Patents

Literature

246results about How to "Low alkali content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium transition metal complex oxide for lithium ion secondary battery cathode active material and method for producing the same, lithium ion secondary battery cathode active material, and lithium ion secondary battery

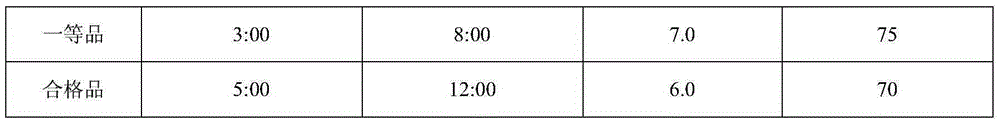

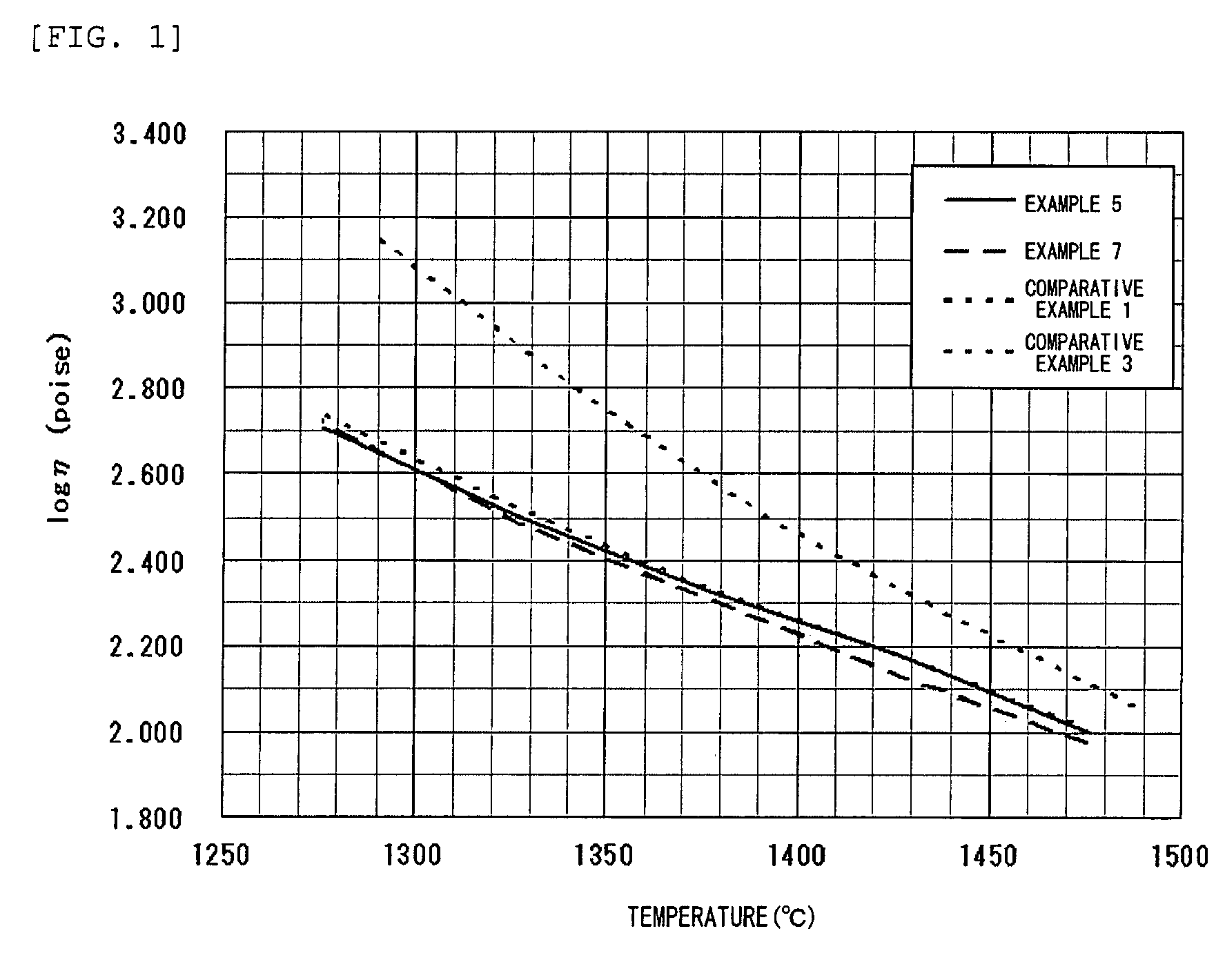

InactiveUS20080241693A1Improve featuresAvoid security issuesIron compoundsCobalt compoundsLithium compoundSilicon

A lithium transition metal complex oxide for a lithium ion secondary battery cathode active material contains 100 to 1000 ppm of silicon and 300 to 900 ppm of fluorine. A method for producing the lithium transition metal complex oxide includes the step of mixing a lithium compound, a transition metal compound, a fluorine compound, and a silicon compound to prepare a raw material mixture, and the step of firing the raw material mixture to produce the lithium transition metal complex oxide.

Owner:NIPPON CHECMICAL IND CO LTD

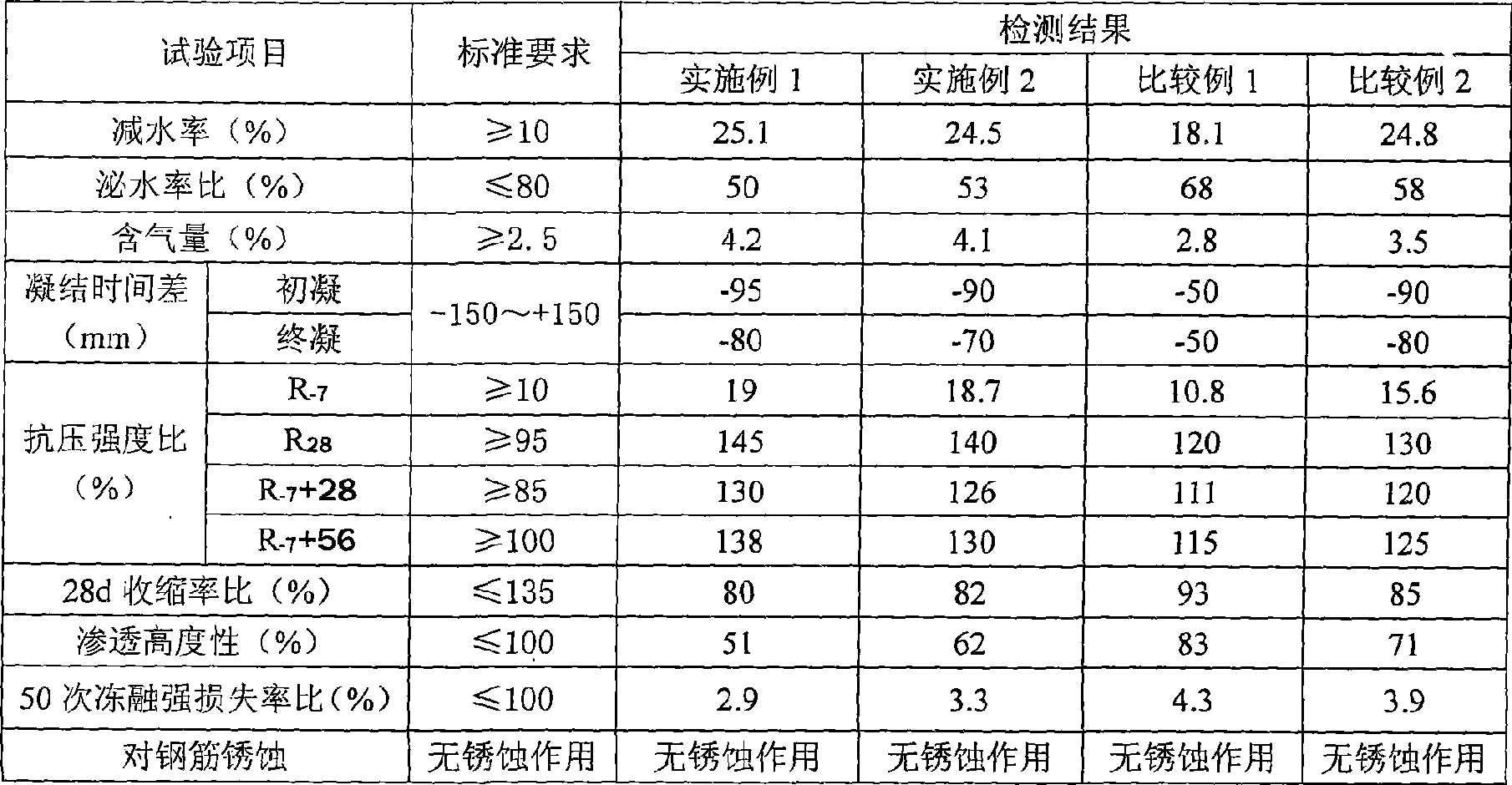

High-early strength antifreezing polycarboxylate high performance water reducing agent and preparation

The invention discloses an early-strength antifreezing polycarboxylate high-performance water reducing agent and a method for preparing the same. The early-strength antifreezing water reducing agent is prepared from a polycarboxylate water reducing agent, an early-strength antifreezing agent, an air entraining agent and water. The method comprises the following steps: A, the synthesis of the polycarboxylate high-performance water reducing agent: (1) esterification reaction; adding methacrylic acid, and the like to a reaction kettle, and (2) polymerization reaction; heating big monomer methoxy polyethyleneglycol methacrylic ester; B, the preparation for the solution of an early-strength antifreezing agent: a, weighing water and adding the same to the reaction kettle, and adding calcium formate to the reaction kettle, and b, adding triethanolamine, and the like to the reaction kettle to prepare the early-strength antifreezing agent solution; C, the preparation of the air entraining agent: weighing water and adding the same to the reaction kettle, and adding powdered three-level colophony to the reaction kettle to obtain the air entraining agent; and D, the preparation of the finished product: weighing the polycarboxylate water reducing agent and adding the same to the reaction kettle, and adding the air entraining agent and the early-strength antifreezing agent solution to the reaction kettle. The early-strength antifreezing polycarboxylate high-performance water reducing agent has higher water reducing rate and remarkable enhancing effect, and is suitable to prepare various common concrete and high-performance concrete at a negative temperature range of between 20 DEG C below zero and 0 DEG C.

Owner:武汉市联合石油化工有限责任公司

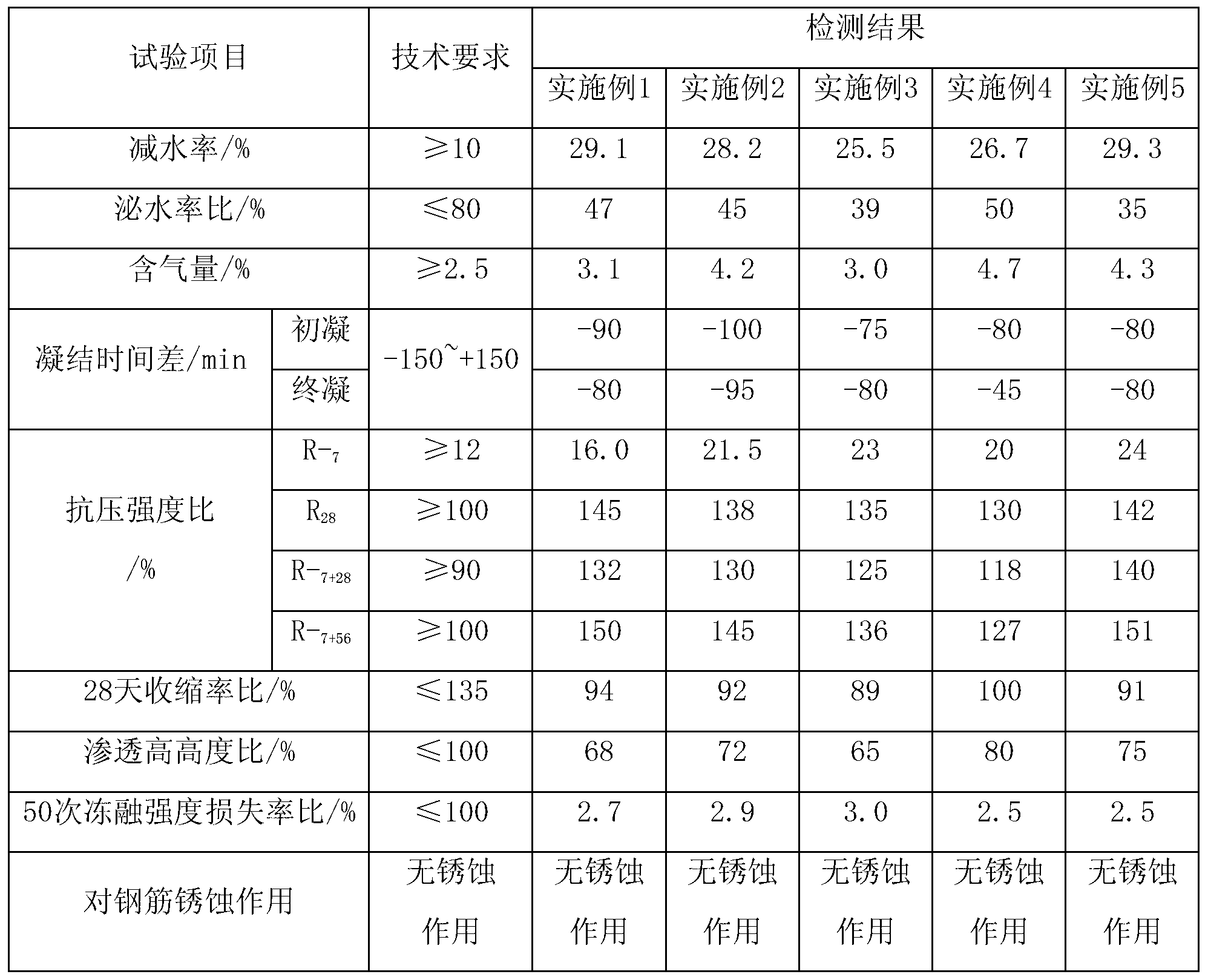

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Novel alkali-free liquid accelerator based on synthesis of polymeric aluminum sulfate

