Patents

Literature

648 results about "Coesite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coesite is a form (polymorph) of silicon dioxide SiO₂ that is formed when very high pressure (2–3 gigapascals), and moderately high temperature (700 °C, 1,300 °F), are applied to quartz. Coesite was first synthesized by Loring Coes Jr., a chemist at the Norton Company, in 1953.

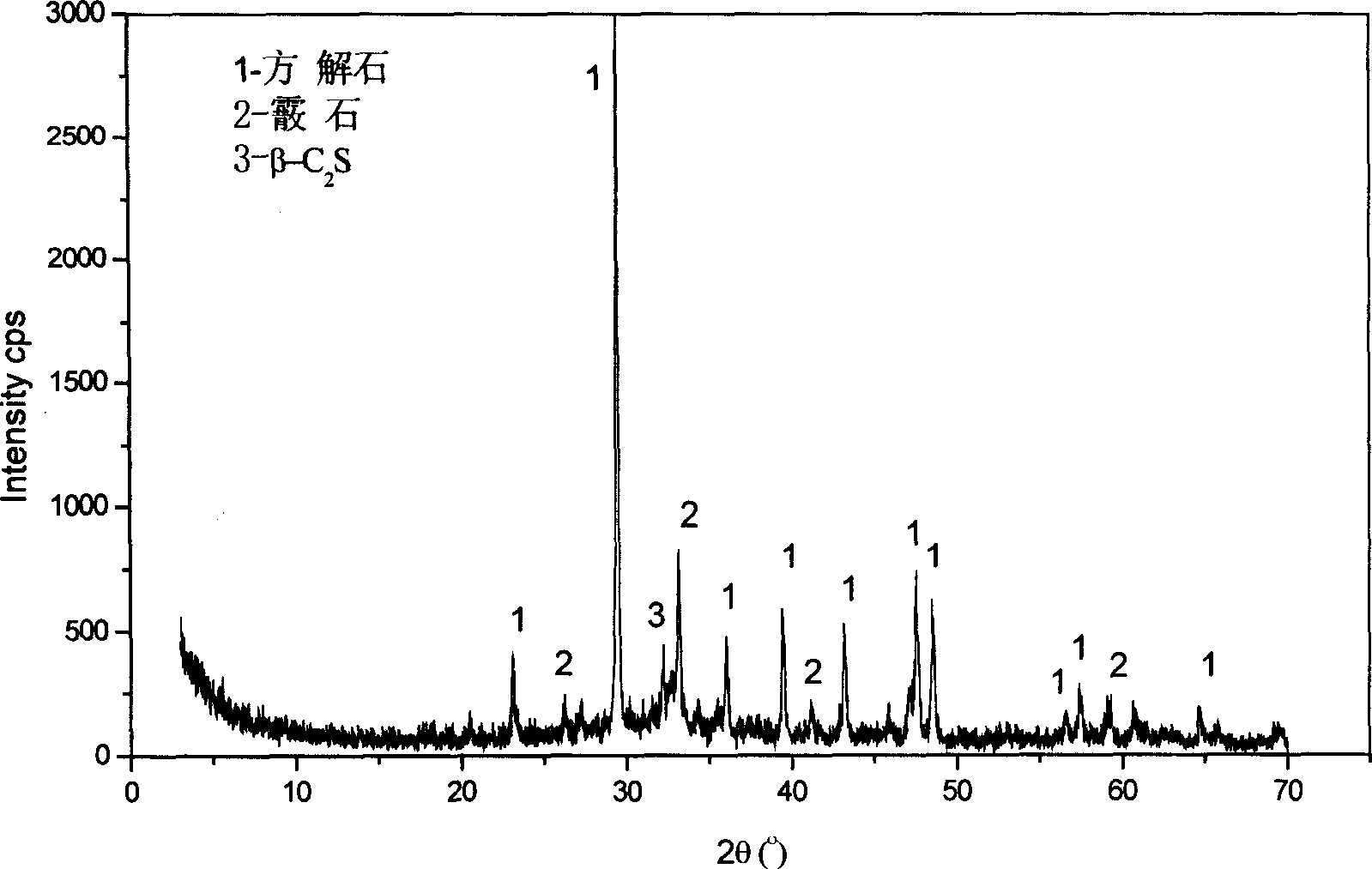

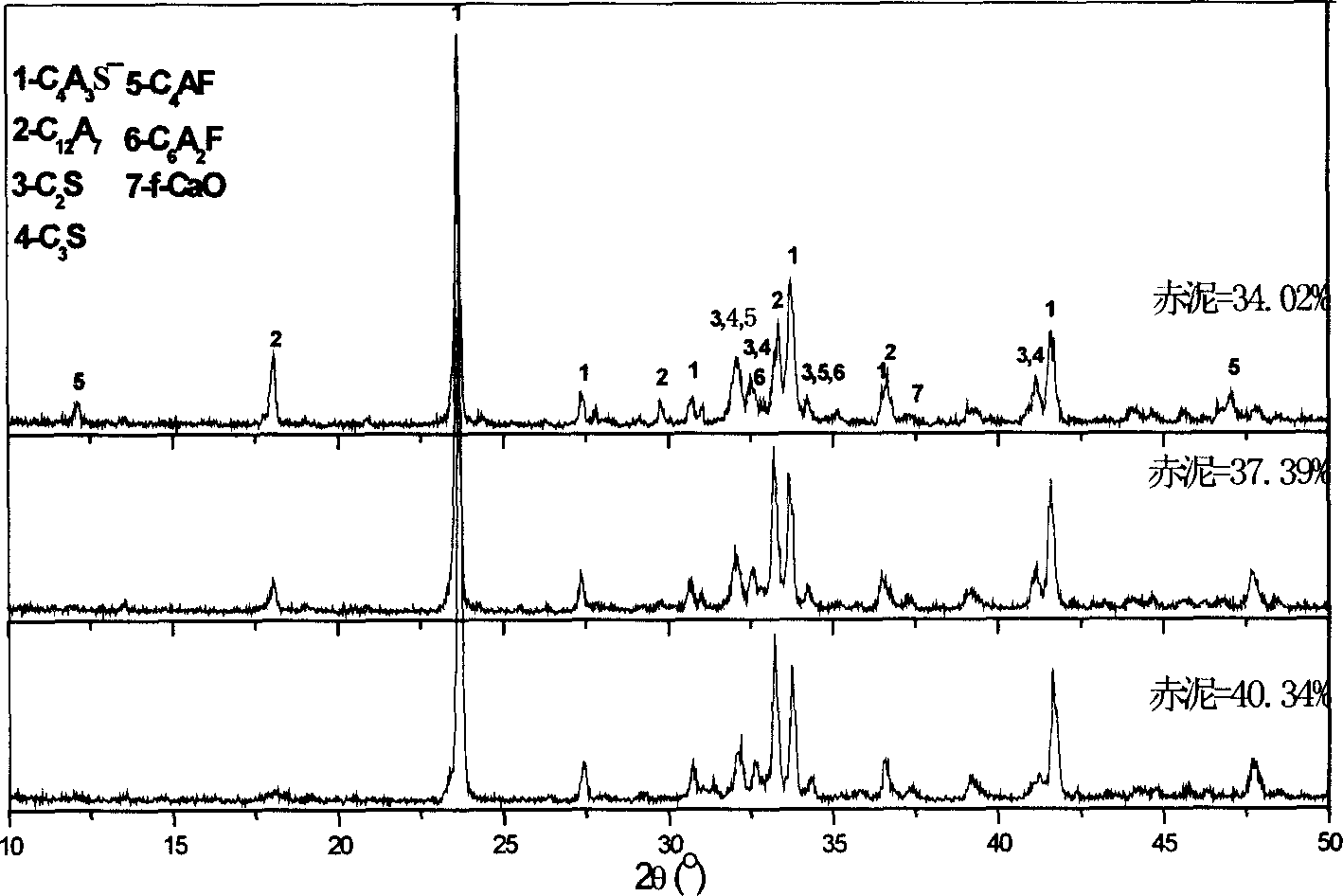

Method for preparing sulphate aluminium cement by red mud

InactiveCN1837121AImprove developmentDevelopmental enhancement and stabilityCinker content reductionCalcium in biologyRed mud

The invention discloses a red mud preparing sulpho-aluminate cement, which is characterized by the following: using 26%-41% red mud to take place of part of aluminium and calcium raw material and whole silica and irony raw material of regular sulpho-aluminate cement production; grinding for certain fineness; desining the C4A3S,C2S,C4AF and main mineral of cement clinker; Preparing sulpho-aluminate cement by alumina, lime carbonate, calcium sulfate and other burdens. The sulpho-aluminate cement has quick induration speed and high early strength.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Coating for lost foam cast iron

InactiveCN101569918AStrong ability to absorb EPSExempt from cleanupFoundry mouldsFoundry coresSodium BentoniteHigh surface

The invention belongs to the technical field of coatings for lost foam, in particular to a coating for lost foam cast iron. The invention provides the coating for the lost foam cast iron, which comprises the following components (calculated as the weight): 70 portions of bauxite, 30 portions of quartz powder, 2 to 5 portions of bentonite, 0.5 to 2 portions of white latex, 0.5 to 1.0 portion of sodium carboxymethyl cellulose, 2 to 3 portions of water soluble phenolic resin, 0.5 to 2 portions of attapulgite, 2 to 5 portions of spodumene powder, 0.01 to 0.03 portion of surfactant, and 0.01 to 0.02 portion of defoaming agent. The coating has thin and even coatings and good air permeability; the surfaces of castings are smooth, clean, and level and easy to peel off, and black defects are eliminated; and the castings have level surfaces and high surface quality.

Owner:山东醴泉机械科技有限公司

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Method for producing waterless taphole mix for blast furnace from high-alumina waste refractory materials

The invention discloses a method for producing a waterless taphole mix for a blast furnace from high-alumina waste refractory materials. The produced low-cost waterless taphole mix can satisfy the operating requirements for plugging tapholes of large and medium blast furnaces. The method comprises the selection of raw materials for production, the processing of the raw materials for production, the proportioning of the raw materials for production, and the production process. The waterless taphole mix produced by the method has the characteristics of low cost, good plasticity and sintering property, high middle-and-high-temperature strength, favorable slag and iron erosion resistance and the like, and can completely satisfy the operating requirements of large and medium blast furnaces. Compared with the existing waterless taphole mix, the cost can be reduced by 40-60%; since a great amount of waste refractory materials are used, the emission of the solid waste can be decreased, and a great amount of high-quality refractory materials such as brown corundum, premium / extra grade alumina and the like can be saved; and meanwhile, the energy consumption and the emission of carbon dioxide gas during the smelting of brown corundum and premium / extra grade alumina can be decreased.

