Synthesizing method of water-based nano conductive sol and transparent conductive thin film made of water-based nano conductive sol

A transparent conductive film, nano-conductive technology, applied in the direction of solid-state chemical plating, titanium oxide/hydroxide, metal material coating technology, etc., can solve the constraints of large-scale production and industrial application of nano-materials, increase product production costs, Poor product dispersibility and other problems, to achieve the effect of good superiority, short operation cycle, mild and controllable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

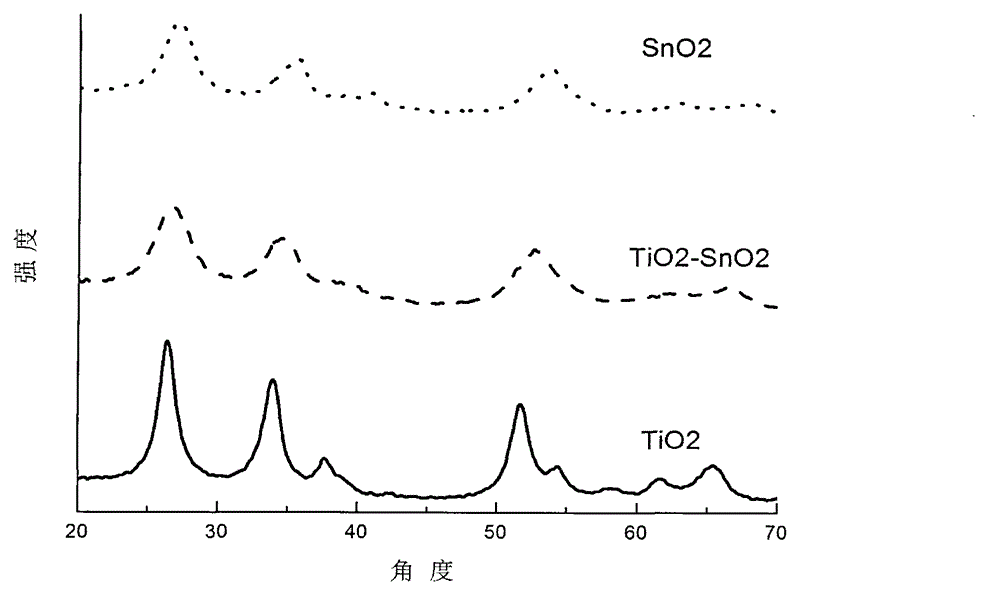

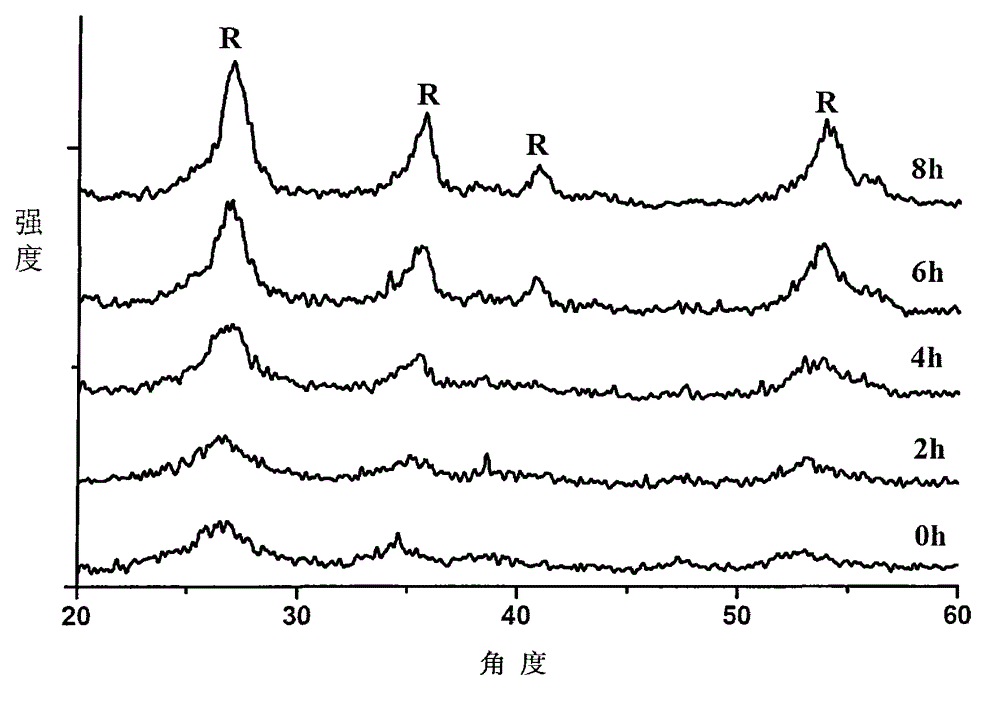

[0039] 0.94g (4.16×10 -3 mol)SnCl 2 2H 2 O dissolved in 400mL0.2mol / L TiCl 4 In the solution (the molar ratio of tin salt to titanium salt is 0.052), adjust the pH of the solution to 8 with ammonia water, and filter to obtain yellow tin-titanium hydroxide precipitate. The precipitate was dispersed in 5.5 mL of 30% hydrogen peroxide solution (H 2 o 2 The molecular molar ratio of Sn:Sn is 11.6), adding water to adjust the volume to 150mL, and refluxing at 84.5°C for 12 hours to obtain a tin-titanium oxide solid solution sol. attached figure 1 It is the XRD spectrum of the tin-titanium oxide solid solution sol prepared in Example 1, from which it can be seen that tin oxide and titanium oxide in the tin-titanium oxide solid solution sol of the present invention are in crystalline form and are composite intergrown crystals.

Embodiment 2

[0041] In addition to adjusting the SnCl 2 2H 2 O and TiCl 4 Except that the molar ratio is 0.008, the tin-titanium oxide solid solution sol was prepared in the same manner as in Example 1.

Embodiment 3

[0043] In addition to adjusting the SnCl 2 2H 2 O and TiCl 4 Except that the molar ratio is 0.012, the tin-titanium oxide solid solution sol was prepared in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com