Self-healing cement-based capillary crystalline waterproof coating and preparation method thereof

A permeable crystalline waterproof, cement-based technology, applied in the field of building materials, can solve the problems of insufficient strength of cement-based materials, expensive core masterbatch, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

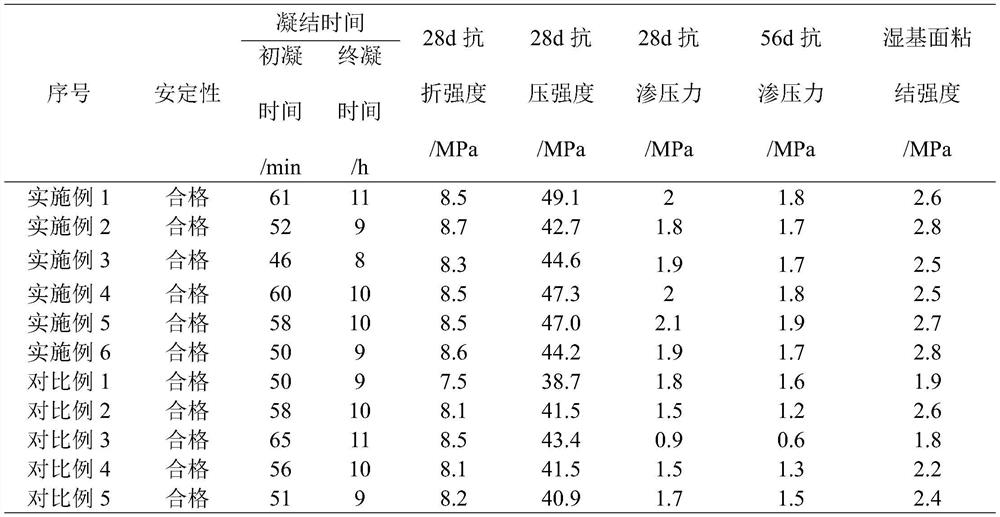

Examples

preparation example Construction

[0041] The above-mentioned preparation method of self-healing cement-based permeable crystalline waterproof coating is characterized in that it comprises the following steps:

[0042] Mix Portland cement and quartz sand, and magnetically stir to obtain the mixture;

[0043] Adding fast-setting and fast-hardening cement, graphene-modified steel slag powder and calcium carbonate to the mixture, and magnetically stirring to obtain a premix;

[0044] Add sodium sulfate, core masterbatch and thickener to the premix, and stir it magnetically to obtain it.

[0045] The present invention also discloses a core masterbatch of self-healing cement-based permeable crystalline waterproof coating, which is a mixture of bentonite, citric acid and isobutyl triethoxysilane. The bentonite, citric acid and isobutyl triethoxysilane The mass ratio of ethoxysilane is 100:(30-40):(5-10).

[0046] The present invention will be described in detail below in conjunction with specific embodiments.

Embodiment 1

[0048] Taking 100g of the product of the present invention as an example, it is prepared from raw materials of the following qualities: 40.9g of Portland cement, 40g of quartz sand, 5g of fast-setting and fast-hardening cement, 8g of graphene-modified steel slag powder, and 1.5g of calcium carbonate , Sodium sulfate 1g, core masterbatch 1.6g, thickener 2g.

[0049] The aforementioned Portland cement is 42.5 grade Portland cement. The grain size of the above-mentioned quartz sand is in the range of 0.5mm-4mm.

[0050] The one-hour compressive strength of the fast-setting and fast-hardening cement is 20.3MPa, and the 28-day compressive strength is 60.2MPa.

[0051] The above-mentioned graphene modified steel slag powder is a mixture of graphene and steel slag powder, the mass ratio of graphene and steel slag powder is 1:1000, and the specific surface area of graphene is 2630m 2 / g, light transmittance is 97.7%, conductivity is 10 6 S / m, thermal conductivity is 5000W / m·k, specific su...

Embodiment 2

[0060] The differences between this embodiment and Embodiment 1 are listed below, and the contents not listed are the same.

[0061] Taking 100g of the product of the present invention as an example, it is prepared from the following quality raw materials: Portland cement 38.7g, quartz sand 45g, fast-setting fast-hardening cement 7g, graphene modified steel slag powder 4g, calcium carbonate 1g, Yuan Ming Powder 1.3g, core masterbatch 1.2g, thickener 1.8g.

[0062] The graphene modified steel slag powder is a mixture of graphene and steel slag powder, and the mass ratio of graphene and steel slag powder is 2:1000. Specific surface area of steel slag powder 450cm 2 / g.

[0063] The above-mentioned core masterbatch is a mixture of bentonite, citric acid and isobutyltriethoxysilane, and the mass ratio of bentonite, citric acid and isobutyltriethoxysilane is 100:35:5.

[0064] The thickener is a mixture of methyl cellulose and polypropylene monofilament fibers, and the mass ratio of met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com