Patents

Literature

75results about How to "Small loss over time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

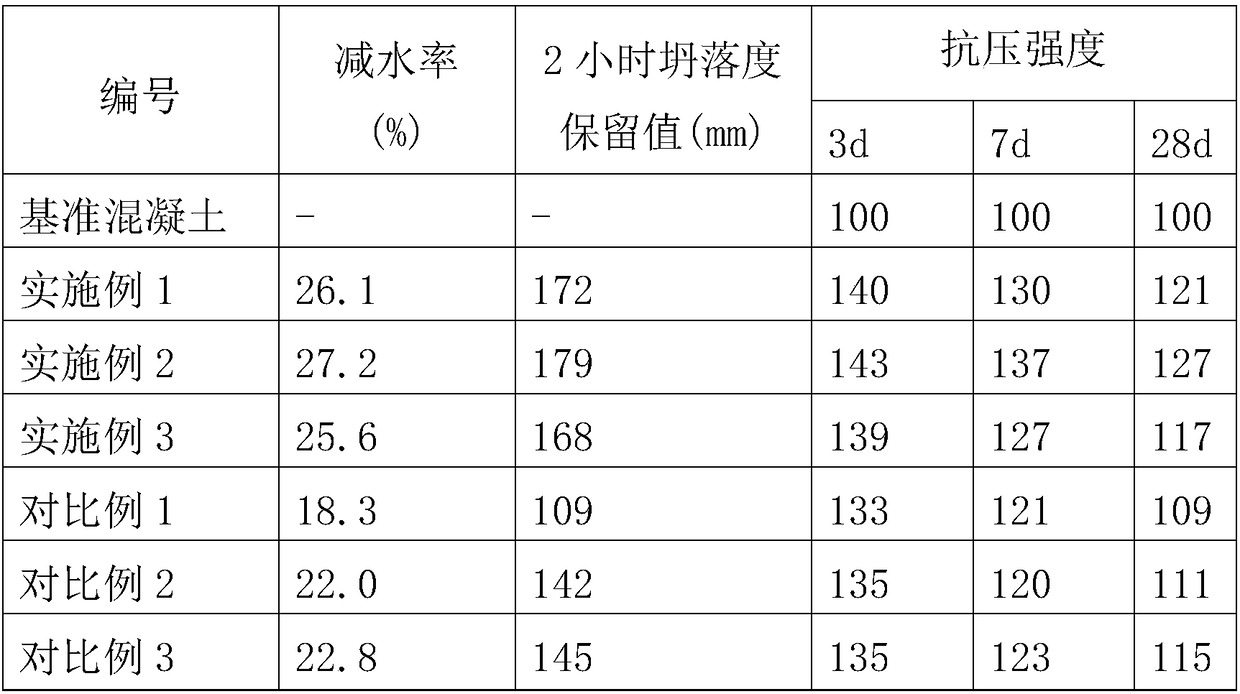

Super early strength accelerator for portland cement concrete

InactiveCN104710128AReduce lossesMeet the requirements for patching open trafficSuperplasticizerSodium aluminate

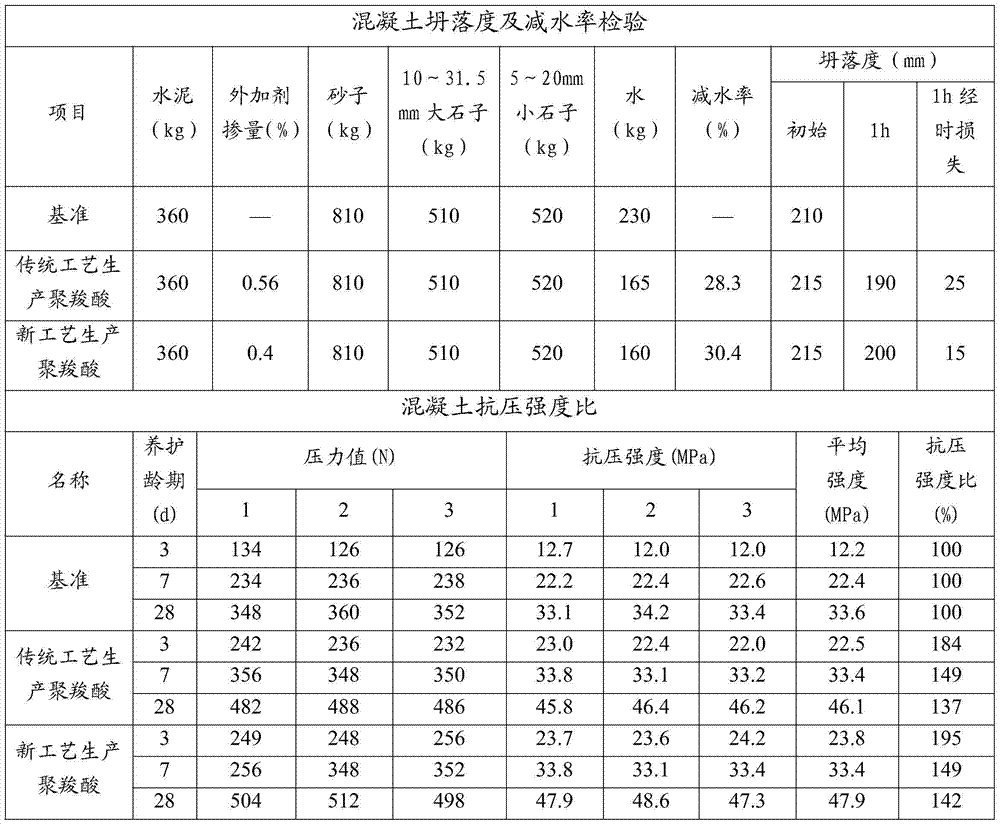

The invention discloses a super early strength accelerator for portland cement concrete. The super early strength accelerator is prepared from the following constituents in percent by weight: 20-50% of an early strength constituent, 10-40% of quick setting constituent, and 20-45% of a water reducing constituent, wherein the early strength constituent is obtained by compounding at least two of hydramine, an organic salt and an inorganic salt; the quick setting constituent is one of sodium aluminate, aluminum sulfate and sodium silicate; the water reducing constituent is one of a polycarboxylate type high performance water reducer, a high-performance naphthalene-based superplasticizer, and a high-performance aliphatic superplasticizer. The super early strength accelerator disclosed by the invention is free of chlorine and alkali; the 16 h compressive strength of the portland cement concrete prepared by using the super early strength accelerator in a low temperature environment in winter is up to 20 MPa above, so that the portland cement concrete can meet the requirement on quick road repair, and achieves the excellent construction performance.

Owner:SOUTHEAST UNIV

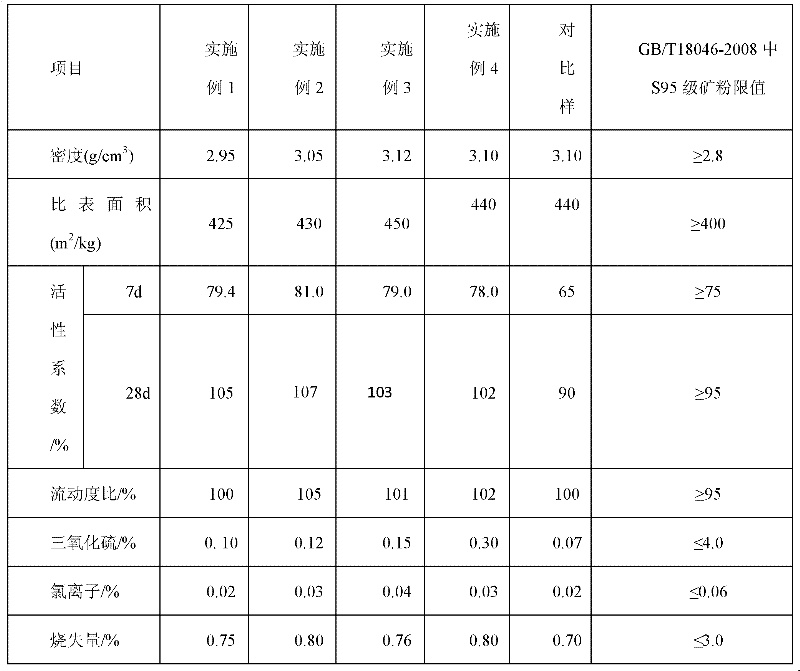

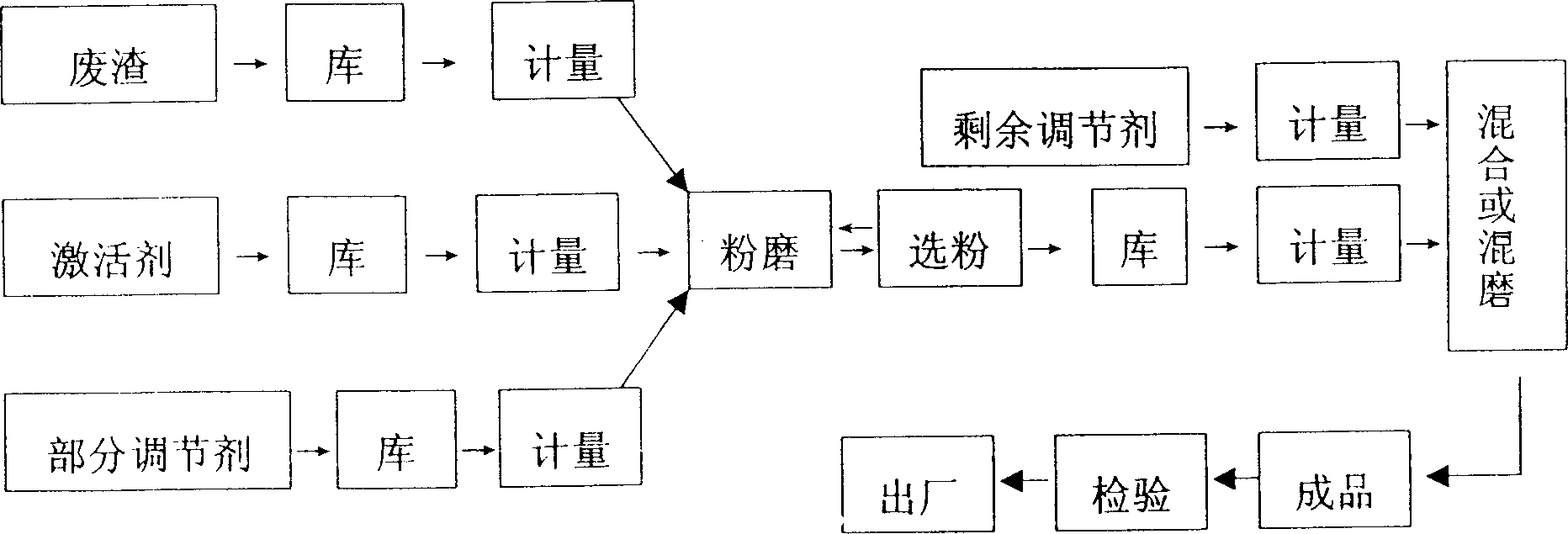

Modified steel slag composite admixture and preparation method thereof

InactiveCN102491664AOvercoming stability issuesImprove early activitySolid waste managementWork performanceSlag

The invention discloses a modified steel slag composite admixture and a preparation method thereof. The modified steel slag composite admixture comprises 55-75wt% of micro mineral slag powder, 20-40wt% of micro steel slag powder, and 1-5wt% of sintering desulphurization slag. Concrete prepared by mixing the modified steel slag composite admixture of the invention with cement has the following characteristics: the seven day active index is greater than 75%, the twenty-eight day active index is greater than 100%, the specific surface area is equal to or greater than 400m<2> / kg, the sulfur trioxide content is equal to or less than 4.0%, the chloride ion content is equal to or less than 0.06%, the ignition loss amount is equal to or less than 3.0%, and the autoclaving stability is qualified. The modified steel slag composite admixture which allows a low early strength disadvantage of steel slag composite admixtures to be overcome, working performances of concrete to be effectively improved, the strength and the endurance of concrete to be improved, and energy consumption required by slag grinding to be effectively reduced and is in favor of the low carbon economy realization, is a resource use type concrete admixture.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

