Patents

Literature

62results about How to "Mild and controllable reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

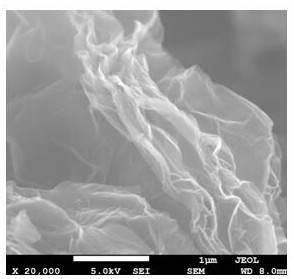

Preparation method for oxidized graphene-poly-dopamine composite aerogel

InactiveCN105254916AIntegrity guaranteedGuaranteed stabilityOther chemical processesAlkali metal oxides/hydroxidesPorosityFreeze-drying

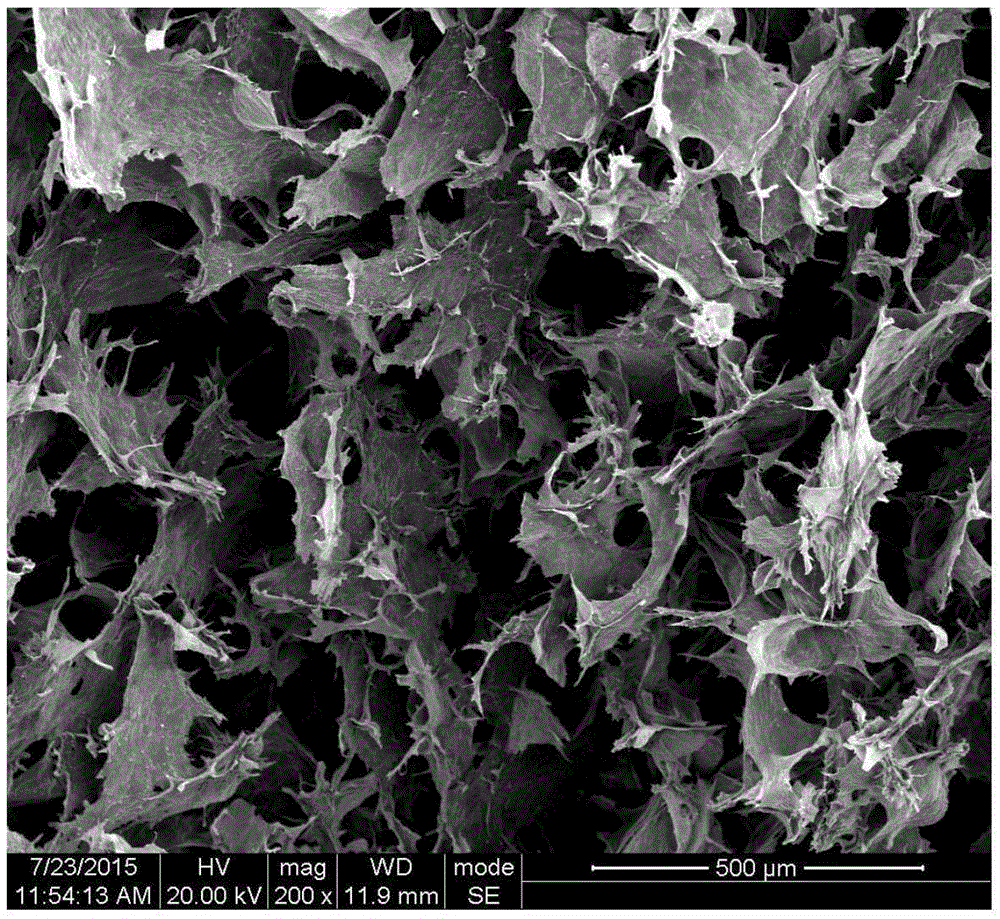

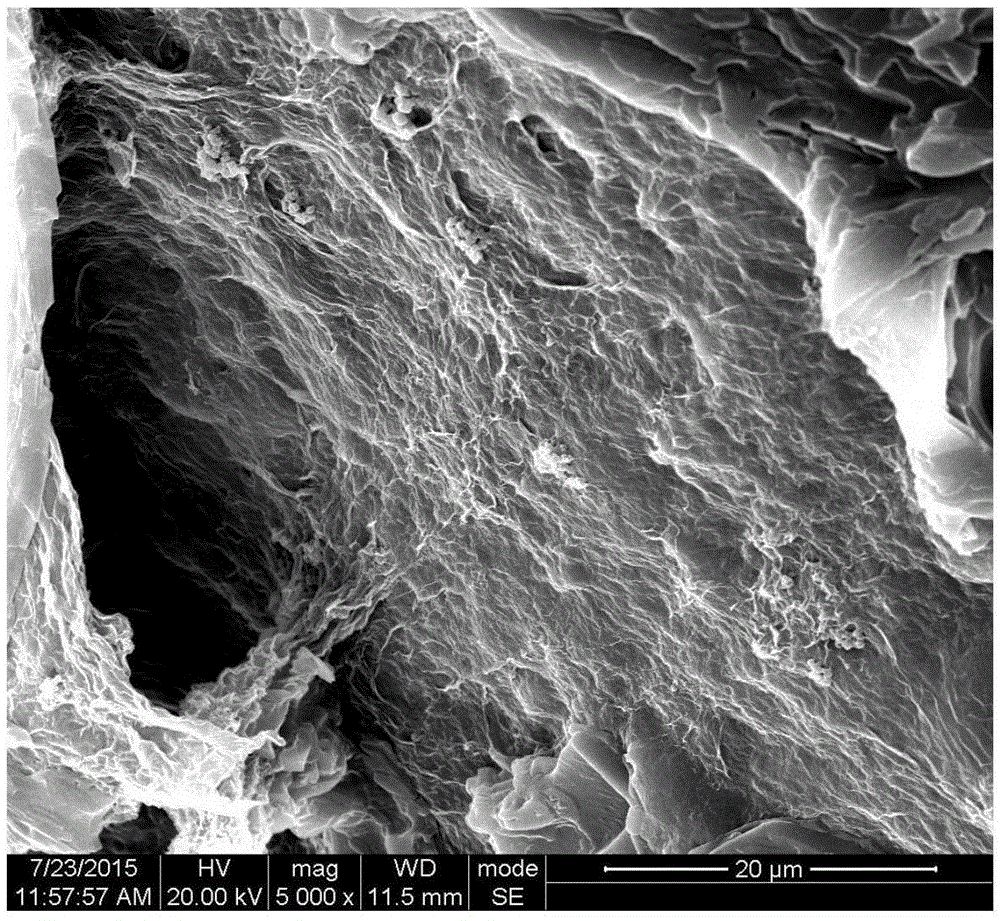

The invention provides a preparation method for oxidized graphene-poly-dopamine composite aerogel. The preparation method comprises the following steps that 1, 0.15-0.7 g of dopamine powder is dissolved in 10-18 ml of distilled water, the dopamine aqueous solutions are mixed with 50-60 ml of oxidized graphene aqueous solutions with the concentration of 5-6 mg / ml, and stirring is performed to obtain oxidized graphene-dopamine mixed solutions; 2, 3-9 ml of tris aminomethane buffer solutions with the concentration of 0.1-0.12 mol / L are dropwise added into the mixed solutions while stirring is performed, stirring is continuously performed for 2-2.5 h, and standing is performed to enable the dopamine to be fully polymerized to obtain oxidized graphene-poly-dopamine composite aquogel; 3, after being placed in an environment with the temperature ranging from minus 20 DEG C to minus 10 DEG C to be frozen for 24-30 h, the composite aquogel is processed through freeze drying, and then the oxidized graphene-poly-dopamine composite aerogel is obtained. The method is simple in technology, and the prepared composite aerogel has the advantages of being high in porosity, excellent in adsorptivity, high in strength and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Method for preparing graphene by low-temperature chemical reduction method

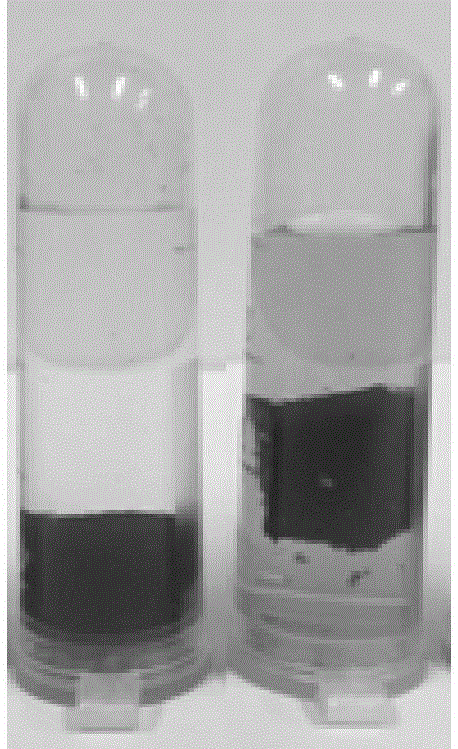

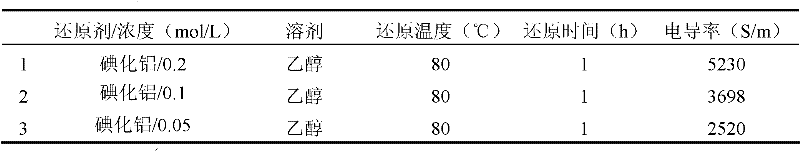

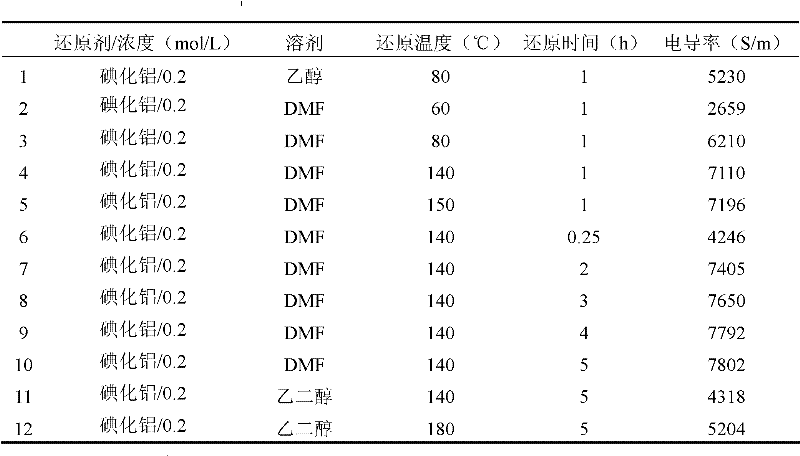

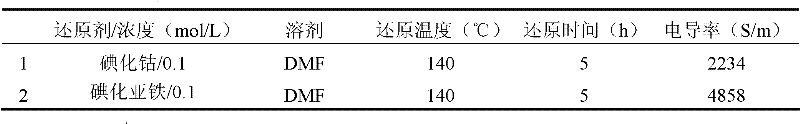

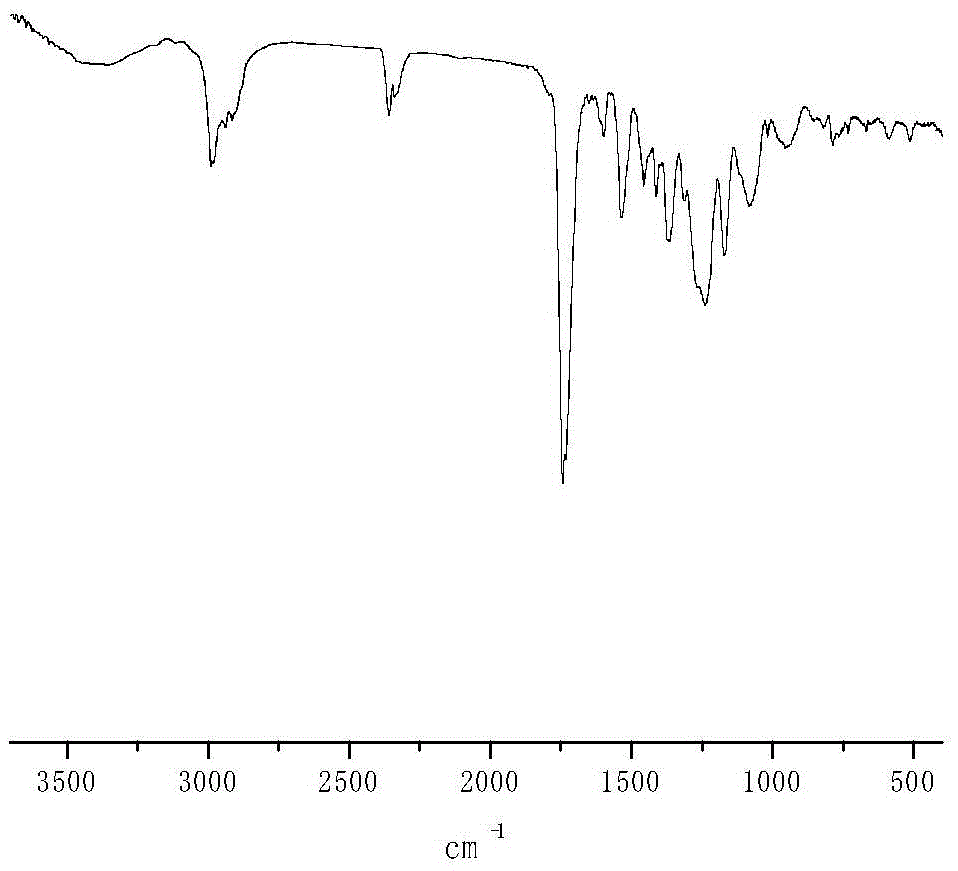

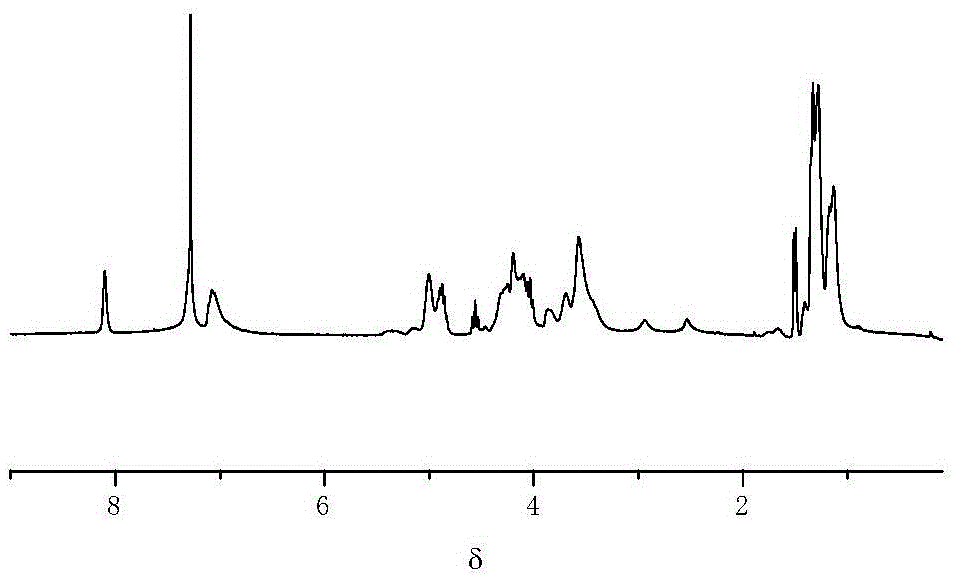

The invention discloses a method for preparing graphene by a low-temperature chemical reduction method, which belongs to the technical field of chemical composition of graphene. In the method, graphene oxide prepared by chemical oxidation is used as a raw material. The method comprises the reduction reaction step of reducing the graphene oxide into graphene; in the reduction reaction step, aluminum iodide is used as a reducer; the reduction of the graphene oxide is realized by controlling the concentration of the reducer and a solvent type at 60 DEG C to 180 DEG C; oxygen-containing functional groups (epoxy group, hydroxyl group, carboxyl group and carbonyl group) on the graphene oxide are removed; the electric conductivity of the graphene is recovered more thoroughly; and the graphene isprepared. The method provided by the invention is a method for preparing the graphene by a low-temperature chemical method, which is suitable for large-scale industrial production. The method has theadvantages of low reduction temperature, mild and controllable reaction, more thorough reduction, environmental-friendly performance, suitability to industrial production, etc.

Owner:TSINGHUA UNIV

Cationic waterborne polyurethane resin and preparation method thereof

The invention discloses cationic waterborne polyurethane and a preparation method thereof, and relates to the technical field of polyurethane. The problems that an existing cationic waterborne polyurethane preparation method is complex in technology, and prepared waterborne polyurethane emulsion cannot get rid of the dependency on petrochemical resources are solved. The structural formula of the cationic waterborne polyurethane is shown as a formula (1) (please see the formula in the description). The invention further provides a preparation method of cationic waterborne polyurethane resin. The preparation method comprises the steps that firstly, under protection of inert gas, poly(carbonic ester-ether)dihydric alcohol reacts with diisocyanate in organic solvent to obtain a first intermediate; secondly, the first intermediate reacts with a hydrophilic chain extender under action of a catalyst to obtain a second intermediate; lastly, the second intermediate reacts with butanediol, acid is added for neutralization, deionized water is added to remove the solvent through emulsifying and steaming, and then the cationic waterborne polyurethane resin is obtained. The polyurethane resin is excellent in performance, and waterborne polyurethane can reduce the dependency on the petrochemical resources.