ActiveCN105271867ALow alkali contentReduce the risk of alkali-aggregate reactionAlkali freeSynthesis methods

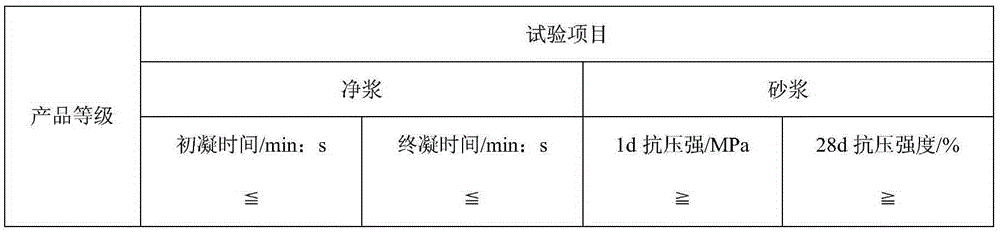

The invention discloses a polymeric aluminum sulfate synthesis method and discloses a preparation method of a novel alkali-free liquid accelerator based on synthesis of polymeric aluminum sulfate. According to the alkali-free accelerator, an aluminum sulfate solution is neutralized by ammonia water, active aluminum hydroxide gel is prepared, active aluminum hydroxide is filtered, dried and ground into powder, then the aluminum sulfate solution is added, and the polymeric aluminum sulfate is prepared. The alkali-free accelerator comprises, in percentage, 45%-55% of the polymeric aluminum sulfate, 0%-5% of inorganic acid, 0%-2% of a stabilizer, 0%-2% of an organic early strength agent, 0%-2% of an organic tackifier and the balance of water. The cement setting time and the colloidal mortar strength of the accelerator can meet the requirement of first-class accelerators for JC477-2005 sprayed concrete under the condition of the lower mixing amount, and meanwhile, the accelerator is an alkali-free liquid accelerator and can effectively avoid adverse effects caused by excessively high alkali content. The cement types of the accelerator have good adaptability.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Crystallized glass

InactiveUS20090118113A1Improve productivityReduce manufacturing costMagnetic materials for record carriersRecord information storageIn planeMaterials science

In all of an in-plane magnetic recording system and a perpendicular magnetic recording system, there is provided a crystallized glass for a disk substrate for information recording medium, etc., which has satisfactory surface properties capable of sufficiently adapting with a lamp loading system for high-density recording, has high strength such that it is able to withstand high-speed rotation and impact, has heat expansion properties and heat resistance in agreement with respective drive members, has a low melting temperature, has excellent productivity and is reduced in the elution amount of an alkali from the raw material, namely excellent in chemical durability. The crystallized glass of the invention is a crystallized glass containing an SiO2 component and an Li2O component; further containing at least one member selected from an SrO component and a BaO component in a total content of more than 3.5% and not more than 15% in terms of % by mass; and containing at least one member selected among lithium disilicate, lithium monosilicate, α-quartz, an α-quartz solid solution and a β-quartz solid solution as a main crystal phase on the oxide basis.

Owner:OHARA

Super plasticizer of polyether for rapid hardening concrete

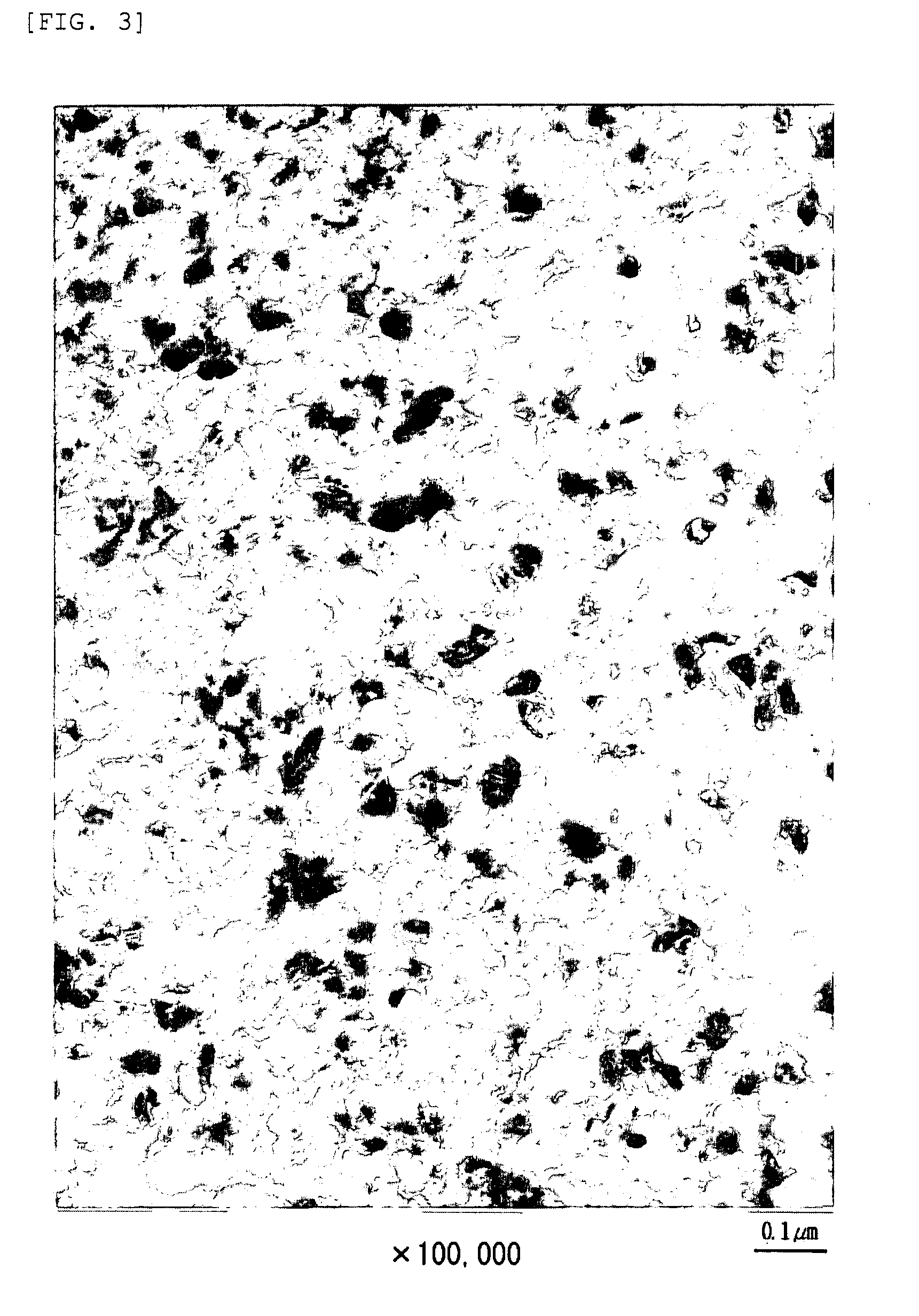

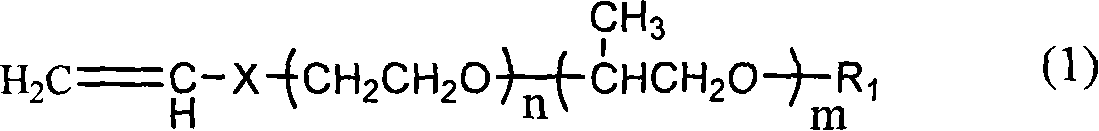

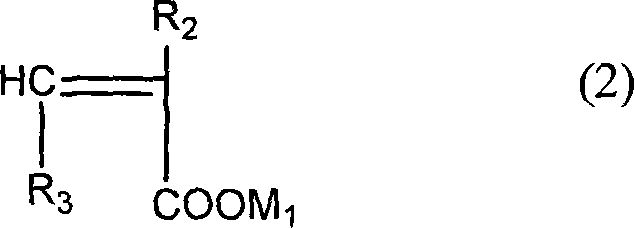

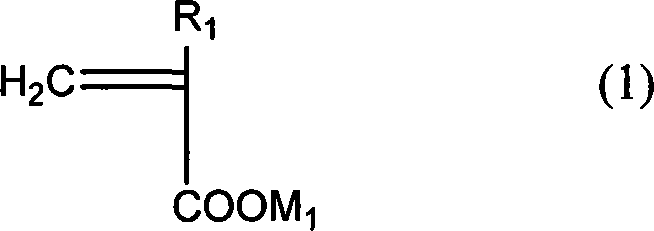

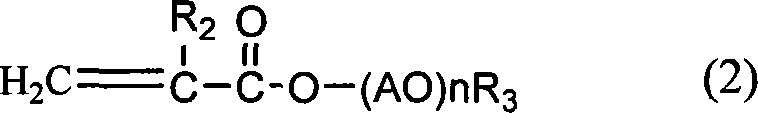

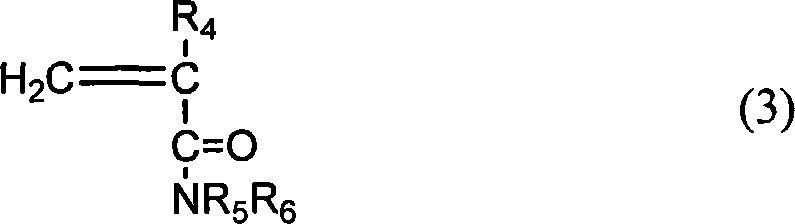

ActiveCN101066853AReduce drying shrinkageOvercoming the defect of increasing concrete drying shrinkageWater basedPlasticizer

The present invention relates to one kind of super plasticizer of polyether for rapid hardening concrete. The super plasticizer is prepared through the first free radical copolymerization of monomer A in 84-94 wt%, monomer B in 5-15 wt% and monomer C in 1-3 wt% in water-base medium; and the subsequent neutralization reaction of the copolymer and alkoxyl organic amine to regulate the pH value of the copolymer to 6.0-7.5. The super plasticizer has excellent dispersing performance and reinforcing effect, especially obvious early reinforcing effect, and is favorable to raise construction speed and raising the durability of concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

Red mud dealkalization method

ActiveCN101423318ALow alkali contentRemarkable effect of sodium removalSludge treatmentSocial benefitsBrick

The invention discloses a dealkalization method for red mud. The method comprises a dilute sulphuric acid dealkalization step and a pressure calcium oxide dealkalization step. Red mud is prepared into slurry and introduced into a grinder to be ground; according to the content of alkaline in the red mud, the slurry is slowly added with required dilute sulphuric acid to be ground, filtered and washed to obtain a filter cake and the content of alkaline in the filter cake is analyzed; according to the analyzed content of alkaline in the filter cake, the filter cake is added with calcium oxide and uniformly mixed to be introduced to a high pressure reaction kettle and heated for reaction, and after reaction, the mixture is cooled, filtered and washed; and the obtained filter cake is dried and content of alkaline in the dried filter cake is analyzed. The invention can use only the pressure calcium oxide method to carry out dealkalization of the red mud. Red mud subjected to dealalization treatment of the method has low alkaline content and can be used more in fields such as concrete production, high quality brick and transformed brickproduction. The method solves the problem of the red mud of severe pollution and achieves remarkable economic and social benefits.