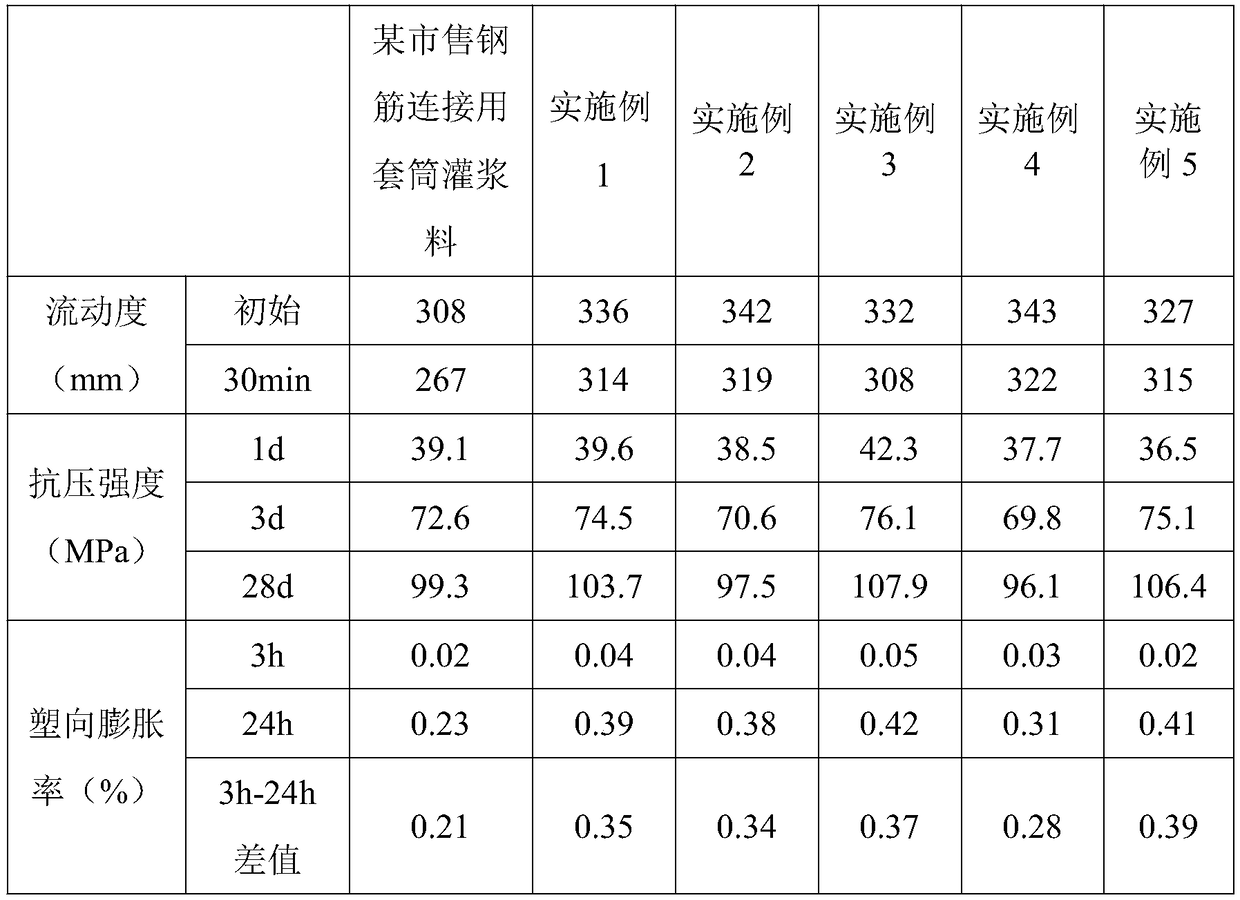

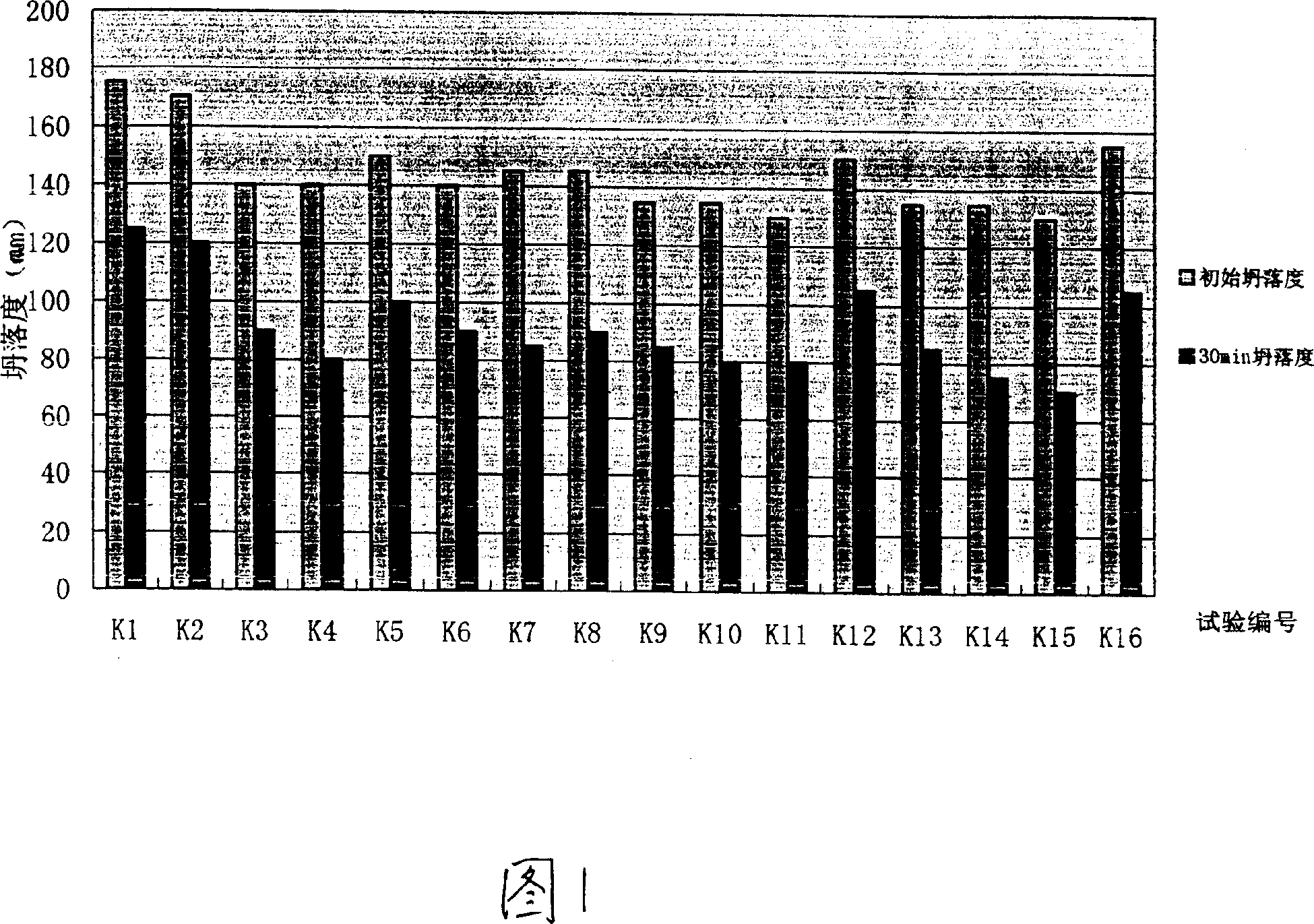

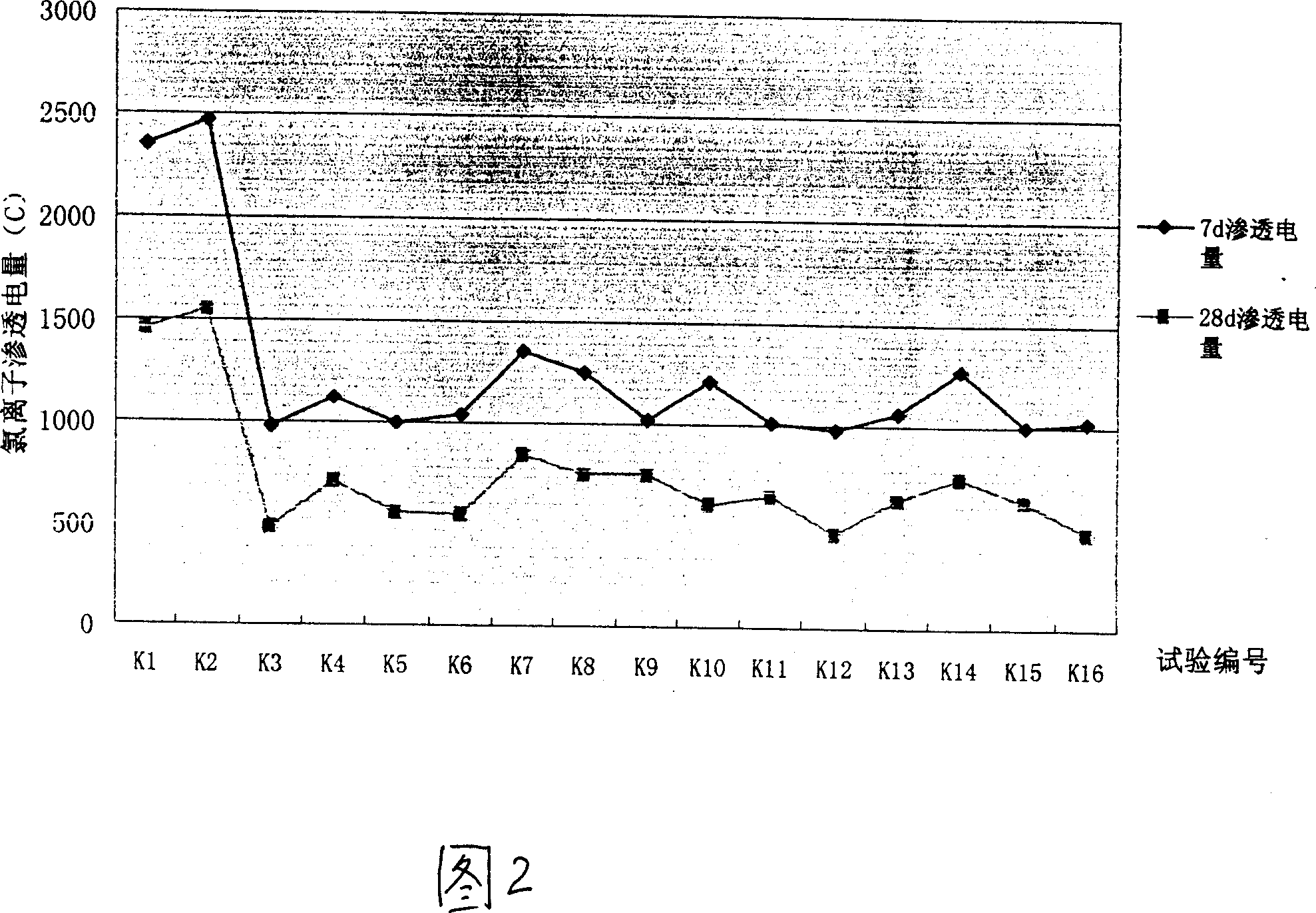

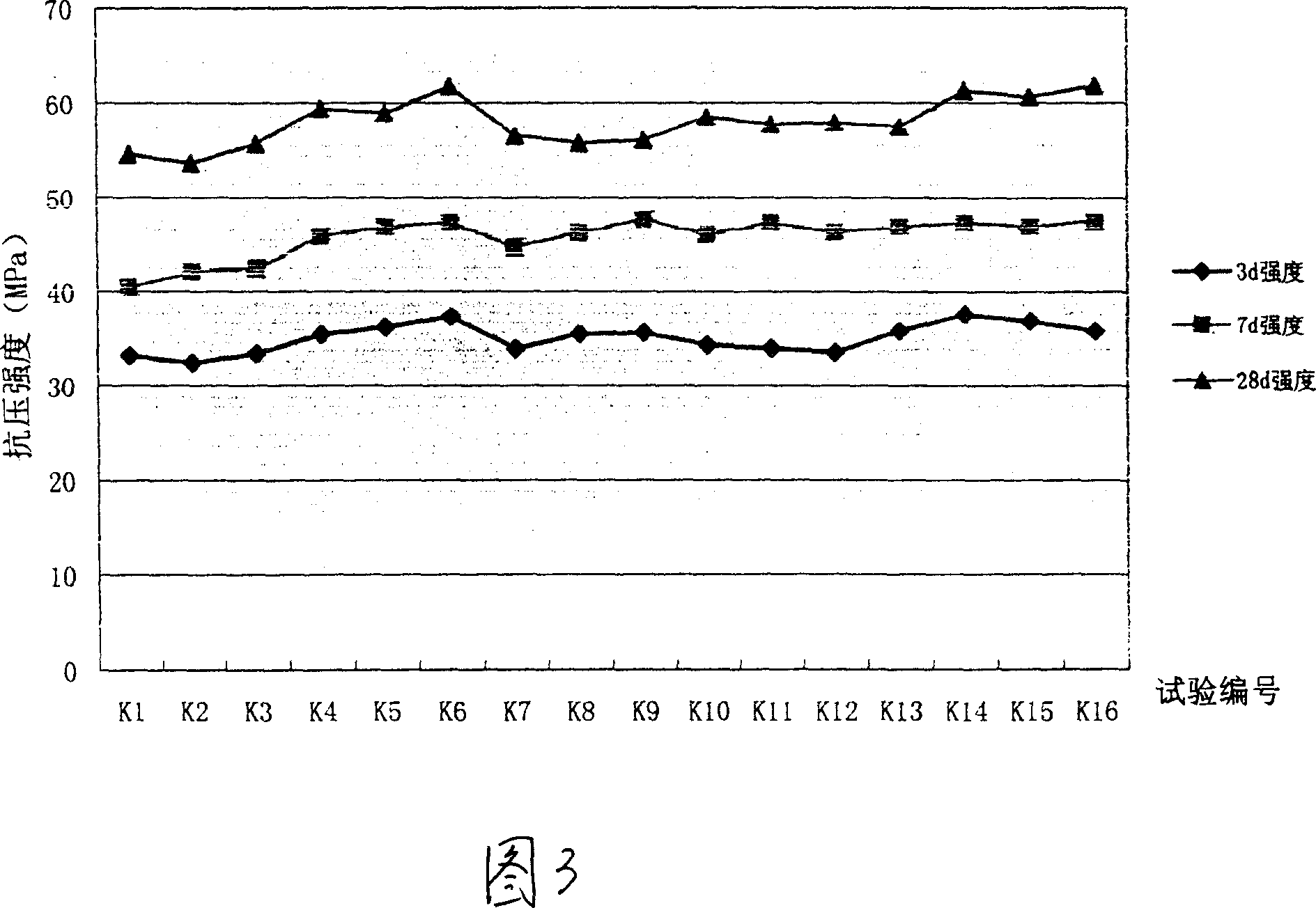

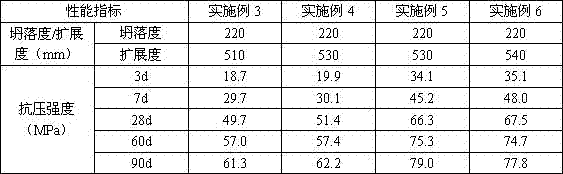

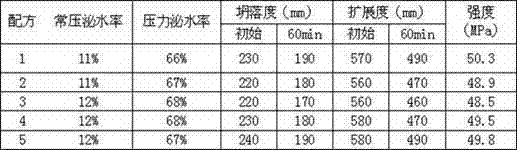

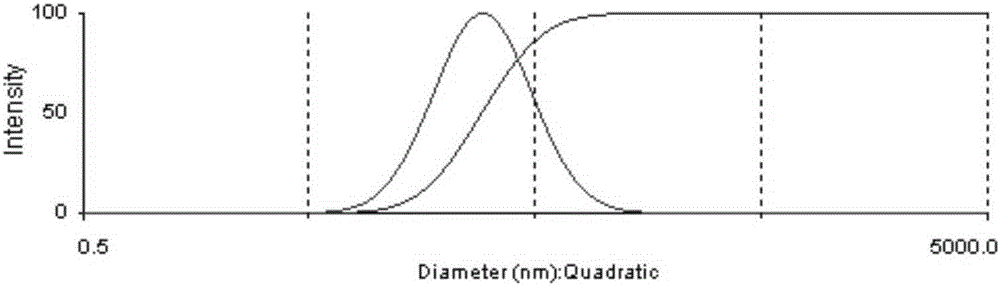

High-fluidity sleeve grouting slurry for rebar connection and preparation method thereof

The invention belongs to the field of building materials and particularly discloses a high-fluidity sleeve grouting slurry for rebar connection and a preparation method thereof. The grouting slurry isprepared from the following materials in parts by weight: 390-410 parts of cement, 90-110 parts of admixture, 460-500 parts of sand, 0.05-0.07 part of a water-retaining agent, 1.4-1.6 parts of a de-foaming agent, 6-8 parts of a compound water reducer, 40-50 parts of compound retarder, 35-40 parts of a compound expanding agent, 7-10 parts of a compound early strength agent and 135-145 parts of water. The preparation method for the grouting slurry comprises the steps of proportionally weighting the raw materials and uniformly stirring in a certain stirring manner. The sleeve grouting slurry forrebar connection prepared according to the invention is high in fluidity and can solve the problems of more insufficient initial fluidity or lower surplus initial fluidity and poorer fluidity holdingability than those of standard slurry of the present sleeve grouting slurry for rebar connection in practical engineering application.