Owner:中科应化(长春)科技有限公司

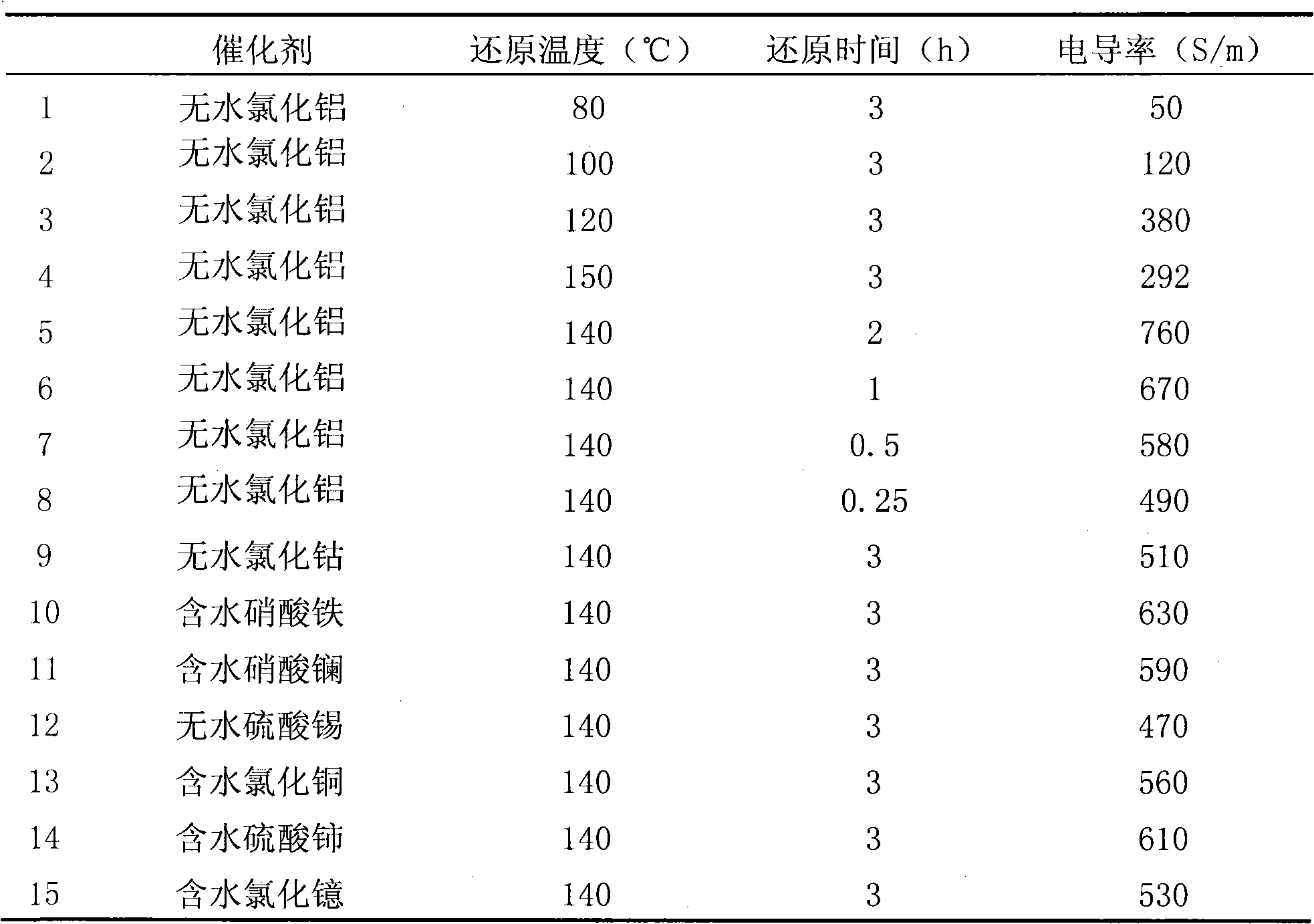

Process for preparing graphene by cryochemical method

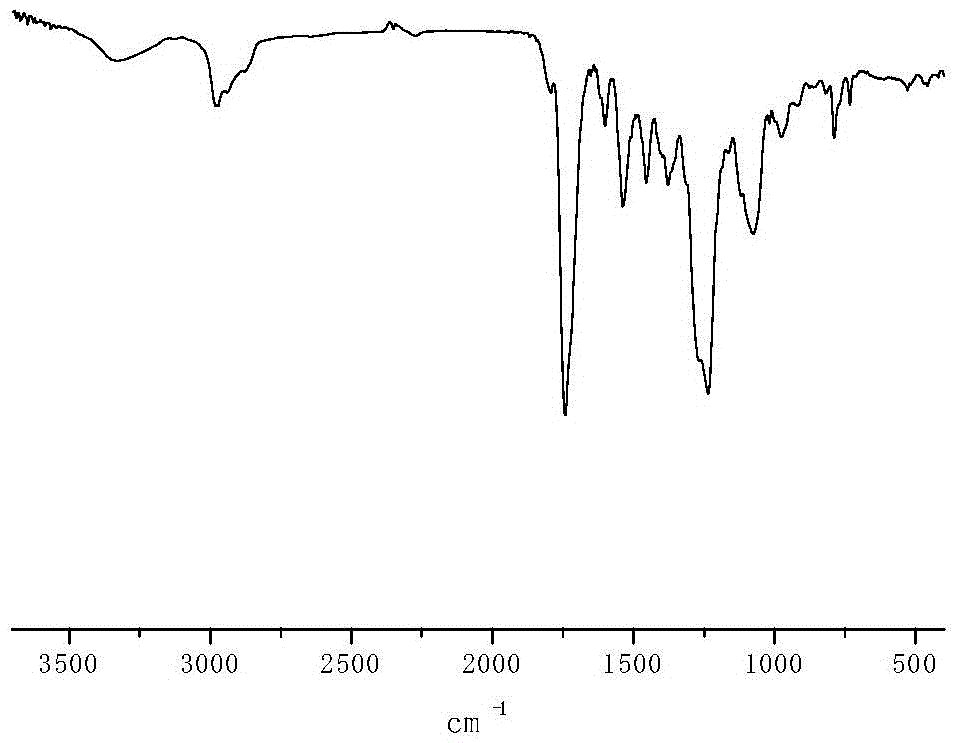

ActiveCN102452650AConductivity recoveryLow reduction temperaturePhysical/chemical process catalystsGrapheneEpoxyChemical synthesis

The invention discloses a process for preparing graphene by a cryochemical method, belonging to the technical field of chemical synthesis of graphene. The process uses graphene oxide prepared by chemical oxidation as a raw material, and comprises the step of reducing reaction in which graphene oxide is reduced into graphene. The reducing reaction step implements reduction of the graphene oxide at80-150 DEG C by using sodium borohydride as a reducer by the aid of a catalyst, oxygen-containing functional groups (epoxy group, hydroxy group, carboxy group and carbonyl group) on the graphene oxide are removed, and the electric conductivity of the graphene is thoroughly recovered, thereby preparing the graphene. The process disclosed by the invention is suitable for large-scale industrial production. The process has the advantages of low reduction temperature, mild and controllable reaction, thorough reduction, environment friendliness and the like, and is suitable for industrial production.

Owner:TSINGHUA UNIV

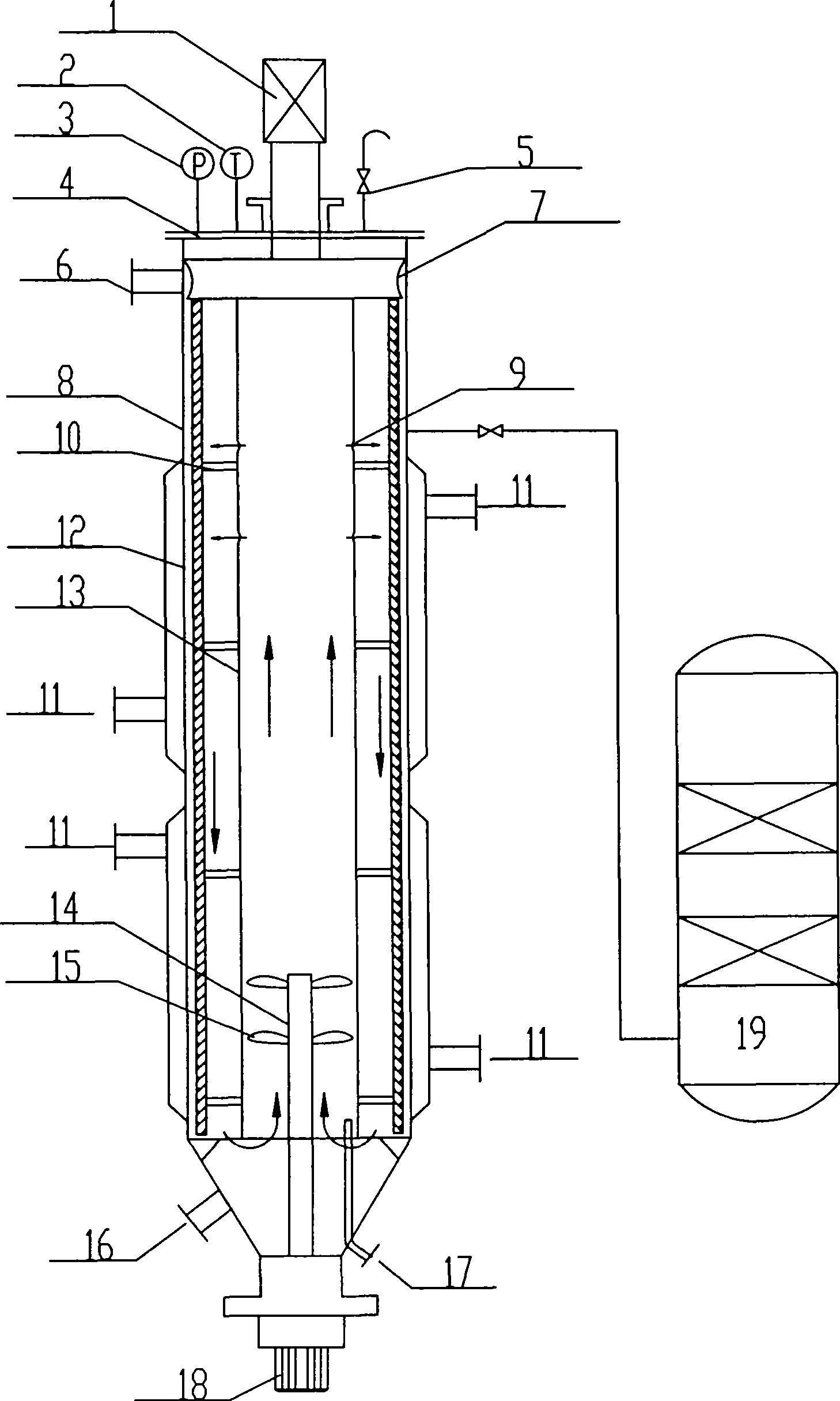

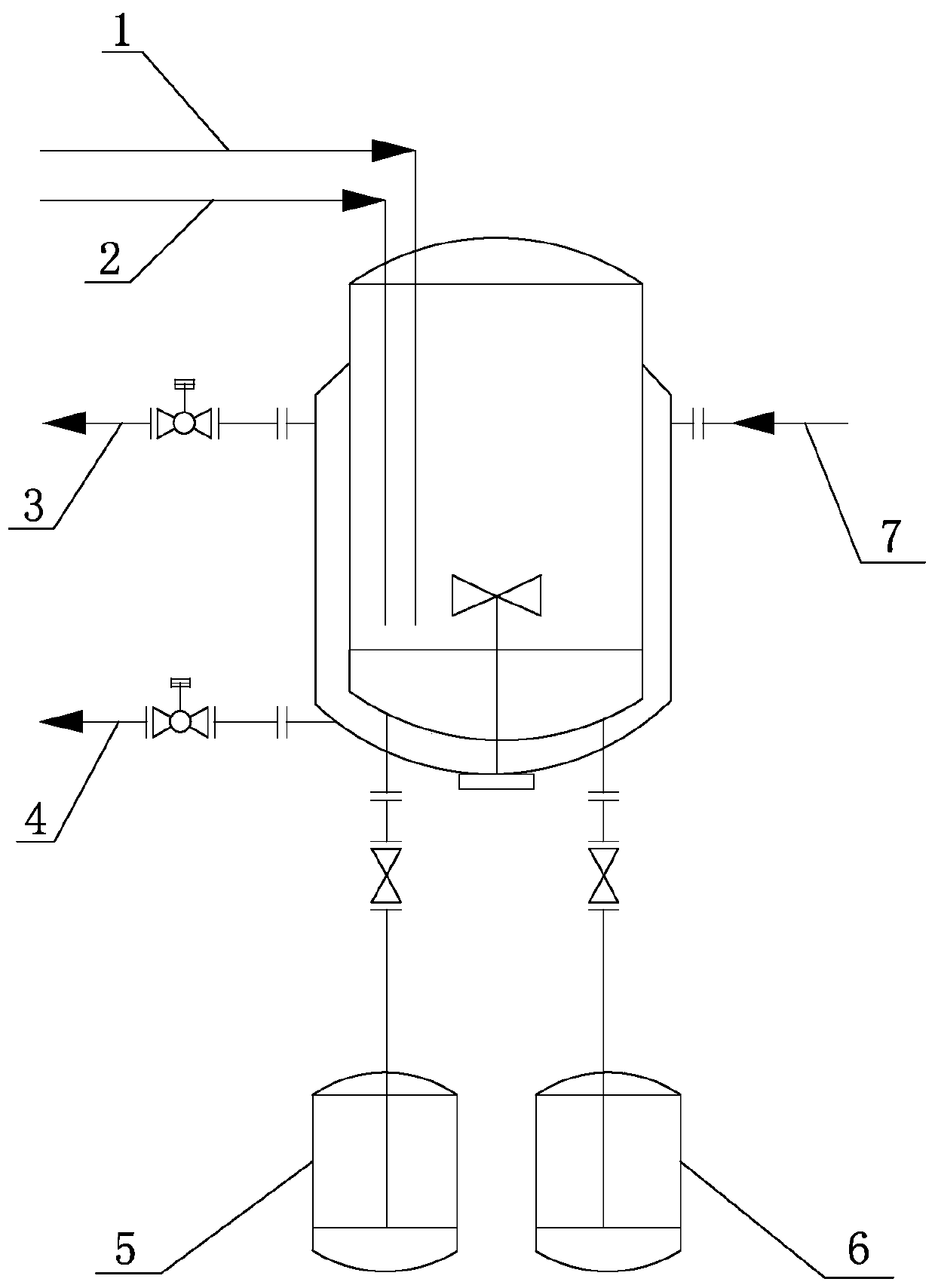

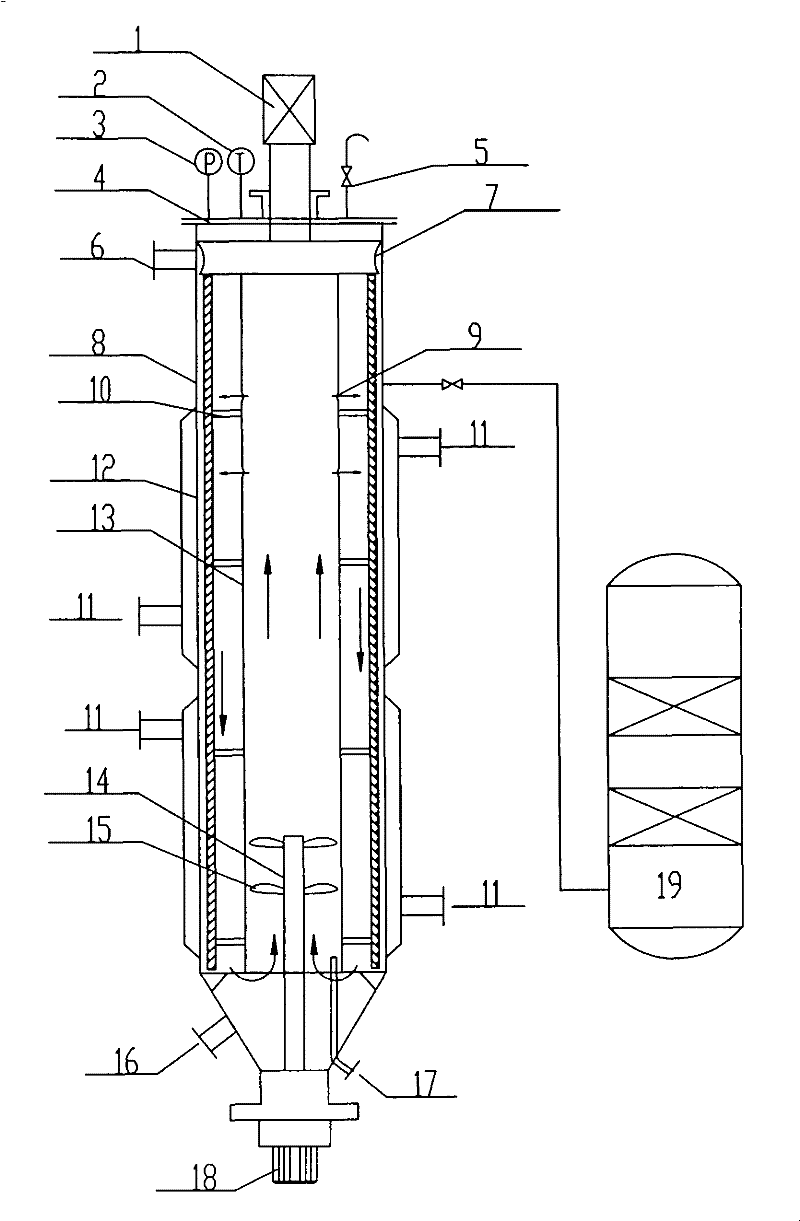

Gas phase SO3 film-scrapping sulfonating technology

InactiveCN101445418ALess investmentReduce energy consumptionLiquid-gas reaction of thin-film typeSulfo/sulfonyldioxy group formation/introductionGas phaseProduct gas

The invention relates to a gas phase SO3 film-scraping sulfonating technology which belongs to the technical field of production technology which prepares anionic surfactant by using gas phase SO3 film-scraping sulfonating liquid organic materials. The invention is carried out according to the following steps: A: liquid SO3 is vaporized to gas phase SO3, the gas phase SO3 is sucked in a mixer shaft through a turbo-blower, the gas phase SO3 is mixed with inert gases recycled in a sulfonating reactor to reaction gas with the volume concentration being 0.1 to 10 percent, and then the reaction gas goes into a reaction cylinder body through reaction gas distribution holes on the upper part of the scraping plate shaft; B: the organic materials go into the sulfonating reactor and downwards flow along the inner wall of the reaction cylinder body, a scraping plate is rotated along with the mixer shaft under the action of a transmission system, the organic materials are continuously suffered with film scaping-spread coating-film scaping in the inner wall of the reaction cylinder body, the organic material are alternately updated and uniformly coated on the inner wall of the reaction cylinder body, and the organic materials are completely contacted and reacted with the reaction gas which goes from the reaction gas distribution holes to form reaction products. The design of the technology is reasonable, and the invention can be suitable for sulfonating or sulphating materials with various viscosities.

