Patents

Literature

52results about "Cinker content reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

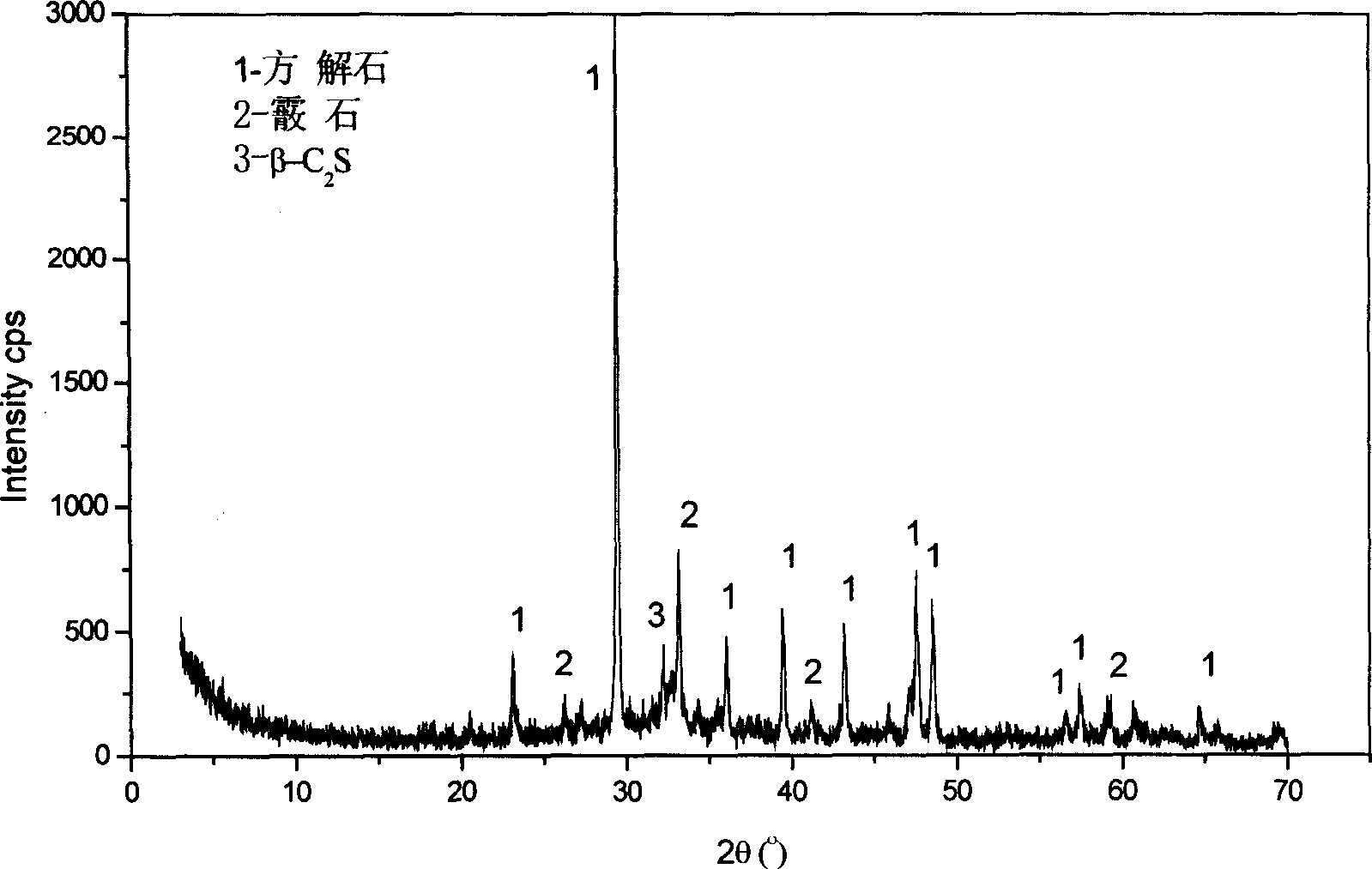

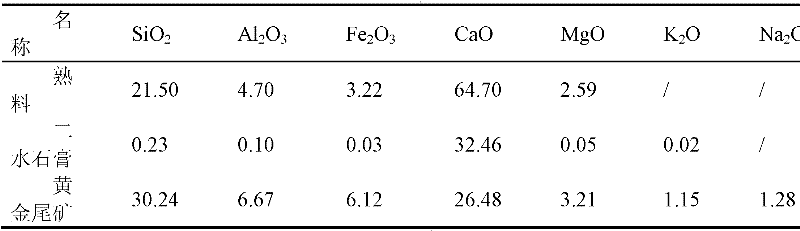

Method for preparing sulphate aluminium cement by red mud

InactiveCN1837121AImprove developmentDevelopmental enhancement and stabilityCinker content reductionCalcium in biologyRed mud

The invention discloses a red mud preparing sulpho-aluminate cement, which is characterized by the following: using 26%-41% red mud to take place of part of aluminium and calcium raw material and whole silica and irony raw material of regular sulpho-aluminate cement production; grinding for certain fineness; desining the C4A3S,C2S,C4AF and main mineral of cement clinker; Preparing sulpho-aluminate cement by alumina, lime carbonate, calcium sulfate and other burdens. The sulpho-aluminate cement has quick induration speed and high early strength.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

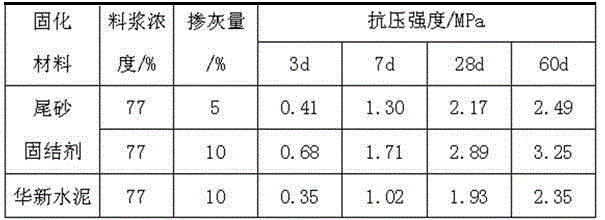

Clinker-free compound-type tailing consolidating agent as well as preparation and application for same

InactiveCN103145354ARealize resource utilizationIncrease profitClinker productionCinker content reductionSlagEngineering

The invention relates to a clinker-free compound-type tailing consolidating agent as well as a preparation and an application for the same, wherein the clinker-free compound-type tailing consolidating agent comprises the following components in percentage by weight: 55-72% of blast furnace water-quenched slag, 20-35% of desulfurization ash, and 2-15% of compound excitant. Via the clinker-free compound-type tailing consolidating agent disclosed by the invention, a new way is opened up for comprehensive utilization for the industrial solid wastes aforementioned, the cemented filling cost of tailing is reduced, and the purpose of treating wastes by using wastes is realized, thus obtaining remarkable, economic, social and environmental benefits.

Owner:HENAN AGRICULTURAL UNIVERSITY

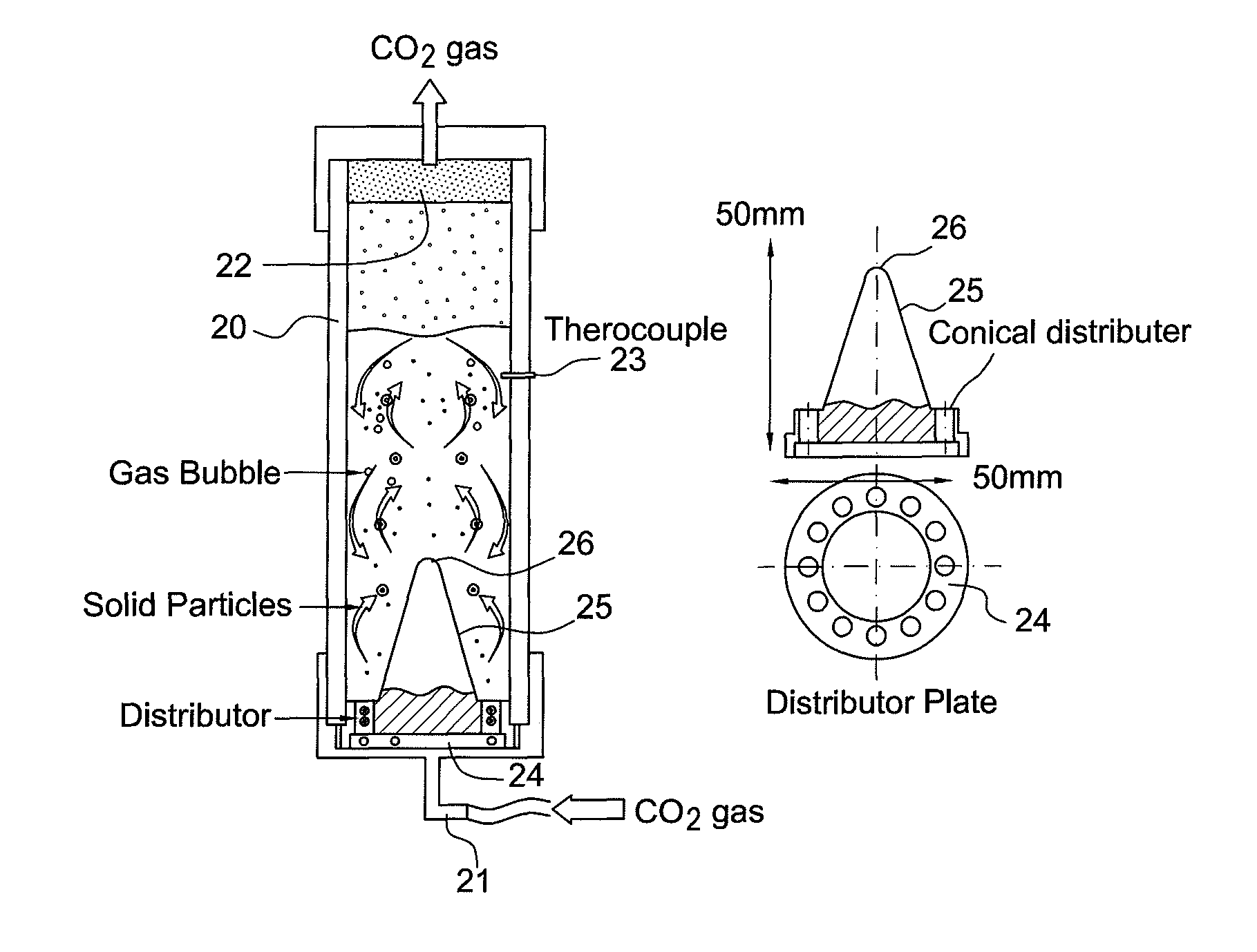

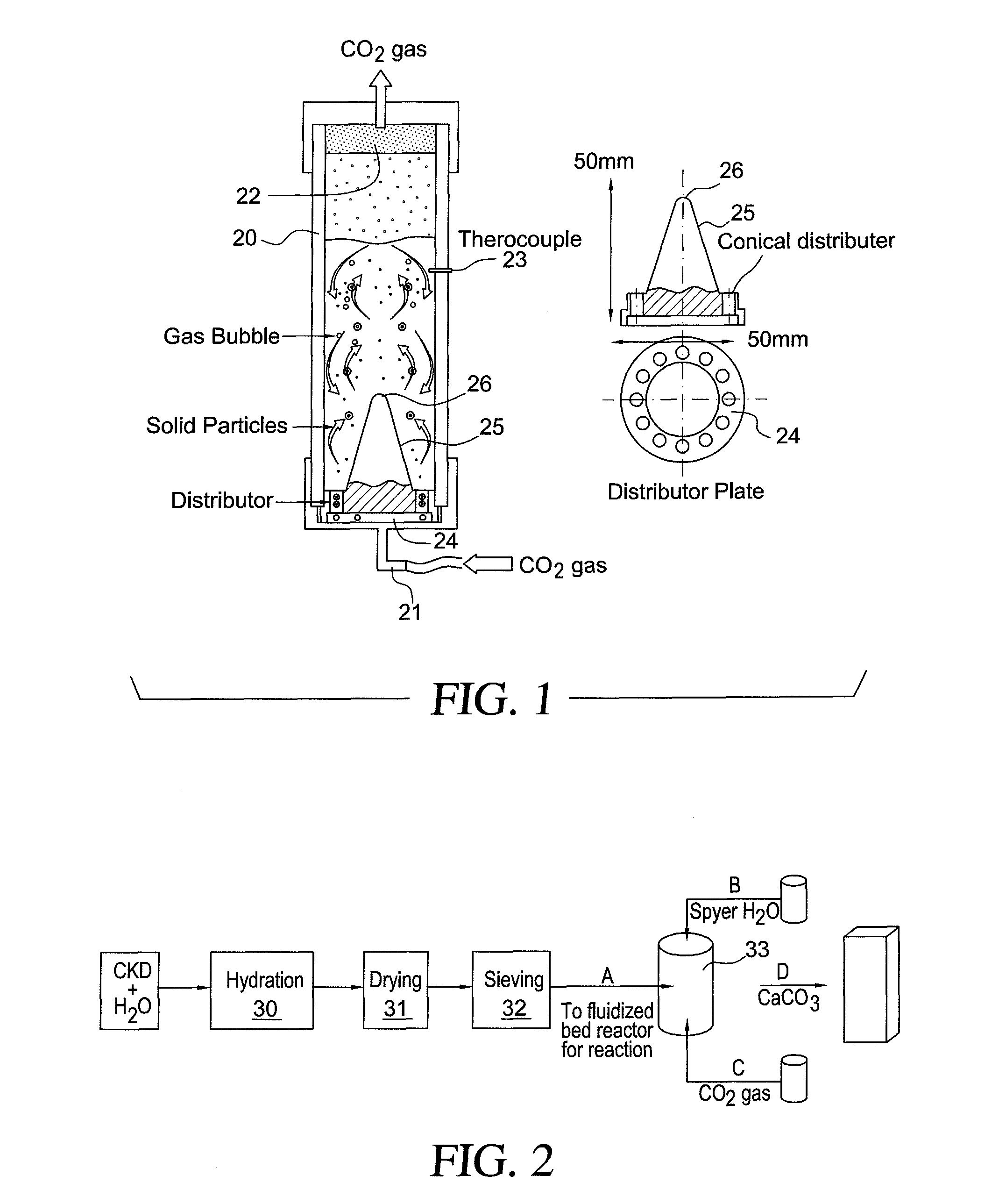

Method for treating cement kiln dust

InactiveUS8043426B2Reduce releaseHighly effectiveSolid waste managementCinker content reductionCalcium hydroxideFluidized bed

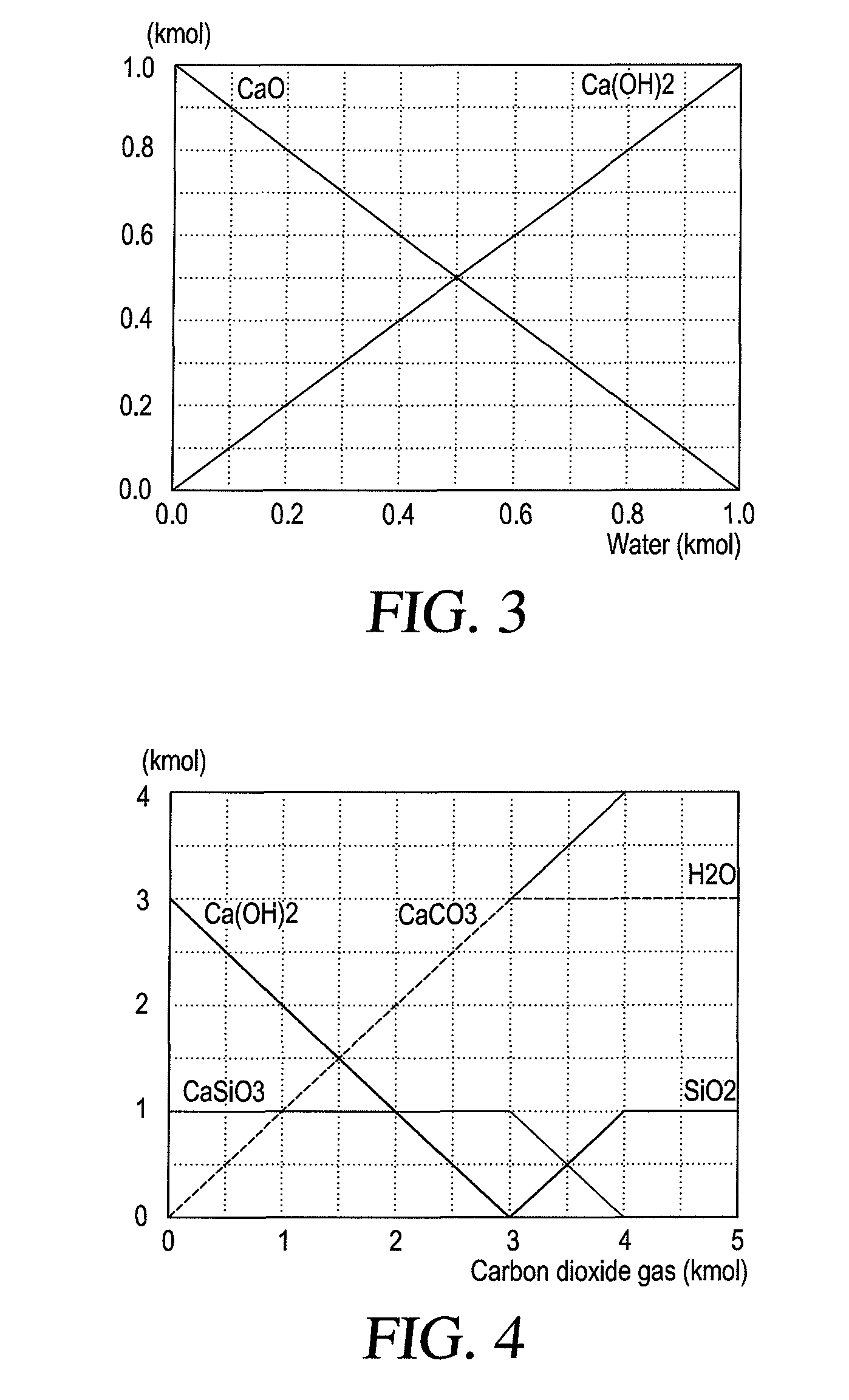

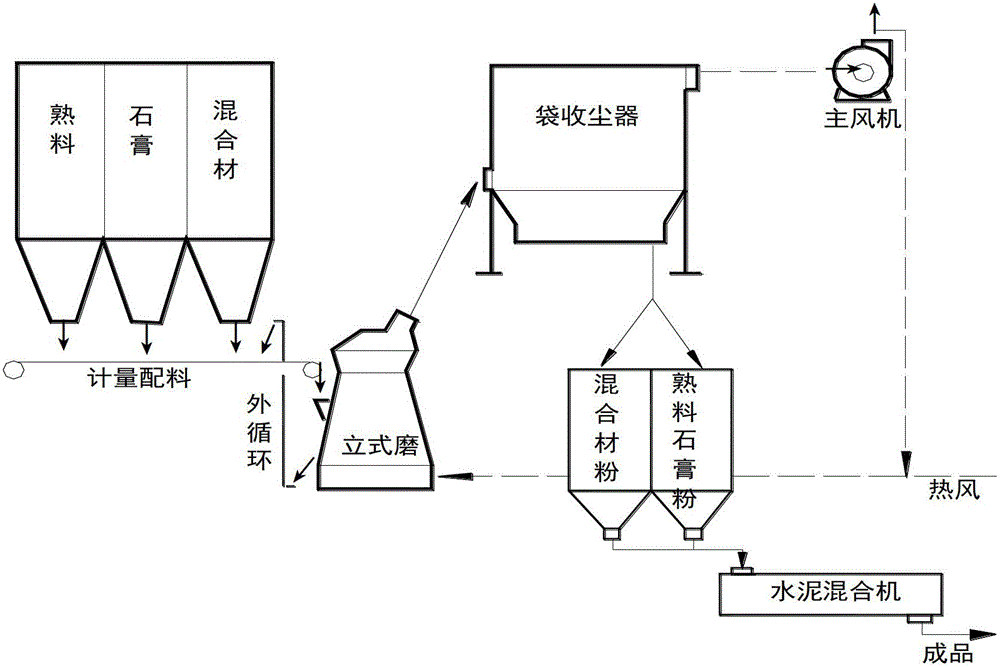

A method for treating cement kiln dust containing alkaline metal salts includes the steps of hydration (formation of calcium hydroxide), dehydration i.e. drying, fractionation by sieving and carbonation (reaction of the fractionated moistened cement kiln dust) with CO2 gas in a fluidized bed reactor.