Owner:成都宏基建材股份有限公司

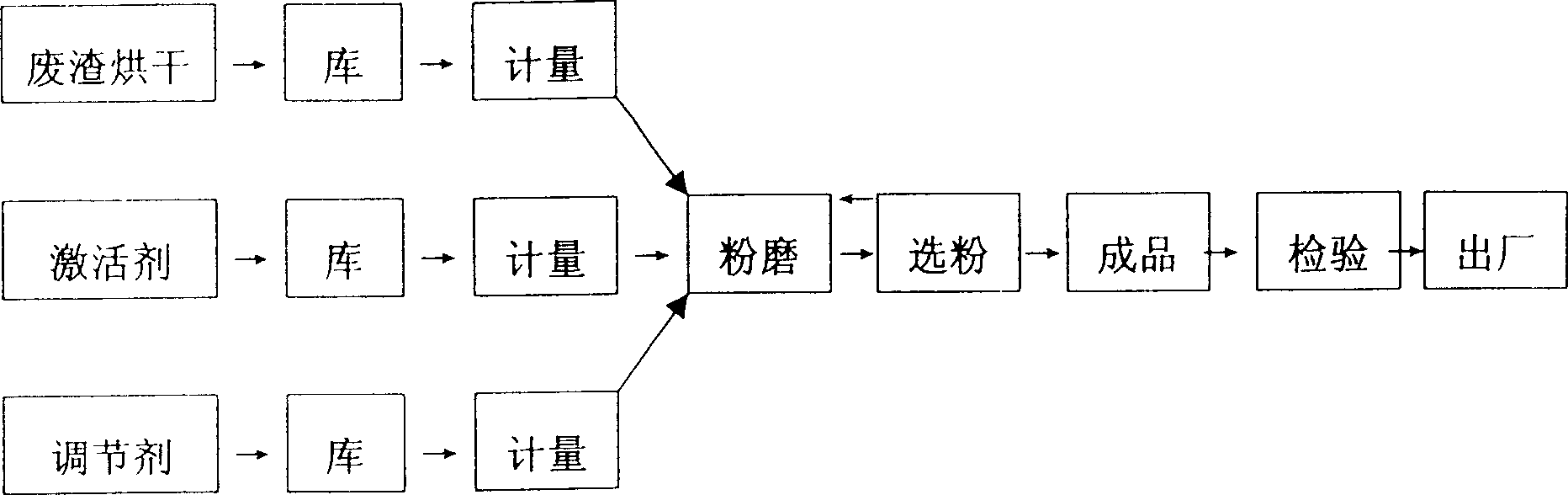

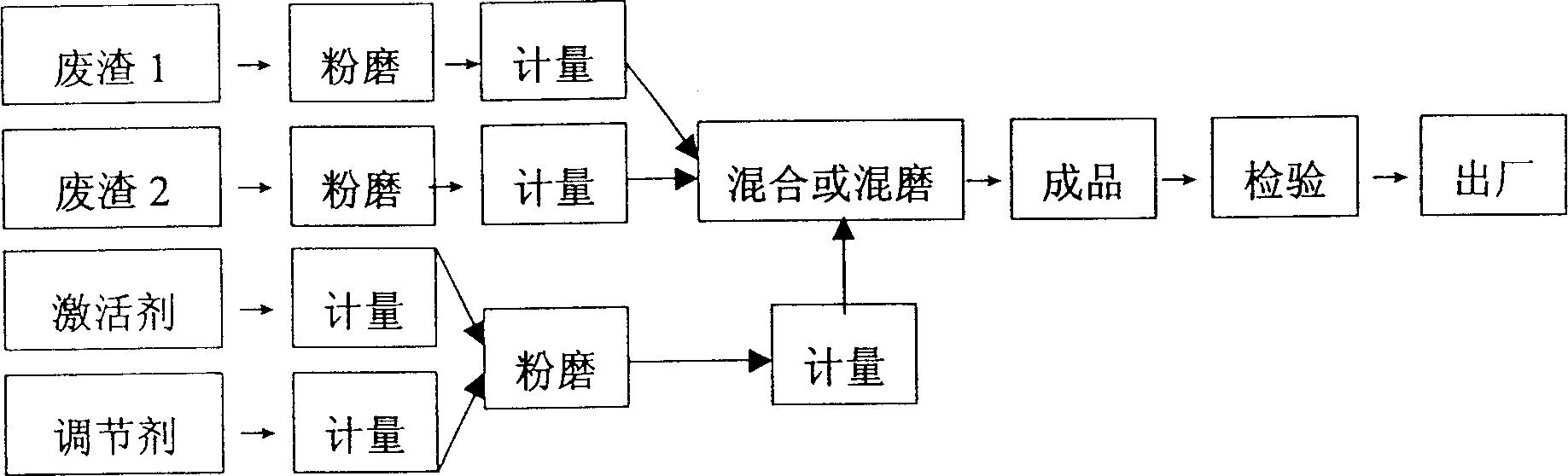

High-performance cement and concrete and their production

InactiveCN1896024AImprove compactnessImprove liquidityCement productionMaterials scienceHeating energy

High-performance cement, concrete and its production are disclosed. The cement consists of industrial fag end, activator, functional regulator and performance regulator, and Bosi specific surface is 300-550m2 / kg. Its advantages include excellent fluidity and endurance, less loss and hydrated heat energy, better density and strength.

Owner:张卫党

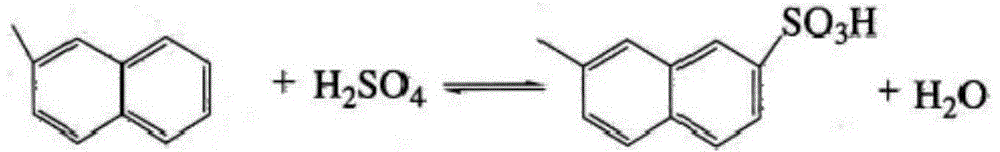

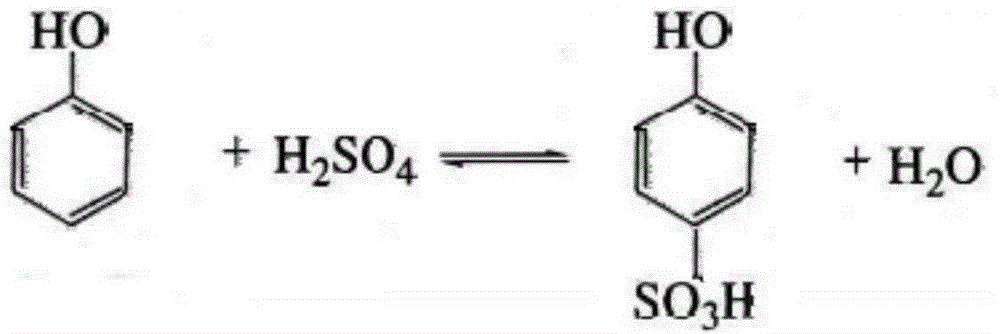

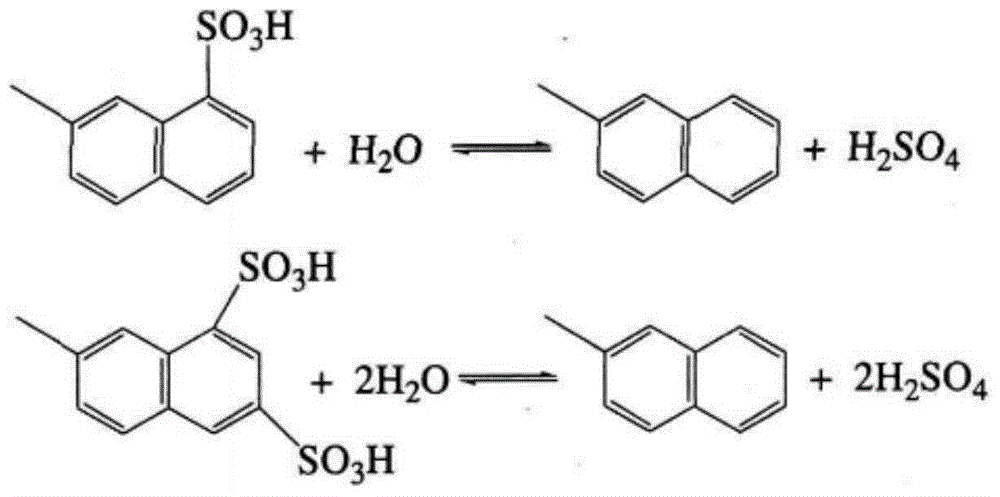

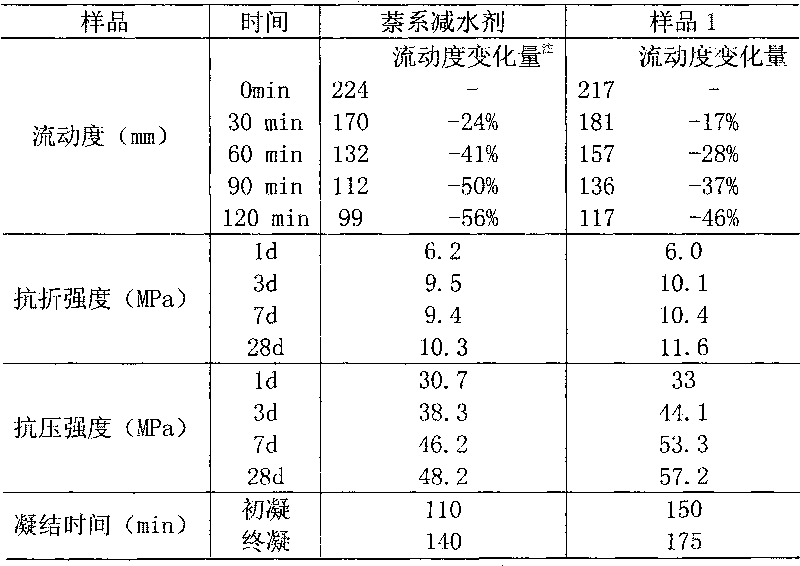

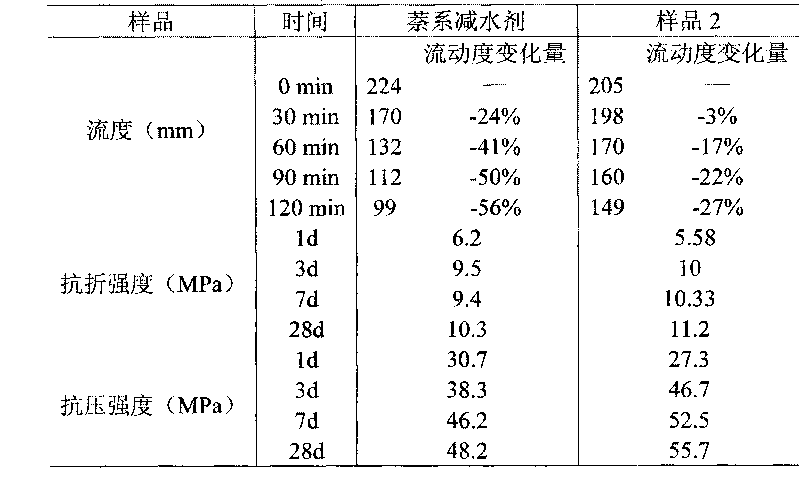

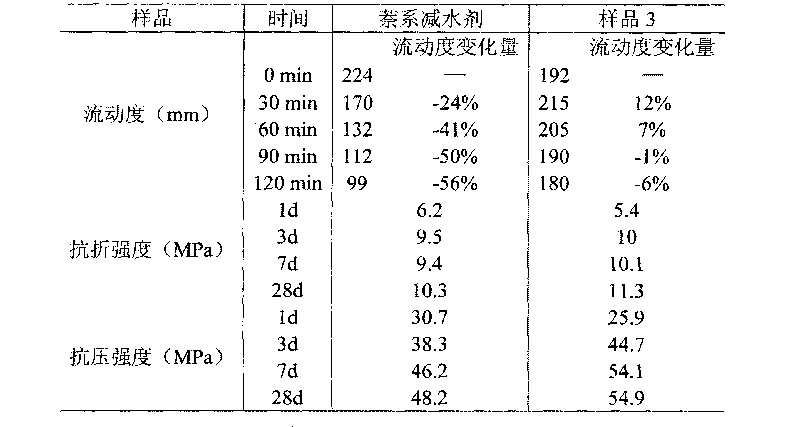

Preparation method of naphthalene-series water reducing agent

ActiveCN105236798ASolve the defect of poor plastic retention performanceHigh densityMethyl groupPhenol

The invention relates to a preparation method of a naphthalene-series water reducing agent. The method comprises the following steps: (1) methylnaphthalene and phenol are separately sulfonated, such that a sulfonated methylnaphthalene material and a p-hydroxybenzenesulfonic acid material are obtained; (2) the sulfonated methylnaphthalene material is subjected to a hydrolysis reaction; un-reacted methylnaphthalene or homologs thereof are removed through zeotropy; the rest of the sulfonated methylnaphthalene material enters a reaction in the step (3); (3) the sulfonated methylnaphthalene material obtained in the step (2) and the p-hydroxybenzenesulfonic acid material obtained in the step (1) are subjected to a condensation reaction with formaldehyde acidified with concentrated sulfuric acid, such that a condensed material is obtained; and (4) alkali liquid is added into the condensed material obtained in the step (3), such that a neutralization reaction is carried out, until the pH value is 7.5-9; and the naphthalene-series water reducing agent is obtained when the reaction is finished. The naphthalene-series water reducing agent provided by the invention has the excellent performances of good adaptability to cement, good concrete workability, high plasticity-maintaining performance, low concrete gradual loss, high water reducing rate, and the like. The preparation method has the advantages of simple process and easy-to-control reaction conditions. With the method, naphthalene-series water reducing agent production cost can be reduced.

