Patents

Literature

179 results about "Titanium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium Hydroxide (Orthotitanic Acid) is generally immediately available in most volumes. High purity, submicron and nanopowder forms may be considered.

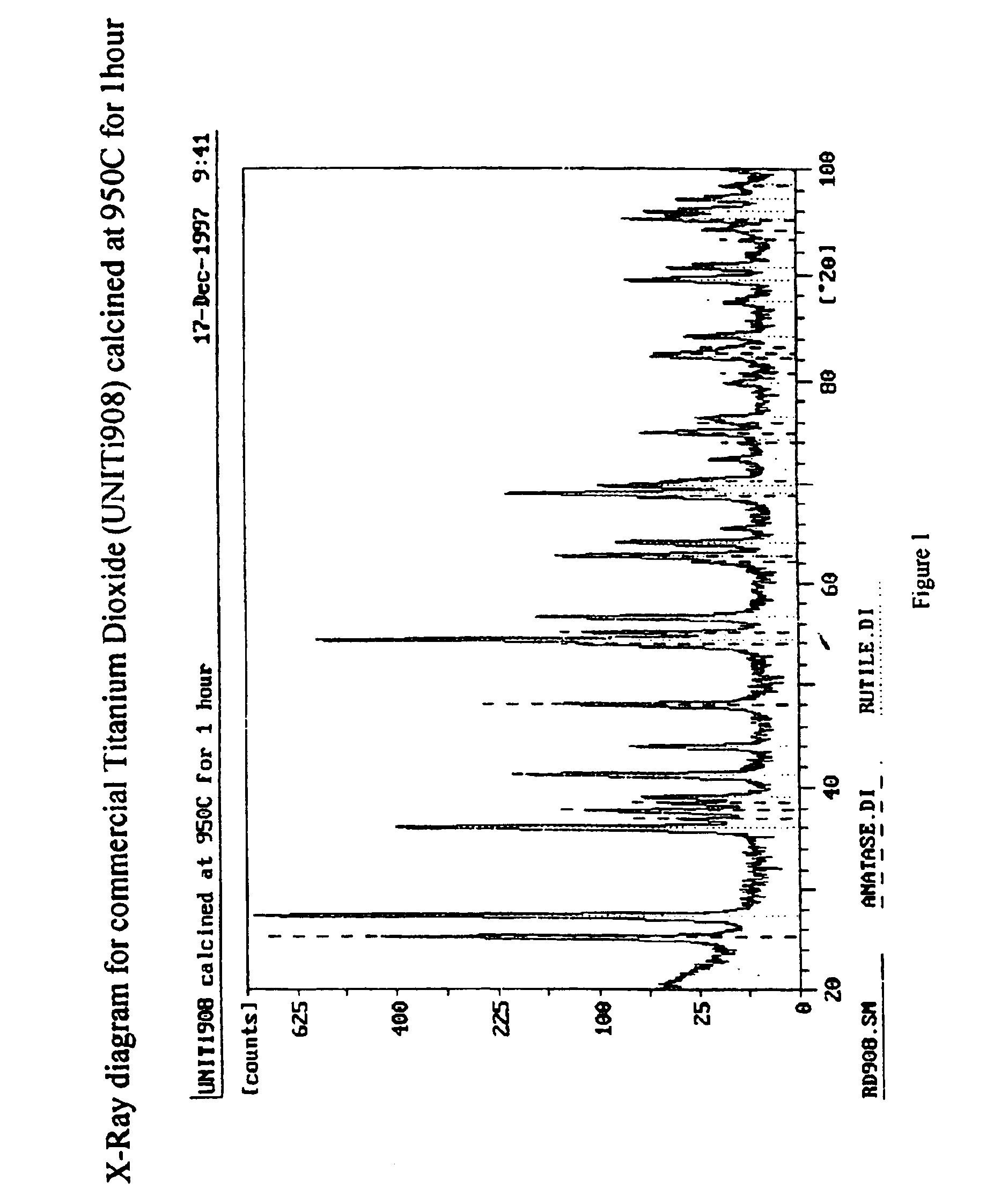

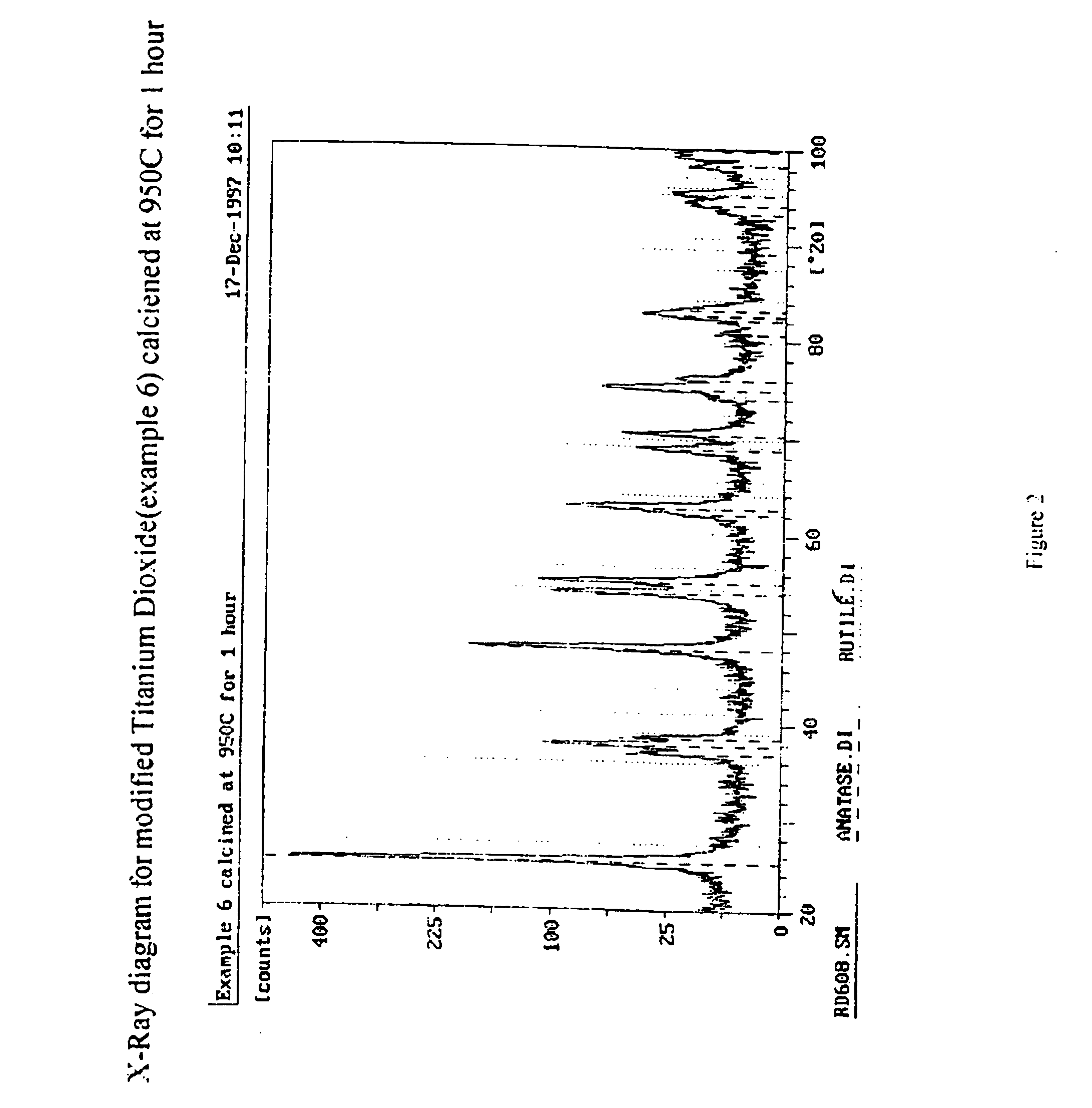

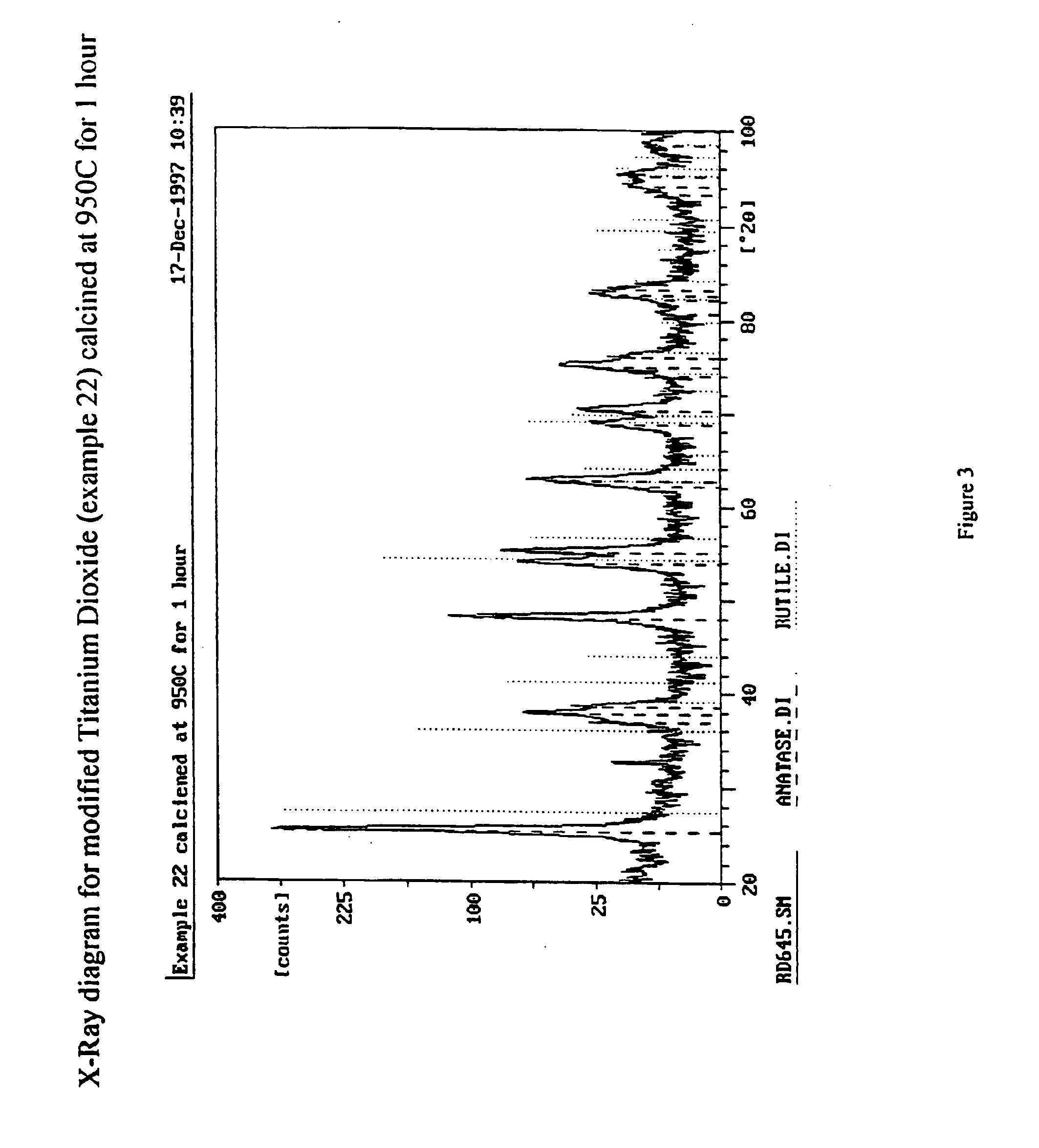

Modified titanium dioxide and a method for its preparation

The invention relates to a composite material comprising silicon and titanium dioxide characterized by an enhanced thermal and hydrothermal stability of the pore structure. The composite is obtainable by precipitating titanium hydroxide from an aqueous solution containing sulfate salts and urea, followed by an hydrothermal treatment in the mother liquor, and by reacting the precipitate with a basic silica sol. The composite has a specific surface area of up to 228 m2 / g for a material calcined at 800° C. for 3 hours, and is suitable for catalyzing a variety of reactions, including Claus reaction and degradation of organic impurities.

Owner:ROTEM AMFERT NEGEV

Photocatalytic body and method for making same

An amorphous titanium peroxide sol made by a process which includes adding an alkali hydroxide to an aqueous titanium salt solution and reacting the resulting amorphous titanium hydroxide with an aqueous hydrogen peroxide solution to obtain an amorphous titanium peroxide sol. The amorphous titanium peroxide sol is afterward raised to a temperature sufficient to obtain an anatase titanium oxide sol. The resulting anatase titanium oxide sol can thereafter be heated to a temperature sufficient to obtain anatase titanium oxide. The claimed compositions are useful as binders to support the particles of a photocatalyst on a variety of substrates.

Owner:SAGA KEN

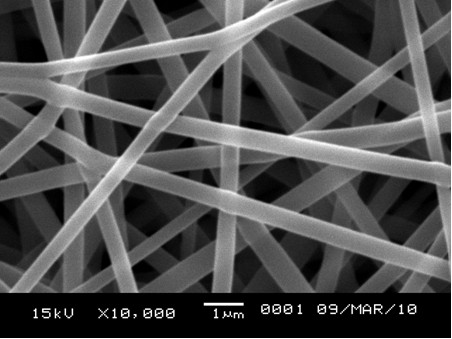

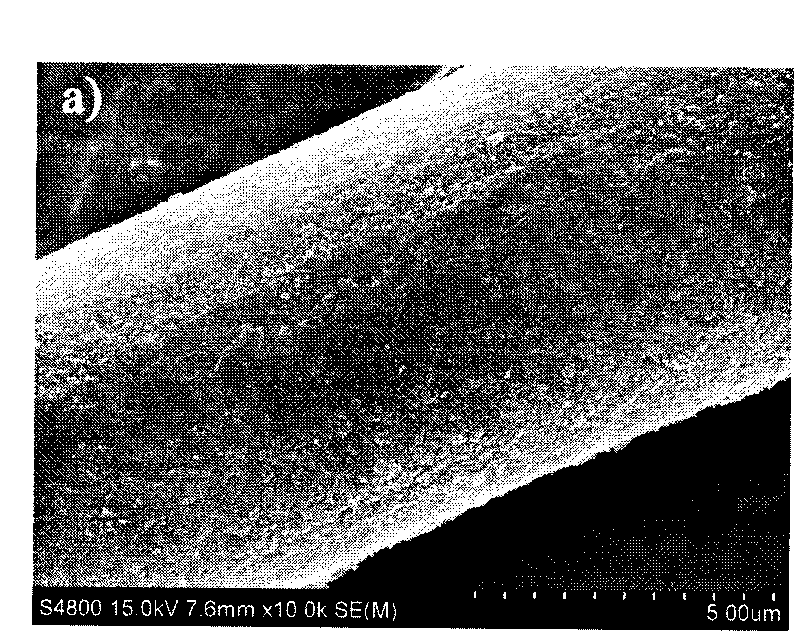

Preparation method of titanium dioxide/active carbon composite nanofibrous membrane

InactiveCN102021676AAchieve mass productionImprove bindingWater/sewage treatment by irradiationOther chemical processesSpinningPhosphoric acid

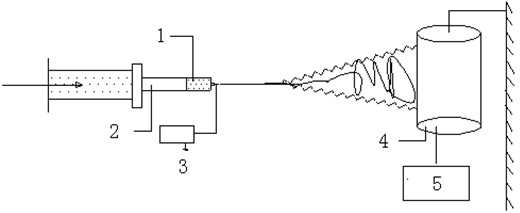

The invention provides a preparation method of a titanium dioxide / active carbon composite nanofibrous membrane, characterized by comprising the following specific steps: dissolving polyacrylonitrile powder in N, N-dimethyl formamide; mixing titanium hydroxide gel with the polyacrylonitrile solution to obtain electrostatic spinning stock solution, and performing electrostatic spinning to get the composite nanofibrous membrane; placing the composite nanofibrous membrane in an electrically heated drying cabinet for being pre-oxidized; soaking the composite nanofibrous membrane in phosphoric acid or potassium hydroxide solution, washing the solution to be neutral by distilled water, and drying the composite nanofibrous membrane in the drying cabinet; and then, under nitrogen protection, heating up to 450-550 DEG C, and cooling to room temperature to get the titanium dioxide / active carbon composite nanofibrous membrane. The preparation method improves combination firmness between fibers and active ingredients of a photocatalyst, and also improves charge capacity of the fibers; the titanium dioxide / active carbon composite nanofibrous membrane is high in photo catalytic activity, good in absorption effect, reproducible and simple in a reproduction method, and can use sunlight, so that operations are easy and operation cost is low.

Owner:DONGHUA UNIV

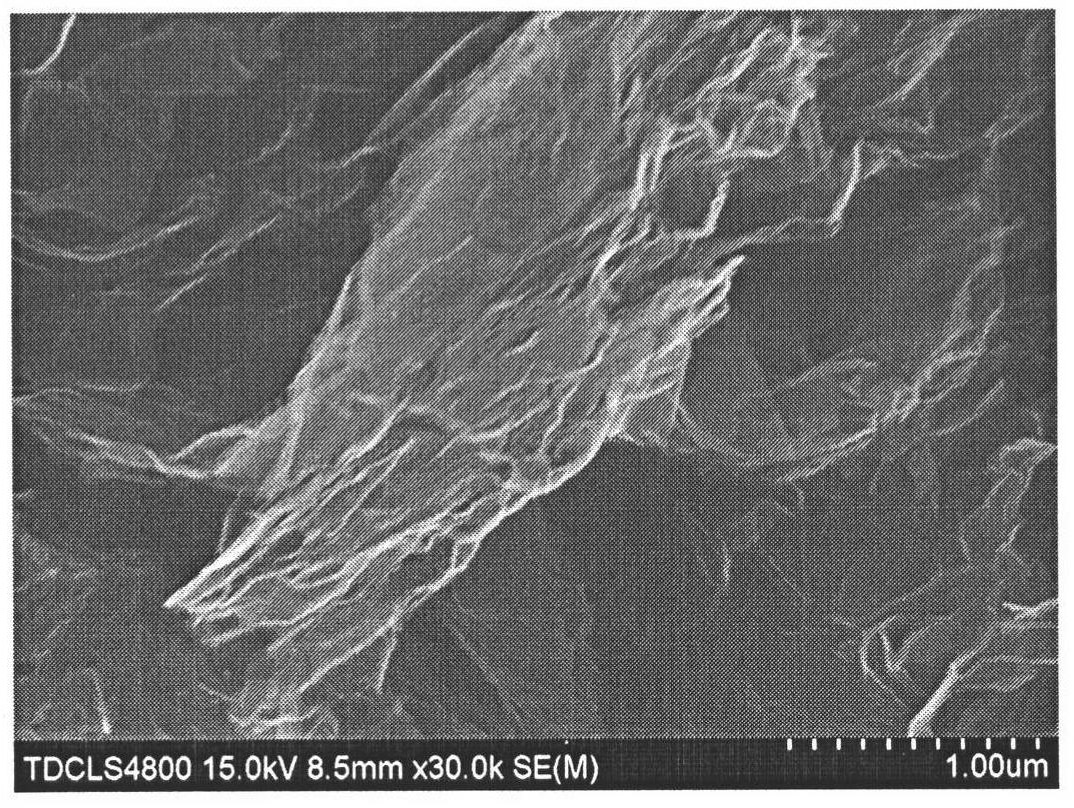

Preparation method of graphene loaded with anatase type nano titanium dioxide and application thereof

