Back field aluminum paste composition of solar battery and preparation method thereof

A technology for solar cells and back-field aluminum paste, which is used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of rising battery contact resistance, harm to health, environment and human body, and reduce warpage and stress. Small, the effect of eliminating lead pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

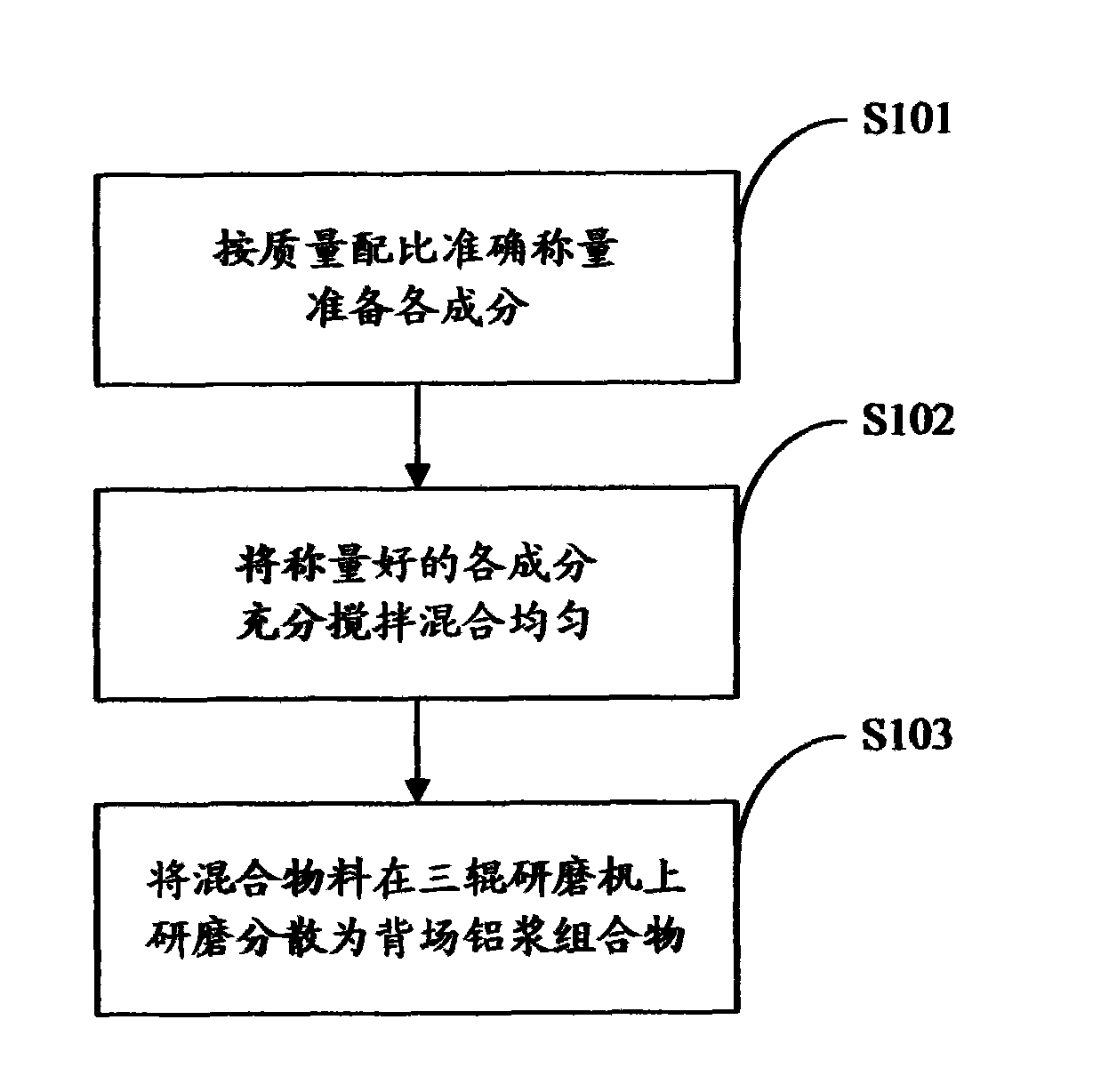

Method used

Image

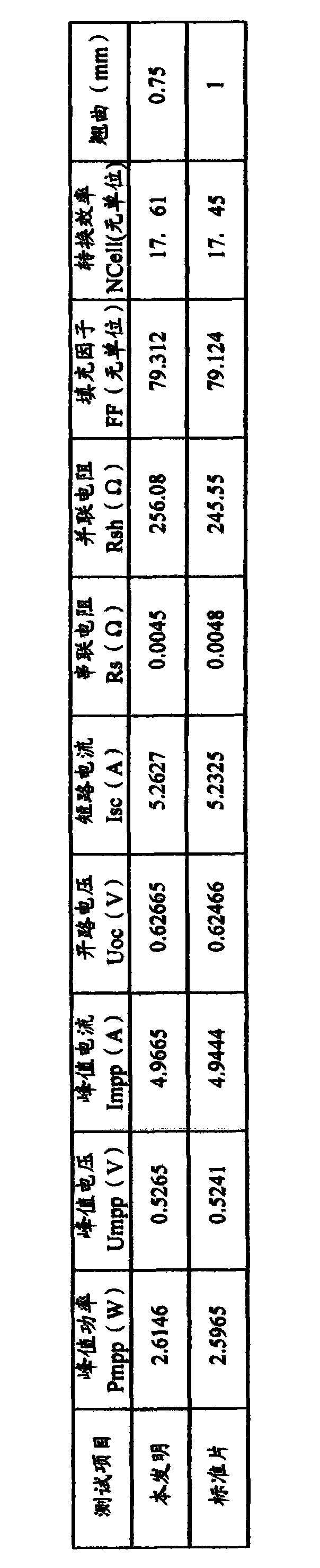

Examples

Embodiment Construction

[0032] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0033] The components of the solar cell back field aluminum paste composition in the embodiment of the present invention include aluminum powder, glass bonding phase and organic carrier, and the mass ratio of each component is: aluminum powder, 70-76%; glass bonding phase, 1-3% %; organic vehicle, 20-30%. Among them, the above-mentioned aluminum powder is formed by mixing fine aluminum powder with a particle size of 3-5 μm and coarse aluminum powder with a particle size of 6-8 μm according to a preset mass ratio, and the particle size ratio of the fine aluminum powder to the coarse aluminum powder is greater than 0.414 . Moreover, the preferred mass ratio of the fine aluminum powder and the coarse aluminum powder is 4:6. In addition, both the fine aluminum powder and the coarse aluminum powder are preferably spherical aluminum powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com