Owner:中国长城铝业有限公司

Glass fiber for reinforcing polycarbonate resin and polycarbonate resin formed article

To provide a glass fiber which can improve the refractive index of the glass fiber to the same level as a polycarbonate and maintain the transmittance of a molded product after the fiber is reinforced, and a glass fiber-reinforced polycarbonate resin molded product using the glass fiber. A glass fiber to be used as a glass fiber for reinforcing a polycarbonate resin comprising, as inorganic components in whole glass fiber, from 50 to 60 mass % of SiO2, from 10 to 15 mass % of Al2O3, from 15 to 25 mass % of CaO, from 2 to 10 mass % of TiO2, from 2 to 8 mass % of B2O3, from 0 to 5 mass % of MgO, from 0 to 5 mass % of ZnO, from 0 to 5 mass % of BaO, from 0 to 5 mass % of ZrO2, from 0 to 2 mass % of Li2O, from 0 to 2 mass % of Na2O and from 0 to 2 mass % of K20, wherein the total content of the above Li2O, Na2O and K2O is from 0 to 2 mass % based on the above whole glass fiber, and the refractive index of the above glass fiber is from 1.580 to 1.590.

Owner:ASAHI FIBER GLASS CO LTD

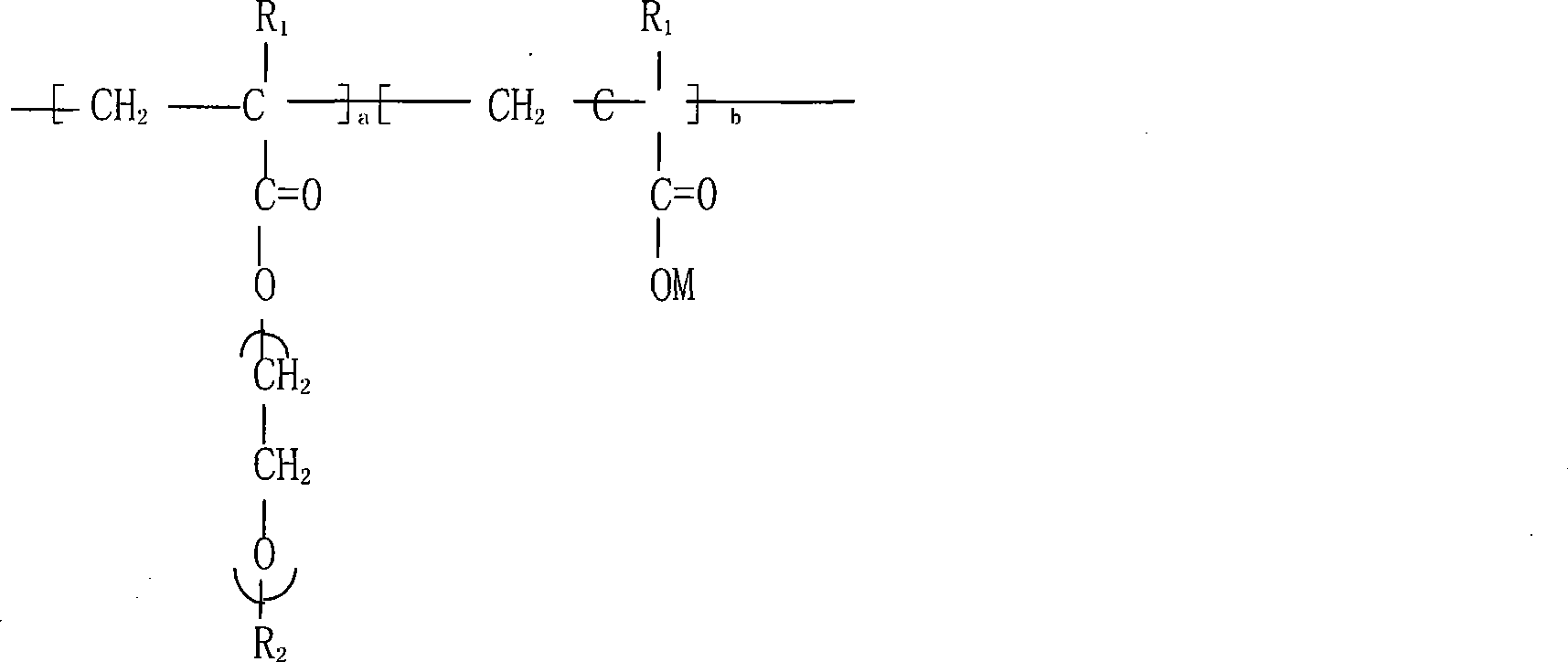

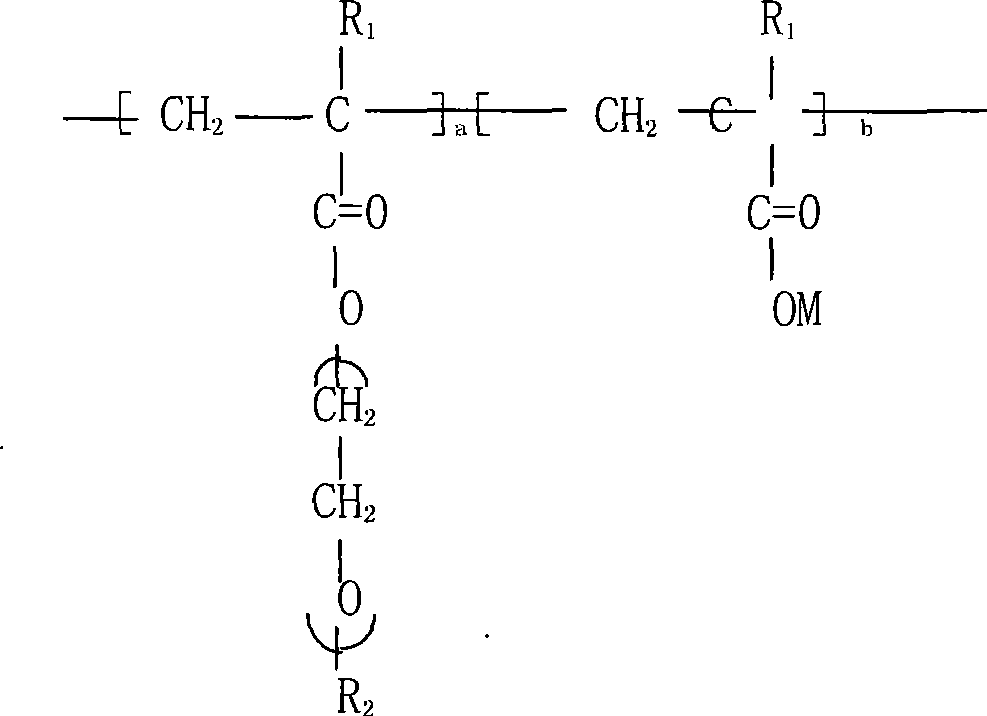

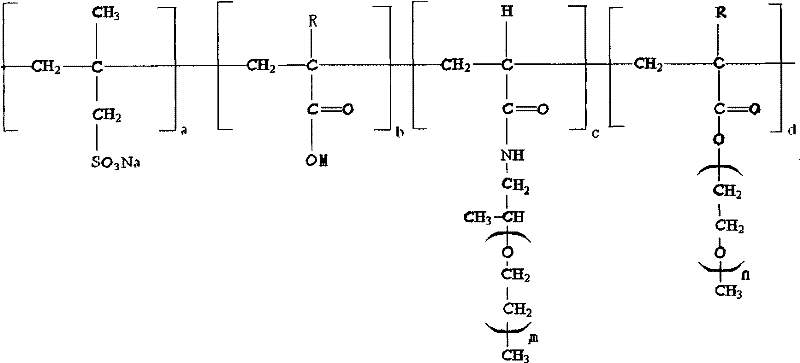

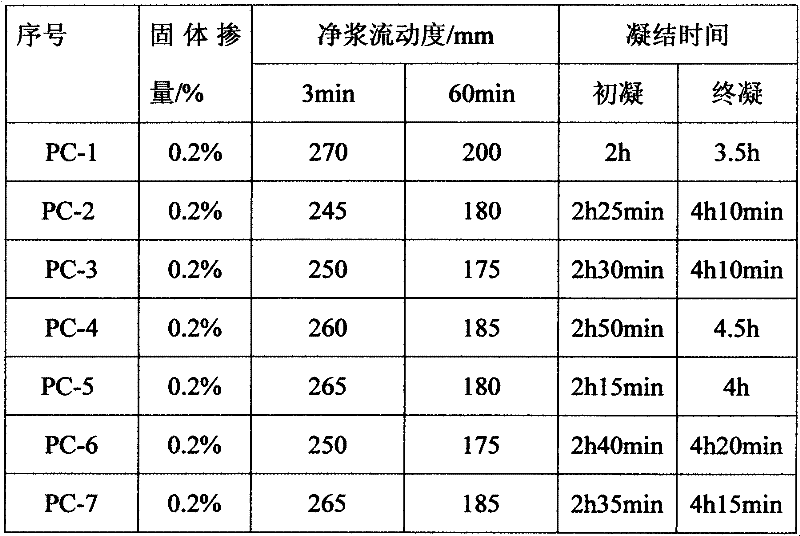

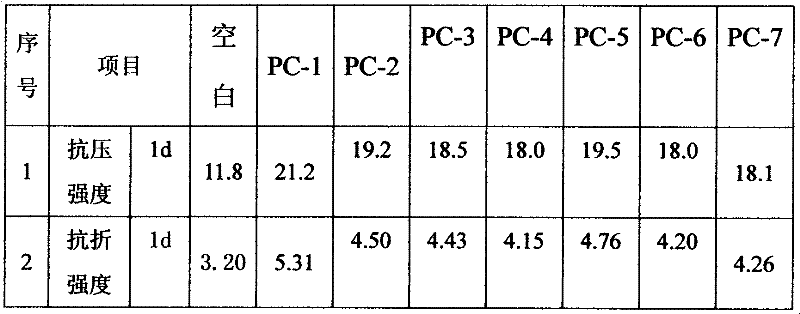

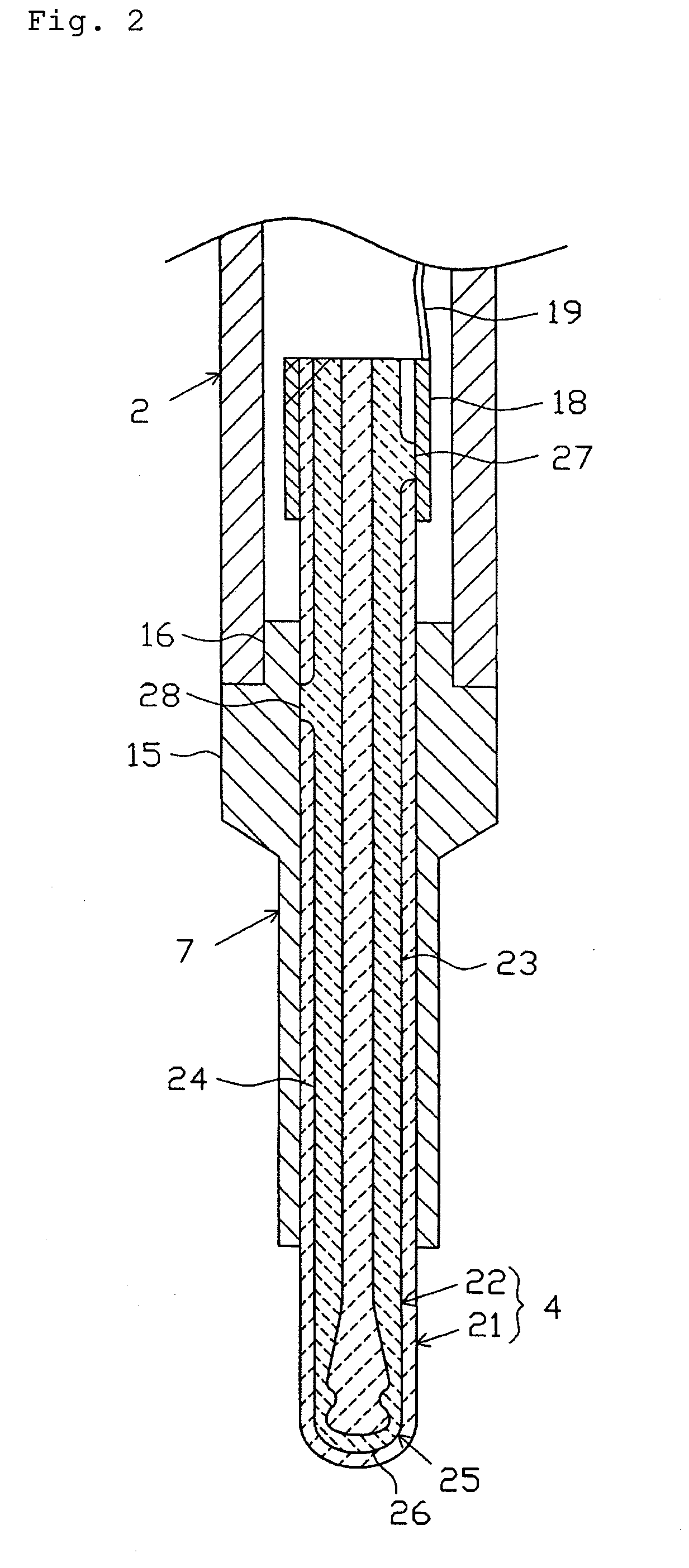

Early-strength polycarboxylic acid water reducing agent

The invention relates to an early-strength polycarboxylic acid water reducing agent and a preparation method thereof. The early-strength polycarboxylic acid water reducing agent is in a liquid state, and the solid content is 40%. The preparation method comprises the following steps: polymerizing modified polyoxyethylene ether or polyoxypropylene ether, (methyl)acrylic acid or itaconic acid, acrylamide, sodium methyl propenyl sulfonate and other monomers under the actions of a molecular weight chain initiator and a chain transfer agent; and neutralizing to obtain the water reducing agent containing carboxy, amino, sulfonic and polyethenoxy side chains. The early-strength polycarboxylic acid water reducing agent provided by the invention has the advantages of low alkali content and high water reducing rate; and when the early-strength polycarboxylic acid water reducing agent, which accounts for 0.6-1.4 wt of the cementing material, is added to the cementing material, the concrete is labor-saving for operation, and the cement mixture has high flowability and good workability. The early-strength polycarboxylic acid water reducing agent can effectively shorten the setting time and enhance the early strength. The invention has the advantages of simple production technique, easily controlled reaction conditions and no environmental pollution.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