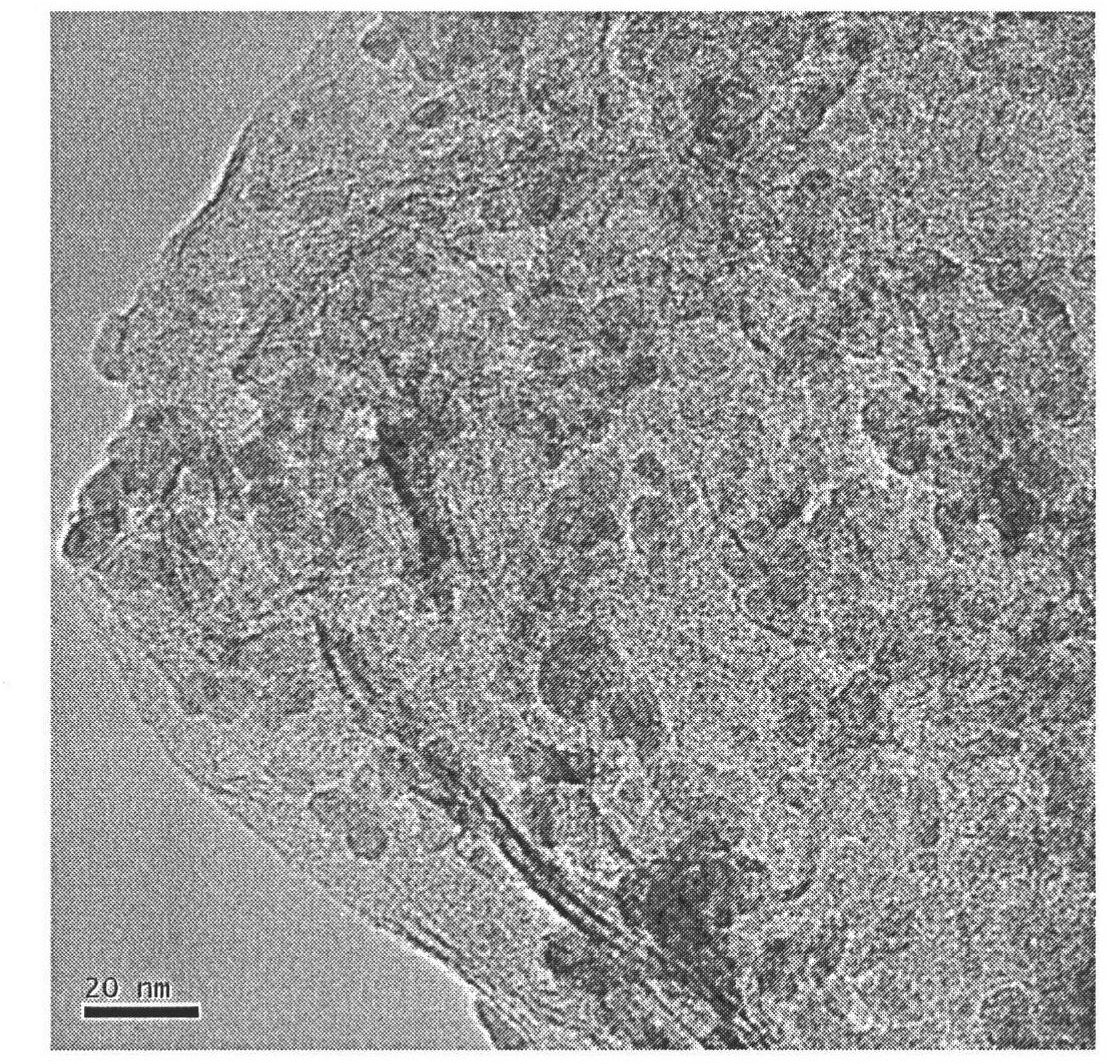

InactiveCN102324505ASmall sizeEvenly dispersedAlkaline accumulator electrodesNanotechnologyFlake graphiteSODIUM DODECYL BENZENE SULFONATE

The invention discloses a preparation method of graphene loaded with anatase type nano titanium dioxide and an application thereof. The preparation method comprises the following steps: preparing graphite oxide from crystalline flake graphite; carrying out reduction reaction on the graphite oxide to obtain graphene by taking hydrazine hydrate as a reducing agent and sodium dodecyl benzene sulfonate as a dispersing agent; preparing titanium hydroxide colloidal solution by taking tetrabutyl titanate as a titanium source; mixing the ethanol solution of graphene and the titanium hydroxide colloidal solution, stirring and calcining to prepare the graphene loaded with anatase type nano titanium dioxide. The graphene loaded with anatase type nano titanium dioxide prepared by the method can be mixed with copper powder to prepare the negative electrode of a nickel-hydride secondary battery. The method provided by the invention has the advantages of simple preparation process and low cost and is easy to operate. When the prepared graphene loaded with anatase type nano titanium dioxide is used as the active material of the cathode of the secondary battery, the effects of high discharge specific capacity and good circulation stability are achieved.

Owner:TIANJIN UNIV

Titanium dioxide/active carbon fiber photocatalyst and its preparation method and uses in air purification

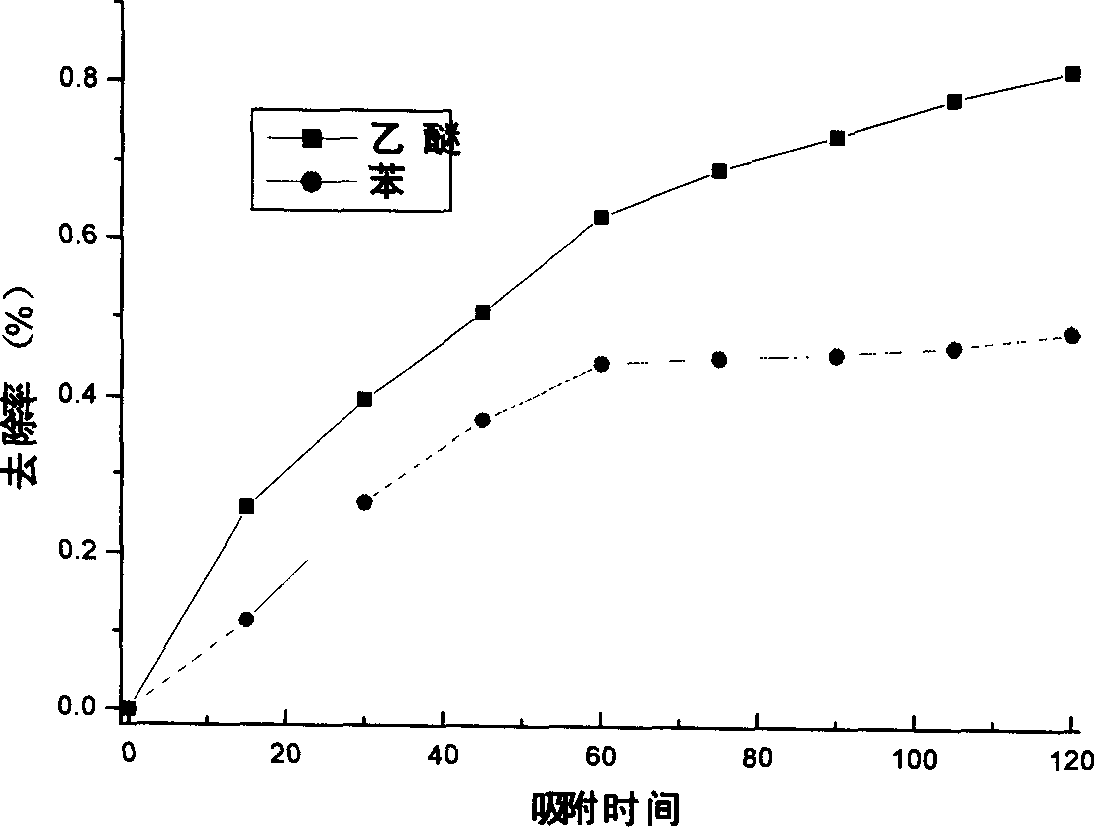

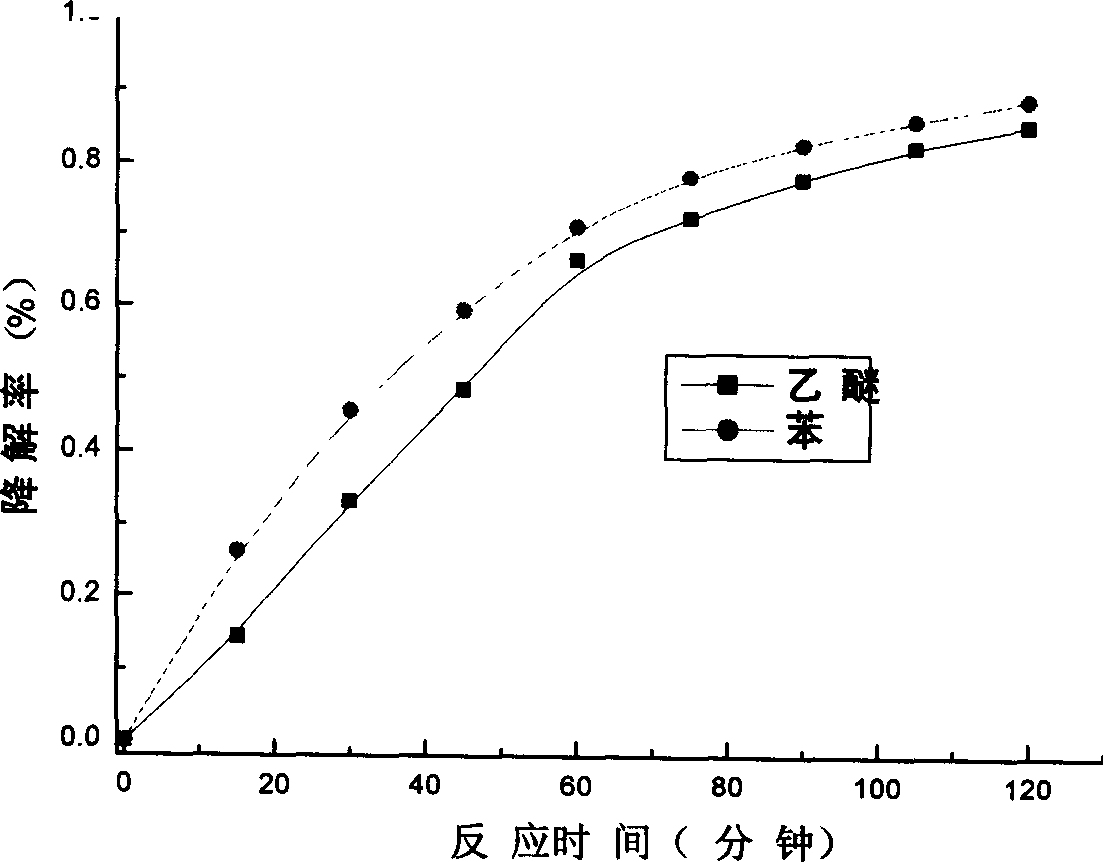

InactiveCN1803291AImprove adsorption capacityReach enrichmentDispersed particle separationCatalyst activation/preparationFiberCarbon fibers

The invention discloses a TiO2 / ACF photocatalyst and making method and appliance in the air purifying domain, which comprises the following steps: adding diluted sulphuric acid solution in the titanium hydroxide emulsion; shocking in the ultrasonic wave after stirring evenly to make the emulsion; soaking the active carbon fiber to wash through ultrasonic wave; drying; immersing the fiber in the acid emulsion and shocking by ultrasonic wave; drying to produce photocatalytic pioneer with titanium hydroxide; sintering the pioneer to make the TiO2 / ACF photocatalyst.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

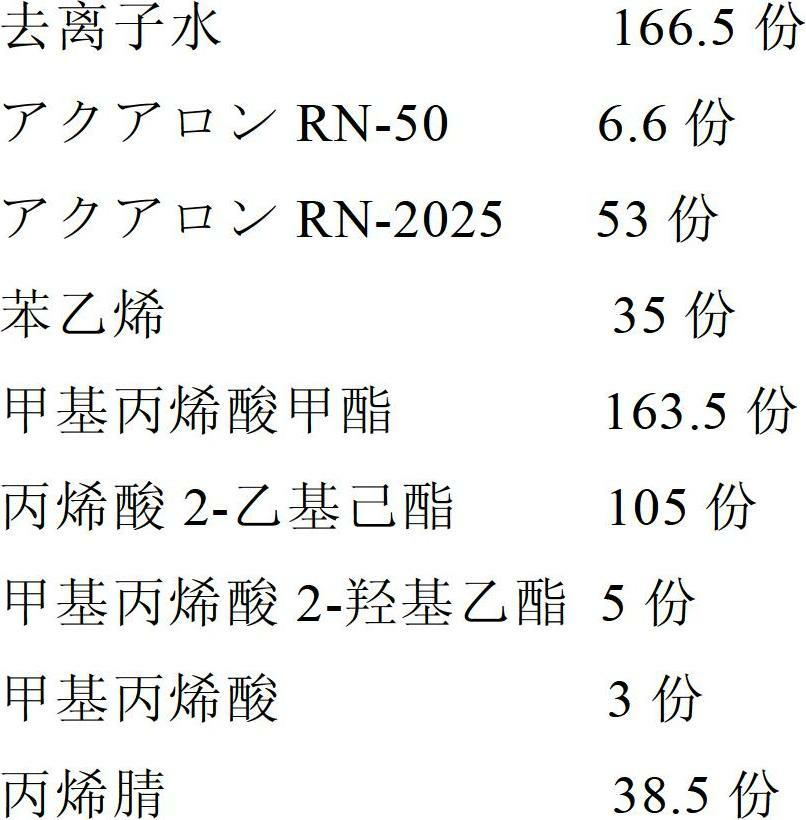

Surface-treating composition, and surface-treated steel sheet

InactiveCN102666921AImprove barrier propertiesAccelerated corrosionAnti-corrosive paintsConstructions elementsWater dispersiblePhosphate

Owner:JFE STEEL CORP

Titania-metal composite and method for preparation thereof, and film forming method using dispersion comprising the composite

ActiveUS20050271892A1Reduce and preventReducing and preventing oxidationPigmenting treatmentHeterogenous catalyst chemical elementsFiberOrganic dye