Owner:UNIV OF SCI & TECH LIAONING

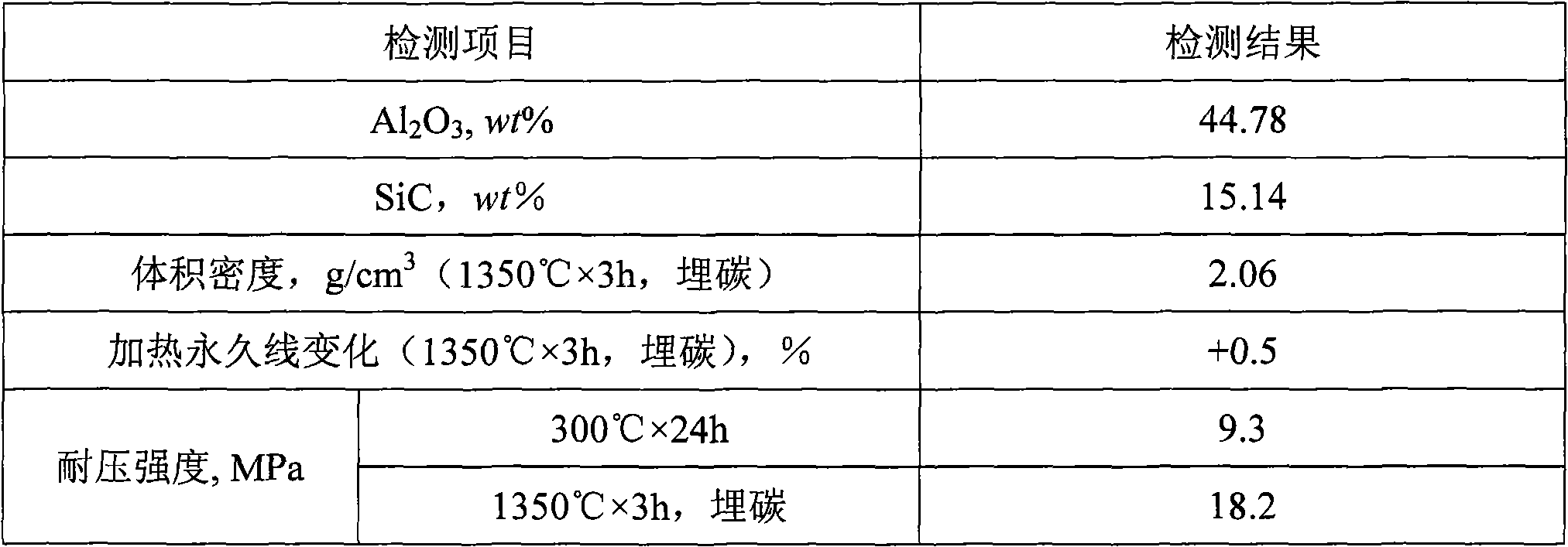

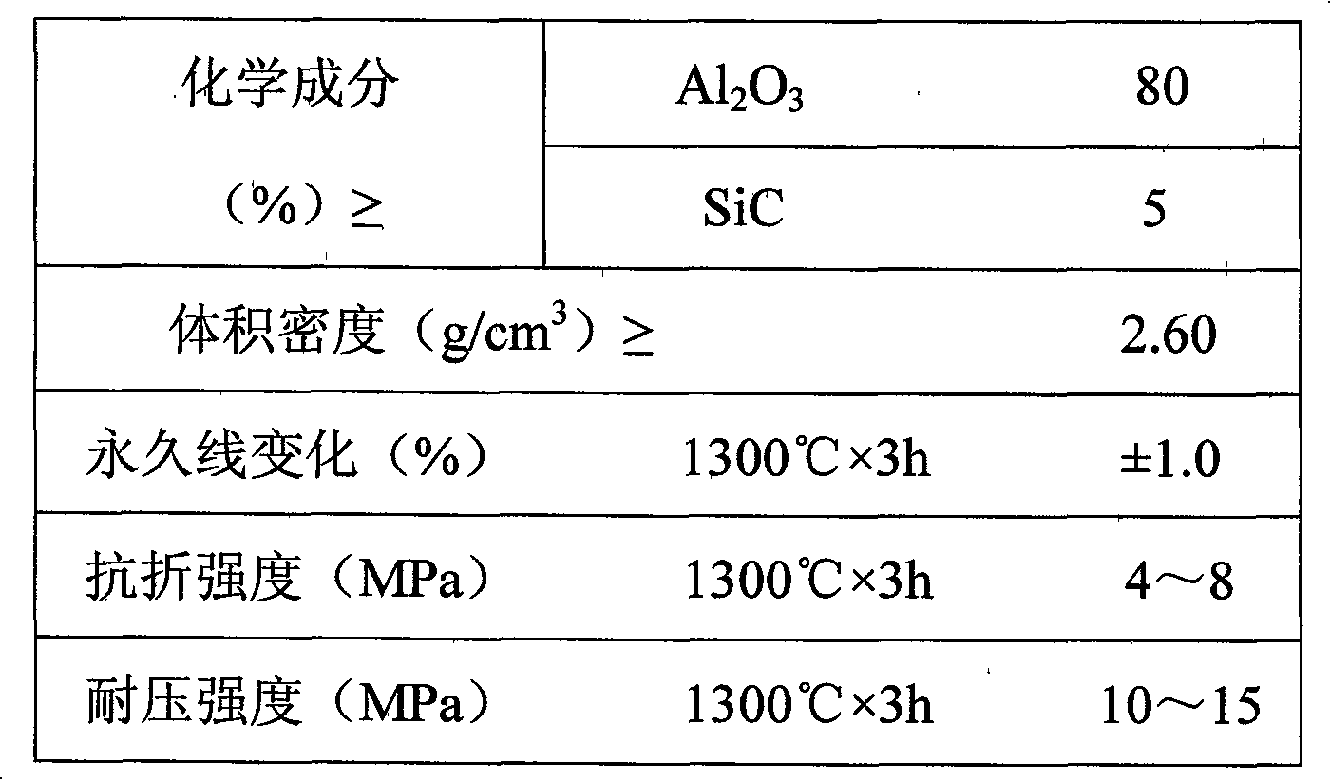

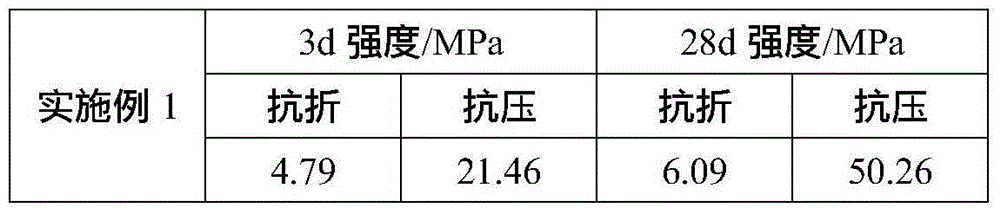

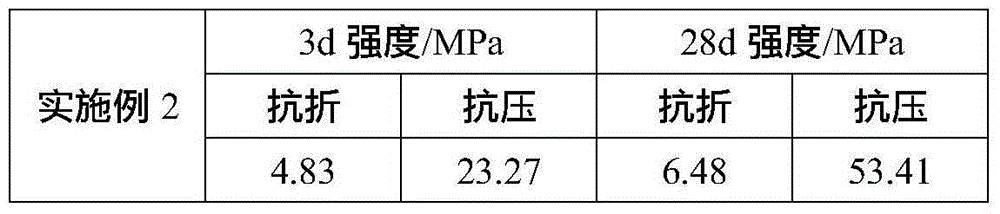

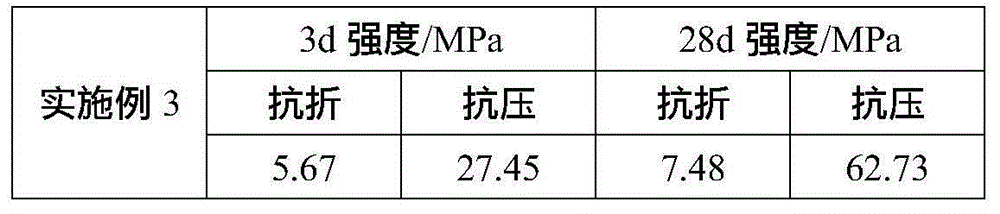

Composite combined aluminum oxide-silicon carbide-(carbon) system amorphous refractory material

The invention relates to a complex combination alumina-carborundum-(carbon) series amorphous fire proof material, and the formula comprises: 36 to 32 percent of 8-3mm corundum or bauxite, 18 to 26 percent of 3-1mm corundum or bauxite, 10 to 22 percent of 1-0.0088mm corundum or bauxite, 0 to 15 percent of 1-0.088mm carborundum, 0 to 3 percent of 1-0.0088 spherical asphalt, 0 to 20 percent of d90 less than 0.088mm corundum or bauxite, 0 to 20 percent of d90 less than 0.088 carborundum, 0 to 3 percent of d90 less than 0.088mm high-carbon materials, 0 to 5 percent of alpha alumina micro powder, 1 to 8 percent of alumina hydrate, 1 to 6 percent of silicon ash, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of plus super-plasticizer (polycarboxylic acids+sulfonated naphthalene formaldehyde polymer+sulfonated melamine polymer), 1 to 6 percent of plus polypropylene acid series latex and 1 to 6 percent of plus water. Compared with low-cement aluminum carborundum carbon material, the material has good anti-corrosion performance. Therefore, the service life of a kilneye of a cement kiln and a main groove slag line of a blast furnace can be prolonged when a product is combined by the complex combination alumina-carborundum-(carbon) series amorphous fire proof material instead of the cement.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Lost foam casting coating and preparation method thereof

The invention discloses a lost foam casting coating, which comprises fire-proof powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol, wherein the fire-proof powder includes bauxite and quartz powder. The bauxite is formed by uniformly mixing the following components: 80% of particles with the granularity ranging from -280 to -310, 14% of particles with the granularity ranging from -280 mesh to -190 mesh and 6% of particles with the granularity ranging from -90 mesh to -190 mesh. The preparation method of the lost foam casting coating is as follows: calcining selected bauxite ore at the temperature of 1510-1550 DEG C; grinding calcined clinkers to acquire the granularity particles with the granularities respectively; evenly mixing the particles according to the composition proportion; and mixing the mixed bauxite with quartz powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol. According to the invention, bauxite is distributed according to particle sizes, and bauxite particles of different sizes are alternately arranged after even mixing. As a result, the compactness is changed, the air permeability is strengthened, the cold shut phenomenon occurring between liquid metal and the coating is avoided, and finally the quality of the casting produced through lost foam casting is improved.

Owner:ANYUE COUNTY JINLONG MACHINERY MFG

Titanium-containing calcium aluminate-high alumina bauxite modified refractory material, as well as preparation method and application thereof

ActiveCN104609872AHigh melting pointSmall coefficient of thermal expansionMelt-holding vesselsSteelmakingAluminate