Owner:ZANYU TECH GRP CO LTD

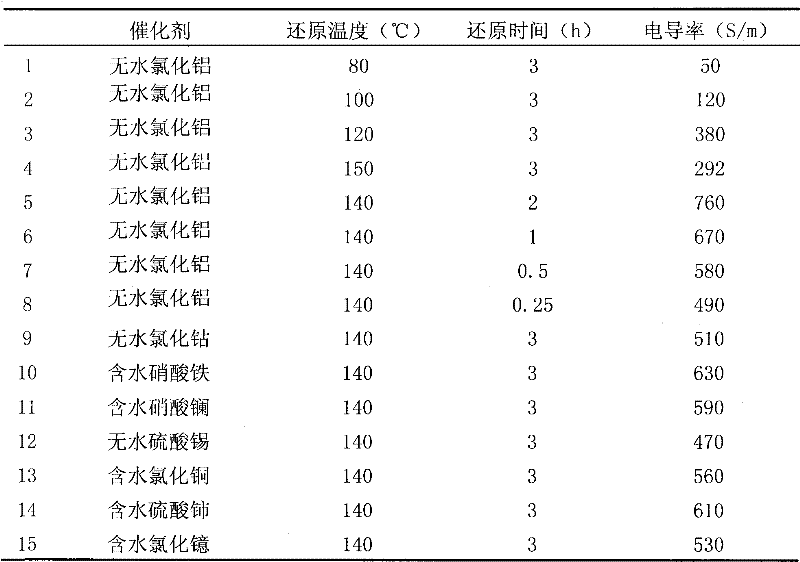

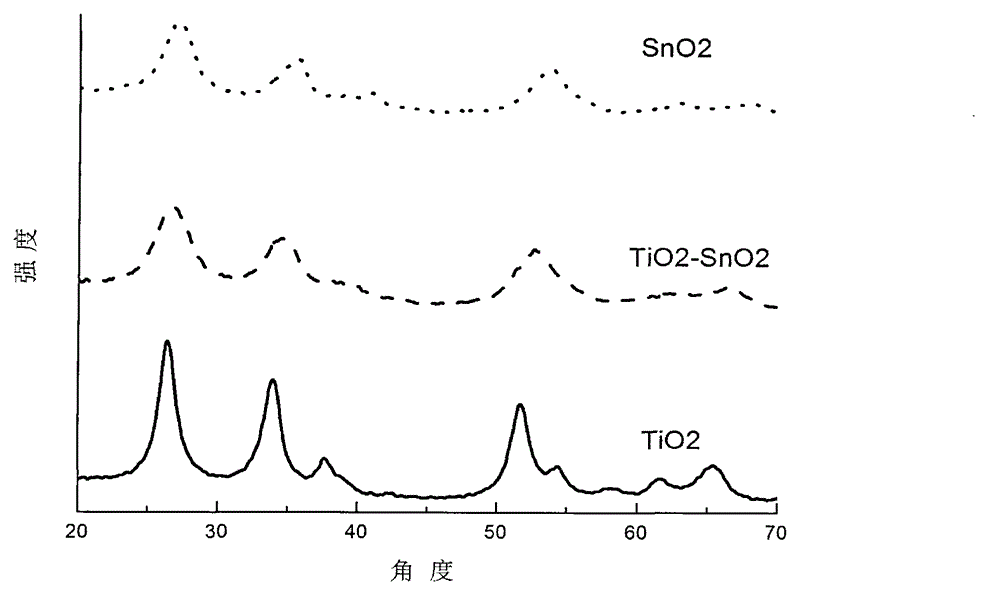

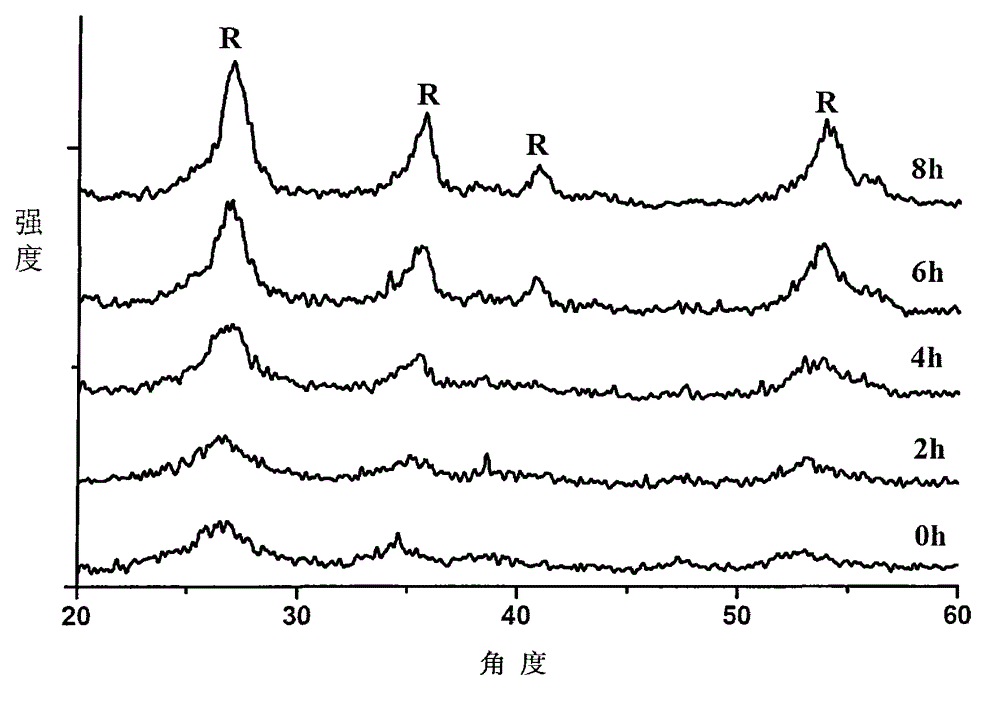

Synthesizing method of water-based nano conductive sol and transparent conductive thin film made of water-based nano conductive sol

InactiveCN102910672AWide variety of sourcesLow priceSolid/suspension decomposition chemical coatingTitanium oxides/hydroxidesTin dioxideWater based

The invention relates to a synthesizing method of tin dioxide / titanium dioxide solid solution nano sol composite and a film forming technique for preparing transparent conductive thin films on surfaces of different substrates on the basis of the sol. The synthesizing method includes the steps of firstly, precipitating tin-titanium hydroxide; secondly, dispersing precipitate with hydrogen peroxide; and thirdly, synthesizing final product. The synthesizing method is few in steps and simple in process. The synthesized tin-titanium oxide solid solution nano sol is water-based, defects in the prior art are overcome, environmental pollution is avoided, synthesizing of water-based sol at normal pressure and low temperature is achieved, and film forming is easy.