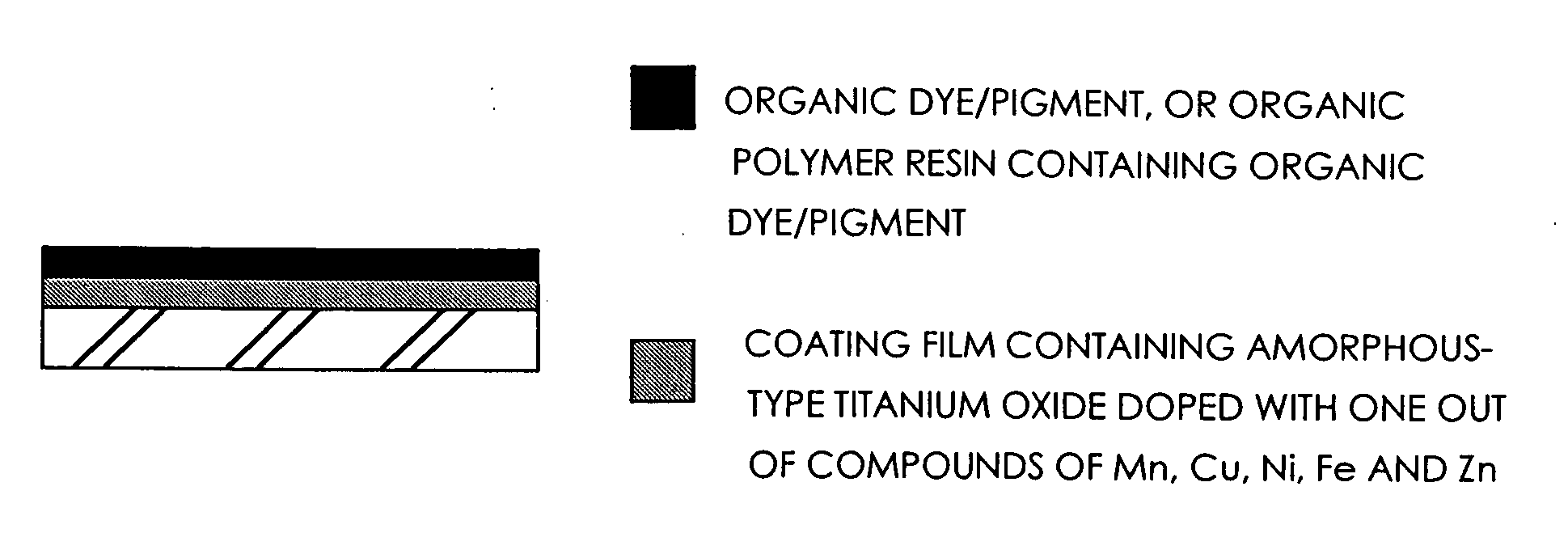

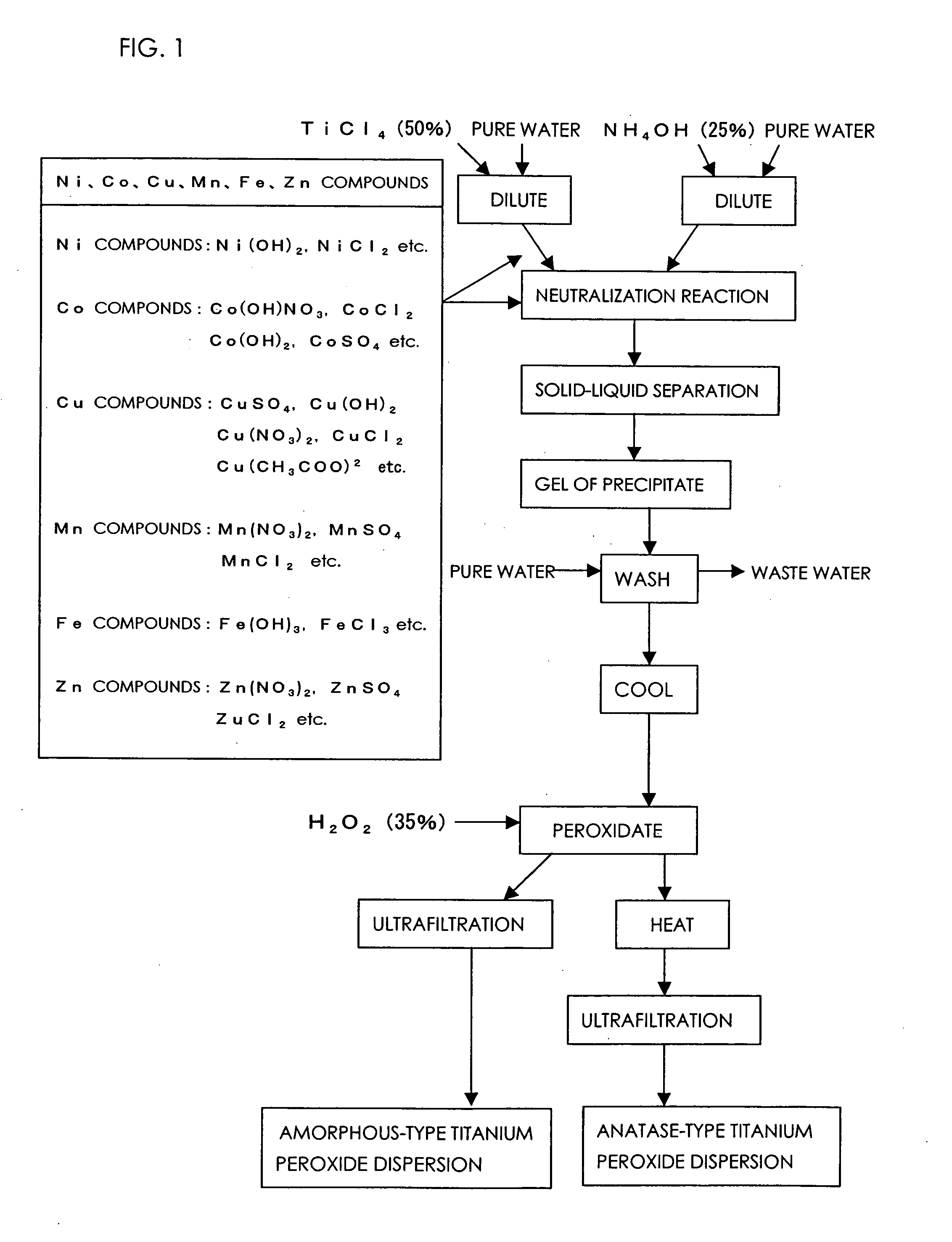

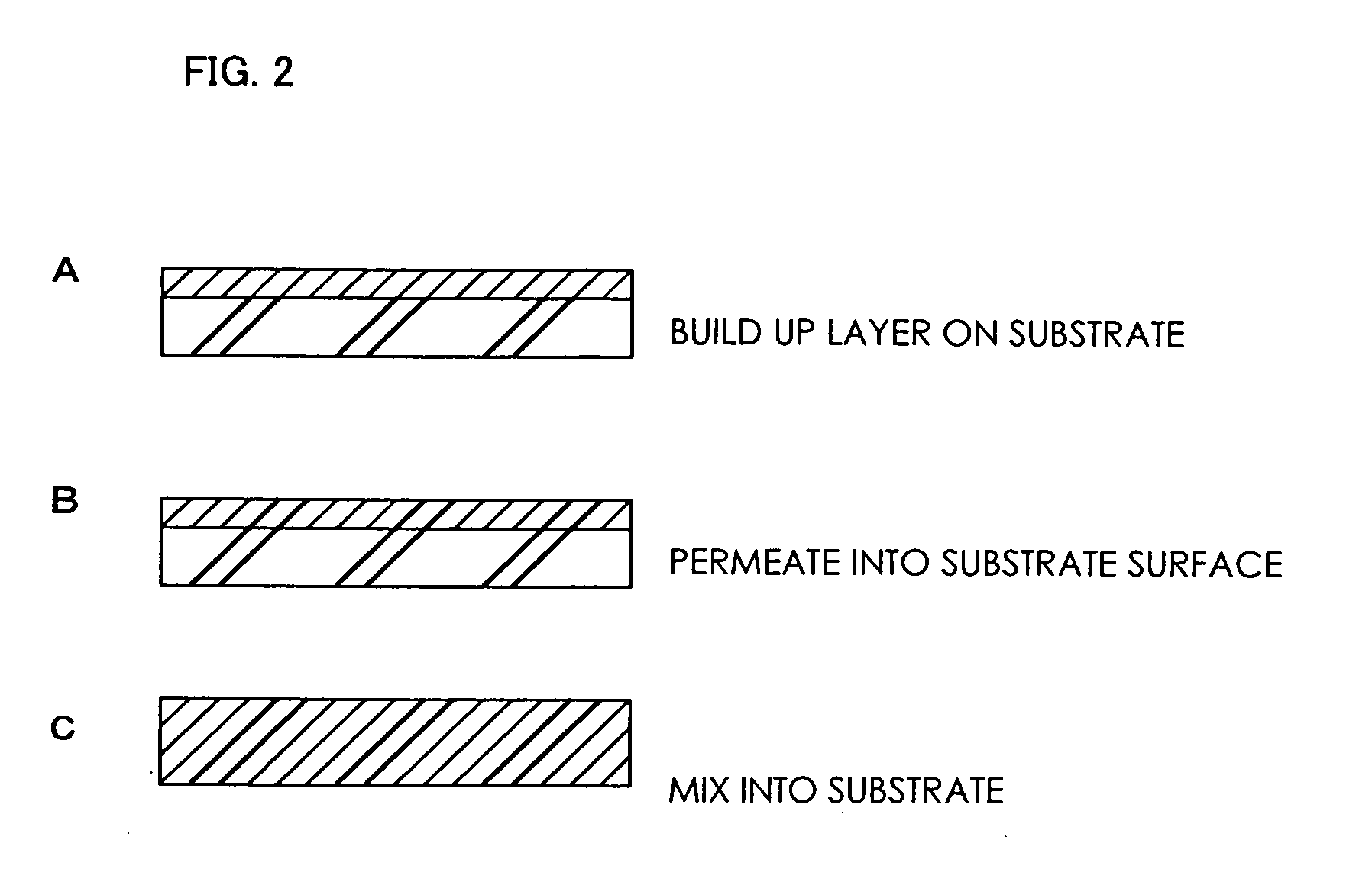

Under the presence of at least one out of copper, manganese, nickel, cobalt, iron, zinc, and compounds thereof, a tetravalent titanium salt solution and a basic solution are reacted together to form a hydroxide of titanium and the above metal, and then the titanium hydroxide is peroxidated with an oxidizing agent to manufacture an aqueous liquid or dispersion having therein titanium oxide fine particles having peroxy groups; by using this alone to form a coating film adjacent to a coating film of an organic dye or pigment, or using this to form a coating film together with an organic dye or pigment, a drop in decorativeness of color due to fading or discoloration of a coating material, a printed article, a building material, a fiber, an organic polymer resin product or the like can be prevented, and moreover surface anti-soiling and hydrophilic properties can be realized.

Owner:SUSTAINABLE TITANIA TECH

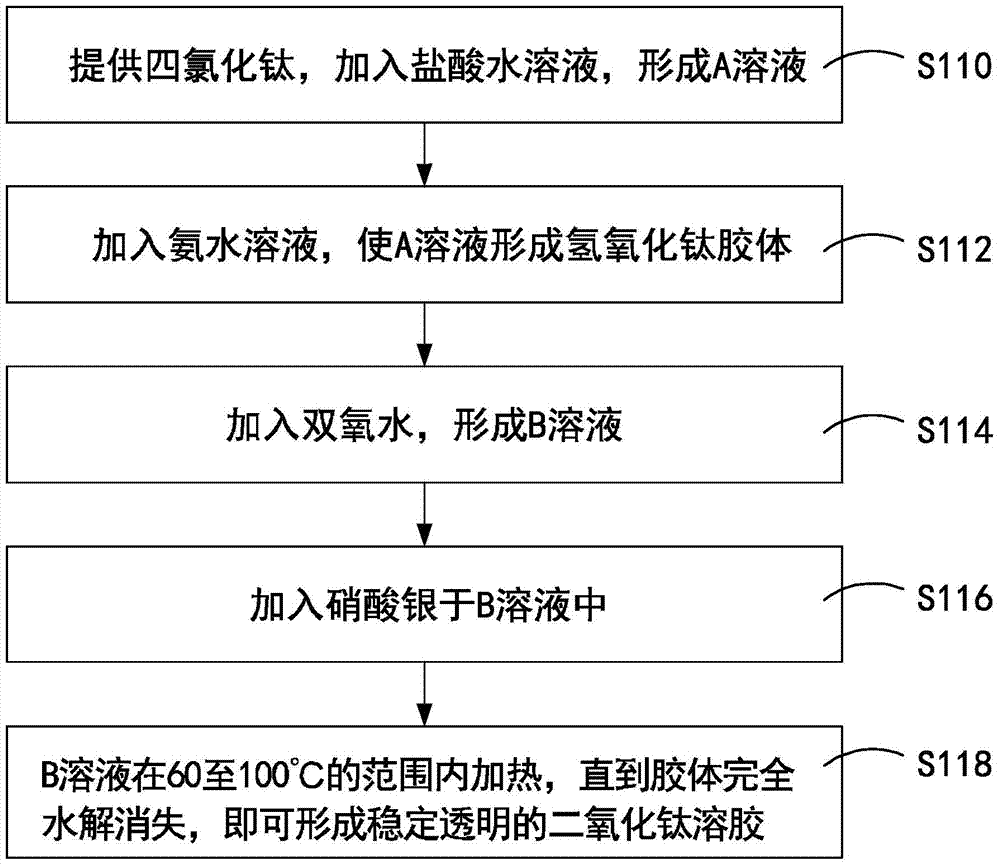

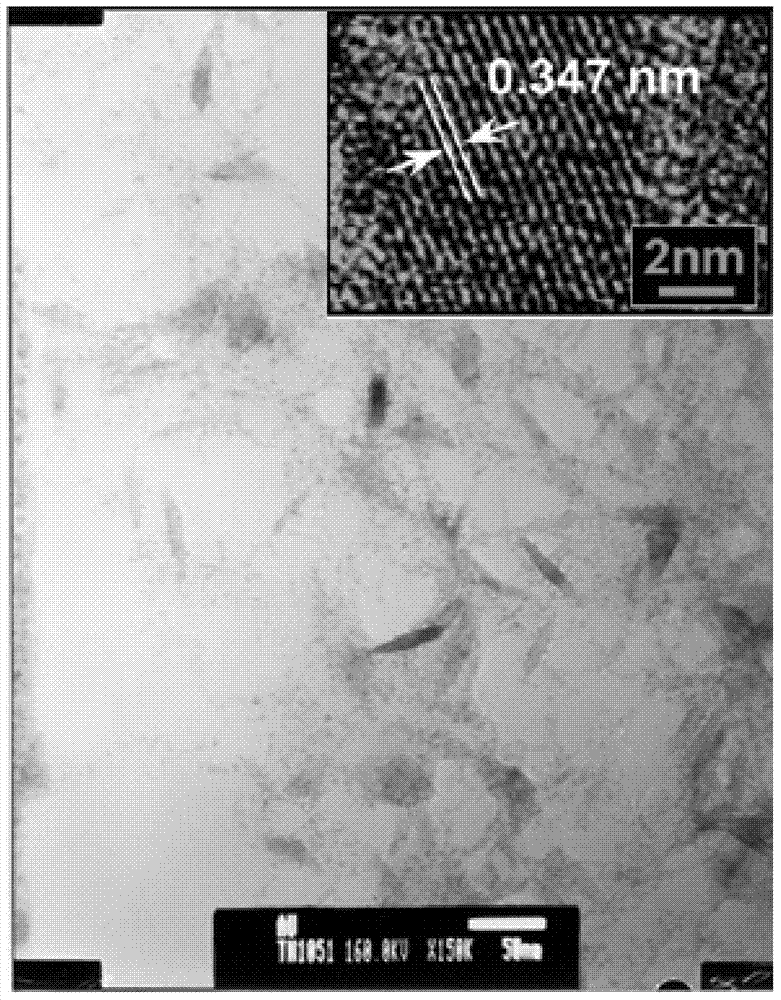

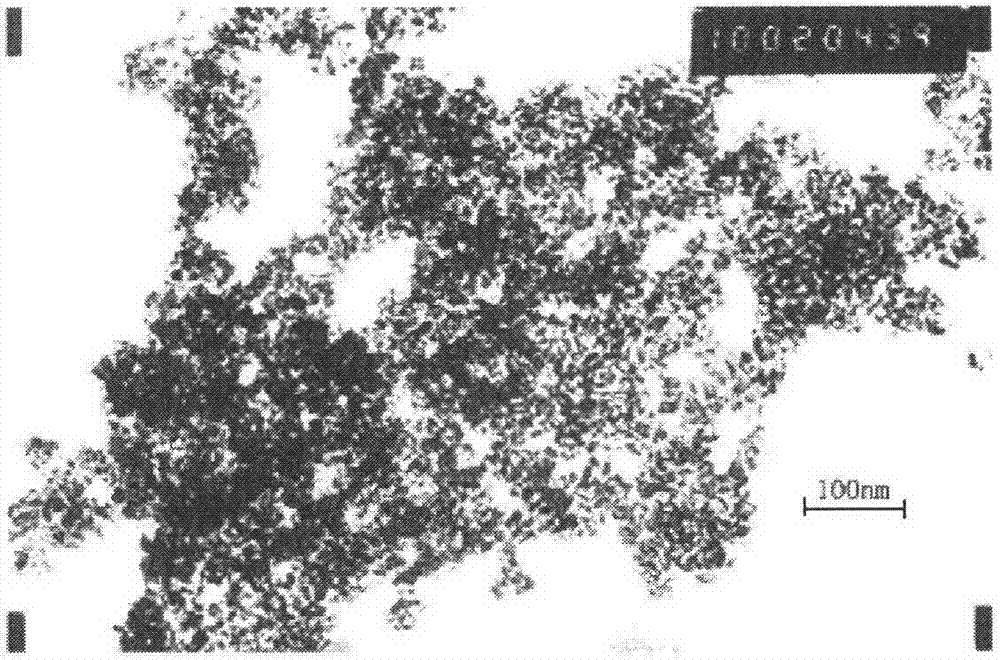

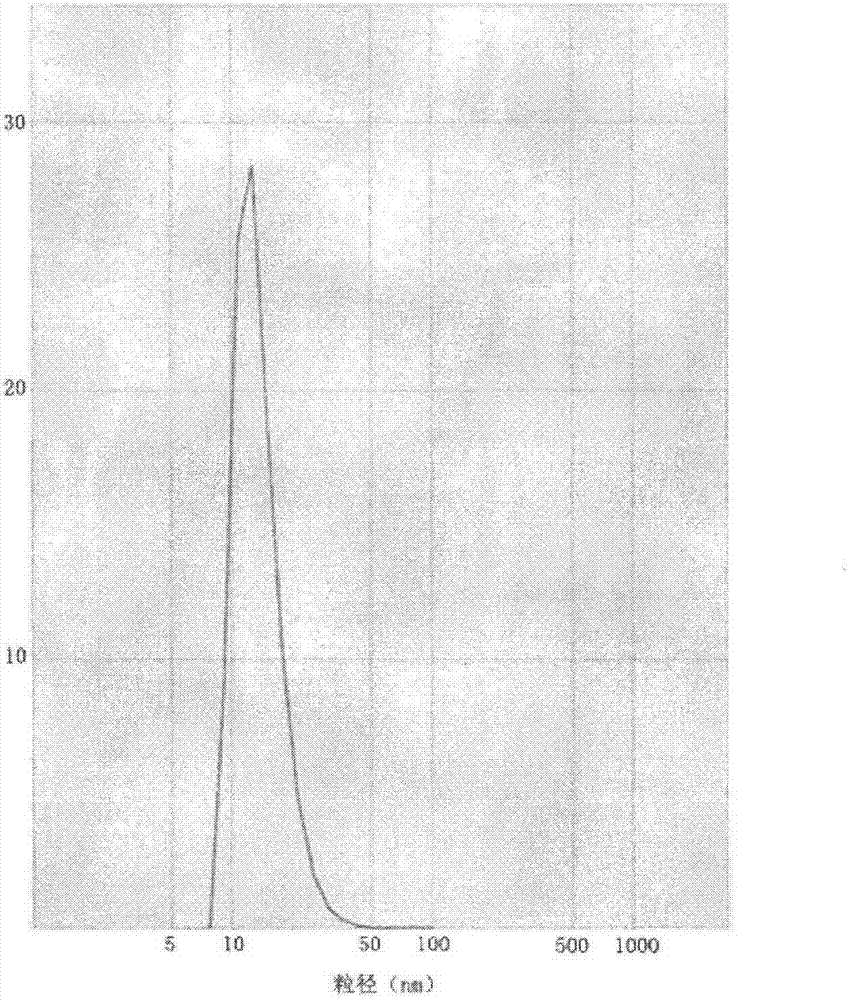

Preparation method of nano-silver composite titanium dioxide sol photocatalyst, masking liquid, component and usage

The invention provides a preparation method of nano-silver composite titanium dioxide sol photocatalyst. The nano-silver composite titanium dioxide sol photocatalyst can be used as raw materials of coating carriers. Titanium tetrachloride used as raw materials is firstly added into hydrochloric acid solution in ice bath in 0-5 DEG C, and then ammonium hydroxide alkaline solution is added, so titanium hydroxide is prepared. After several times of centrifugation and washing, chloride ions are completely removed and then hydrogen peroxide is added. At present, ratio of solid titanium dioxide to water is 0.01%-3.0%. The mole ratio of the hydrogen peroxide to titanium is 1:1-9:1. Metallic silver is then added, so the temperature of the solution is 60-100 DEG C. After being heated for a while when the titanium hydroxide is completely hydrolyzed, stable transparent nano-silver composite titanium dioxide sol photocatalyst can be formed.

Owner:MATERIAL TECH

Titanium oxide - aluminum oxide composite carrier, preparation method and application thereof

ActiveCN1689702AEasy to prepareThe reaction temperature is easy to controlCatalyst carriersCatalyst activation/preparationAluminateTitanium oxide

The present invention discloses one kind of composite titania-alumina carrier and its preparation process and application. The composite carrier contains titania in 10-50 wt% and in anatase and / or rutile form and contains alumina in alpha-Al2O3 form. The composite carrier has acid surface and total acid amount of 0.6-8 A / g / sq cm. The preparation process includes the following steps: mixing titanium tetrachloride solution and AlCl3.6H2O crystal through stirring and diluting, mixing with sodium meta-aluminate solution to obtain aluminum titanium hydroxide precipitate, ageing, filtering, washing, drying, crushing, kneading, and roasting at 800-1200 deg.c to obtain the carrier. The composite carrier is used in selective hydrogenation and is favorable to reducing side product 'green oil' and prolonging the life of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

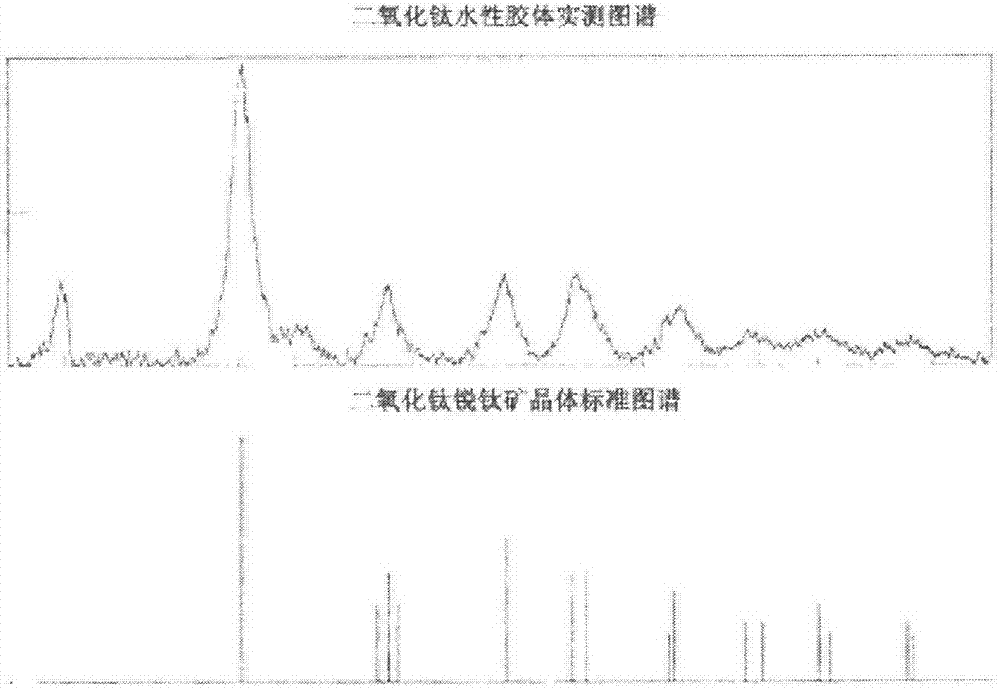

Preparation method of aqueous nano-TiO2 colloid

InactiveCN102730754ASimple production processReduce manufacturing costNanotechnologyTitanium dioxideWater bathsHydrolysate

The invention discloses a preparation method of an aqueous nano-TiO2 colloid. The preparation method comprises the following steps: dumping deionized water to a temperature-controlled water bath device, adding a titanate to the deionized water, and stirring while adding under normal temperature and normal pressure conditions to completely hydrolyze the titanate to titanium hydroxide; adding an inorganic acid to the prepared titanium hydroxide hydrolysate to make the pH value of the titanium hydroxide hydrolysate be 1-4; and heating the temperature-controlled water bath device to make precipitated titanium hydroxide be gradually dissolved and gel to a hydrosol with a -O-Ti-O- structure. The preparation method of the aqueous nano-TiO2 colloid has the advantages of very simple process and very simple production equipment, and the colloid has the characteristics of very low production cost, extremely easy industrialized production, and high crystallization degree, and is a 100% anatase phase; and particle sizes are less than 15nm, and the colloid of the invention has the advantages of good repeatability, good stability, environmental protection, no pollution, no deterioration because of realization of long term storage, realization of arbitrary concentration or dilution with water, good coating capability and film forming capability, and strong photocatalytic activity.