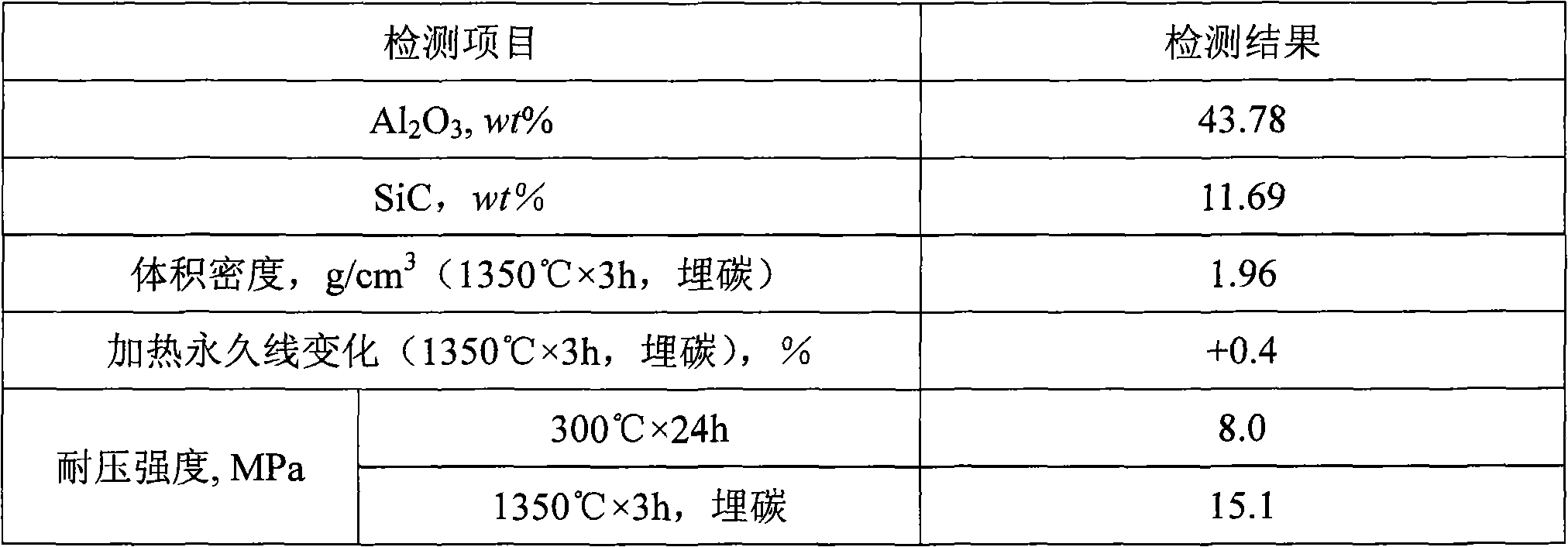

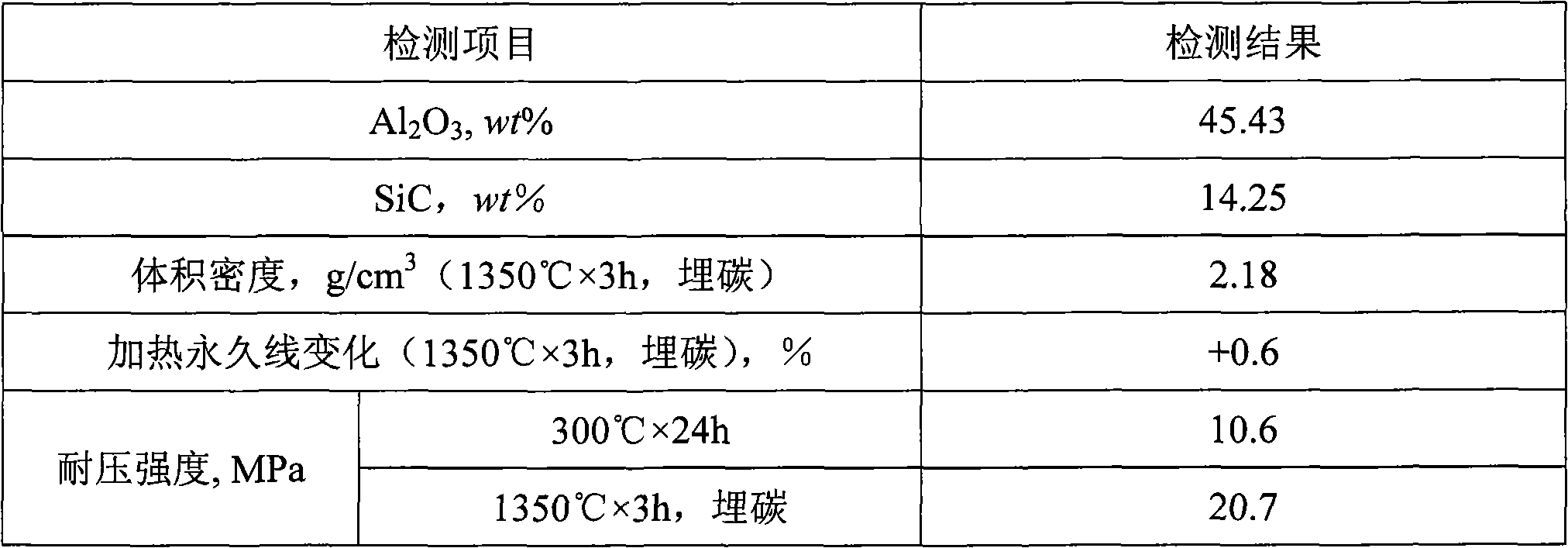

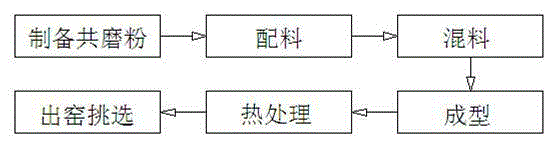

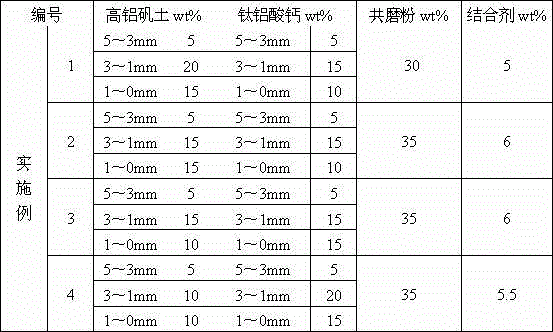

The invention discloses a titanium-containing calcium aluminate-high alumina bauxite modified refractory material, as well as a preparation method and application thereof, belongs to the field of refractory materials, and adopts the technical scheme that the modified refractory material comprises 25 to 40 wt% of high alumina bauxite, 25 to 40 wt% of titanium-containing calcium aluminate, and 30 to 35 wt% of co-ground powder, and a phenolic resin binding agent which accounts for 3 to 6 wt% of the total mass of the raw materials is additionally added, wherein the co-ground powder is formed by uniformly mixing titanium-containing calcium aluminate fine powder, alpha-Al2O3 micro-powder, graphite powder, silicon carbide fine powder, graphite powder, silicon carbide fine powder, metal aluminum powder and high-temperature asphalt powder; titanium-containing calcium aluminate comprises the following ingredients by ratio: 76.21% of Al2O3, 10.6% of TiO2, 10.16% of CaO, 0.6% of Fe2O3, 1.82% of MgO, and 0.62% of SiO2. According to the invention, titanium-containing calcium aluminate being industrial slag of steelmaking is effectively recycled, so as to greatly reduce the production and manufacture cost; as titanium-containing calcium aluminate is a solid solution of calcium hexaluminate, calcium dialuminate, aluminum titanate, calcium titanate and rutile, the modified refractory material is favorable in thermal shock resistance and heat-insulating property.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

Lost foam casting cast iron coating for preventing carbon defects and preparation method thereof

InactiveCN101767184AGood suspensionImprove thixotropyFoundry mouldsFoundry coresPolyvinyl alcoholOctanol

The invention discloses a lost foam casting cast iron coating for preventing carbon defects, which comprises the following components by weight percent: 60.5%-64.5% of bauxite, 13.5-17.5% of kaolin, 3.5%-6.0% of talc powder, 1.7%-3.5% of attapulgite, 0.4%-0.8% of sodium lignosulphonate, 2.5%-6.0% of aluminum sulfate, 1.7%-3.5% of polyvinyl alcohol, 3.5%-5.0% of silica sol, 0.1%-0.2% of iron oxide powder and 0.01%-0.02% of n-octanol, and the sum of the components is 100%. The lost foam casting cast iron coating is prepared by respectively preparing water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, evenly mixing the bauxite, the kaolin, the talc powder and the iron oxide powder for preparing mixed powder material, mixing the water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, the silica sol and the refractory mixed powder material with the n-octanol, stirring and grinding. The coating has the advantages of good thixotropy, good coating property, high coating strength and good gas permeability; and the surface of a cast is smooth and has no wrinkles and other carbon defects.

Owner:NANTONG XINZHENGDA SPECIAL STEEL

Method for preparing casting titanium and titanium-aluminum base alloy porous ceramic mould shell

InactiveCN101104195AQuality improvementReduce residual strengthFoundry mouldsFoundry coresHigh pressurePorous ceramics

Disclosed is a preparation method of a porous ceramic shell of cast titanium and titanium aluminum alloys, relating to the melt mould precise casting field. The invention solves the problem that cracks are caused when the thin-walled titanium and the titanium aluminum alloys castings are solidified and shrunk due to the large residual intensity of the present shell of cast titanium and titanium aluminum alloys. The method is as following: firstly, wax mould pressing; secondly, coating and hanging four surface layers, and the manufacturing processes of each layer are that coating and hanging coatings of the surface layer, sprinkling zirconic sand, drying in the room temperature, and then the next layer is coated and hung; thirdly, coating and hanging two transitional layers, whose differences from coating and hanging the surface layers lie in that each coated and hung transitional layer comprises a high polymer and a back coating of water latex, and bauxite sand of 50 to 70 orders is sprinkled; fourthly, coating and hanging four to eight reinforcing layers, whose differences from hanging and coating the transitional layers lie in that the bauxite sand of 30 to 40 orders is sprinkled; fifthly, coating and hanging the coatings of an outer layer , which will be dried in the room temperature; sixthly, dewaxing by high pressure steam; seventhly, roasting the shell. The invention can be widely applied in the manufacturing of the shell of titanium and titanium aluminum alloys castings for the national defense and domestic use.

Owner:HARBIN INST OF TECH

Method for preparing TiAl-based alloy formwork by wax mold casting

The invention relates to the field of precision casting, in particular to a method for preparing a shuttering for an investment casting TiAl-based alloy with low cost and strong stability. The method comprises the following steps: preparing slurry of which flow cup viscosity is 10 to 25 seconds from Y2O3 powder of 200 to 400 meshes on granularity and silica sol according to a weight ratio of 2:1-3:1; then, coating the slurry on a wax mould, sprinkling electric melting Y2O3 sand of which sand granularity is 40 to 100 meshes on the wax mould, and drying the wax mould; preparing slurry of which flow cup viscosity is 10 to 30 seconds by adopting Al2O3 powder of 200 to 400 meshes on granularity and silica sol according to a weight ratio of 3:1-4:1, coating the second layer, sprinkling electric melting Al2O3 sand of which sand granularity is 40 to 80 meshes on the wax mould, and drying the wax mould; preparing slurry by adopting bauxite and silica sol according to a weight ratio of 3:1-4:1, and sprinkling coal gangue sand of which sand granularity is 16 to 24 meshes on the wax mould; after three layers, finally hanging the bauxite slurry, and drying the slurry; and then removing wax, and sintering the mould. The method has the advantages of simple shuttering preparation process and low cost of the shuttering, can effectively control reaction of a TiAl-based alloy cast and a shuttering surface material, reduce oxygen feeding amount of the alloy, and is suitable for casting a TiAl-based alloy cast.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

