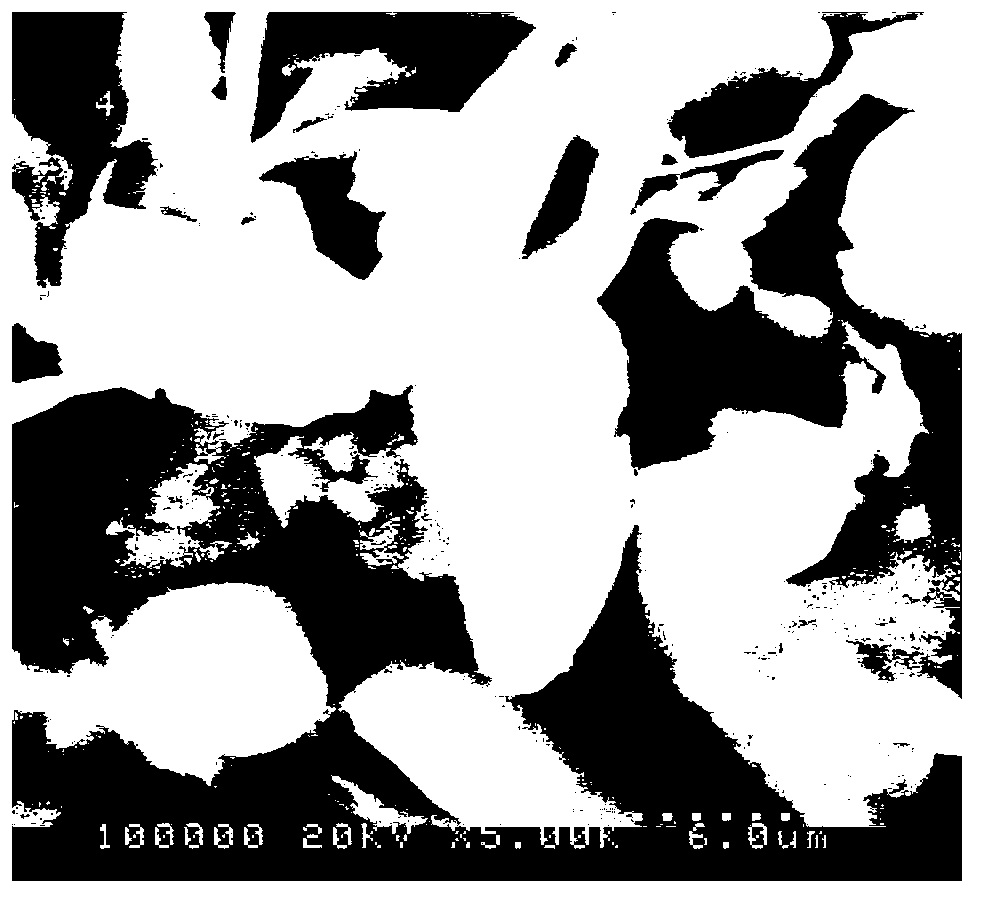

Method for manufacturing high-metal-sense aluminum silver paste

ActiveCN101708553AFlat surfaceNarrow particle size distributionPigment physical treatmentHigh carbonSteel ball

The invention discloses a method for manufacturing high-metal-sense aluminum silver paste, which is realized in a way that: high-carbon steel balls with the diameters of 0.4-1.0 mm are used as the milling medium of the ball mill, fine spherical aluminum powder (d50 is smaller than 5 mum), an organic solvent and lubricant are evenly mixed according to the weight proportion of 40:300:1, ball-milling is carried out in the ball mill for 25-50 hours, pressure filter is carried out on the discharged material, and the filtrate returns to the ball milling process for cycle use; press cakes enter the sieve classification process, the material passing through a 500-mesh sieve enters a wet whirl classification process and then pressure filter is carried out, and the filtrate returns to the sieve process for cycle use; and the press cakes enter the kneading process to be surface-treated, and then is packed to obtain the high-metal-sense aluminum silver paste. In the invention, small steel balls are used for carrying out mild transformation operation on the fine spherical aluminum powder for a long time, oil for the ball mill and oil for sieving are used separately, and the material passing through the 500-mesh sieve is processed in a wet classification way, so that the flaky aluminum pigment particles have the advantages of smooth surface and narrow particle size distribution, thereby ensuring the high metal sense of the aluminum paste.