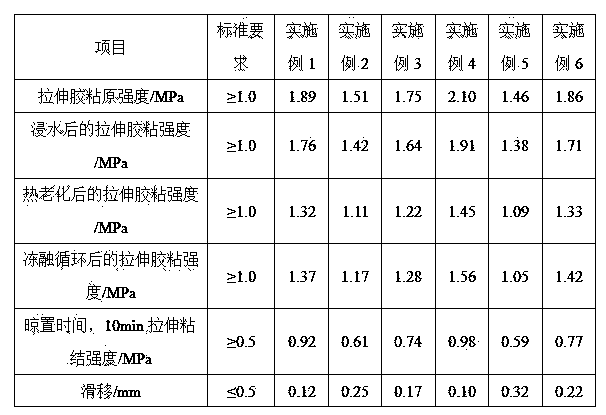

Low-alkalinity tile glue

The invention discloses a low-alkalinity tile glue, which comprises the following components in parts by weight: 30 to 45 parts of cement, 40 to 60 parts of fine aggregate, 8 to 15 parts of filling material, 0.2 to 0.5 part of water-retaining and thickening agent, 0 to 0.1 part of starch ether, 1 to 3 parts of redispersable latex powder, 0.1 to 0.3 part of water reducer, 0.1 to 0.3 part of retarder, 0.1 to 0.4 part of salt-petering resisting agent, 0.1 to 1.0 part of fiber, and 15 to 22 parts of water. The tile glue has the advantages of low alkalinity, salt-petering resistance, good construction performance, high adhesive strength, cavity and cracking resistance, and slippage resistance.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

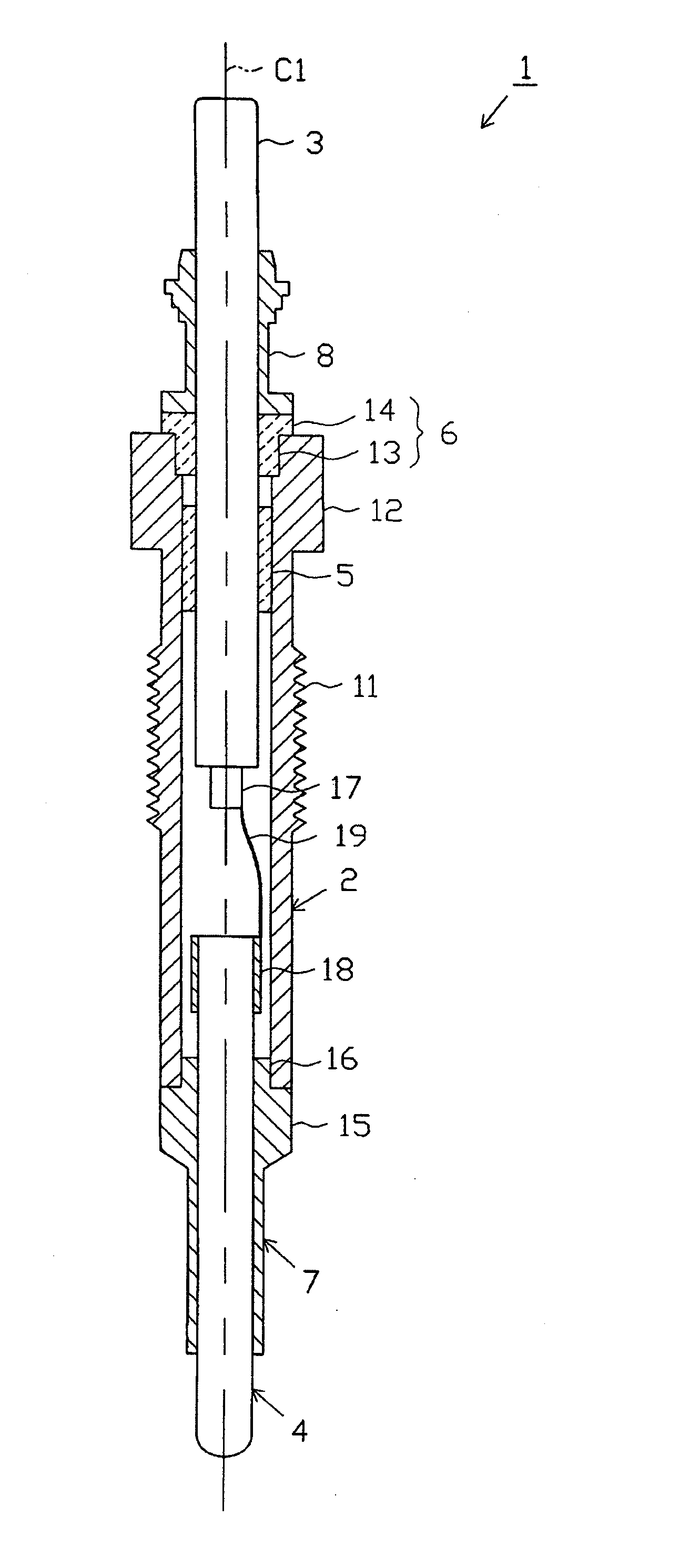

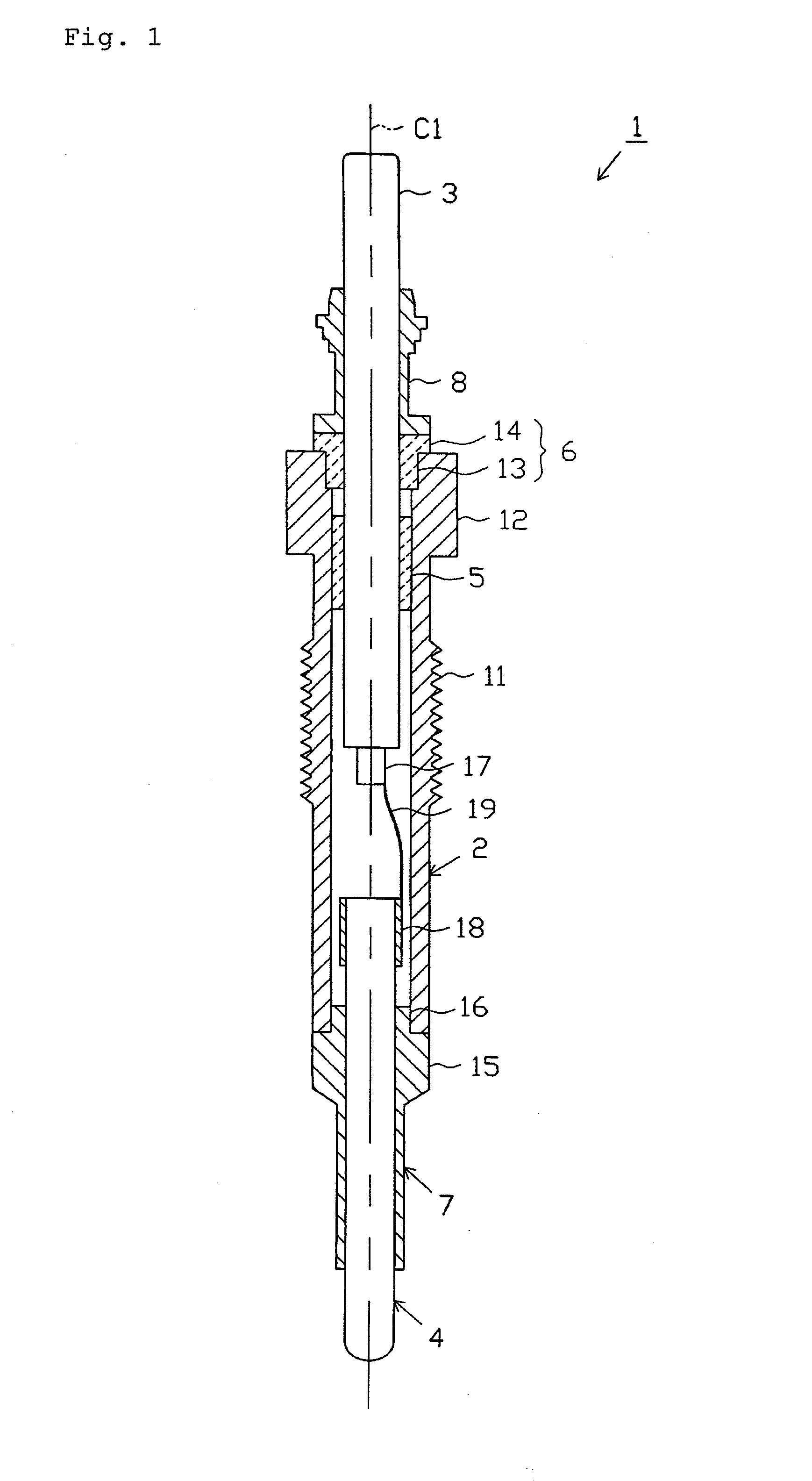

Ceramic Heater and Glow Plug

ActiveUS20090194519A1Reduced strengthProcess controlIncandescent ignitionOhmic-resistance heatingRare-earth elementChromium silicide

Disclosed is a ceramic heater capable of preventing failures due to the thermal stress, such as cracks, and corrosion by a calcium component. The ceramic heater has a heating element including at least one substance selected from silicides, nitrides and carbides of molybdenum and silicides, nitrides and carbides of tungsten as a main component, and a base mainly containing silicon nitride in which the heating element is embedded, wherein the base includes: a rare earth element component in an amount from 4 to 25% by mass in terms of an oxide thereof; a silicide of chromium in an amount from 1 to 8% by mass in terms of chromium silicide; and an aluminum component in an amount from 0.02 to 1.0% by mass in terms of aluminum nitride.