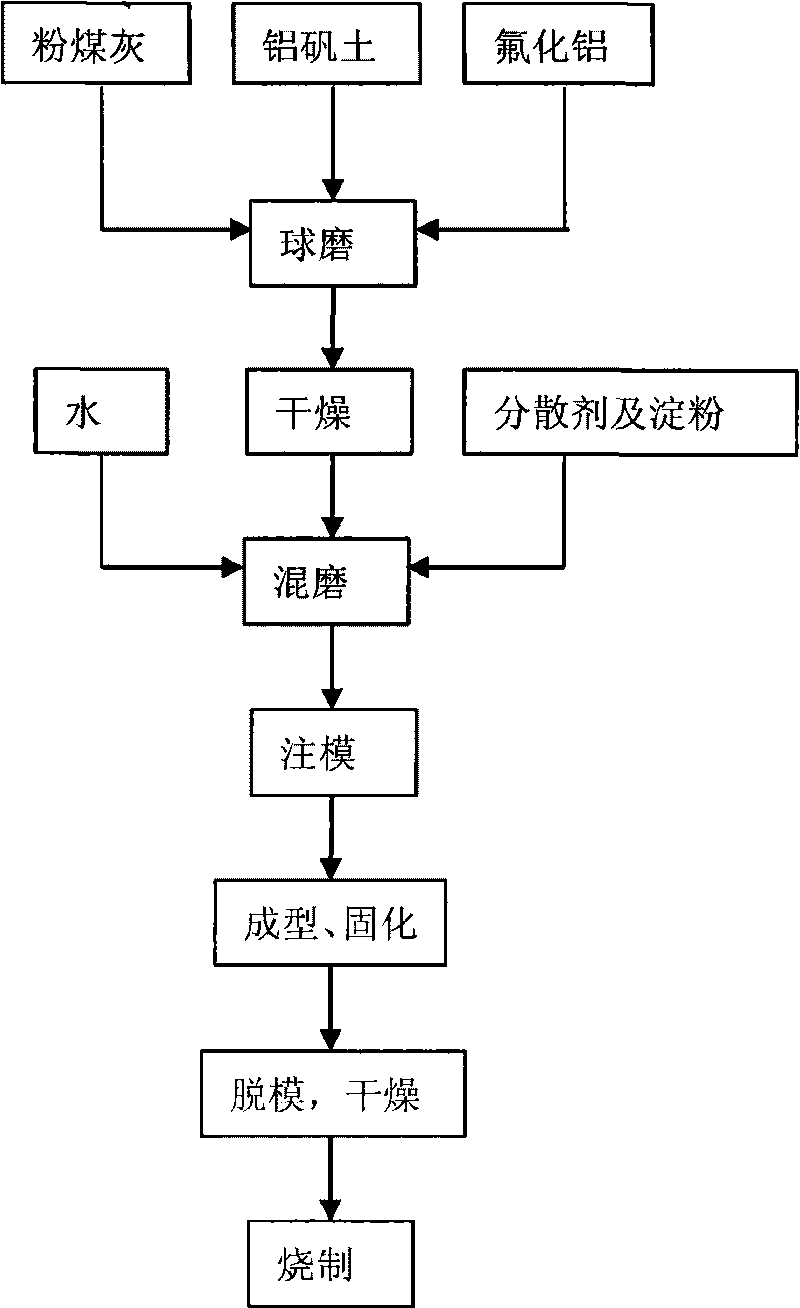

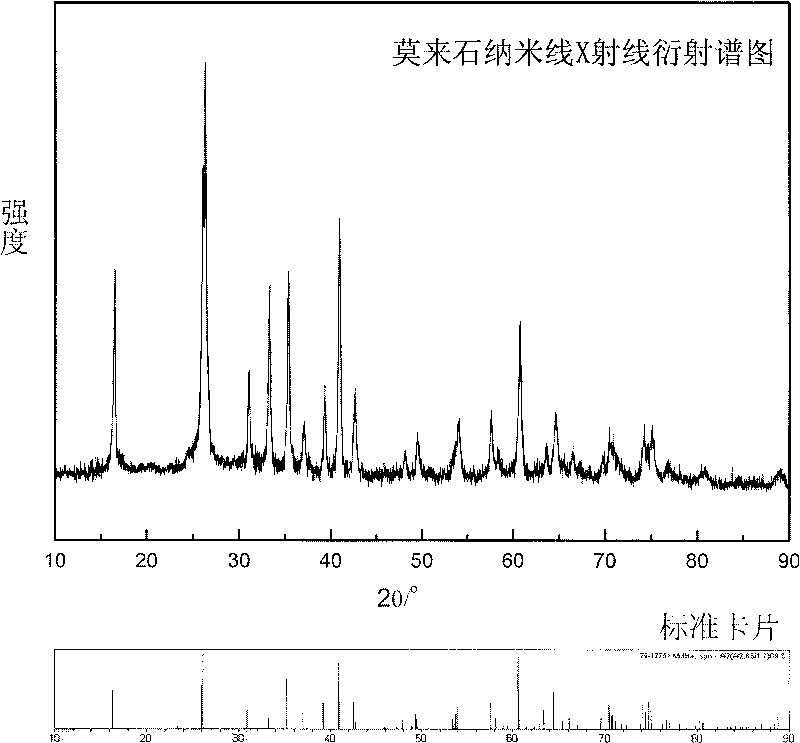

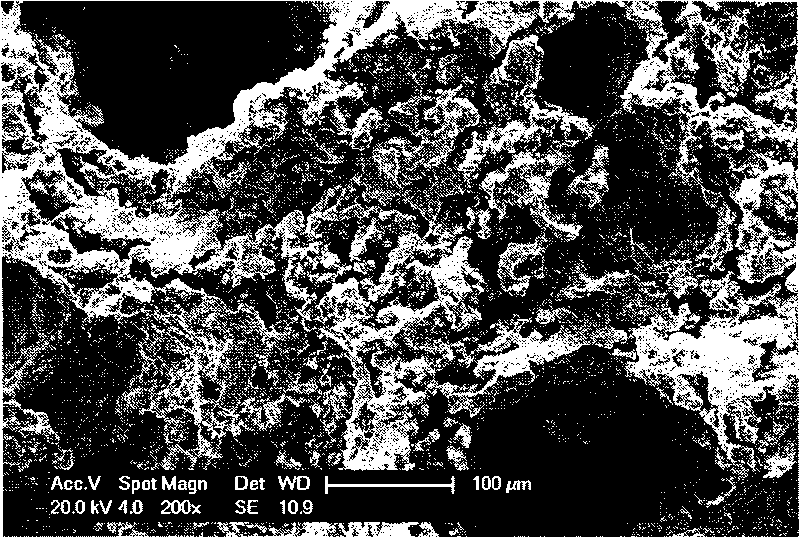

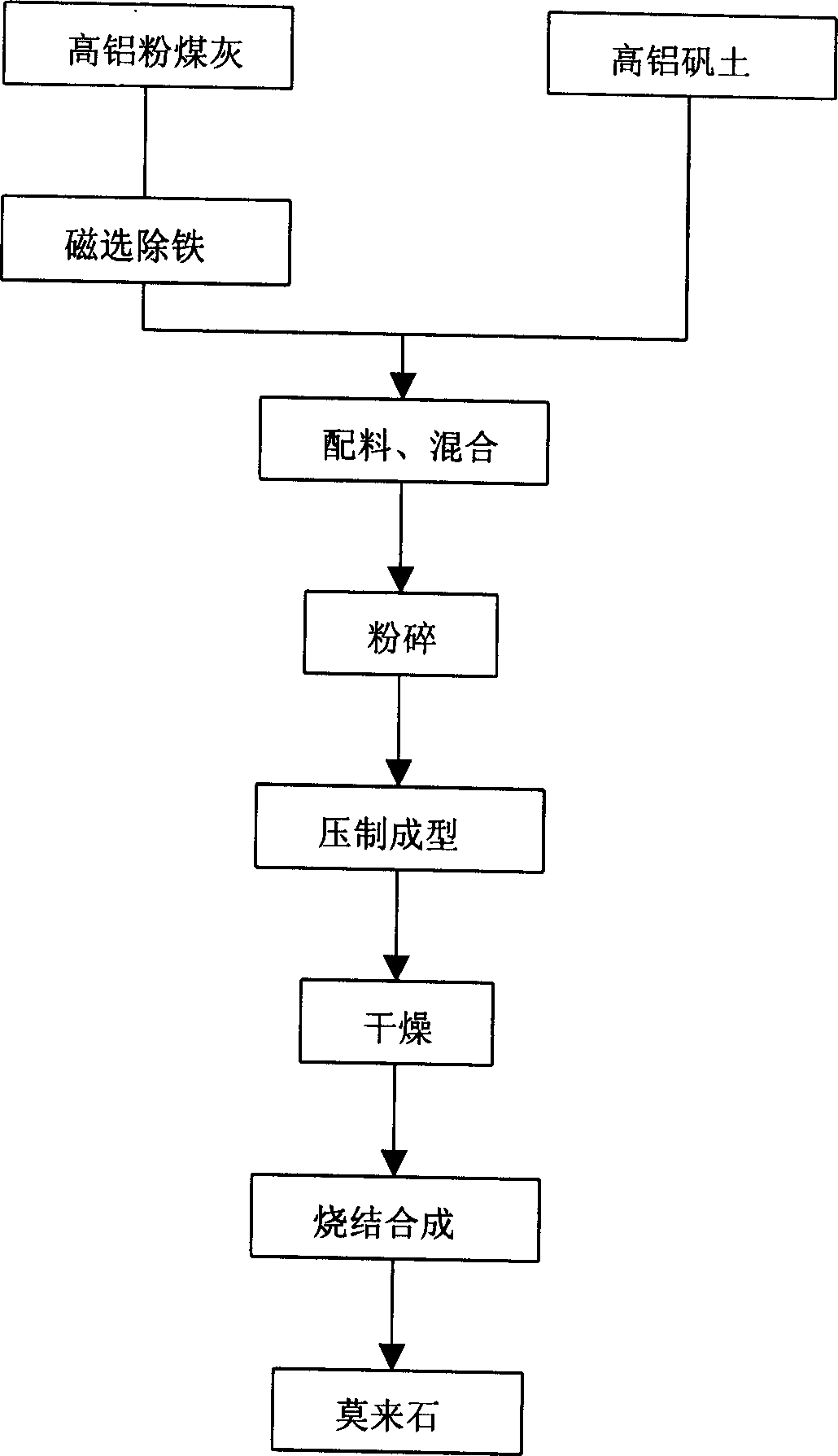

Method for preparing porous mullite

InactiveCN101759430AHigh strengthImprove high temperature resistanceCeramicwarePore distributionMullite

The invention discloses a method for preparing porous mullite, which comprises the following steps of: (1) performing magnetic separation to fly ash to remove iron; (2) proportioning the iron-removed fly ash, bauxite and aluminium fluoride; (3) adding a dispersing agent and a firming agent to prepare a mixed sizing agent; (4) pouring into a mold, and demolding after heating and curing; (5) preserving the demolded dry blank at the temperature of 350-400 DEG C for 0.5-2 h; (6) preserving the temperature at 1300-1500 DEG C for 2-4 h, and cooling. The method not only greatly utilizes fly ash which is a solid pollutant to achieve the purposes of energy saving, pollution reduction and environmental protection, but also has simple technology. The prepared porous mullite ceramics have reasonable pore diameter distribution, even pore distribution, high mullite content and great high-temperature resistance, and are applicable to multiple application requirements on high and low temperatures.

Owner:TIANJIN UNIV

Ceramic Al203SiC refractory and preparation method thereof

A refractory ceramic Al2O3-SiC brick with high strength and low porosity is prepared through proportionally mixing high-Al alumine, white corundum, brown corundum, industrial silicon carbide, andalusite, ceramic additive, adhesive and water, stirring or grinding, die pressing, drying at 60-110 deg.C for 12-24 hr or natural drying, and calcining at 1400-1470 deg.C.

Owner:WUHAN UNIV OF SCI & TECH

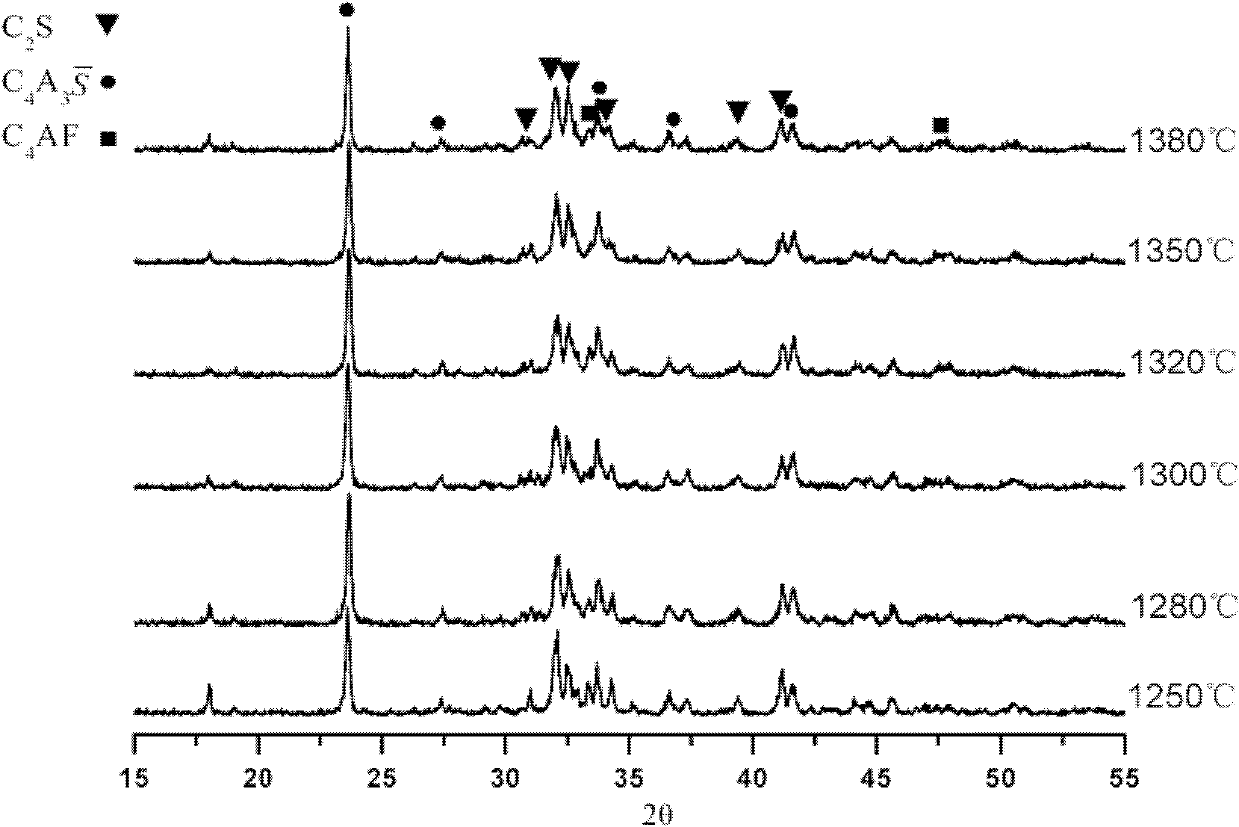

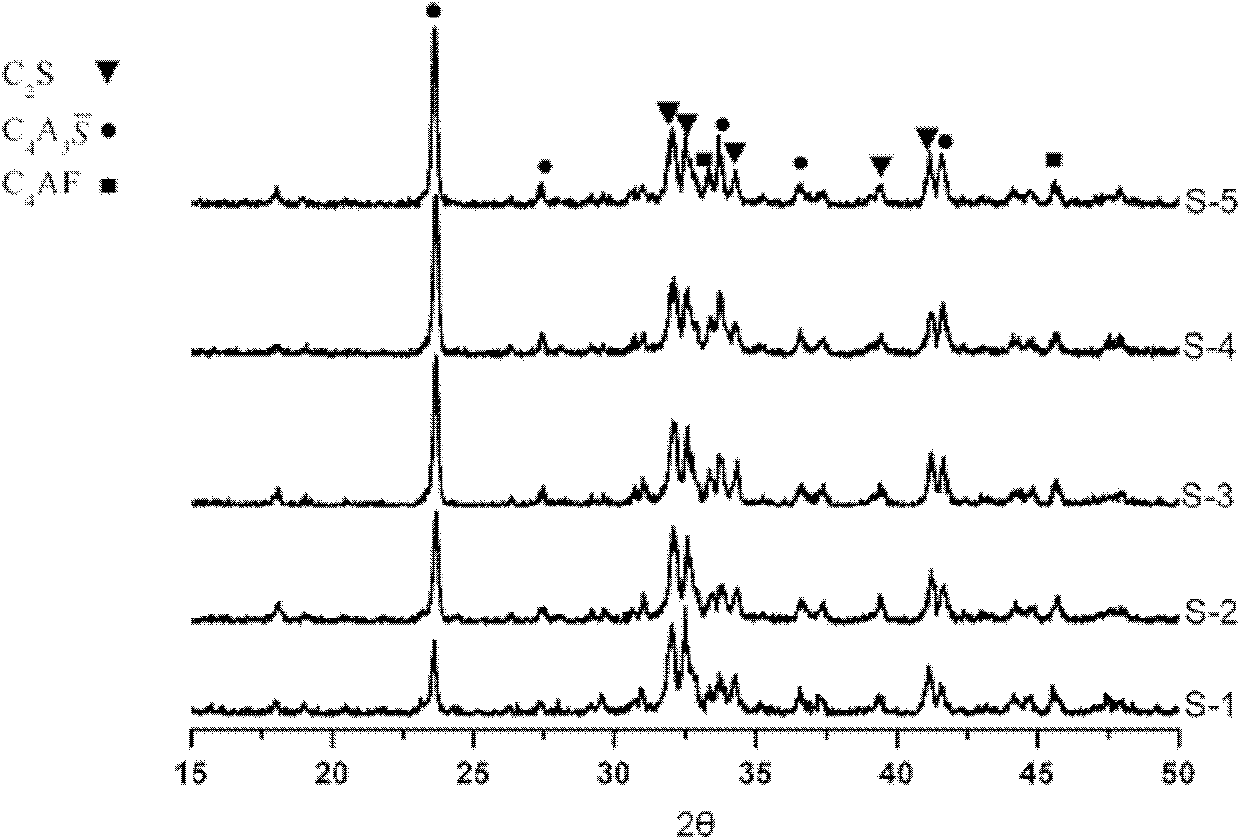

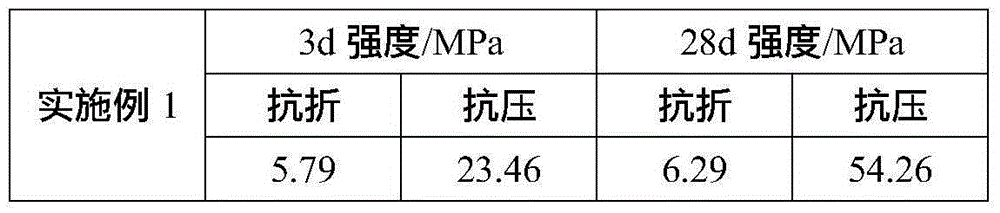

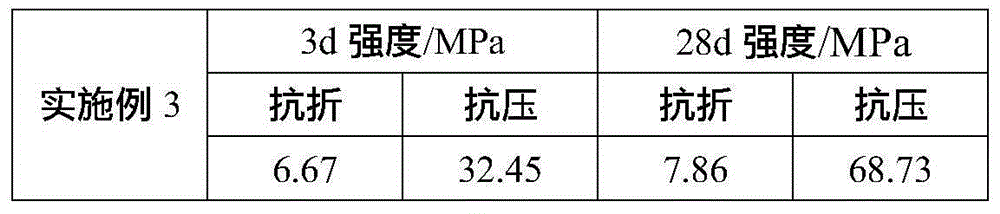

Low-energy-consumption and low-emission cement and preparation method and application thereof