Owner:长沙奥特金属颜料有限公司

Method for manufacturing novel ball aluminum pigment

ActiveCN101629027AGood dispersionImprove flicker performancePigment physical treatmentPigment treatment with non-polymer organic compoundsGlass ballFilter press

The invention relates to a method for manufacturing a novel ball aluminum pigment, which adopts a formula comprising the following raw materials: atomized ball aluminum powder, organic matters, aerosol and a ball milling medium. The method comprises the following steps: (1) mixing the atomized ball aluminum powder, the organic matters and the aerosol in a certain proportion and then putting the mixed raw materials in a vertical ball mill for milling by using glass balls with a diameter of 0.5-1 mm as the milling medium; (2) carrying out sieving and filter pressing to manufacture raw materials into an aluminum paste filter cake; and (3) adding the aluminum paste filter cake to a proper organic matter to knead so as to manufacture a finished ball aluminum pigment product.

Owner:长沙族兴新材料股份有限公司

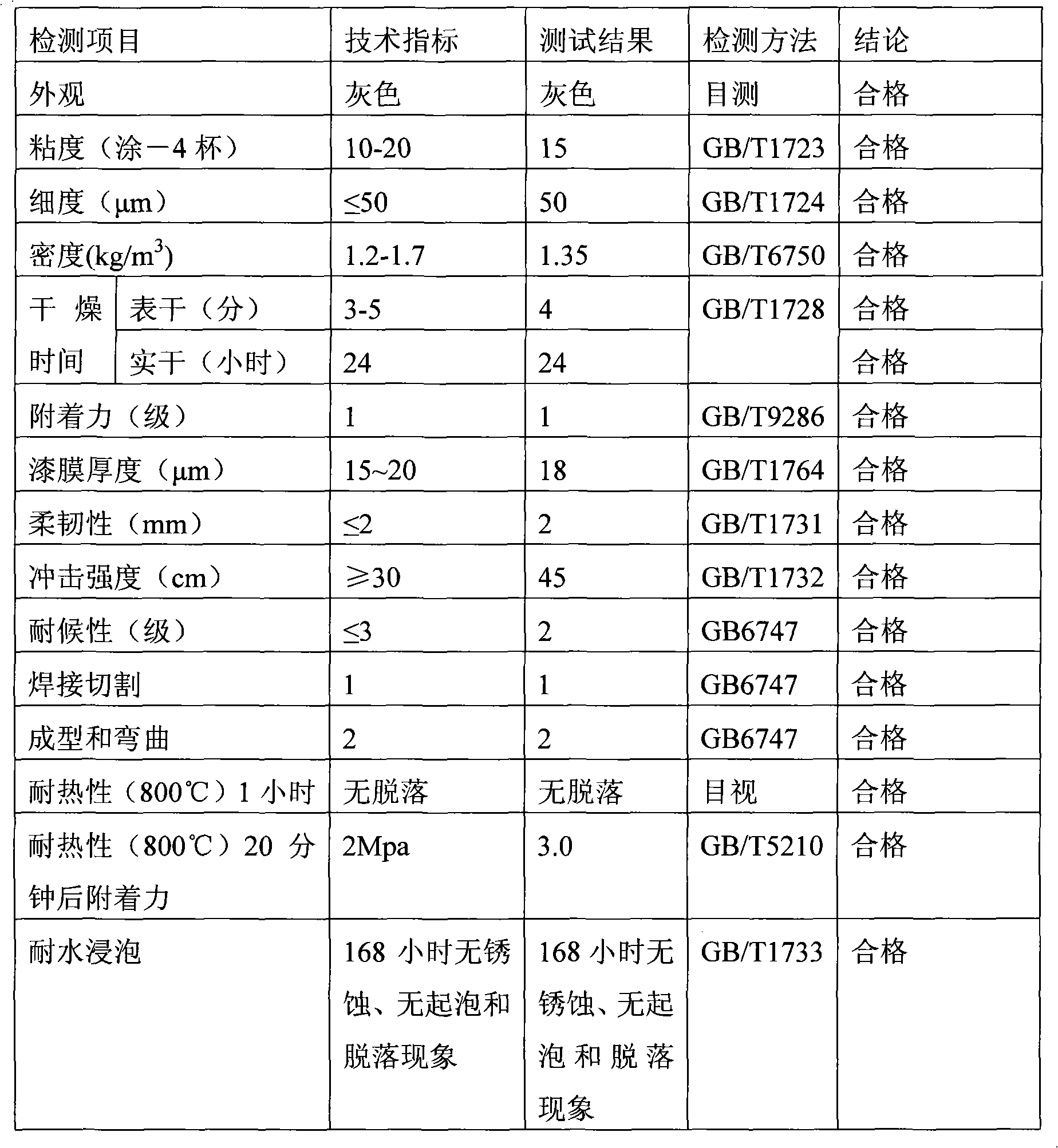

High-temperature resistant workshop primer and preparation process thereof

InactiveCN101619195AImprove high temperature resistanceReduce foggingAnti-corrosive paintsSodium BentoniteGas phase