Owner:程明明 +2

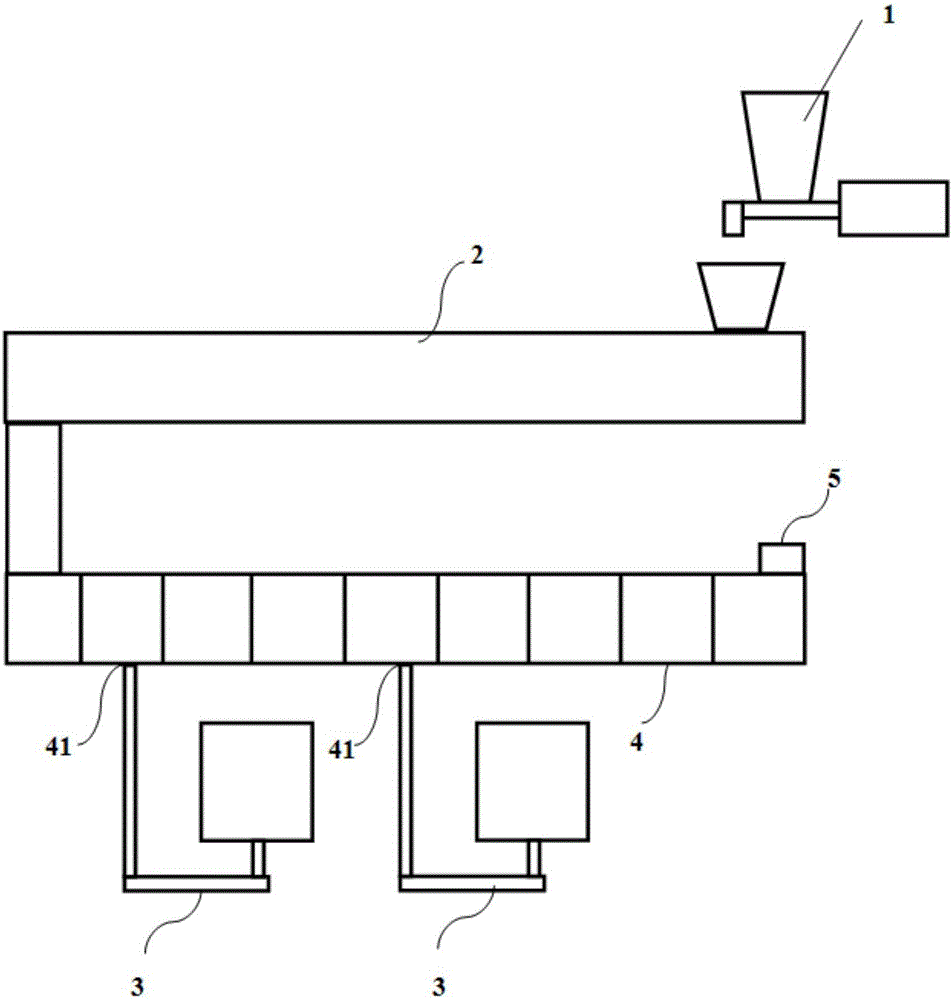

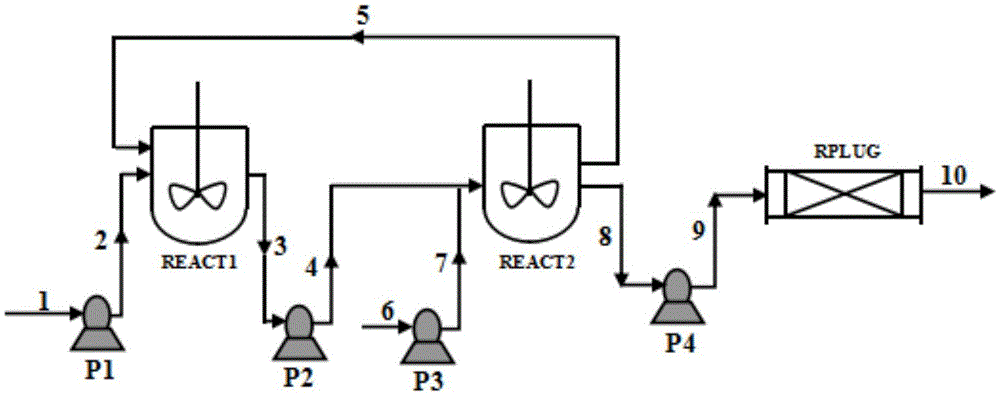

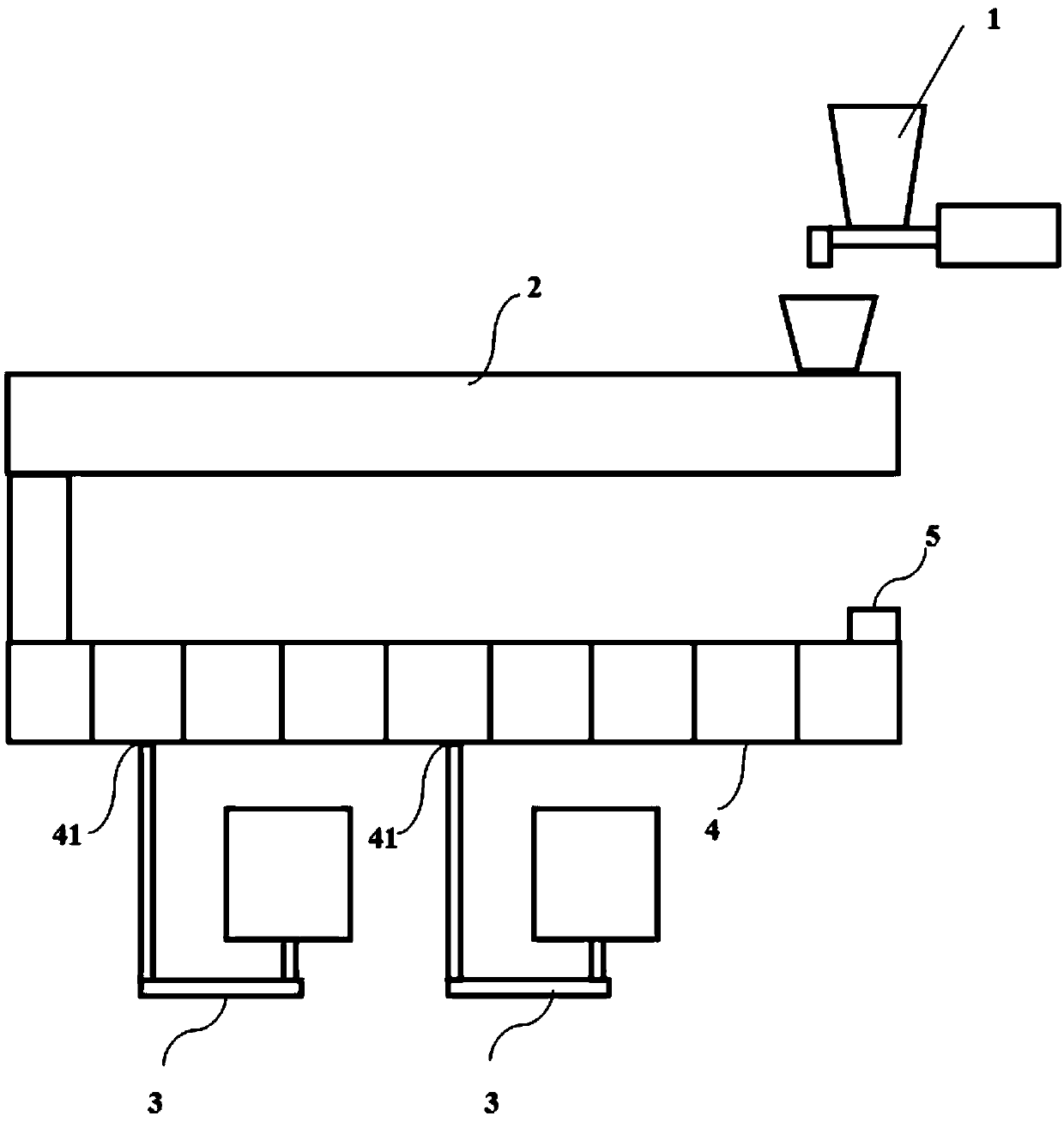

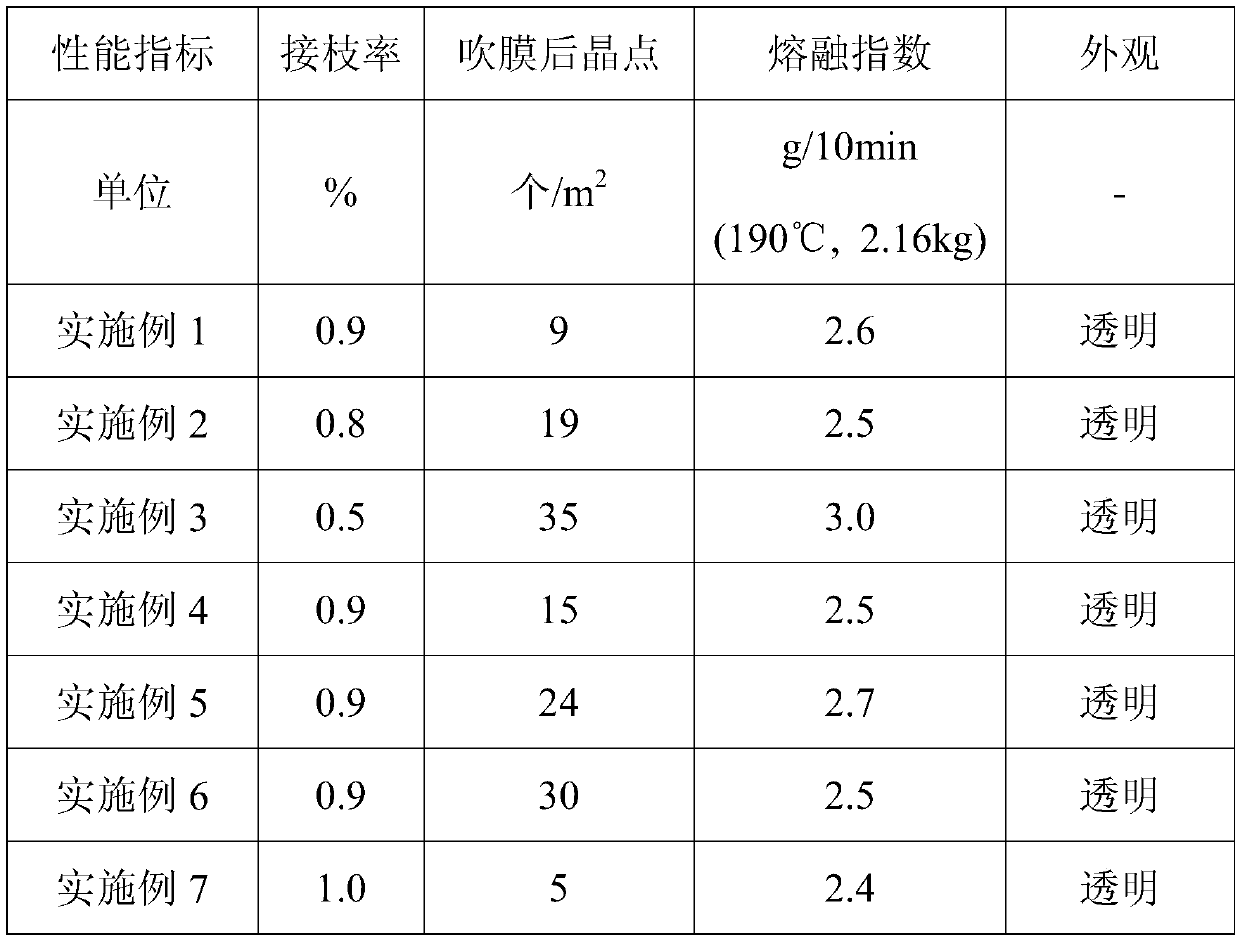

Grafting reaction device and use method thereof

The invention discloses a grafting reaction device and a use method thereof. The grafting reaction device comprises a weightlessness feeding device, a single-screw melting device, an aid adding device, a twin-screw grafting reaction device and a vacuum devolatilization device. The use method comprises steps as follows: 1) a premix is added to the single-screw melting device by the weightlessness feeding device; 2) the single-screw melting device plasticizes and melts the premix into polymer melt and introduces the polymer melt into the twin-screw grafting reaction device; 3) the aid adding device adds aids to one or two heating zones of the twin-screw grafting reaction device; a graft polymer is formed through a grafting reaction in the twin-screw grafting reaction device and then introduced into the vacuum devolatilization device; 4) a solvent and non-reacted grafting aids are removed from the vacuum devolatilization device, and a finished product is obtained. The reaction device can effectively reduce crosslinked byproducts in the melting graft process of the polymer.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

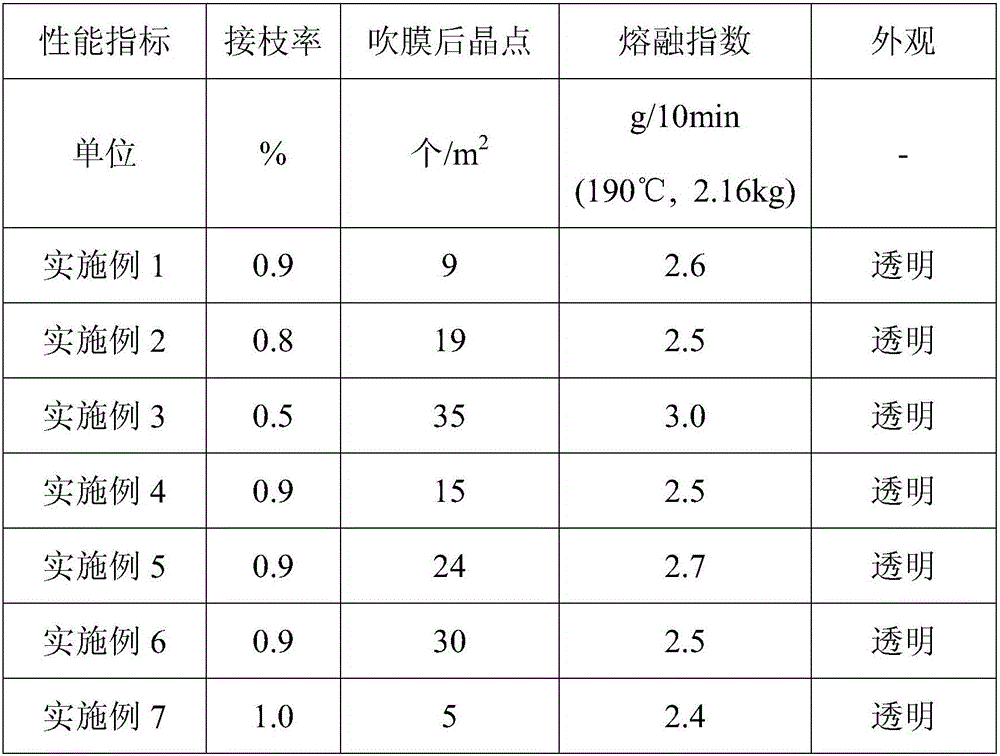

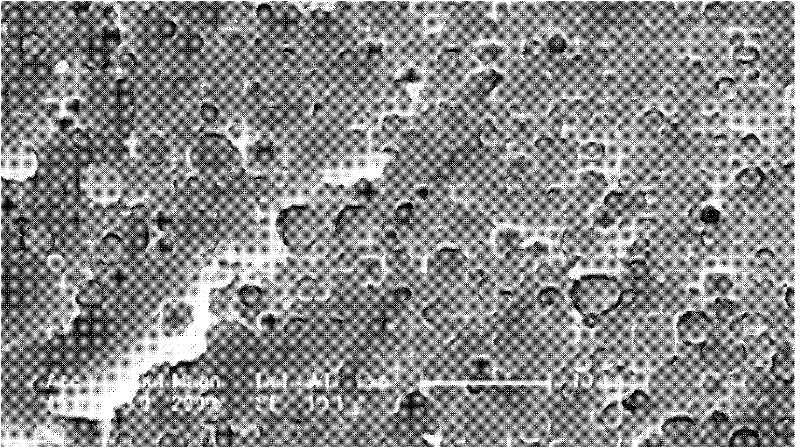

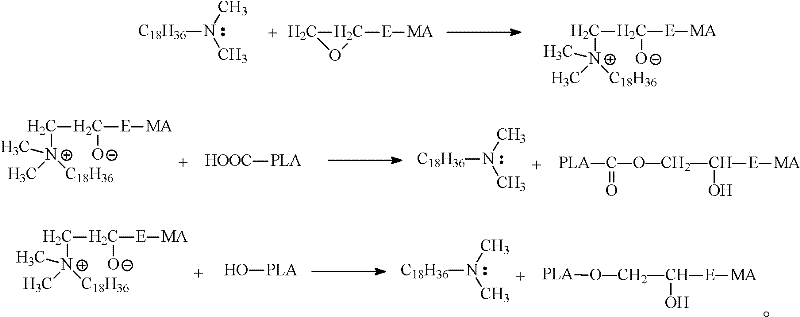

Modified poly(lactic acid) and preparation method thereof

The invention provides modified poly(lactic acid), which is prepared by a reaction between poly(lactic acid) and an ethylene-acrylate-glycidyl methacrylate copolymer under the action of a catalyst, wherein the catalyst is a tertiary amine catalyst or a phosphorus catalyst. The catalyst used for the modified poly(lactic acid) provided by the invention improves the reaction efficiency and optimizesthe reaction conditions, so that an elastomer has smaller particle size in the matrix, more uniform particle size and stronger interfacial adhesion. Experiments show that the notched impact strength of the modified poly(lactic acid) provided by the invention is improved significantly, compared with the prior art. The invention also provides a preparation method of the modified poly(lactic acid).

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

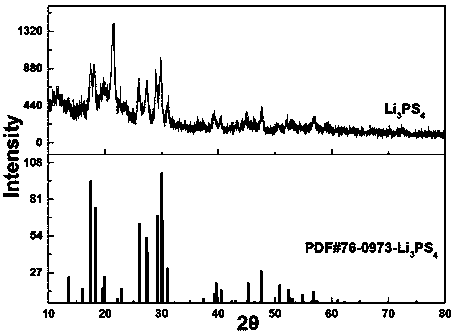

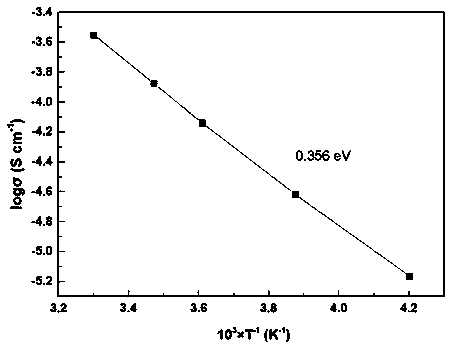

Preparation method of sulfide solid electrolyte

PendingCN110867606ANothing producedComposition is easy to adjustSolid electrolytesSecondary cellsSolid state electrolyteMetallic lithium

The invention provides a low-cost preparation method of a sulfide solid electrolyte composed of Li, P and S elements and with freely controllable components. The preparation method comprises the following steps: adding elemental sulfur and phosphorus pentasulfide into an organic ether solution of a metal lithium-aromatic compound, and mixing to obtain a mixed solution; and sequentially carrying out mixing reaction, separation, precipitation, drying and heat treatment on the mixed solution to obtain the sulfide solid electrolyte containing Li, P and S as constituent elements. According to the preparation method of the sulfide solid electrolyte, raw materials are cheap and easy to obtain, the process is simple, production is safe, product components are easy to adjust, and production cost can be greatly reduced.

Owner:YANGTZE RIVER DELTA PHYSICS RES CENT CO LTD +2

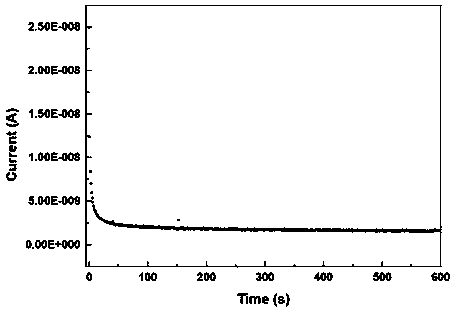

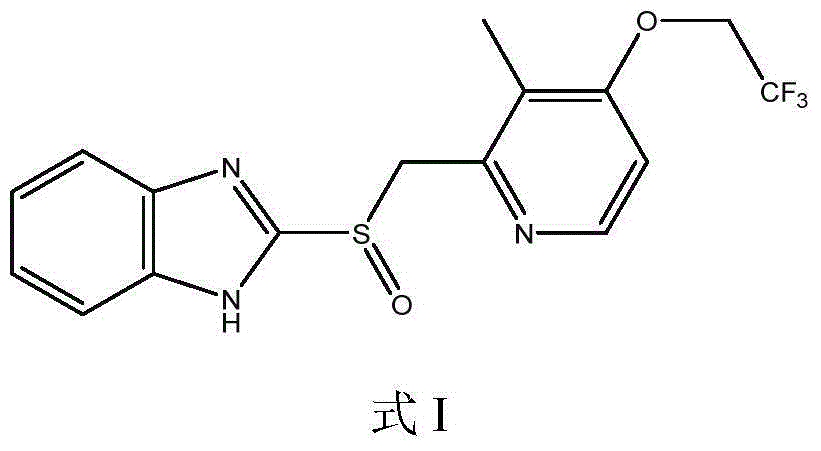

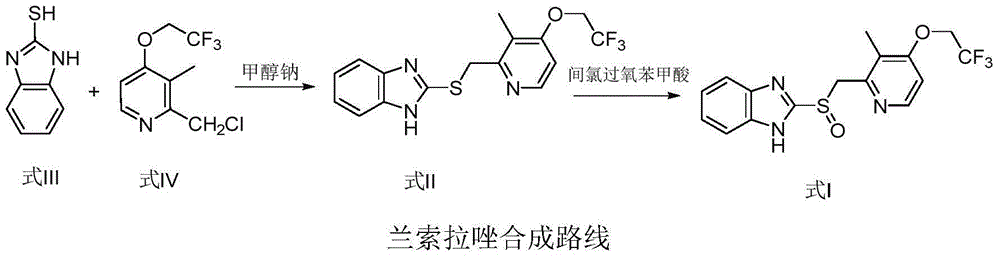

Lansoprazole preparation method

The invention relates to a preparation method of lansoprazole compounds, in particular to a one-pot preparation method of the lansoprazole compounds. By means of the preparation method, the process is easy and convenient, operation is simple, and the lansoprazole compounds are suitable for large-scale industrial production. Lansoprazole prepared through the method is high in total yield and content, and the quantity of related substances is low.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD +1

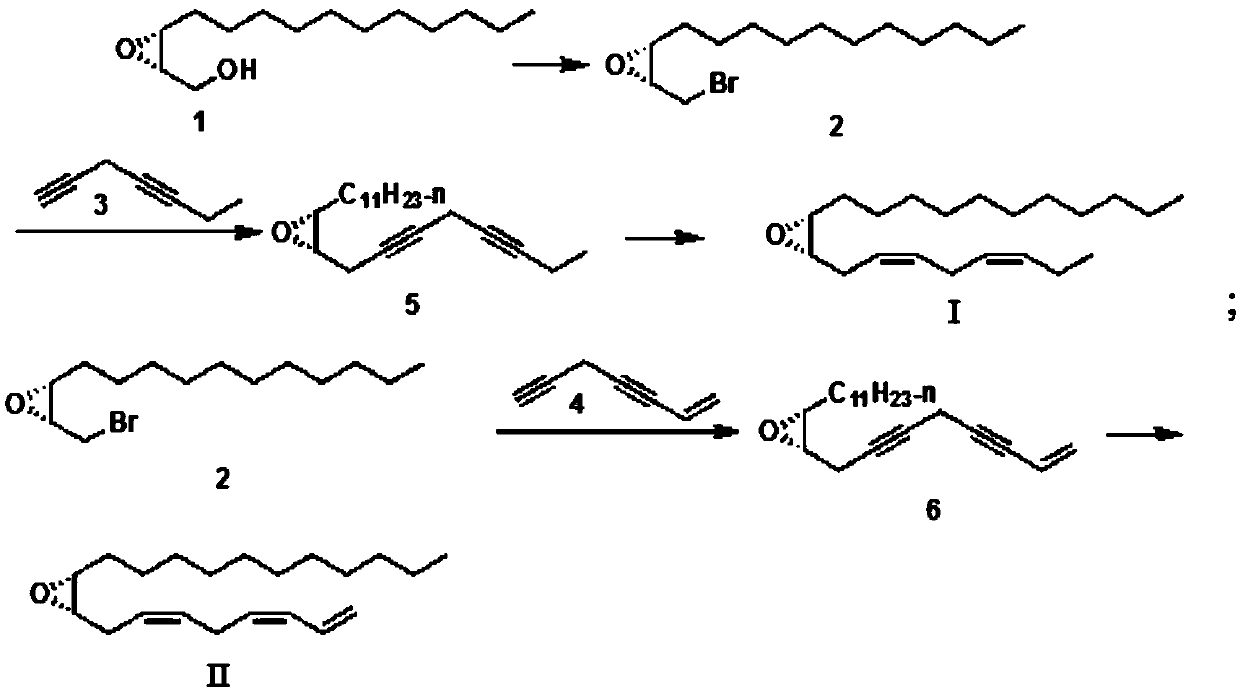

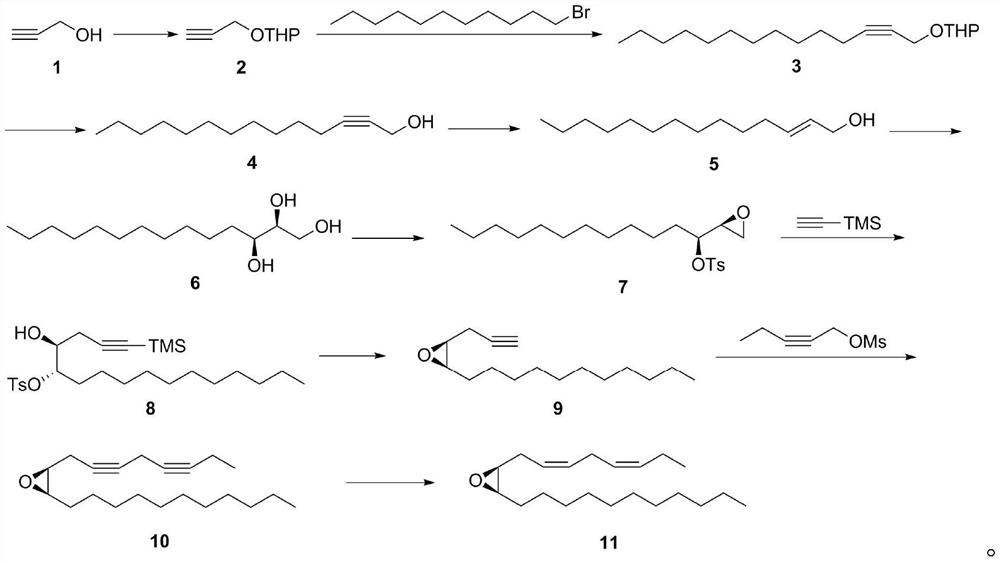

Synthetic method of hyphantria cunea sex pheromone components

ActiveCN110845447AHigh yieldFew reaction stepsPest attractantsOrganic chemistry methodsEpoxySexual Pheromones

The invention discloses a synthetic method of hyphantria cunea sex pheromone components, and belongs to the technical field of chemical production. (2S, 3R)-2, 3-epoxy-1-tetradecanol is used as a rawmaterial, and the hyphantria cunea sex pheromone components (3Z, 6Z, 9S, 10R)-9, 10-epoxy-3, 6-heneicosadiene and (3Z, 6Z, 9S, 10R)-9, 10-epoxy-1, 3, 6-heneicosatriene are obtained through bromination, coupling and hydrogenation. The process is mild and controllable in reaction, good in yield, simple and convenient to operate, few in reaction steps, low in production cost and suitable for large-scale production. The lure prepared from the sex pheromone components synthesized by the synthesis method can effectively trap and kill a large number of hyphantria cunea male moths in combination witha trap, is applied to hyphantria cunea pest situation forecasting and green prevention and control, and can reduce chemical pesticide application, thereby reducing pollution, protecting the environment and remarkably improving economic, social and ecological comprehensive benefits.