Owner:UNITED ARAB EMIRATES UNIVERSITY

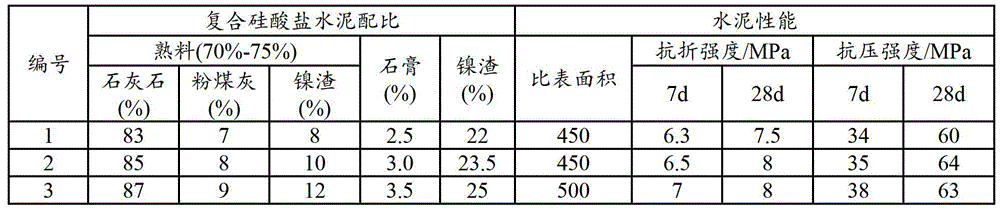

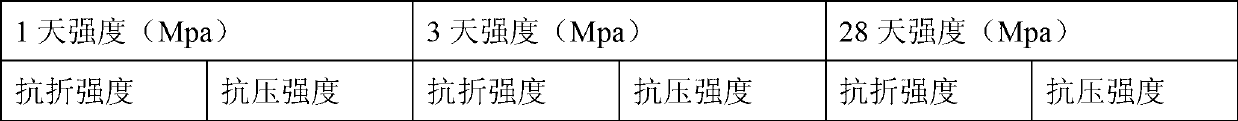

Production method of nickel slag composite portland cement

The invention discloses a production method of nickel slag composite portland cement. The production method comprises the following steps of: preparing cement clinker ingredients in proportion, and roasting the prepared cement clinker ingredients into cement clinker, wherein the cement clinker ingredients include 83-87wt% of limestone, 7-9wt% of coal ash and 8-12wt% of nickel slag; and respectively grinding the cement clinker, plaster and nickel slag, and mixing in proportion to form a cement product, wherein the cement product comprises 70-75wt% of cement clinker, 2.5-3.5wt% of plaster and 22-25wt% of nickel slag powder. According to the technical scheme, the production method has a positive effect of reducing the lowest liquid phase eutectic point and liquid phase viscosity of clinker, and is capable of improving burnability of raw materials, thereby being very beneficial to formation of clinker mineral.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Cement clinker production method by utilization of artificial slabstone waste

InactiveCN103130430AAchieve the purpose of usingWon't happenClinker productionCinker content reductionSlagMixed materials

The invention relates to a cement clinker production method by utilization of artificial slabstone waste. The artificial slabstone waste is used as raw materials, cement is fired through a drying method preheater, the artificial slabstone waste can be thoroughly processed, part of natural raw materials can be replaced, and energy-saving and emission-reducing purposes are achieved. The method includes the following steps: mixing artificial stone calcium aluminum plate waste, artificial quartz stone waste and steel slag according to a mixing ratio, drying, grinding, screening, and evenly mixing the mixed materials to obtain cement raw materials, and calcining the cement raw materials to obtain cement clinker by adopting a calcining process of an existing novel drying method kiln which is provided with a precalcining kiln. Cooled cement clinker is grinded through a mill, and the cement clinker meeting production requirements is obtained.

Owner:SHANDONG JIANZHU UNIV

Method for preparing ordinary portland cement by taking gold mine tailings as raw materials

InactiveCN102515581AImprove performanceCompact structureCinker content reductionPortland cementMixed materials

The invention discloses a method for preparing ordinary portland cement by taking gold mine tailings as raw materials. Cement clinker, gypsum, gold mine tailings and an activating agent are used as the raw materials, and the weight ratio of the cement clinker to the gypsum to the gold mine tailings to the activating agent is (60-95): (1-10): (5-40): (1-10). The concrete preparation method comprises the following steps of: firstly, uniformly mixing the gold mine tailings and the activating agent according to the proportion, then grinding to be fine; proportioning the cement clinker and the gypsum according to the proportion, then, uniformly mixing and grinding to be fine; and uniformly mixing the four raw materials which are ground to be fine to prepare the portland cement. In the method, the gold mine tailings with stable performance and low cost are used as mixed materials of the ordinary portland cement, the activity of the ordinary portland cement is improved by introducing the activating agent or an exciting agent, and the prepared portland cement is compact in structure and excellent in performance. The raw materials selected in the whole preparation process are simple, the characteristics of the gold mine tailings are sufficiently utilized, and portland cement with excellent performance can be synthesized.

Owner:安徽乌江水泥有限公司 +3

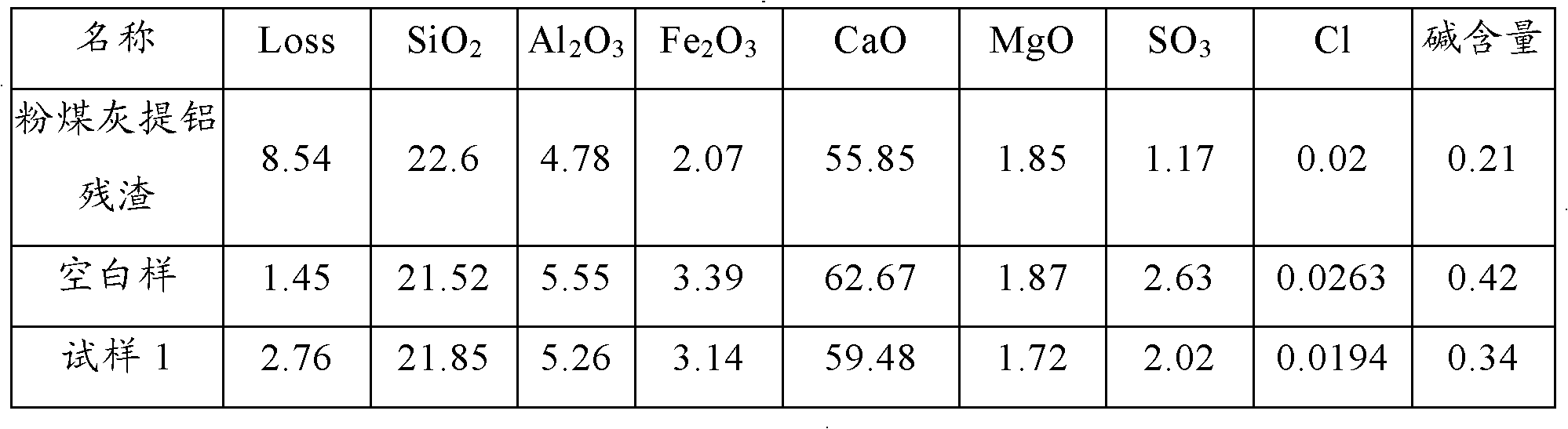

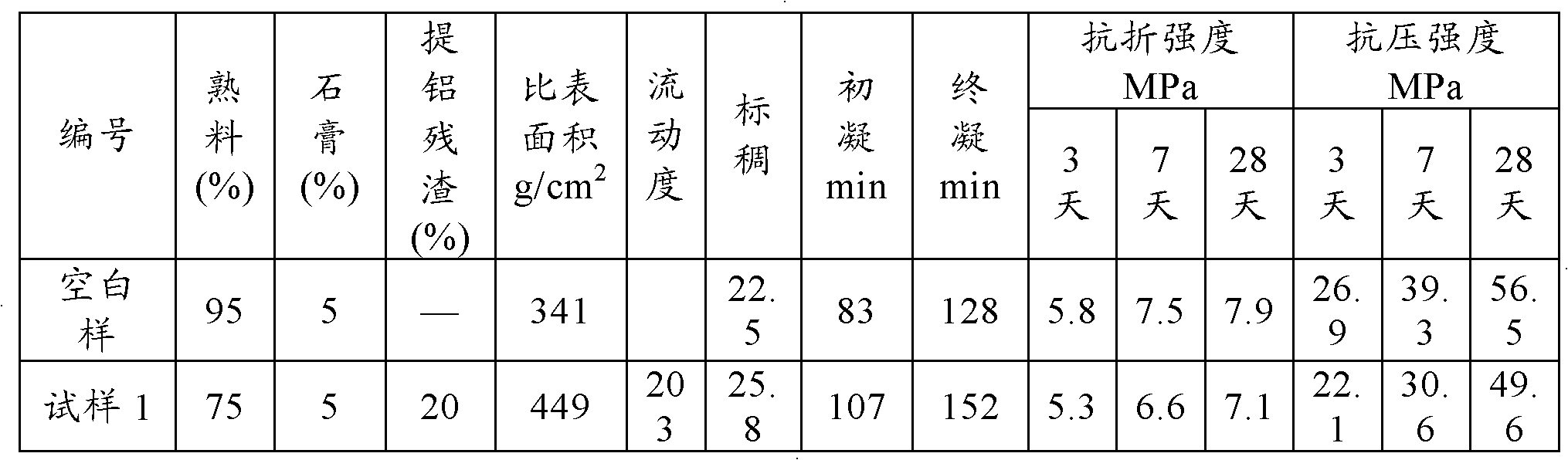

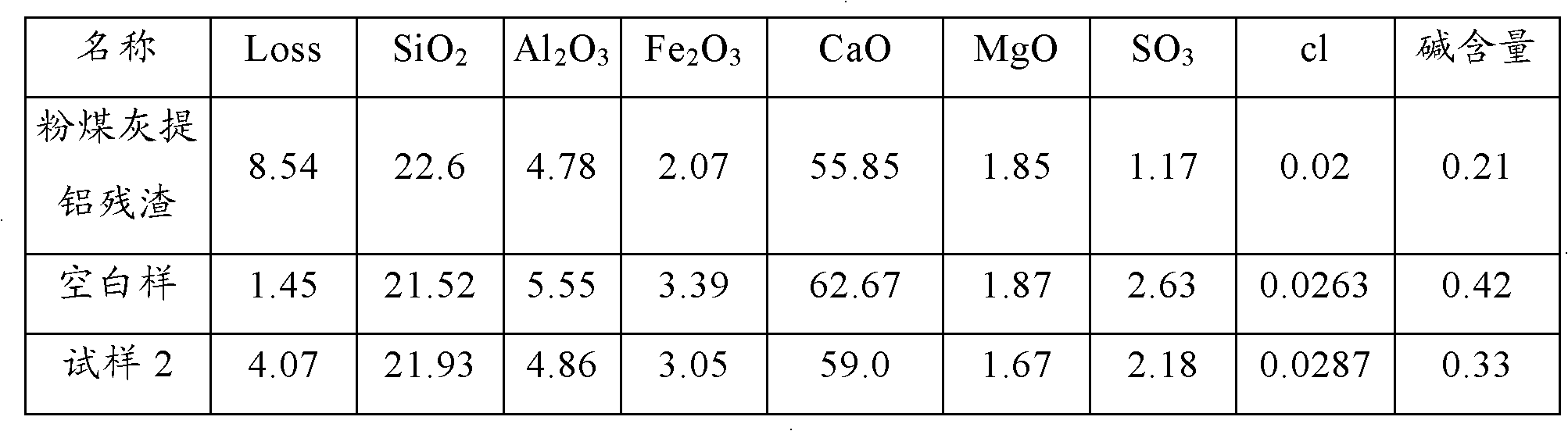

Fly ash aluminum extraction residue cement

InactiveCN102276175AWear value is smallReduce wearCinker content reductionUltimate tensile strengthFly ash

The invention discloses a fly ash aluminum extraction residue cement, which is prepared from raw materials in the following weight proportions: 10-50 parts of fly ash aluminum extraction residue; 90-50 parts of clinker; and 1-5 parts of gypsum. After the above raw materials are mixed according to the ratio, they are sent to the cement mill, and the coarse powder is selected by the powder separator and returned to the cement mill, and the fine powder is directly sent to the cement storehouse to be the fly ash aluminum extraction residue cement. The performance of the fly ash aluminum extraction residue cement of the present invention meets the requirements of the 32.5 or 42.5 label. It overcomes many shortcomings of the prior art and realizes the advantages of simple and easy-to-obtain raw materials, scientific and reasonable process, small investment in equipment, good physical and chemical properties of cement, high early strength, and relatively stable strength increase.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Cementitious compositions containing feldspar and pozzolanic particulate material, and method of making said composition

ActiveUS8066813B2Increases the pH of the feldsparReadily availableSolid waste managementCement mixing apparatusSlagSlurry

A method of making a cementitious composition comprises (a) selecting at least one pozzolanic particulate material; (b) selecting and grinding at least one feldspar material to a fineness of at least 3000 Blaine; (c) mixing calcium oxide or calcium hydroxide with gypsum; (d) mixing the ground feldspar with the lime-gypsum mixture to produce an activator; (e) conditioning the pozzolanic particulate material with an aqueous solution; (f) adding the activator to the conditioned material to produce a slurry; and (g) curing the slurry in a sealed container. The pozzolanic particulate material can be slag, fly ash, or siliceous rock. A cementitious composition of the invention comprises a pozzolanic particulate material, a ground feldspar material, a lime compound and gypsum, and uses readily available materials, as an economic replacement for Portland cement, fly ash or other materials in filling, backfilling and paving, particularly for backfilling or stabilizing mine sites.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Concrete compositions with reduced drying time and methods of manufacturing same