InactiveCN102249576AImprove performanceWith the advantages of energy saving and emission reductionClinker productionCoesiteResource consumption

The invention discloses low-energy-consumption and low-emission cement and a preparation method and application thereof. Cement clinker mainly comprises the following minerals in parts by weight: 35-65 parts of C2S, 20-50 parts C4A3S and 5-15 parts of C4AF. A corresponding green stock consists of the following components in parts by weight: 30-60 parts of CaO, 25-35 parts of SiO, 5-35 parts of Al2O3, 1-6 parts of SO3 and 1-10 parts of Fe2O3. The cement clinker is a product which is prepared by calcining limestone, alumina and clay or sandstone and gypsum serving as raw materials at the temperature between 1,280 DEG C and 1,300 DEG C for 45-70 minutes by combining the advantages of low calcium content, low-temperature baking and high later strength of a belite mineral, low-temperature baking and high later strength of anhydrous calcium sulphoaluminate, and the like. The cement product has the advantages of excellent performance, low energy and resource consumption and low carbon dioxide emission, can play an important role in the field of construction, and has a wide application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

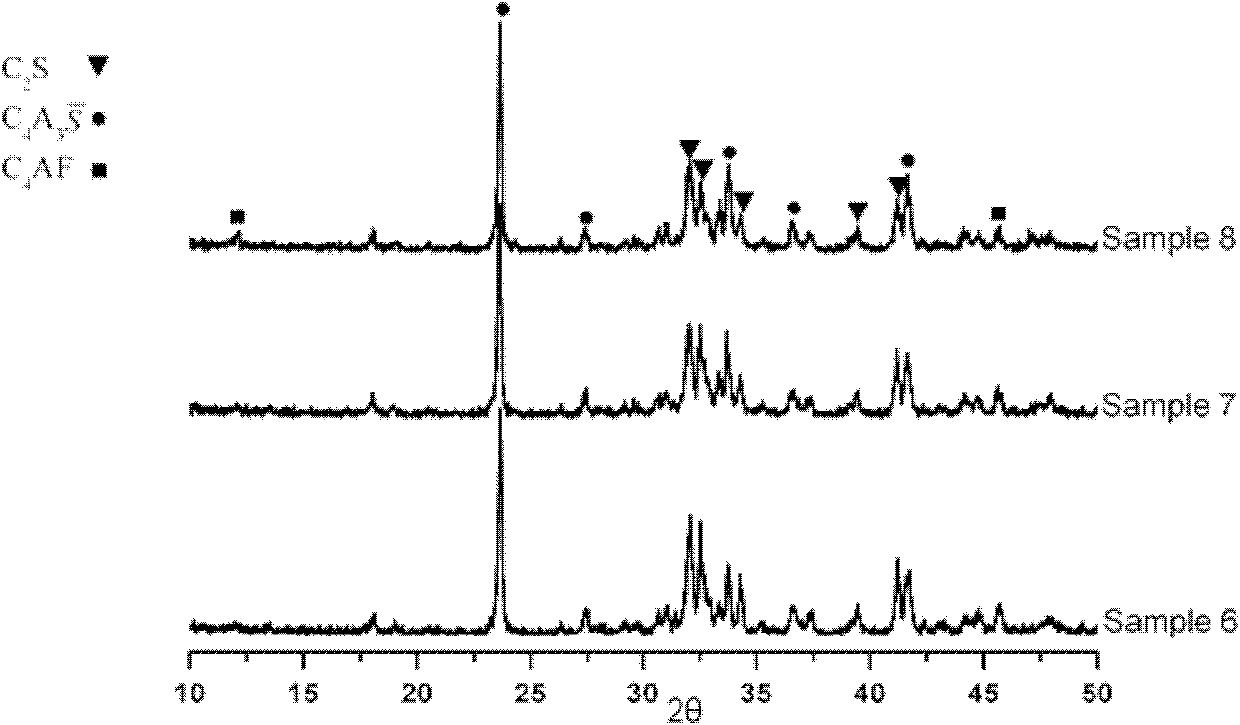

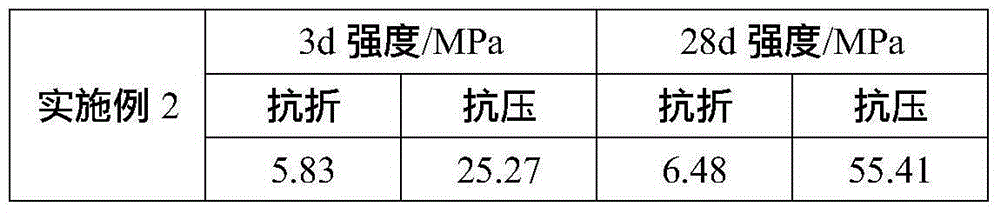

Belite-sulphoaluminate-ferrous aluminate cement and preparation method thereof

ActiveCN105060745ALow firing temperatureImprove performanceCement productionToxic industrial wasteMaterials science

The invention discloses belite-sulphoaluminate-ferrous aluminate cement which comprises the following components by mass percent: 38-70% of beta-C2S, 27-37% of C4A3S-(refer to the description) and 3-25% of C4AF. The invention further discloses a preparation method of the belite-sulphoaluminate-ferrous aluminate cement. The preparation method comprises the following steps: with industrial waste residue and industrial gypsum as the raw materials, mixing the raw materials with aluminous corrective addition namely bauxite or tailing bauxite, forming, performing hydrothermal reaction, crushing, calcining and grinding to obtain the belite-sulphoaluminate-ferrous aluminate cement. According to the invention, the low-carbon belite-sulphoaluminate-ferrous aluminate cement is prepared at low temperature; in addition, limestone is not used, so that no carbon dioxide is generated to increase the environmental pressure; moreover, the calcining temperature is low, so that the energy consumption is low, and the preparation method is a low-carbon and environment friendly preparation method.

Owner:天瑞集团萧县水泥有限公司

Production method of casting alcohol based paints using resin bonded sand

InactiveCN101288898AEasy to useImprove stabilityFoundry mouldsFoundry coresPolyvinyl butyralSodium Bentonite

The invention provides a production method for casting alcohol-based coating with a resin sand, comprising the compositions as follows: high bauxite powders, graphite powders, dextrin powders, bentonite powders, polyvinyl butyral, ferric oxide powders, colophony and 665 phenolic resin; the proportion of the composition is as follows: 60% of high bauxite powders, 20% of graphite powders, 5%-7% of dextrin powders, 5%-7% of bentonite powders, 0.5%-1% of polyvinyl butyral, 2%-3% of ferric oxide, 2%-3% of colophony and 2%-3% of 665 phenolic resin. The method of the invention solves the problems of the current clay sand dry-typed casting coating such as high cost, coarse surface after coating and easy cracking and is suitable for the application in the casting production.