Owner:NANJING FORESTRY UNIV

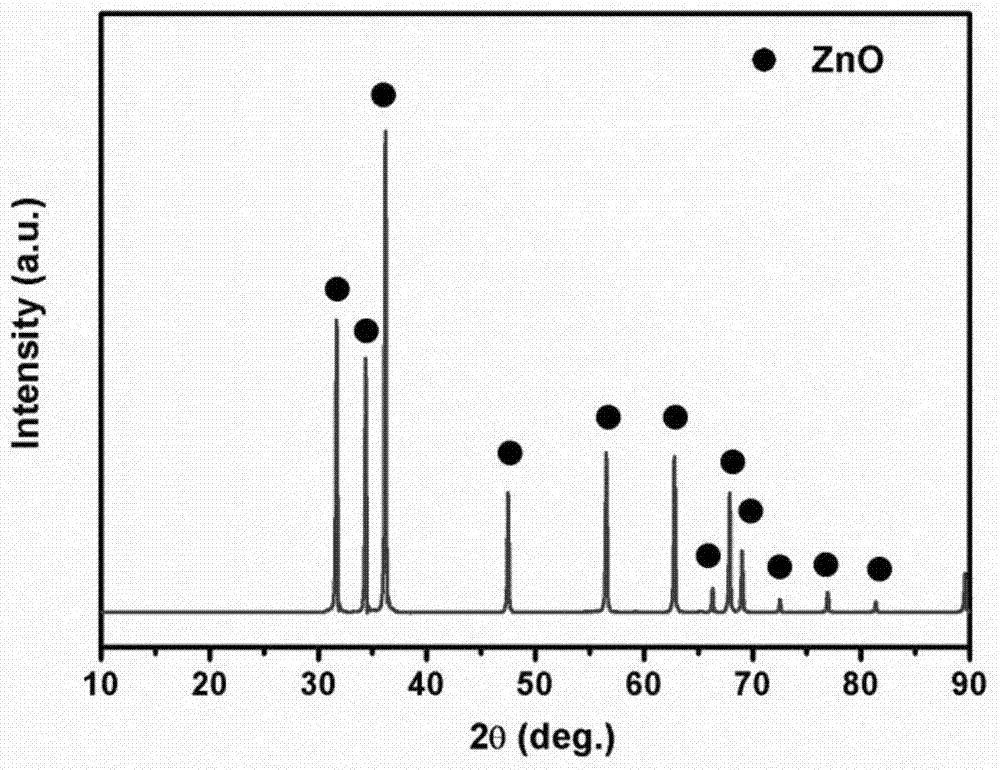

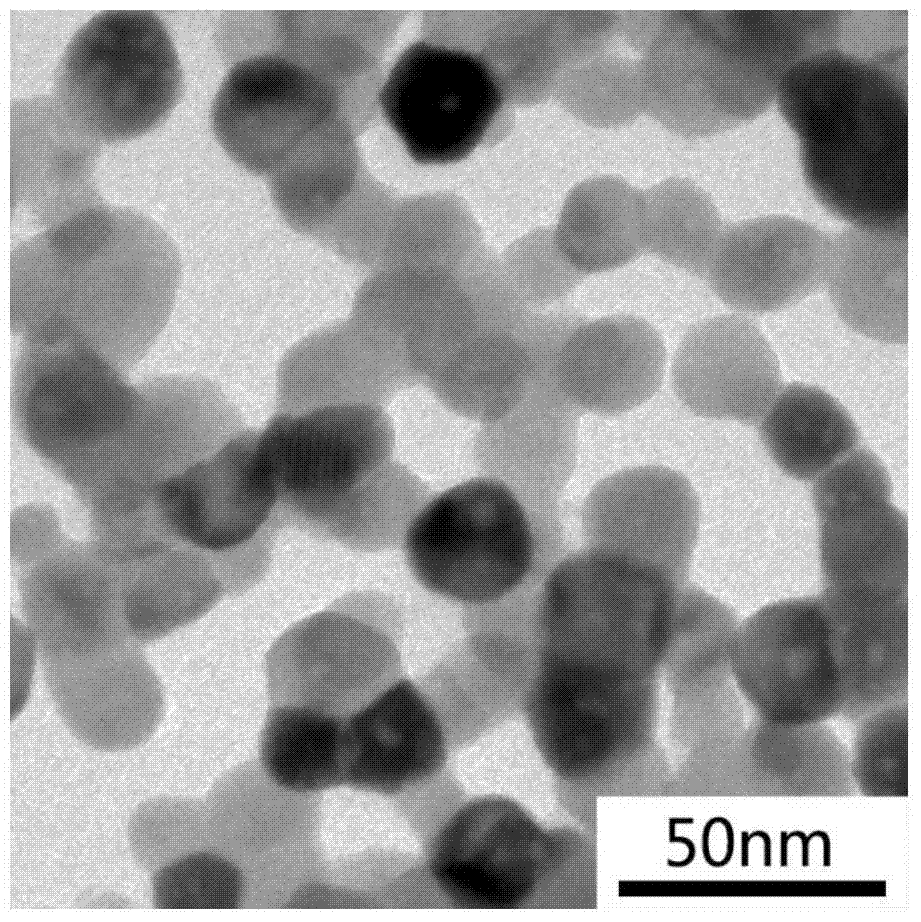

Preparation method of aluminum-doped zinc oxide nano powder

ActiveCN104741069ASimple processAvoid reunionOther chemical processesZinc oxides/hydroxidesAdjuvantZinc nitrate hexahydrate

The invention relates to a method for producing aluminum-doped zinc oxide nano powder, and belongs to the technical field of the preparation of a nano material. The preparation method comprises the following technological processes: (1) preparing a solution from zinc nitrate, aluminum nitrate, amine organic matters and adjuvant according to certain proportions; (2) heating the solution, and carrying out reaction after the solution is volatilized and concentrated so as to obtain precursor powder; and (3) reacting the precursor powder in air within a temperature range of 400-800 DEG C for 1-5h so as to obtain the aluminum-doped zinc oxide nano powder. The preparation method disclosed by the invention is simple in process, low in cost and easy in industrialization; and the prepared aluminum-doped zinc oxide nano powder is fine in crystalline grain, good in dispersity and controllable in grain size, and the nano powder has a mesoporous structure and is applicable to the fields of organic pollutant adsorption and the like.

Owner:UNIV OF SCI & TECH BEIJING

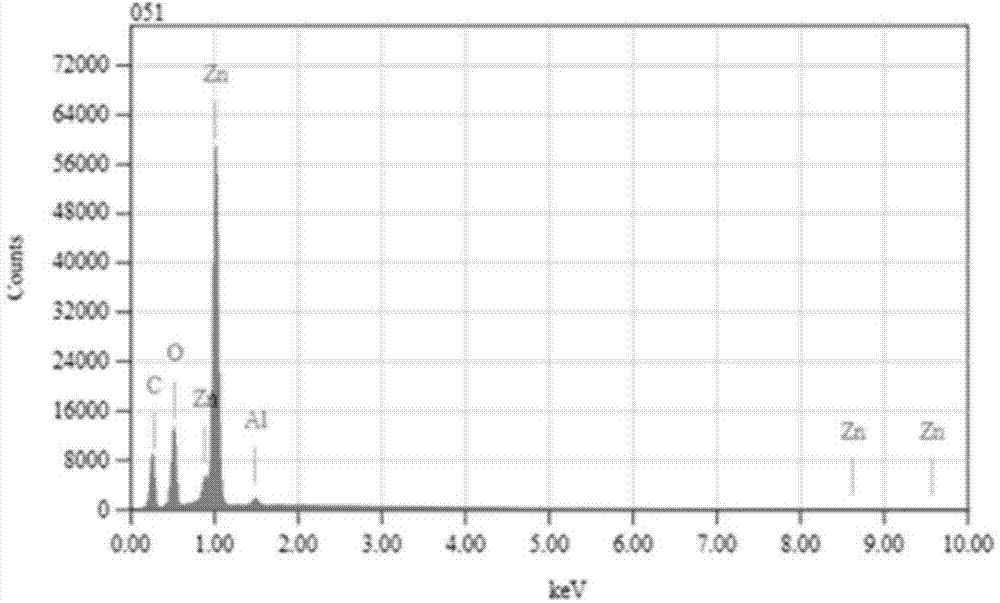

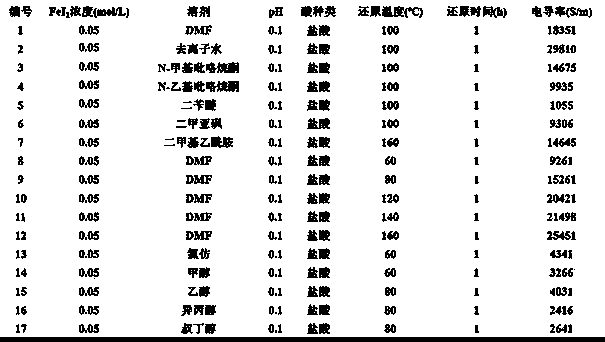

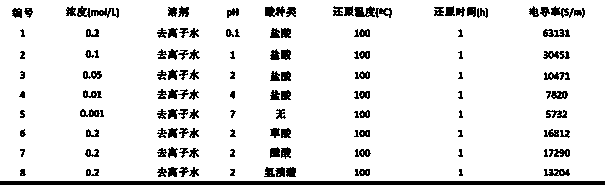

Method for preparing graphene film through reduction of ferrous iodide acid solution

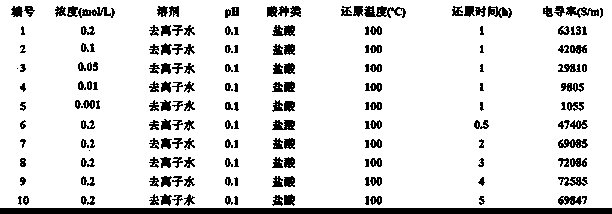

The invention discloses a method for preparing a graphene film through reduction of a ferrous iodide acid solution, belonging to the technical field of chemical synthesis of graphene. A graphene oxide prepared through chemical oxidation is taken as a raw material, and the method comprises a reduction reaction step of reducing the graphene oxide into graphene, wherein the ferrous iodide solution is taken as a reducing agent in the reduction reaction step, rapid reduction of the graphene oxide is realized by controlling the solution concentration, reduction time, reduction temperature, types and pH values of solvents and types of inorganic acids used for pH regulation, oxygen-containing functional groups such as epoxy group, hydroxyl, carboxyl and carbonyl on the graphene oxide are removed, the conductivity of the graphene is completely restored, and the graphene film is prepared. The method is a method for preparing graphene through a low-temperature chemical method suitable for large-scale industrial production. The method has the advantages of low reduction temperature, mild and controllable reactions, complete reduction, environment friendliness and suitableness for industrial production.

Owner:SICHUAN INST OF MATERIALS & TECH

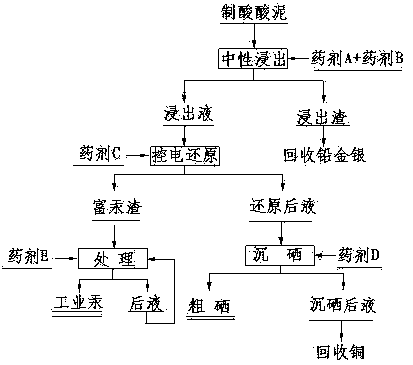

Wet treatment method of copper smelting acid-making acid mud

ActiveCN111235396ARealize resource processingEasy to controlElemental selenium/telluriumPregnant leach solutionChemical agent

The invention discloses a wet treatment method of copper smelting acid-making acid mud. The wet treatment method comprises the following steps that acid-making acid mud is pulped, a chemical agent A and a chemical agent B are added for leaching after pulping, solid-liquid separation is carried out after leaching is finished to obtain leached residues and neutral leachate, and lead, gold and silverare recovered from the leached residues; a chemical agent C is added into the obtained leachate for reduction, the final reduction potential is controlled to be 300 mV-450 mV, and solid-liquid separation is carried out to obtain mercury-rich residues and a reduced solution; the pH value of the reduced solution is controlled to be less than 1, a chemical agent D is added for reduction, solid-liquid separation is carried out after the reaction is ended to obtain crude selenium and a selenium-precipitated solution, and the selenium-precipitated solution is conveyed to a water treatment procedureto recover copper; and water is added into the mercury-rich residues for pulping, a chemical agent E is added into the solution for reaction, solid-liquid separation is carried out after the reactionis ended, after solid is separated and dried, industrial mercury is obtained, liquid can be recycled, and periodic open-circuit treatment is carried out.

Owner:HENAN ZHONGYUAN GOLD SMELTERY

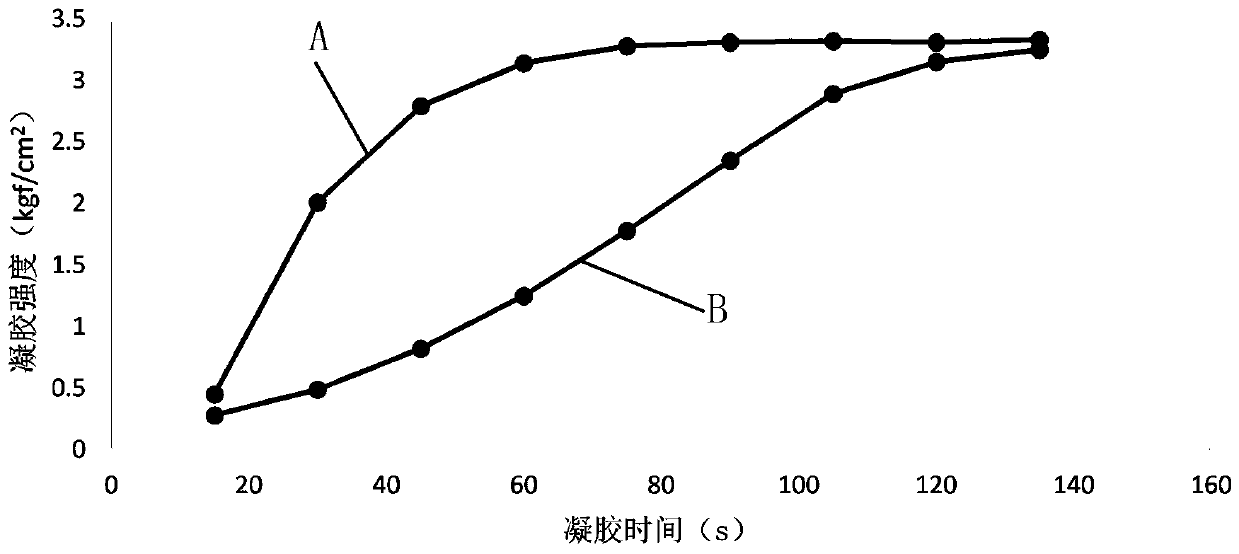

Method for reducing gelation speed of konjac

The invention discloses a method for reducing the gelation speed of konjac. The method comprises the following steps: firstly, adding alcohol into konjaku flour, adding a deacetylate agent, enabling the pH value to reach 7.5 to 9, carrying out a deacetylation reaction and adjusting the pH value to be neutral after reaction, and filtering and then drying filter residue; secondly, adding the powderobtained in the first step into water in a stirring state, heating to enable the powder to sufficiently swell, adding gel, uniformly mixing and enabling the pH value to reach 8.5 to 10; and finally, injecting into a mold and enabling the konjac to be subjected to gel moulding by utilizing residual temperature. By adopting the operation, the aim of reducing the gelation speed of the konjac can be achieved, compound phosphate is used as the deacetylation agent to carry out limited deacetylation modification on the konjac powder, and the deacetylation reaction of the konjac powder is mild and controllable in a low pH environment; by using compound alkali as the gel, the gelation is performed in the alkaline environment of coexistence of D-sodium erythorbate, sodium carbonate and phosphate, sothat the gelation speed is reduced, the gelation strength is not significantly affected and the gelation time is prolonged, and the gelation strength of a product is not significantly reduced.