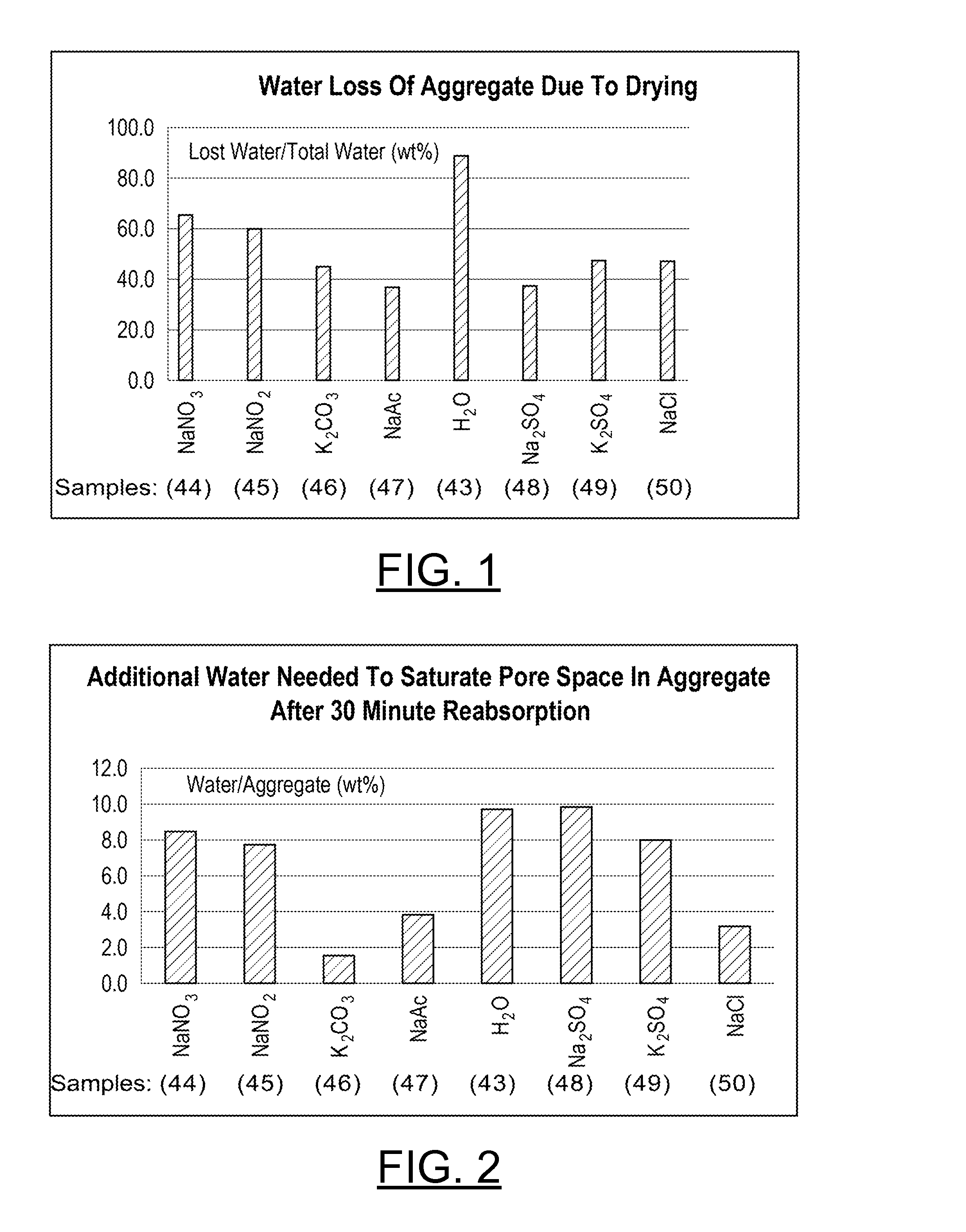

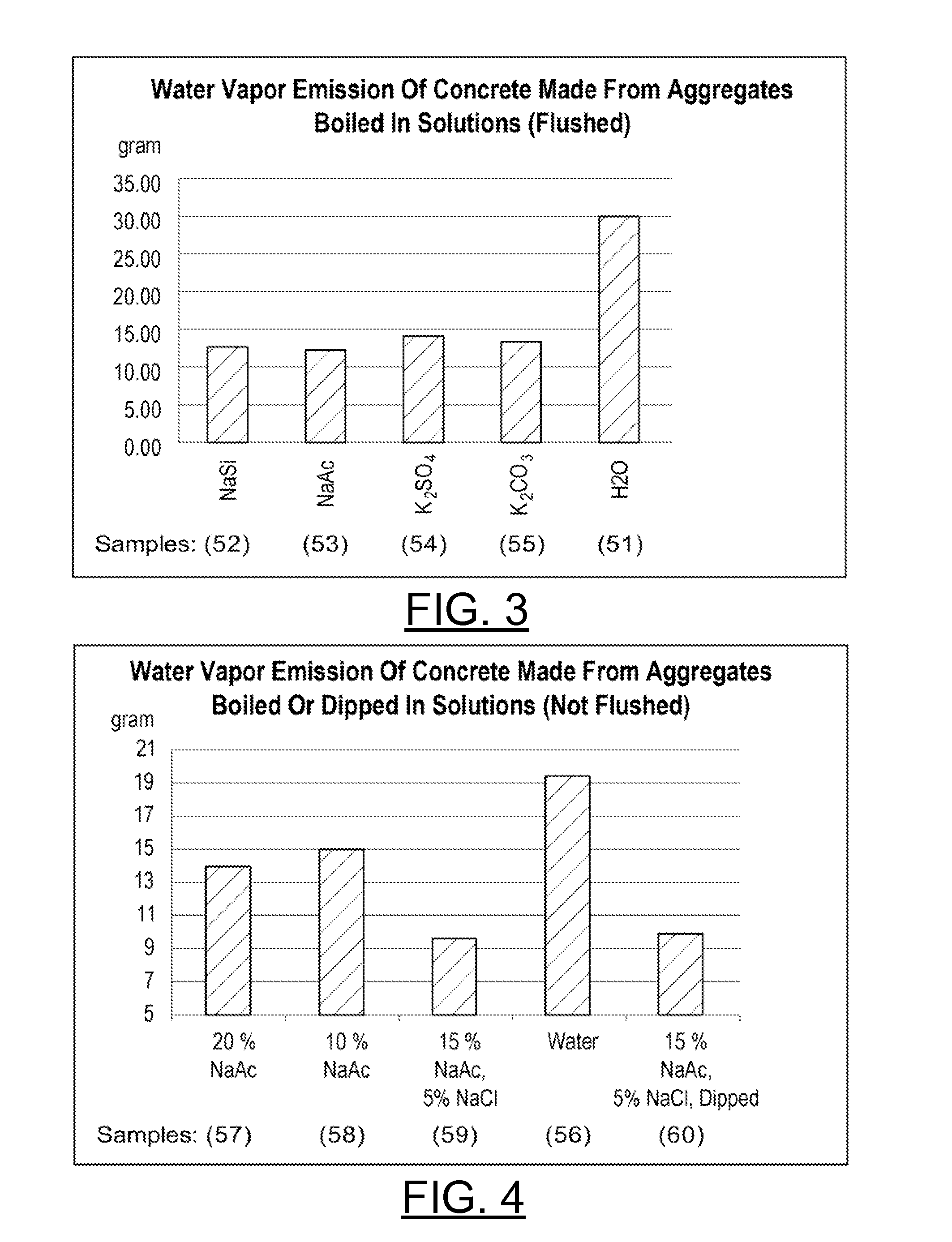

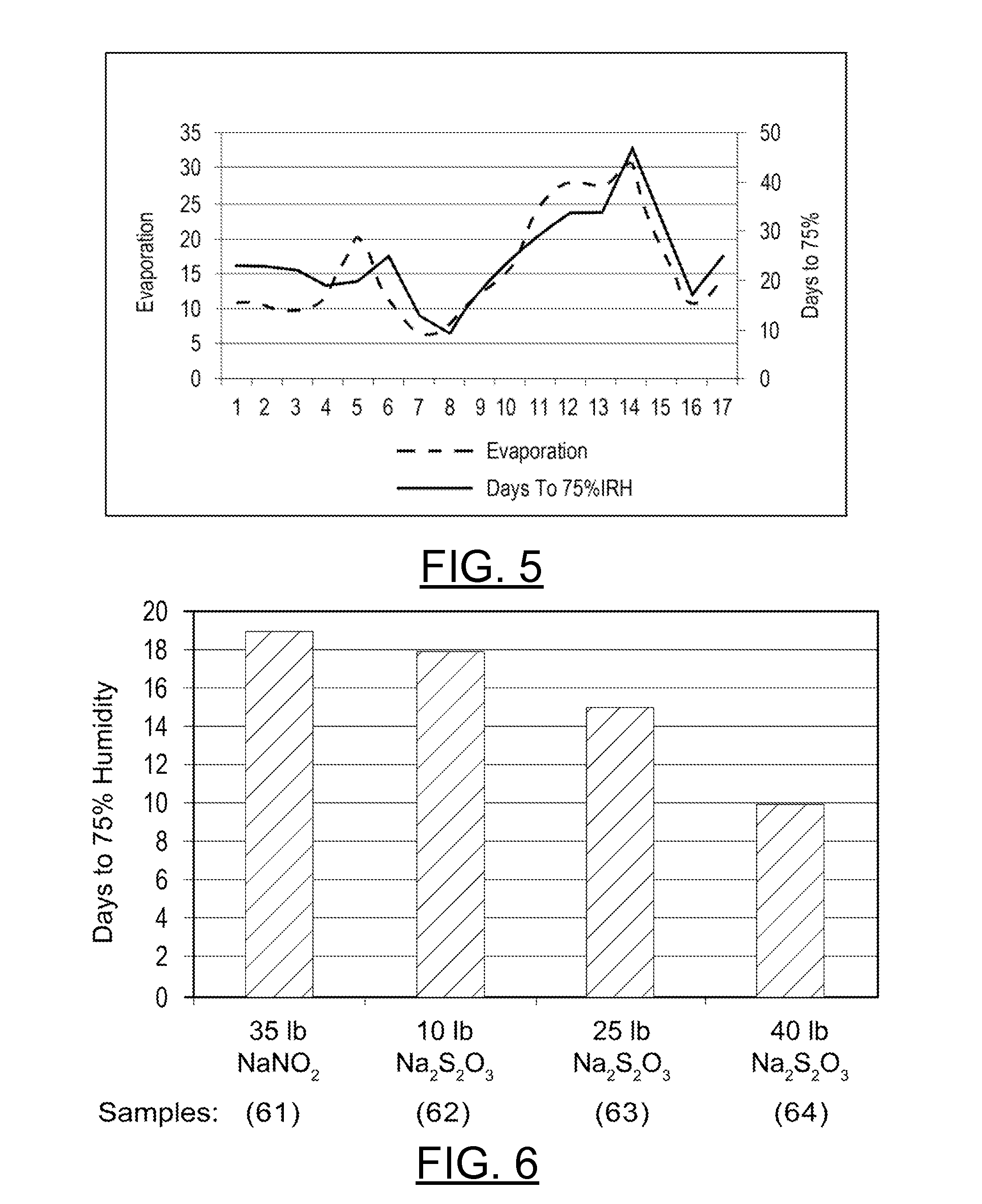

ActiveUS9382157B2Decreased internal relative humidity and rate of water vapor emissionFast dryingSolid waste managementCinker content reductionWater vaporWater soluble