Owner:ZHEJIANG JISHENG CHEM BUILDING MATERIALS

Formula of seaport engineering concrete chloride ion penetration resistant reinforcing agent

InactiveCN101134649AImprove permeabilityReduce penetration rateSolid waste managementFiberMicro structure

The present invention provides the recipe of chlorine ion penetration resisting reinforcer for concrete in harbor engineering. The chlorine ion penetration resisting reinforcer consists of superfine silica powder 15-20 wt%, washed and calcined kaolin 20-25 wt%, high grade fly ash 20-25 wt%, ground blast furnace slag 20-25 wt%, nanometer fiber 5-10 wt%, superplasticizer 6 wt%, slump keeping agent 0.09 wt%, air entraining agent 0.09 wt%, and organic active excitant 0.12 wt%. The chlorine ion penetration resisting reinforcer has inorganic components as main functional materials dispersed homogeneously in concrete cementing material, and can improve the micro structure and hydration product composition inside concrete, raise compactness, adsorb and fix chlorine ion and lower the penetration of chlorine ion in hardened concrete, so as to improve the chlorine ion penetration resisting capacity of hardened concrete.

Owner:LETS HLDG GRP CO LTD +1

Formula for preparing white faced as-cast finish concrete composition

ActiveCN101955342AThe proportion of components is scientific and reasonableSmall amount of shrinkageWork performanceTitanium

The invention discloses a formula for preparing a white faced as-cast finish concrete composition. The formula comprises the following components in part by weight: 200 to 280 parts of cement, 85 to 105 parts of water, 330 to 390 parts of sand, 500 to 580 parts of stone, 2.2 to 4.0 parts of admixture and 1 part of titanium white powder. The component proportion of the formula for preparing the white faced as-cast finish concrete composition is scientific and reasonable, the working performance of the formula meets the concrete pumping and casting requirements, and the formula can achieve the effects on no bleeding, no dissociation, low shrinkage and compactness and strong texture of the formed concrete. The high-flow white as-cast finish concrete prepared by adopting the formula has the advantages of good liquidity, good workability and good water-retaining property during concrete construction, low loss in slump, strong pumping property and the like; and the formula can ensure good strength and surface finish of the formed concrete and ensure that the chromatic aberration meets the quality requirement of the faced as-cast finish concrete.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

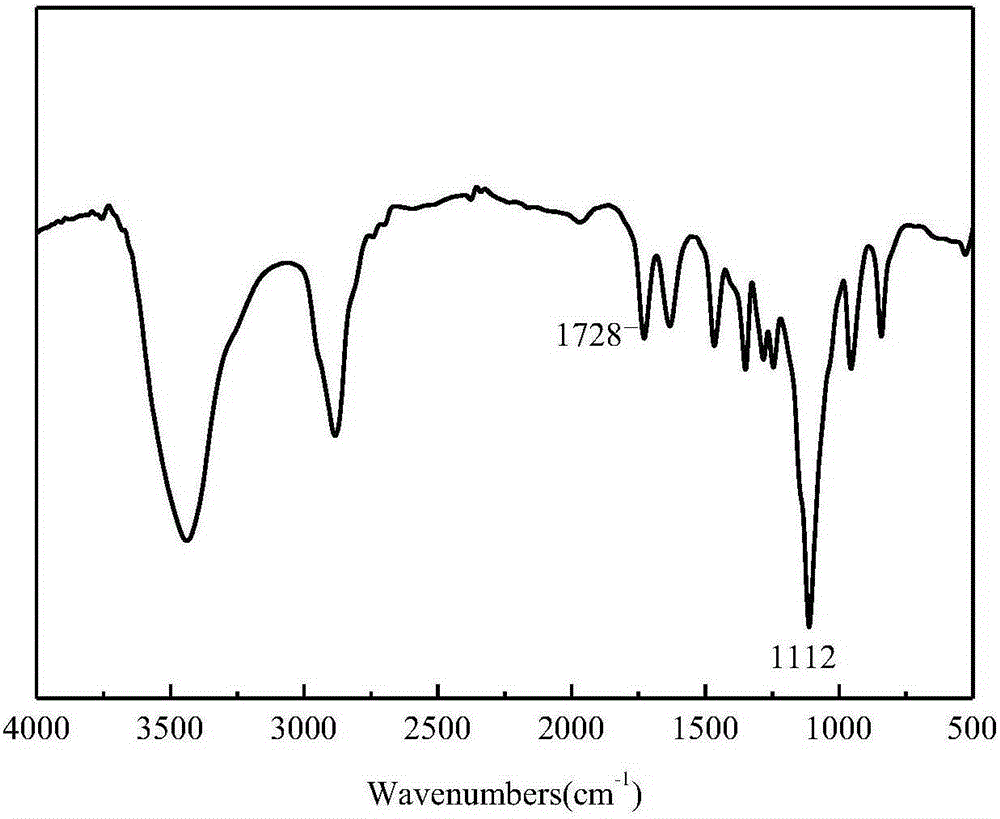

Mud-resistant polycarboxylate superplasticizer as well as preparation method and application thereof

InactiveCN110002784AGood water reduction effectGood collapsibilityMaterials preparationThermal insulation

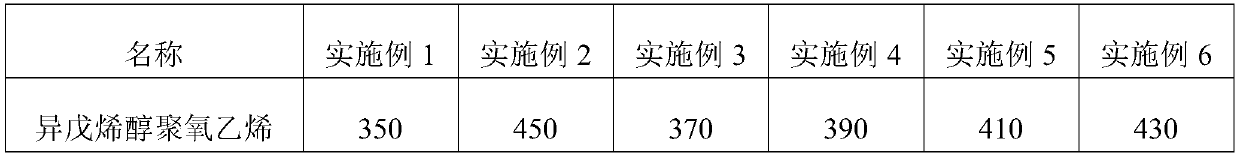

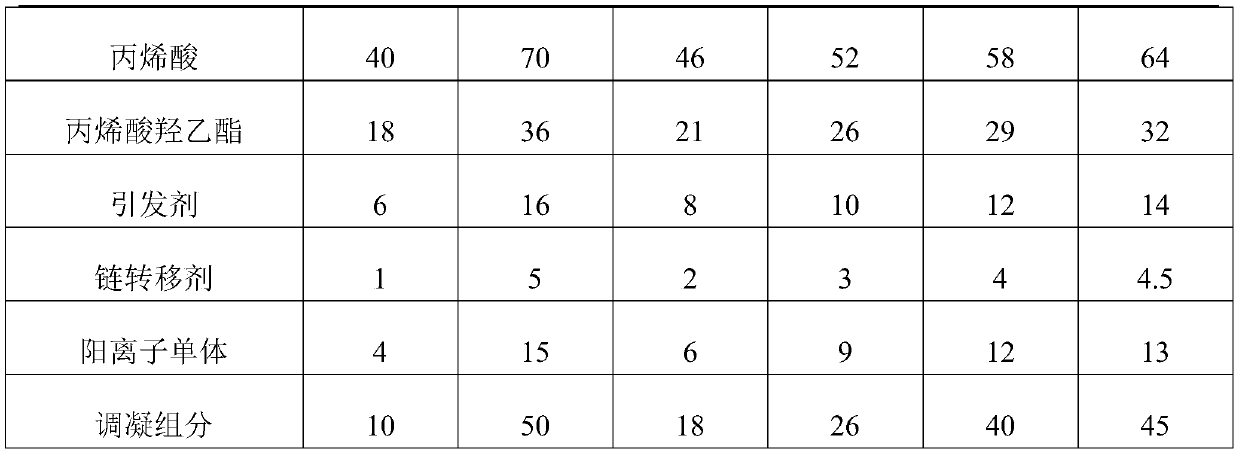

The invention belongs to the technical field of concrete and proposes a mud-resistant polycarboxylate superplasticizer. The mud-resistant polycarboxylate superplasticizer is prepared from components in parts by weight as follows: 350-450 parts of isoamyl alcohol polyoxyethylene ether, 40-70 parts of acrylic acid, 18-36 parts of hydroxyethyl acrylate, 6-16 parts of an initiator, 1-5 parts of a chain transfer agent, 4-15 parts of a cationic monomer and 10-50 parts of a coagulation adjusting component. The preparation method of the mud-resistant polycarboxylate superplasticizer comprises steps asfollows: material preparation, preparation of materials A and B, dissolution, droplet adding of the materials A and B, thermal insulation ageing, neutralization and the like. The mud-resistant polycarboxylate superplasticizer is applied to preparation of concrete. With the adoption of the technical scheme, the problem that application of the polycarboxylate superplasticizer is affected due to massive adsorption by mud in the prior art is solved.

Owner:兰州同邦建材有限公司

High-performance lithium slag pump concrete

The invention discloses high-performance lithium slag pump concrete. The proportion of mixture of the concrete is cement:water:mineral powder:fly ash:lithium slag:sand:gravel:synergist: additive being (340-520):(165-200):(0-50):(0-50):(40-150):(700-850):(1,000-1,100):(2-3.5):(7-12) according to the component unit of kg / m<3>. By means of selection of the raw materials and design of proportioning, the high-performance lithium slag concrete which is good in working performance, mechanical performance and durability and can be used for pumping is obtained.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