Owner:NGK SPARK PLUG CO LTD

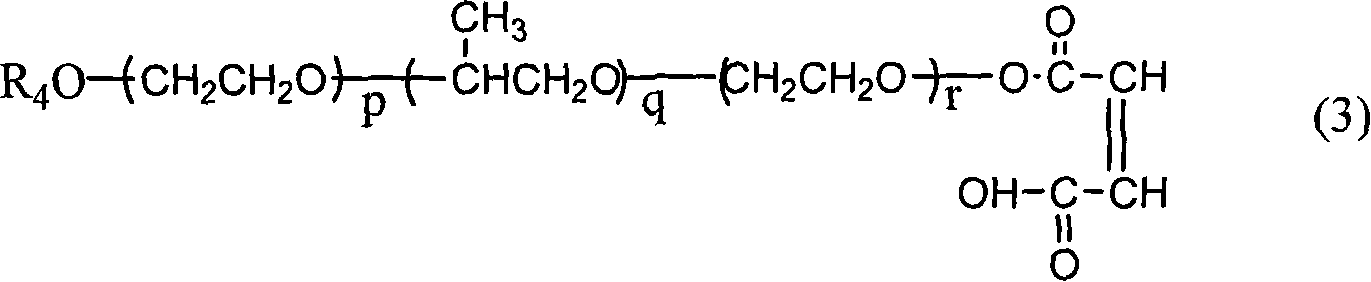

Super controlled release type polycarboxylate slump retention agent and preparation method thereof

The invention discloses a super controlled release type polycarboxylate slump retention agent and a preparation method thereof. The preparation method of the polycarboxylate slump retention agent comprises the following steps: carrying out free radical polymerization on a monomer A, namely polyoxyethylene ether (TPEG), a monomer B, namely maleic anhydride or polyethylene glycol maleic acid esters, a monomer C, namely acrylic acid, a monomer D, namely hydroxyalkyl acrylate or vinyl acetate, an initiator, a chain transfer agent and water, adding an alkaline liquor to neutralize the mixture, wherein a molar ratio of the monomer A to the monomer B to the monomer C to the monomer D is 1 to (1.0-2.5) to (1.0-2.5) to (2.0-4); the dosage of the initiator accounts for 1%-8% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D; the dosage of the chain transfer agent is 1%-3% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D. The super controlled release type polycarboxylate slump retention agent disclosed by the invention is in a liquid state, has solid content of 50%, and has performances of low alkaline content, a low water-reducing rate and excellent slump retention performance. Besides, the production process is simple, the reaction conditions are easy to control, and the environmental pollution is avoided.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

Liquid accelerator for sprayed concrete and preparation method and application thereof

The invention relates to a low rebound low-alkaline liquid accelerator for sprayed concrete, and a preparation method and application thereof, belonging to the technical field of mine and tunnel construction. The liquid accelerator comprises the following components in parts by mass: 35-45 parts of aluminum sulfate, 4-8 parts of triethanolamine, 3-9 parts of sodium fluoride, 1-3 parts of regulating component, 6-12 parts of rebound inhibitor component and 35-55 parts of water. The accelerator can effectively solve the general problem at present that the sprayed concrete has high rebound rate, low strength and poor durability, so that the sprayed concrete has characteristics of high workability (low rebound rate and less dust) and high durability (high strength, high anti-permeability and high corrosion resistance), the construction production environment condition of the sprayed concrete is improved, and long-term safe usability of the sprayed concrete structure is improved.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

Method for preparing regenerated cellulose fibers with cellulose carbamate

InactiveCN102691125AImprove solubilityLow costArtificial filaments from cellulose derivativesWet spinning methodsCarbamateCellulose fiber

The invention relates to a method for preparing regenerated cellulose fibers with cellulose carbamate. The method is characterized by using a solvent composition for dissolving the cellulose carbamate, uniformly dispersing a certain amount of cellulose carbamate in the solvent composition, freezing to the temperature below minus 10 DEG C at a low temperature condition, taking out the frozen mixture and thawing the frozen mixture at a temperature not higher than 50 DEG C, carrying out wet spinning and obtaining the regenerated cellulose fibers after solidifying, washing and drying silk, wherein the solvent composition is a water solution containing 6-10wt% of sodium hydroxide and 0.1-3wt% of zinc oxide. The method has the effect of solving the two problems of difficult dissolution of the cellulose carbamate and instable solution in the previous processes and has high industrial application value.

Owner:WUHAN UNIV +1

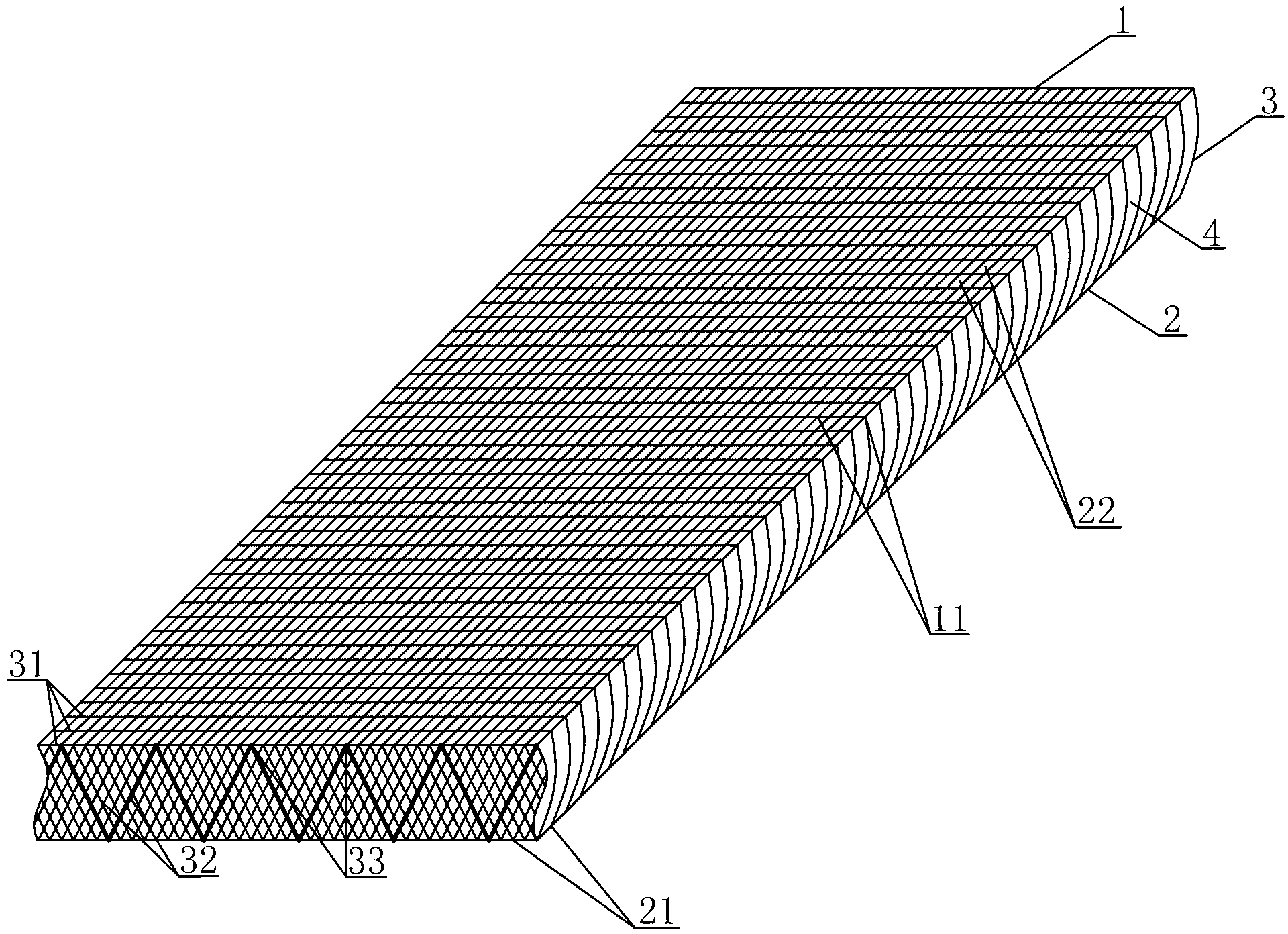

Multifunctional composite carpet and ditch construction technology thereof

The invention discloses a multifunctional composite carpet comprising three-dimensional warp knitting fabric composed of a top layer, a bottom layer and a connecting layer connecting the top layer and the bottom layer. The top layer, the bottom layer and the connecting layer enclose to form a cavity. The multifunctional composite carpet is characterized in that composite which can be solidified is filled in the cavity, the top layer is made of mesh fiber fabric, the bore diameter of each mesh of the mesh fiber fabric ranges from 0.02mm to 60mm, and the meshes in the top layer are in regular or irregular shapes. The multifunctional composite carpet and the ditch construction technology thereof have the advantages of good overall performance, environment friendliness, flexibility in application, convenience in using, mounting, demounting and transporting; the solidified composite can form special materials of mesh composite concrete layer with serialized functions and having certain thickness and hardness; the ditch construction technology is simple in technology, convenient to construct, high in efficiency, good in overall performance and attractive in appearance.

Owner:蔡晓民 +1

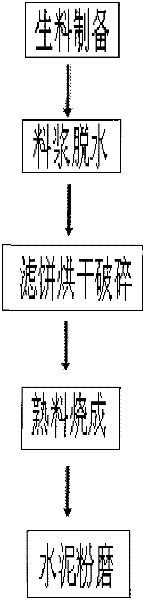

Method using alkaline process to extract alumina in coal ash

ActiveCN102627305AIncrease productivityLow alkali contentSolid waste managementAluminium oxide/hydroxide preparationAluminium hydroxideSlurry

A method using an alkaline process to extract alumina in coal ash relates to a method using coal ash to produce alumina and is characterized by comprising the steps of (1) manufacturing coal ash, limestone or lime into raw slurry with alkali liquid; (2) firing the raw slurry into clinker; (3) performing alkaline leaching on the clinker; (4) desiliconizing leaching liquid to perform liquid-solid separation; (5) carbonating and resolving desiliconized liquid after liquid-solid separation to obtain aluminium hydroxide; (6) roasting the aluminium hydroxide to achieve alumina; (7) performing alkaline leaching on solid phase residues obtained from the step (3); (8) using leaching liquid obtained from the step (7) to adjust molecular ratio of a system in desiliconization treatment; or adding lime in the leaching liquid obtained from the step (7), filtering after reaction, and obtaining filter residues which are used for desiliconization of the step (4). The method can be used for treating coal ash raw materials from different sources to produce alumina.

Owner:河南华慧有色工程设计有限公司 +1

Composite high-efficient environment-friendly powdery cement grinding aid

The invention belongs to the technical field of cement technology admixtures, and particularly relates to a composite high-efficient environment-friendly powdery cement grinding aid which is made by materials with the following weight ratio: 40 to 50 percent of treated citric acid slag, 10 to 20 percent of flyash, 5 to 10 percent of molasses, 5 to 10 percent of anhydrous sodium sulfate, 5 to 10 percent of sodium silicate, 1 to 3 percent of triethanolamine, 1 to 3 percent of tri-isopropanolamine, 5 to 10 percent of slaked lime, and 10 to 20 percent of calcium lignosulphonate. The treated citric acid slag is obtained by ultrasonication. The composite high-efficient environment-friendly powdery cement grinding aid has the beneficial effects of: wide applicability, low dosing amount, improved grinding aiding effect, improved early-stage strength and later-stage strength of cement, saved cement clinker, adoption of industrial residue as the main body, and being green and environment-friendly.