Owner:江苏恒智纳米科技有限公司

Electrode active material for lead-acid storage battery

InactiveCN106876666AHigh specific powerIncrease specific energyLead-acid accumulatorsCell electrodesTitanium nitrideAtomic cluster

The invention discloses an electrode active material for a lead-acid storage battery. The electrode active material comprises lead powder and a non-metallic titanium compound; the lead powder comprises one or more kinds of metal lead powder, ball-milling lead powder, Barton lead powder, Pb<2>O powder, PbO powder, Pb<2>O<3> powder, Pb<3>O<4> powder and PbO<2> powder; and the non-metallic titanium compound comprises one or more kinds of titanium sulfide, titanium nitride, titanium boride, titanium carbide, titanium hydride, titanium hydroxide, titanium silicide, a symbiotic blend of the abovementioned compounds on an atomic micro level or atomic cluster level, and doped compounds formed by doping the abovementioned compounds with one or more kinds of F, Sb, Sn, Ca, Bi, Co, Ca, Al, Mg, N, P, O and C. By virtue of the electrode active material for the lead-acid storage battery with an improved formula, the specific power, specific energy, charging-discharging efficiency, cycle life, low-temperature performance and the like of the lead-acid storage battery can be obviously improved.

Owner:杨春晓

Titanium-silicon composite oxide carrier and preparation method thereof

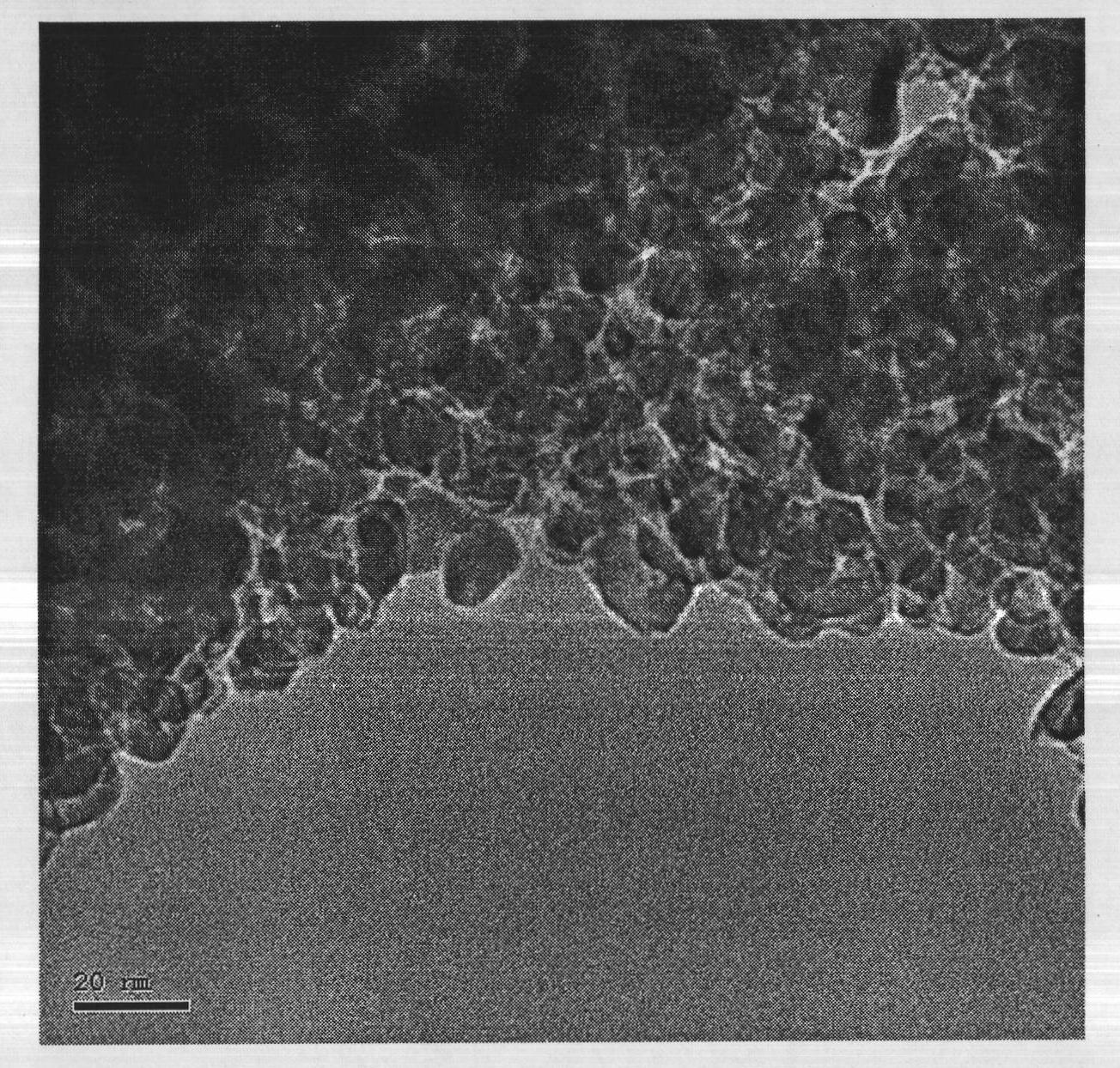

The invention discloses a titanium-silicon composite oxide carrier and a preparation method thereof. The carrier is prepared from titanium hydroxide-silicon hydroxide gel prepared by a super-solubilizing micelle method; and because the gel contains surfactant and hydrocarbon components, nano titanium oxide and silicon oxide particles formed by dehydrating the polymerized titanium hydroxide and the polymerized silicon hydroxide still have a rod-like basic structure after molding and roasting, and the nano particles are randomly piled to form a framework structure. The carrier has large pore volume, large aperture, high porosity, large outer surface orifice and good pore penetrability, does not inactivate a catalyst due to orifice blockage for macromolecules in particular compared with an orifice of an ink bottle type, and is favorable for increasing the deposition of impurities and prolonging the running period of the catalyst. The carrier can be used for catalytic reaction containing macromolecular reactants or products.

Owner:CHINA PETROLEUM & CHEM CORP +1

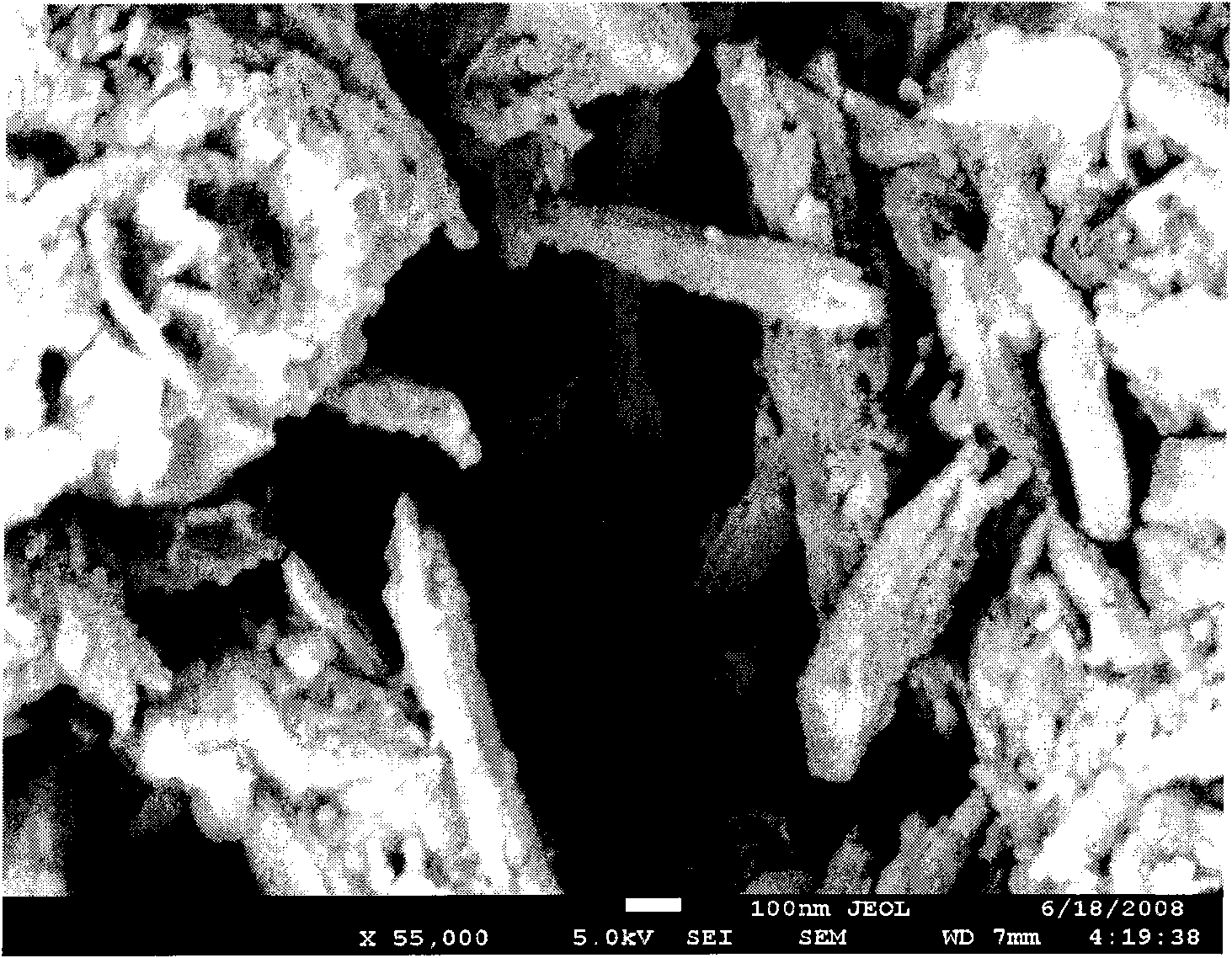

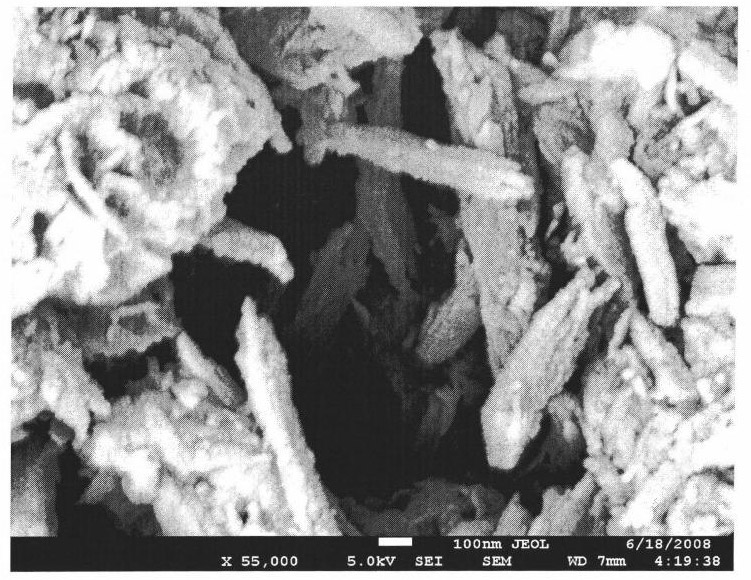

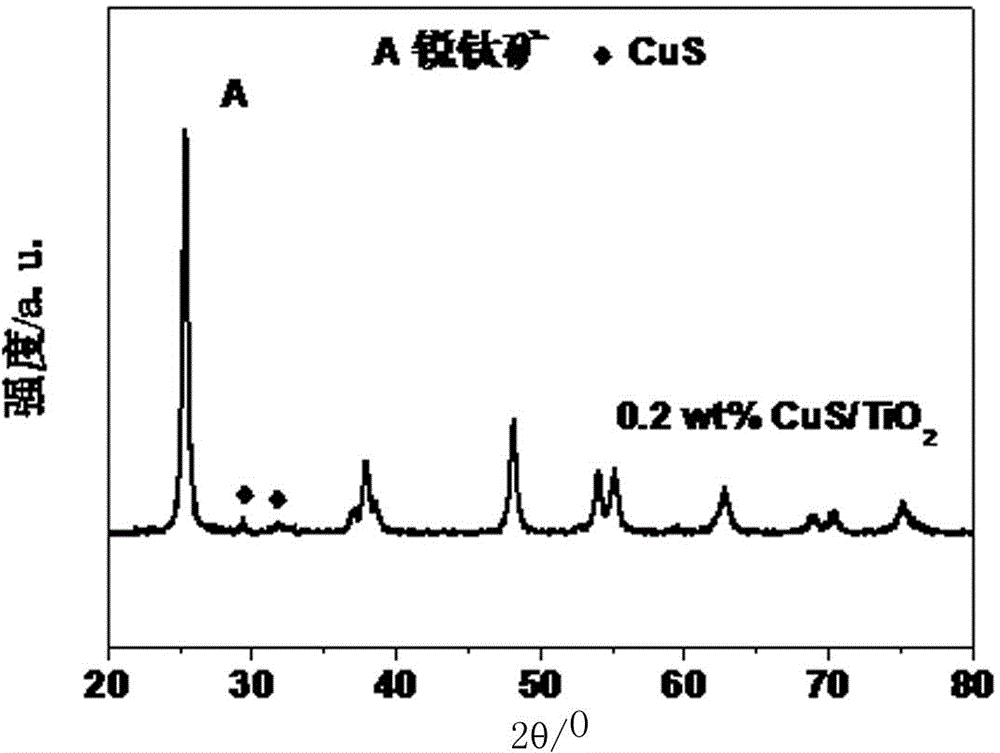

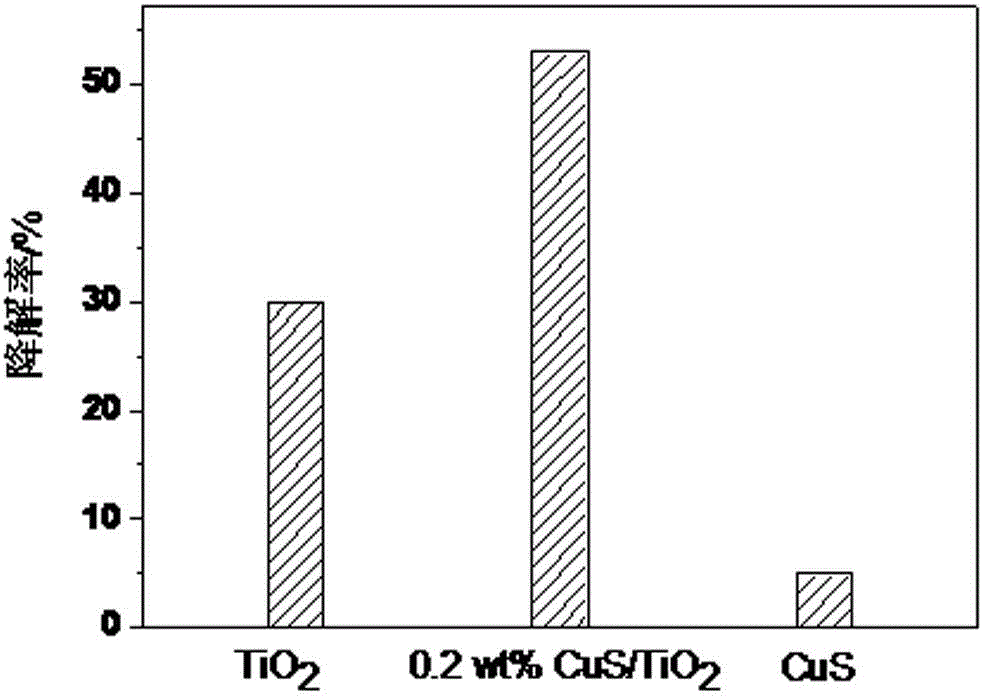

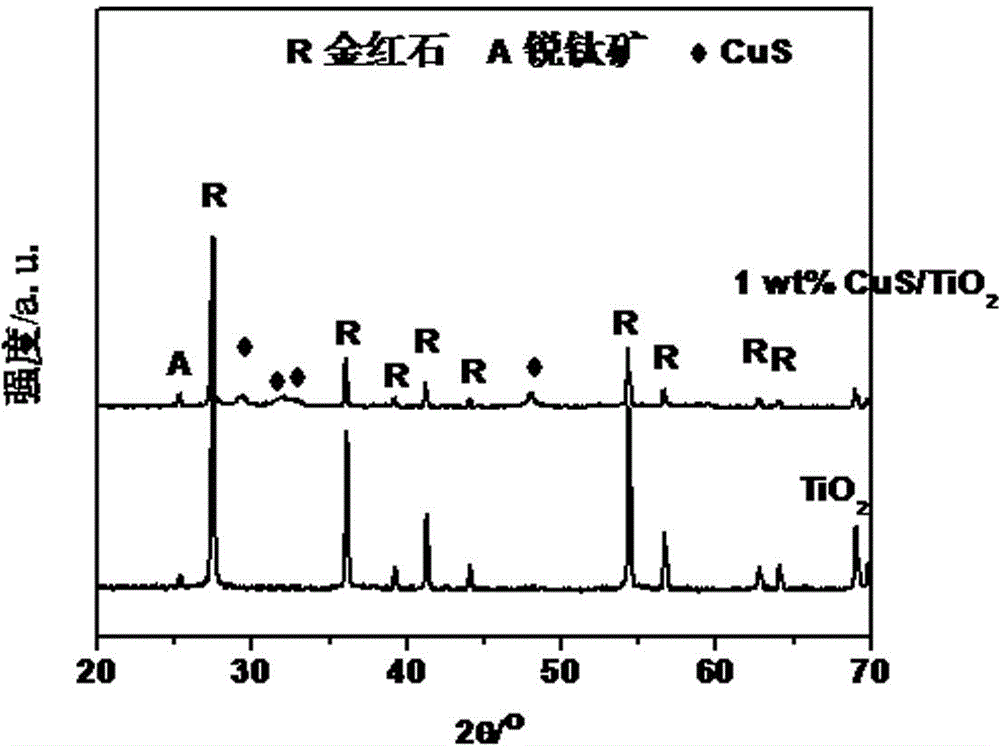

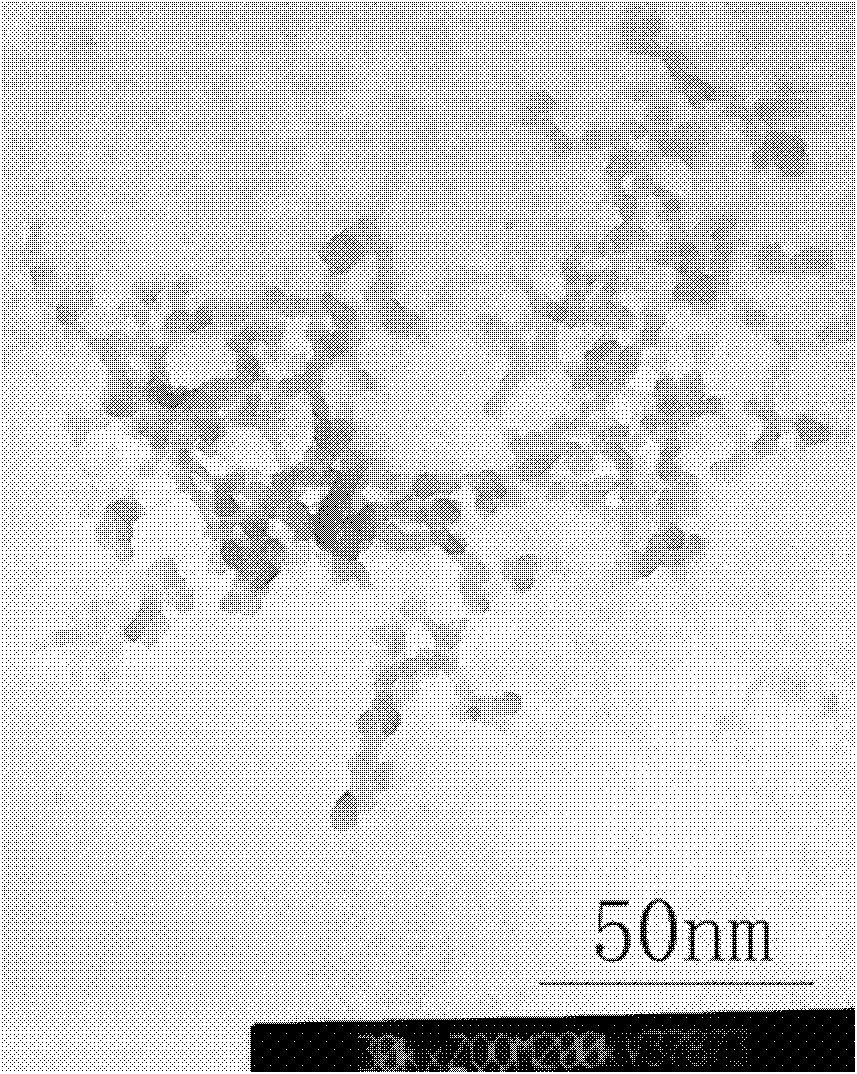

Low-temperature preparation method of copper sulfide/titanium oxide hetero-junction photocatalyst