Light aggregate concrete pumping agent

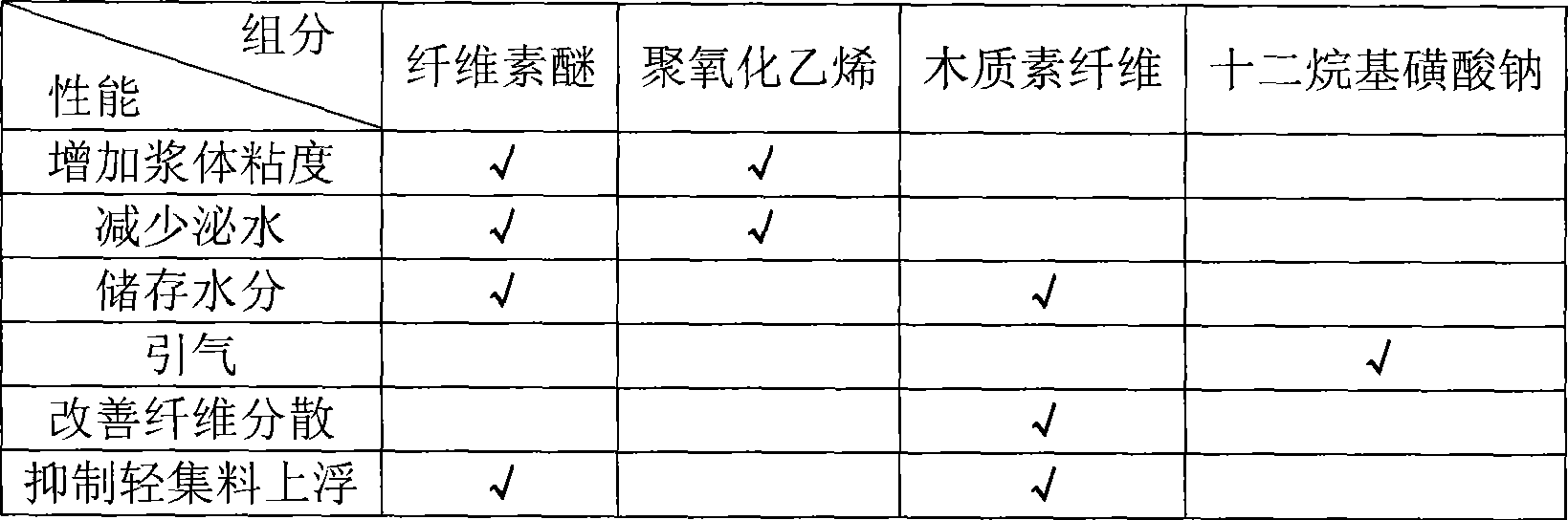

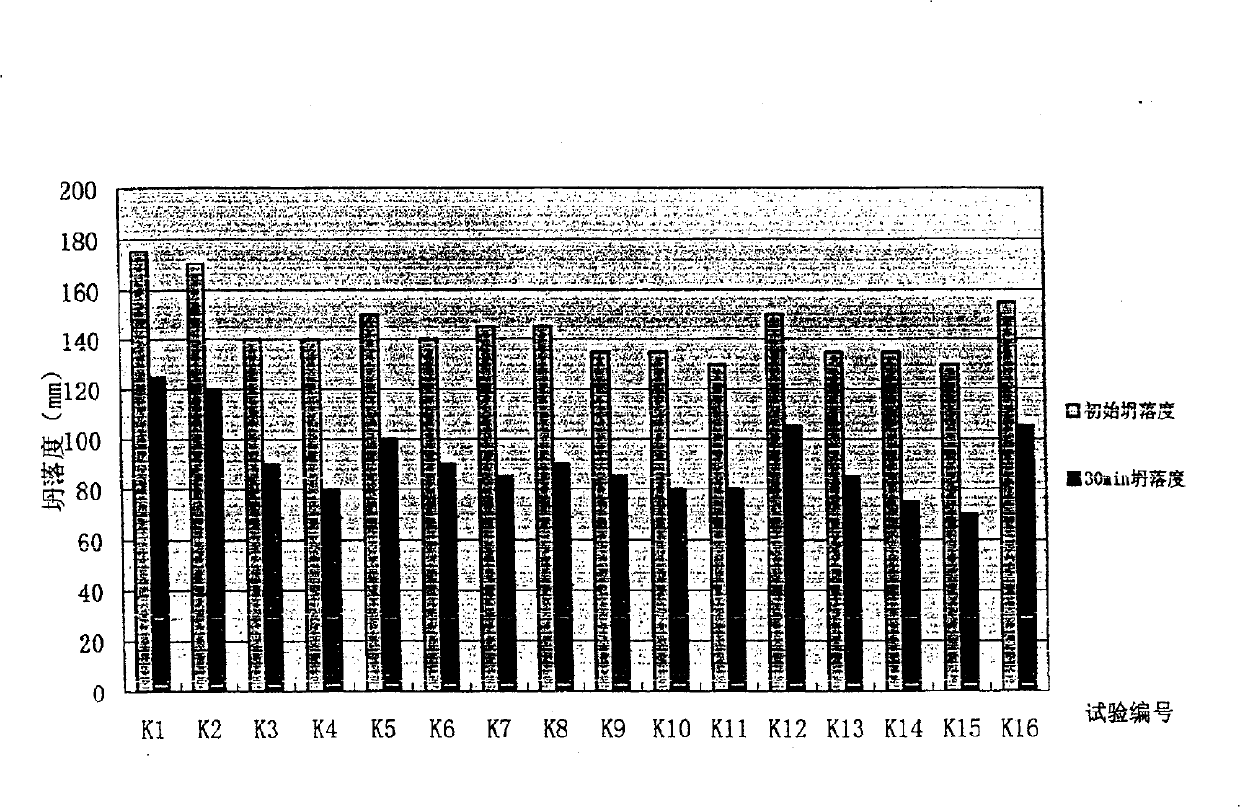

InactiveCN101143771AImprove homogeneitySmall loss over timeSolid waste managementMarket potentialDodecylsulfonic acid

The invention relates to a pumping aid in pumping delivery of lightweight aggregate concrete. A lightweight concrete pumping aid is characterized by having a homogeneous mixture made of cellulose ether, polyethylene oxide, methyl cellulose, sodium dodecyl sulfate and siliceous dust, wherein the formulated rate is arranged by weight as: 8-12 portions of cellulose ether, 1-5 portions of polyethylene oxide, 30-300 portions of methyl cellulose, 5-15 portions of sodium dodecyl sulfate and 100-300 portions of siliceous dust. The pumping aid is used for delivery of lightweight aggregate concrete, which can dramatically improve the homogeneousness of lightweight aggregate concrete, reduce the gradual loss in slump of lightweight aggregate concrete, reduce the performance loss in the process of pumping up lightweight aggregate concrete and improve pumping capacity of lightweight aggregate concrete, thereby having a tremendous market potential in the construction of large-span bridges, high-rise buildings and special structures.

Owner:WUHAN UNIV OF TECH

Retarding composite limestone powder admixture

InactiveCN103833242ASmall loss over timeImprove mechanical propertiesCement productionWork performanceSlag

The invention relates to a retarding composite limestone powder admixture which comprises the following components by weight: 75-90% of limestone powder; 15-20% of steel slag; 3-8% of phosphorus slag; 0.3-2% of grinding aid. The components are well mixed according to the ratios, and then grinded into fine powder with a fineness specific surface area of not less than 350 m2 / kg to obtain the admixture. The admixture has retarding effect, reduces gradual loss in slump of concrete, facilitates smooth construction, and meets requirements of working performance, mechanical properties, and durability of concrete during construction; the admixture adopts limestone powder instead of cement or fly ash, thereby preventing resource waste; concrete prepared by the admixture of the invention is suitable for various building constructions.

Owner:CHONGQING XINCAI CONCRETE GRP

Slag powder-doped composition for preparing white facing as-cast finish concrete

The invention discloses a slag powder-doped composition for preparing white facing as-cast finish concrete. The composition is characterized by consisting of the following components in parts by weight: 180-260 parts of cement, 85-110 parts of water, 330-390 parts of sand, 500-580 parts of stone, 2.0-4.0 parts of additive, 1 part of titanium dioxide and 20-60 parts of slag powder. In the composition disclosed by the invention, the proportion of the components is more scientific and reasonable, and the working performance meets the requirements on concrete pumping and pouring; and moreover, the bleeding and separation are avoided, the shrinkage is low, and the formed concrete is dense and has strong texture. With the formula, the large-flow regime white as-cast finish concrete has the advantages of good fluidity, good workability, good water-retaining property, low slump loss, strong pumpability and the like in concrete construction; and the strength of the formed concrete can be guaranteed, the surface gloss is good, and the chromatic aberration meets the requirement on the quality of the facing as-cast finish concrete.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

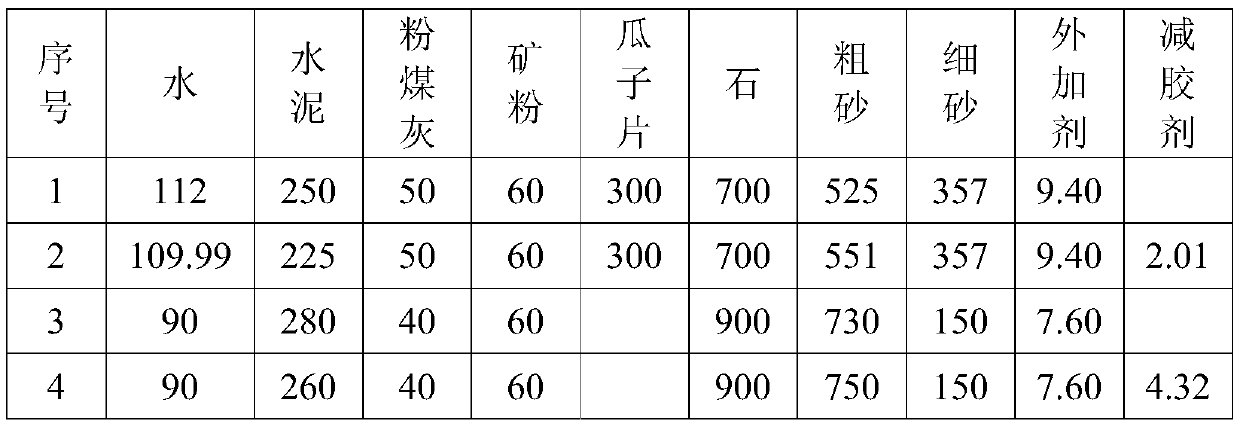

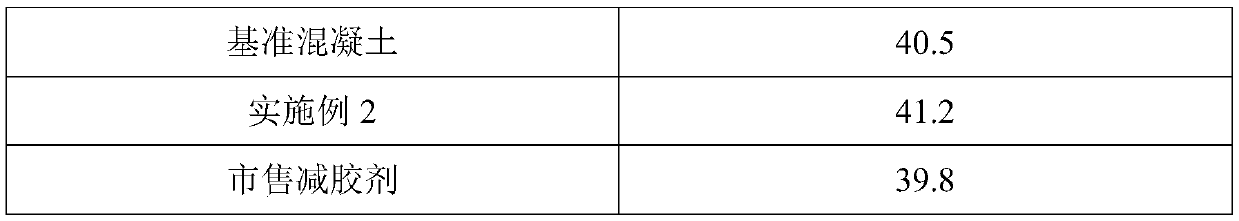

Concrete glue reducing agent and preparation method thereof

The invention relates to the technical field of concrete preparation, and in particular, relates to a concrete glue reducing agent and a preparation method thereof. The glue reducing agent is composedof the preparation raw materials in parts by weight: 20-30 parts of substituted organic amine and 40-60 parts of water, wherein substituent groups of the substituted organic amine are selected from one or more of ester groups, sulfonic acid groups, carboxylic acid groups and hydroxyl groups. The invention provides the glue reducing agent. The glue reducing agent can be used in concrete, can obviously reduce the cement consumption, avoids the reduction of the concrete strength and slump, effectively reduces the time loss of the concrete, improves the harmony of the concrete, can act together with a water reducing agent and the like, saves the cost while ensuring the physical properties of the concrete, and conforms to JC / T2469-2018.

Owner:南通瑞特建筑材料有限公司

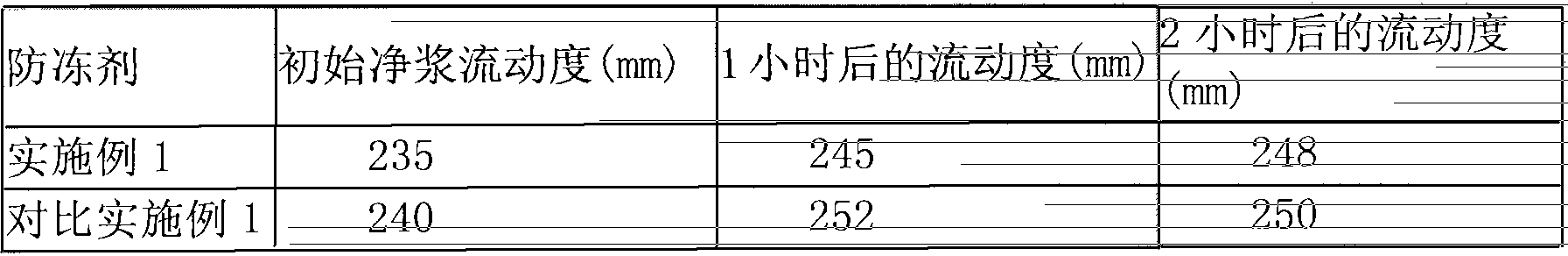

Anti-freezing type polycarboxylic acid high-performance water reducer and preparation method thereof

ActiveCN103922628AExcellent antifreeze and antirust effectImprove adaptabilityVitamin CSynthesis methods

The invention discloses an anti-freezing type polycarboxylic acid high-performance water reducer and a preparation method thereof. The anti-freezing type polycarboxylic acid high-performance water reducer is prepared from the following materials in parts by weight: 25-35 parts of acrylic acid, 10-20 parts of mercaptoacetic acid, 30-50 parts of isopentenol polyoxyethylene ether, 1-10 parts of hydrogen peroxide, 1-10 parts of vitamin C, 1-5 parts of white sugar, 0.5-2 parts of sodium dodecyl sulfate, 1-10 parts of sodium nitrite, 1-5 parts of calcium chloride, 1-3 parts of air entraining agent and 25-60 parts of water. The invention further provides a preparation method of the water reducer. The production process in the invention is simple to operate, free of heating and pure water, low in energy consumption, green and environment-friendly, realizes zero pollution and zero emission in the production process, is a green synthesis method, and satisfies novel environment health requirements.

Owner:SHANDONG DAYUAN IND

Novel polycarboxylate water reducer, preparation method and application thereof

The invention discloses a novel polycarboxylate water reducer which is prepared from following raw materials, by weight: 48 parts of a polyalkoxylvinyl long-chain unsaturated monomer, 2.88-10.08 parts of an unsaturated carboxylic acid, 0.2-2 parts of a chain transfer agent, 0.2-3 parts of an oxidizing agent, 0.1-1 part of a reducing agent, 154 parts of water and 0.08-0.24 parts of a micro-crosslinking agent. The polycarboxylate water reducer has high initial mortar fluidity and can hold a stable mortar fluidity for a long time, can effectively reduce time loss of slump degree and solves a problem of too fast loss of slump degree of usage of the concrete, and brings a great convenience to engineering construction in the fields of highway, bridge, dam, tunnels and high-rice buildings and the like. Meanwhile, the polycarboxylate water reducer is less in process, is simple in preparation step, is high in efficiency, is low in cost, is green and environment-friendly and is very suitable for industrial application.

Owner:SICHUAN UNIV

Recycled concrete and preparation method thereof

The invention discloses a recycled concrete, which is characterized in that the recycled concrete is prepared from the following components by weight: 60~95 parts of water, 40~64 parts of cement, 38~62 parts of ore powder, 22~34 parts of fly ash, 280~350 parts of natural sand, 210~260 parts of recycled coarse aggregate, 70~120 parts of recycled fine aggregate, 6~8 parts of silicon powder, and 1~2parts of modified polyacrylic acid high-efficiency water reducing agent. In conclusion, the recycled concrete has the advantages of improving the compressive property of concrete and improving the rheological property, mechanical property, volume stability and durability of concrete.

