Process for preparing graphene by cryochemical method

A low-temperature chemistry and graphene technology, which is applied in the low-temperature catalytic reduction preparation of graphite nanomaterials and the low-temperature chemical method for graphene preparation, can solve the problems of severe reduction reaction, incomplete reduction, and high reaction activity, and achieves low reduction temperature and reduced reduction. Simple method, mild reaction and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of graphene oxide used in the example: mix 3g of graphite powder, 3g of sodium nitrate and 138ml of concentrated sulfuric acid in an ice bath; then slowly add 18g of potassium permanganate, magnetically stir and mix, and then heat in a 35°C water bath for 1h; Then add 240ml of deionized water and heat at 90°C for 0.5h. After the heating, add 600ml of deionized water and 18ml of hydrogen peroxide.

[0024] The reduced graphene is prepared into a graphene film by means of suction filtration, and then the film thickness of the graphene film is measured by a step meter, and its electrical conductivity is measured by a four-probe method.

Embodiment 1

[0026] 120 mg of graphene oxide (GO) was dispersed in 200 ml of N,N-dimethylformamide (DMF), 1 g of sodium borohydride was dissolved in 25 ml of DMF, and 0.07 g of anhydrous aluminum chloride was dissolved in 25 ml of DMF. Then the three solutions were mixed and reduced at 140 °C for 3 h under magnetic stirring.

[0027] The test result is: the conductivity of the graphene film is 820S / m.

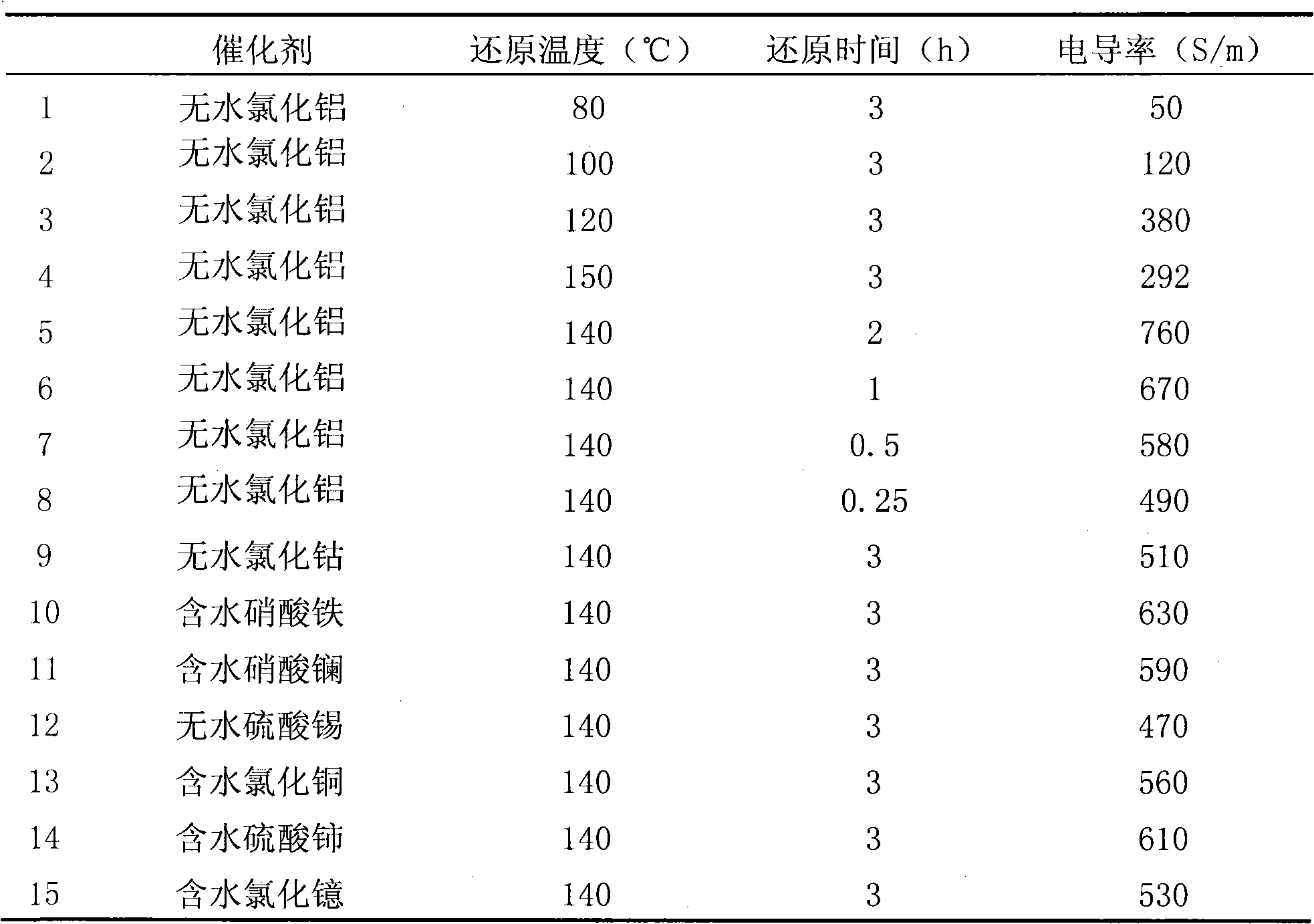

[0028] Under the catalytic conditions of different catalysts, the reduction temperature and reduction time are changed, and other conditions remain unchanged, the conductivity of other graphene obtained is shown in the following table:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com