The invention discloses a high-temperature resistant workshop primer, which consists of curing agent and slurry according to a weight ratio of 1:2-4, wherein the slurry comprises the following components in portion by weight: 10 to 30 portions of isopropanol, 0.5 to 4 portions of bentonite, 0.1 to 2 portions of nano gaseous silica, 0 to 5 portions of precipitated silica, 2 to 10 portions of butanol, 1 to 10 portions of industrial ethanol, 50 to 70 portions of zinc powder, 5 to 15 portions of dimethyl benzene, 0 to 20 portions of ferro-phosphorus powder, 0 to 10 portions of ferrotitanium powder, 0 to 5 portions of stainless steel powder, 0 to 2 portions of nickel powder, 0 to 2 portions of titanium white powder, 0 to 2 portions of alumina powder, 0 to 2 portions of precipitated barium sulfate, 0 to 5 portions of feldspar powder, and 0 to 2 portions of aluminum paste. The curing agent comprises the following components in portion by weight: 0 to 2 portions of ammonia water, 0 to 2 portions of sodium ethylate, 0 to 2 portions of potassium fluoride, 15 to 50 portions of ethyl silicate, 0 to 2 portions of AMP-95, 0.05 to 1 portion of sulfuric acid, 0 to 0.5 portion of potassium hydroxide, 3 to 15 portions of distilled water, 5 to 10 portions of industrial ethanol, 15 to 60 portions of isopropanol, and 0 to 10 portions of silicon resin. The temperature resistance of the high-temperature workshop primer can reach 800 DEG C, and the burned area of the workshop primer in welding seams and fire areas can be reduced after high-temperature processing such as welding, cutting, fire correcting and the like.