Owner:禹州市国泰建工科技有限公司

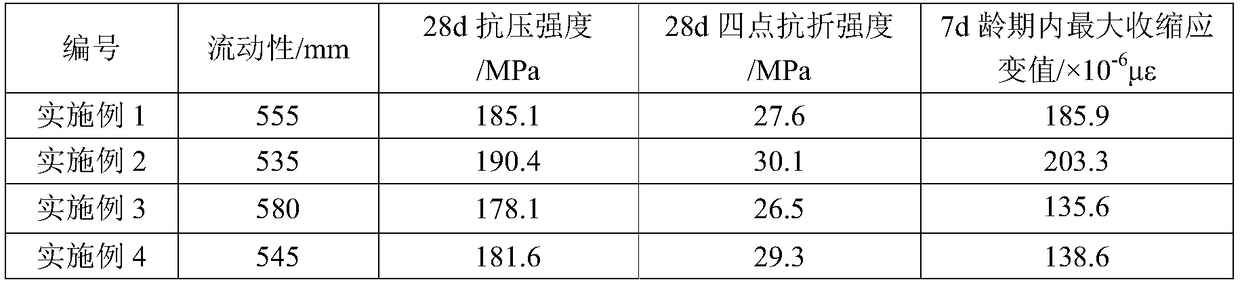

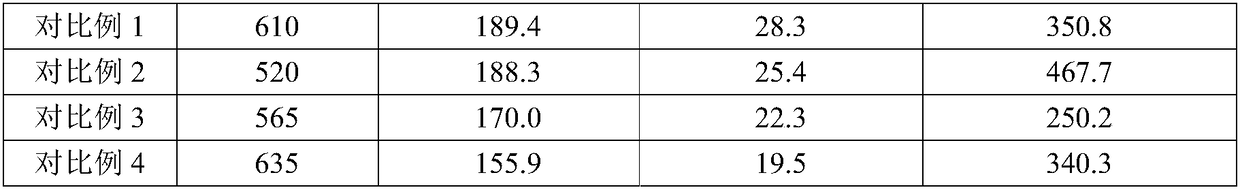

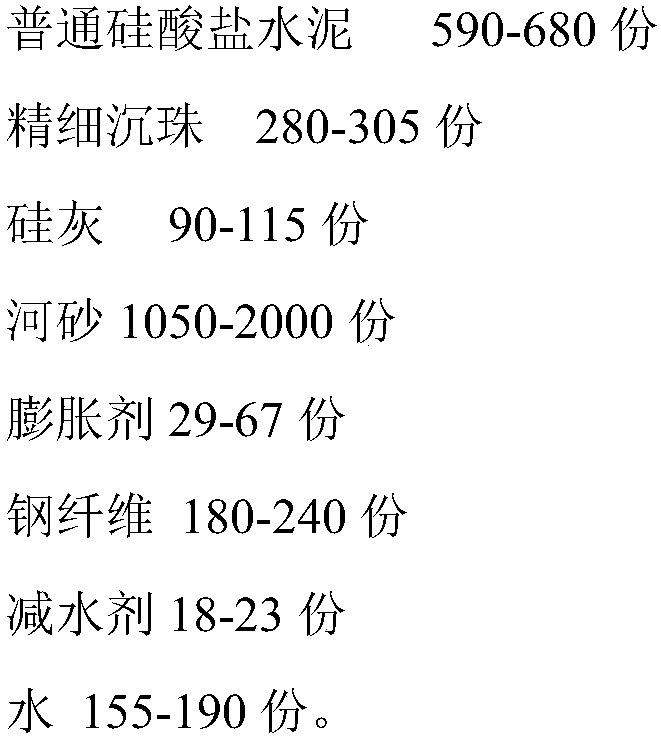

Ultrahigh-property cement-based material with low shrinkage and high toughness and preparation method thereof

The invention discloses an ultrahigh-property cement-based material with low shrinkage and high toughness and a preparation method thereof. The ultrahigh-property cement-based material with low shrinkage and high toughness is prepared from the main components in parts by weight: 590-680 parts of ordinary Portland cement, 280-305 parts of fine sinking beads, 90-115 parts of silica fume, 1050-2000 parts of river sand, 29-67 parts of expanding agent, 180-240 parts of steel fiber, 18-23 parts of water reducing agent and 155-190 parts of water. The ultrahigh-property cement-based material and the preparation method disclosed by the invention have the beneficial effects that the preparation process is simple, and the ultrahigh-property cement-based material with excellent properties in all the aspects of fluidity, strength and the like can be prepared by adopting a conventional cement mortar planetary stirring machine; in addition, on the basis of meeting the basic specification requirementsof all admixtures and by common action of the raw materials, the use amount of cementitious materials can be obviously saved. The obtained ultrahigh-property cement-based material has the advantagesof low use amount of the cementitious materials, simple forming process, excellent working property, low comprehensive cost and less early shrinkage, so that the application prospect is wide.

Owner:SOUTHEAST UNIV

Low slump loss modified naphthalene series water-reducing agent and preparation method thereof

InactiveCN101759393AHigh water reduction efficiencyGood slump performanceWater reducerReducing agent

The invention discloses a low slump loss modified naphthalene series water-reducing agent which is characterized in that: the water-reducing agent is formed by mixing 87-97 percent of naphthalene series water-reducing agents and 3-13 percent of oxidation-etherification starch by weight percentage; by adopting the invention, the water-reducing agent contains a great amount of hydroxyl, cement hydration can be prevented, so as to lead the cement hydration products to be uniform and improve the slump-blocking performance of the water-reducing agent; the water-reducing agent in the invention is applied to the cement, the reducing amount of the mobility is more than 6 percent after two hours, 28d intensity is improved by more than 12 percent, therefore, the invention not only can ensure the water-reducing effect and reduce the slump economic loss, but also can effectively improve the cement and concrete intensity.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

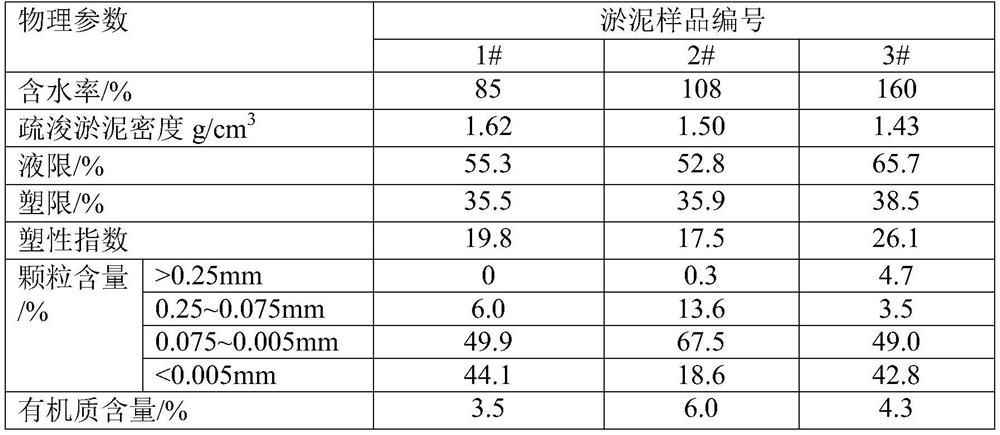

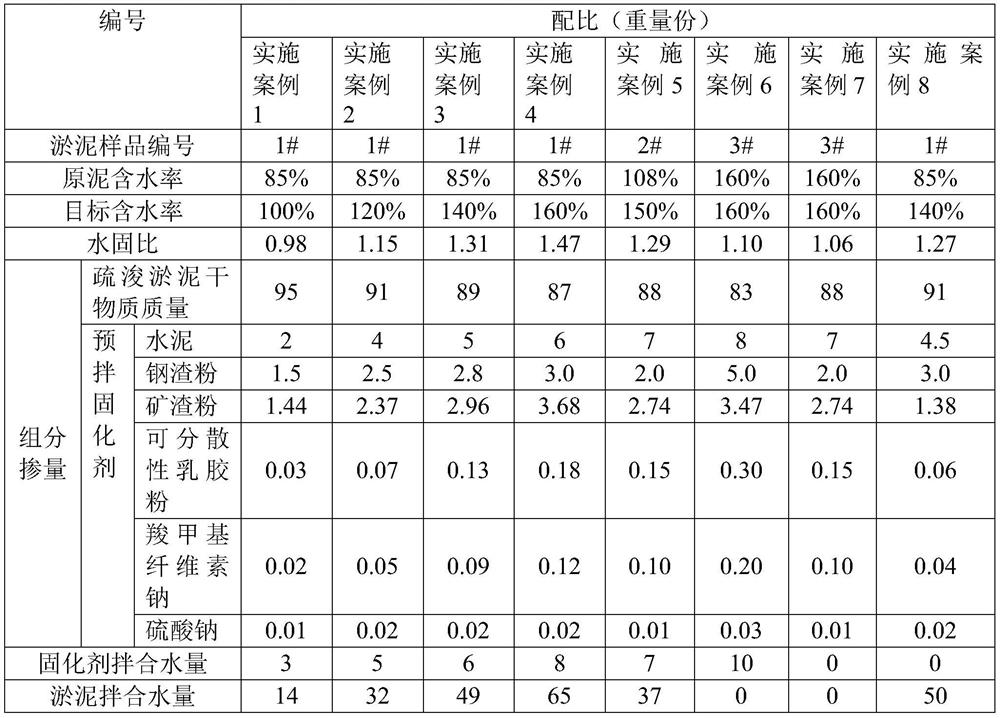

Formula and preparation method of polymer composite flow type dredged silt solidified soil

InactiveCN112321231AImprove adaptabilityConducive to unified and standardized productionCelluloseCarboxymethyl cellulose

The invention relates to a formula and a preparation method of polymer composite flow type dredged sludge solidified soil. The formula of the polymer composite flow type dredged sludge solidified soilcomprises the following components in percentage by mass: 80%-97% of dredged sludge; 2%-10% of cement; 1.0%-8.0% of steel slag powder; 1.2-5.6% of slag powder; 0.01%-0.05% of sodium sulfate, and 0.03%-0.40% of redispersible latex powder; and 0.02%-0.30% of sodium carboxymethyl cellulose; The flow type dredged silt solidified soil prepared by the method has the characteristics of high strength, high construction efficiency, good durability and low cost, and can be applied to road engineering, fill engineering, dike engineering and other engineering.

Owner:江苏叁山生态环境发展有限公司 +1

Concrete containing natural zeolite powder and preparation method thereof

The invention relates to the technical field of concrete preparation, in particular to concrete containing natural zeolite powder. The concrete is prepared from the following components in parts by mass: 54-81 parts of lightweight sand, 30-56 parts of lightweight aggregates, 38-60 parts of cement, 9-14 parts of zeolite powder, 0.5-2 parts of a water reducer, and 18-28 parts of water. A preparationmethod comprises the following steps: S1, adding lightweight sand, lightweight aggregates, cement and zeolite powder into a stirrer, starting the stirrer to obtain a material mixture; and S2, addingwater and water reducer into the material mixture, continuously stirring for a certain period of time to obtain the concrete containing the natural zeolite powder. The concrete provided by the invention can effectively improve water-retaining property of the concrete, improves viscosity of the concrete, reduces gradual loss of the concrete, and meanwhile guarantees good pumpability performance ofthe concrete, boosts production efficiency, and also effectively relieves dead load, and guarantees structure safety.

Owner:广西建宏水泥制品有限公司

Preparation method of modified naphthalene water reducer

InactiveCN108239248ASolve performance deficienciesSmall loss over timeLiquid productPolyethylene glycol

The invention provides a preparation method of a modified naphthalene water reducer, which comprises the following steps: adding naphthalene and naphthol to a reaction kettle in a ratio of 1:1, heating and adding concentrated sulfuric acid, and then performing sulfonation reaction; cooling the materials and adding polyethylene glycol 600 for further reaction; then adding cold water for hydrolysis,cooling and controlling the temperature between 100-110 DEG C, adding naphthylacetic acid and uniformly mixing, adding formaldehyde for condensation; preserving heat for 2.5h, neutralizing with alkaline, so as to obtain a modified naphthalene water reducer liquid product, and performing spray drying, thus obtaining a powdery product. According to the invention, by adding naphthol and naphthylacetic acid, hydroxyl and carboxyl are introduced to the water reducer; after sulfonation reaction, a monomer which has a polyoxyethylene ether long chain and can participate in condensation reaction canbe produced by further acid catalysis action; a water reducer obtained by copolycondensation has sulfonyl, hydroxyl, carboxyl and polyoxyethylene ether long chain in the molecular chain. Sulfonyl, hydroxyl and carboxyl have a synergistic water reducing effect.

Owner:四川金江建材科技有限公司

Method for homogeneously modifying pulverized coal ash by vapor deposition process

The invention relates to a method for homogeneously modifying pulverized coal ash by a vapor deposition process. The method comprises the following steps of (1) atomizing a composite grinding aid, then, naturally depositing the atomized composite grinding aid on the surface of the pulverized coal ash, carrying out uniformly mixing, and then, carrying out grinding; (2) naturally depositing an atomized surface modifier on the surface of the ground pulverized coal ash; and (3) mixing a slow-setting slump-resisting component with the pulverized coal ash, thereby obtaining the modified pulverized coal ash. The method has the advantages that (1) the grinding efficiency for the pulverized coal ash is increased; (2) with an efficient dispersion component of the surface modifier, the problem that the volume of water required by the pulverized coal ash is increased due to mechanical activation is avoided, and the workability of concrete is improved; (3) with a reinforcing component of the surface modifier, the early strength of the pulverized coal ash is enhanced; (4) the stability for the properties of the pulverized coal ash is guaranteed; and (5) industrial solid waste, i.e., ardealite, serves as the slow-setting slump-resisting component and is added into the pulverized coal ash, so that the gradual loss of the concrete can be greatly reduced.