Owner:U S CONCRETE

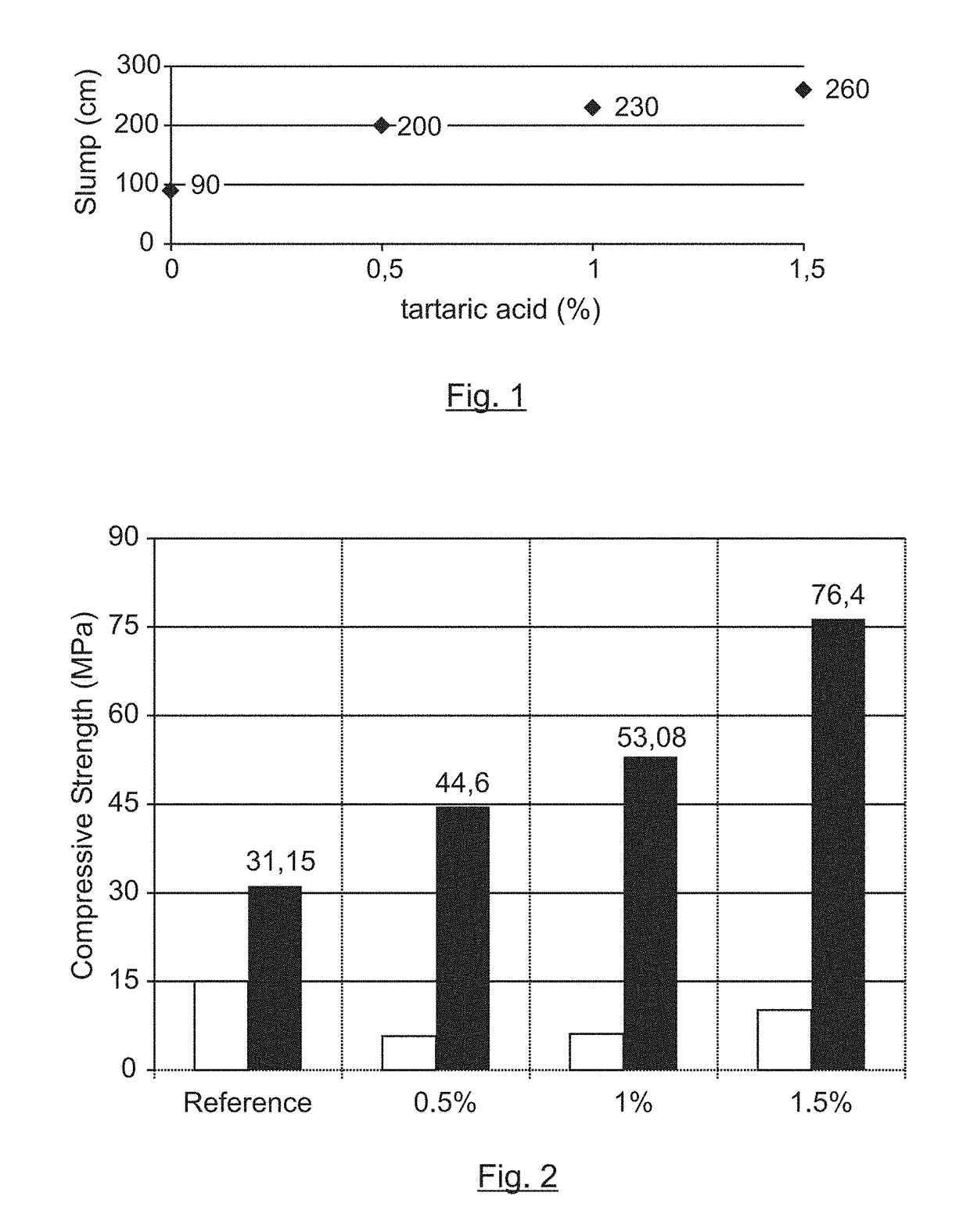

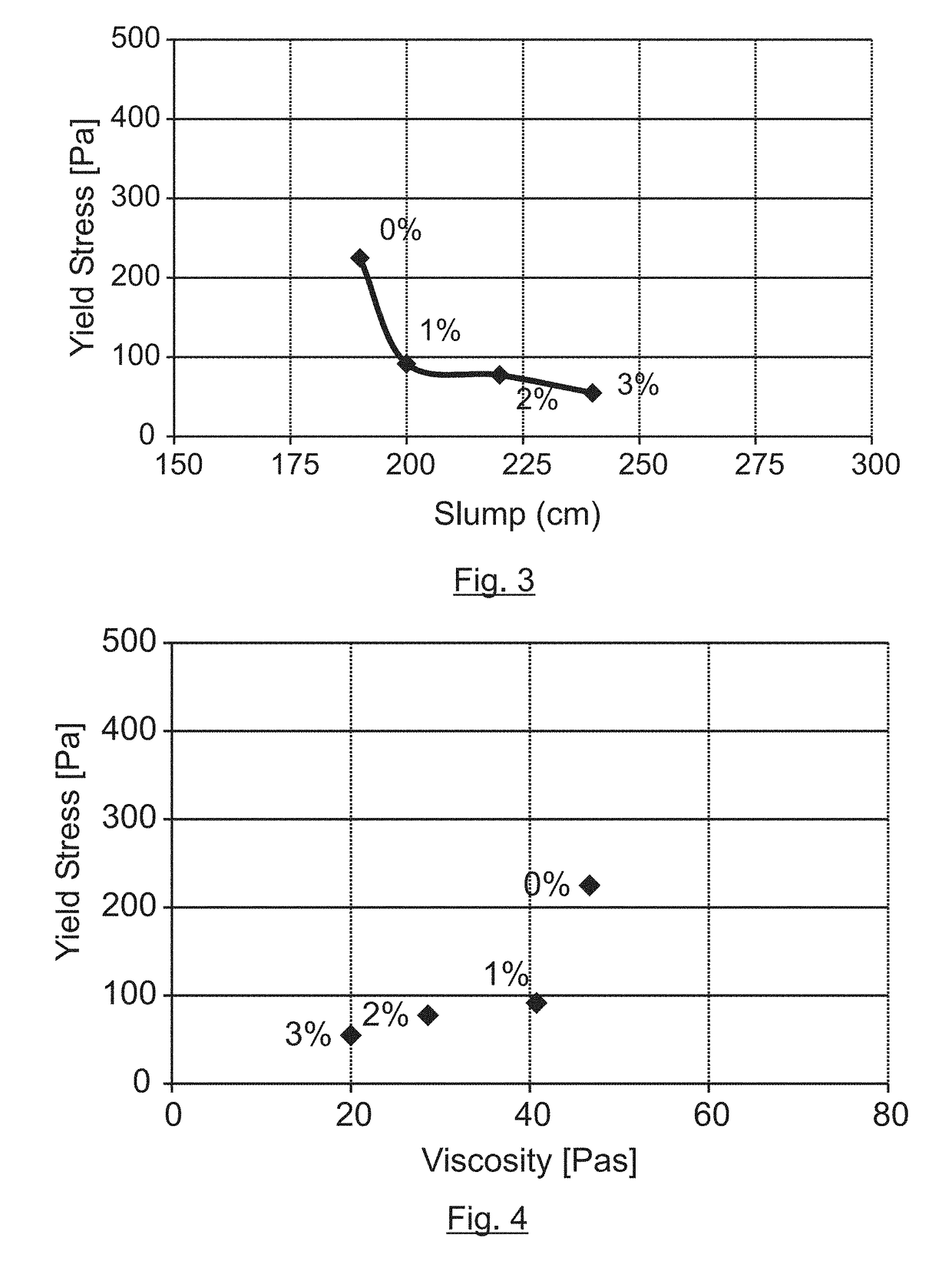

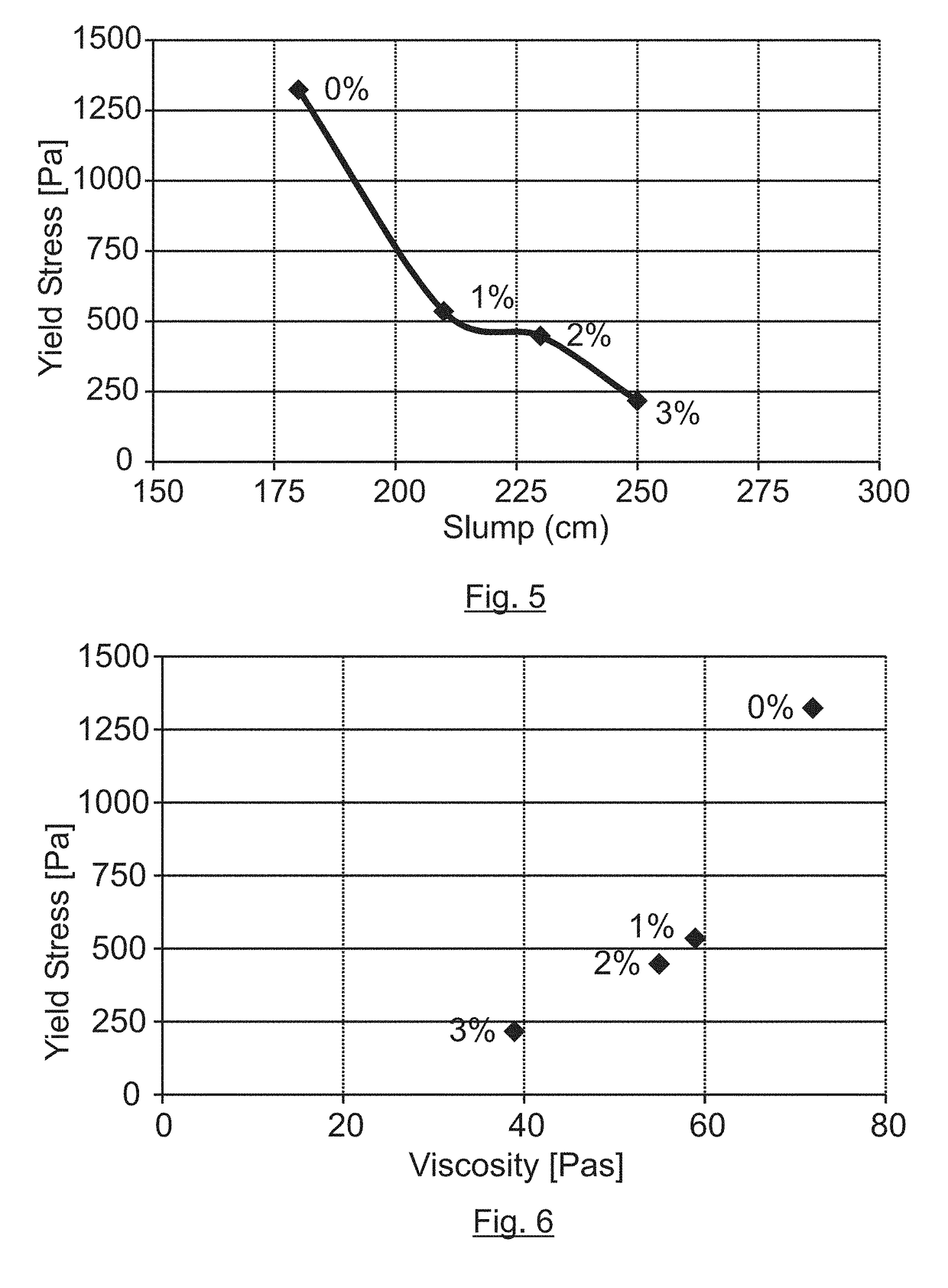

Construction castable material with controllable flow or slump

Owner:CEMEX INNOVATION HLDG LTD

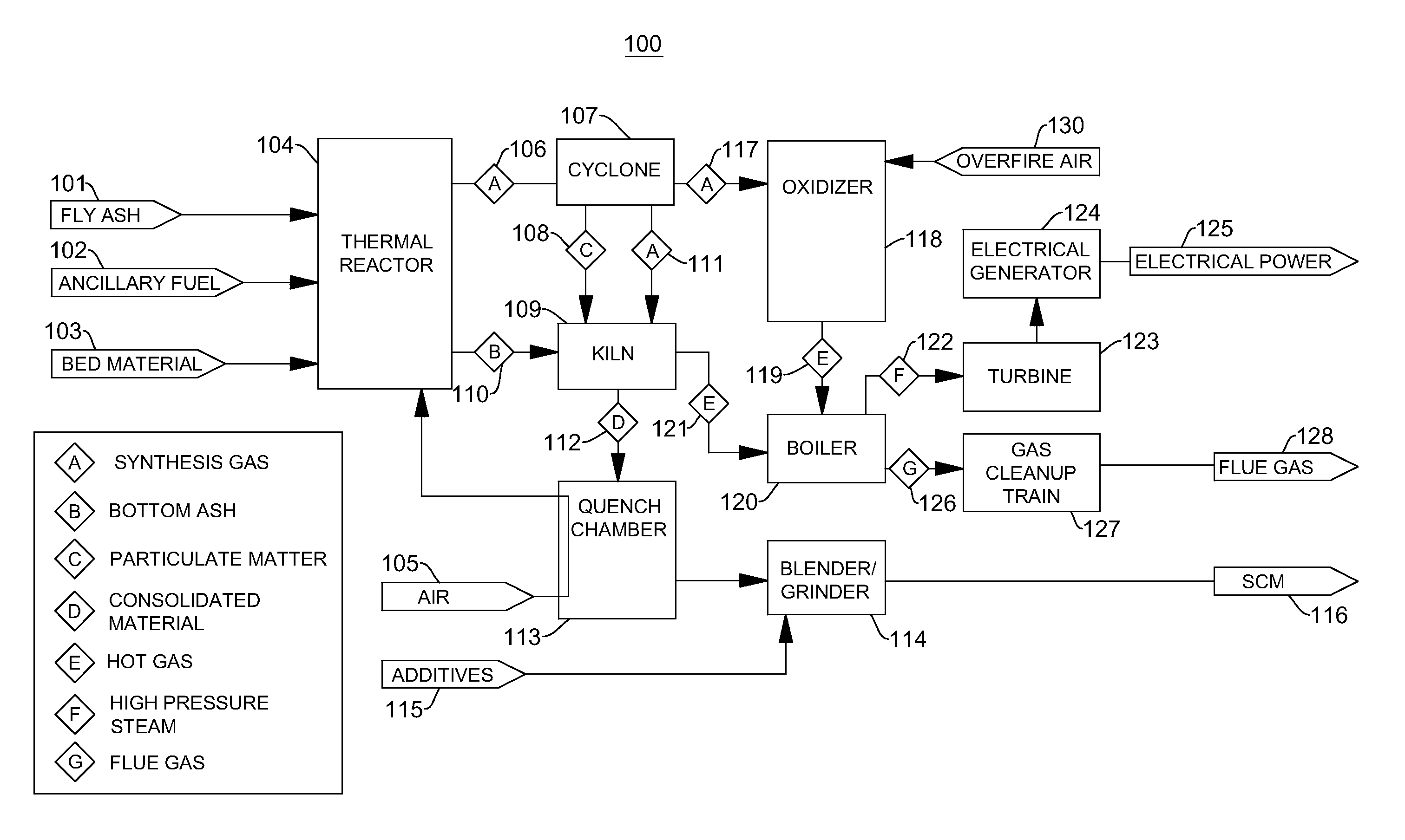

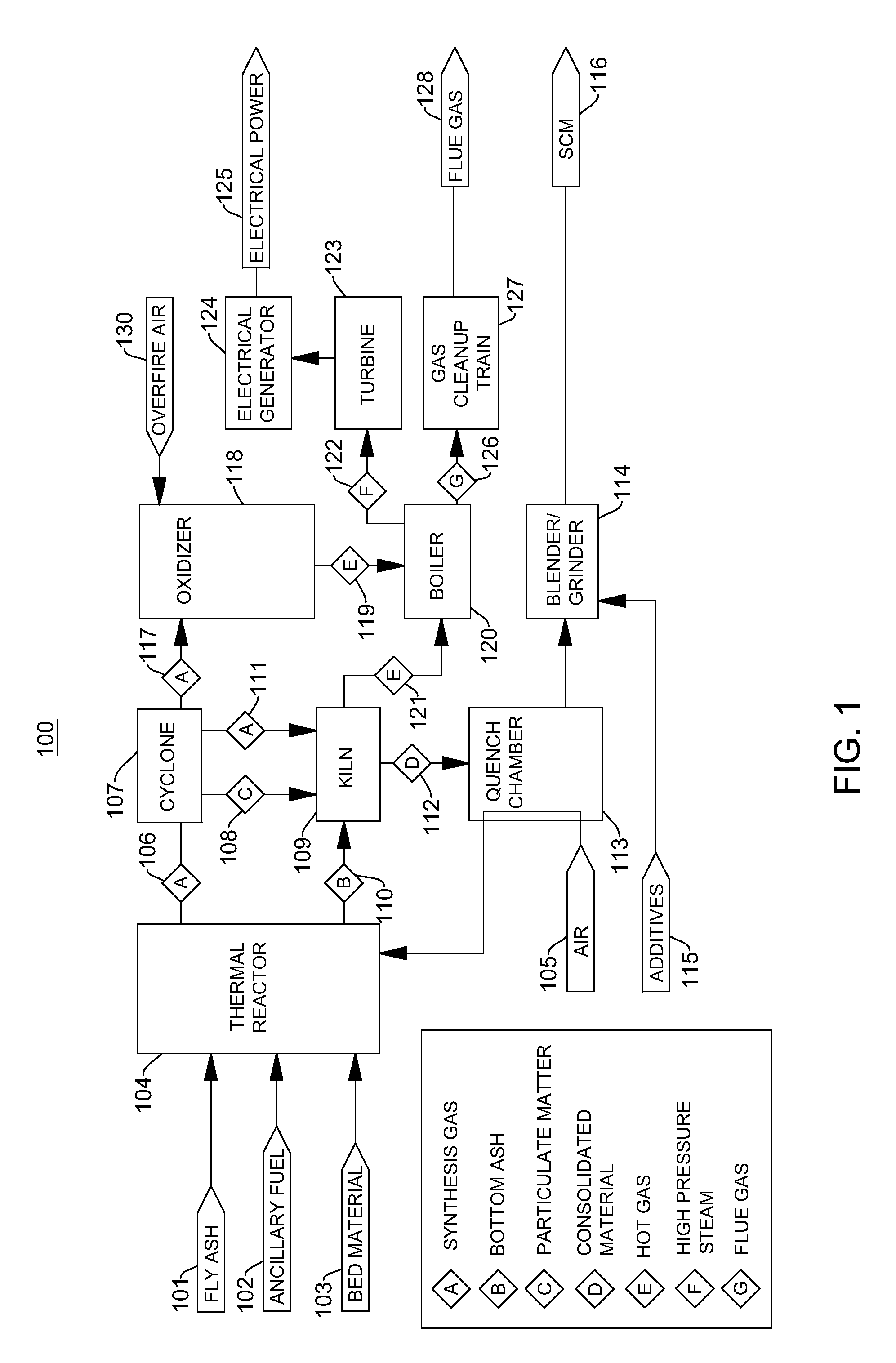

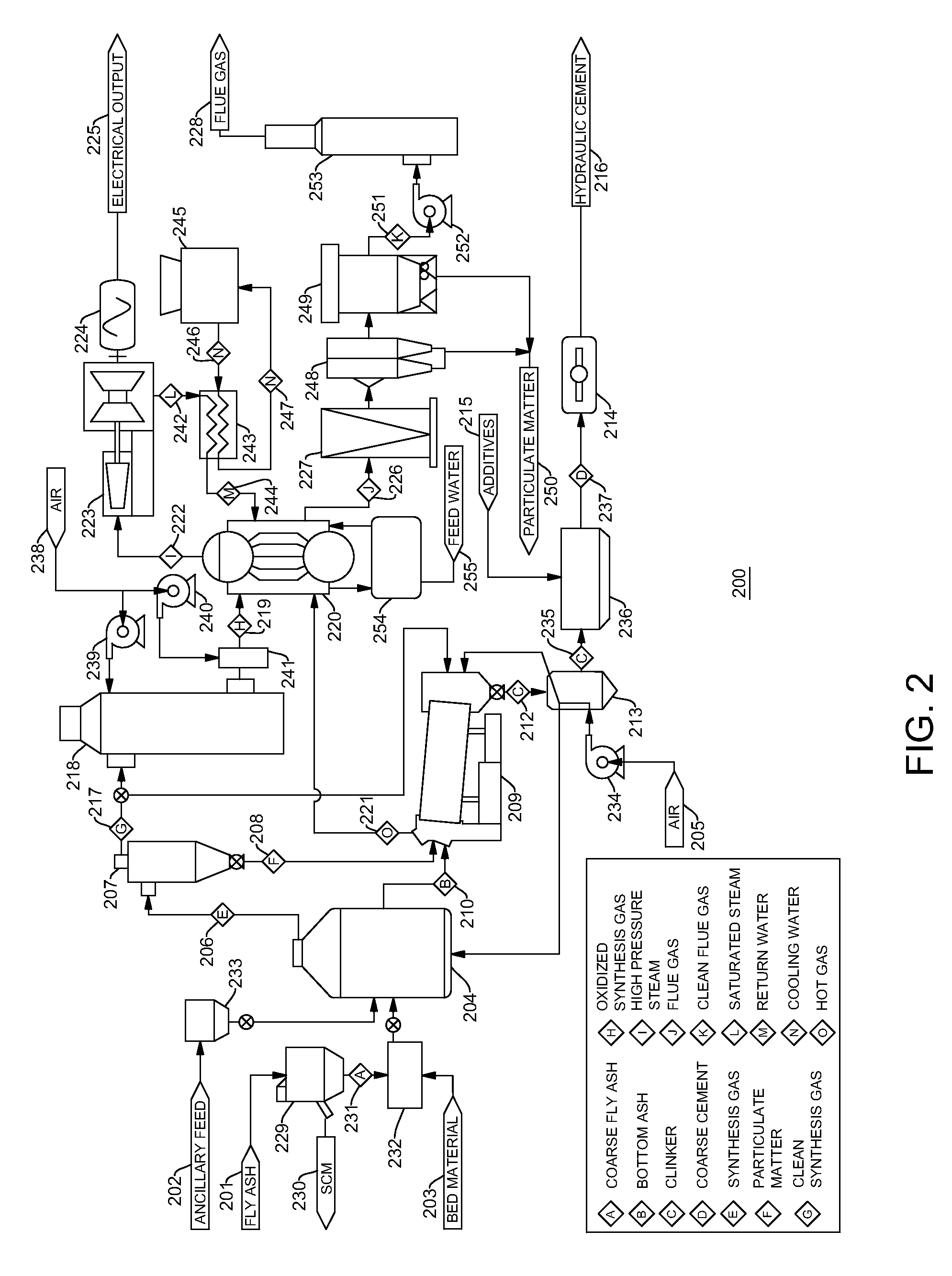

Method and system for reprocessing high carbon coal fly ash to produce cementitious materials

ActiveUS9284219B2Improve early compressive strengthHigh strengthGasification processes detailsCombustible gas purificationElectricityHigh carbon

A method is provided of thermally processing carbonaceous ash and ancillary carbonaceous material to produce a carbon-free inert, pozzolanic, or cementitious material and synthesis gas. The carbonaceous ash and ancillary fuels are fed into a thermal reactor along with oxides provided in the ash or in additives including limestone or glass. Carbon in the ancillary fuel and coal fly ash is converted to synthesis gas that is combusted to generate process steam and electricity. Remaining ash exits the thermal reactor chamber for processing at high temperature in a kiln gasifier to react the remaining fixed carbon and produce carbon-free partially-fused nodules or clinker that are cooled and ground to a desired fineness for cementitious or aggregate material in concrete. Carbonaceous ash, especially high carbon coal fly ash and other carbonaceous waste, are converted to energy and non-toxic, carbon-free aggregate or cementitious material used as architectural fill or in concrete mixes.

Owner:MOBIL TENSOR HLDG LLC

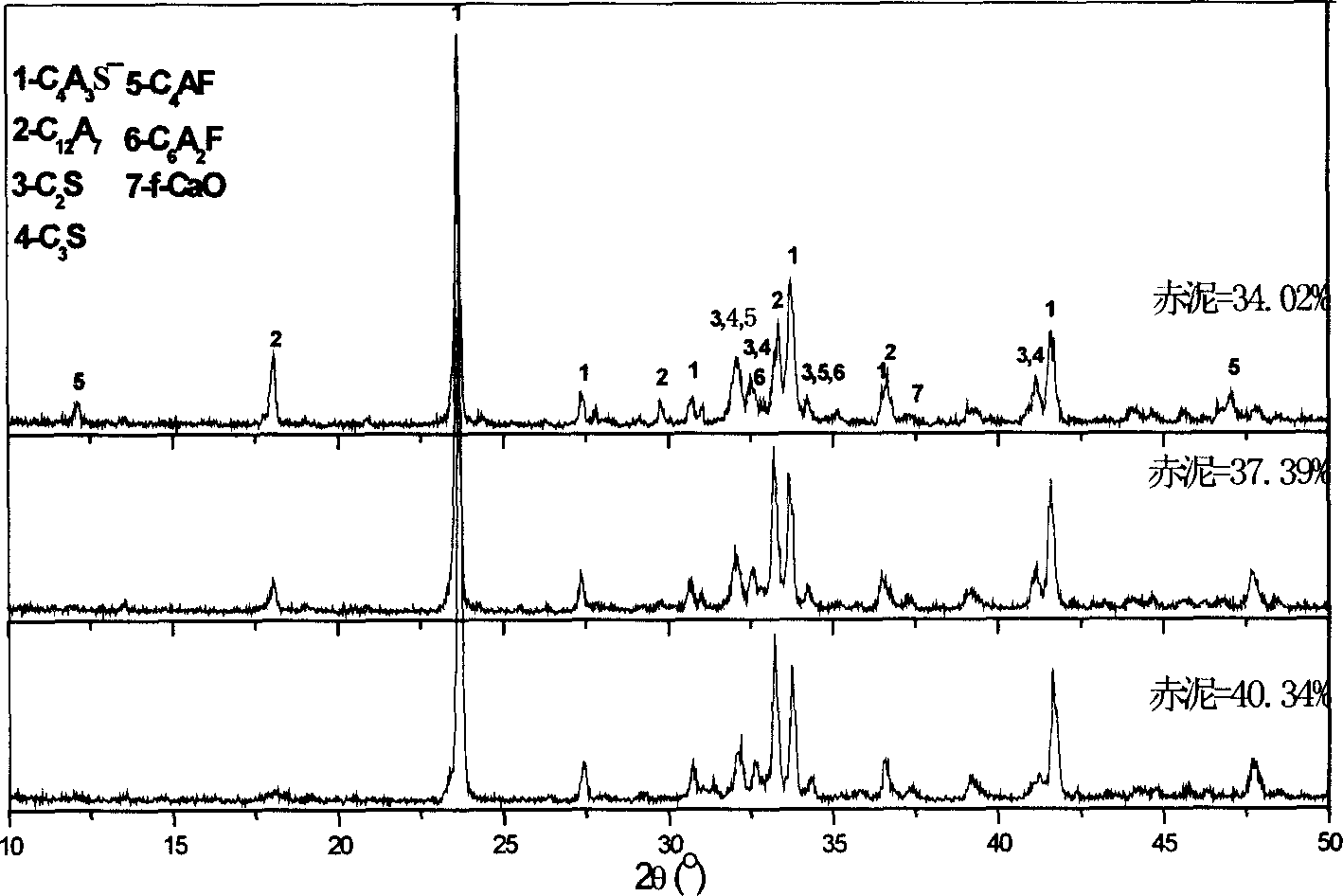

Rapid-setting and hardening, high-belite sulfoaluminate cement clinker as well as application and production process thereof

ActiveUS9822036B2Increase heightHigh-strength rapid-hardeningSolid waste managementCinker content reductionChemical compositionSlag

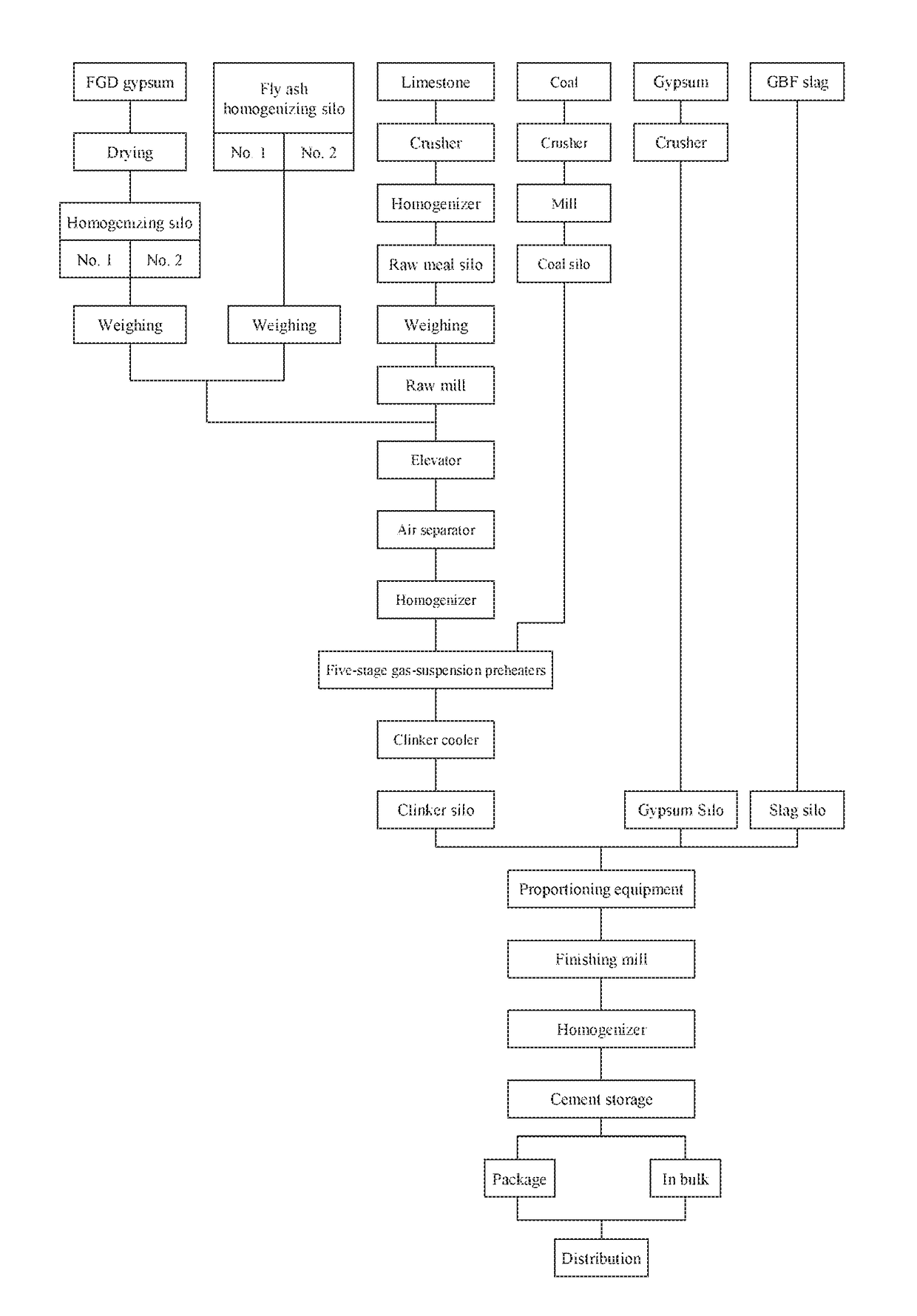

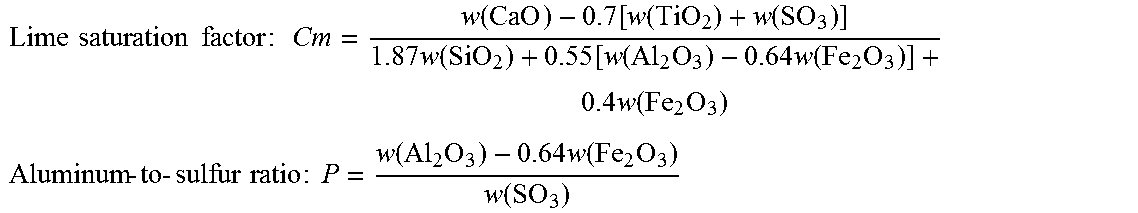

The invention discloses a rapid-hardening high-belite calcium sulfoaluminate cement clinker and relates generally to a rapid-hardening high-belite calcium sulfoaluminate cement clinker and methods to use and to manufacture the clinker. The clinker of the present invention comprises 20% to 35% by weight of C4A3S 3% to 9% by weight of C4AF, 37% to 47% by weight of C2S, 0.5% to 4.6% by weight of f-CaO and 14% to 26.3% by weight of CaSO4. The chemical compositions of the clinker are 12.9% to 16.1% by weight of SiO2, 12% to 19% by weight of Al2O3, 1% to 3% by weight of Fe2O3, 49% to 54% by weight of CaO and 12% to 18.43% by weight of SO3. It is manufactured by calcining, at a temperature of 1300° C.±50° C. in a rotary kiln, the raw meal, comprising 33% to 62% by weight of limestone, 10.5% to 28% by weight of fly ash, and 19% to 45% by weight of FGD gypsum. A group of rapid-hardening high-strength cements of various strength classes can be manufactured by mixing and grinding 26% to 97% by weight of clinker, 3% to 19% by weight of anhydrite and 0% to 55% by weight of granulated blast furnace slag.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