Owner:上海暄洋化工材料科技有限公司

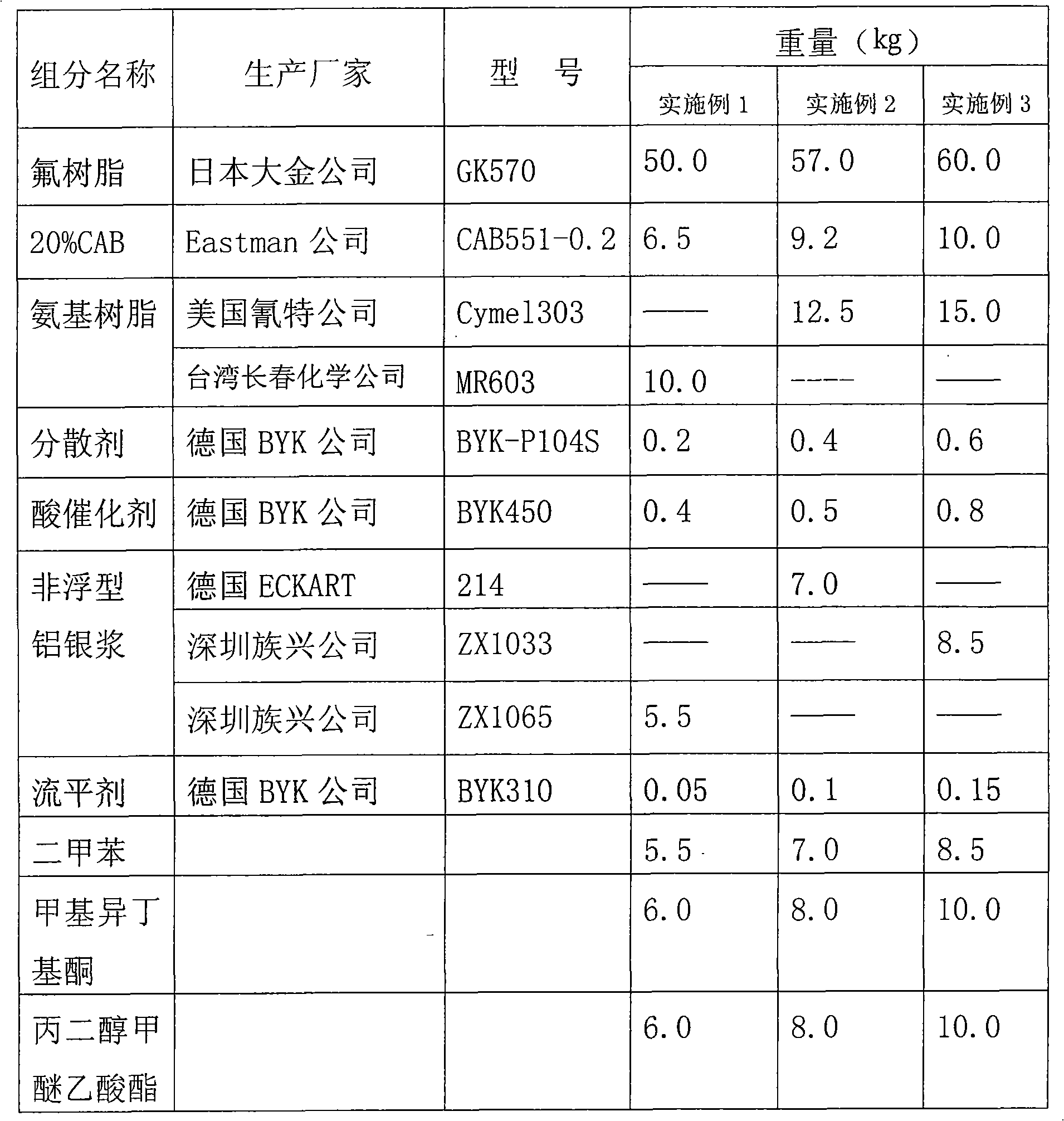

Single-component fluorine-carbon-aluminum powder baking varnish, preparation, special thinning agent and use method thereof

A single-component fluorocarbon aluminum paint comprises, by weight ratio, fluororesin 50 to 60, 20 percent CAB551-0.2 6 to 10, aminoresin 10 to 15, dispersant 0.2 to 0.6, acid catalyst 0.4 to 0.8, leveling agent 0.05 to 0.15, non-floating aluminum paste 5.5 to 8.5, pre-dispersant of the non-floating aluminum paste 5.5 to 8.5, and solvent 12 to 20, wherein the fluororesin is the polymer of tetrafluoroethylene / vinyl monomer and has a fluorine content of 35 to 40 percent; and the aminoresin is hexamethoxy methyl melamine resin with solid content equal to or larger than 98 percent. The method for producing the single-component fluorocarbon aluminum paint comprises the following steps: pre-dispersing the aluminum paste; stirring and mixing fluororesin, 20 percent CAB551-0.2 and aminoresin at low to middle speed, adding the dispersant, stirring at middle speed, adding the leveling agent, the acid catalyst and the solvent, and uniformly stirring at low to middle speed; adding the pre-dispersed aluminum paste under low-speed stirring, stirring and dispersing uniformly; and filtering to obtain the fluorocarbon aluminum paint. The invention further relates to a special diluting agent and the use method. The paint has a weathering resistance equal to or even larger than that of PVDF fluorocarbon paint, high hardness and greatly widened color selectivity, and can be re-coated only by baking at middle temperature without special treatment.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