Owner:湖北一致嘉纤生物科技有限公司

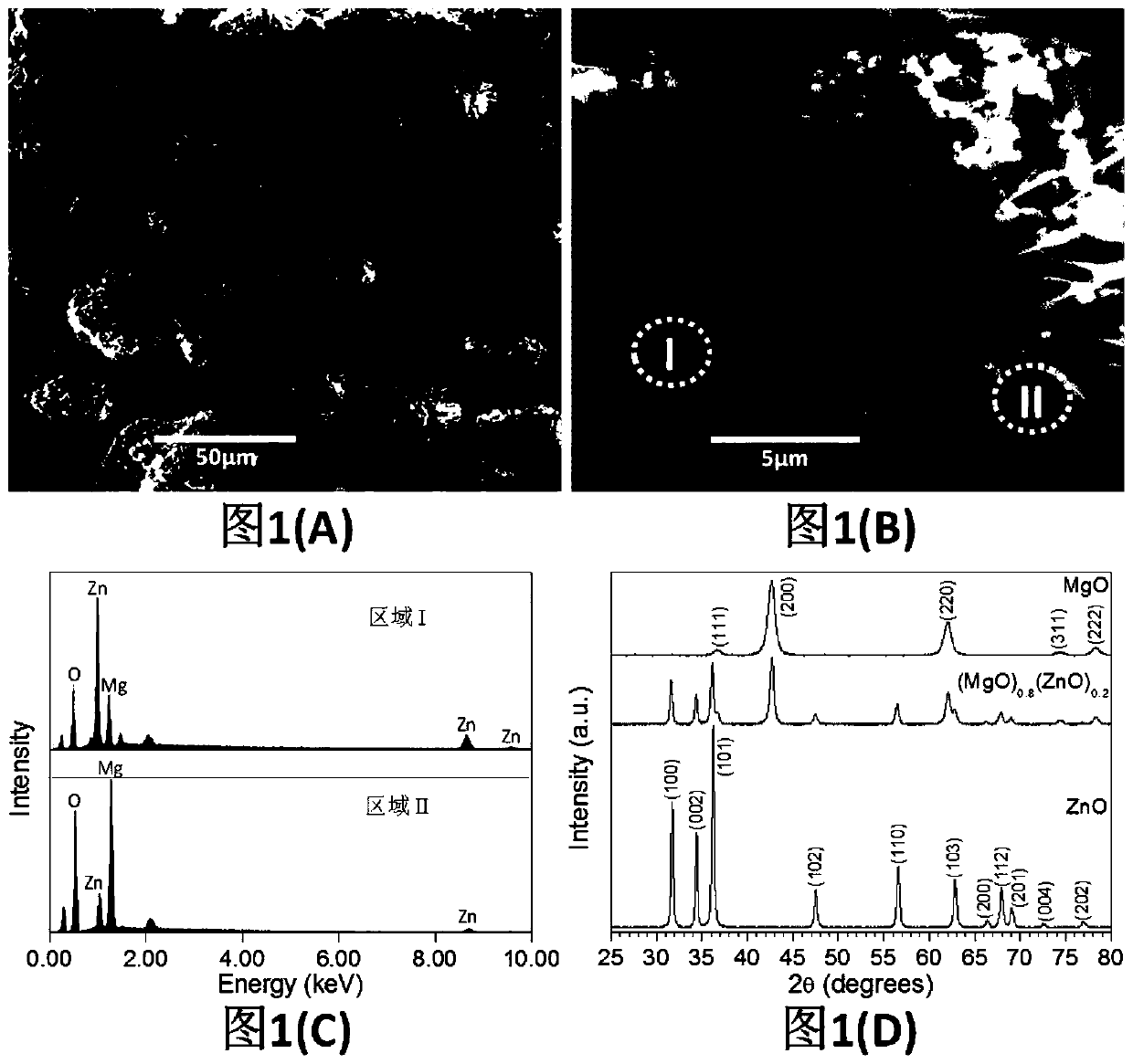

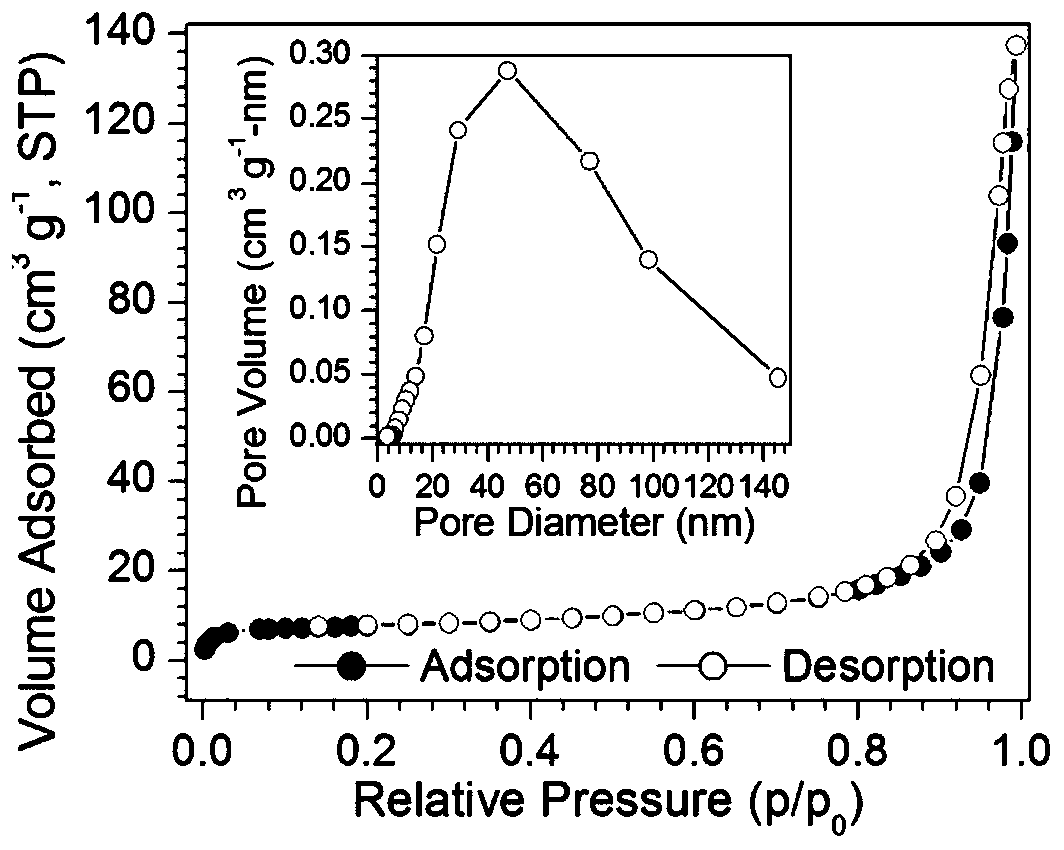

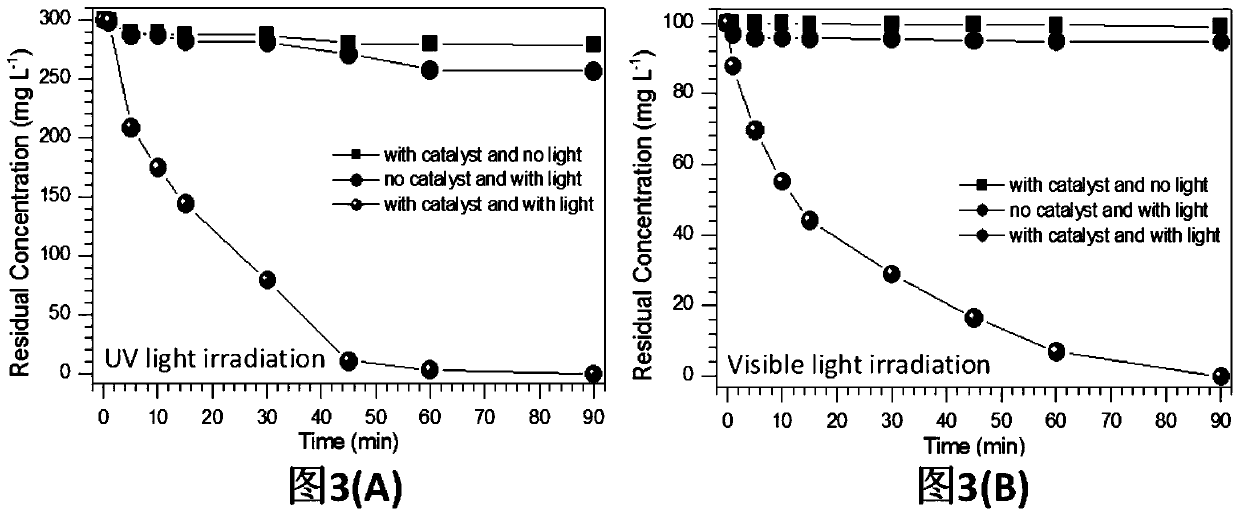

Method of preparing high-activity photocatalyst zinc magnesium composite oxide for degradation of organic dyes

ActiveCN109985615AEasy to operateRaw materials are easy to getWater/sewage treatment by irradiationWater treatment compoundsFiltrationOrganic dye

The invention discloses a method of preparing a high-activity photocatalyst zinc magnesium composite oxide for degradation of organic dyes. Mg(NO3)2.6H2O and Zn(NO3) 2.6H2O are weighed and dissolved in deionized water to get a solution A. Na2CO3 is weighed and dissolved in deionized water to get a solution B. The pH values of the solutions A and B are adjusted respectively. Then a Mg (NO3)2 solution is heated, a Na2CO3 solution is quickly added to the Mg(NO3)2 solution under vigorous stirring, and stirring is continuously conducted for 2.0-6.0 min. A white precipitate is obtained after standing and ageing, and flower-like aMgCO3.bZnCO3.cMg(OH)2.dZn(OH)2.eH2O is prepared after the white precipitate is subjected to filtration, washing and drying. The flower-like aMgCO3.bZnCO3.cMg(OH)2.dZn(OH)2.eH2O is roasted in a muff furnace, and finally a high-activity spherical zinc magnesium composite oxide Mg0.8Zn0.2O catalyst with a diameter of 36 [mu]m is obtained. The invention has the advantages that the preparation method is simple, raw materials are easy to obtain, and the prepared Mg0.8Zn0.2O catalyst has high activity and a high repeated utilization ratio. Under the irradiation of ultraviolet or visible light, the prepared catalyst has higher catalytic degradation activity for organic dyes in aqueous solutions and better degradation activity for organic dyes.