Owner:山东天汇科技有限公司

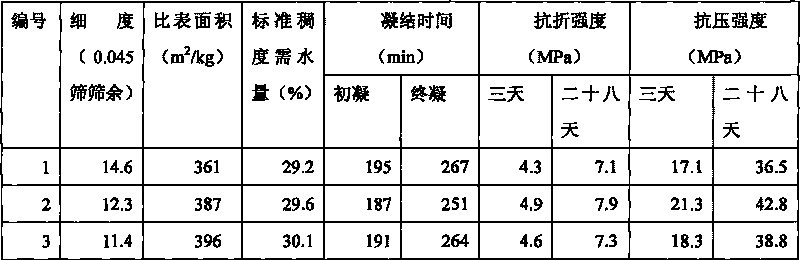

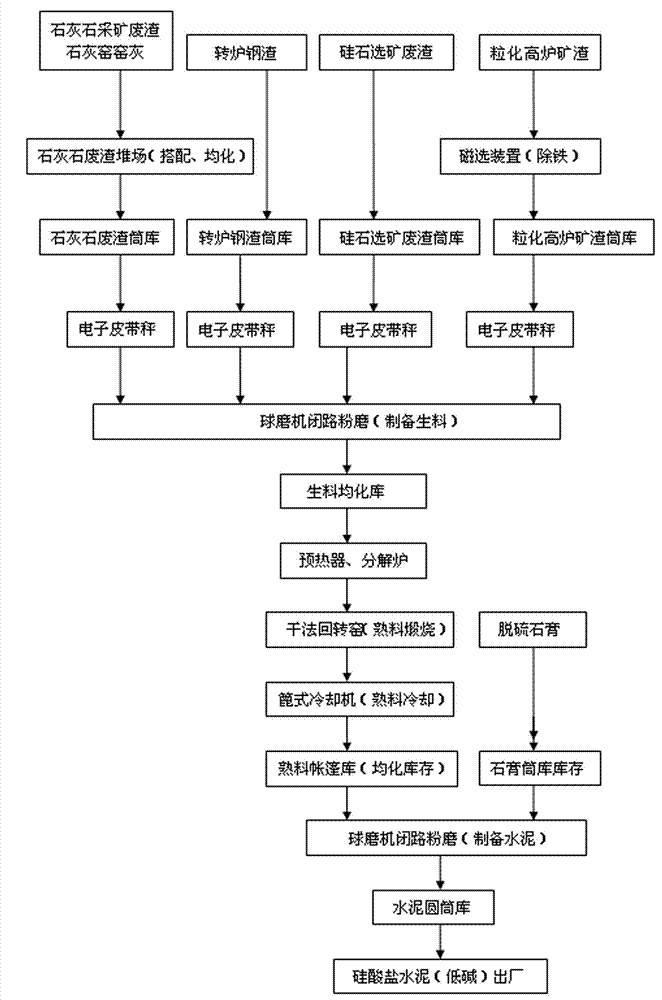

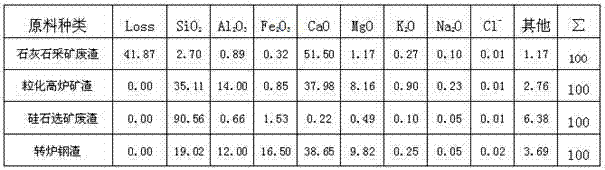

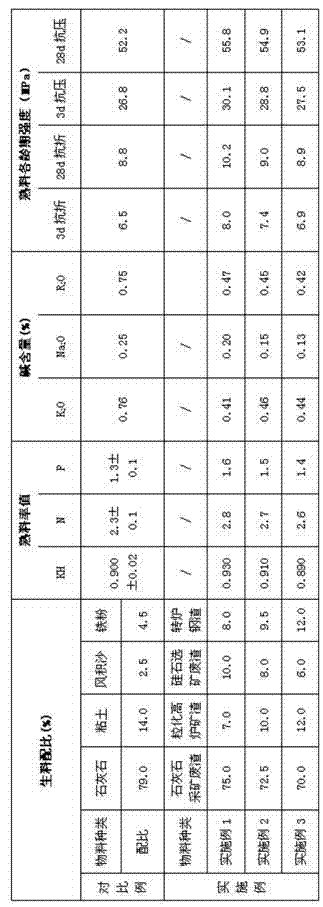

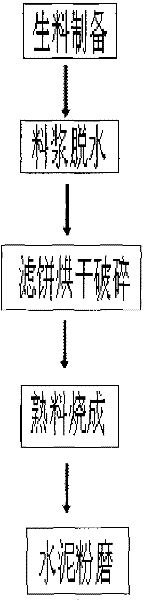

Method for producing low-alkali Portland cement by using industrial solid waste

The invention discloses a method for producing low-alkali Portland cement by using industrial solid waste and aims to overcome the problem that alkali content in cement produced by using traditional methods is high. The method comprises the following steps: A, preparation of the raw materials of 70 to 75% of mining debris of limestone, 7.0 to 12.0% of granulated blast-furnace slag, 6.0 to 10.0% of rejects of silica and 8.0 to 12.0% of converter steel slag; B, clinker calcination; and C, cement grinding. The method provided in the invention has the following characteristics: rejects of silica are used as a silico-regulating material, and not only the characteristic of low alkali content of the rejects of silica is made use of, but also the silica modulus N of the clinker can be adjusted by adjusting the proportion of the rejects of silica so as to inhibit the probability of skinning of a preheater and ring formation in a rotary kiln caused by excessively good burnability of materials. Lime kiln ash, the granulated blast-furnace slag and the converter steel slag are subjected to high temperature calcination, so alkali in the above-mentioned materials greatly volatilizes; therefore, alkali content in the raw materials is decreased, thereby meeting compounding requirements and creating conditions for production of low alkali cement.

Owner:嘉峪关祁连山水泥有限公司

Bayer process dissolving-out method

InactiveCN101117230ASimple processEasy to implementCarbon captureAluminium oxides/hydroxidesAluminium oxideSolid content

The invention provides a dissolving method with Bayer process, relating to a preparation method used in the dissolving process, in which diasporic bauxite is used as a raw material and aluminum oxide is produced with Bayer process. The invention is characterized in that: in the dissolving process, sodium ferrate, lime and the lye is added into bauxite, the amount of sodium ferrate and lime is calculated according to silicon content in bauxite which can be completely changed into molten iron garnet(3CaO.Fe2O3.nSiO2.(6-2n)H2O); the lye concentration NK is 100g / L to 450g / L, aluminium oxide concentration is less than 5g / L, the solid content of the dissolved preparation ore pulp is 50g / L to 300g / L, the temperature is 80 DEG C to 180 DEG C the dissolving time is 0.5 hour to 12 hours., and then the solid and the liquid are separated, the solid is dissolved in the condition of the conventional Bayer process. Through the invention, the existing form of silicate mineral of the dissolved red mud is mainly molten iron garnet instead of the usual sodium-silicon residue. The invention reduces the alumina-silicon ratio A / S and the sodium-silicon ratio N / S of the dissolved red mud. The invention is adapted to process diasporic bauxite source of Chinese high alumina-silicon.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Polyethers ultra early and strong type concrete superplasticizer

The invention relates to a polyether early- strength super-plasticizing agent. The preparation method comprises following steps: (1) copolymerization of water- borne free radical: 5%- 15% monomer a, 82%- 92% monomer b, 2%- 8% monomer c, and 1%- 3% monomer d copolymerizes in water- borne medium, the total amount of said monomers is 100%; (2) neutralizing reaction: adding alkoxy organic amine e showed in general formula (6) and (7) into copolymer after polymerizing reaction for neutralization, moderating the copolymer pH to be between 6.0- 7.5. The invention is characterized in that: (1) the dispersing performance and strengthening effect are outstanding at very low amount, and the strengthening effect at normal temperature or lower temperature at early stage is excellent, and the effect at middle and later stage grows stably; (2) it can reduce the concrete contract, and the contract rate is less than 90% of that of standard concrete; (3) it barely contains no chloride ion and is helpful for concrete durability increase.

Owner:JIANGSU SOBUTE NEW MATERIALS

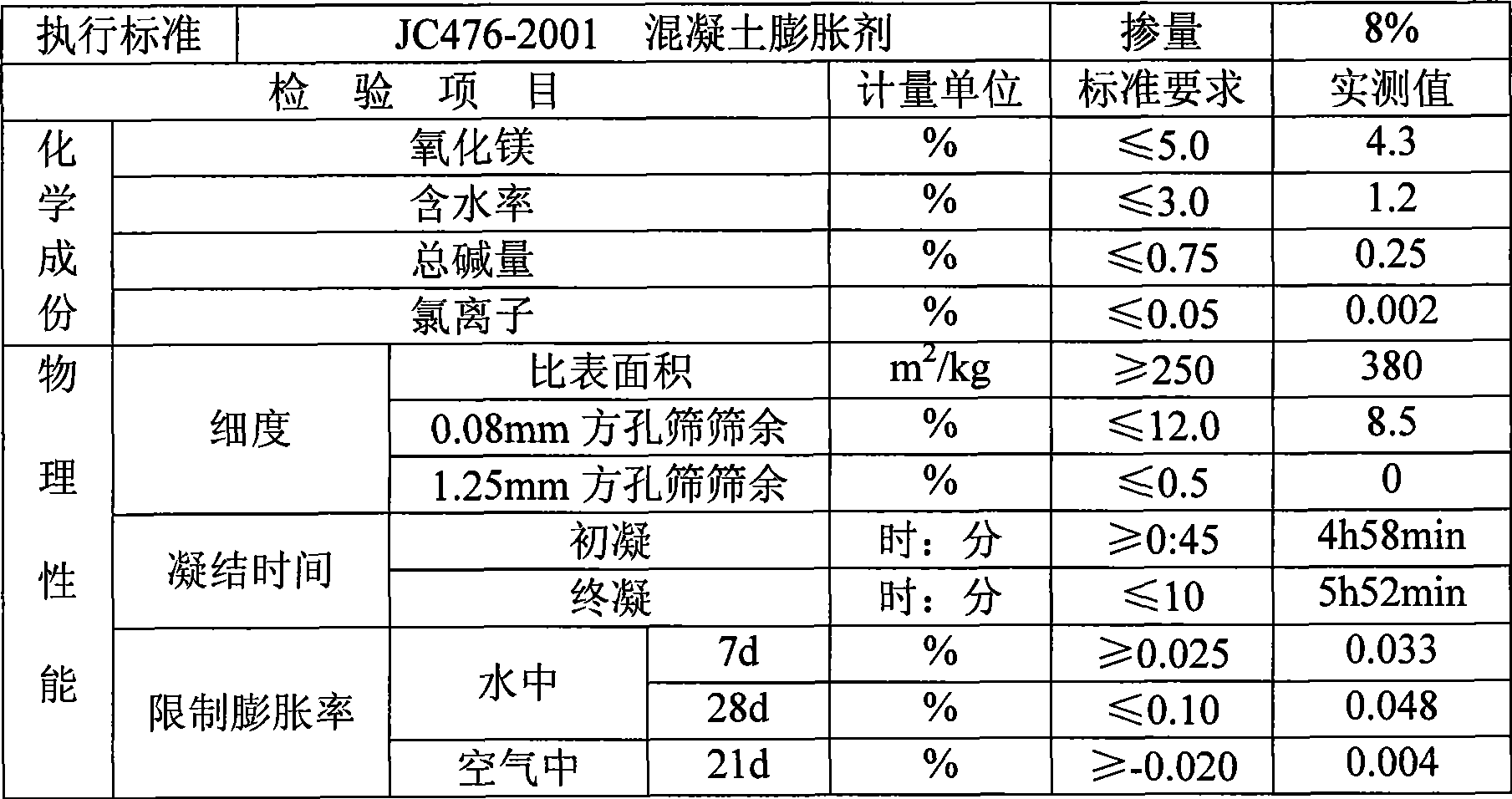

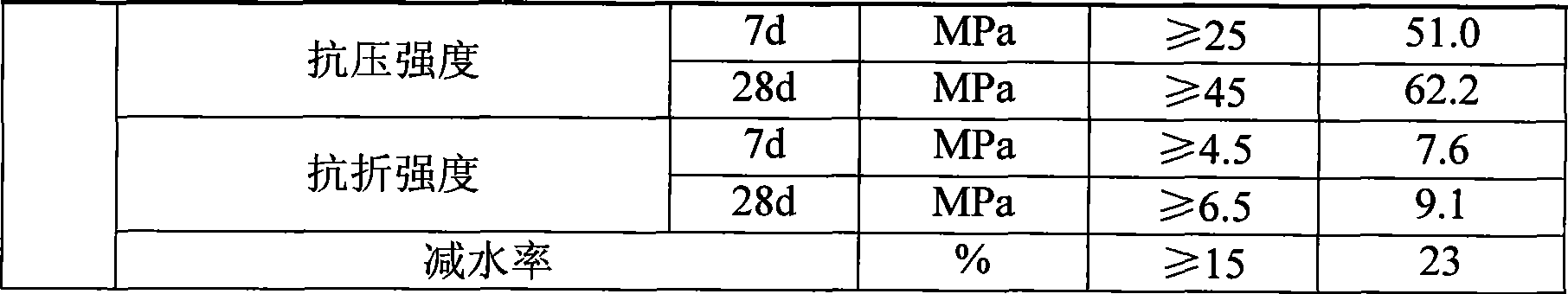

High-energy delay expanding agent for closed concrete and its prepn

InactiveCN1772692AGood expansion performanceExtended inflation timeSolid waste managementCeramicwareHigh energyMaterials science

The present invention relates to one kind of expanding agent with high-energy delay expanding effect on closed concrete and its preparation process. The expanding agent features that it consists of sulfoaluminate cement clinker, steel solution;alag, CaO, MgO, anhydrite, porous ore powder and porous material in certain weight proportion. The expanding agent has high expanding efficacy, long expanding time, low alkali content, high strengthening effect, low cost and simple preparation process.

Owner:WUHAN UNIV OF TECH

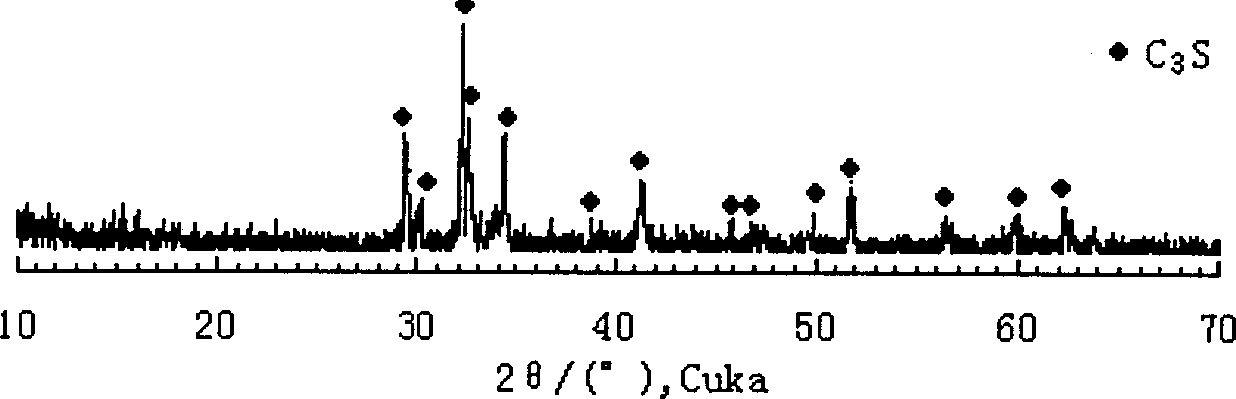

High alite silicate cement clinker and its preparation method

InactiveCN1785876APromote sustainable developmentRaw materials are cheap and easy to getPortland cementMaterials science

The present invention relates to a high-alite content Portland cement clinker prepared by using lead-zinc tails and shale instead of clay and its preparation method. Its composition includes (by wt%) 78-87% of limestone, 6-19% of lead-zinc tails, 2-11% of shale and 0-1.7% of iron ore. Said invention also provides the concrete steps of its preparation method.