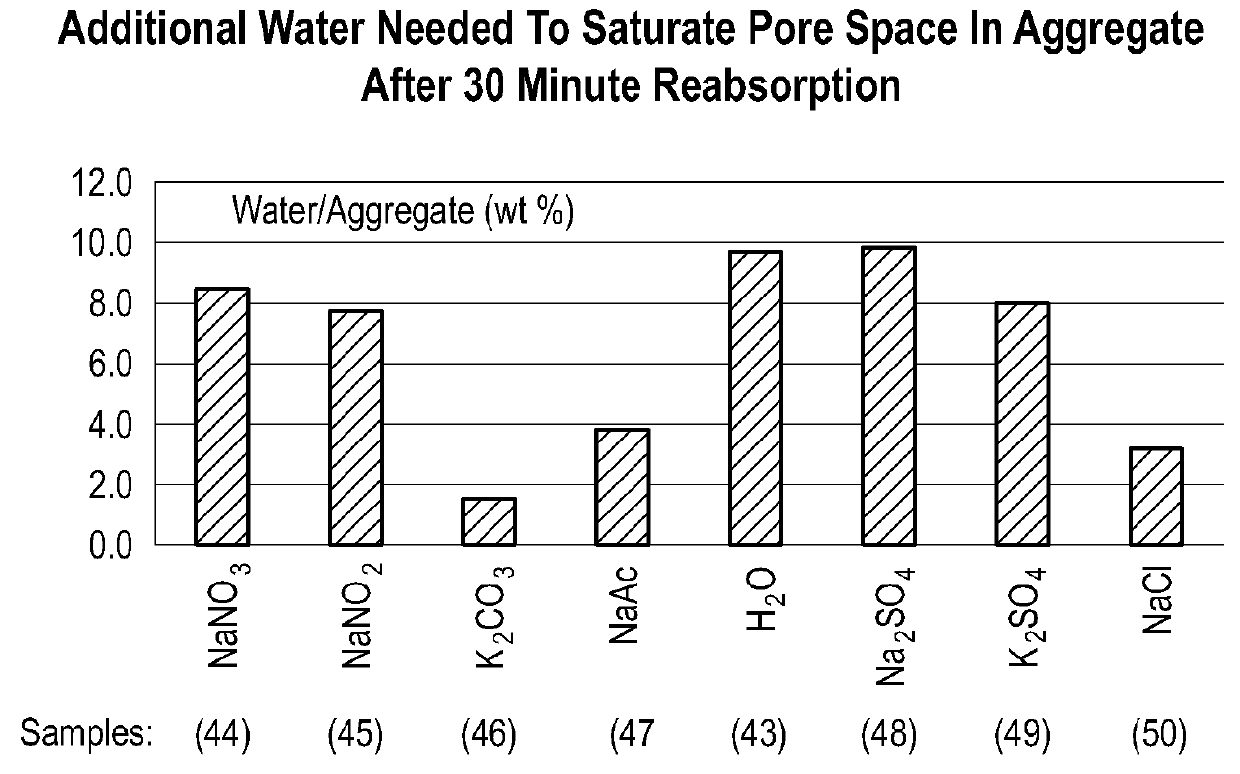

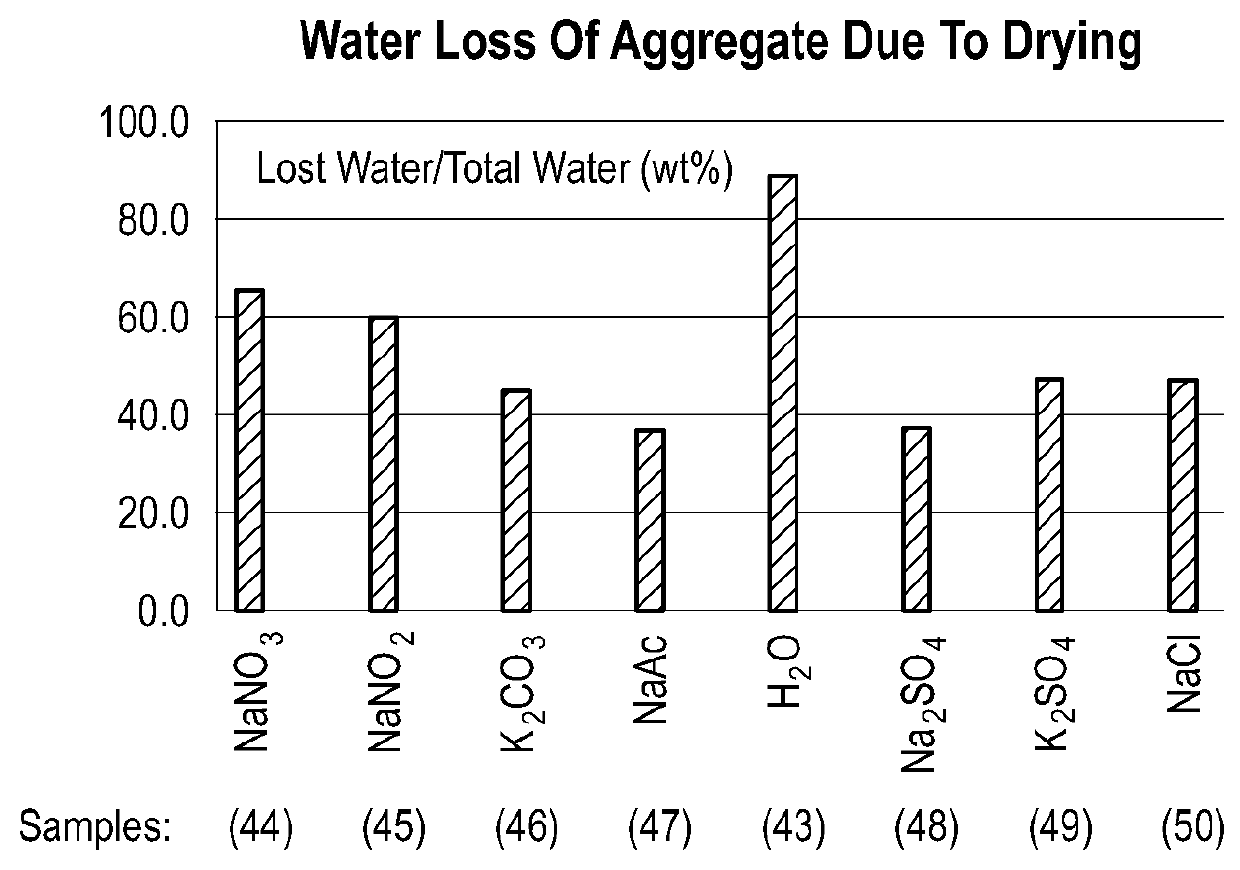

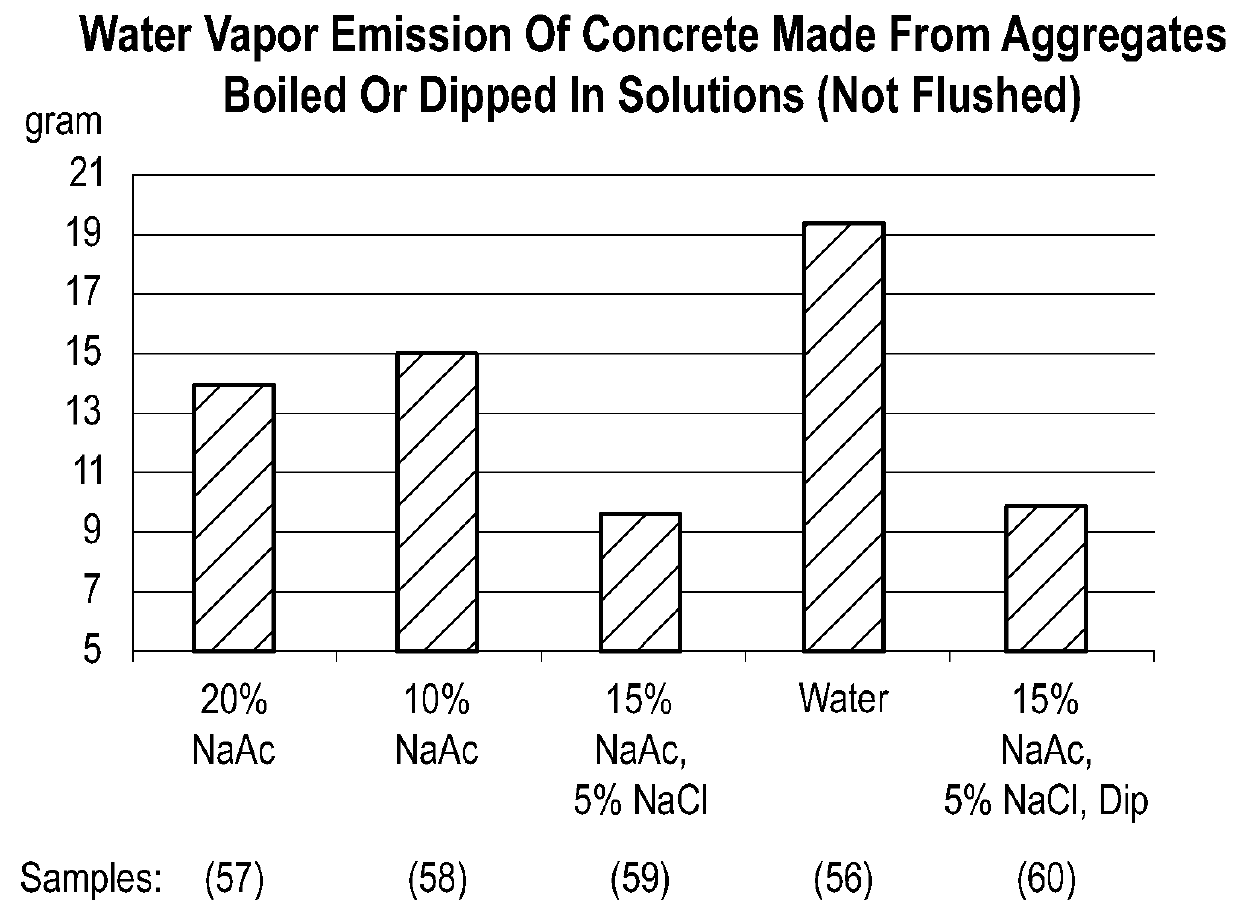

Accelerated Drying Concrete Compositions and Methods of Manufacturing Thereof

ActiveUS20160016852A1High retention rateInhibited DiffusionSolid waste managementCinker content reductionWater vaporWater soluble