InactiveCN104475129AHigh catalytic activityEasy to separatePhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsSolvent

The invention relates to a low-temperature preparation method of a copper sulfide (CuS) / titanium oxide (TiO2) hetero-junction photocatalyst. The method comprises the steps of (1) preparing titanium hydroxide (Ti(OH)4) by using an inorganic salt or an organic salt of titanium as a precursor and adopting a precipitation method or a sol-gel method; (2) roasting Ti(OH)4 at the temperature of 400-650 DEG C for 2-4h to obtain a TiO2 carrier; (3) dispersing copper powder and sulfur powder into a specific solvent, soaking the TiO2 carrier into the solvent, performing magnetic stirring, and heating for 4-24h in a water bath of 40-60 DEG C, wherein CuS generated by the copper powder and the sulfur powder can be loaded to the TiO2 carrier in the process; and (4) cooling the CuS / TiO2 sample to room temperature, and filtering, washing and drying the sample to obtain the CuS / TiO2 hetero-junction photocatalyst.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

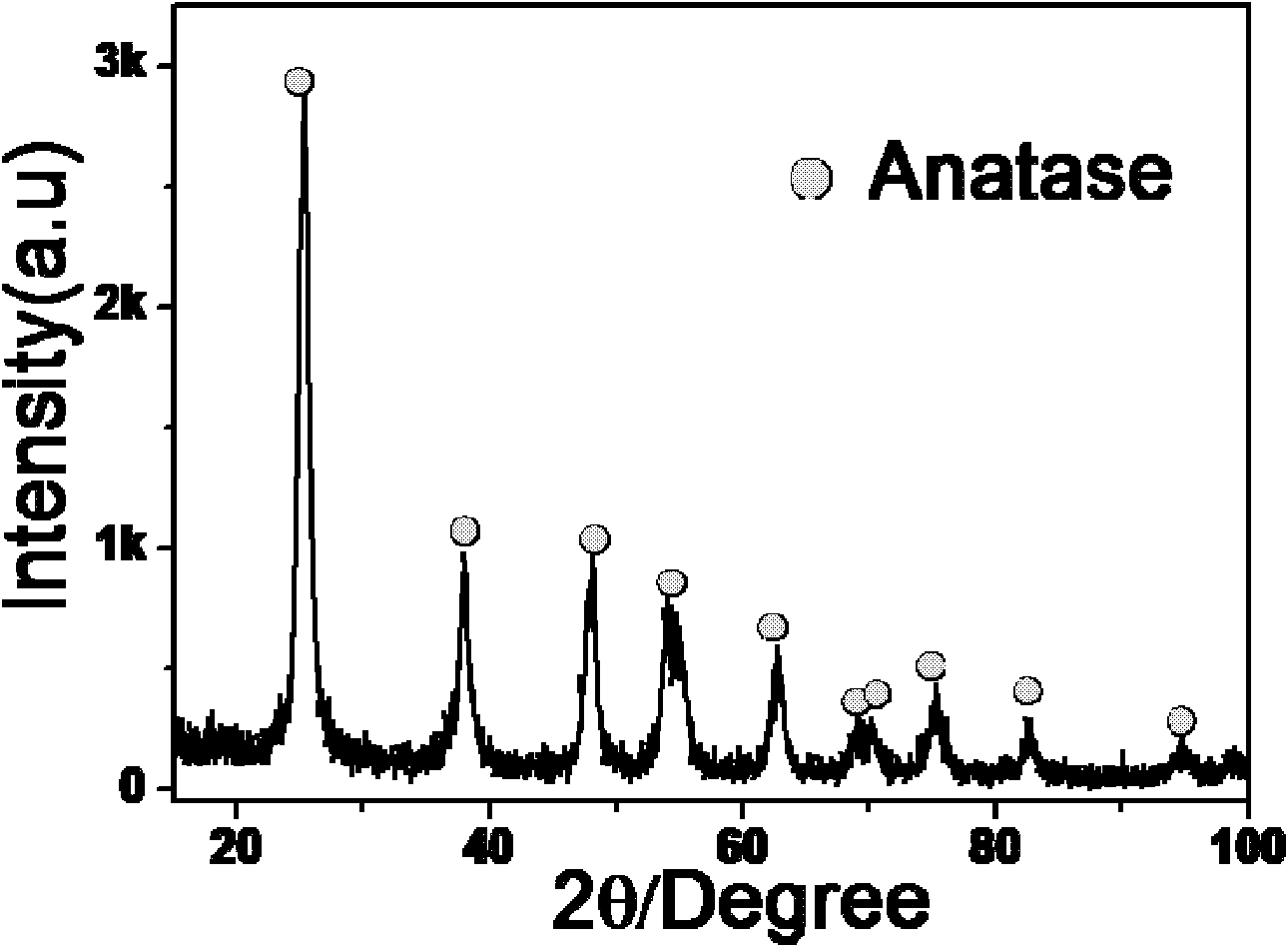

Method for preparing anatase titanium dioxide sol used for solar batteries

InactiveCN101891247APromote the process of industrializationHigh degree of bindingTitanium dioxideSpray coatingSolar battery

The invention discloses a method for preparing anatase titanium dioxide sol used for solar batteries. The method comprises the following steps of: performing coprecipitation titration of a titanium source and reaction solution to obtain a white precipitate of titanium hydroxide, dissolving the precipitate in a molar ratio of Ti4<+> to organic acid to hydrogen peroxide of 1:2:2-1:10:10, adjusting a pH value to 7.5, and standing the mixed solution stand for 12 hours to obtain a precursor of titanium dioxide sol; and performing hydrothermal treatment of the precursor of titanium dioxide sol at the temperature of between 70 and 250 DEG C to obtain the yellow anatase titanium dioxide sol. The anatase titanium dioxide sol used for dye-sensitized solar batteries undergoes spin coating or spray coating to form a film which is the titanium dioxide dense film used for high-performance dye-sensitized solar batteries, the bonding degree between the titanium dioxide film and the matrix is improved, the contact between the electrolyte and an light anode can be effectively avoided, so that the electron recombination is lowered, the performance of the battery is greatly improved, and the industrialization of the dye-sensitized solar battery industry is pushed forward.

Owner:IRICO

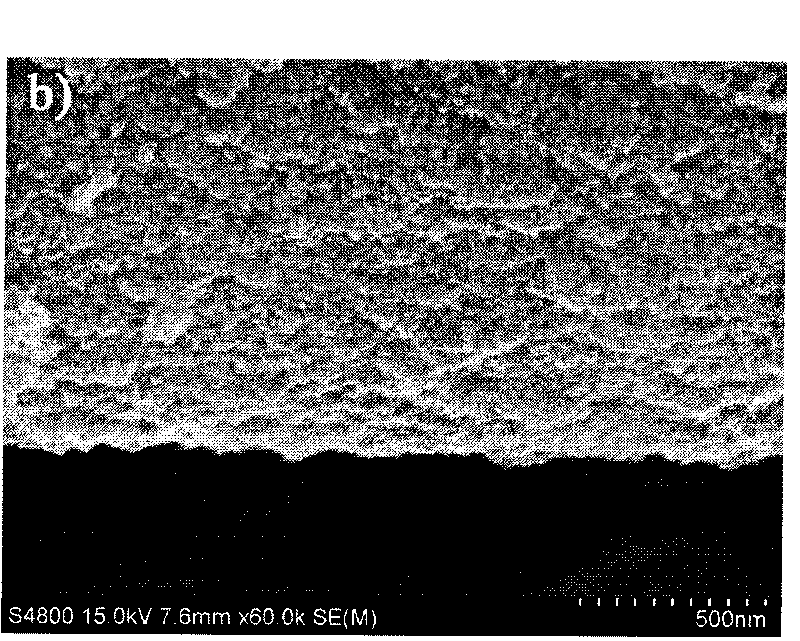

Method for preparing modified glass microspheres

InactiveCN102001835AGuaranteed compactnessLight-sensitive devicesSolid-state devicesMicrosphereTitanium hydroxide

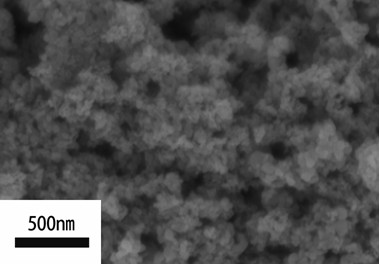

The invention discloses a method for preparing modified glass microspheres, which comprises the steps of: firstly, coprecipitating a titanium source and a basic hydrolysis reaction solution in water, reacting to obtain a white titanium hydroxide deposit; obtaining a titanium dioxide sol precursor after carrying out washing, peptizing and aging; then carrying out hydro-thermal treatment to obtain anatase phase titanium dioxide sol; mixing the anatase phase titanium dioxide sol with glass microspheres; mill-grinding, and cooling after thermal treatment to obtain the titanium dioxide modified glass microspheres for light scattering of a dye sensitization solar battery. The finished glass microsphere product prepared by using the method for preparing the modified glass microsphere is wrapped with well-crystallized anatase phase titanium dioxide particles on the surface; and the mill-ground glass microspheres have irregular shapes, and have maximum particle diameter of about 400nm and minimum particle diameter of about 200nm, which ensures the compactness of the glass microspheres subjected to film formation.

Owner:IRICO

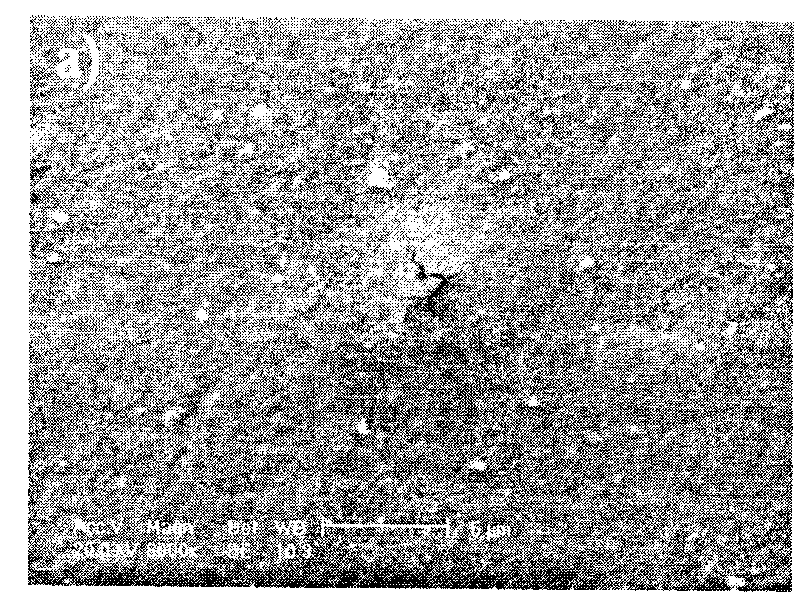

Medical prosthetic devices having improved biocompatibility

The invention relates to a medical prosthetic device comprising a metal material, such as titanium or an alloy thereof, where the surface parts of the metal material are coated with a layer of a corresponding hydroxide material, such as titanium hydroxide. Preferably, the hydroxide layer comprises one or more biomolecule substances associated therewith. The invention also relates to an electrolytic process for the preparation of a medical prosthetic device.

Owner:STRAUMANN HLDG AG

Method for preparing calcium titanate nanoparticles

InactiveCN102139914ASimple processEasy to controlNanotechnologyTitanium compoundsPotassium hydroxideCalcium nitrate

The invention discloses a method for preparing calcium titanate nanoparticles. The method comprises the following steps of: adding a mineralizing agent, namely potassium hydroxide, with proper concentration, into hydrothermal reaction materials, namely titanium hydroxide coprecipitate and deionized water solution of calcium nitrate; introducing solution obtained by hydrothermally decomposing glucose into a hydrothermal system to influence nucleation and control the particle size of products; and synthesizing the calcium titanate nanoparticles of which the diameter is 30 to 60nm by hydrothermal reaction. The process is simple and is easy to control; the method is environment-friendly and low in cost; and the products are easy to produce.

Owner:ZHEJIANG UNIV

Method for preparing a gel containing nanometer titanium dioxide powders for visible light photocatalysis

ActiveUS7090823B1Photochemical and self-cleaning efficiencyEffective lightingPigmenting treatmentNanotechUltraviolet lightsTitanium hydroxide

Owner:ONID TECH

Antifogging element and method for forming the same

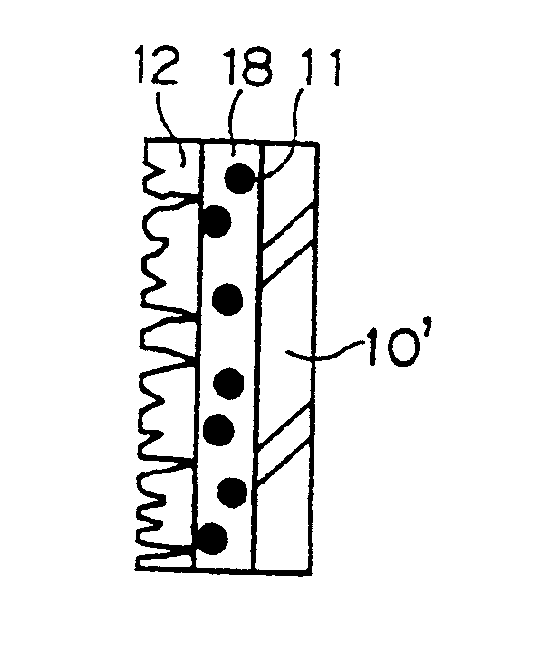

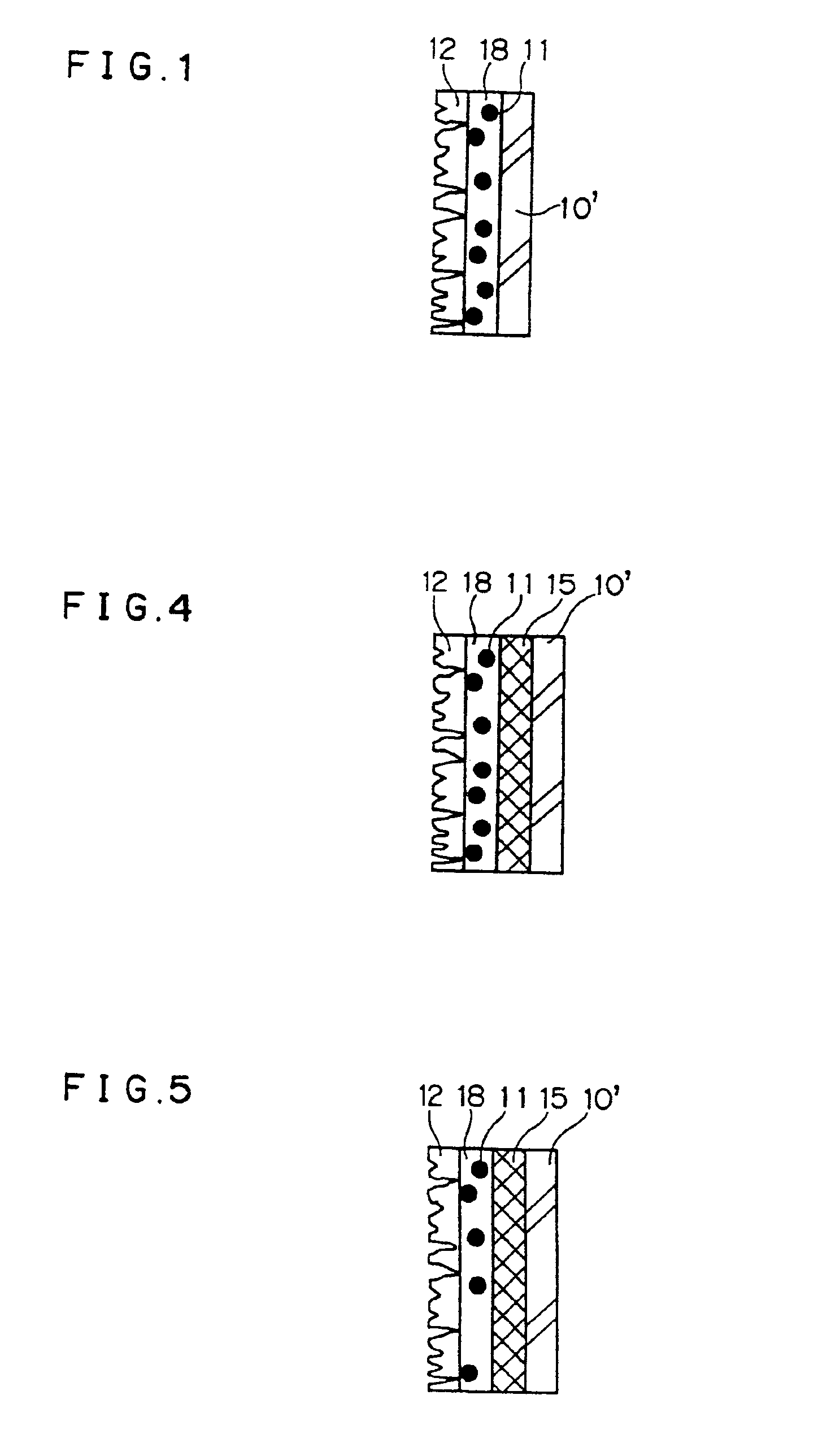

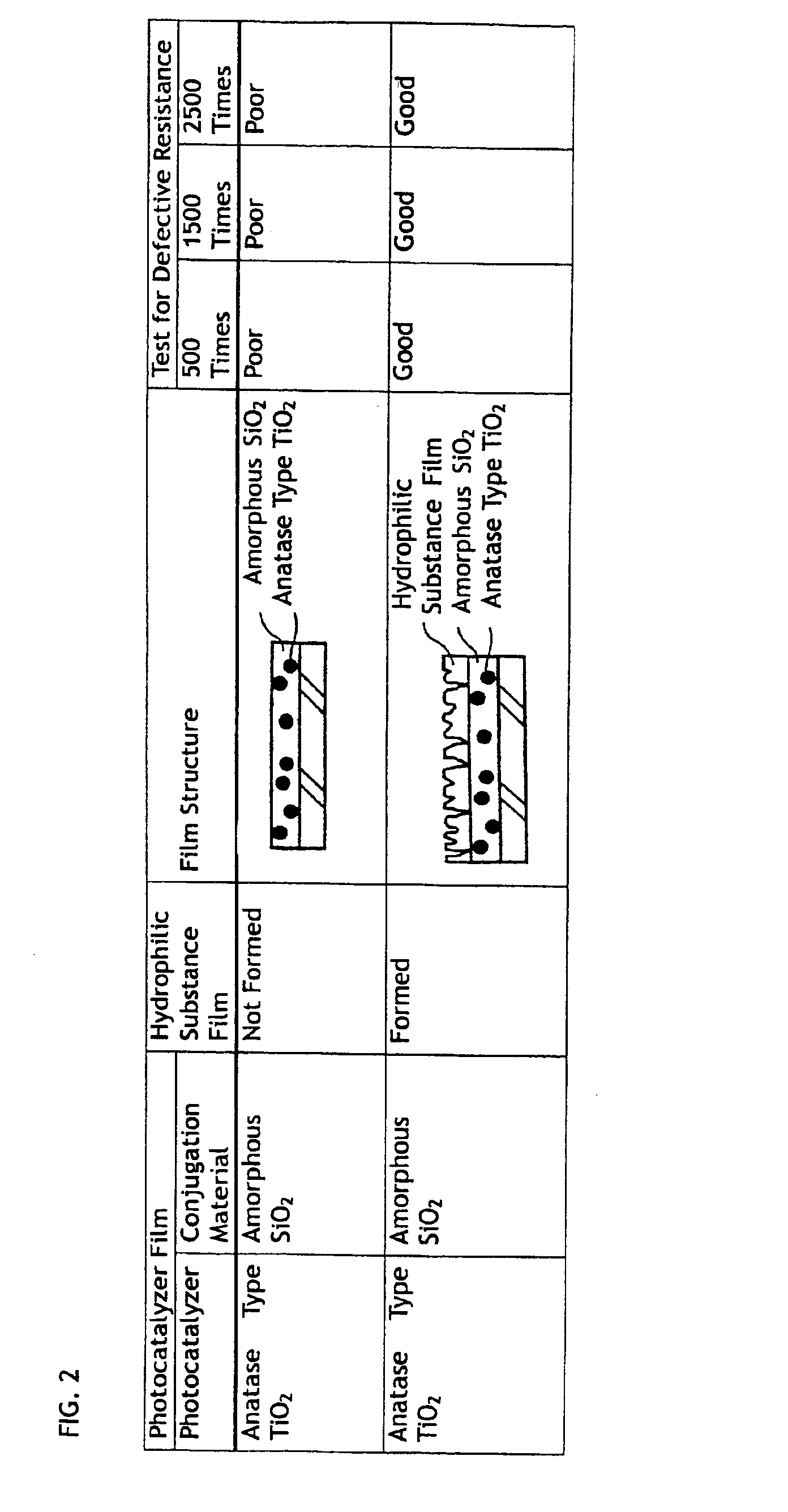

A coating agent including photocatalyst particles dispersed in a titanium peroxide solution obtainable by causing titanium hydroxide (orthotitanic acid) gel to act with hydrogen peroxide being used as a material for the photocatalyzer film is used to a photocatalyzer film having photocatalyst particles supported therein. By forming a porous hydrophilic substance film on the photocatalyzer film, the defects of the film caused by the wiping can be prevented. Also, a film formed by using the coating agent including photocatalyst particles dispersed in a titanium peroxide solution at a temperature of from normal room temperature to 200° C. is of high porosity in comparison with a film formed at a higher temperature and with a film not having a photocatalyst particles dispersed therein. Consequently, the photocatalyzer film and the hydrophilic substance film have good adhesion property when use with each other.