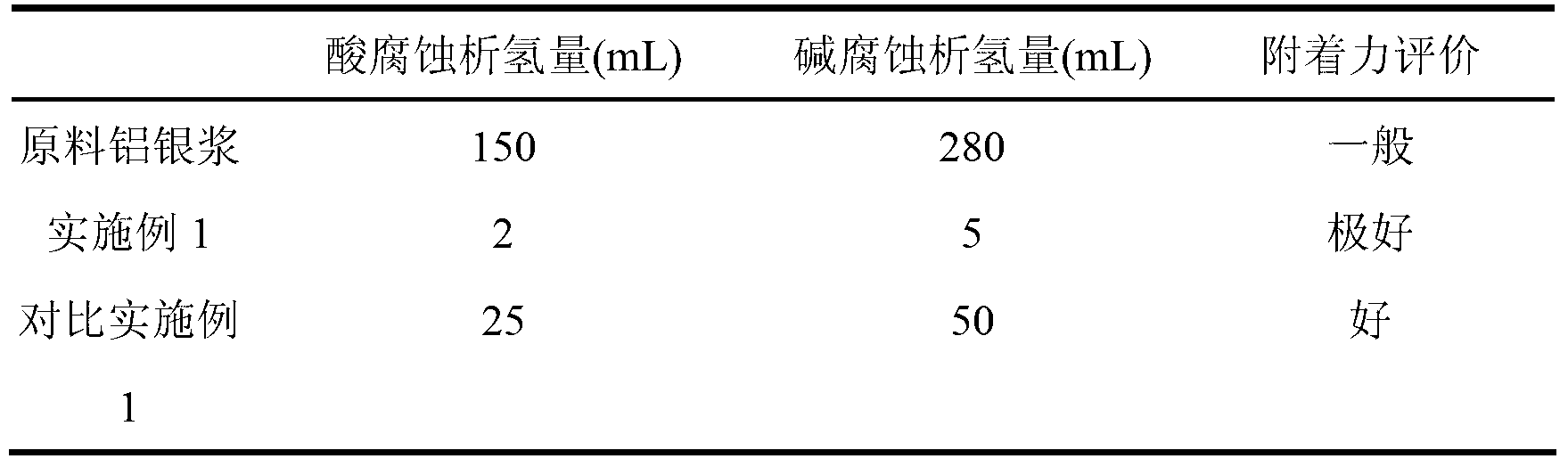

Preparation method of inorganic-organic double-layer coated type aluminum paste

InactiveCN103319916AEvenly dispersedImprove acid and alkali corrosion resistanceCoatingsPigment treatment with macromolecular organic compoundsSolventSilicon dioxide

The invention discloses a preparation method of an inorganic-organic double-layer coated type aluminum paste. The method comprises the following steps of: dispersing the aluminum paste in an alcohol-water mixed solvent to obtain a mixture; dropwise adding tetraethoxysilane into the obtained mixture, stirring the resulting product for hydrolysis reaction, cooling the obtained product after the hydrolysis reaction is finished, washing and filtering hydrolyzed products to obtain an inorganic silicon dioxide coated aluminum paste, dispersing the inorganic silicon dioxide coated aluminum paste in a benzene solvent, sequentially adding an organic coupling agent and an azo initiator while stirring, then dropwise adding an organic polymerized monomer, carrying out polymerization reaction in the presence of an inert gas, after the dropwise addition of the organic polymerized monomer is finished, increasing the temperature for further carrying out polymerization reaction, cooling the obtained product after the polymerization reaction is finished, and washing and filtering polymerized products to obtain the inorganic-organic double-layer coated type aluminum paste. The aluminum paste prepared by adopting the method disclosed by the invention especially has acid and alkali corrosion resistance, in addition, can be well dispersed in an organic matrix, and has wide industrial application prospect.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com