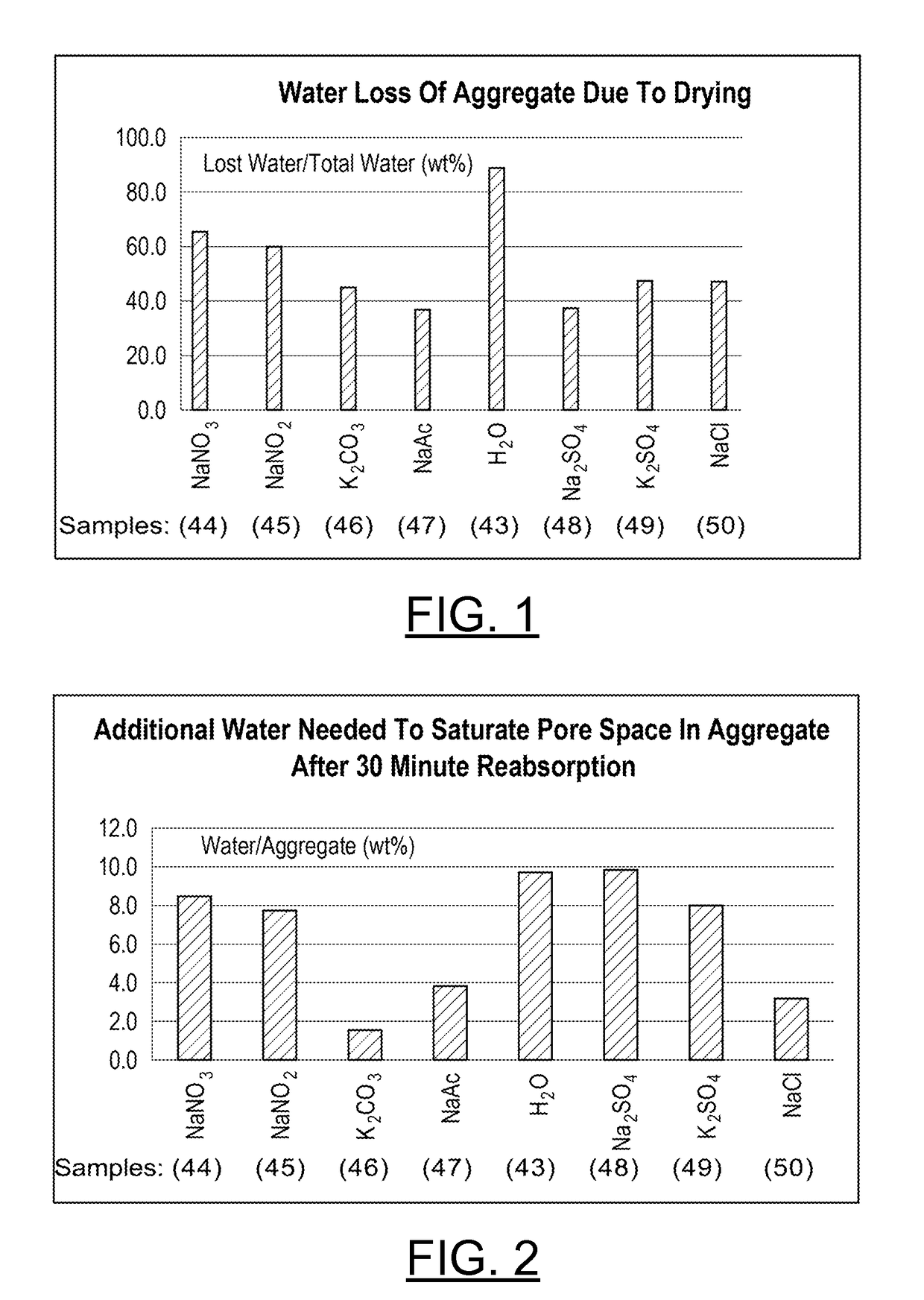

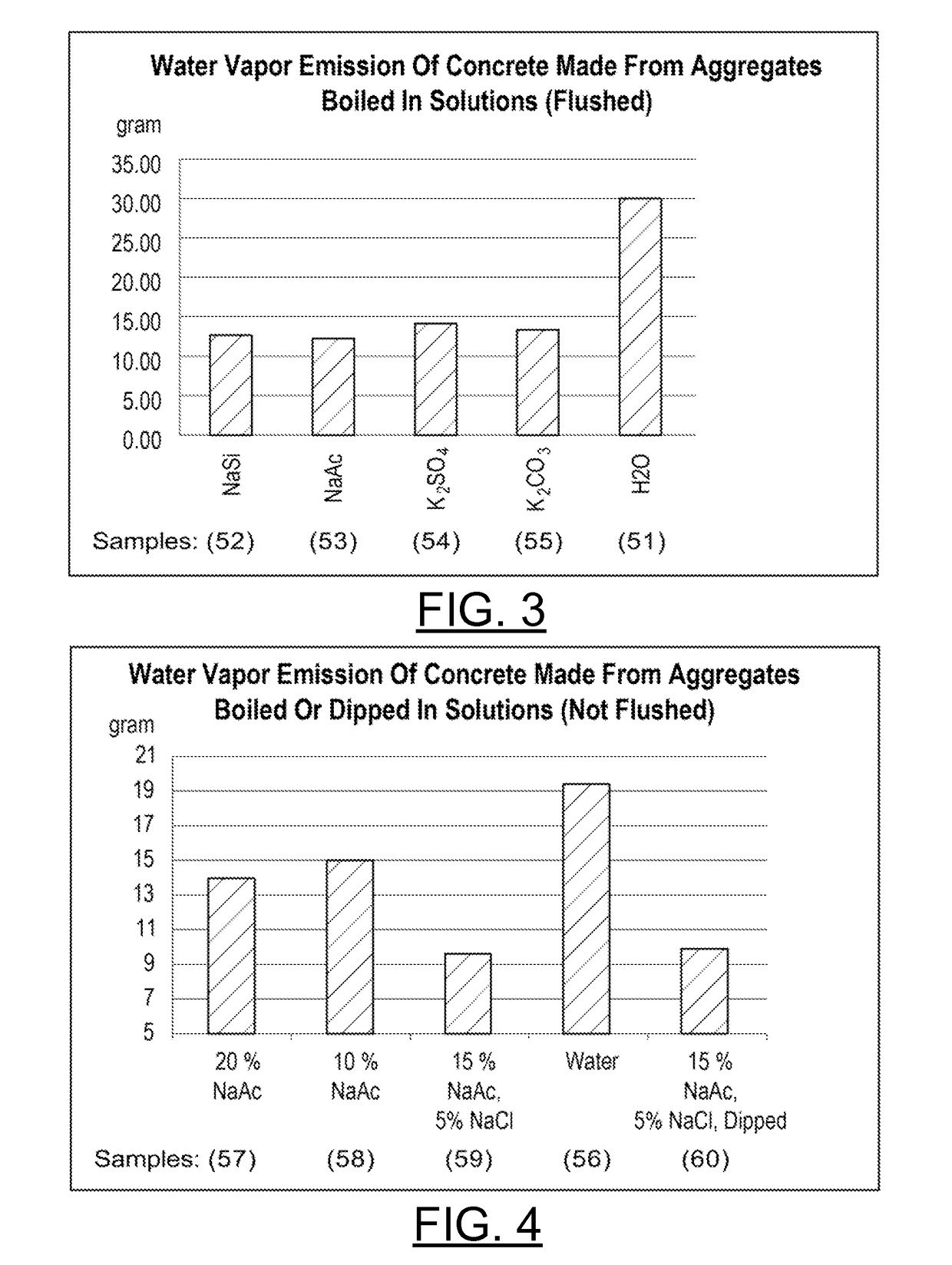

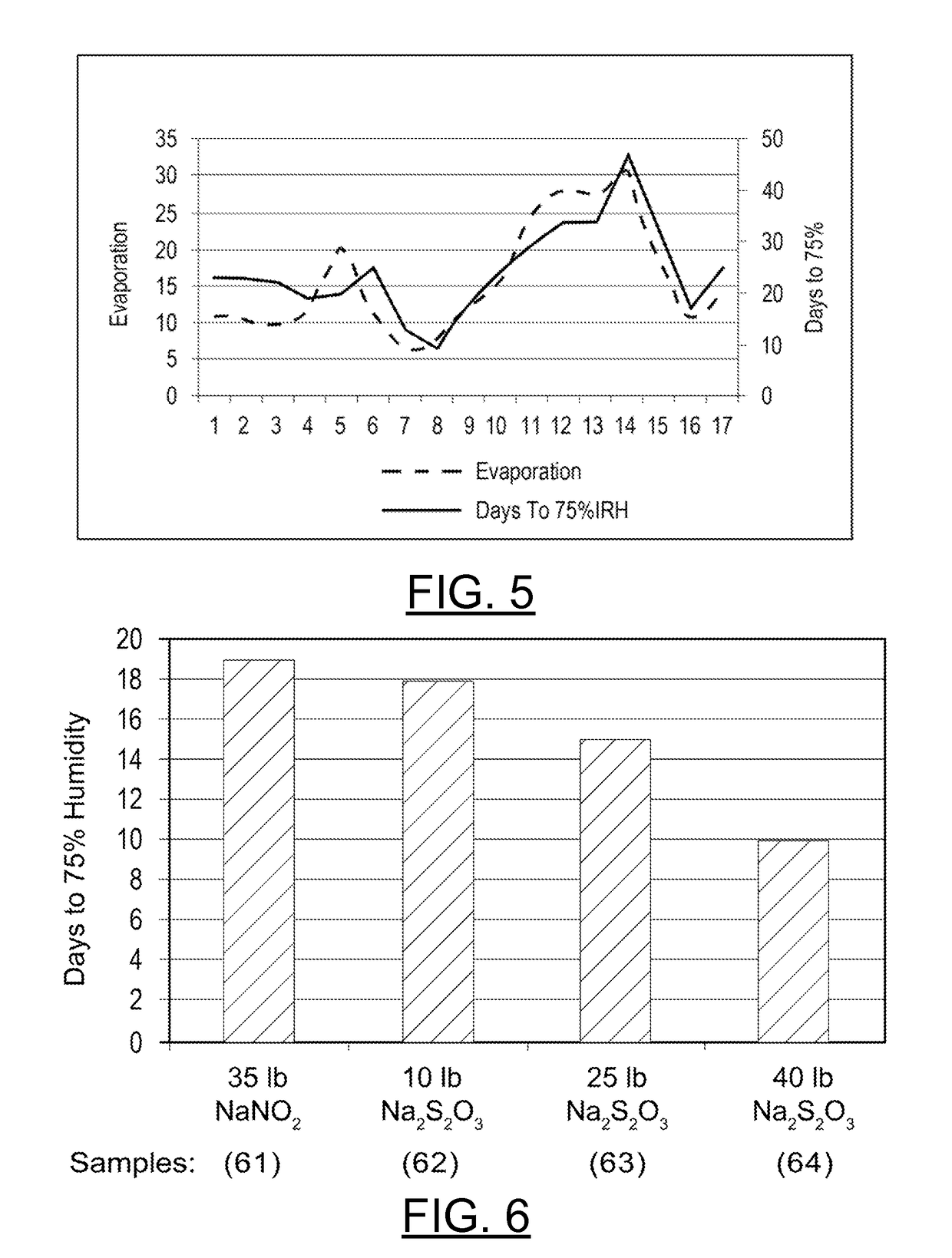

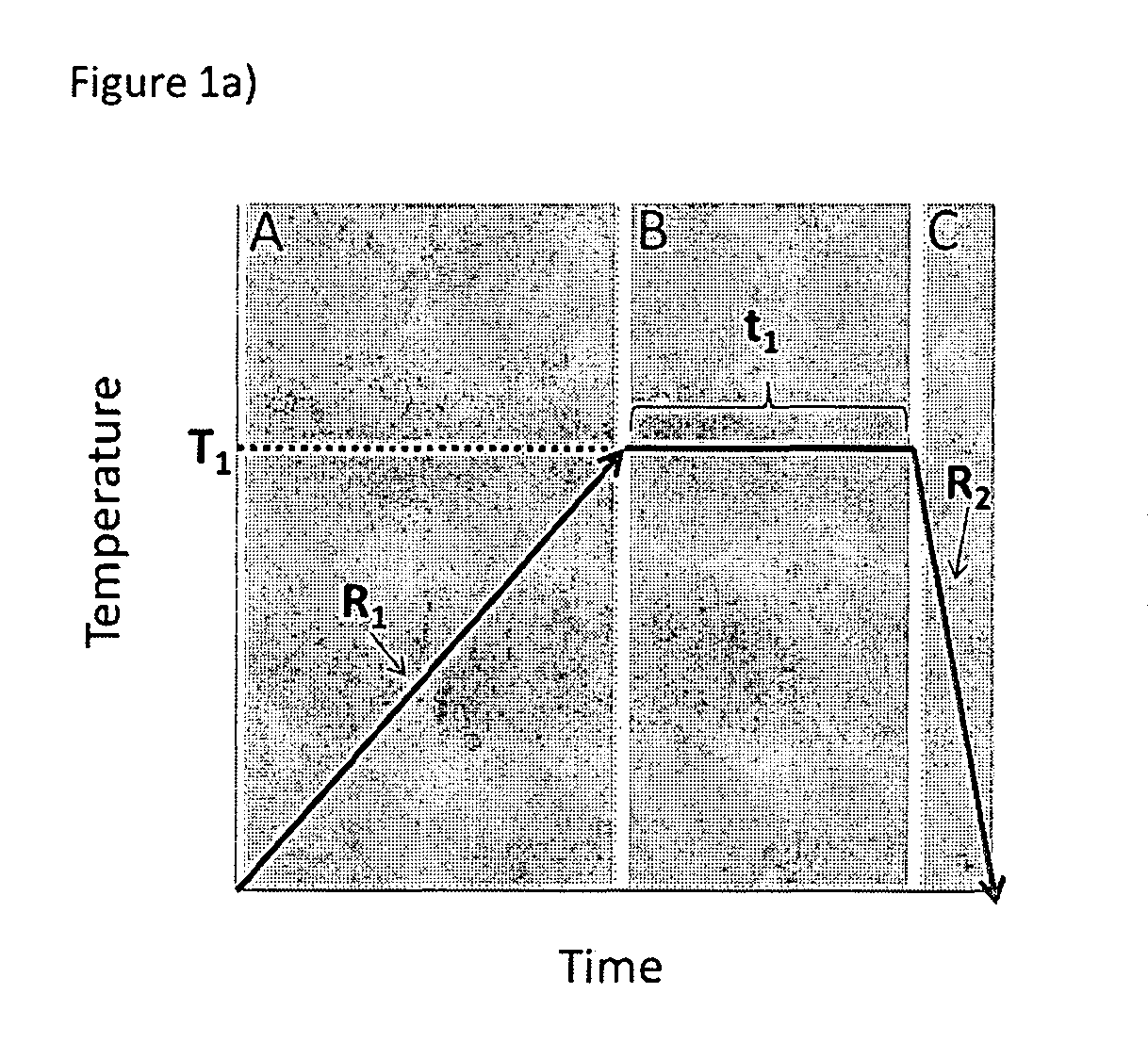

Cementitious compositions and processes for preparing and using the cementitious compositions are provided. The cementitious compositions are characterized by the property of a reduced or an attenuated water vapor emission from a cementitious mix and a concrete formed therefrom. Certain cementitious compositions are characterized by the property of accelerated drying while still maintaining good workability. Methods of improving water retention and surface drying of concrete, including lightweight concrete are provided. A water soluble ionic salt may be used to sequester water within the pores and capillaries of the cement paste and / or porous lightweight aggregate. In some examples, the salt may be added directly to concrete or aggregates may be infused with a water-salt solution to provide treated porous aggregates having improved water saturation and water retention.

Owner:U S CONCRETE

Method for producing G-level high oil-resistant well cement clinker and cement clinker produced by method

ActiveCN103113029AReduce pollutionReduce manual labor intensityDrilling compositionCinker content reductionIron powderSludge

The invention discloses a method for producing a G-level high oil-resistant well cement clinker and a cement clinker produced by the method, and particularly relates to a method for producing the G-level high oil-resistant well cement clinker by urban sludge ingredients, and a cement clinker produced by the method. The aim of the invention is achieved by the following processes of adding municipal sludge after utilizing excellent marble, quartz stone, iron powder and clay ingredients with high calcium content, then burning in a kiln and producing the G-level high oil-resistant well cement clinker. Compared with the prior art, not only is the municipal sludge utilized, but also municipal pollution can be reduced to a certain extent; particularly, the yield of a grinding machine can be improved; the artificial labor intensity is reduced; and the production cost can be further reduced.

Owner:新疆天山水泥有限责任公司

Inorganic composite conglutination powder and preparation method thereof

InactiveCN103102088AGood value for moneySolve environmental pollutionCinker content reductionSlagResource saving

The invention discloses inorganic composite conglutination powder. The inorganic composite conglutination powder comprises the following materials in parts by weight: 1.5-6 parts of sodium sulphate, 6-12 parts of cement, 27.4-61.2 parts of blast furnace slag micro powder, 9-15.3 parts of industrial waste gypsum, 6.1-12.7 parts of carbide slag, 2-8 parts of salty mud, 10-25 parts of coal ashes and 0.05-5 parts of additives. The preparation method of the inorganic composite conglutination powder comprises the following steps of: drying the materials by a dryer; conveying the dried materials to a ball mill by a conveyor belt for being grinded and storing the grinded materials in a material storage bin; and preparing the materials in proportion, conveying the prepared materials by the conveyor belt for being sufficiently mixed, and storing the mixed materials to an finished product storage bin. The inorganic composite conglutination powder is inverted on the basis of saving energy and reducing emission, and reducing the cost of domestic mine underground filling material, and is an inorganic conglutination material which adopts industrial solid waste as the main material. The inorganic composite conglutination powder has the advantages of being low in cost, extensive in application, resource-saving and energy-saving.

Owner:上海质能新型材料科技有限公司

Cement clinker and preparation method

The invention discloses cement clinker. The raw materials are prepared by the following materials by weight ratio: 37-77 percent of waste crushed stone concrete, 10-20 percent of iron ore, 10-20 percent of chromium salt slag, 1-10 percent of clay, 5-15 percent of coal and 1-4 percent of sulfuric-acid residue. The method for preparing the cement clinker comprises the following steps: 1, crushing and pre-homogenization; 2, raw material homogenization; 3, preheating and decomposition: a preheater is used for completing preheating and partial decomposition of the raw materials; 4, cement clinker sintering: after completing preheating and predecomposition in a cyclone preheater, the raw materials enter a rotary kiln for sintering of the clinker in the next procedure; and 5, cement grinding, so as to obtain the cement clinker. According to the invention, the use amount of high-quality limestone can be reduced, Cao and Mgo contained in chromium salt slag do not need thermal decomposition, and each ton of clinker can save raw materials by 10-20 percent; and due to fluxing and mineralization action of microelements, the viscosity of a liquid phase is reduced, and the mechanical strength of the cement clinker is greatly enhanced.

Owner:田翔鹰

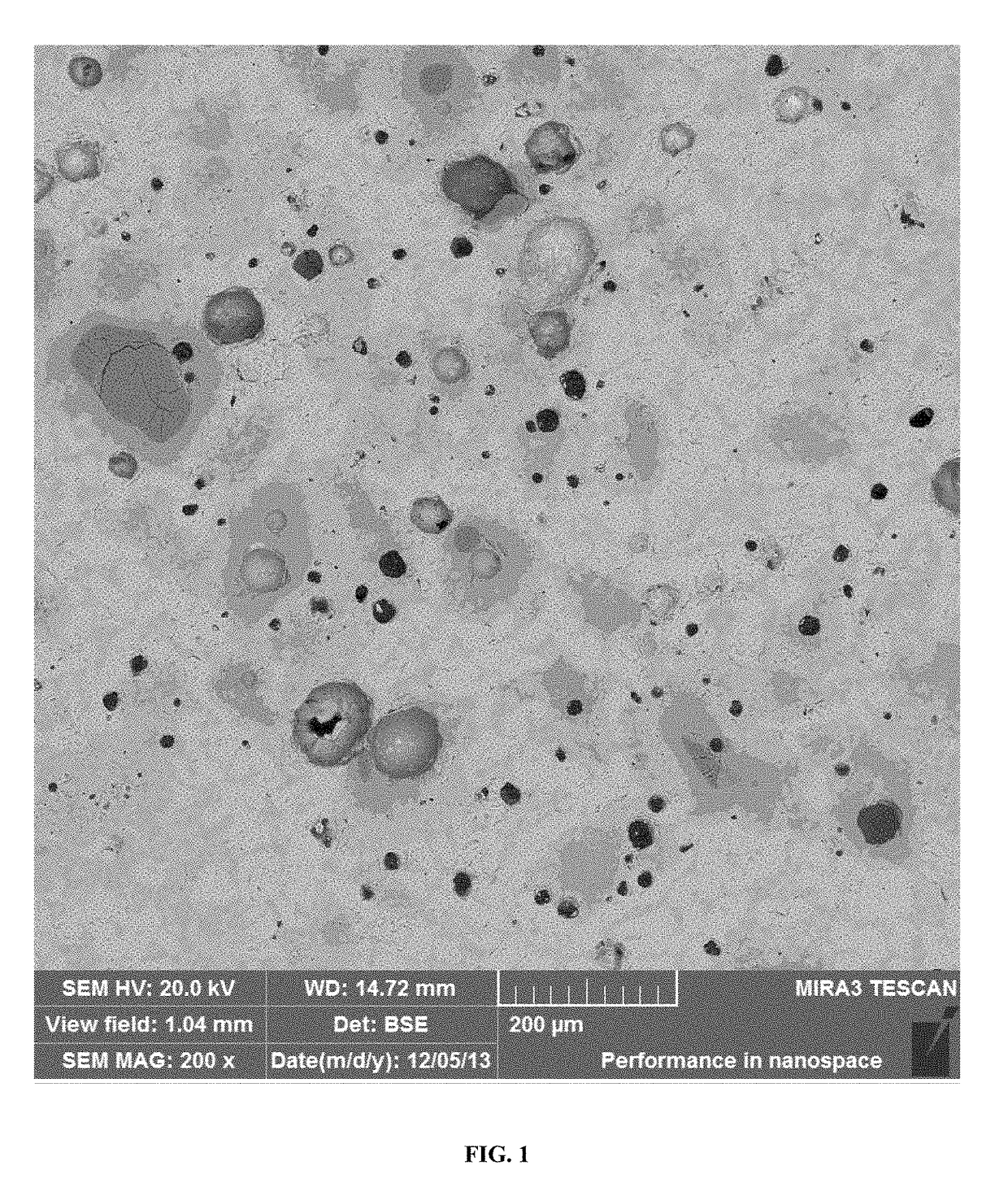

Microstructured carbonatable calcium silicate clinkers and methods thereof

ActiveUS9926235B2Improve grindabilityHigh reactivitySolid waste managementCinker content reductionCalcium silicatePortland cement

The invention provides novel, microstructured clinker and cement materials that are characterized by superior grindability and reactivity. The disclosed clinker and cement materials are based on carbonatable calcium silicate and can be made from widely available, low cost raw materials via a process suitable for large-scale production. The method of the invention is flexible in equipment and processing requirements and is readily adaptable to manufacturing facilities of conventional Portland cement.