Owner:XI'AN PETROLEUM UNIVERSITY

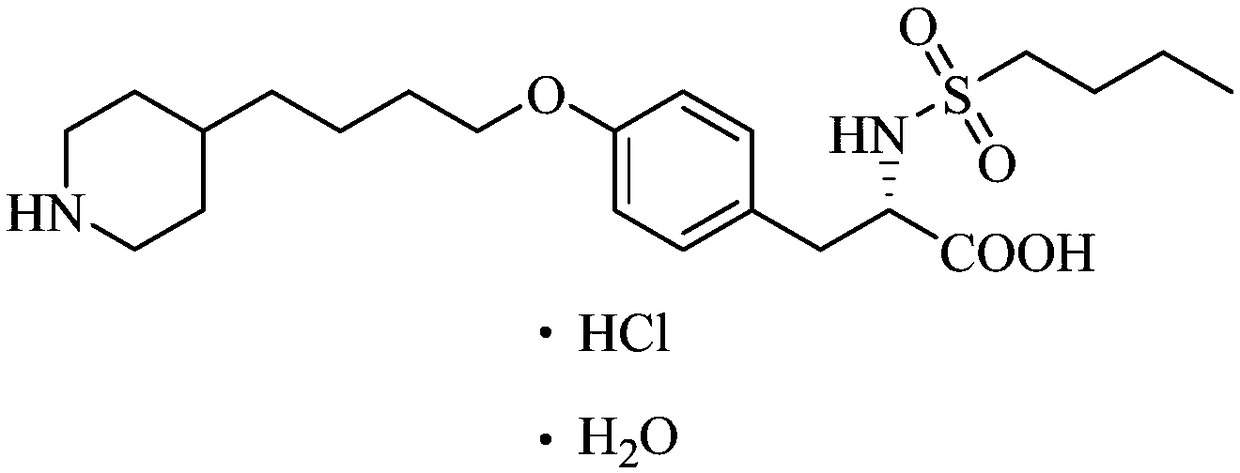

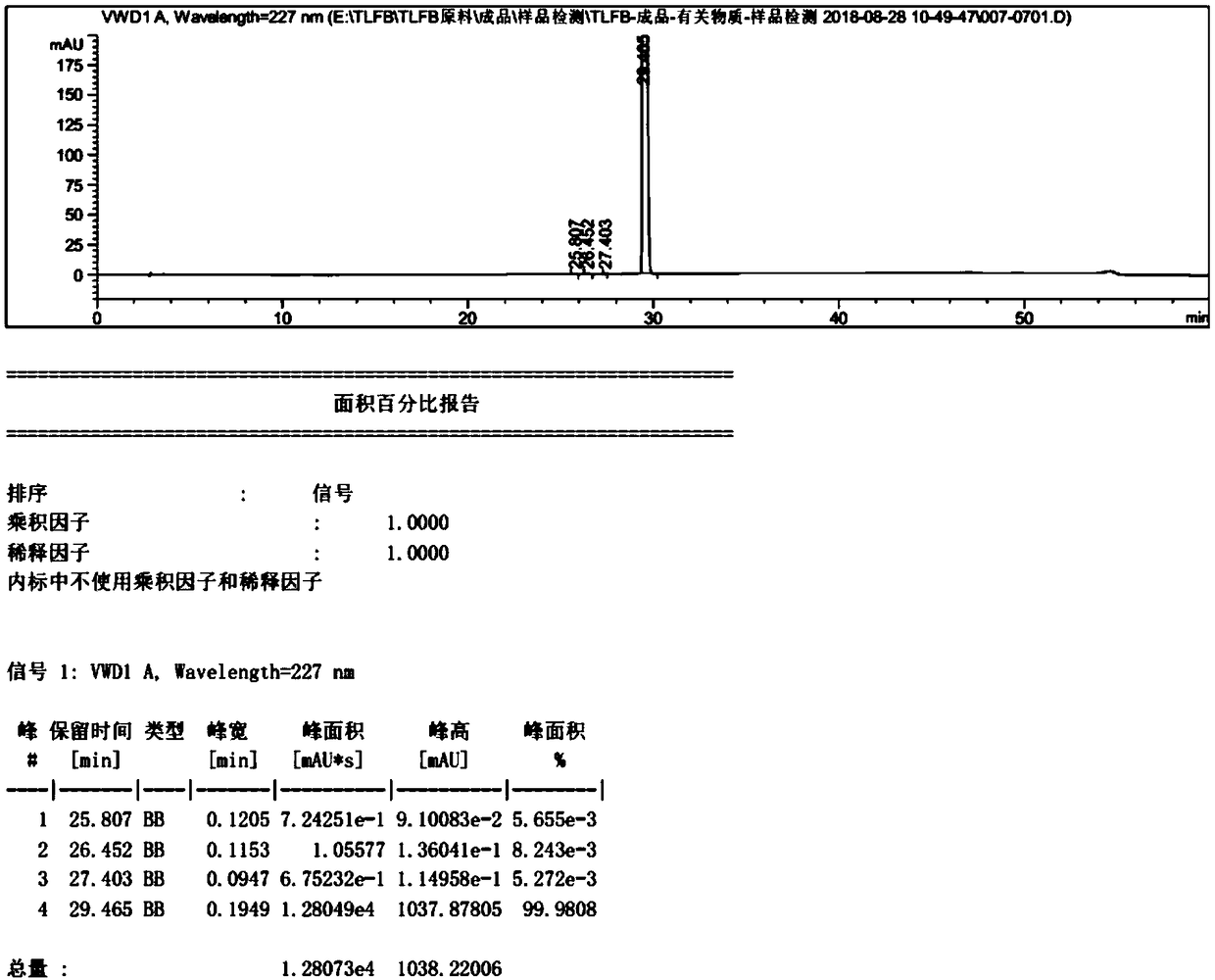

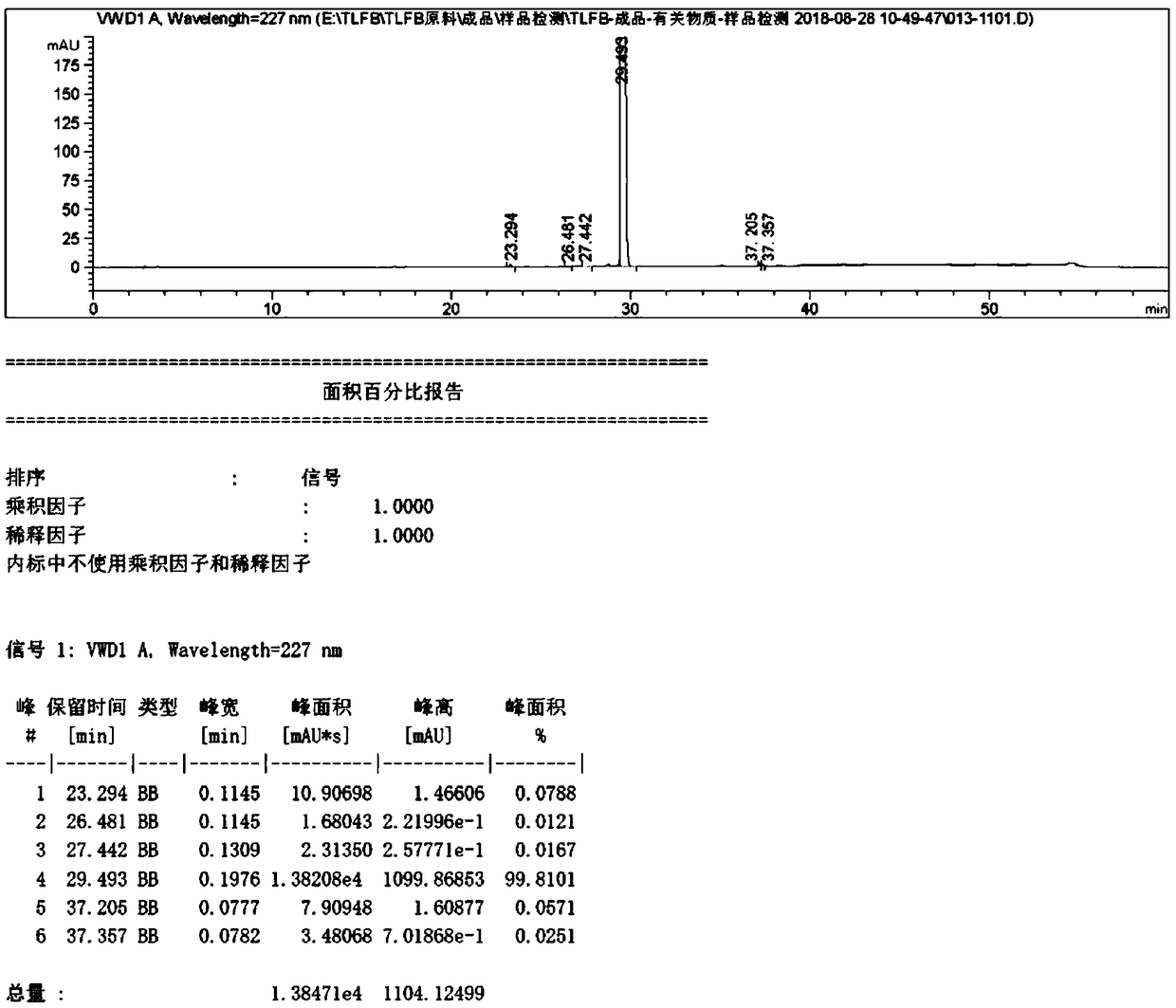

Preparation method of tirofiban hydrochloride

ActiveCN108997198ASimple processMild and controllable reactionOrganic chemistryEthyl acetateAqueous solution

The invention provides a preparation method of tirofiban hydrochloride, which includes steps of: dissolving N-(n-butylsulfonyl)-O-[4-(4-piperidyl)butyl]-L-tyrosine in a diluted hydrochloric acid watersolution, decolorating the raw material with active charcoal, extractively eluting the raw material with ethyl acetate, dropwise adding a product solution to a hydrochloric acid solution, and regulating acidity with stirring to separate a crystal. The method is simple in processes, is stable in yield and is high in product purity, and is suitable for production and preparation of high-purity tirofiban hydrochloride used for preparations.

Owner:无锡富泽药业有限公司

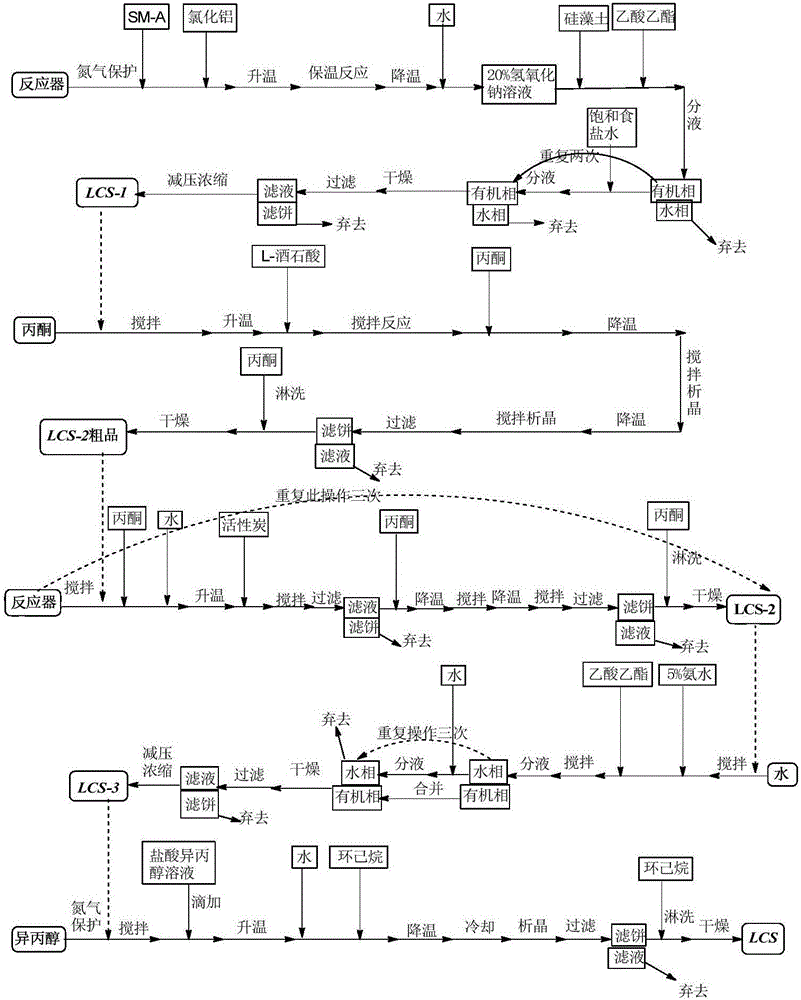

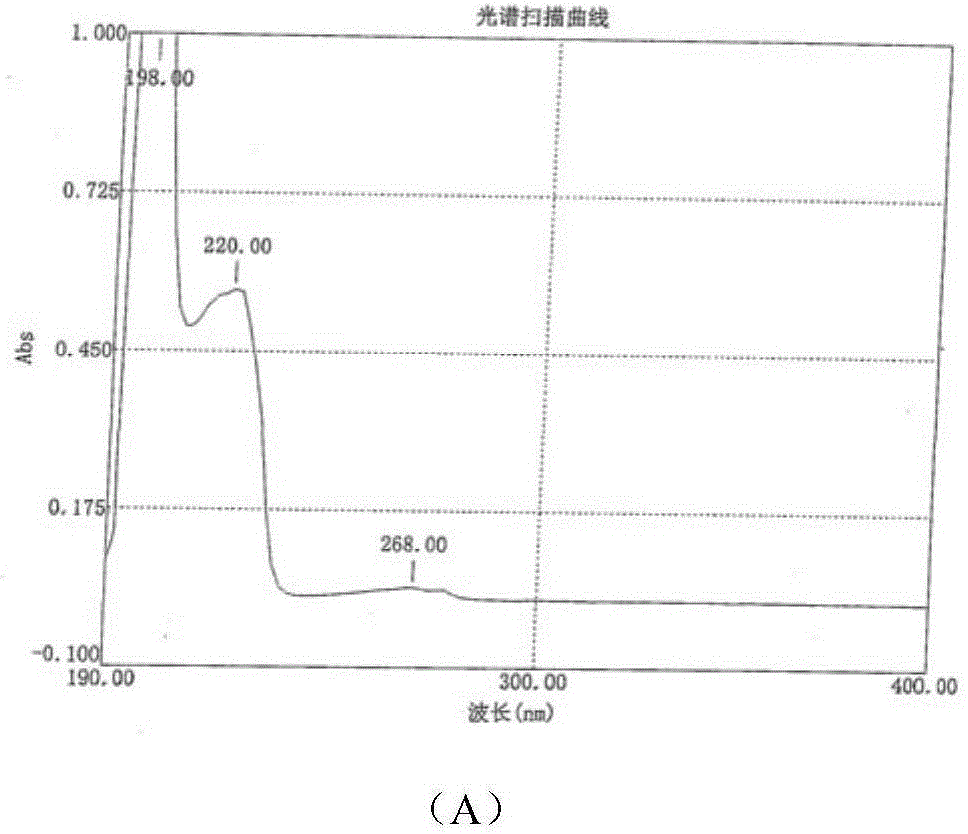

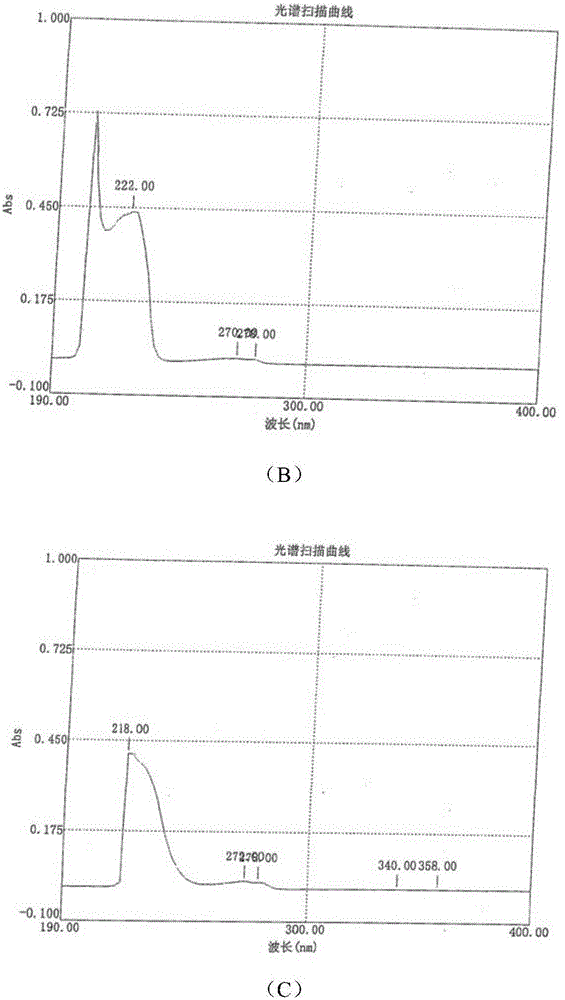

Preparation method for hemihydrate lorcaserin hydrochloride

The invention discloses a preparation method for hemihydrate lorcaserin hydrochloride. The preparation method comprises the following steps: (1) making a compound shown as a formula III react with ammonia to obtain a compound shown as a formula II; (2) under the protection of nitrogen gas, dissolving the compound shown as the formula II in an organic solvent, adding a hydrogen chloride solution of which the solvent is the organic solvent to salify, and adding water and cyclohexane to form a hemihydrate in order to obtain the compound shown as a formula I, wherein the organic solvent is isopropanol or 1,4-dioxane. In the preparation method disclosed by the invention, ammonium hydroxide substitutes for potassium carbonate in the prior art, so that unqualified ignition residues of a finial product caused by potassium chloride generated after salt removal can be avoided; an isopropoxide hydrochloride solution substitutes for the conventional hydrogen chloride gas, so that other impurities can be prevented from being introduced in a preparation process under the improper control of dosage and rate of the gas.

Owner:科兴生物制药股份有限公司

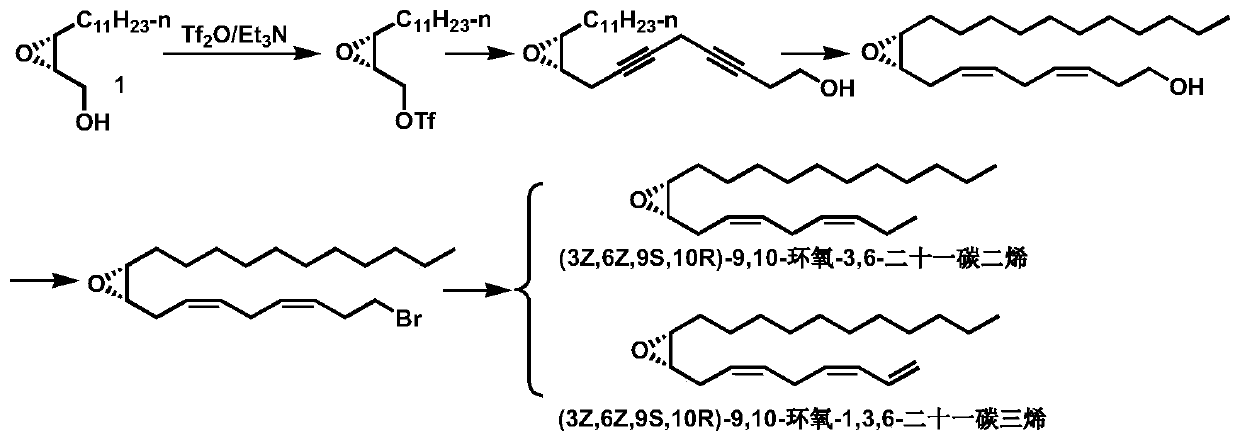

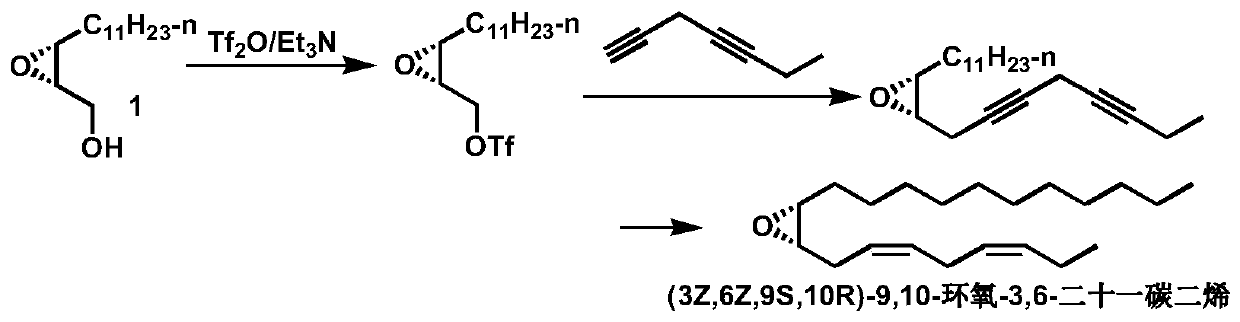

Method for synthesizing sex pheromone of hyphantria cunea

ActiveCN112661725AHigh activityHigh selectivityOrganic chemistryTrifluoromethanesulfonic anhydrideSide reaction

The invention relates to the technical field of hyphantria cunea prevention and treatment, in particular to a synthetic method for synthesizing sex pheromone of hyphantria cunea. According to a traditional method for synthesizing (3Z,6Z,9S,10R)-9,10-epoxy-3,6-heneicosadiene by using propargyl alcohol as a starting material in the traditional technology, various side reactions are liable to occur during a sulfonic acid esterification reaction on a key intermediate (2S,3R)-2,3-epoxy-1-tetradecanol by using trifluoromethanesulfonic anhydride. In order to solve the problems, the (3Z,6Z,9S,10R)-9,10-epoxy-3,6-heneicosadiene is successfully synthesized by taking propargyl alcohol as an initial raw material and taking a Sharpless asymmetric dihydroxylation reaction as a key step without the step of the sulfonic acid esterification reaction on a key intermediate (2S,3R)-2,3-epoxy-1-tetradecanol by trifluoromethanesulfonic anhydride in the preparation process. Therefore, the whole reaction is mild and controllable and few in side reactions, and enantioselectivity is high.

Owner:江苏宁录科技股份有限公司

Comprehensive utilization method of solvent and by-product in preparation of HFPO by oxygen oxidation method

ActiveCN110845448BReduce usageReduce processing costsPreparation from carboxylic acid halidesOrganic compound preparationChemical industryCarboxylic acid

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Process for preparing graphene by cryochemical method

ActiveCN102452650BLow reduction temperatureThe recovery method is simplePhysical/chemical process catalystsGrapheneEpoxyChemical synthesis

The invention discloses a process for preparing graphene by a cryochemical method, belonging to the technical field of chemical synthesis of graphene. The process uses graphene oxide prepared by chemical oxidation as a raw material, and comprises the step of reducing reaction in which graphene oxide is reduced into graphene. The reducing reaction step implements reduction of the graphene oxide at80-150 DEG C by using sodium borohydride as a reducer by the aid of a catalyst, oxygen-containing functional groups (epoxy group, hydroxy group, carboxy group and carbonyl group) on the graphene oxide are removed, and the electric conductivity of the graphene is thoroughly recovered, thereby preparing the graphene. The process disclosed by the invention is suitable for large-scale industrial production. The process has the advantages of low reduction temperature, mild and controllable reaction, thorough reduction, environment friendliness and the like, and is suitable for industrial production.