Owner:NANJING TECH UNIV

Cellulose carbamate dissolved combined solvent and using method thereof

ActiveCN102432894AImprove solubilityImprove stabilityArtificial filaments from cellulose solutionsHigh concentrationFiber

The invention relates to a cellulose carbamate dissolved combined solvent. The solvent is an aqueous solution comprising 6 to 10 weight percent of sodium hydroxide and 0.1 to 3 weight percent of zinc oxide. A dissolving method comprises the following steps of: dispersing a certain amount of cellulose carbamate in a solvent composite, freezing at the temperature of between -20 and -10 DEG C for 3 to 5 hours or freezing in liquid nitrogen for 3 to 5 minutes, unfreezing at the temperature of less than or equal to 50 DEG C, and dissolving to obtain the cellulose carbamate solution at high concentration of 4 to 15 weigh percent. The obtained cellulose carbamate solution is low in sodium hydroxide content, high in solution stability, and has high mobility after standing at normal temperature for several days, and a gel phenomenon is avoided. The cellulose carbamate solution can be used for preparing fibers and films.

Owner:WUHAN UNIV

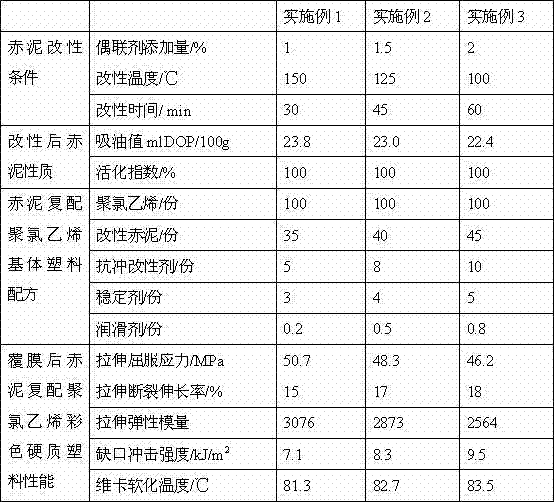

Production method of red mud complexed polyvinyl chloride colorized rigid plastic

ActiveCN102492234ALow alkali contentRealize comprehensive utilizationSynthetic resin layered productsLaminationRed mudPolyvinyl chloride

The invention relates to a production method of modified red mud complexed polyvinyl chloride colorized rigid plastic. The method is characterized in that: graded red mud with a specification of -800 meshes is modified by using a titanate coupling agent; 35-45 parts of the modified red mud, 100 parts of polyvinyl chloride, 5-10 parts of an impact modifier, 3-5 parts of a stabilizing agent, and 0.2-0.8 parts of a lubricating agent are subject to high-speed mixing, melt extrusion and filming, such that the colorized rigid plastic is obtained. According to the invention, red mud is subject to a modification treatment, such that the compatibility of the red mud and polyvinyl chloride is substantially improved. When the plastic is subject to the filming treatment, a monotonic brownish red color of the red mud complexed polyvinyl chloride substrate plastic is changed, a woody pattern is provided, the color is diversified, and the plastic is provided with a good appearance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Special cement and its production process

The specific cement is produced with cement clinker, mineral slag, flyash and gypsum in certain weight proportion, and the cement clinker is produced with limestone, loess, silica and iron ore in certain weight proportion and through calcination. The production process of the specific cement includes high temperature calcination of raw material at 1400-1500 deg.c to produce cement clinker while controlling exhaust temperature not lower than 900 deg.c for exhausting alkali to alkali content not more than 0.4 %; and pulverizing cement clinker, mineral slag, flyash and gypsum while controlling specific surface area not smaller than 350 sq m / Kg to obtain the specific cement. The specific cement has low alkali content, high wear resistance, high strength, fast coagulation and other advantages.

Owner:TONGHUA SPECIAL CEMENT GROUP JILIN PROV

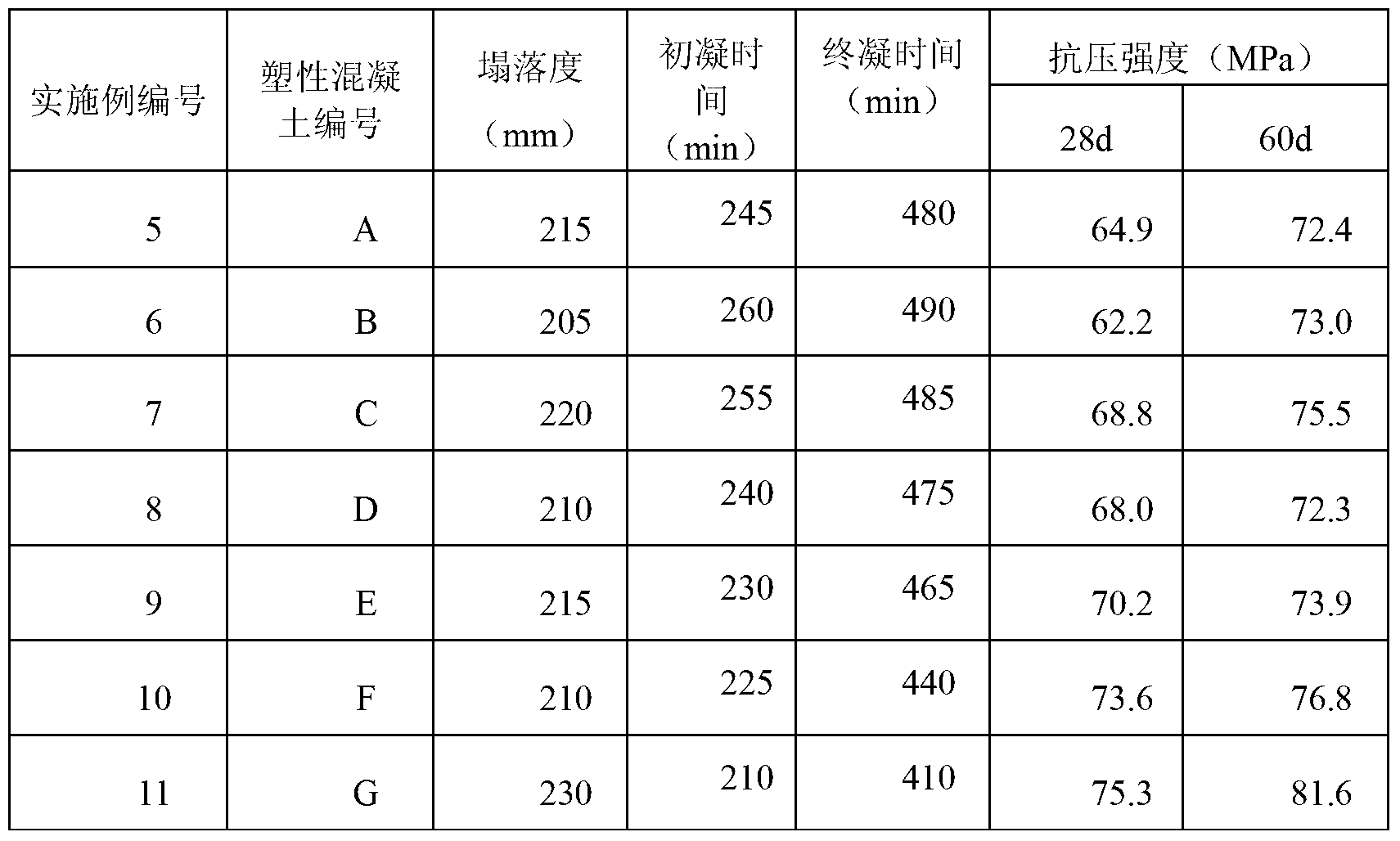

Compound activator and geopolymer cement concrete prepared from same

ActiveCN103172295ASuitable base stimulated activityReduce alkali chemical attackCement productionKaolin clayPolymer concrete

The invention provides a compound activator. The compound activator comprises triethanolamine, a naphthalene water reducer, quartz powder and lime milk. The invention further provides geopolymer cement concrete prepared from the compound activator. The geopolymer cement concrete comprises a binding material, an aggregate and the compound activator; by the geopolymer cement concrete per cubic meter, the addition amount of the binding material is 510-650kg, the addition amount of the aggregate is 1410-1550kg, the specific value of the addition amounts of the compound activator and the binding material is (0.22-0.35):1, the water-binder ratio is 0.35-0.37, and the sand ratio of the aggregate is 25-35%; and the binding material comprises one or more of metakaolin, slag powder and pulverized fuel ash, and the aggregate comprises sand and cobbles. The geopolymer cement concrete provided by the invention is low in cost, can be maintained at a normal temperature and has the advantages of high strength, high volume stability and durability, so that the geopolymer cement concrete can be widely applied to building fields such as civil engineering, highways and bridges instead of common Portland cement.

Owner:北京中联新航建材有限公司

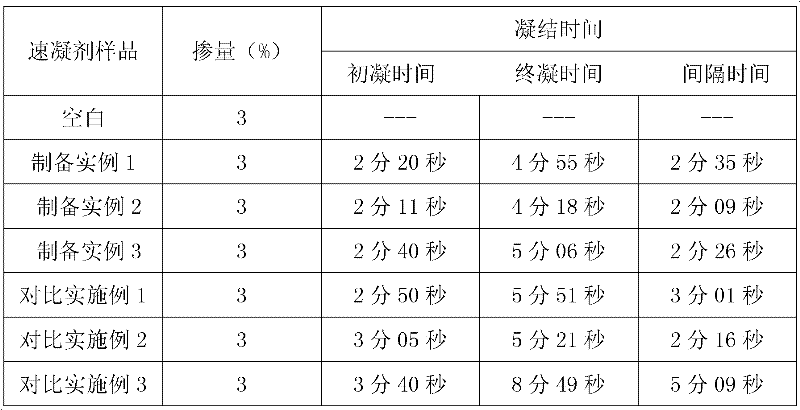

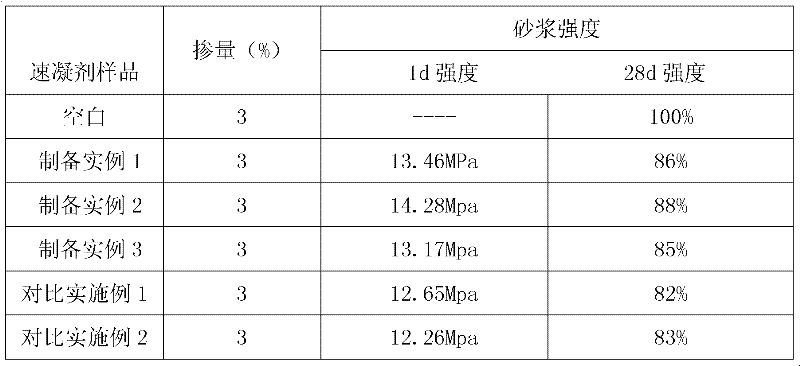

Method for preparing novel low-alkaline liquid setting accelerator

The invention relates to the field of building materials, in particular to a method for preparing a novel low-alkaline liquid setting accelerator. The novel low-alkaline liquid setting accelerator is prepared by the following steps: adding sodium hydroxide, potassium hydroxide and aluminum hydroxide into water according to proportion, and reacting for 2-3h under the temperature being 95-120 DEG C, thereby obtaining aluminate mother liquor; dissolving sodium fluoride in water, and adding silicate into the water solution under a certain temperature, thereby obtaining a modifier; and finally, dropping the modifier into the aluminate composite mother liquor, and reacting fully, thereby obtaining the novel low-alkaline liquid setting accelerator. The setting accelerator has the properties of short setting time, low alkali content and good cement adaptability.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