Owner:SOLIDIA TECH

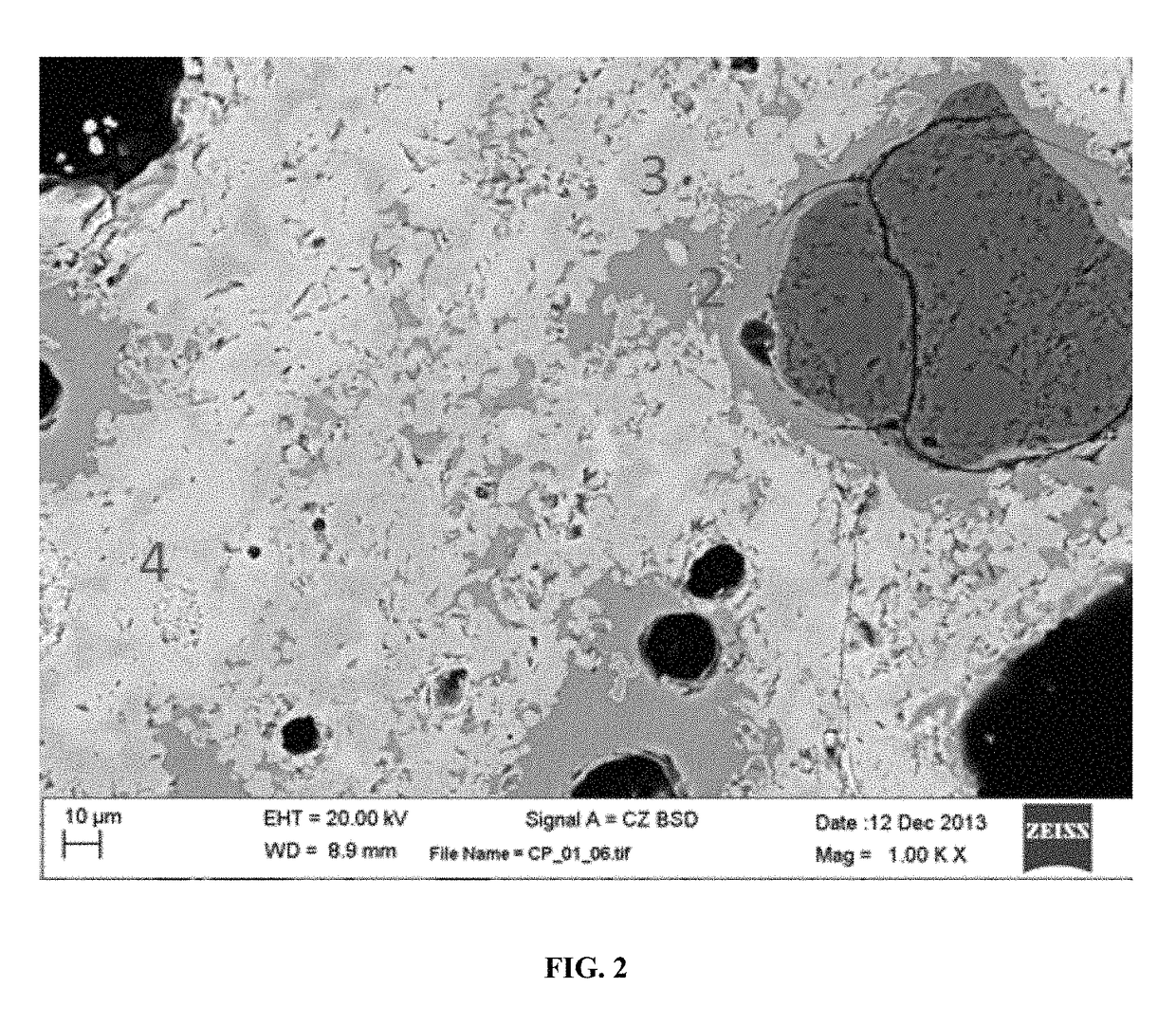

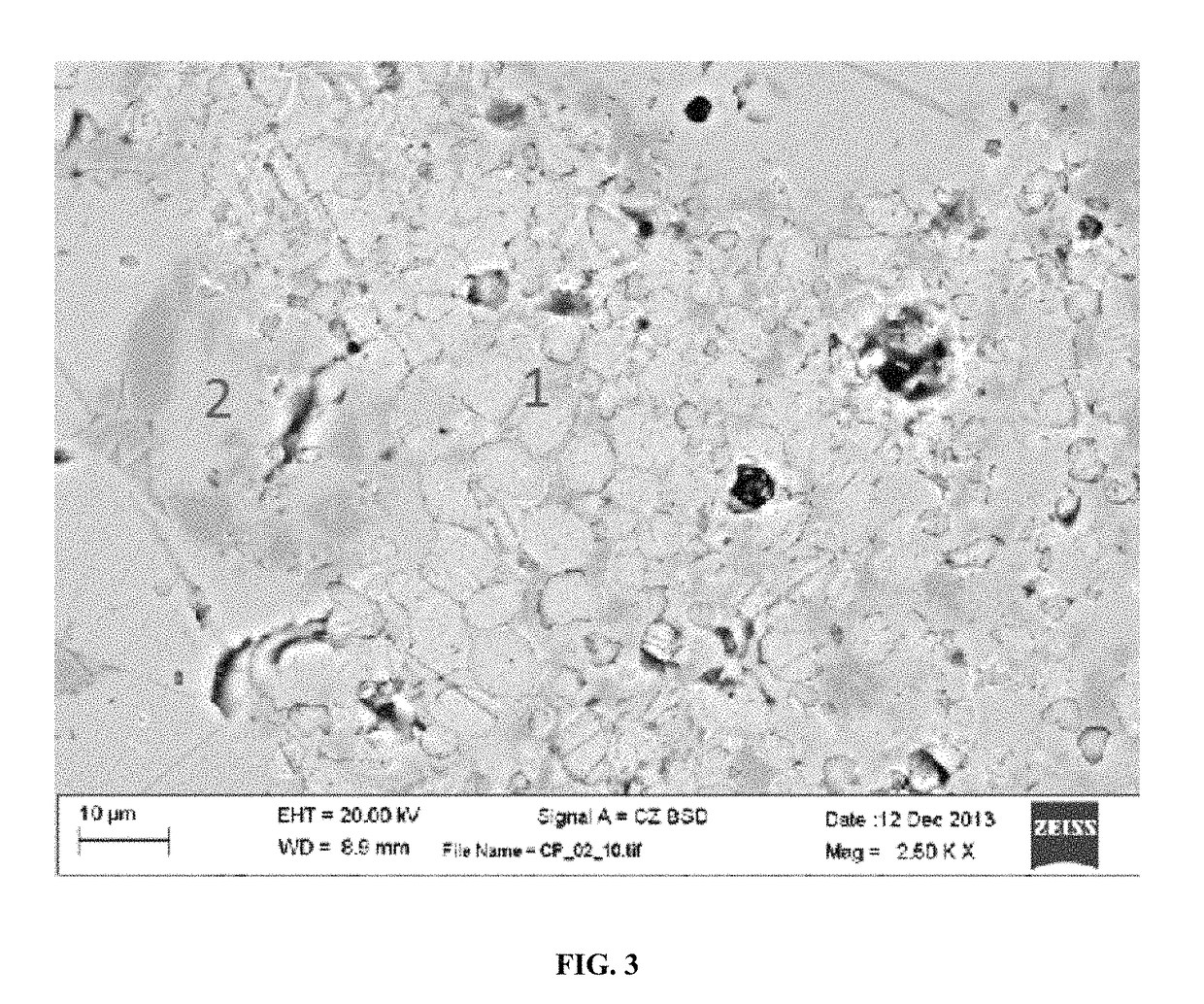

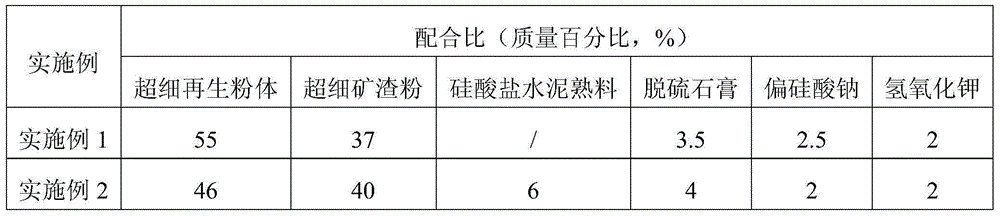

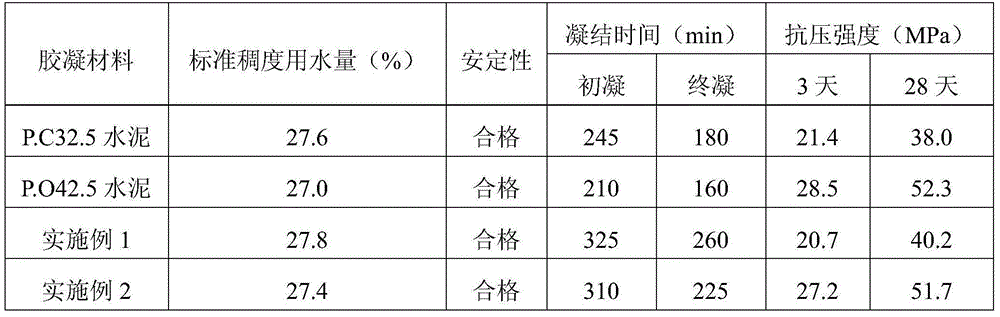

A superfine recycled powder composite geopolymer gelling material

ActiveCN103787602BIncrease valueEasy to useSolid waste managementCinker content reductionSodium metasilicateBrick

Owner:北京联绿技术集团有限公司

Accelerated drying concrete compositions and methods of manufacturing thereof

ActiveUS10000414B2High retention rateInhibited DiffusionSolid waste managementCinker content reductionWater vaporWater soluble

Owner:U S CONCRETE

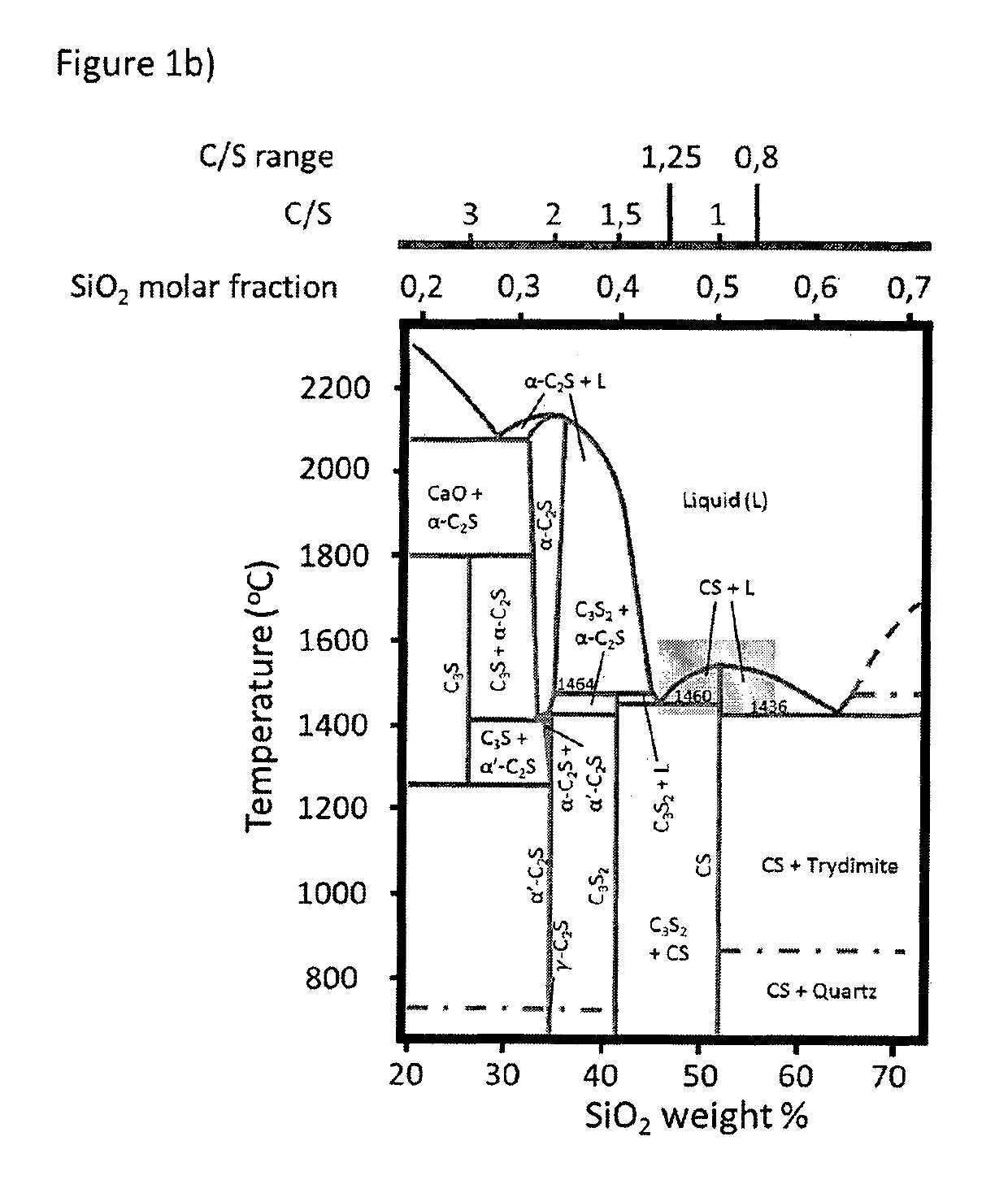

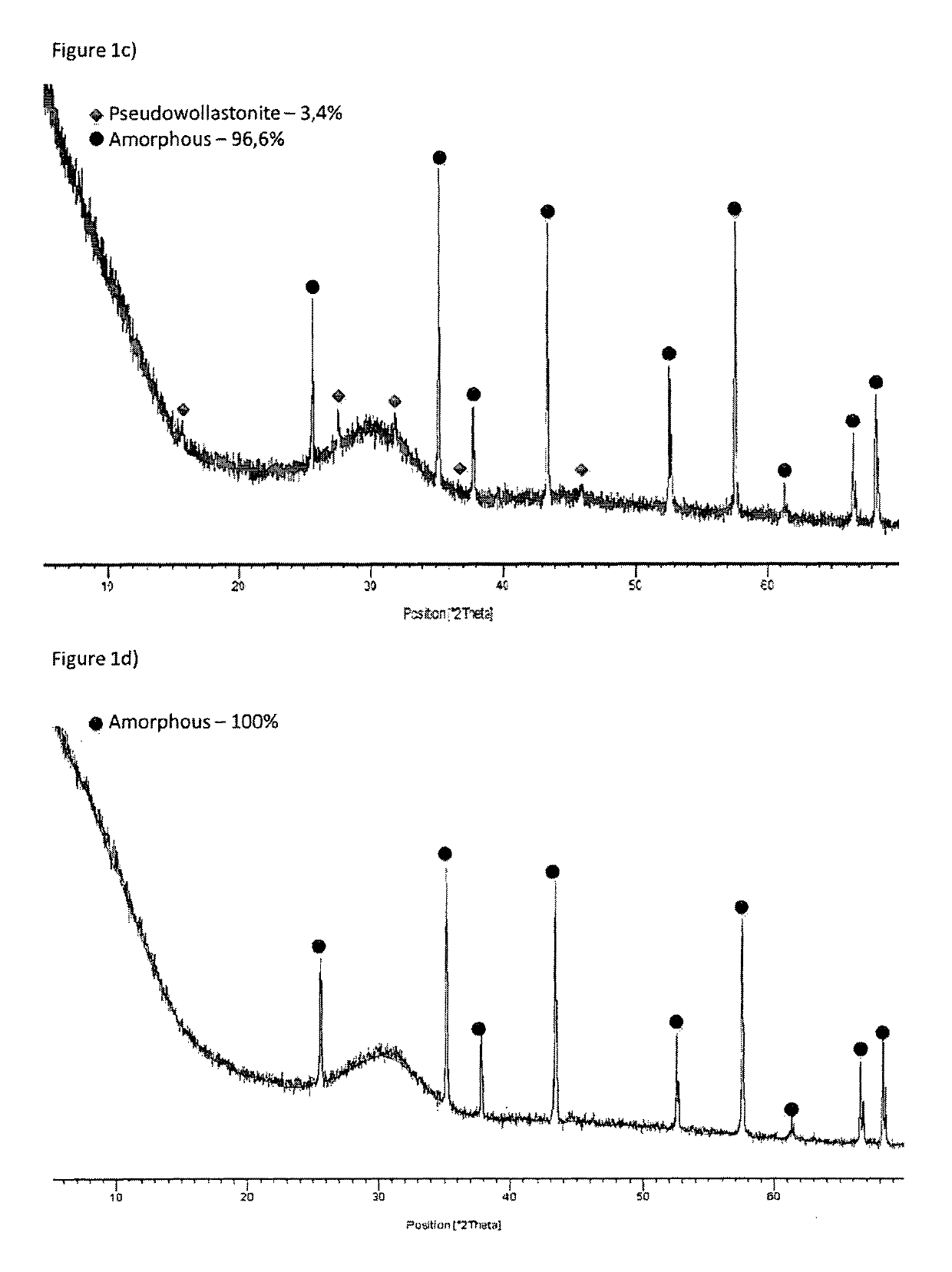

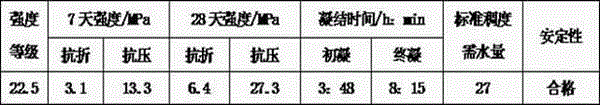

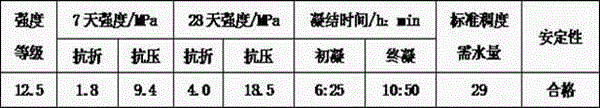

Amorphous low-calcium content silicate hydraulic binders and methods for their manufacturing

The invention relates to a hydraulic binder consisting essentially in a hydraulically active amorphous calcium silicate phase, having in its constitution less than 20% in weight of a crystalline material. The said hydraulically active amorphous calcium silicate phase is a continuous matrix that may contain embedded fractions of crystalline material, being the overall C / S molar ratio of this hydraulic binder comprised between 0.8 and 1.25.The crystalline fraction of this material is essentially composed by wollastonite in both of its polymorphic structures, α and β. Furthermore, the invention relates to methods of producing the hydraulic binder by liquefying the raw materials, in a specified C / S molar ratio, followed by fast cooling to room temperature. Finally, the invention relates to a building material made by setting the binder or a mixture containing this binder with water and subsequent hardening.The invention enables the production of a hydraulic binder with a significant reduction of CO2 emissions, when compared to OPC clinker, by reducing the amount of limestone in the raw materials while obtaining competitive overall values of compressive strength of the hardened material.

Owner:CIMPOR PORTUGAL SGPS SA +1

An ecological cementitious material

ActiveCN102515588BReduce manufacturing costReduce consumptionCinker content reductionSodium metasilicateBrick

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

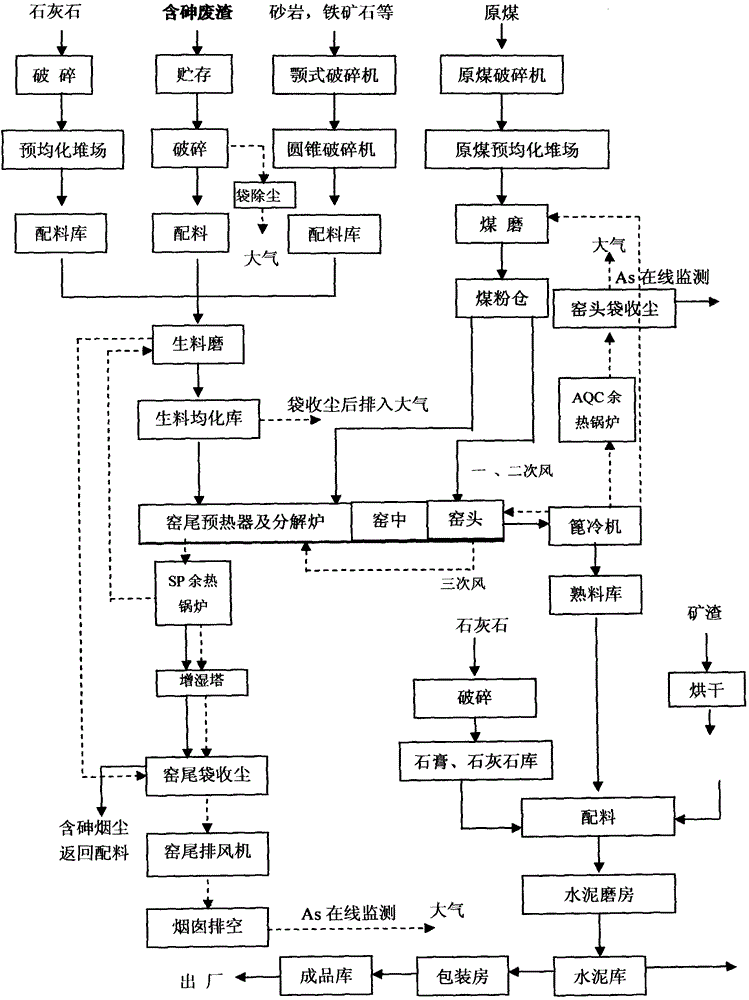

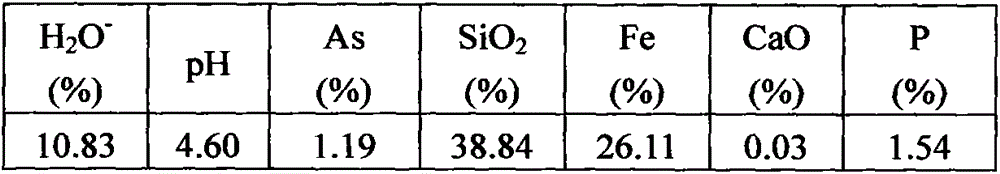

A method for treating waste residue containing arsenic by cement rotary kiln

ActiveCN103755169BReduced activityRealize harmless disposalCinker content reductionResource utilizationSlag

The invention discloses a method for treating arsenic-containing waste residues by using a cement rotary kiln, belonging to the field of solid waste and hazardous waste treatment and disposal technologies. The method comprises the steps of (1) mixing the arsenic-containing waste residues with a cement raw material to obtain a raw material for preparing a cement clinker, wherein the arsenic-containing waste residues account for 0.6-4.0% of the weight of the raw material; and (2) putting the raw material obtained by mixing in the step (1) into the cement rotary kiln to prepare an arsenic-containing cement clinker. The method disclosed by the invention has the advantages that the arsenic-containing waste residues are treated through the existing dry method cement rotary kiln to facilitate harmless and resource utilization of the arsenic-containing waste residues, potential environmental pollution risks and secondary pollution during harmless treatment of the arsenic-containing waste residues are effectively controlled, and the environmental benefit and economic benefit are obvious.

