Flexible graphene film capable of being repeatedly folded, preparation method of flexible graphene film and flexible device comprising flexible graphene film

A technology of flexible graphite and graphene film, applied in the direction of graphene, chemical instruments and methods, hybrid capacitor electrodes, etc., can solve the problem that the realization or improvement of the flexible graphene film’s repeatable foldability cannot be said to be sufficient, and achieve expansion The effect of using conditions and methods, small amount of reducing agent, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0050] In the first embodiment of the present invention, a repeatedly foldable flexible graphene film is provided.

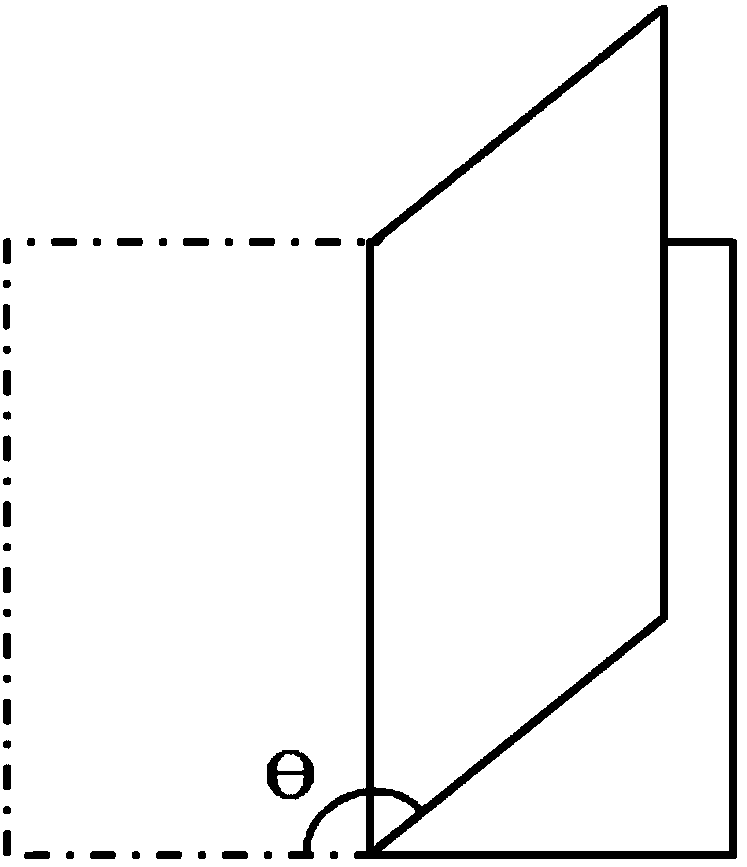

[0051] The flexible graphene film is obtained by reducing the graphene oxide film, the flexible graphene film has a porous structure in the thickness direction, and the flexible graphene film can recover quickly after being folded without leaving creases. in particular:

[0052]

[0053] The graphene oxide film in the present invention means that the dispersion liquid of graphene oxide powder or graphite oxide powder is subjected to film-forming treatment or the powder is subjected to film-pressing treatment.

[0054] At present, the preparation methods of graphite oxide mainly include physical methods and chemical methods. Physical methods usually use cheap flake graphite or expanded graphite as raw materials, and directly prepare single-layer or multi-layer graphite through substrate-free gas phase synthesis, thermal expansion exfoliation, mechanical exfoli...

no. 2 approach

[0079] The second embodiment of the present invention provides a method for preparing a repeatedly foldable flexible graphene film. The method comprises the steps of:

[0080] Step 1: performing a film-forming treatment on the dispersion of graphene oxide powder or graphite oxide powder or performing a film-pressing treatment on the powder to obtain a graphene oxide film;

[0081] Step 2: reducing the graphene oxide film to obtain a graphene film step,

[0082] Classically, the preparation method of the present invention can be carried out according to the following steps:

[0083] Pre-preparation of raw materials for the formation of graphite oxide, such as dissolving natural flake graphite into a strong protic acid, the dissolution process is preferably formed under the action of shear force, such as can use conventional stirring equipment, more typically such as using magnetic force Stirring equipment. The temperature for forming the above solution is preferably 0-4°C. ...

no. 3 approach

[0094] In the third embodiment of the present invention, a flexible device is provided, such as a flexible energy storage and conversion electrode, a flexible sensor, a flexible supercapacitor, a flexible electromagnetic shielding film, a flexible conductive material or a flexible thermal conductive material, etc. The flexible device includes or uses the flexible graphene film according to the first embodiment or the refoldable flexible graphene film obtained by the method for preparing the flexible graphene film according to the second embodiment, and obtained by device assembly.

[0095] The flexible device of the present invention can typically be a flexible supercapacitor.

[0096] In such a molded product, the existence of the flexible graphene film makes the supercapacitor also have the property of being flexible and foldable. After multiple single folds or multiple folds, it can still quickly return to its original shape without leaving creases. equipment offers the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com