Preparation method of water-borne coating additive for oily aluminum paste and water-borne coating prepared from water-borne coating auxiliary

A technology of water-based additives and water-based coatings, which is applied in coatings, fibrous fillers, dyed polymer organic compounds, etc., which can solve the problems of affecting the brightness, sparkle and hiding power of aluminum powder, difficulties in marketing, and high manufacturing costs. and other problems, to achieve the effect of resistance to pipeline cycle performance, high price and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

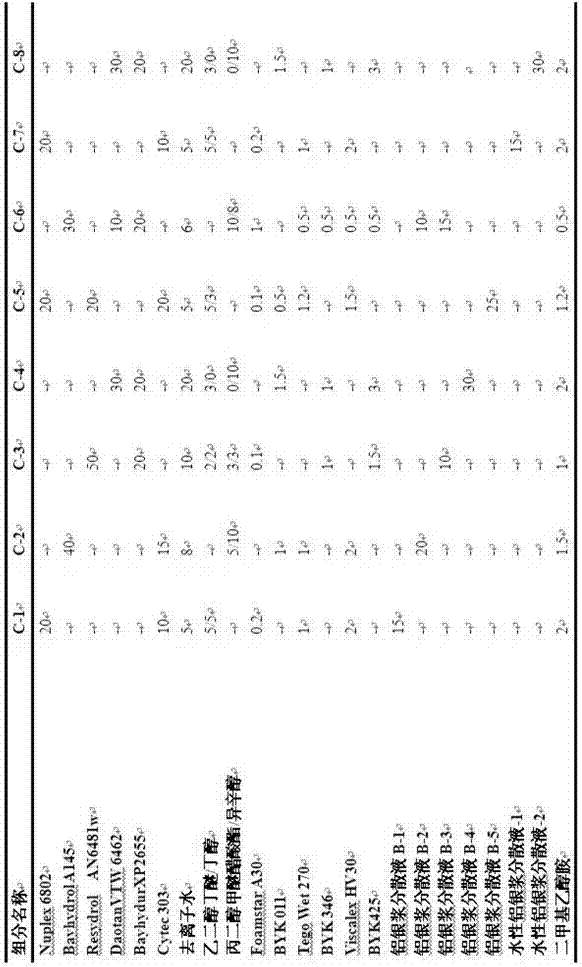

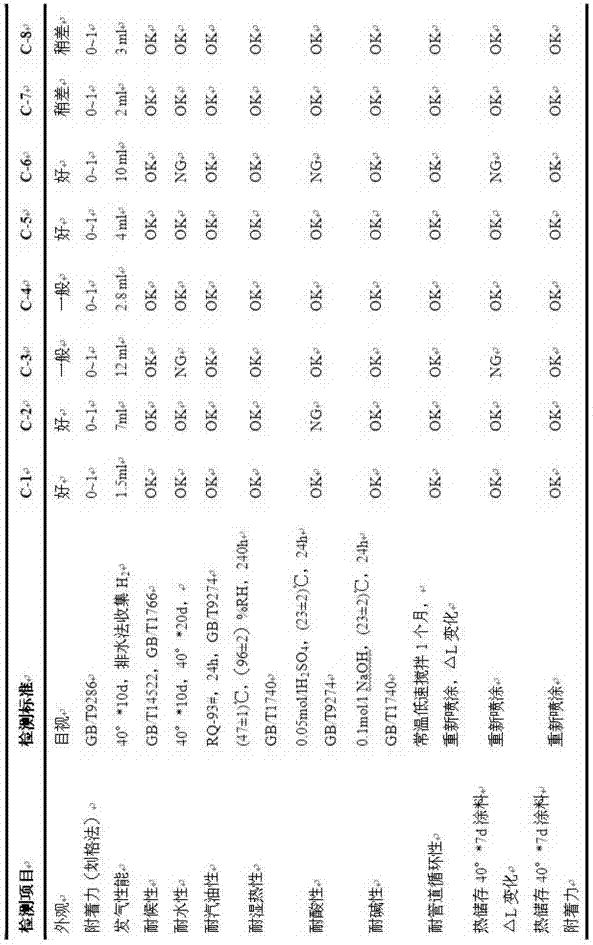

Examples

Embodiment 2

[0047] Put 50g propylene glycol methyl ether acetate into the reaction kettle, heat up to 120°C, drop into monomer and initiator mixed solution (monomer mixed solution I consists of 20g acrylic acid, 20g hydroxyethyl acrylate, 5g glycidyl acrylate, 10g methyl Lauryl acrylate, 2g acetoacetoxy ethyl methacrylate, 9g 3-butene-1-alcohol ether capped polyethylene glycol allyl ether, 3.2g sodium dihydrogen phosphate), initiator I is 5g peroxide 2 - tert-butyl ethylhexanoate, react for 4hr, keep warm for 2hr, continue to drop into monomer and initiator mixed solution, (monomer mixed solution II consists of 4g acrylic acid, 4g hydroxyethyl acrylate, 2g glycidyl acrylate, 3g formazan Lauryl acrylate, 8g 3-butene-1-alcohol ether capped polyethylene glycol allyl ether, 5g sodium dihydrogen phosphate), initiator II is 3,3-bis(tert-amylperoxy)butyric acid Ethyl ester, reaction 2hr, insulation 0.5hr, continue to drop into monomer III2g phosphorus pentoxide, initiator III0.2g tert-amyl perox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com