Calcium hexaluminate blue ceramic pigment and preparation method thereof

A ceramic pigment, calcium hexaaluminate technology, applied in fibrous fillers and other directions, can solve the problem of high price of cobalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] CaAl 12-2x Ni x Ti x o 19 The preparation method of the calcium hexaaluminate blue ceramic pigment whose value of x is 0.6 comprises the steps:

[0028] (1) by CaAl 10.8 Ni 0.6 Ti 0.6 o 19 The stoichiometric ratios of Ca, Al, Ni, and Ti in the middle are weighed respectively for aluminum hydroxide (Al(OH) 3 ), titanium hydroxide (Ti(OH) 4 ), nickel oxide (NiO), calcium carbonate, put the above raw materials into a ball mill tank, pour them into anhydrous ethanol ball mill for 24 hours, and obtain a uniformly mixed and refined slurry; the ratio of the total mass of raw materials to anhydrous ethanol is 1: 2;

[0029] (2) Put the slurry obtained in step (1) into a drying oven at an environment of about 80°C to dry;

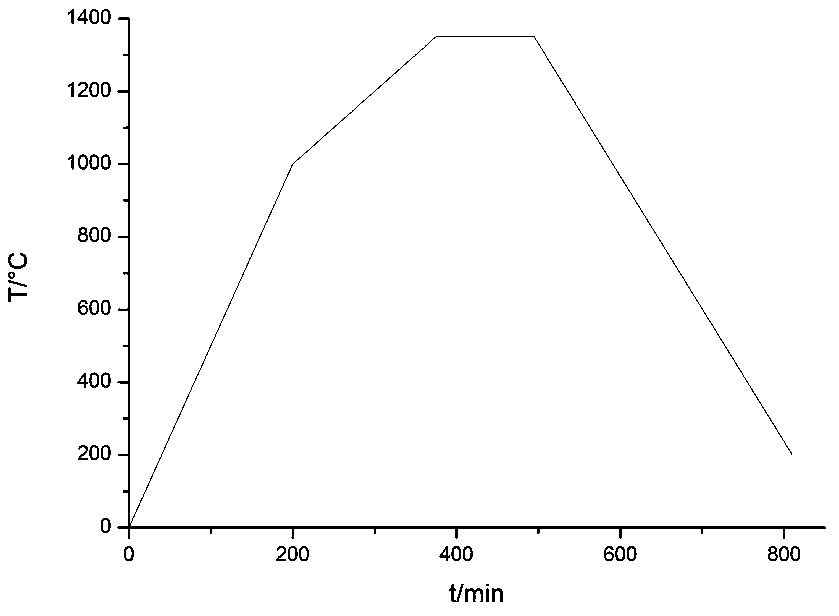

[0030] (3) Put the dried powder in step (2) into a box-type electronic furnace for calcining with a cover. The temperature control degree is: from room temperature to 1000°C at a rate of 5°C / min, and then at a rate of 2°C / min The temperature was ra...

Embodiment 2

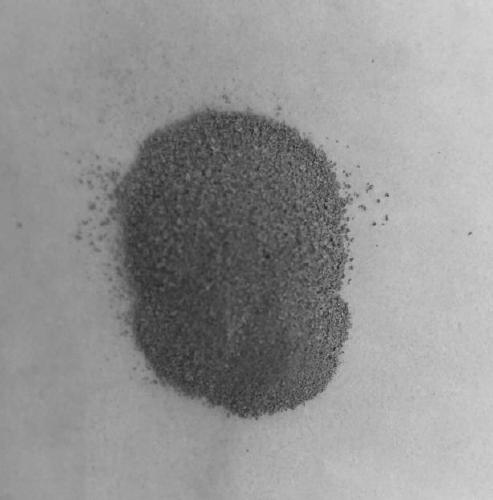

[0032] With the value of x among the embodiment 1 being 0.8, the blue ceramic pigment that adopts same preparation method to make is as image 3 shown.

Embodiment 3

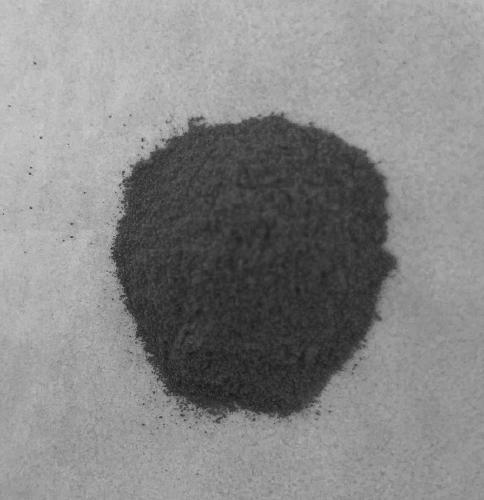

[0034] With the value of x among the embodiment 1 being 1.0, the blue ceramic pigment that adopts same preparation method to make is as Figure 4 shown.

[0035] Comparative analysis

[0036] The CIELAB color parameters were measured using a Konica Minolta colorimeter, and three related parameters L*a*b* were obtained, which were expressed as brightness, red / green and yellow / blue color values; as Figure 5 Shown is the real photo of the existing cobalt blue powder, its b* value is -38.19, and the lightness value L* is 53.98; the chromaticity values of the above three kinds of ceramic pigments are shown in Table 1. When 1.0, its color basically reaches the color of cobalt blue, especially for samples with x=0.8, its b value reaches -37.07, which is equivalent to the blueness value of cobalt blue, and the lightness value L* is higher than the existing cobalt blue powder;

[0037] The ultraviolet-visible diffuse reflectance spectrum of the sample was measured by a spectrophot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com