Owner:TSINGHUA UNIV

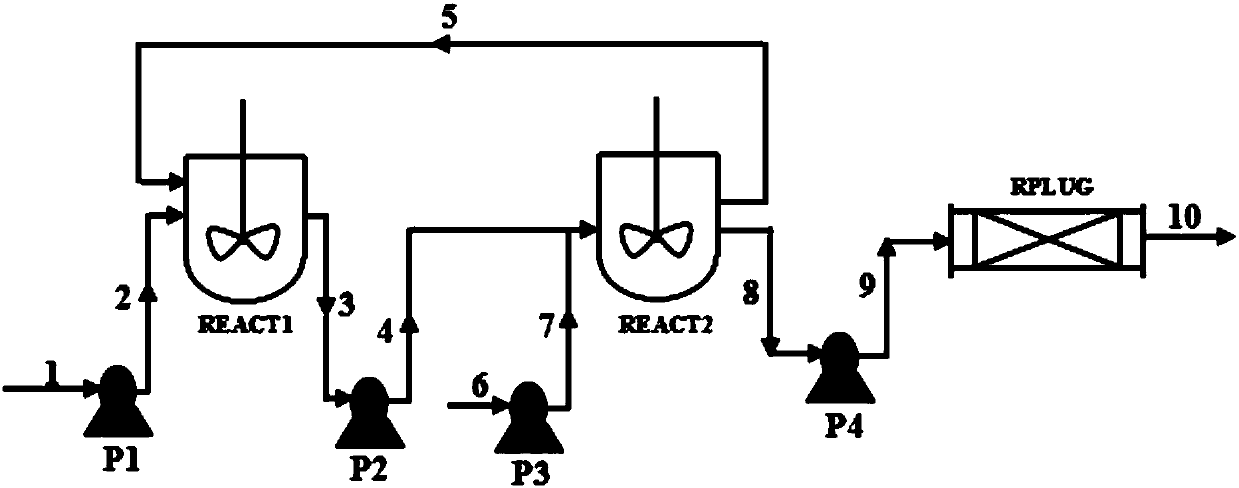

A kind of method for continuously manufacturing potassium diformate

ActiveCN105566093BReduce generationLess severeOrganic compound preparationCarboxylic acid salt preparationPotassium hydroxideReaction temperature

The invention provides a method for continuously manufacturing potassium diformate. The method is characterized in that carbon dioxide gas serves as a regulating agent, formic acid and potassium hydroxide serve as raw materials, potassium diformate is synthesized in one step, and no gas is emitted in the whole reaction process. In the production process, solid potassium hydroxide is prepared into a solution, a certain quantity of the potassium hydroxide solution is obtained, and the carbon dioxide gas is introduced into the potassium hydroxide solution to prepare a potassium hydroxide and potassium carbonate mixed solution; potassium ions and formic acid with the molar ratio of 1:(2.0-3.0) are added in the mixed solution, and stirring reaction is conducted; in the reaction process, reaction temperature is kept to be 55-75 DEG C; the carbon dioxide gas generated due to reaction of formic acid and the mixed solution is recycled and reacts with a newly introduced potassium hydroxide solution; the product of the primary reaction is taken out, secondary reaction continues, reaction temperature is kept to be 55-75 DEG C, and secondary reaction lasts for 1-2.5 hours. The whole reaction is mild, controllable and free of emission, continuous production is achieved, and the method is suitable for large-scale industrial production.

Owner:BEIJING UNIV OF CHEM TECH +2

Multi-key cooperative controllable method for promoting stabilization of medium-low temperature asphalt

ActiveCN110317621AAchieve stabilizationReduce escapeWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by thermal meansTube furnaceCarbon product

The invention discloses a multi-key cooperative controllable method for promoting the stabilization of medium-low temperature asphalt. The method includes heating and mixing the medium-low temperatureasphalt and an accelerator uniformly in a high-pressure reaction kettle, cooling and discharging to obtain modified asphalt; placing a molding intermediate prepared from the modified asphalt in a tubular furnace, heating to 180-330 DEG C by heating 1-5 DEG C per minute, keeping the temperature for 0-5 hours, cooling and discharging to obtain a stabilized asphalt product; and carbonizing the stabilized product at 500-1500 DEG C to obtain an asphalt-based carbon product. The method has the advantages of simple operation process and low cost, solves the problems of difficult stabilization and poor controllability of medium-low temperature asphalt, promotes the high-value utilization of low-value raw materials, and is expected to be popularized industrially.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Electrochemical mineral leaching process

InactiveCN107964589AMild and controllable reactionReduce the amount of saline wastewaterPhotography auxillary processesProcess efficiency improvementElectrochemistryLow graded

The invention discloses an electrochemical mineral leaching process. The electrochemical mineral leaching process comprises the following steps: (1) crushing an acid-soluble mineral to 100 to 300 meshes; (2) adding water of which the volume is 2 to 10 times the volume of the mineral to the mineral obtained in the step (1) to form slurry; (3) adding an electrolyte to the mineral slurry obtained inthe step (2); (4) inserting an anode plate and a cathode plate into the mineral slurry obtained in the step (3), and afterwards performing direct-current electrolysis for 2 to 12 hours at the voltageof 1 V to 15 V and at a current density of 1 A / m<2> to 300 A / m<2>; and (5) after electrolysis is ended, collecting elements which can be electrodeposited under an acidic condition by using the cathodeplate, and performing solid and liquid separation on the mineral slurry to obtain a material solution. According to the electrochemical mineral leaching process, salt electrolysis is used for replacing acid reaction to perform mineral leaching; the reaction is mild and controllable; the salt electrolysis effect is better than a direct acid solution effect; moreover the amount of salt-containing waste water can be greatly reduced; cyclic utilization is realized; and the electrochemical mineral leaching process disclosed by the invention is applicable to processing of various metal minerals, realizes comprehensive utilization of the minerals and is especially applicable to low-grade minerals.

Owner:四川英创环保科技有限公司

Method for continuously manufacturing potassium diformate

ActiveCN105566093AReduce generationLess severeOrganic compound preparationCarboxylic acid salt preparationPotassium hydroxideReaction temperature

The invention provides a method for continuously manufacturing potassium diformate. The method is characterized in that carbon dioxide gas serves as a regulating agent, formic acid and potassium hydroxide serve as raw materials, potassium diformate is synthesized in one step, and no gas is emitted in the whole reaction process. In the production process, solid potassium hydroxide is prepared into a solution, a certain quantity of the potassium hydroxide solution is obtained, and the carbon dioxide gas is introduced into the potassium hydroxide solution to prepare a potassium hydroxide and potassium carbonate mixed solution; potassium ions and formic acid with the molar ratio of 1:(2.0-3.0) are added in the mixed solution, and stirring reaction is conducted; in the reaction process, reaction temperature is kept to be 55-75 DEG C; the carbon dioxide gas generated due to reaction of formic acid and the mixed solution is recycled and reacts with a newly introduced potassium hydroxide solution; the product of the primary reaction is taken out, secondary reaction continues, reaction temperature is kept to be 55-75 DEG C, and secondary reaction lasts for 1-2.5 hours. The whole reaction is mild, controllable and free of emission, continuous production is achieved, and the method is suitable for large-scale industrial production.

Owner:BEIJING UNIV OF CHEM TECH +2

Preparation method of graphene oxide

InactiveCN112850699AHigh degree of oxidationRaw materials are cheap and easy to getGrapheneO-Phosphoric AcidWarm water

The invention relates to the technical field of graphene manufacturing, in particular to a preparation method of graphene oxide. The preparation method comprises the following steps: 1, mixing concentrated sulfuric acid and phosphoric acid in a mass ratio of 5: 1 to obtain mixed acid; 2, taking a certain amount of mixed acid, adding natural crystalline flake graphite powder with the mesh number of 100-5000, stirring and dispersing, and then adding potassium permanganate; 3, continuously stirring and reacting the materials in warm water at 20-60 DEG C; 4, maintaining the temperature of the mixture at 85-99 DEG C, and then adding hydrogen peroxide under a stirring condition to remove residual potassium permanganate; 5, separating the solution prepared in the step 4 by using a centrifugal machine; 6, adding a certain amount of deionized water into the precipitate obtained in the step 5, stirring and dispersing, and introducing into a homogenizer for uninterruptedly and circularly stripping; 7, separating the material obtained in the step 6 by using the centrifugal machine, and washing once by using hydrochloric acid and deionized water respectively; 8, separating the washed solids by using the centrifugal machine; the raw materials are cheap and easy to obtain, operation is safe, dispersity is good, and industrial production is facilitated.

Owner:GUANGDONG MORION NANOTECHNOLOGY CO LTD

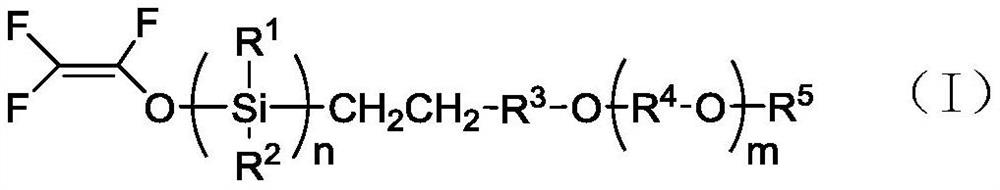

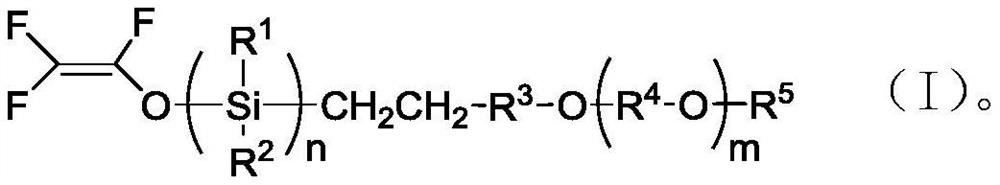

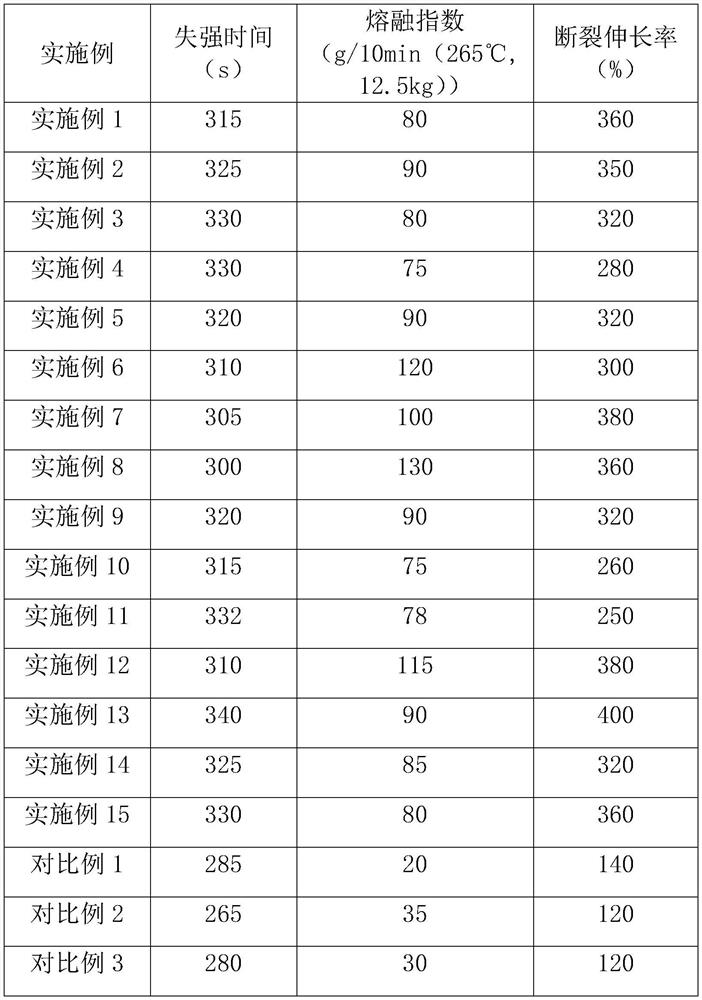

Modified polytrifluorochloroethylene and preparation method thereof

ActiveCN112979857AHigh loss temperatureMeet processing application needsPhotovoltaic energy generationVinyl etherPolymer science

The invention discloses modified polytrifluorochloroethylene, which is formed by polymerizing trifluorochloroethylene and at least one siloxane compound containing trifluorovinyl ether as shown in the following structural formula (I), and also discloses a preparation method of the modified polytrifluorochloroethylene. The modified polytrifluorochloroethylene provided by the invention has relatively high strength loss temperature and relatively large melt index and elongation at break, and is suitable for being used as a drug packaging film and a solar cell front panel film.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +1

A kind of grafting reaction device and using method thereof

The invention discloses a grafting reaction device and a use method thereof. The grafting reaction device comprises a weightlessness feeding device, a single-screw melting device, an aid adding device, a twin-screw grafting reaction device and a vacuum devolatilization device. The use method comprises steps as follows: 1) a premix is added to the single-screw melting device by the weightlessness feeding device; 2) the single-screw melting device plasticizes and melts the premix into polymer melt and introduces the polymer melt into the twin-screw grafting reaction device; 3) the aid adding device adds aids to one or two heating zones of the twin-screw grafting reaction device; a graft polymer is formed through a grafting reaction in the twin-screw grafting reaction device and then introduced into the vacuum devolatilization device; 4) a solvent and non-reacted grafting aids are removed from the vacuum devolatilization device, and a finished product is obtained. The reaction device can effectively reduce crosslinked byproducts in the melting graft process of the polymer.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Gas phase SO3 film-scrapping sulfonating technology

InactiveCN101445418BLess investmentReduce energy consumptionLiquid-gas reaction of thin-film typeSulfo/sulfonyldioxy group formation/introductionGas phaseProduct gas

The present invention relates to a gas phase SO3 film-scraping sulfonating technology which belongs to the technical field of production technology which prepares anionic surfactant by using gas phase SO3 film-scraping sulfonating liquid organic materials. The invention is carried out according to the following steps: A: liquid SO3 is vaporized to gas phase SO3, the gas phase SO3 is sucked in a mixer shaft through a turbo-blower, the gas phase SO3 is mixed with inert gases recycled in a sulfonating reactor to reaction gas with the volume concentration being 0.1 to 10 percent, and then the reaction gas goes into a reaction cylinder body through reaction gas distribution holes on the upper part of the scraping plate shaft; B: the organic materials go into the sulfonating reactor and downwards flow along the inner wall of the reaction cylinder body, a scraping plate is rotated along with the mixer shaft under the action of a transmission system, the organic materials are continuously suffered with film scaping-spread coating-film scaping in the inner wall of the reaction cylinder body, the organic material are alternately updated and uniformly coated on the inner wall of the reaction cylinder body, and the organic materials are completely contacted and reacted with the reaction gas which goes from the reaction gas distribution holes to form reaction products. The design of the technology is reasonable, and the invention can be suitable for sulfonating or sulphating materials with various viscosities.

Owner:ZANYU TECH GRP CO LTD

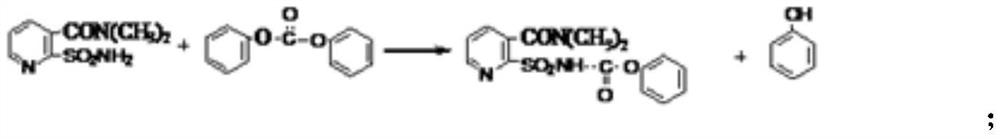

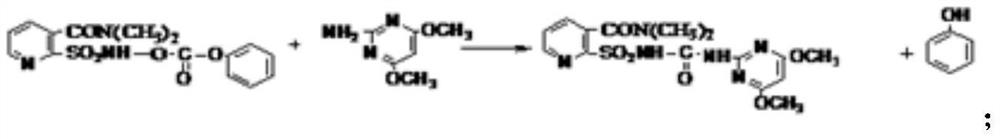

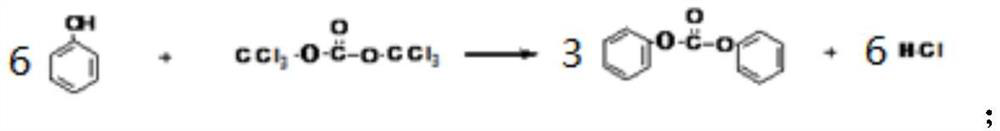

Method for circularly producing nicosulfuron active compound by using byproduct phenol

ActiveCN113387928AMild and controllable reactionSimple process equipmentPreparation from phosgene or haloformatesSide productPyrimidine

The invention relates to the technical field of production of a nicosulfuron active compound, in particular to a method for circularly producing the nicosulfuron active compound by using a byproduct phenol. The method for circularly producing the nicosulfuron active compound by using the byproduct phenol comprises the following steps: reacting diphenyl carbonate with sulfonamide to generate a phenyl ester intermediate and a byproduct phenol; reacting phenyl ester with pyrimidinamine to generate nicosulfuron and a byproduct phenol; extracting and collecting phenol as a byproduct of the reaction in the two steps, and conducting reacting with solid light to obtain diphenyl carbonate; and subjecting the diphenyl carbonate obtained by the reaction to reaction with sulfonamide, and then producing phenol as a byproduct for next cyclic utilization. According to the method for circularly producing the nicosulfuron active compound by utilizing the byproduct phenol, provided by the invention, the reaction steps are mild and controllable, the process equipment is simple, the wastewater amount is small, the production cost is low, the product quality meets the requirements of high-end customers, a wastewater device of the byproduct phenol is omitted, the energy is saved, the production environment is improved, and the comprehensive utilization rate of resources is high.

Owner:ZIBO NAB AGROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com