Owner:QINGDAO HAILONG MACHINERY GRP

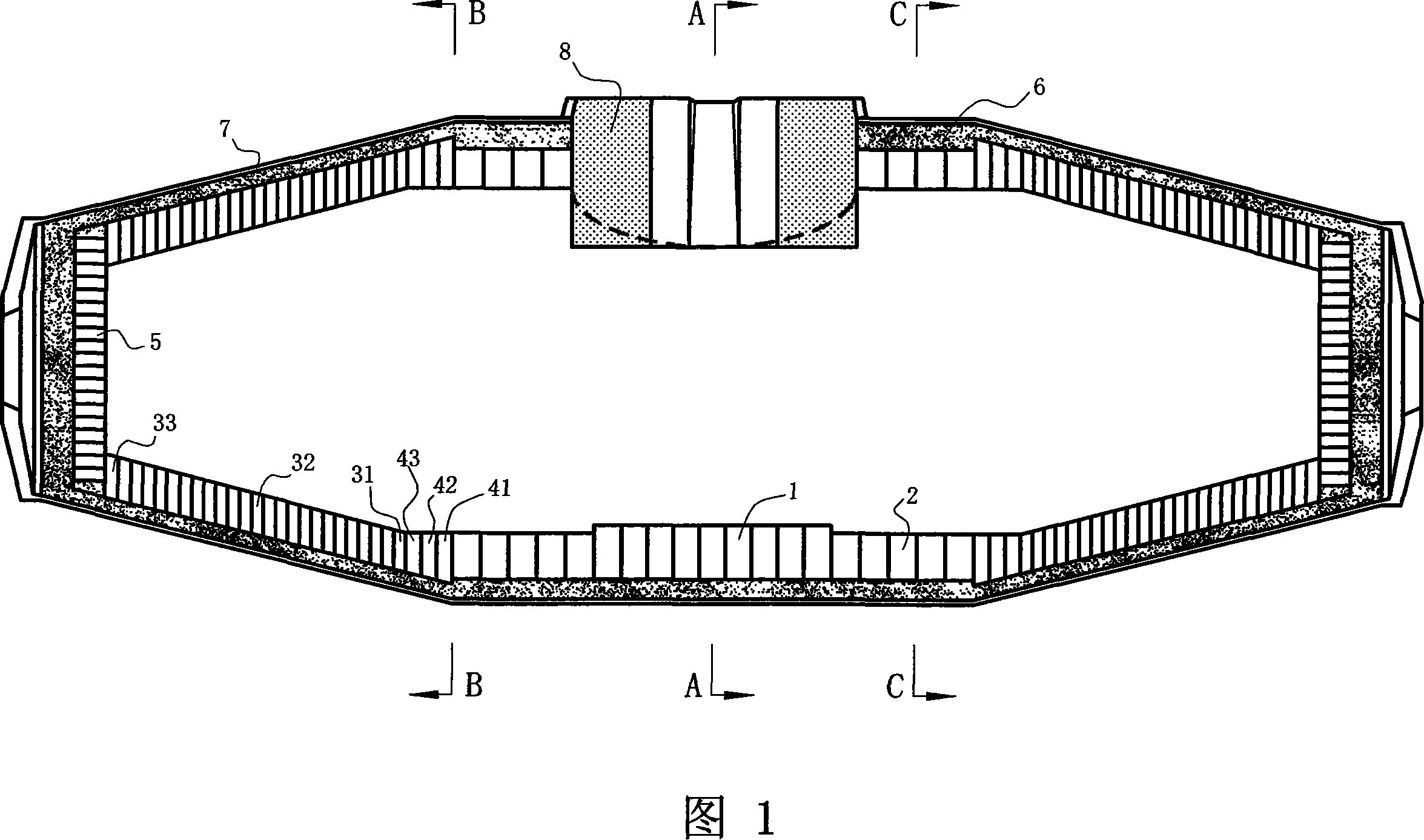

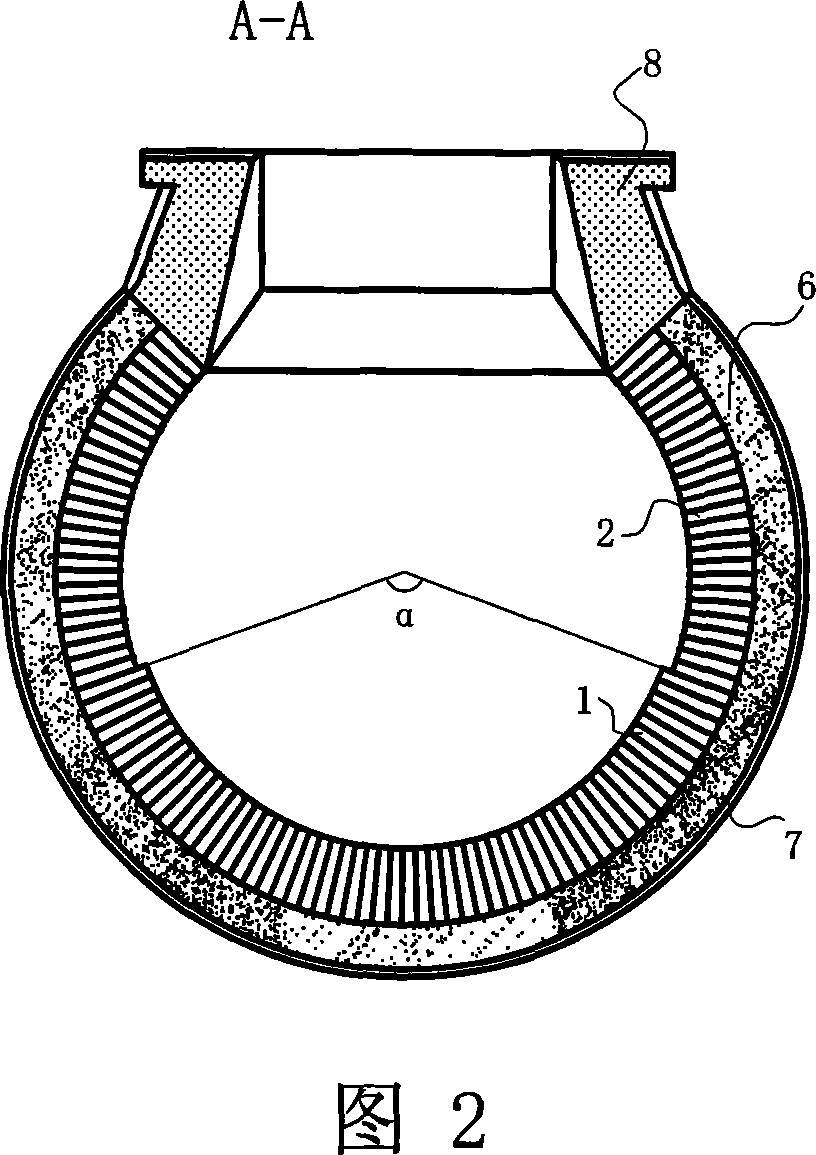

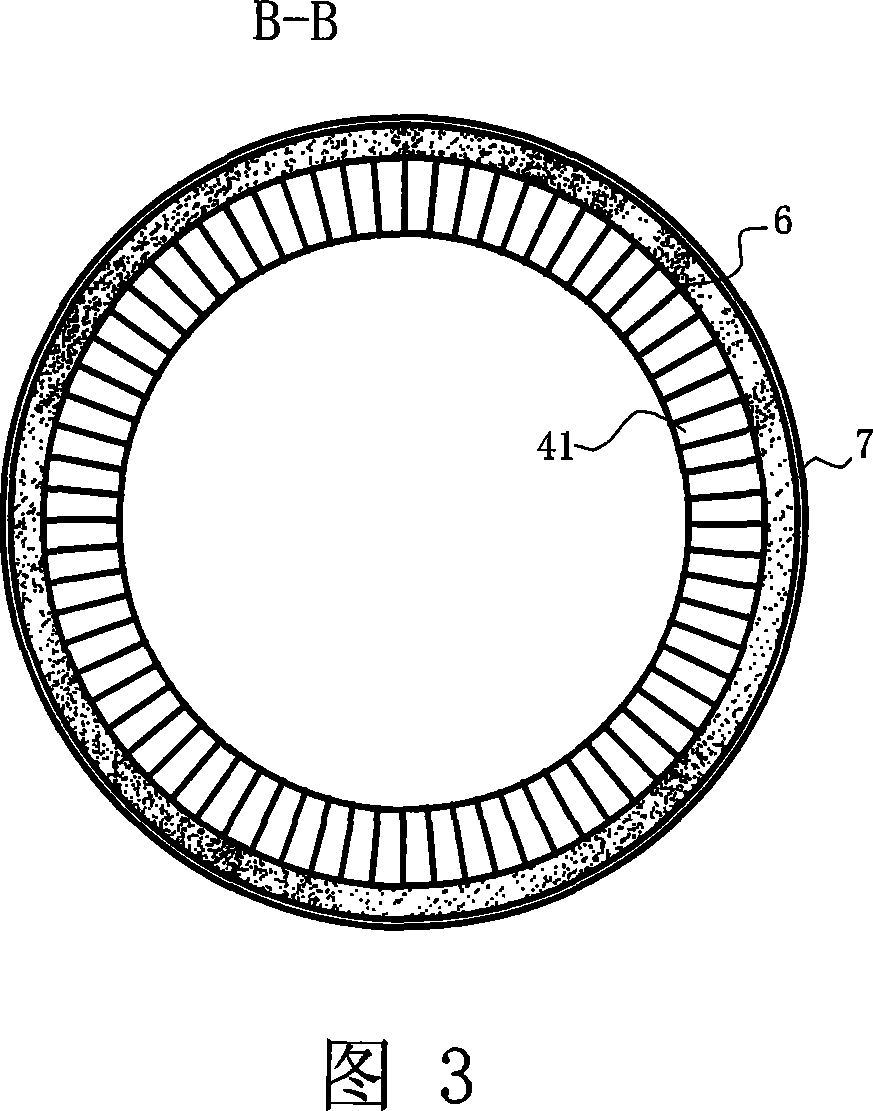

Inner lining structure for torpedo pot and aluminium carbonize silicon carbide brick and high aluminium brick used for torpedo pot

InactiveCN101058116ALifetime SynchronizationChange the phenomenon of less frequent useMelt-holding vesselsBrickCoesite

The invention relates to a torpedo pot liner structure and torpedo pot used aluminum carbonized silicon carbon brick, high aluminum brick. Bottom of the torpedo pot impact part uses nonburning aluminum carbonized silicon carbon brick, most of the rest using burnt stripping resistant high aluminum brick. Material for the aluminum carbonized silicon carbon brick comprises the alumina, electro-melting corundum, carbofrax, carbite, sintered corundum, aluminum, silicon, astringent, and so on, and the high aluminum brick comprises alumina, electro-melting corundum, carbofrax, silicon, silicon powder, bindeton and paper waste liquid. It is reasonable in formulation, mature in production process, with forming no need of high temperature baking with lower production cost. Using these two kinds of bricks, using durability of the overall torpedo can basically reach synchronic feature, application over 1700 times, with good effect and significant economical benefit.

Owner:GONGYI WINNA SCI & TECH DEV

Fly ash oil fracturing proppant and preparation method thereof

The invention provides a fly ash oil fracturing proppant which is prepared from the following constituents: 1wt%-60wt% of fly ash, 1wt%-30wt% of potash feldspar powder and balance of bauxite powder. According to the invention, the low-cost fly ash is used as the raw material, in the preparation process, the Al2O3 in the fly ash generates mullite, the surplus SiO2 in the raw material is transformed into low-apparent density minerals, such as the phosphorous quartz, and the apparent density of product is reduced. The K2O in the potash feldspar powder is used as the mineralizer, consequentially, the material is more compact, and thus, the strength of the oil fracturing proppant is increased. Moreover, when the Al2O3 and the SiO2 in the raw material are dissolved to a certain concentration, the Al2O3 and the SiO2 react with each other to generate the acicular mullite under the action of devitrification, and the mullite is continuously dissolved and devitrified so as to be changed from solid-phase reaction to liquid-phase reaction, as a result, the reaction speed is accelerated greatly, and the temperature needed for reaction is lowered.

Owner:HEBI TIANRUI PETROLEUM PROPPANT

Refractory casting material

The present invention relates to a fire-resistant pouring material, its composition includes 65-70% of first-grade alumina aggregate whose grain size is less than 5 mm, 16-20% of first-grade alumina powder material whose grain size is less than 0.088 mm, 2-3% of active magnesium oxide whose grain size is less than 0.088 mm, 5-6% of sintered first-grade magnesite clinkes whose grain size is less than 0.088 mm, 5-6% of silicon dioxide micropowder, besides, 0.15-0.3% of sodium polyphosphate salt is added. Said invention utilizes the addition of active magnesium oxide in Al2O3.SiO2 series refractory material and has no cement dispersing agent so as to make the formed pouring material have high strength, good antioxidation property, good resistance of corrosion of molten refuse and good thermal stability.

Owner:宜兴天霸非金属材料有限公司

Composite magnesia alumina spinel/Sialon ceramic material and its prepn process

The present invention relates to one kind of composite magnesia-alumina spinel / Sialon ceramic material and its preparation process. The technological scheme is that the materials including alumina ash 25-95 wt%, fine magnesia powder 0.1-2 wt%, fine bauxite chamotte 0.5-55 wt%, fine silicon powder 0-30 wt%, fine aluminum powder 0-10 wt% and fine SiO2 powder 0-50 wt%, are prepared into the composite magnesia-alumina spinel / Sialon ceramic material through mixing, forming into biscuit, sintering in nitrogen atmosphere first at 1000-1100 deg.c for 0.5-5 hr, then at 1300-1350 deg.c reached in the rate of 2-5 deg.c / min for 1-6 hr and finally at 1360-1500 deg.c reached in the rate of 2-5 deg.c / min for 2-10 hr, and naturally cooling to room temperature in nitrogen atmosphere. The present invention has waste alumina ash as main material, environment friendship and low production cost.

Owner:WUHAN UNIV OF SCI & TECH

Refractory spray castable

The present invention discloses a refractory spray castable. The castable comprises components of the following percentages by weight: 25 to 45% of alumina particle, 5 to 20% of alumina fine powder, 5 to 30% of mullite particle, 5 to 20% of mullite fine powder, 5 to 25% of corundum fine powder, 1 to 15% of calcium aluminate cement, 2 to 8% of micro silicon powder, 2 to 10% of micro alpha-Al2O3 powder, 1 to 10% of micro Cr2O3 powder, 2 to 10% of SiC powder and 0.1 to 2.5% of compound additive. The compound additive comprises a water reducing agent, an adhesive and an accelerating agent. Practice proves that the refractory spray castable has the advantages of good adhesion, small resilience rate, big thickness of die-free continuous construction, capability of on-line maintenance under proper construction conditions, good anti-corrosion properties and low manufacture and use cost.

Owner:WUHAN BOZE HIGH TEMPERATURE NEW MATERIAL

Preparation method of high-volume fly ash ceramsite proppant

ActiveCN103805160AReduce dosageReduce consumptionFluid removalDrilling compositionCalciteExpanded clay aggregate

The invention discloses a preparation method of a high-volume fly ash ceramsite proppant. The preparation method comprises the following steps: evenly mixing 20-65wt% of bauxite, 30-75wt% of fly ash, 0-5wt% of calcite powder, 0-10wt% of talcum powder, 1-5wt% of titanium dioxide, 0-20wt% of soft refractory clay and 1-5wt% of barite powder together to obtain the raw materials, putting the raw materials in a ball mill and then putting the ball mill in a closed stirring mixer for pelletizing, and adding a sodium silicate aqueous solution having the mass concentration of 10% a plurality of times while pelletizing to obtain a ceramsite blank, drying the ceramsite blank, next, carrying out autogenous grinding and rounding in a pelletizer and then sieving to obtain raw nodules, and then heating and firing the raw nodules and then cooling along with the furnace to obtain the high-volume fly ash ceramsite proppant. The fly ash replacement of the preparation method can be within the range from 30% to 75%, and the dosage of bauxite in the raw materials is obviously reduced without affecting the performance of the ceramsite proppant, so that the cost is greatly reduced and the resource consumption is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Phosphate-bonded aluminum silicon carbide brick and preparation method thereof

