Formula and preparation method of polymer composite flow type dredged silt solidified soil

A dredging sludge and flow-type technology, applied in the field of engineering material preparation, can solve the problems of high construction cost, increase the curing effect of cement content, insufficient output, etc., achieve good tensile and shear resistance, and meet the requirements of pumping Construction requirements, the effect of rapid early strength growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

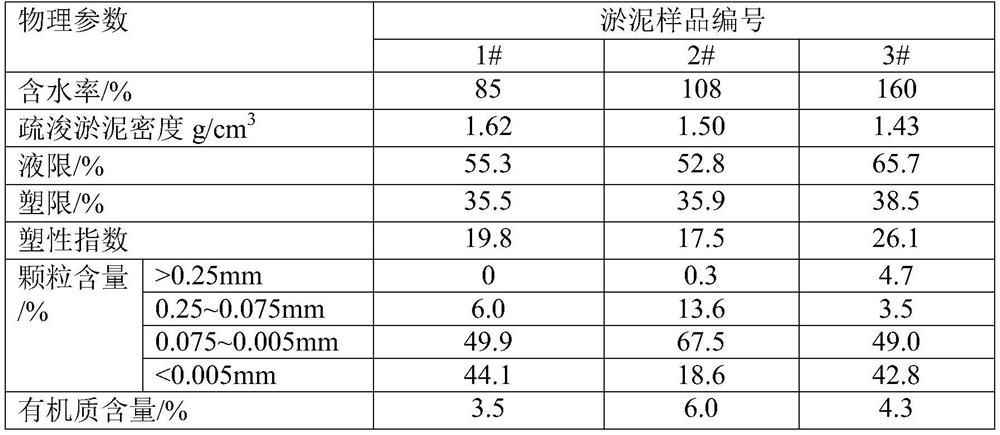

[0021] Embodiment 1: choose 3 kinds of dredged silt samples for test, and the physical index of silt is as follows:

[0022]

[0023] The cement used in this patent implementation case is P·O42.5 grade cement that complies with the provisions of "Universal Portland Cement GB175-2007". Steel slag powder is selected to meet the requirements of "Steel Slag Powder Used in Cement and Concrete GB / T 20491-2017". The slag powder is selected from the S95 grade slag powder that meets the requirements of "Granulated Blast Furnace Slag Powder Used in Cement, Mortar and Concrete GB / T18046-2017". The redispersible latex powder is a commercially available latex powder whose active ingredient is vinyl acetate-ethylene copolymer.

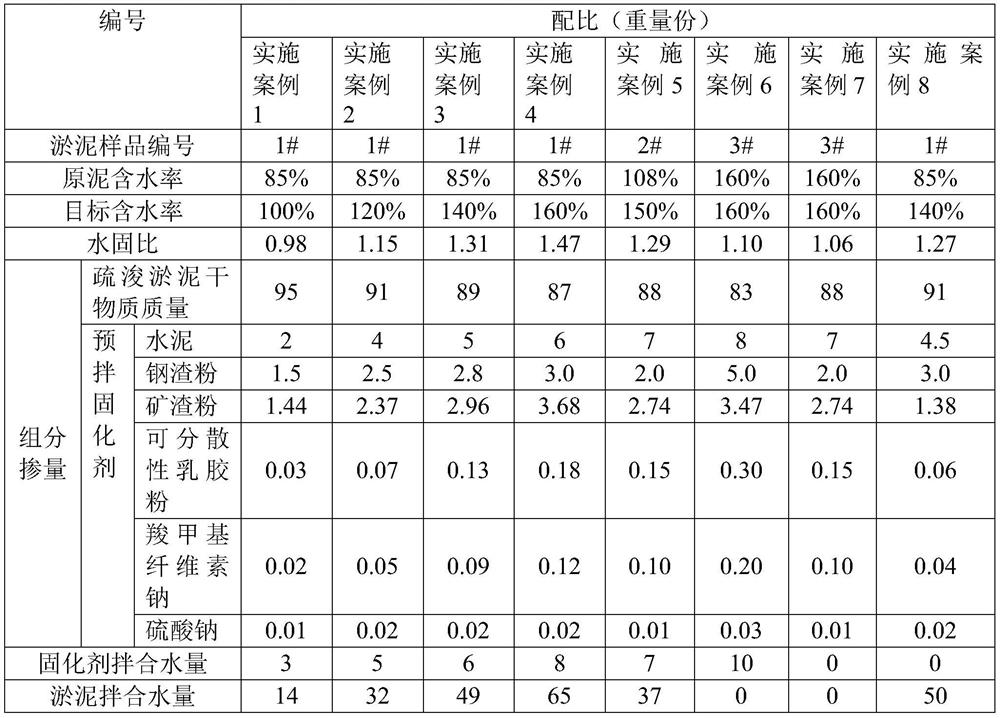

[0024] The mix ratio design of a kind of polymer composite flowing dredging silt solidified soil is as follows:

[0025]

Embodiment example 1、 Embodiment example 2

[0026] Implementation case 1, implementation case 2, implementation case 3, implementation case 4, implementation case 5, implementation case 6 are formed by slurry mixing method; implementation case 7 and implementation case 8 are formed by dry powder mixing method.

[0027] Indoor experiment:

[0028] Slurry mixing method molding: weigh the corresponding quality cement, steel slag powder, slag powder, sodium sulfate, and dispersible latex powder according to the mixing ratio shown in the above table, and mix them evenly to obtain a ready-mixed curing agent. Add mud mixing water to the dredged sludge to adjust to the target water content, and stir evenly to obtain fluid dredging sludge; add the pre-mixed curing agent to the curing agent and mix water to prepare the curing agent slurry, and stir the curing agent slurry for 10 minutes, then mix with the flowing dredging The silt was mixed and stirred for 5 minutes to obtain a fluid dredged silt solidified soil. The slump test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com