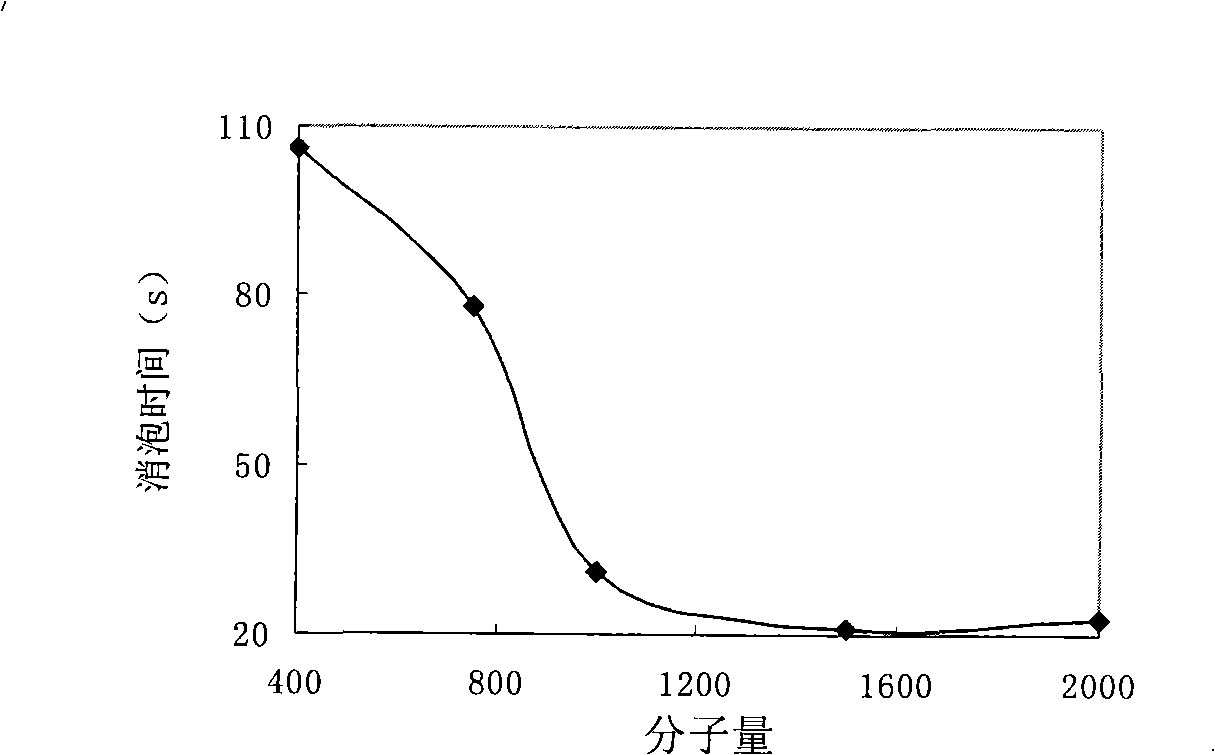

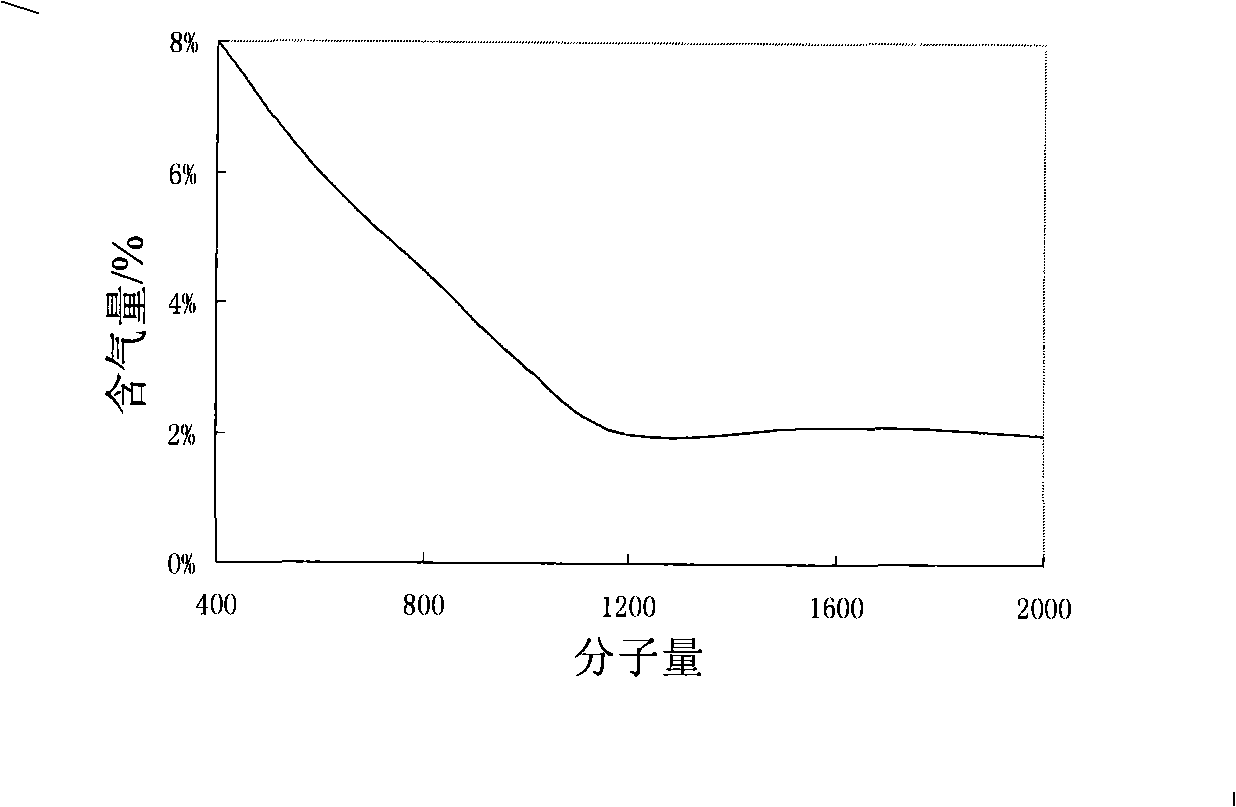

Method for preparing bleed air bleed air controllable polycarboxylic acids water reducing agents

The invention relates to a method for preparing an air entrainment-controllable polycarboxylate water-reducing agent. The method comprises the following steps: an aqueous solution of polyethylene glycol methyl ether methacrylate and methylacrylic acid is added dropwise into 75-80 DEG C water and an aqueous initiator solution is added dropwise in water at the same time, the temperature is maintained at 75-80 DEG C and the addition of reactants is completed within 6-7 hours, the temperature is maintained at 78-80 DEG C for 2-3 hours, the reaction product is naturally cooled down to room temperature and neutralized with a diluted alkali solution until the pH value is in the range from 6.5 to 7.5, and the air entrainment-controllable polycarboxylate water-reducing agent is obtained. The method has the advantages of simple synthetic processing equipment, controllable reaction conditions, no pollution, low cost and suitability for industrialized production. Under the condition of low mixing amount, the synthesized air entrainment-controllable polycarboxylate water-reducing agent exhibits high water-reducing rate, good fluidity and fluidity retention, and controllability in air content; and can efficiently increase concrete workability, prevent the bleeding and segregation of concrete and improve the frost resistance and water impermeability of hydraulic concrete.

Owner:WUHAN UNIV OF TECH

Ultra low-alkali portland cement and production method thereof

The invention relates to a production method of ultra low-alkali portland cement, characterized by strictly selecting crude fuel with low alkali content and using a scientific clinker formula, wherein, the scientific clinker formula comprises that: the lime saturation factor (LSF) is 95+ / - 1.5, the silica modulus (SM) is 2.20 + / -0.1, the aluminium modulus (AM) is 0.80+ / -0.1, so that the optimal proportioning principle of raw material consisting of 80.3 wt% of high calcium limestone, 12.5 wt% of high silicon sandstone, and 7.2 wt% of converter slag is calculated. According to the invention, the silicate cement clinker produced by using a wet-grinding dry-sintering semidry method has the f-CaO of no larger than 1.0 %, and the litre weight of no less than 1100 g / l; an optimal formula of cement material comprising a ratio of ultra low-alkali portland clinker to ferroalloy slag to high calcium limestone of 70-90 to 7-13 to 4-8 to 2-7 is used to produce 425# ultra low-alkali portland cement, wherein, the alkali content is no larger than 0.4 %, the average alkali content is 0.37 %, so that the international standards of low alkali cement are satisfied.

Owner:GUANGXI YUFENG CEMENT

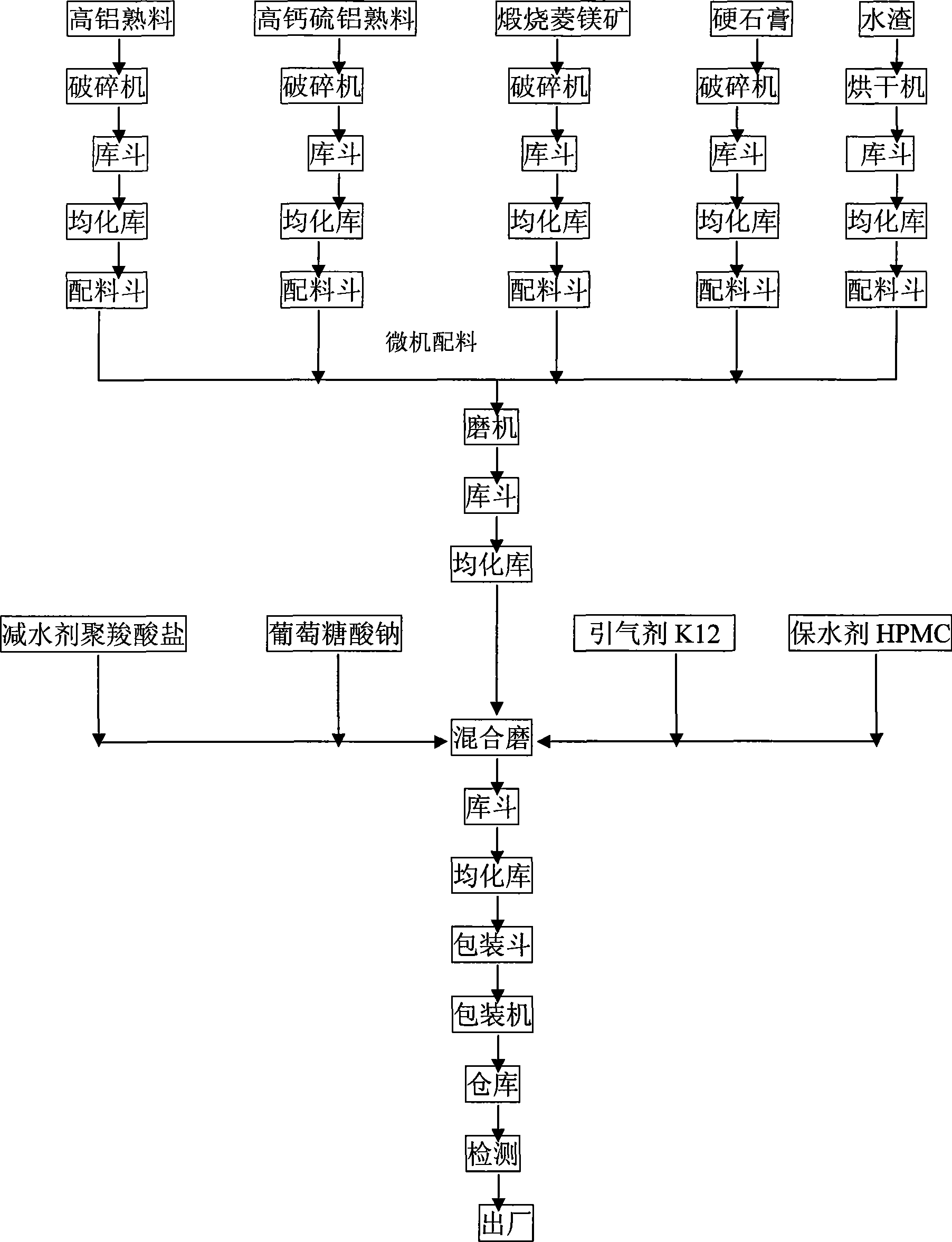

Retardation pumping type three-expansion source cement expansive material

The invention discloses a slow hardening pump deliver type three expansion source concrete expansion agent, which is characterized by comprising preparation of raw materials such as anhydrite, high alumina chamotte, high-calcium sulphoaluminate chamotte, calcined magnesite and so on by weight portion and externally doped slushing agent, water retention agent, air entraining agent and retardant. The preparation method of the expansion agent comprises steps of crushing, common mixture, mixing and grinding and external doping mixture and finish product forming. The product has low alkali content, excellent expansion performance, strong suitability with concrete, balanced mechanical property after hardening, and small gradual slump loss of concrete shrinkage compensation, contributes to improving safety and durability of reinforced concrete, obviously improves the cracking resistance, volume stability, impermeability and frost resistance, and is simple and convenient to use and easy to control quality in construction. The slow hardening pump deliver type three expansion source concrete expansion agent can meet construction use requirements of commercial concrete, long distance pump-delivering concrete and mass concrete.

Owner:广西云燕特种水泥建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com