Owner:MURAKAMI CORP

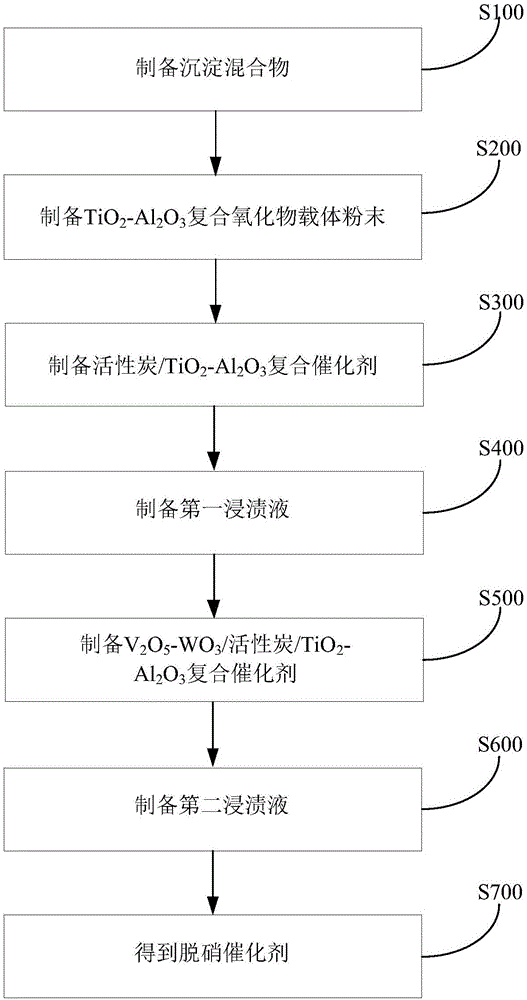

Denitration catalyst and preparation method thereof

The invention discloses a denitration catalyst and a preparation method thereof. The preparation method comprises the following steps: preparing a precipitate mixture of titanium hydroxide and aluminium hydroxide; drying and roasting the precipitate mixture to obtain TiO2-Al2O3 compound oxide carrier powder; extruding, forming, sizing and drying the TiO2-Al2O3 compound oxide carrier powder, activated carbon powder, enamelled powder and an adhesive to obtain an activated carbon / TiO2-Al2O3 compound catalyst; dissolving ammonium metatungstate and ammonium metavanadate in oxalic acid to obtain first impregnation liquid; impregnating the activated carbon / TiO2-Al2O3 compound catalyst in the first impregnation liquid to obtain a V2O5-WO3 / activated carbon / TiO2-Al2O3 compound catalyst; preparing second impregnation liquid; and impregnating the V2O5-WO3 / activated carbon / TiO2-Al2O3 compound catalyst in second impregnation liquid to obtain the denitration catalyst. The denitration catalyst prepared by the method disclosed by the invention has relatively high denitration catalytic activity, is high in wear resistance and acid resistance and wide in active temperature region, and can recover waste heat while performs denitration treatment on to-be-treated flue gas.

Owner:SHENWU TECH GRP CO LTD

Method for coating hollow microbeads with titanium-lanthanum oxides

InactiveCN102226042AImprove thermal insulation performanceImprove bindingReflecting/signal paintsPigment physical treatmentSurface oxidationRutile

The present invention discloses a method for coating hollow microbeads with titanium-lanthanum oxides. By the method, the surfaces of the hollow microbeads are evenly coated with rutile nano titanium oxide and have a good reflection effect, and the heat-insulation effect of the coating is improved. The method comprises: heating a mixed solution of titanium sulfate solution and lanthanum sulfate solution while stirring to 75-90 DEG C, maintaining the constant temperature and controlling the stirring speed at 500-800 rpm, and simultaneously adding soaked hollow microbeads to the mixed solution at a constant speed within 60-90 minutes; adjusting the pH value of the system to 8.0-9.5, then stirring the system at the stirring speed of 30-80 rpm for 40-90 minutes, and simultaneously ultrasonically vibrating the system; then filtering and washing until the material has a solid content of more than 40%; then carrying out microwave treatment for 15-25 minutes until the material has a solid content of more than 90% and fluffy oxidized surfaces; and heating the material in a roaster to 300 DEG C, maintaining for 1-3 hours, then heating to 900 DEG C and maintaining for 30-60 minutes so that titanium hydroxide coated on the surface of the hollow microbeads is transformed into rutile titanium dioxide.

Owner:TIANJIN HENGSHITONG ENG TECH DEV

Medical prosthetic devices having improved biocompatibility

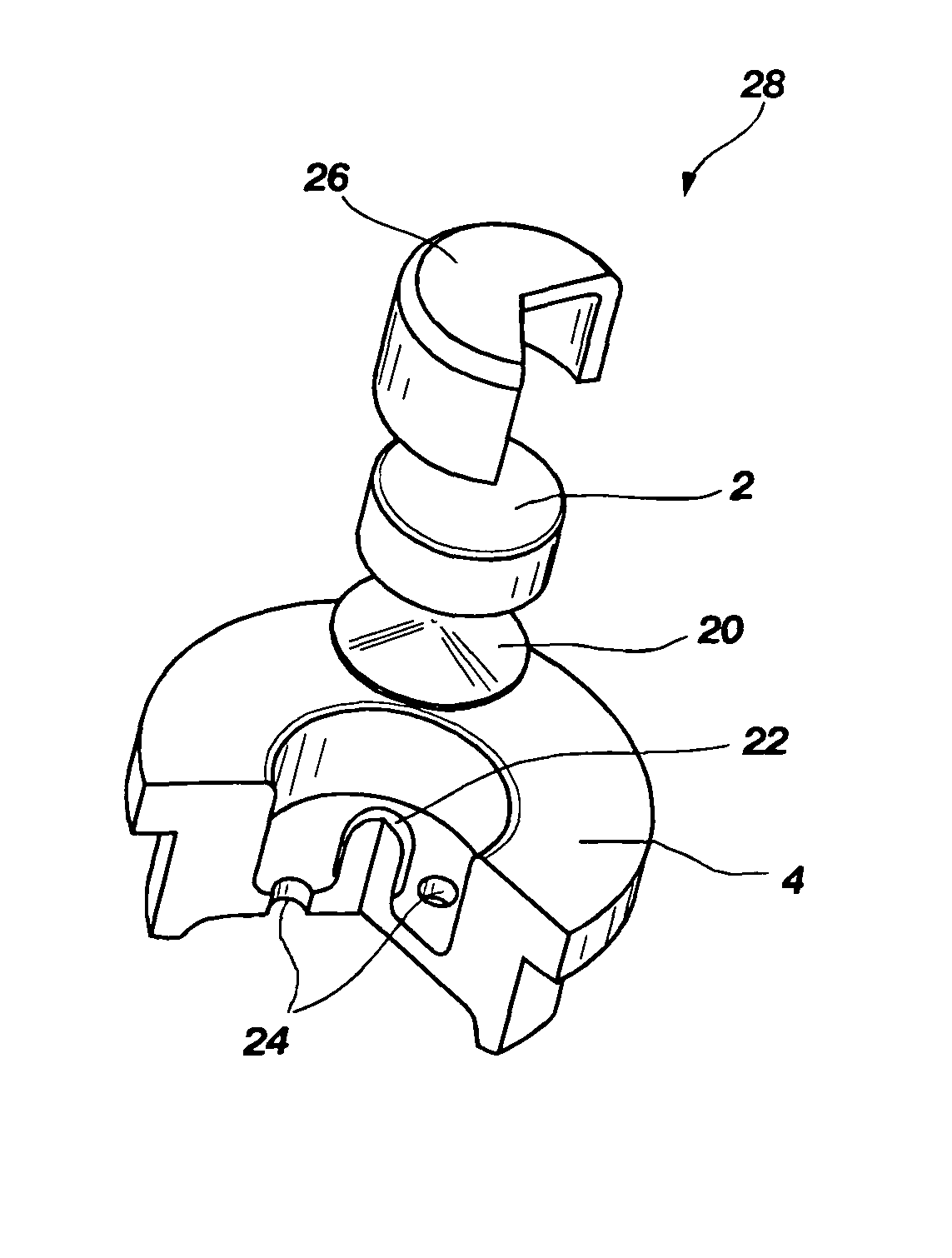

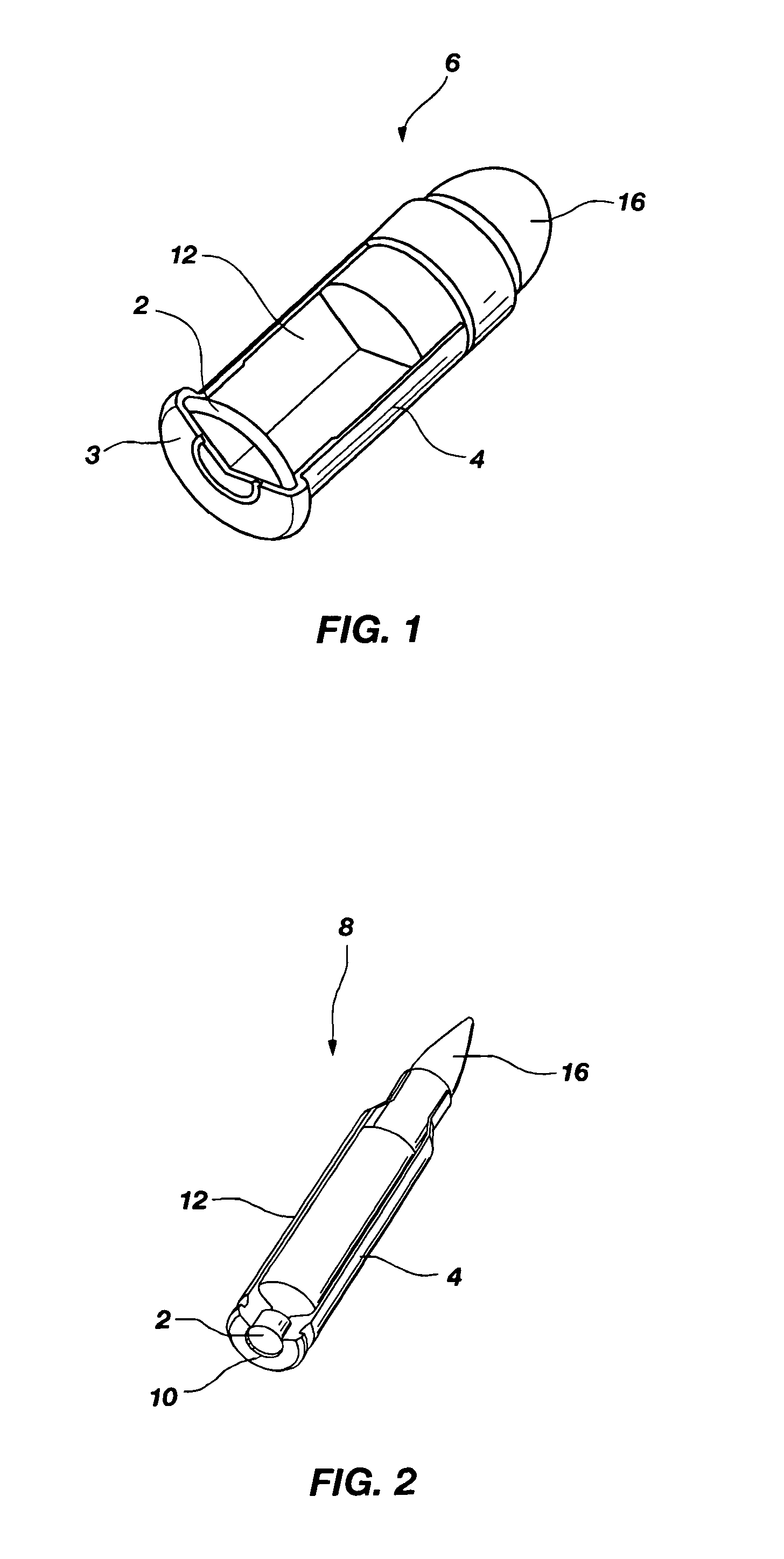

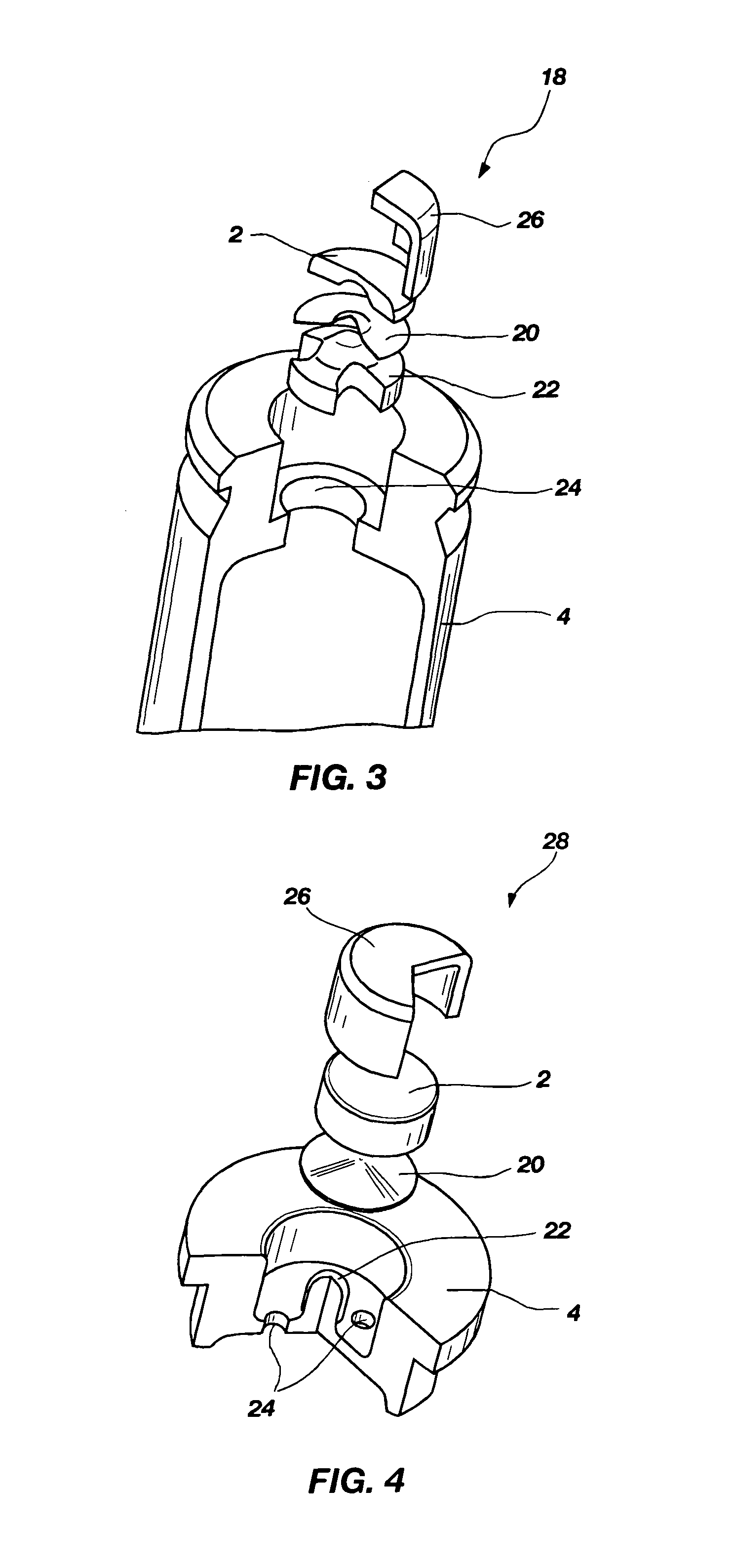

InactiveUS7410502B2Simple structureAdvantageous biocompatibility propertyBone implantSurgeryBiocompatibility TestingMetallic materials

The invention relates to a medical prosthetic device having a metal material, such as titanium or an alloy thereof, where the surface parts of the metal material are coated with a layer of a corresponding hydroxide material, such as titanium hydroxide. Preferably, the hydroxide layer includes one or more biomolecule substances associated therewith. The invention also relates to an electrolytic process for the preparation of a medical prosthetic device.

Owner:STRAUMANN HLDG AG

Method for preparing strontium titanate nanoparticles

InactiveCN102139916ASimple processEasy to controlNanotechnologyTitanium compoundsStrontium titanium oxideNanoparticle

The invention discloses a method for preparing strontium titanate nanoparticles. The method comprises the following steps of: adding a mineralizing agent, namely potassium hydroxide, with proper concentration, into hydrothermal reaction materials, namely titanium hydroxide coprecipitate and deionized water solution of strontium nitrate; introducing solution obtained by hydrothermally decomposing glucose into a hydrothermal system to influence nucleation and control the particle size of products; and synthesizing the strontium titanate nanoparticles of which the diameter is 20 to 50nm by hydrothermal reaction. The process is simple and is easy to control; the method is environment-friendly and low in cost; and the products are easy to produce.

Owner:ZHEJIANG UNIV

Preparation method of titanium oxide and its application

InactiveCN1442366AExcellent adhesionNot easy to fall offPigmenting treatmentTitanium dioxideTitanium hydroxideTitanium

A process for preparing titanium oxide includes such steps as converting the Ti-contained aqueous solution to titanium hydroxide, adding hydrogen peroxide and generating thermal reaction to obtain the solution of anatase-type titanium oxide solution with complex group, and drying. It can be used to prepare coating solution, while has high adhesion and no corrosion to substrate.

