Method for preparing sulphate aluminium cement by red mud

A technology of sulphoaluminate cement and red mud, which is applied in the field of cement materials, can solve the problems of high cost and difficulty in industrialization promotion, and achieve the effects of high early strength, wide industrial application prospects, and good burnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

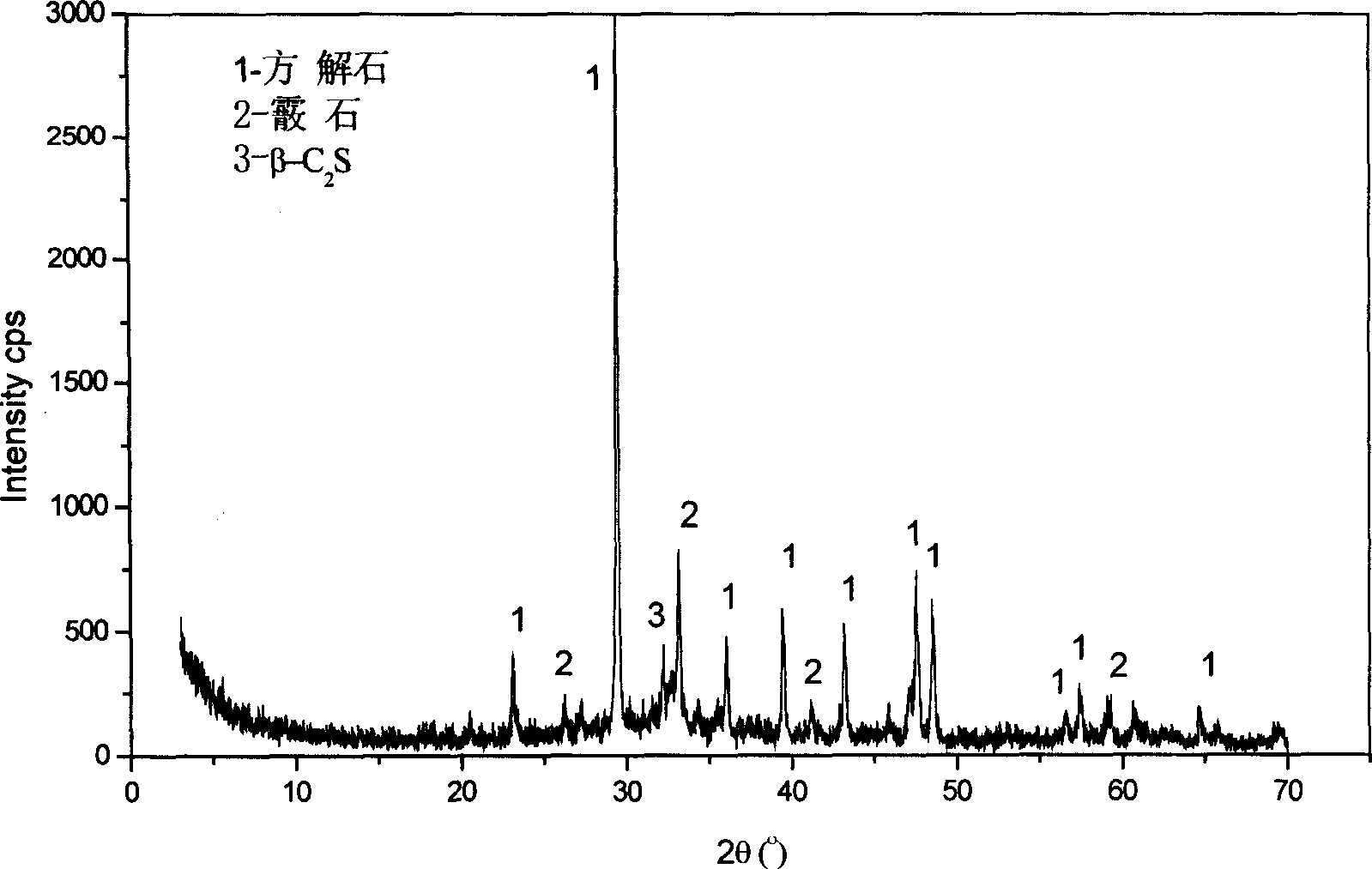

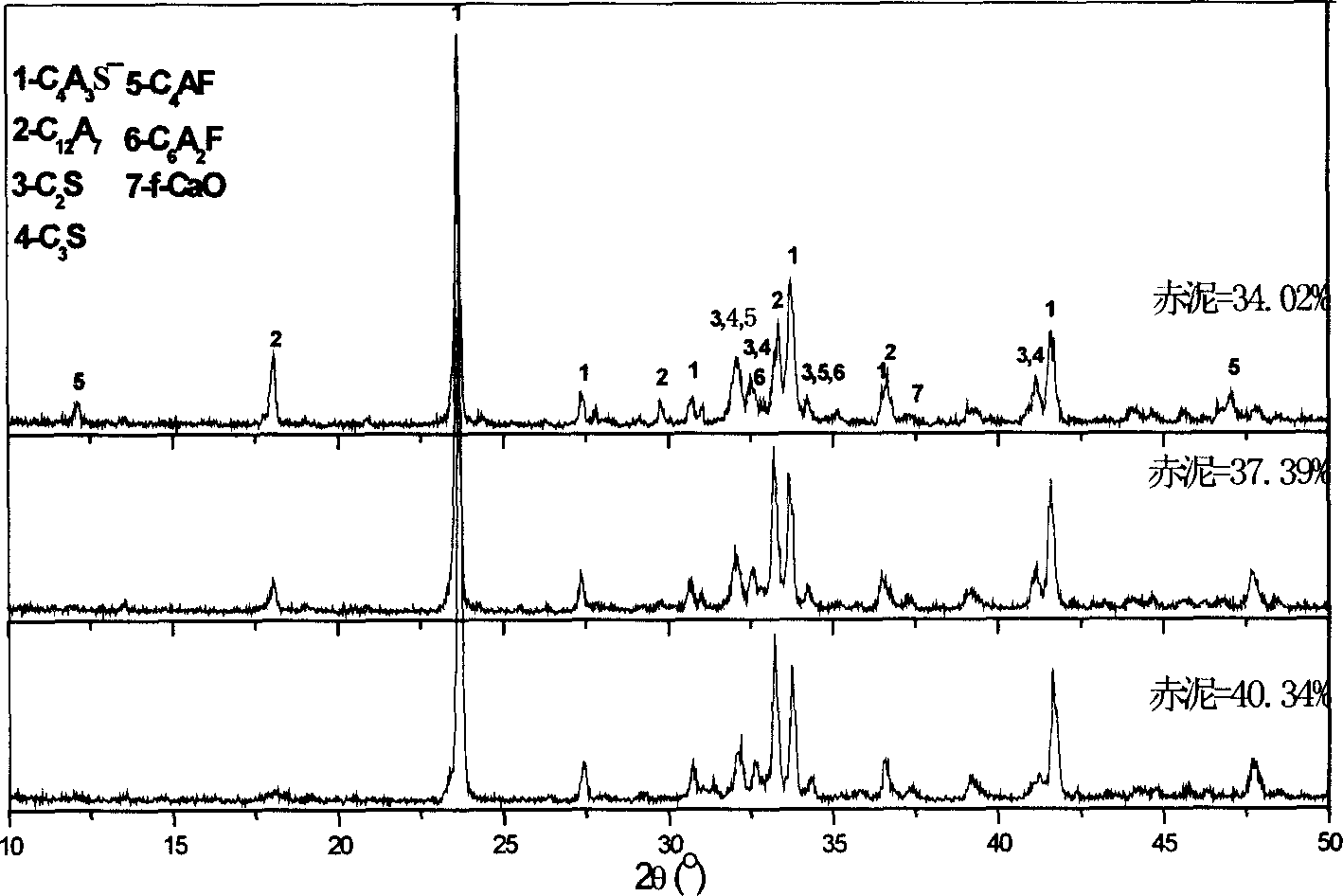

[0041] Embodiment 1: Design cement clinker mineral composition C 4 A 3 S 60%, C 2 S 24%, C 4 AF 16%; specific ingredients added (percentage by weight): 40.34% red mud, 26.42% limestone, 22.98% bauxite, 10% gypsum.

Embodiment 2

[0042] Embodiment 2: Design cement clinker mineral composition C 4A 3 S 56%, C 2 S 30%, C 4 AF 14%; specific ingredients added (weight percentage): red mud 37.39%, limestone 30.49%, bauxite 22.71%, gypsum 9.41%.

Embodiment 3

[0043] Embodiment 3: design cement clinker mineral composition C 4 A 3 S 52%, C 2 S 36%, C 4 AF 12%; specific ingredients added (percentage by weight): 34.02% red mud, 34.73% limestone, 22.43% bauxite, 8.82% gypsum.

[0044] Example result:

[0045] The present invention utilizes red mud to prepare sulfoaluminate cement and the hydration characteristics of various ages, carry out XRD, SEM analysis and show that, clinker main mineral C 4 A 3 S and others are well developed, and the hydration products are mainly colloids such as petal-shaped or sheet-shaped AFm, short columnar AFt, and C-S-H, which are interspersed and filled with each other, and the slurry structure is dense, which is the main source of high strength of cement. In the embodiment of the present invention, the mechanical properties of sulphoaluminate cement prepared from red mud are shown in Table 2, and compared with the quick-hardening sulphoaluminate cement produced by Beijing Saiyang Special Cement Fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com