Owner:云南省环境科学研究院(中国昆明高原湖泊国际研究中心)

A kind of preparation method of active manganese slag micropowder

ActiveCN103880307BImprove activity indexReduce pollutionCinker content reductionClinker (waste)Red mud

The invention discloses a preparation method of active manganese residue micro powder. The preparation method comprises the following steps: (1) preparing materials in percentage by weight: 70%-90% of manganese residues, 4%-16% of red mud and 5%-20% of cement clinker, wherein the red mud refers to Bayer-process red mud or sintering-process red mud with over 1% (in percent by weight) of K2O and Na2O in total; (2) respectively drying the red mud and the manganese residues in the step (1) until moisture content is smaller than 1%; (3) respectively grinding the cement clinker, the red mud in the step (2) and the manganese residues in a ball mill until specific surface area is 380 m<2> / kg-450m<2> / kg for later use; and (4), preparing the micro powder in the step (3) according to the proportion in the step (1), and uniformly mixing to obtain the active manganese residue micro powder. Based on a current situation that activity of manganese residues is low, and a comprehensive utilization problem of the red mud is to be solved, active indexes of the manganese residue micro powder are improved by adding a certain amount of red mud and cement clinker to stimulate activity of the manganese residue micro powder; and meanwhile, a certain amount of red mud is consumed, so that pollution of red mud on environment is reduced, and resource utilization of waste residues is realized.

Owner:湘潭市华昇环保科技有限公司

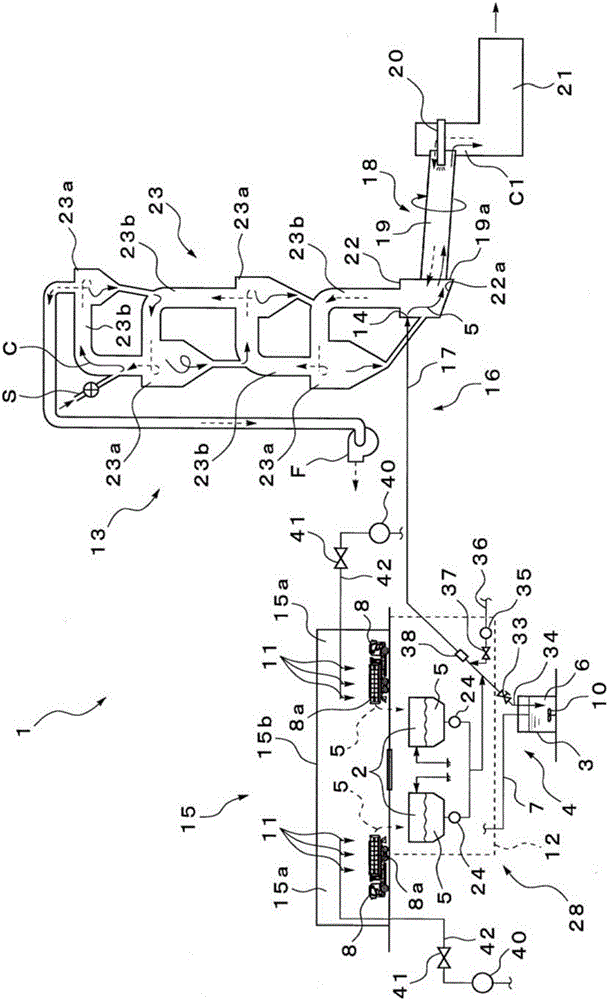

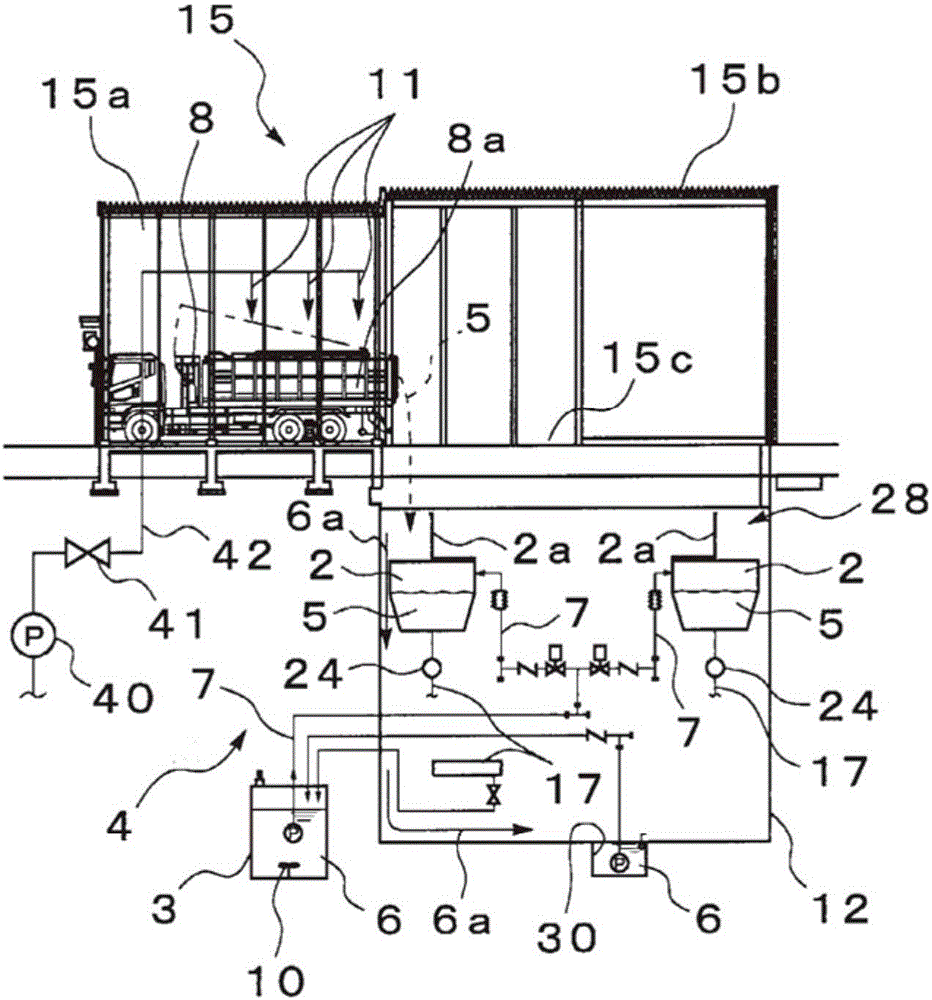

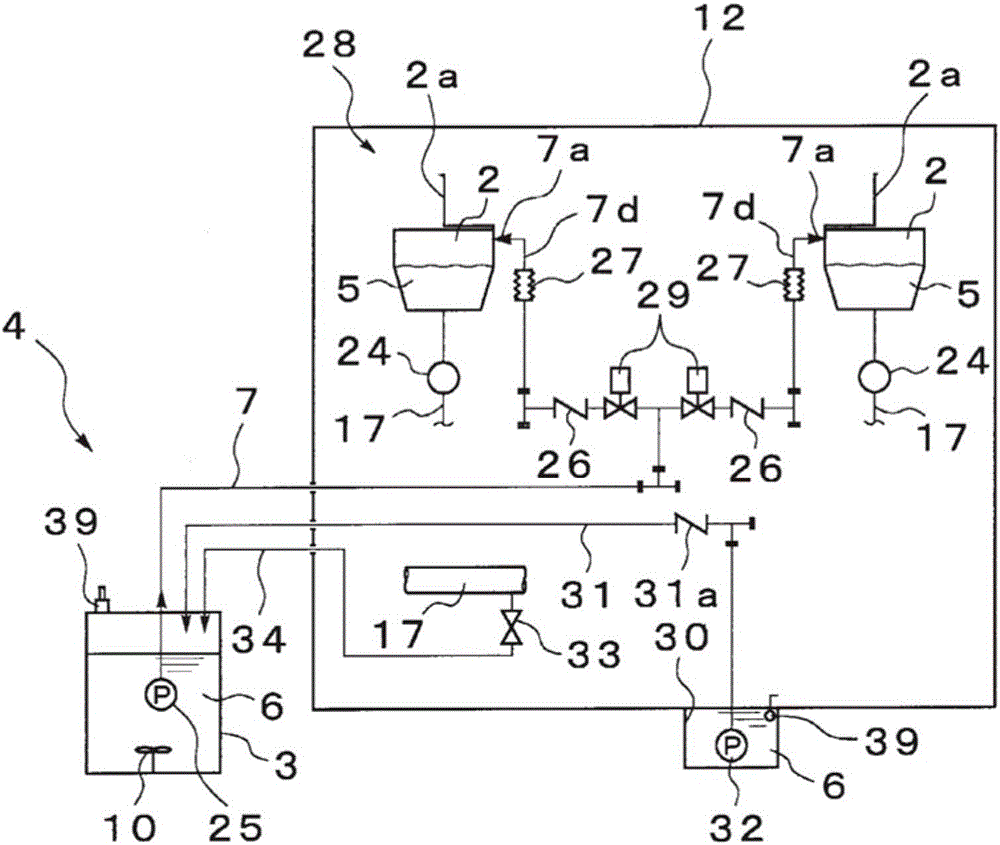

Sludge treatment equipment

ActiveCN104136382BAvoid storageReduce the burden onSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgeSewage

Provided is sludge treatment facility that can spray contaminated water evenly in water-containing sludge that has been deposited in a sludge hopper. This sludge treatment facility (1) is provided with a contaminated water recovery mechanism (4) which comprises: a contaminated water recovery tank (3) for recovering contaminated water (6) resulting from cleaning either a sludge hopper (2) that stores water-containing sludge (5) transported from a sewage treatment plant by truck (8) or pipes in the sludge treatment facility (1); and a contaminated water return pipe (7) that transports the water from the contaminated water recovery tank (3) to the sludge hopper (2). The water-containing sludge (5) that is stored in the sludge hopper (2) is treated by a cement manufacturing process (13). A water spraying unit (7a) on the sludge hopper (2) side of the contaminated water return pipe (7) is disposed above the dropping position for the water-containing sludge (5) into the sludge hopper (2) from the truck (8) such that the contaminated water (6) is sprayed onto the peak (5a) of the water-containing sludge (5) that has collected within the sludge hopper (2).

Owner:MITSUBISHI MATERIALS CORP

52.5-grade slag portland cement and preparation method thereof

ActiveCN102627419BReduce heat of hydrationExtended service lifeCinker content reductionSlagPortland cement

Owner:SHANGHAI HAILI NEW ENVIRONMENTAL PROTECTION BUILDING MATERIAL CO LTD

Ultra low-alkali portland cement and production method thereof

The invention relates to a production method of ultra low-alkali portland cement, characterized by strictly selecting crude fuel with low alkali content and using a scientific clinker formula, wherein, the scientific clinker formula comprises that: the lime saturation factor (LSF) is 95+ / - 1.5, the silica modulus (SM) is 2.20 + / -0.1, the aluminium modulus (AM) is 0.80+ / -0.1, so that the optimal proportioning principle of raw material consisting of 80.3 wt% of high calcium limestone, 12.5 wt% of high silicon sandstone, and 7.2 wt% of converter slag is calculated. According to the invention, the silicate cement clinker produced by using a wet-grinding dry-sintering semidry method has the f-CaO of no larger than 1.0 %, and the litre weight of no less than 1100 g / l; an optimal formula of cement material comprising a ratio of ultra low-alkali portland clinker to ferroalloy slag to high calcium limestone of 70-90 to 7-13 to 4-8 to 2-7 is used to produce 425# ultra low-alkali portland cement, wherein, the alkali content is no larger than 0.4 %, the average alkali content is 0.37 %, so that the international standards of low alkali cement are satisfied.

Owner:GUANGXI YUFENG CEMENT

A kind of permafrost and silt consolidation material

InactiveCN103396018BStability is not affected by water immersionCinker content reductionSludgeWater immersion

The invention discloses a concretionary material for even frozen soil and sludge. The concretionary material is prepared by following steps: a gel master batch is prepared by grinding C3S-C2S-C4A3S<^>-CaO main mineral clinker, gypsum and industrial mine tailing together; and then 8 to 15% of quicklime powder is added. The C3S-C2S-C4A3S<^>-CaO main mineral clinker is prepared by adding excess CaO into CaO-SiO2-Al2O3-Fe2O3-SO3 pentabasic cement raw batch, wherein the content of the excess calcium oxide b-CaO is between 5 to 8%, basicity coefficient Km is between 1.0 to 1.3, and the mineral clinker is prepared by calcining under 1200 to 1300 DEG C. Stability of the concretionary material for even frozen soil and sludge is seldom influenced by water immersion, so that the concretionary material is especially suitable for engineering construction such as roadbed, riverbed and mountain trail.

Owner:大连铭源全建材有限公司

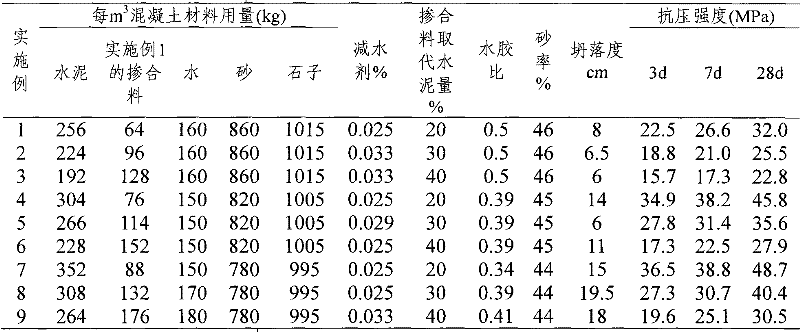

Admixture of active powder of ball milling steel slag tailing slurry and application thereof in preparing concrete

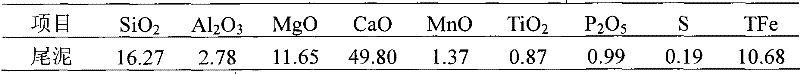

InactiveCN101544480BReduced influence of volume stabilityLow chemical activityCinker content reductionSlagSlurry

The invention relates to an admixture of active powder of ball milling steel slag tailing slurry and the application thereof in preparing concrete. Firstly, the ball milling steel slag tailing slurry with high water content is naturally air-dried and air-cured until the water content of the same is less than 10 percent; secondly, the ball milling steel slag tailing slurry is dried, dehydrated andheated at certain temperature so as to cause the water content of the same to be less than 4 percent, natural gypsum and the dried broken ball milling steel slag tailing slurry are proportionally mixed in a ball mill to be milled into certain fineness so as to be used as concrete admixture; and due to the adoption of proper concrete mixing proportion, the admixture of active powder of ball milling steel slag tailing slurry can be used for partially replacing cement gel according to the weight percentage of 20 to 40 percent, and the concrete with C20-C40 strength degree can be prepared. The invention efficiently utilizes solid wastes of steel enterprises, changes the solid wastes into valuable and has simple production process, obviously reduced concrete production cost and favorable economic and environmental benefit.

Owner:LAIWU IRON & STEEL GRP

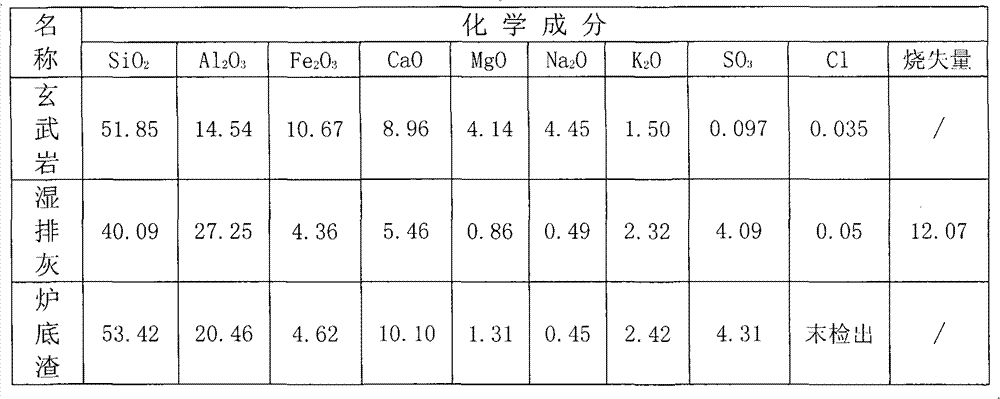

Compound coal ash for concrete

ActiveCN102503199BImprove mechanical propertiesIncreased durabilityCinker content reductionSlagMechanical property

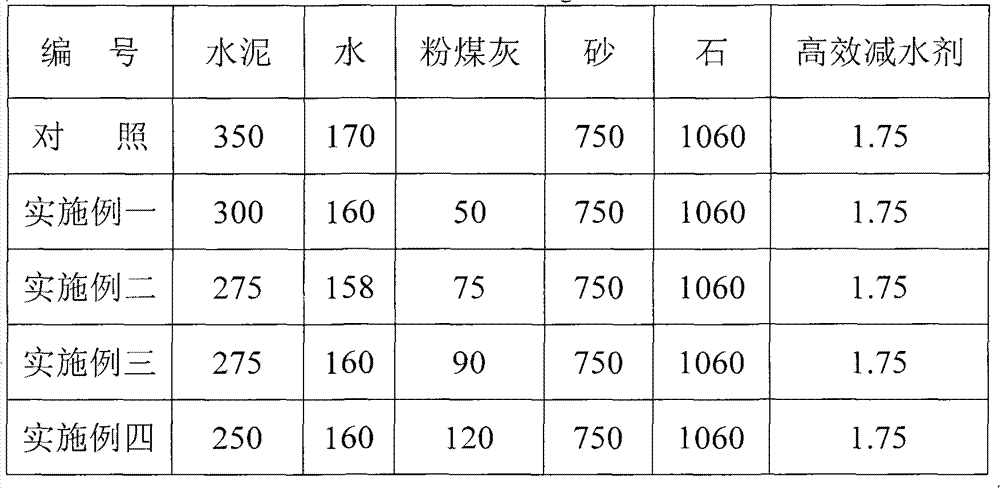

The invention relates to compound coal ash for concrete. The compound coal ash for concrete is prepared according to the following steps: mixing basalt macadam with a grain size less than 50 millimeters and wet coal ash with a moisture content of 15 to 25 percent with hearth slag; drying the mixture; grinding the mixture into powder; and controlling the fineness being 45 microns and the residue on a square hole screen being less than 15 percent and the moisture content of the ground powder being less than 0.5 percent. The production process is simple; the cost is low; the industrial wastes, such as wet coal ash, hearth slag, and the like, are taken as raw materials; a part of cement in the concrete can be replaced by the obtained compound coal ash; the mechanical property and the durability of the concrete can be efficiently increased; the resource and energy source are saved; the industrialized production is boosted; and the environmental protection and the energy saving and emissionreduction are boosted.

Owner:HAINAN LANDAO ENVIRONMENTAL PROTECTION IND

Binder based on activated ground granulated blast furnace slag useful for forming a concrete type material

ActiveUS9856174B2Improve mechanical propertiesLow costCinker content reductionAluminum sulphateSodium hydroxide

A binder material useful for forming a concrete type material includes, calculated on a dry, water and carbon dioxide free basis, a base component constituting 50-95 wt % of the binder material, the base component having ground granulated blast furnace slag and an activator component constituting 5-50 wt % of the binder material. The activator component includes aluminum sulfate and a sodium hydroxide generating compound. The final binder material includes, calculated on a dry, water and carbon dioxide free basis, ground granulated blast-furnace slag 35-95 wt %, aluminum sulfate AI2(SO4)3 1-25 wt %, and sodium hydroxide generating compound 4-35 wt %.

Owner:STEINKELLER STEPHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com