Owner:广东奥因环保科技有限公司

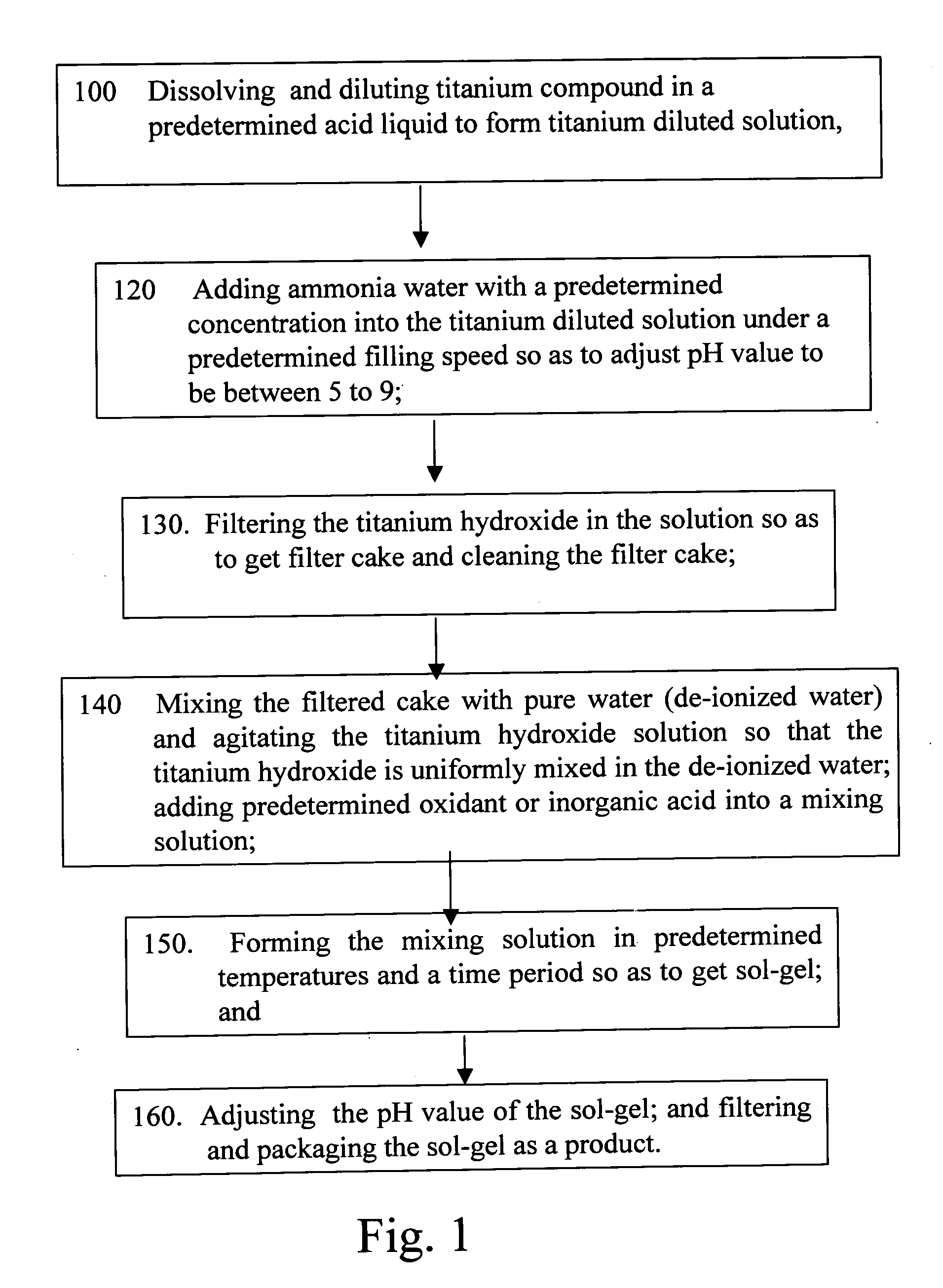

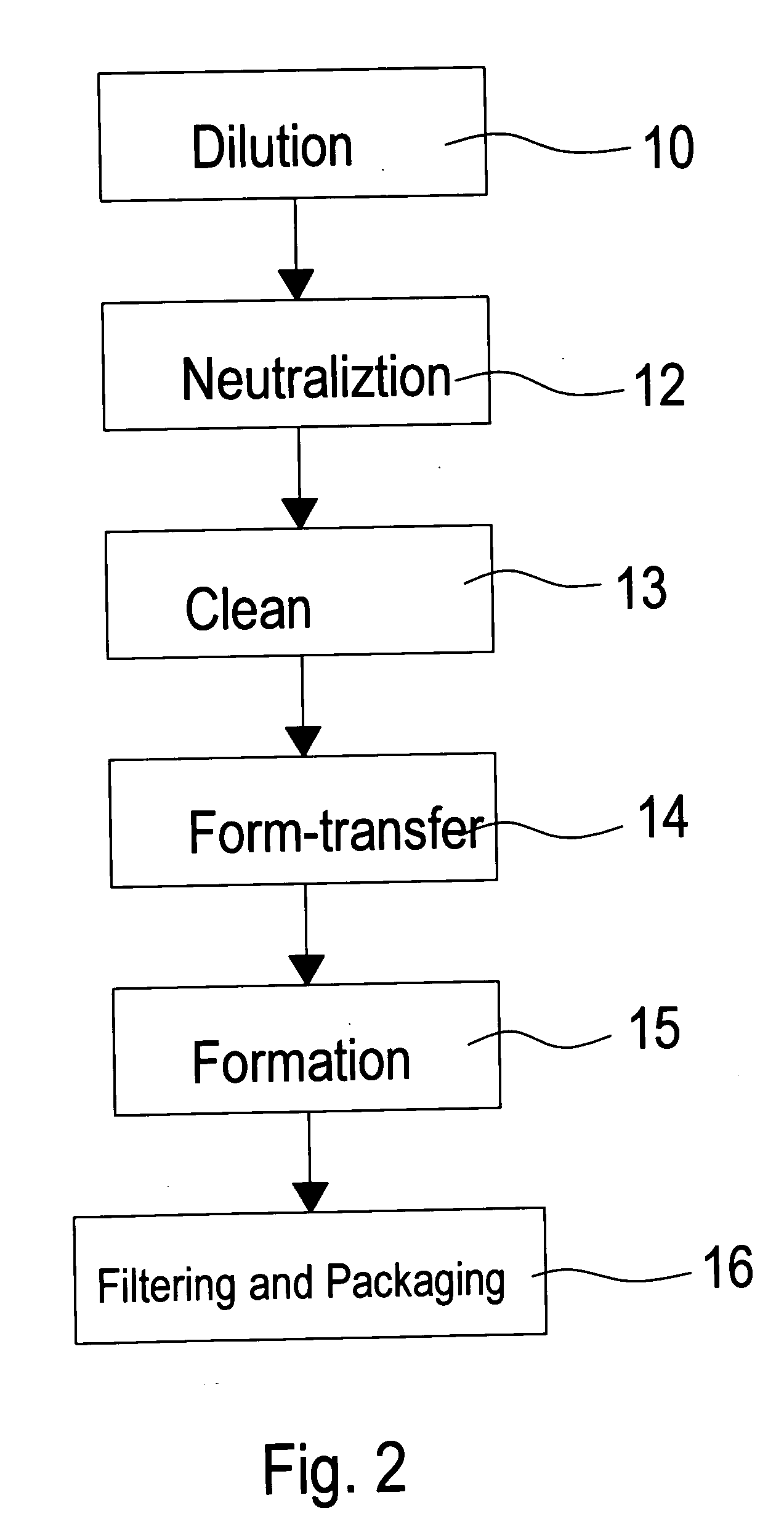

Method for manufacturing nanometer scale crystal titanium dioxide photo-catalyst sol-gel

InactiveUS20050265918A1Improve defectsHigh concentrationMaterial nanotechnologyCatalyst activation/preparationTitanium hydroxideTitanium

A method for manufacturing nanometer scale crystal titanium dioxide photo-catalyst sol-gel is disclosed. Titanium compound is dissolved and diluted in a predetermined acid liquid to form titanium diluted solution, and the pH value is adjusted to be between 7.0 to 9.0. Then titanium hydroxide in the solution is filtered so as to get filter cake and then it is cleaned. Then oxidant and inorganic acid is added to form titanium dioxide sol-gel solution under predetermined conditions. The titanium dioxide sol-gel solution can be transparent or yellow color depending on operation conditions. The content of photo-catalyst is between 0.5 to 10%.

Owner:LIU WEN CHUAN

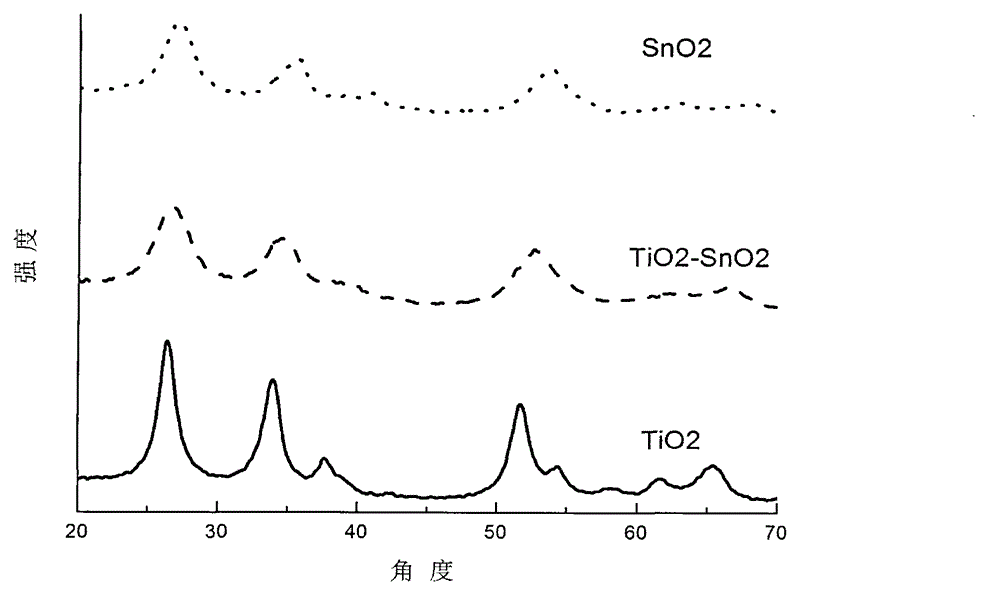

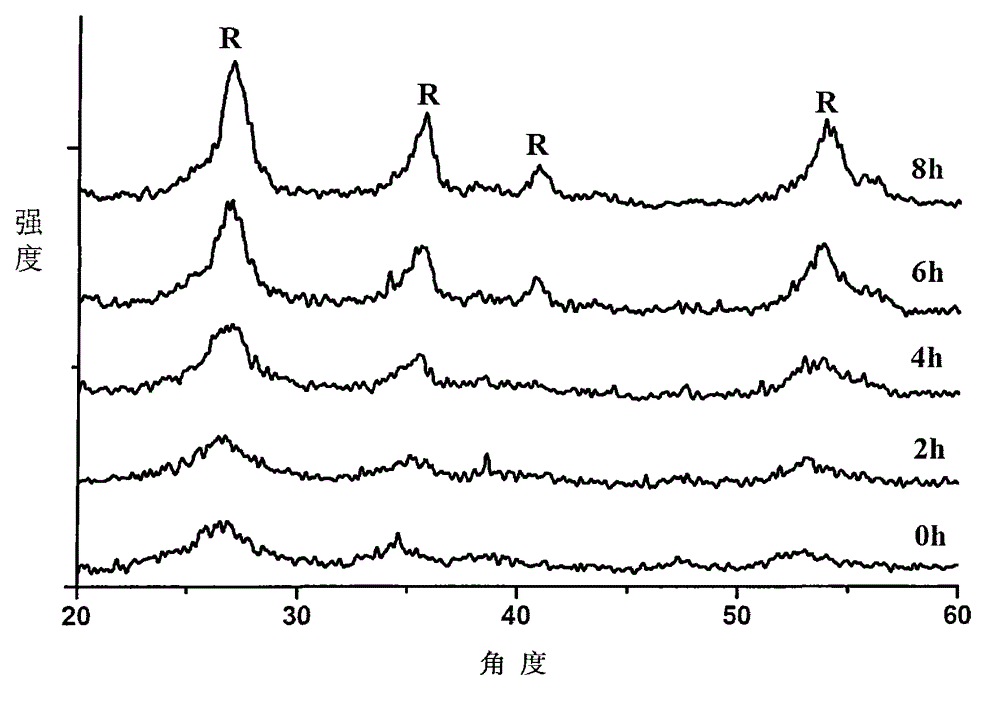

Synthesizing method of water-based nano conductive sol and transparent conductive thin film made of water-based nano conductive sol

InactiveCN102910672AWide variety of sourcesLow priceSolid/suspension decomposition chemical coatingTitanium oxides/hydroxidesTin dioxideWater based

The invention relates to a synthesizing method of tin dioxide / titanium dioxide solid solution nano sol composite and a film forming technique for preparing transparent conductive thin films on surfaces of different substrates on the basis of the sol. The synthesizing method includes the steps of firstly, precipitating tin-titanium hydroxide; secondly, dispersing precipitate with hydrogen peroxide; and thirdly, synthesizing final product. The synthesizing method is few in steps and simple in process. The synthesized tin-titanium oxide solid solution nano sol is water-based, defects in the prior art are overcome, environmental pollution is avoided, synthesizing of water-based sol at normal pressure and low temperature is achieved, and film forming is easy.

