Method for preparing alsifer from high-alumina fly ash and magnetic beads

A high-alumina fly ash and ferroalloy technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of light specific gravity of fly ash pellets, unstable product performance, uneven charge composition, etc. Improve the strength of the ball, avoid the collapse of the material in the furnace, and increase the fluidity of the slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

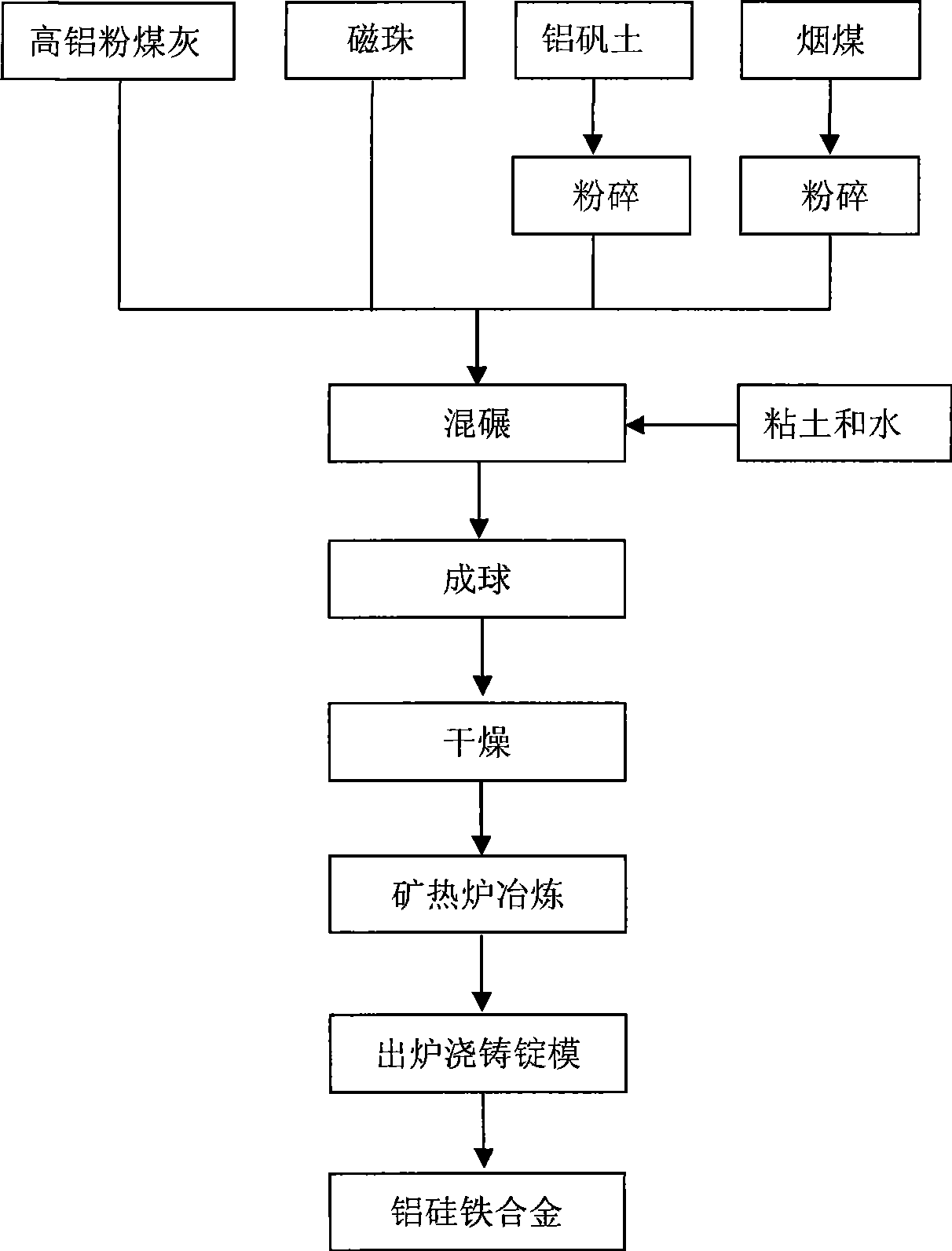

[0027] Referring to the accompanying drawings, the present invention will be described in further detail in combination with specific embodiments.

[0028] ① Raw material selection of high aluminum fly ash containing Al 2 o 3 52%, SiO 2 38%, Fe 2 o 3 2.5%, magnetic beads containing Al 2 o 3 15.4%, SiO 2 25.5%, Fe 2 o 3 55.1%, adding part of bauxite and a small amount of silica. The raw material ingredients are as follows: the weights of high alumina fly ash, magnetic beads, bauxite, silica, and bituminous coal in each batch are 82kg, 68kg, 40kg, 5kg, and 190kg, respectively. Weighing according to the above ratio, the bauxite is coarsely crushed by the jaw crusher first, and then finely crushed by the hammer crusher together with the bituminous coal, and then enters the mixer, and the high-alumina fly ash and magnetic beads directly enter the mixer.

[0029] ② When mixing and milling, add 30kg of binder clay with particle size below 200 mesh and plasticity index...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com