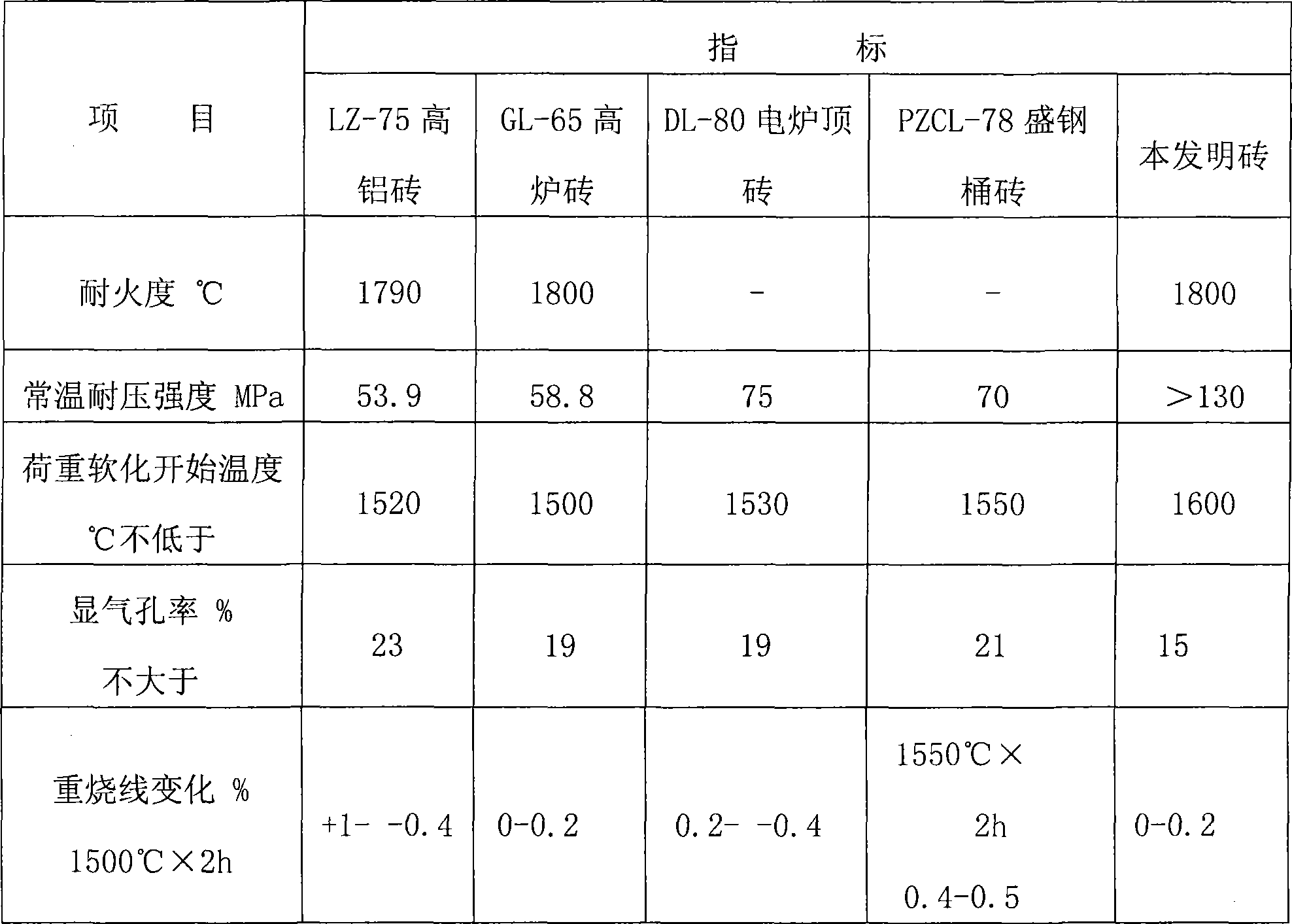

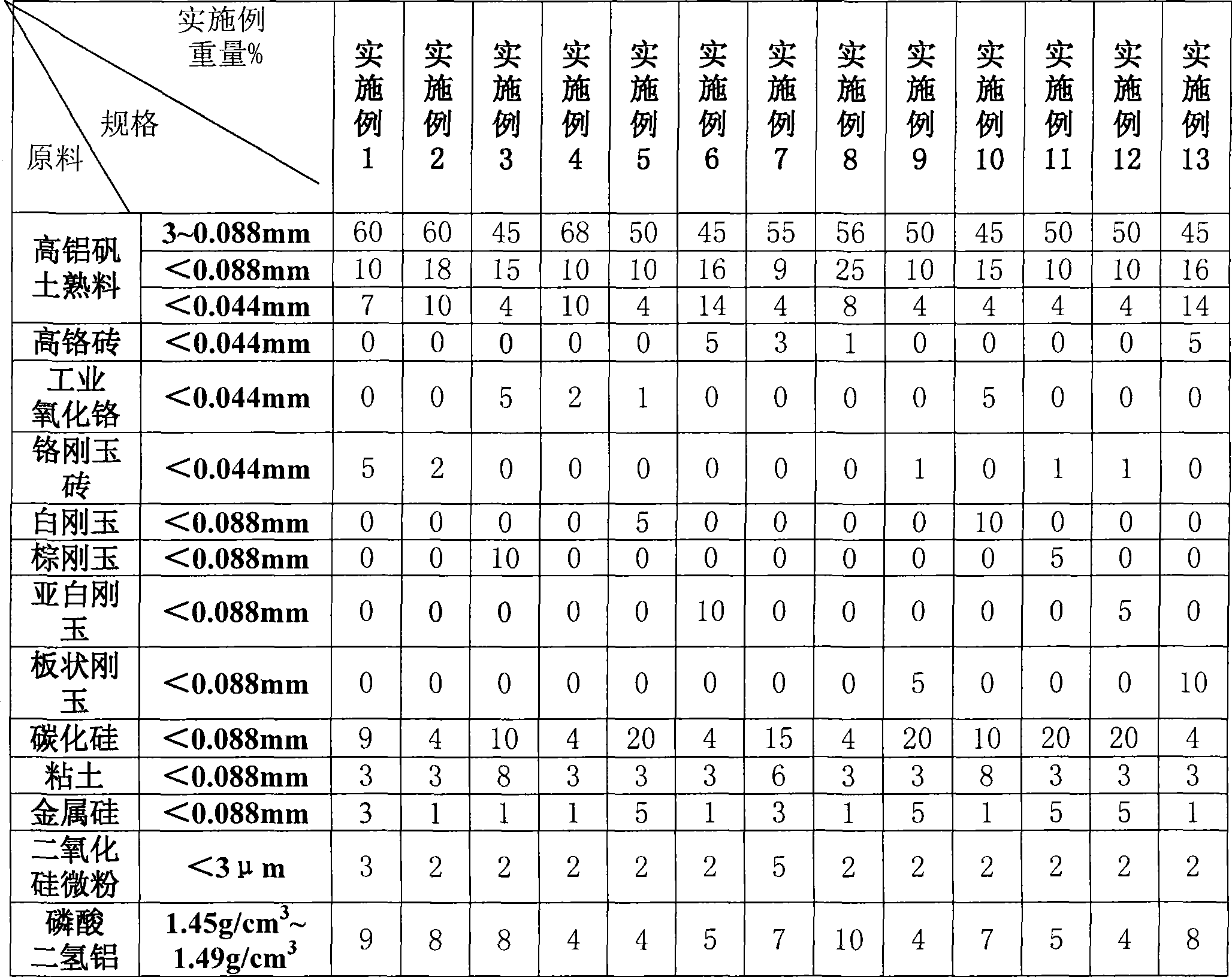

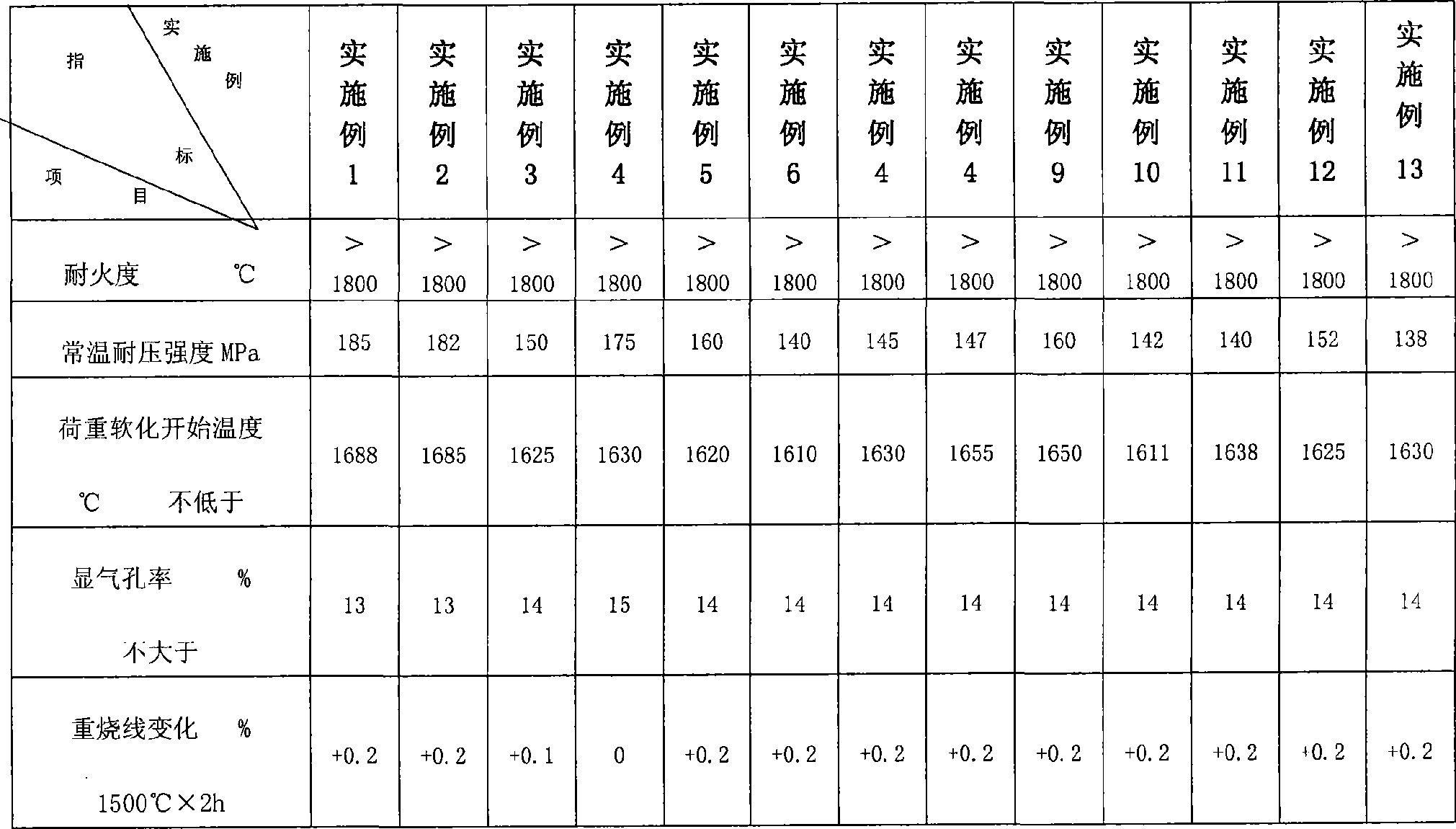

The invention discloses a phosphate-bonded aluminum silicon carbide brick, which is characterized by comprising main ingredients and a phosphate binder, wherein the main ingredients comprise the following raw materials by weight percentage: 45 to 68 percent of bauxite chamotte with a granularity of 3 to 0.088 mm, 10 to 25 percent of bauxite chamotte with a granularity of less than 0.088 mm, 4 to 14 percent of bauxite chamotte with a granularity of less than 0.044 mm, 0 to 10 percent of corundum, 1 to 5 percent of a chromic oxide-containing material, 4 to 20 percent of silicon carbide, 3 to 8 percent of clay, 2 to 5 percent of silicon dioxide micro powder, and 1 to 5 percent of metallic silicon; and the phosphate binder is added in an amount which is 4 to 10 percent of the weight of the main ingredients. The aluminum silicon carbide brick is made into high quality aluminum silicon carbide brick which has an apparent porosity of less than 15 percent, a cold crushing strength of more than 130MPa, a starting refractoriness under load of more than 1,600 DEG C and high inoxidability by ageing mixture, back rolling, forming, drying and baking.

Owner:巩义市金岭耐火材料有限公司

Agglomeration method for synthesizing mullite by using high aluminous fly ash

ActiveCN1696075ARealize comprehensive utilizationReduce manufacturing costTunnel kilnPolymer science

Owner:TSINGHUA UNIV +1

Environment-friendly stemming for blast furnace taphole and preparation method thereof

InactiveCN101613213AReduce tar contentImprove protectionBlast furnace componentsCeramic shaping apparatusInorganic phosphateSocial benefits

The invention discloses an environment-friendly stemming for a blast furnace taphole and a preparation method thereof, which is prepared by the following raw materials according to weight percentage content: 35-50% of bauxite or hard clay or fused alumina with thickness of 0.2-3mm, 1-5% of modified powder resin, 1-5% of high-temperature pitch, 3-8% of inorganic phosphate, 1-20% of silicon carbide, 10-20% of coke powder, 3-10% of sericite, 2-8% of cyanite and 3-8% of tar oil. The preparation method comprises the following steps: weighting each raw material according to the above formula, adding into a heating stirrer for stirring and mixing and molding by using a friction press after mixing. The invention adopts the mixture of organism and inorganic substance as a binder to prepare the stemming, thus greatly reducing the component content of tar oil which pollutes environment, being favor of environmental protection and having remarkable social benefit, and can be hardened quickly.

Owner:HENAN GENGSHENG REFRACTORIES

Preparation method of sulfoaluminate Belite cement

ActiveCN105060744ALow firing temperatureImprove performanceCement productionCalcinationToxic industrial waste

The invention discloses a preparation method of sulfoaluminate Belite cement. The preparation method comprises the following steps: taking industrial waste residues and industrial gypsum as raw materials, taking bauxite or bauxite tailings as a corrective material, adding water for grinding after mixing, molding, carrying out hydrothermal reaction, and then, smashing, calcining and grinding, so as to obtain sulfoaluminate Belite cement, wherein the main components of the sulfoaluminate Belite cement are C4A3S<-> and beta-C2S. According to the invention, the sintering temperature of the sulfoaluminate Belite cement is reduced through the hydrothermal reaction performed in advance, the energy consumption is reduced, the performance of the sulfoaluminate Belite cement is improved through a proper ratio and a proper technology, and the fact that the low-carbon sulfoaluminate Belite cement is prepared under low temperature; besides, limestone is not used, the generation of carbon dioxide is avoided, the environmental pressure is increased, and the energy consumption is low due to low calcination temperature; therefore, the preparation method of the sulfoaluminate Belite cement is low-carbon and environment-friendly.