Owner:程明明 +2

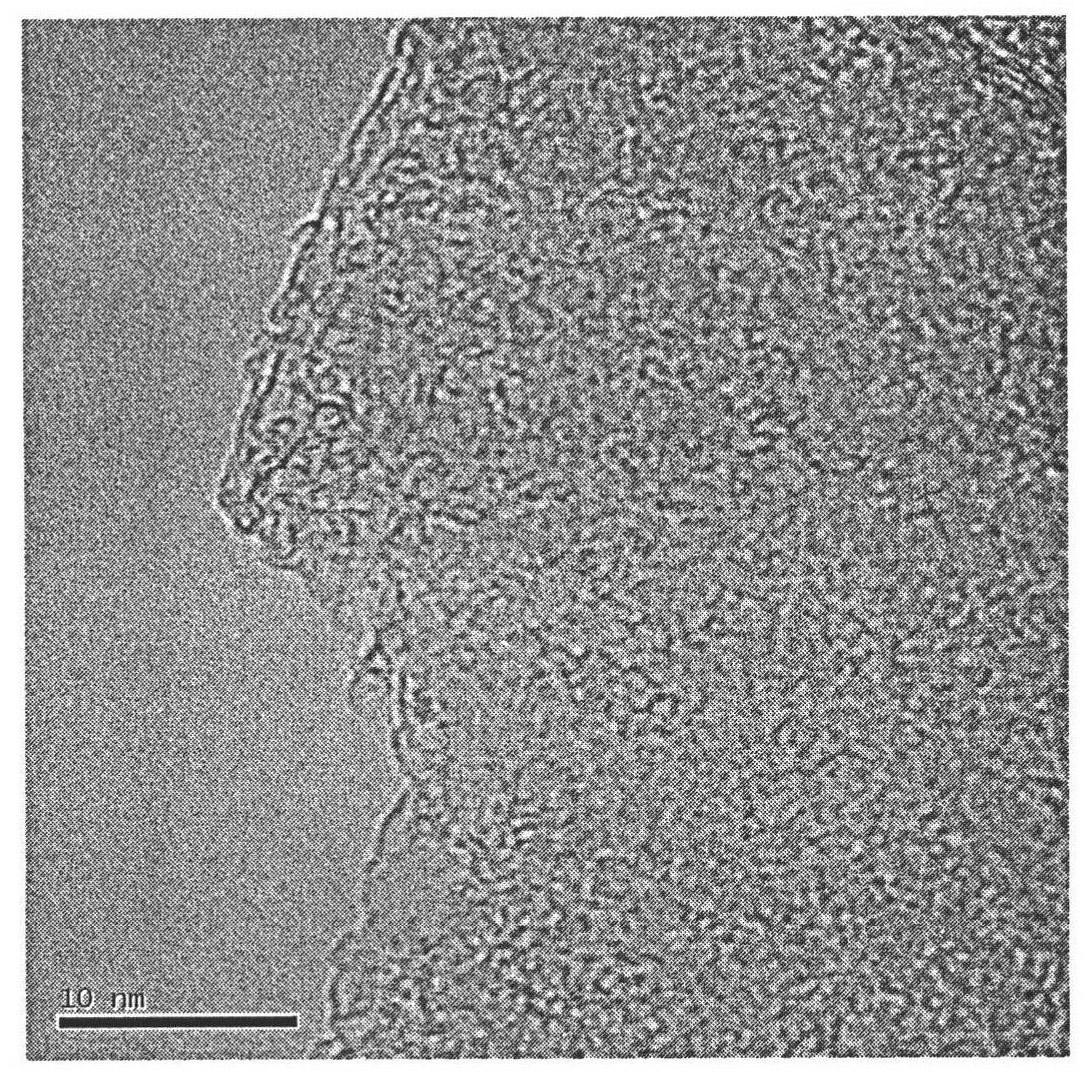

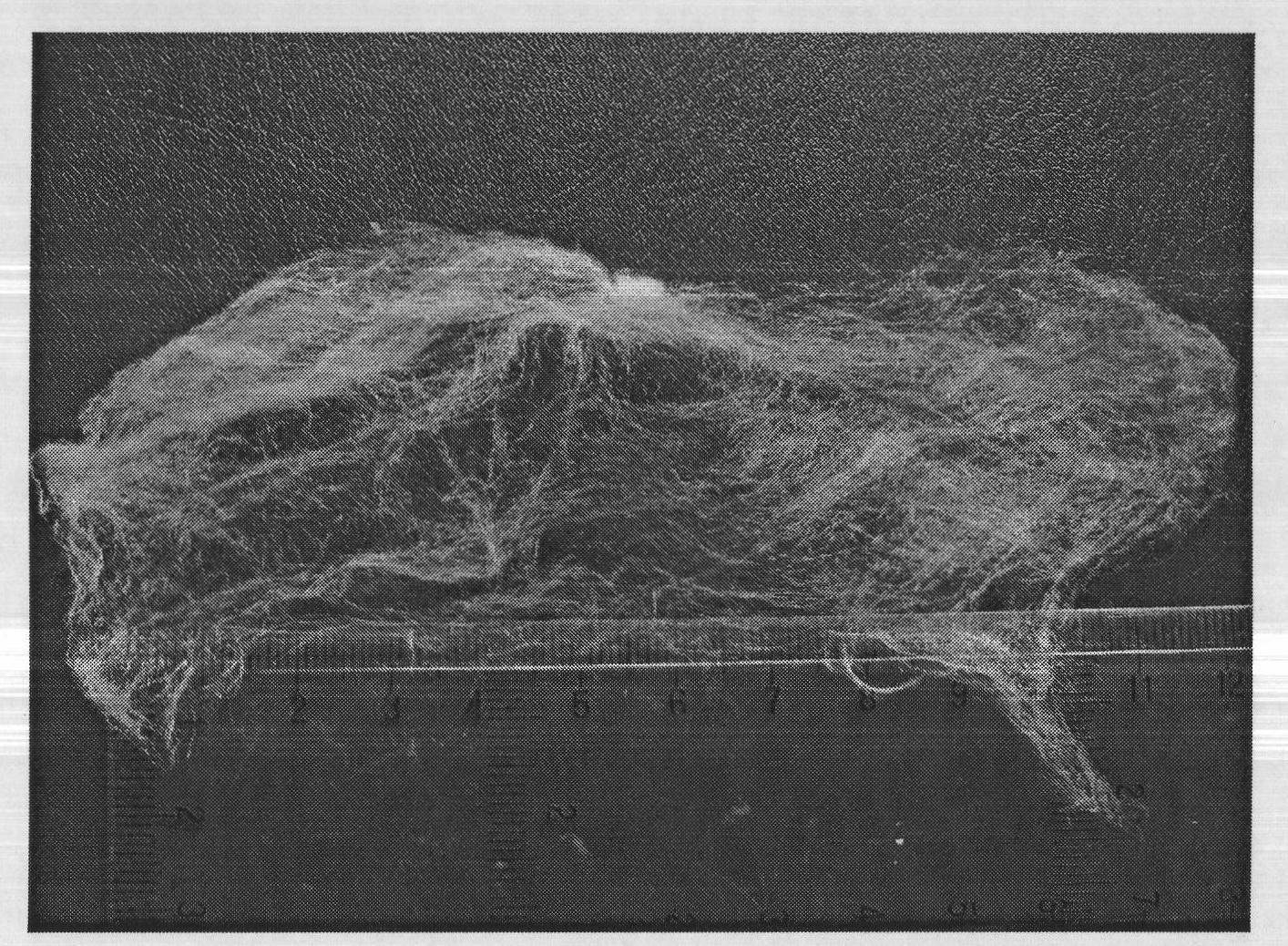

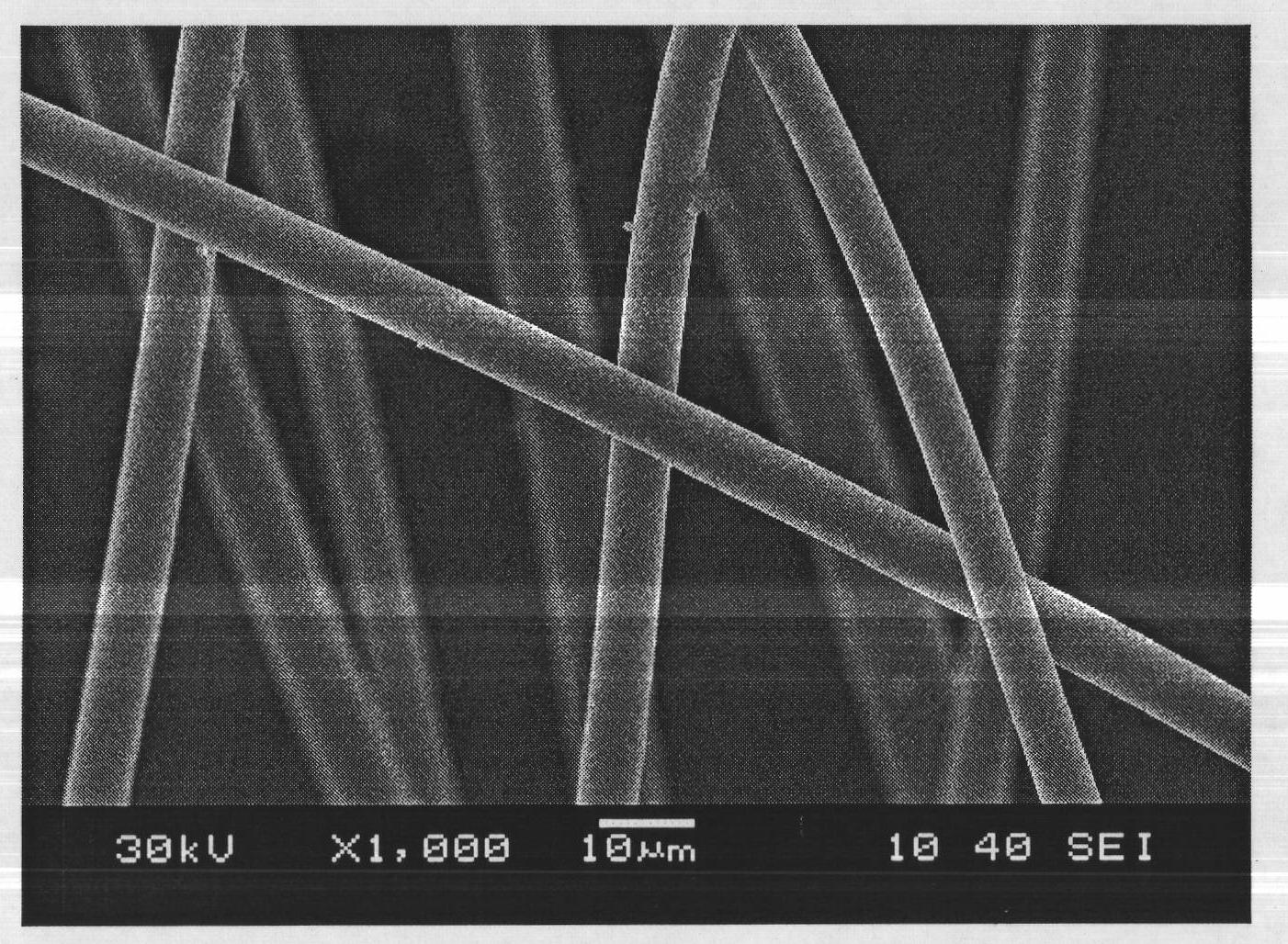

Method for preparing nano-crystalline photocatalysis titanium dioxide fiber

InactiveCN101831728AImprove spinnabilitySpinnableInorganic material artificial filamentsFilament/thread formingFiberSteam activation

The invention discloses a method for preparing a nano-crystalline photocatalysis titanium dioxide fiber, which comprises the following steps of: synthesizing a poly-titanium sol spinning fluid by using titanium hydroxide, aqueous solution of hydrogen peroxide, organic acid and a sol as raw materials; performing centrifugal thread throwing to obtain a poly-titanium gelatinous fiber; and performing steam activation heat treatment on the poly-titanium gelatinous fiber to obtain the nano-crystalline photocatalysis titanium dioxide fiber. Compared with the prior art, the preparation of the spinning fluid is innovative and has obvious advantages, the titanium hydroxide, the hydrogen peroxide, the organic acid and the sol are used as the raw materials, and the poly-titanium sol spinning fluid can be prepared through direct reaction and concentration, so a synthetic process is greatly simplified without rigorous reaction conditions and complicated reaction equipment, and no pollution problems exist.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of non-high-temperature resistant base material loaded with controllable-crystal nano titanium dioxide on surface

InactiveCN101734716ANo damageIncreased durabilityNanostructure manufactureTitanium dioxideMaterials preparationTitanium hydroxide

The invention discloses a preparation method of a non-high-temperature resistant base material loaded with controllable-crystal nano titanium dioxide on surface, which belongs to the technical field of material preparation. The preparation method comprises the following steps: hydrolyzing or precipitating the titanium material by adding alkali to obtain titanium hydroxide, peptizing to obtain a treating fluid for loading, immersing the pretreated base material into the treating fluid for loading, carrying out reaction at 70-100 DEG C for 24-72 hours, cleaning, and drying to obtain the non-high-temperature resistant base material loaded with controllable-crystal nano titanium dioxide. The method has the advantages of simple preparation process and low requirements for equipment. The obtained material can be used for purifying air, degrading organic pollutants, shielding ultraviolet rays and the like.

Owner:YANGZHOU UNIV

Nontoxic, noncorrosive phosphorus-based primer compositions

A primer composition that includes stabilized, encapsulated red phosphorus, at least one oxidizer, at least one secondary explosive composition, at least one light metal, and at least one acid resistant binder. The stabilized, encapsulated red phosphorus may include particles of red phosphorus, a metal oxide coating, and a polymer layer. The metal oxide coating may be a coating of aluminum hydroxide, bismuth hydroxide, cadmium hydroxide, cerium hydroxide, chromium hydroxide, germanium hydroxide, magnesium hydroxide, manganese hydroxide, niobium hydroxide, silicon hydroxide, tin hydroxide, titanium hydroxide, zinc hydroxide, zirconium hydroxide, or mixtures thereof. The polymer layer may be a layer of epoxy resin, melamine resin, phenol formaldehyde resin, polyurethane resin, or mixtures thereof. A percussion cap primer that includes the primer composition, a tertiary explosive composition, and a cup is also disclosed, as are ordnance devices including the primer composition.

Owner:NORTHROP GRUMMAN SYST CORP

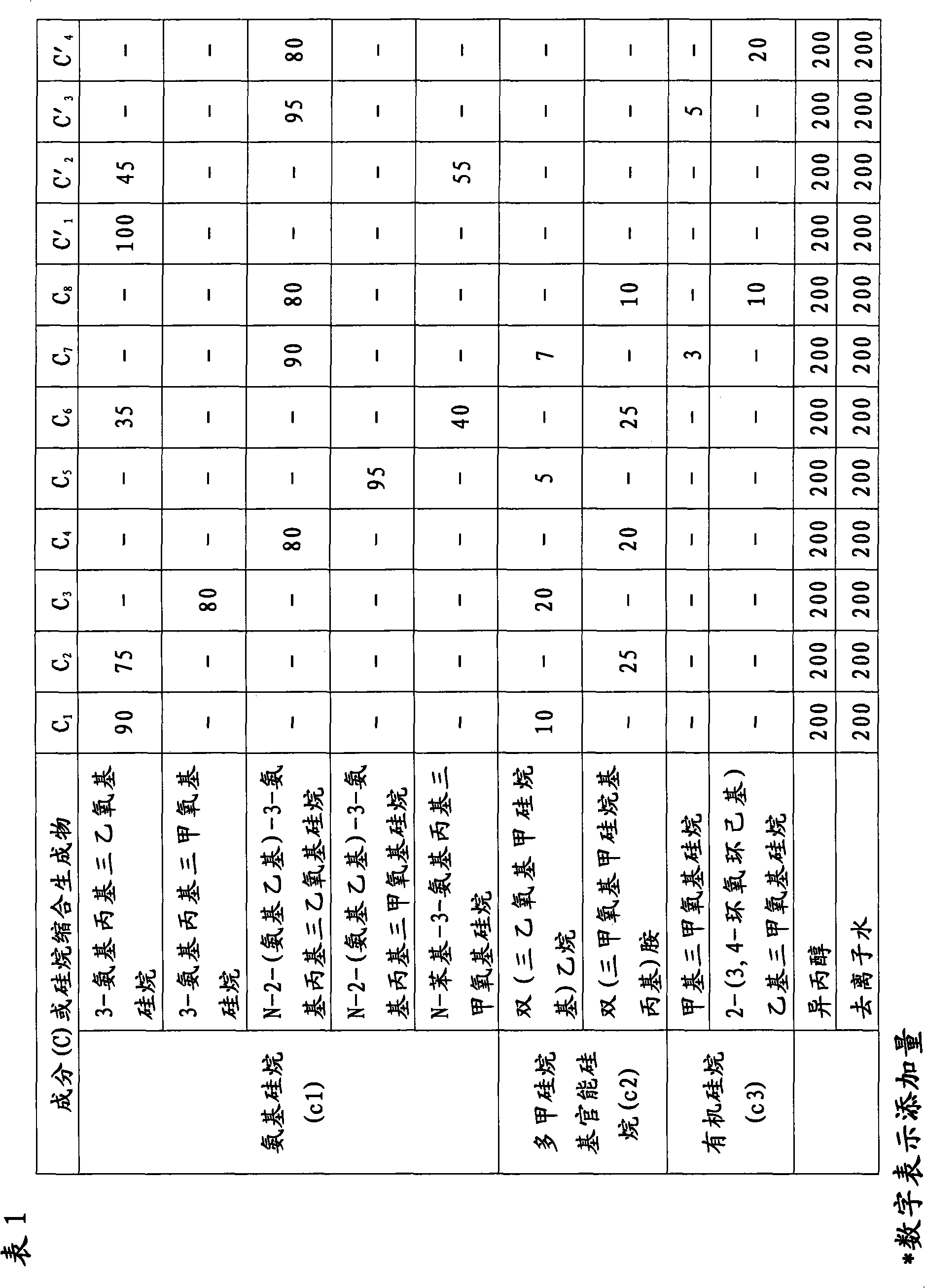

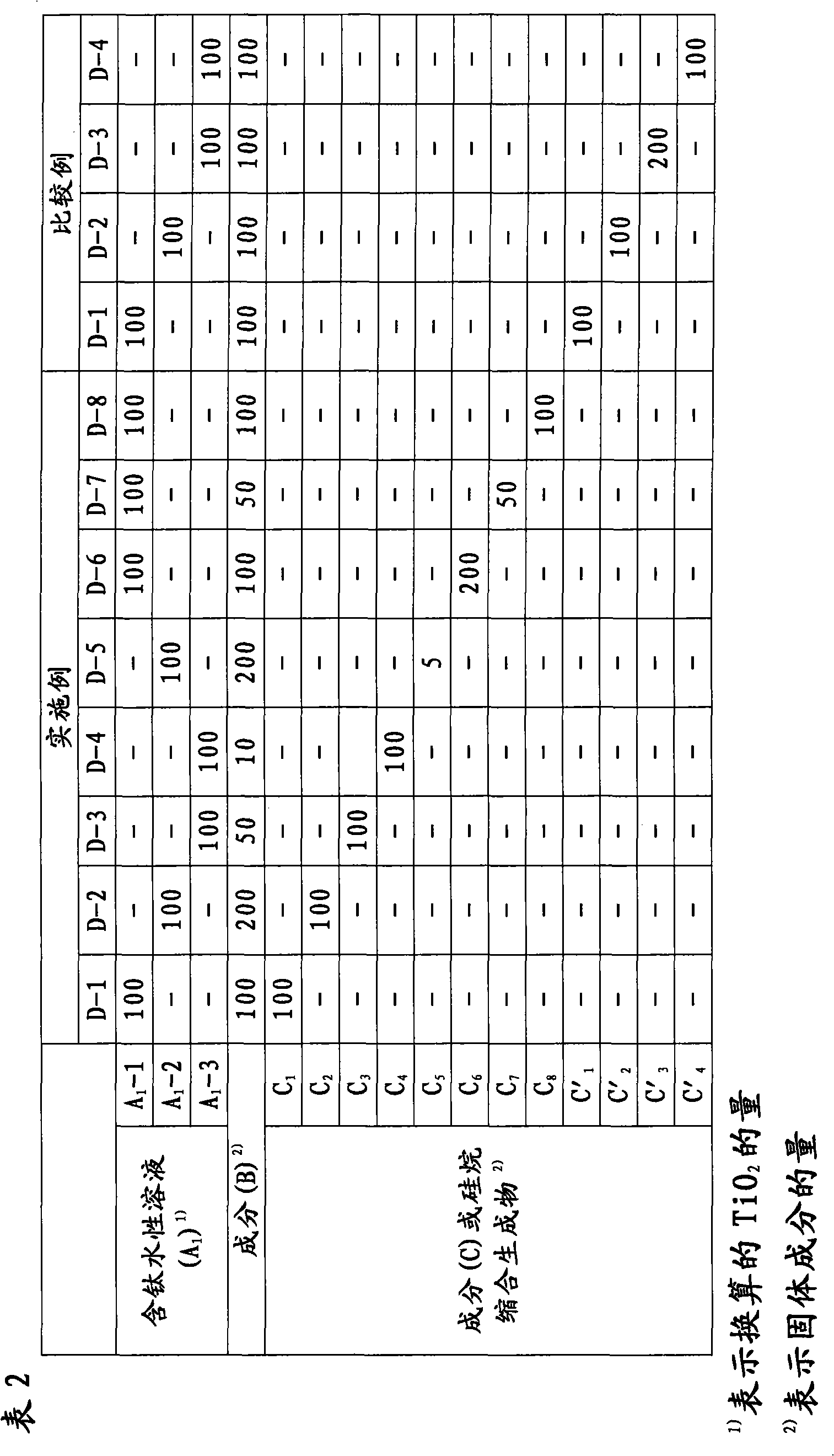

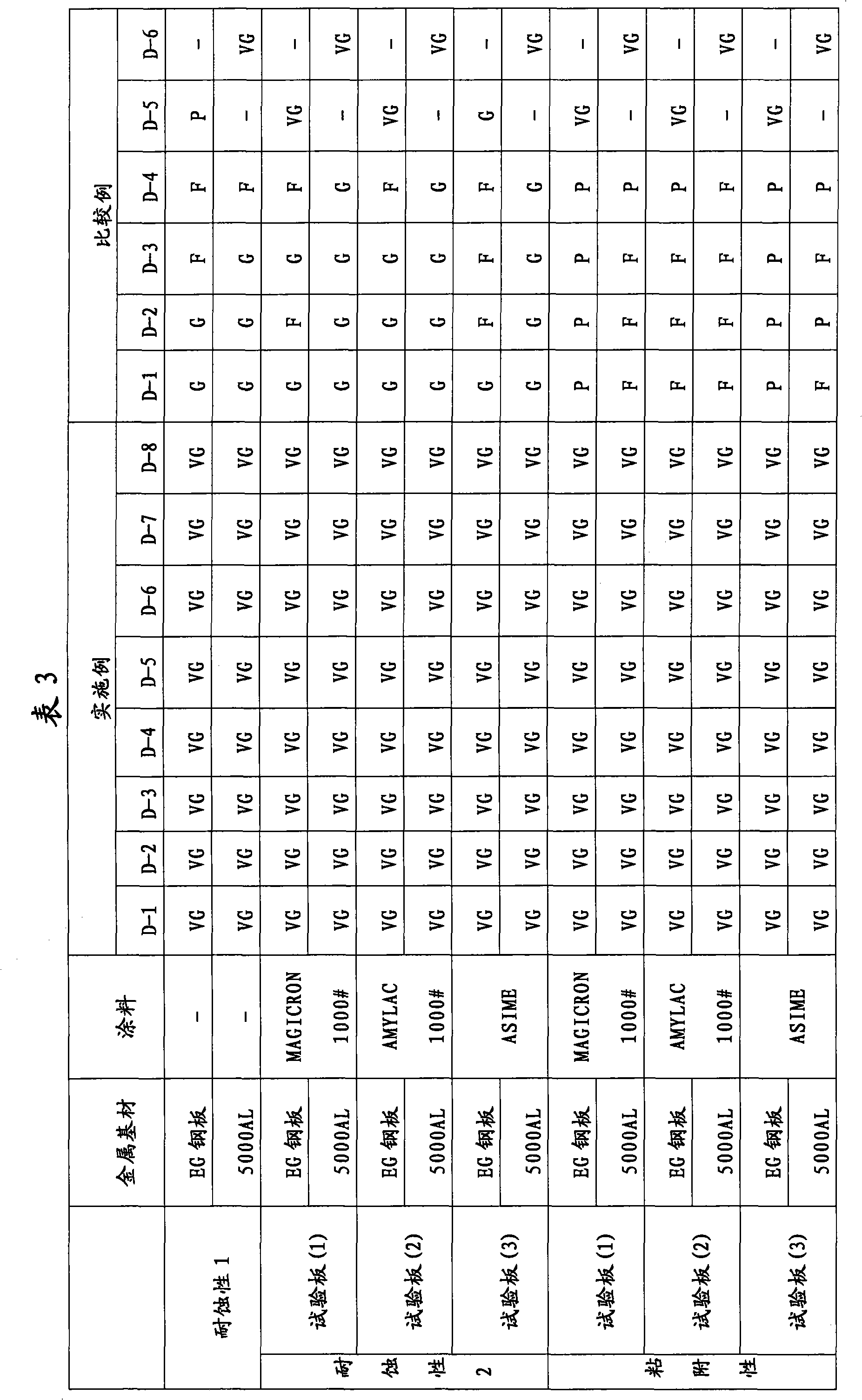

Composition for metallic surface treatment and metallic base material with surface treatment envelope

InactiveCN102086518AEasy to storeImprove corrosion resistanceMetallic material coating processesSilylenePhosphate

The invention provides a composition for metallic surface treatment which is characterized by comprising following components (A) to (C): (A) an aqueous solution obtained by mixing at least one titanium compound selecting from water weakened titanium compound, the condensate of water weakened titanium compound, titanium hydroxide and the condensate of titanium hydroxide with hydrogen peroxide solution(A2), or vanadate peroxide solution (A2); (B) organic phosphate compound; and (C) condensation product of amino silane (c1) and multi-silyl-functional silanes (c2). The composition for metallic surface treatment can form surface treatment envelope which is excellent for storage and has excellent corrosion resistance performance. The adhesive property of a film subjected to a post coating process is good.

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com