Owner:WUHAN UNIV OF TECH

High-early-strength, freeze-proofing and high-performance polycarboxylate water reducer

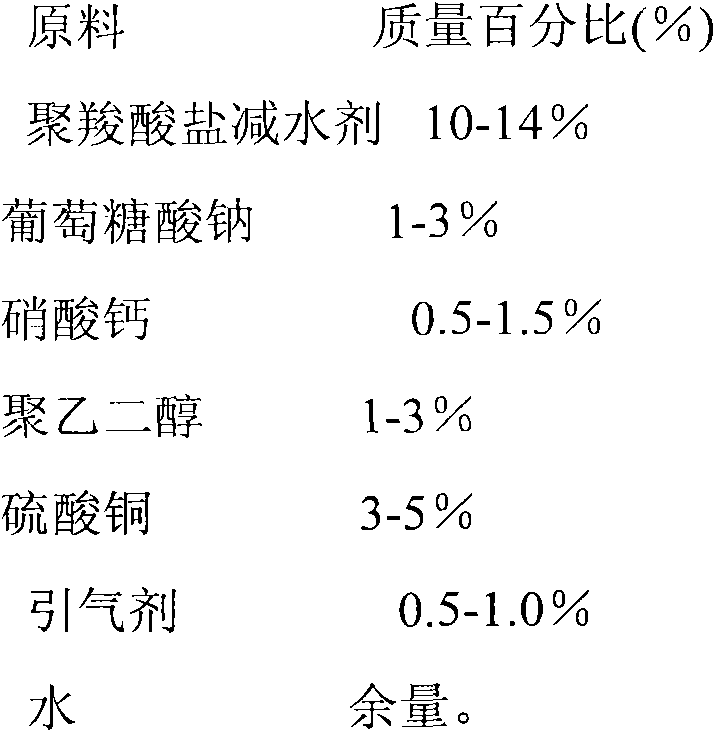

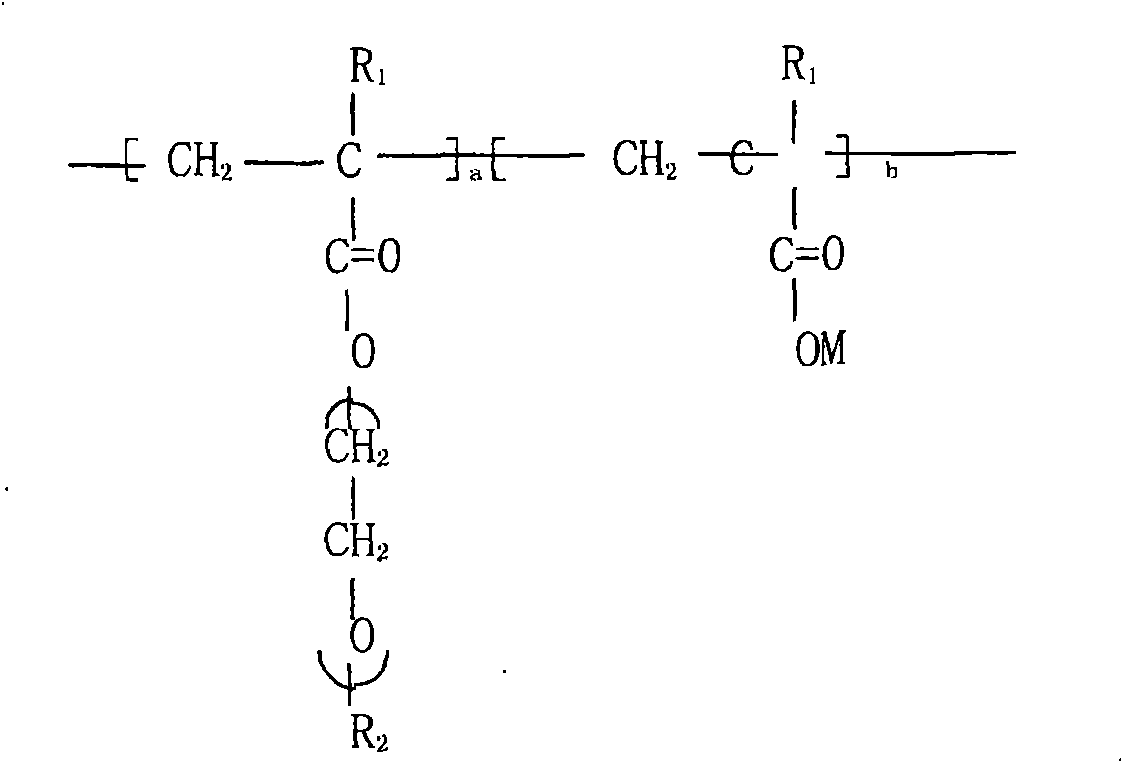

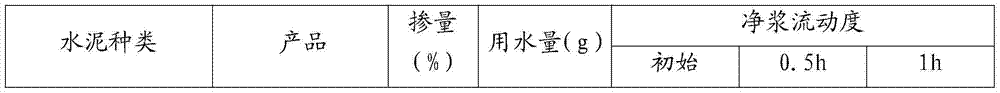

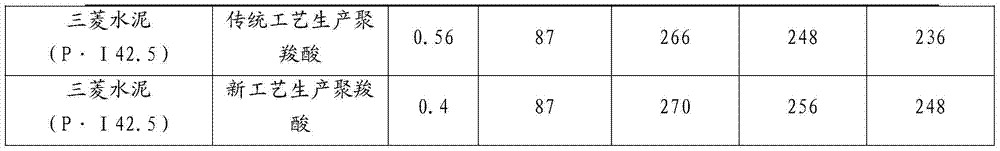

The invention discloses a high-early-strength, freeze-proofing and high-performance polycarboxylate water reducer. The water reducer is prepared from the following components by weight in a preferred range: 10-14 percent of polycarboxylate water reducer, 1-3 percent of sodium gluconate,0.5-1.5 percent of calcium nitrate, 1-3 percent of polyethyleneglycol, 3-5 percent of polyethyleneglycol, 3-5 percent of cupric sulfate, 0.5-1.0 percent of air-entraining agent and the balance of water.

Owner:LANGFANG RONGSHENG CONCRETE

Highly efficient composite concrete anti-freezing agent and preparation method thereof

The invention discloses a highly efficient composite concrete anti-freezing agent and a preparation method thereof which relates to the technical field of concrete anti-freezing agent. The concrete anti-freezing agent comprises lignin sulfonate, sodium sulfate, silicate, triethanolamine, ammonium chloride, beta naphthalene sulfonate formaldehyde condensate, glucose laurate, N sodium laurate, pH regulator, low molecular weight alcohol and water. The agent has the advantages of proper water reducing rate, minimum losses through concrete, short condensation time, good compatibility with water and observable improvement of the early strength of concrete. The anti-freezing agent can make sure of the normal and stable production of concrete, grant the concrete great anti-freezing effects. Moreover the manufacturing process of the anti-freezing agent is simple and not costly.

Owner:四会市恒星智能科技有限公司

Polycarboxylic acid high-performance water reducer

The invention relates to a polycarboxylic acid high-performance water reducer. The poly polycarboxylic acid high-performance water reducer is prepared from the following raw materials in parts by weight: 25-35 parts of acrylic acid, 10-20 parts of mercaptoacetic acid, 30-50 parts of isopentenol polyoxyethylene ether, 1-10 parts of hydrogen peroxide, 1-10 parts of vitamin C, 1-5 parts of white sugar, 0.5-2 parts of sodium dodecyl sulphate and 25-60 parts of water. The polycarboxylic acid high-performance water reducer has excellent performance, high water-reducing rate, low mixing amount, small slump gradual loss, good adaptability and good gel material adaptability, a production process is easy in operation, heating is not needed, purified water is not needed, energy consumption is low, and the polycarboxylic acid high-performance water reducer is green.

Owner:SHANDONG DAYUAN IND

Solid flaky polycarboxylate slump retaining agent prepared by surfactant-free emulsion polymerization and method

InactiveCN110951008AImprove performanceHigh water reduction ratePolymer scienceEmulsion polymerization

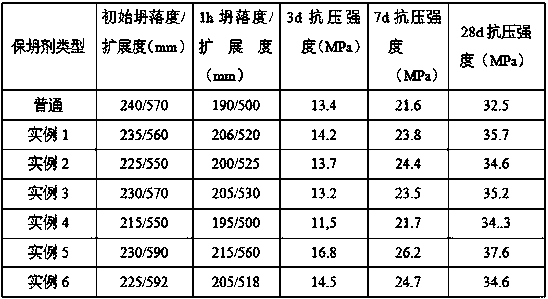

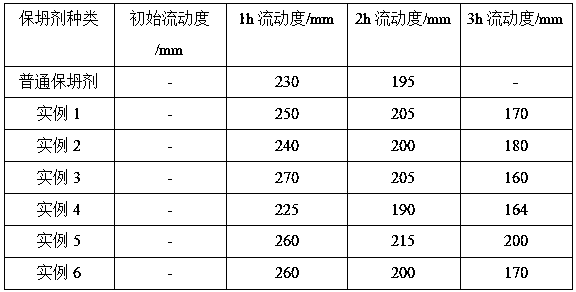

The invention provides a solid flaky polycarboxylate slump retaining agent prepared by surfactant-free emulsion polymerization and a method. The solid flaky polycarboxylate slump retaining agent is prepared from the following components in parts by weight: 18-27 parts of a surfactant-free emulsion ester-based hydrophobic monomer, 0.48-0.72 parts of an initiator a, 9-18 parts of a surfactant-free hydrophilic small monomer, 0.41-0.69 parts of a chain transfer agent a, 765-810 parts of a polyether macromonomer, 32-68 parts of unsaturated dicarboxylic acid, 12-28 parts of an unsaturated sulfonic small monomer, 50-74 parts of alkyl acrylate, 2.3-3.8 parts of a chain transfer agent b, 3.2-5.9 parts of an initiator b, 2.6-4.6 parts of an initiator c, 3.2-4.7 parts of a chain transfer agent c, and7.7-11.5 parts of a pH regulator. The method comprises the following operation steps: (1) preparing a surfactant-free polymer; (2) preparing solutions A, B and C; (3) dropwise adding the solutions A,B and C; and (4) preparing the solid flaky polycarboxylate slump retaining agent. The slump retaining agent can effectively slow down cement hydration, effectively keep concrete slump for a long time, slow down the time-dependent loss of the concrete slump and keep the fluidity and workability of concrete, and the properties in all aspects are more stable.

Owner:HUBEI UNIV OF TECH

Seaport engineering concrete chloride ion penetration resistant reinforcing agent

InactiveCN100515973CImprove permeabilityReduce penetration rateSolid waste managementMicro structureFiber

The present invention provides the recipe of chlorine ion penetration resisting reinforcer for concrete in harbor engineering. The chlorine ion penetration resisting reinforcer consists of superfine silica powder 15-20 wt%, washed and calcined kaolin 20-25 wt%, high grade fly ash 20-25 wt%, ground blast furnace slag 20-25 wt%, nanometer fiber 5-10 wt%, superplasticizer 6 wt%, slump keeping agent 0.09 wt%, air entraining agent 0.09 wt%, and organic active excitant 0.12 wt%. The chlorine ion penetration resisting reinforcer has inorganic components as main functional materials dispersed homogeneously in concrete cementing material, and can improve the micro structure and hydration product composition inside concrete, raise compactness, adsorb and fix chlorine ion and lower the penetration of chlorine ion in hardened concrete, so as to improve the chlorine ion penetration resisting capacity of hardened concrete.