Owner:YANCHENG INST OF TECH

Making process of electrofused mullite

The present invention relates to ceramic and refractory material technology, and is especially making process of electrofused mullite. The making process includes the following steps: 1. the waste aluminum ash pre-treating step comprising calcining waste aluminum ash at 1100 deg.c to convert partial Al into Al2O3, washing with hydrochloric acid and stoving; and 2. the electrofusing step comprising mixing aluminum ash 30-80 wt%, alum 0-50 wt% and silica 10-20 wt%, smelting in an arc furnace, cooling outside the furnace, crushing and sorting. The present invention has low production cost and can eliminate environmental pollution caused by waste aluminum ash.

Owner:SHANGHAI JIAO TONG UNIV

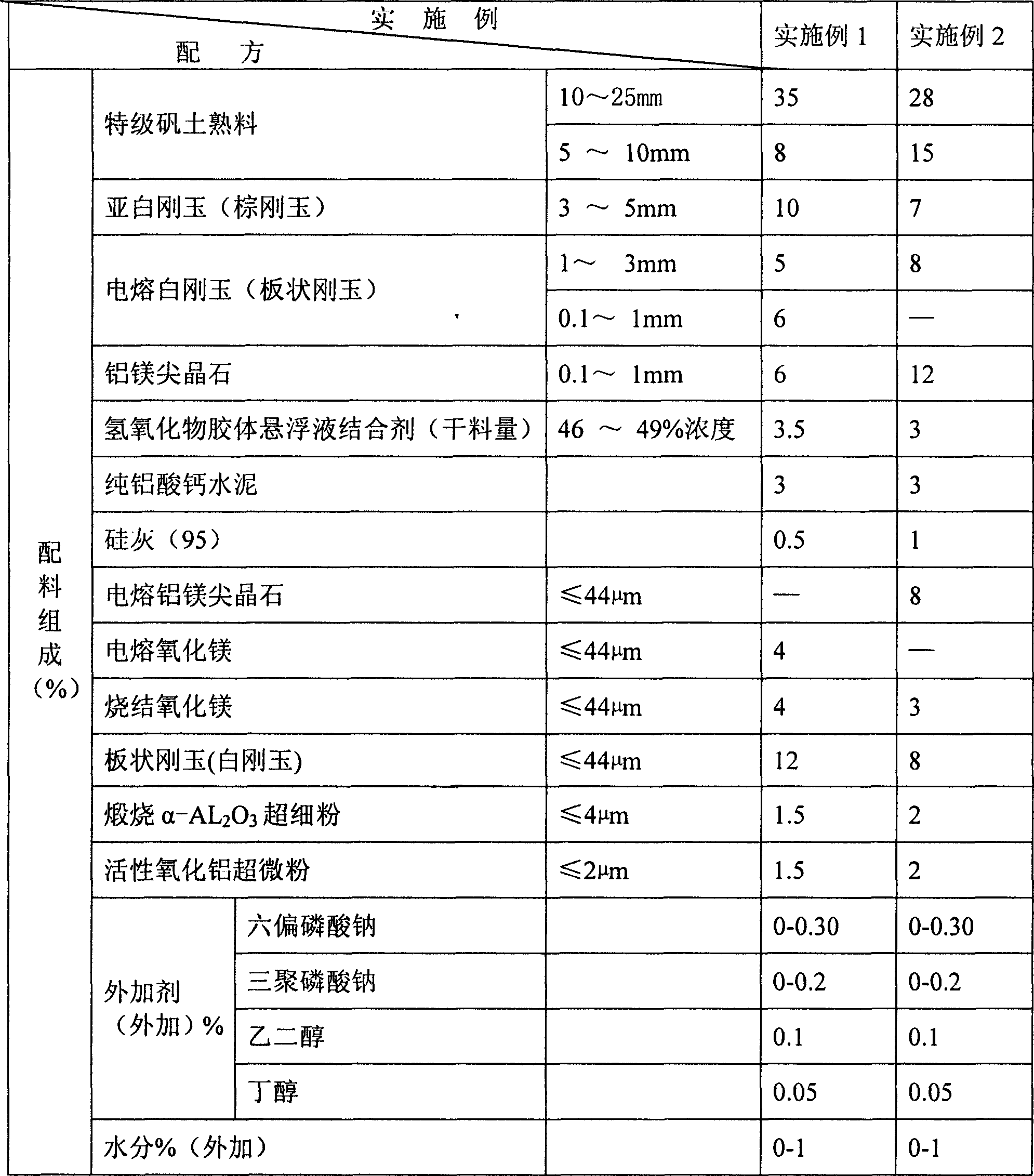

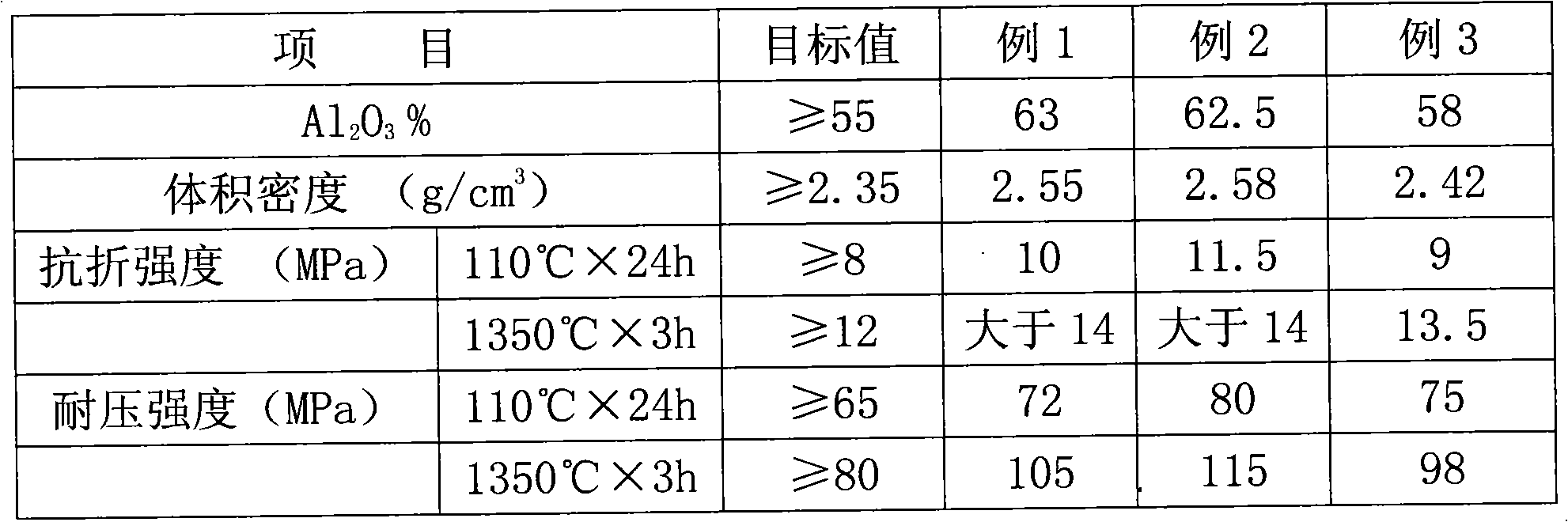

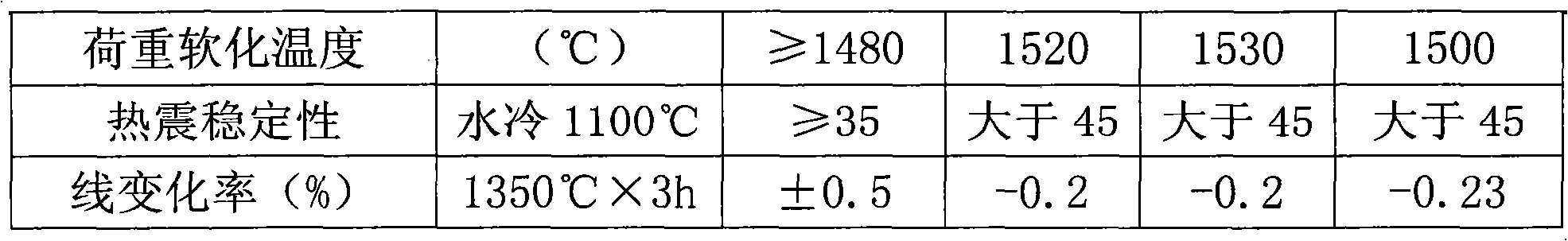

Refractory castable of nanocomposite oxide ceramic combining alumina-spinelle and preparation method thereof

InactiveCN101397212AImprove mechanical propertiesImprove slag erosion resistanceOxide ceramicComposite ceramic

The invention relates to a nanometer composite oxide ceramics binding aluminium-spinel fireproof casting material and a manufacturing method thereof. The composition of ingredients thereof is that various grades of special-class bauxite clinker, brown fused alumina, secondary white fused alumina, white fused alumina and aluminum-magnesium spinel are adopted as skeletal material; and the base material comprises plate-shaped corundum powder, calcinatory alpha-Al2O3 powder, active Al2O3 powder, aluminum-magnesium spinel powder, pure calcium aluminate cement, nanometer Al2O3-MgO composite ceramics binding agent hydrate colloid suspension bonding agent as well as various addition agents. The ingredients are mixed and stirred for making the nanometer Al2O3-MgO composite ceramics binding aluminium-spinel fireproof casting material. The fireproof casting material of the invention has excellent microstructure and mechanics performance, and also has the performances such as special slag corrosion resistance, stability of high temperature structure and high temperature resistance, and the like, is used in the entirely casting LF finery, and the service life thereof is prolonged obviously, and the development demands for effective operation of secondary refining equipment, thus providing the best service for the steal industry.

Owner:高树森

A method for making a sealing cover for the observation and operation hole of the flue wall of a carbon roasting furnace

ActiveCN102276263AImproved thermal shock stabilityExcellent softening temperature under loadFiberFlexural strength

The invention provides a manufacturing method of a seal cover for an operation observation aperture on a carbon calciner fire wall. Raw materials consist of three parts of aggregate, matrix and additive. The aggregate comprises three or more components selected from: granular mullite, high aluminium corundum, bauxite chamotte, flint clay and andalusite; the matrix comprises fine-powdered mullite,bauxite chamotte, andalusite or kyanite or sillimanite, alumina, high-alumina cement, silicon micro powder and high temperature heat resistant steel fiber; the additive is a mixture comprising two ormore components selected from sodium tripolyphosphate, sodium hexametaphosphate, CMC, FDN and sodium lignosulfonate. The manufacturing method includes steps of: proportioning raw materials; mixing bya mixer; adding water with stirring; putting into a die; partitioning into blocks and moulding; carrying out natural maintenance; and drying at 110 DEG C-300 DEG C for 24-48h. The invention has beneficial effect that the seal cover produced by the method has excellent physical and chemical performance indexes, such as high high-temperature flexural strength, good thermal shock stability and refractoiness under load.

Owner:河南鑫诚耐火材料股份有限公司

Dense calcium hexaluminate grog refractory and preparation method thereof

The invention discloses a dense calcium hexaluminate grog refractory and a preparation method thereof. The refractory is prepared from, by weight, 87.04-88.87% of Al2O3, 7.96-8.13% of CaO and 3.00-5.00% of MnO, wherein the relative density is 90.90-94.80%, and the apparent porosity is 2.80-4.40%. The preparation method includes the steps of firstly, grinding and mixing bauxite and limestone; secondly, pressing the mixture into raw balls, and primarily calcining the raw balls to prepare clinker; thirdly, adding manganous oxide fine powder after clinker is ground fine, and pressing the mixture into balls; fourthly, conducting secondary calcining. The manganous oxide fine powder is adopted as a sintering promoter, solid manganous oxide is dissolved in a calcium hexaluminate phase in the calcining process to form a solid solution, and therefore the sintering activity of the calcium hexaluminate phase is improved, the growth of the calcium hexaluminate phase is promoted, and therefore the dense calcium hexaluminate grog refractory can be obtained at a low secondary calcining temperature within a short heat preservation time, production energy consumption is effectively lowered, production efficiency is improved, and energy conservation and emission reduction are promoted.

Owner:LIAONING INST OF SCI & TECH

Pre-molten low-melting point composite calcium aluminate desulfurizer and its prepn.

The invention discloses a kind of premelt-type, low-melting point, calcium aluminate complex desulfurizing agent and its preparation method, which is prepared according to the below components and proportion (weight): aluminum alum earth (calculated according to the Al2O3 content) 30-60%, and calcium oxide 40-70%. In advance perform passivating treatment on calcium oxide, then mix all the components according to the required proportion, then smelt them in the electric stove or the reflecting stove, then cool them, and by crashing, prepare the particle-shape or powder-shape desulfurizing agent. By the premelting treatment, the melting point of desulfurizing agent lowers to 1250-1400 centigrade, which obviously raises its desulfurizing rate in the molten iron molten steel and shortens the reactive time and production cycle.

Owner:盛富春

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com