Owner:LETS HLDG GRP CO LTD +1

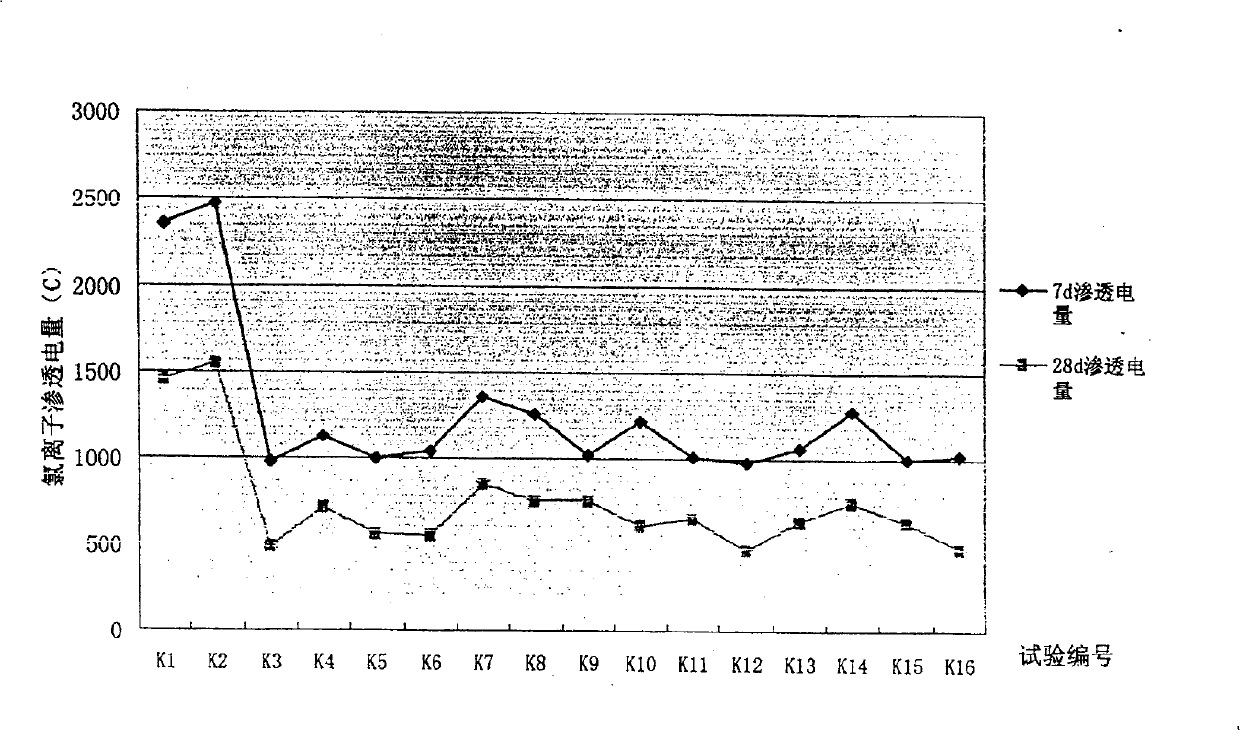

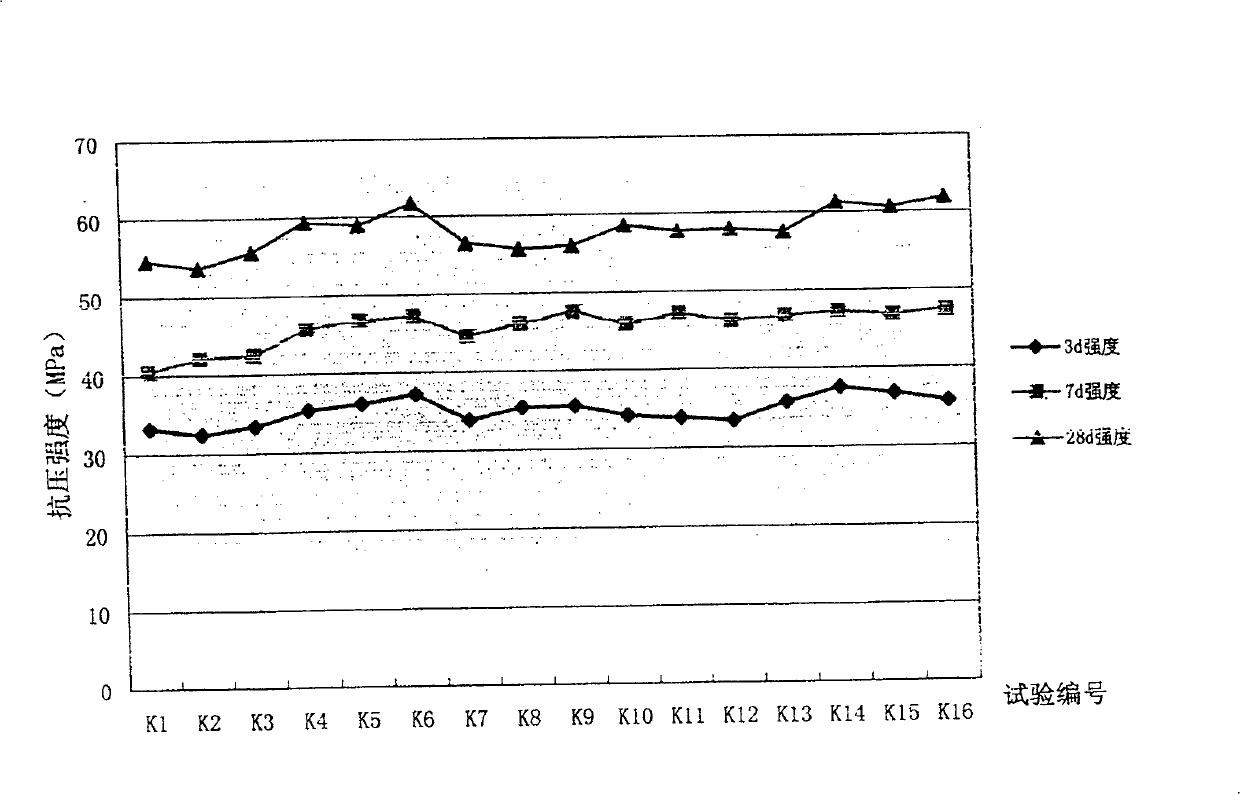

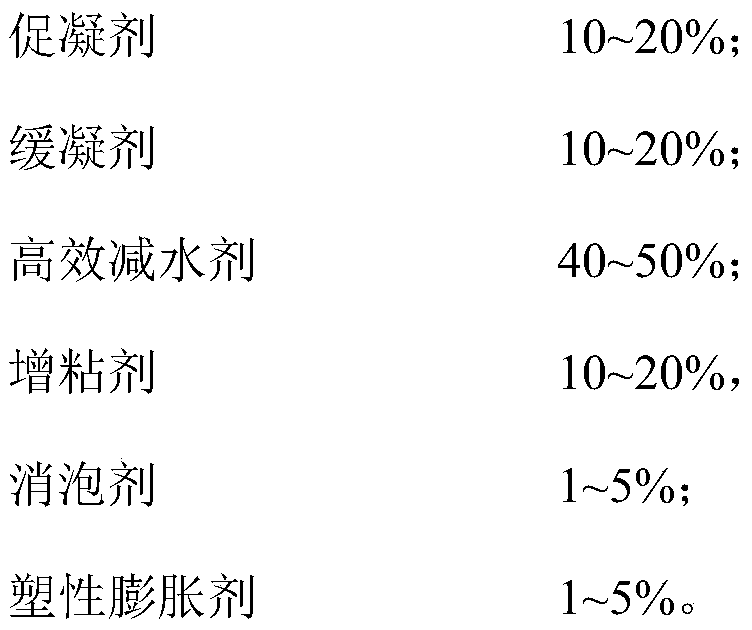

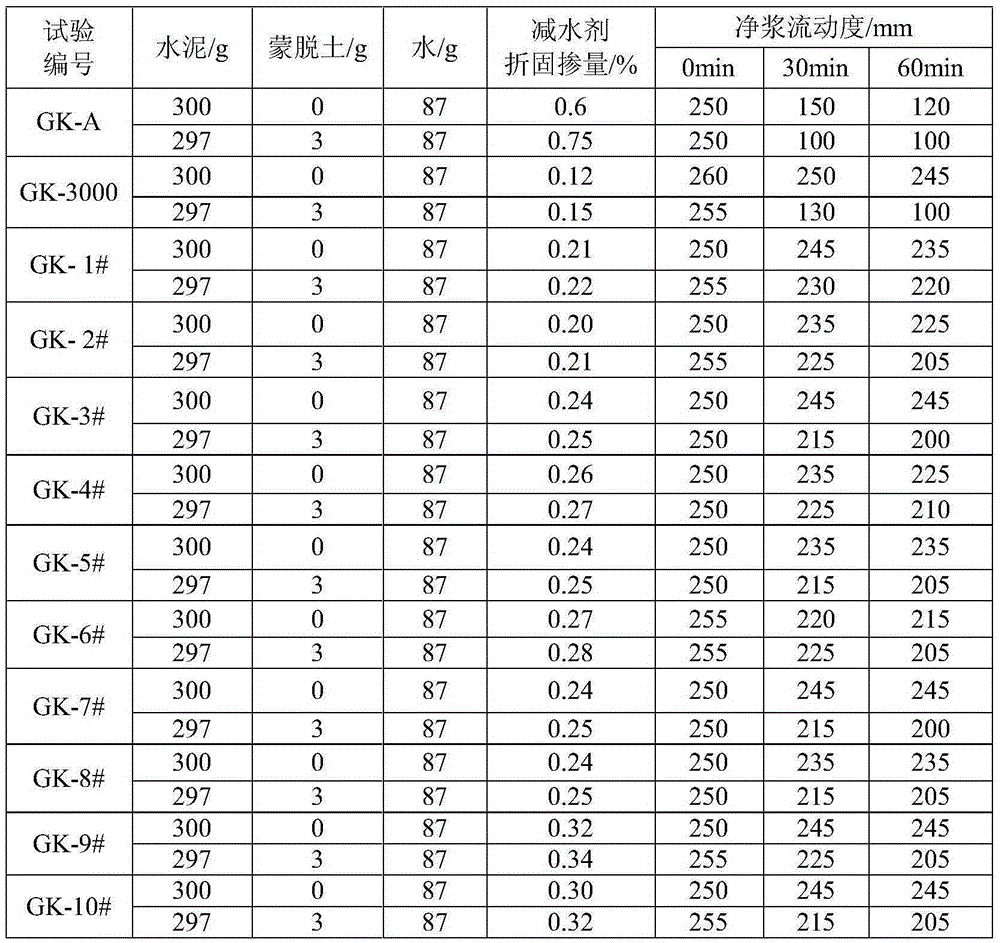

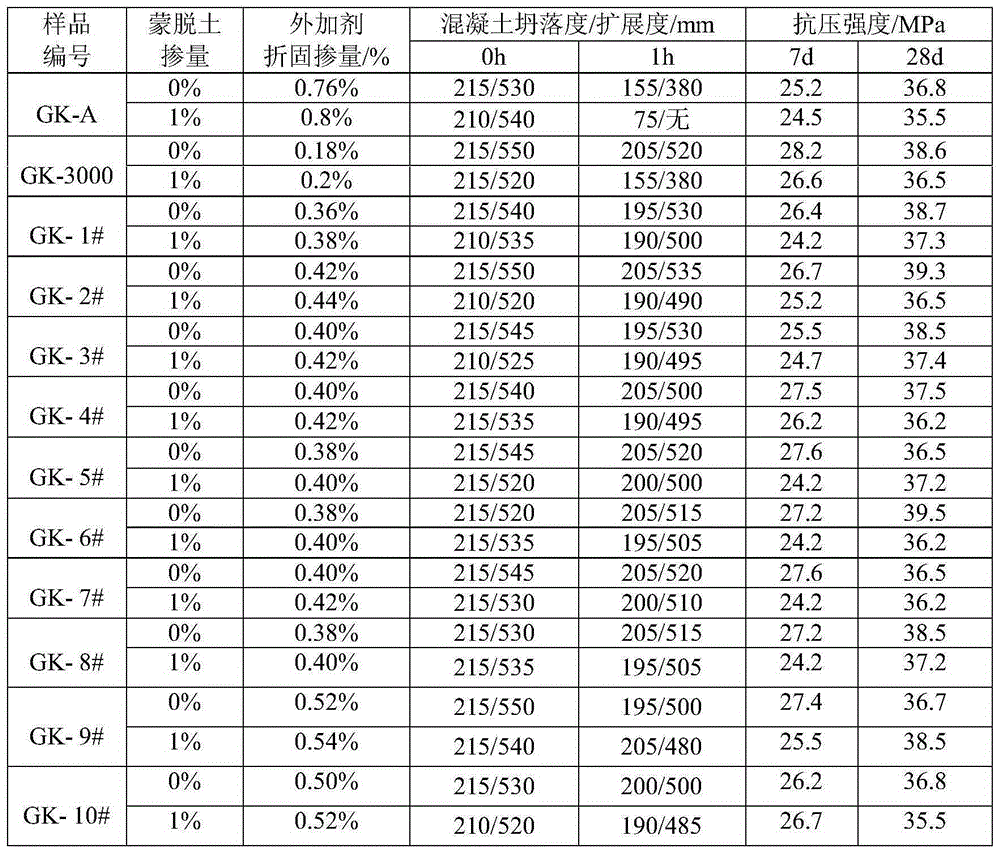

Synchronous shielding grouting material composite admixture

ActiveCN110498633AMeet water dispersion resistanceSatisfy dispersionWork performanceSuperplasticizer

The invention discloses a synchronous shielding grouting material composite admixture which comprises the following raw materials in percentage by mass: 10-20% of a coagulant, 10-20% of a retarder, 40-50% of an efficient water reducer, 10-20% of a tackifier, 1-5% of a defoaming agent and 1-5% of a plasticity expander. The admixture has the effects that in a high-pressure water-enriched stratum environment, on premise that equipment and pipelines are not changed, the curing time can be adjusted, the working performance loss is small within the curing time, and good water dispersibility resistance, efficient filling and rapid curing can be achieved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +2

Super-slump-loss-resistant concrete containing machine-made sand and preparation method of super-slump-loss-resistant concrete

PendingCN113307571AReduced hydration rateSmall loss over timeSolid waste managementChemistrySodium metabisulfite

The invention relates to the field of building materials, and particularly discloses super-slump-loss-resistant concrete containing machine-made sand and a preparation method of the super-slump-loss-resistant concrete. The super-slump-loss-resistant concrete containing the machine-made sand is prepared from the following components: cement, fly ash, mineral powder, the machine-made sand, broken stone, sodium pyrosulfite, a methyl allyl polyoxyethylene ether water reducing agent, hydroxyethyl methyl cellulose and dimethyl hydroxyl silicone oil. The preparation method comprises the following steps: uniformly mixing the sodium pyrosulfite, the methylallyl polyoxyethylene ether water reducing agent, the hydroxyethyl methyl cellulose and the dimethyl hydroxyl silicone oil, and then adding the mixture into the cement, the fly ash, the mineral powder, the machine-made sand and the gravel which are kept to be stirred. The super-slump-loss-resistant concrete containing the machine-made sand has the advantage that the slump retaining time is prolonged.

Owner:佛冈县诚康商品混凝土有限公司

Clay-resistant polycarboxylate water-reducer compoundable with naphthalene-based water-reducer and preparation method thereof

ActiveCN104017125BPrevent insertionEasy to disperse thermal stabilitySuperplasticizerWork Performances

The invention relates to an anti-clay polycarboxylate water reducer capable of being compounded with a naphthalene water reducer and a preparation method thereof. The anti-clay polycarboxylate water reducer is prepared from the following raw materials: a comonomer, a chain transfer agent, an initiator and deionized water. The preparation method comprises the following steps: adding the deionized water into a four-mouth flask and heating to 60-80 DEG C; filling the comonomer, the chain transfer agent and the deionized water in a beaker to prepare a solution A; filling the initiator and the deionized water in another beaker to prepare a solution B; respectively, simultaneously and uniformly dropping the solutions A and B into the four-mouth flask by a constant flow pump, and after reaction, cooling and adjusting the pH value to 6.5-7.0 to obtain the anti-clay polycarboxylate water reducer. The polycarboxylate water reducer provided by the invention can be compounded with the naphthalene water reducer in use, so that the problem that the prior art, the polycarboxylate water reducer and the naphthalene water reducer are incompatible is solved. The anti-clay polycarboxylate water reducer is good in anti-clay performance and can be used for remarkably improving the working performance of high silt content aggregate prepared concrete, and the fresh concrete is good in peaceability, less in gradual loss, high in strength and suitable for industrial production.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com